Warp printing module oriented to sizing machine

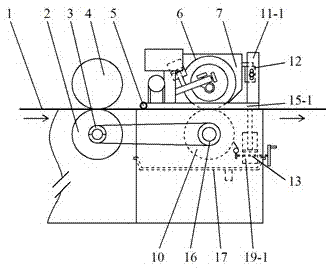

A sizing machine and printing technology, applied in the directions of printing, printing machine, rotary printing machine, etc., can solve the problems of incapable of sizing machine sizing and printing warp synchronously, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

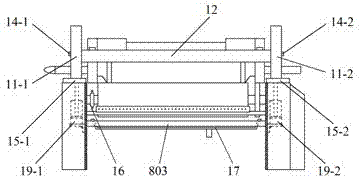

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

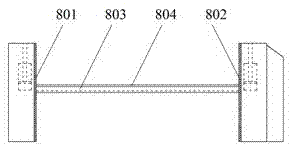

[0017] like image 3 , The structure of the frame is that steel beams 803 and 804 are welded between the left and right wall panels 801 and 802. The left and right wall panels 801 and 802 are made of 15mm thick steel plates, and the steel beams 803 and 804 are made of angle steel. The width between the left and right wall panels 801 and 802 is 1300mm, which is equal to the width between the two wall panels of the sizing machine; the heights of the wall panels 801 and 802 are both equal to 1100mm, which is the frame height of the sizing tank of the sizing machine; the front and rear width of the frame is 600mm, So that it can be conveniently installed between the sizing tank of the sizing machine and the drying room. The rack continues to be provided with box structures and cabinet doors outside the left and right wall panels 801 and 802, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com