Flexible MXene/Si composite material as well as preparation method and application thereof

A composite material and flexible technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of weak bonding force, silicon particle drop, etc., to improve conductivity, solve volume expansion, and make the electroplating process simple and easy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0033] The third embodiment of the present invention provides an application of the above-mentioned flexible MXene / Si composite material in lithium ion batteries, lithium metal batteries and / or solar batteries.

[0034] The fourth embodiment of the present invention provides a lithium ion battery, the negative electrode material is the above-mentioned flexible MXene / Si composite material.

[0035] The fifth embodiment of the present invention provides a lithium metal battery, the current collector adopts the above-mentioned flexible MXene / Si composite material.

[0036] In order to enable those skilled in the art to understand the technical solution of the present invention more clearly, the technical solution of the present invention will be described in detail below in conjunction with specific embodiments.

Embodiment 1

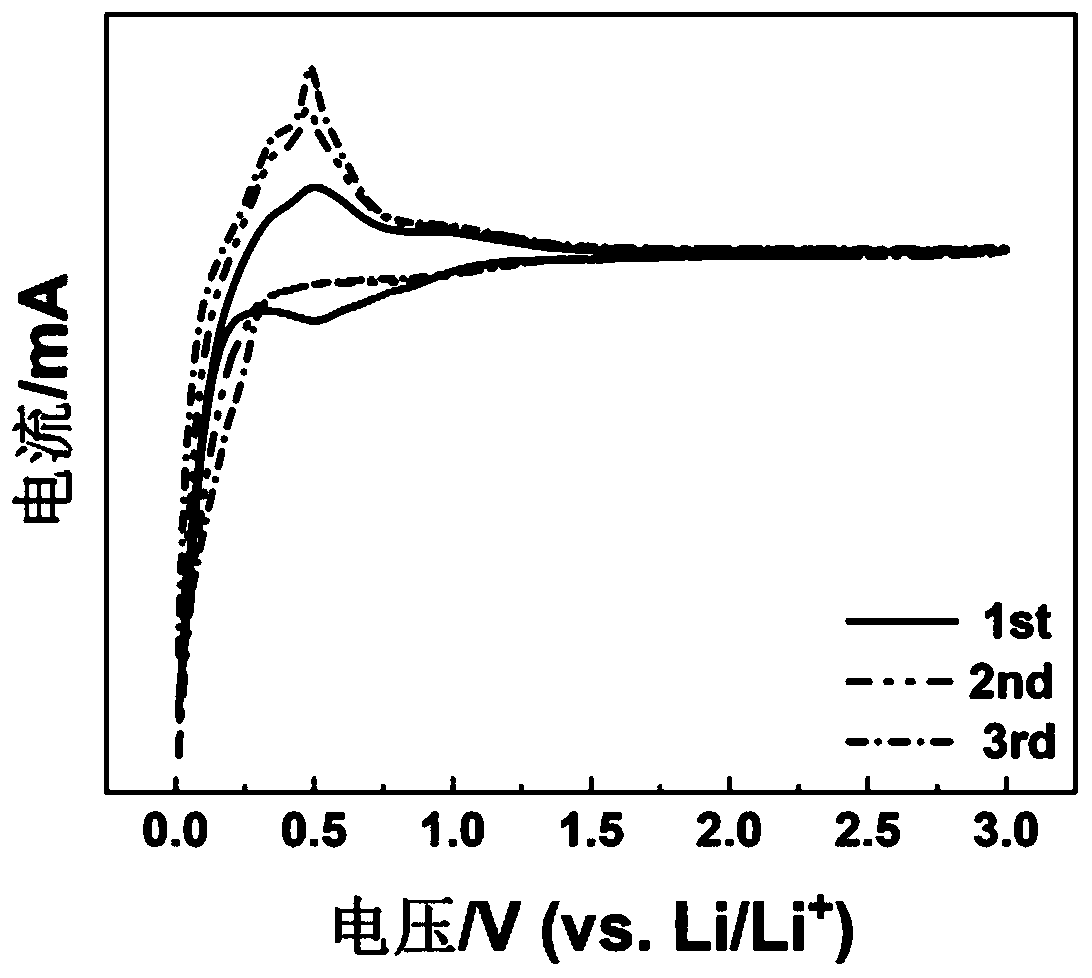

[0038] A kind of preparation method of flexible MXene / Si composite material, comprises the steps: adopt three-electrode system, working electrode is Ti 3 C 2Self-supporting membrane, the reference electrode and the counter electrode are metal platinum sheets, the electroplating solution is 100mL ethylene glycol, 1.8g silicon tetrachloride and 0.2g tetrabutylammonium chloride, at 3mA cm -2 A layer of silicon can be obtained after electroplating at a current density of 10 minutes, and then vacuum dried for 10 hours to obtain a flexible Ti 3 C 2 / Si composite material. It is directly used as the negative electrode material of lithium-ion batteries. In the electrolyte of EC / DEC / lithium hexafluorophosphate, lithium foil is used as the counter electrode and reference electrode to assemble a button battery. The cyclic voltammetry curve is as follows: figure 1 shown.

Embodiment 2

[0040] A kind of preparation method of flexible MXene / Si composite material, comprises the steps: adopt three-electrode system, working electrode is V 2 C self-supporting film, the reference electrode and the counter electrode are metal platinum sheets, the electroplating solution is composed of 100mL propylene carbonate, 1.5g silicon bromide and 0.5g tetrabutylammonium bromide, at 2mA cm -2 A layer of silicon can be obtained after electroplating at a current density of 30 minutes, and then vacuum dried for 10 hours to obtain a flexible V 2 C / Si composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com