A slow-falling shaft mechanism with overload protection

A technology of overload protection and rotating shaft, which is applied to toilet seats or covers, household utensils, liquid shock absorbers, etc. It can solve the problems of parts impact, slow falling rotating shaft mechanism damage, etc., so as to avoid damage and increase oil flow area, the effect of reducing the closing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further illustrated and described below through specific embodiments.

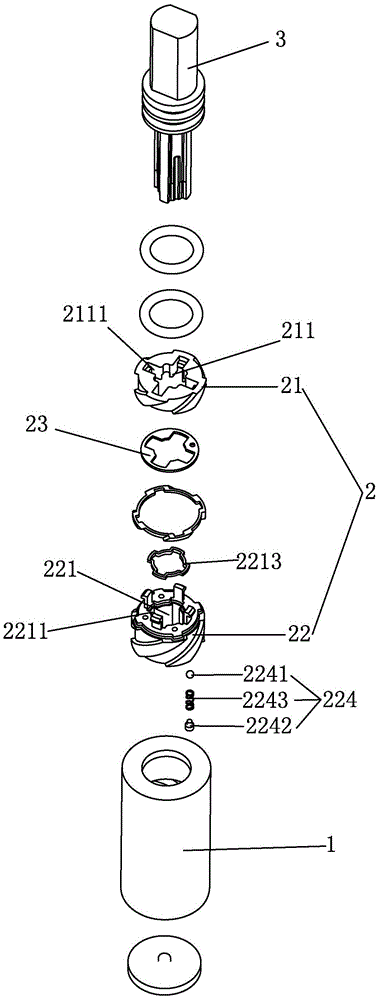

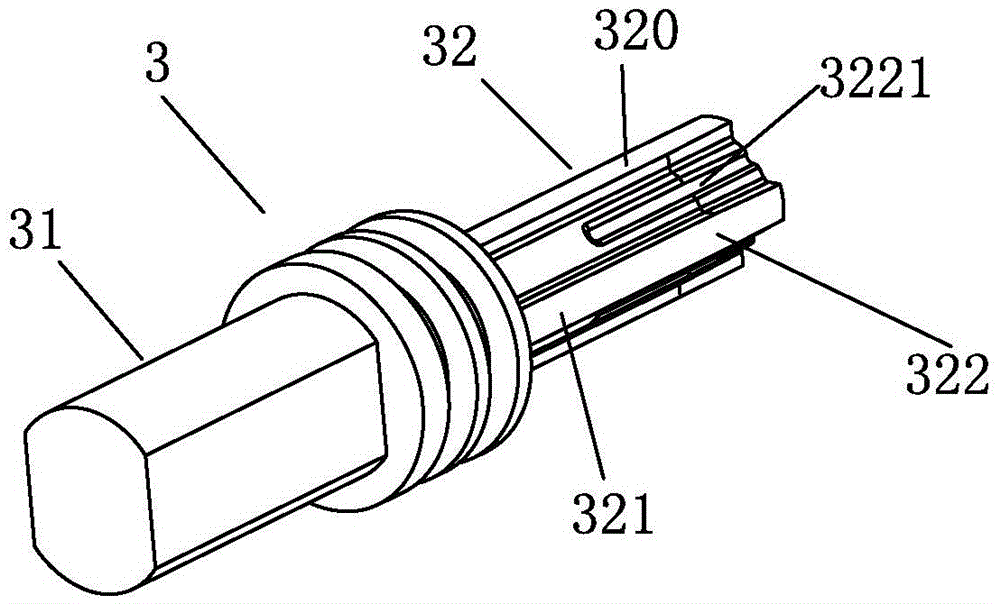

[0027] like Figure 1 to Figure 4 As shown, a slow-fall rotating shaft mechanism with overload protection includes a housing 1 , a guide sleeve assembly 2 and a rotating shaft 3 .

[0028] The housing 1 is a cylindrical structure with a closed right end, and the inner wall of the housing 1 is provided with an internal thread structure.

[0029] The guide sleeve assembly 2 is provided with an external thread structure compatible with the above-mentioned internal thread structure, so that the guide sleeve assembly 2 can be moved along the axial direction of the housing 1 and fitted in the housing 1, and the guide sleeve assembly 2 From left to right, the space in the housing 1 is divided into a first oil chamber 11 and a second oil chamber 12 filled with damping oil;

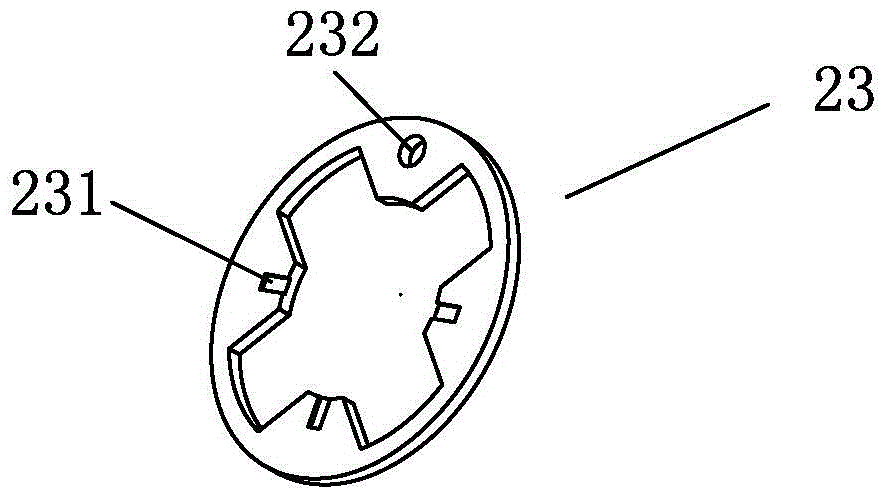

[0030] Specifically, the guide sleeve assembly 2 includes a first guide sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com