Preparation of nano calcium carbonate for siloxane end-capped polyurethane sealant

A polyurethane sealant, nano calcium carbonate technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, dyed silicone compounds, etc., can solve problems such as the discussion of sealant stability, achieve good economic and social benefits, The process is simple and feasible, and the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

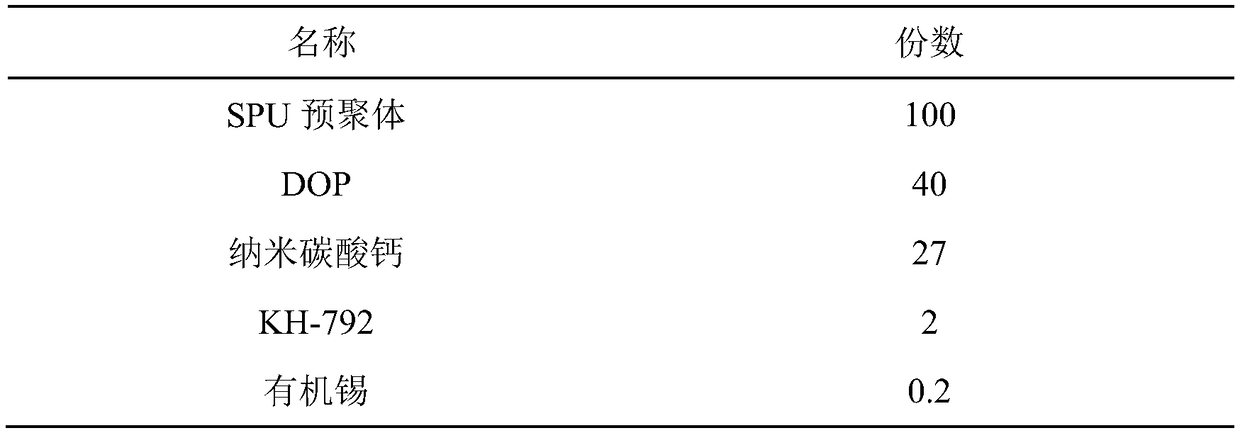

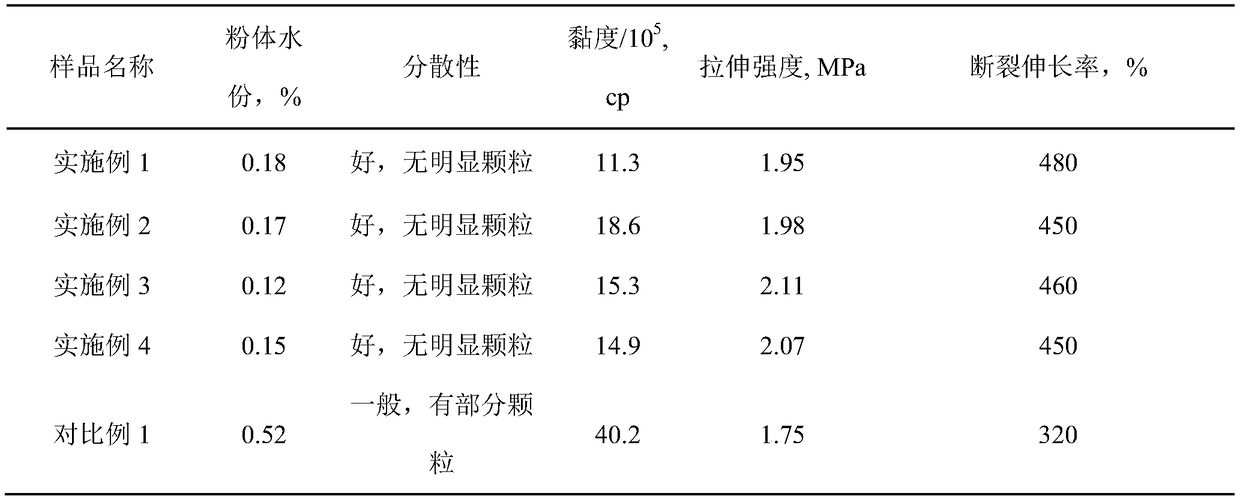

Method used

Image

Examples

Embodiment 1

[0030] A kind of preparation of nano-calcium carbonate for silane-terminated polyurethane sealant, comprises the steps:

[0031] (1) Adjust the specific gravity of the refined milk of lime to 1.065, then introduce it into the bubbling carbonation reactor, adjust the temperature of the milk of lime to 31°C, and introduce CO 2 Concentration is 33% mixed gas, carbonation to pH = 7.0, get nano-calcium carbonate suspension;

[0032] (2) Heat the nano-calcium carbonate suspension to 75°C, add a surface treatment agent compounded by trimethylsilanol, dimethylformamide and sodium stearate, and the amount of the surface treatment agent added is 4.2% of the dry mass of calcium carbonate, of which trimethylsilanol, dimethylformamide and sodium stearate accounted for 40%, 5% and 55% respectively, and the surface modification was completed after stirring for 60 minutes , to obtain modified calcium carbonate suspension;

[0033] (3) The modified calcium carbonate suspension is dehydrated ...

Embodiment 2

[0035] A kind of preparation of nano-calcium carbonate for silane-terminated polyurethane sealant, comprises the steps:

[0036] (1) Adjust the specific gravity of the refined milk of lime to 1.070, then introduce it into the bubbling carbonation reactor, adjust the temperature of the milk of lime to 35°C, and introduce CO 2 Concentration is 33% mixed gas, carbonation to pH = 7.0, get nano-calcium carbonate suspension;

[0037] (2) Heat the nano-calcium carbonate suspension to 80°C, add a surface treatment agent compounded by trimethylsilanol, dimethylformamide and sodium stearate, and the amount of the surface treatment agent added is 4.0% of calcium carbonate on a dry basis, of which trimethylsilanol, dimethylformamide and sodium stearate accounted for 41%, 1% and 55% respectively, and the surface modification was completed after stirring for 60 minutes , to obtain modified calcium carbonate suspension;

[0038] (3) The modified calcium carbonate suspension is dehydrated b...

Embodiment 3

[0040] A kind of preparation of nano-calcium carbonate for silane-terminated polyurethane sealant, comprises the steps:

[0041] (1) Adjust the specific gravity of the refined milk of lime to 1.075, then introduce it into the bubbling carbonation reactor, adjust the temperature of the milk of lime to 33°C, and introduce CO 2 Concentration is 33% mixed gas, carbonation to pH = 7.0, get nano-calcium carbonate suspension;

[0042] (2) Heat the nano-calcium carbonate suspension to 70°C, add a surface treatment agent compounded by trimethylsilanol, dimethylformamide and sodium stearate, and the amount of the surface treatment agent added is 4.5% of calcium carbonate on a dry basis, of which trimethylsilanol, dimethylformamide and sodium stearate accounted for 47%, 3% and 50% respectively, and the surface modification was completed after stirring for 60 minutes , to obtain modified calcium carbonate suspension;

[0043] (3) The modified calcium carbonate suspension is dehydrated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com