Spray cleaning device for shoe uppers

A spray washing device and shoe upper technology, which is applied to shoe uppers, footwear, applications, etc., can solve the problems of wasting manpower and material resources, and achieve the effect of increasing heat and accelerating blood circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further detailed explanation through specific implementation mode below:

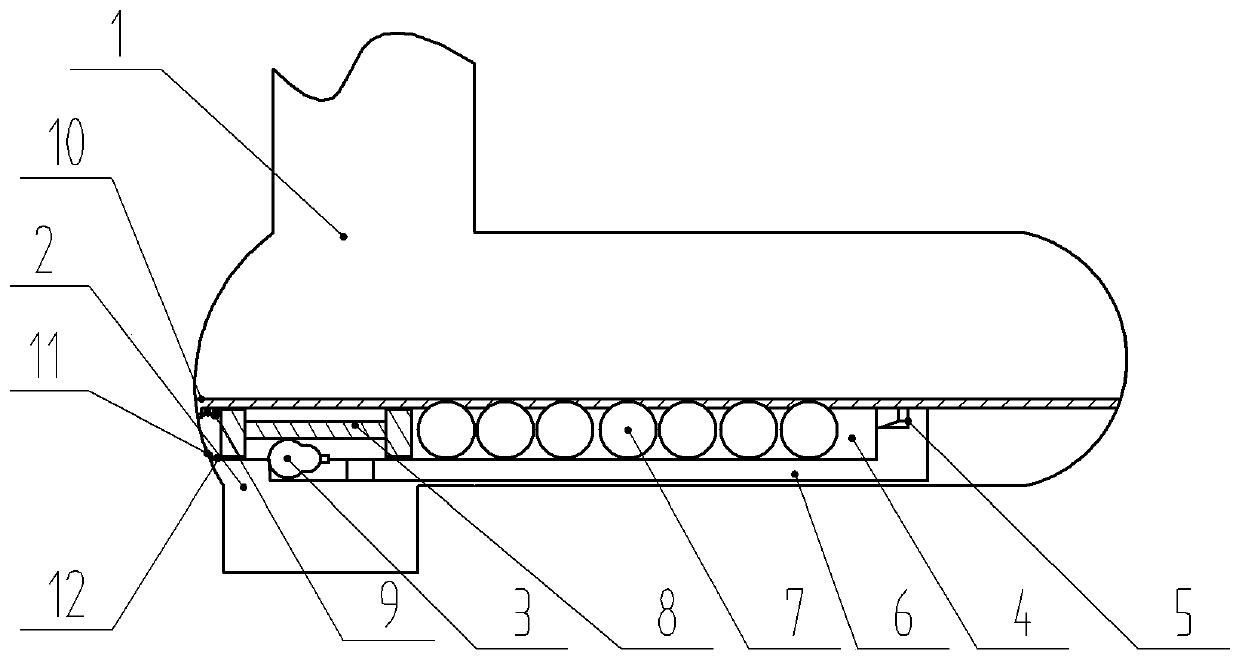

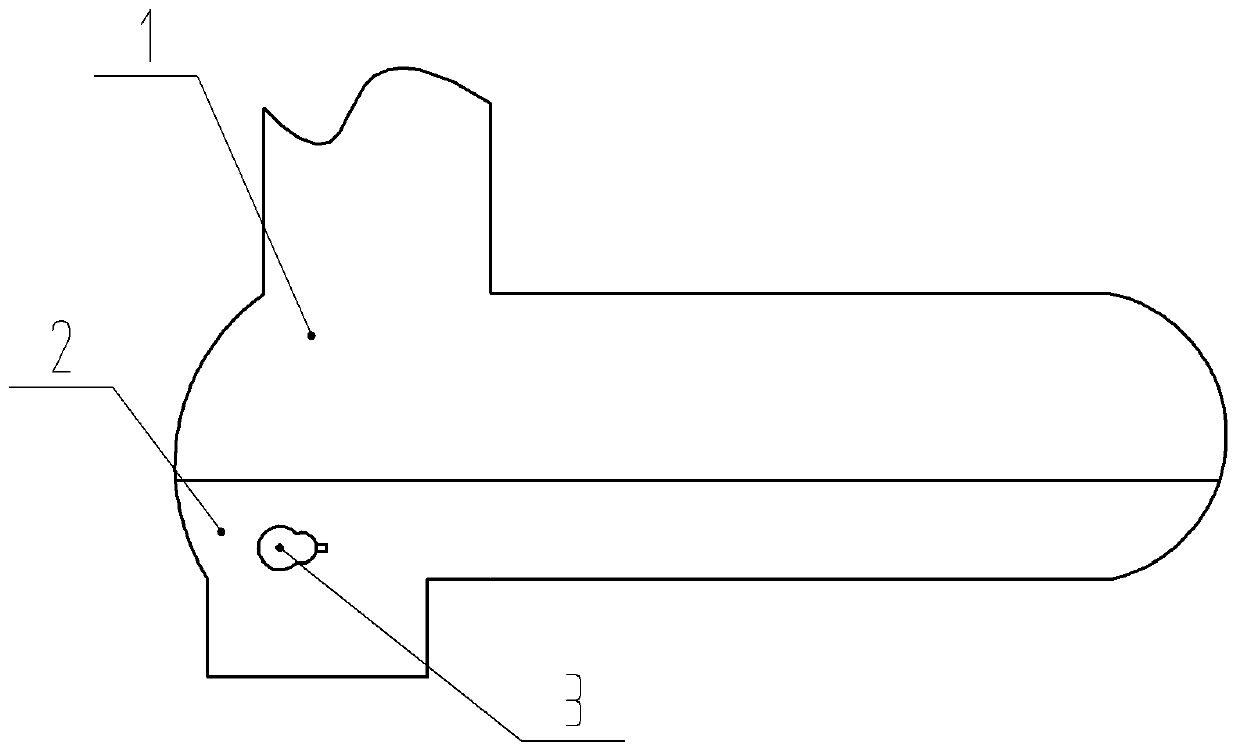

[0022] The reference signs in the accompanying drawings include: rubber shoes 1, shoe upper 2, nozzle 3, motion chamber 4, spikes 5, water delivery pipe 6, water bag 7, piston rod 8, first spring 9, first block 10, The second spring 11, the second stopper 12.

[0023] Note: The up, down, left, and right in this embodiment are subject to the up, down, left, and right of the drawings.

[0024] The embodiment is basically as attached figure 1 and figure 2 Shown: the spray cleaning device for the upper of the shoe, including two spray cleaning channels arranged on the rubber shoe 1, the rubber shoe 1 includes the upper 2 arranged at the bottom of the rubber shoe 1, the upper 2 is detachably connected with the bottom of the rubber shoe 1, the detachable The connection adopts bolt connection, and the two spraying channels are respectively located on both sides of the upper 2. The spraying channel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com