Device for continuous waterless dyeing of spindles by adoption of high-pressure supercritical fluid technology

A supercritical fluid and water-free dyeing technology, which is applied in solvent dyeing, liquid/gas/steam treatment of a certain length of textile materials, and treatment of textile material carriers, etc., can solve problems such as low efficiency, time-consuming, and affecting equipment safety. Achieve even dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] Further description of the content of the present invention in conjunction with the accompanying drawings will help to understand the present invention, but cannot limit the content of the present invention.

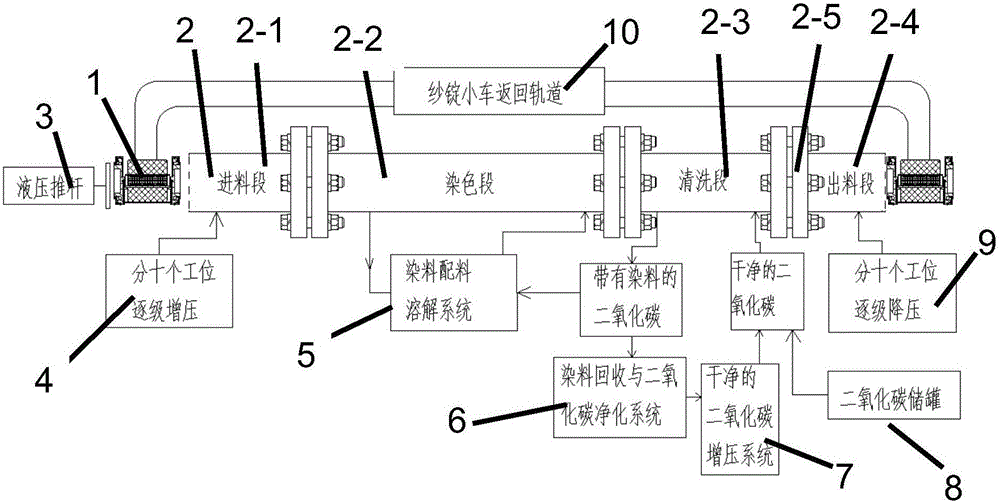

[0103] Figure 1 is a process schematic diagram of the entire operation. The hydraulic push rod pushes a trolley equipped with spindles into the dyeing system according to the set interval time. The whole dyeing system is divided into four working sections: feeding section, dyeing section, cleaning section and discharging section. The feed section and the discharge section are responsible for the dynamic sealing of the entire high-pressure supercritical fluid dyeing system. In order to be able to effectively carry out the dynamic sealing under the high pressure system. The feeding section is divided into ten stations. Pressurize successively in ten stations. In the same situation, it is also divided into ten stations in the discharge section, and the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com