Motor-driven elevator rope gripping device capable of automatic resetting

A motor-driven, automatic reset technology, applied in elevators, transportation and packaging, etc., can solve the problems of elevator wire rope damage, unsafe work, large impact force, etc., and achieve the effects of low cost, low operating noise and fast dynamic response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

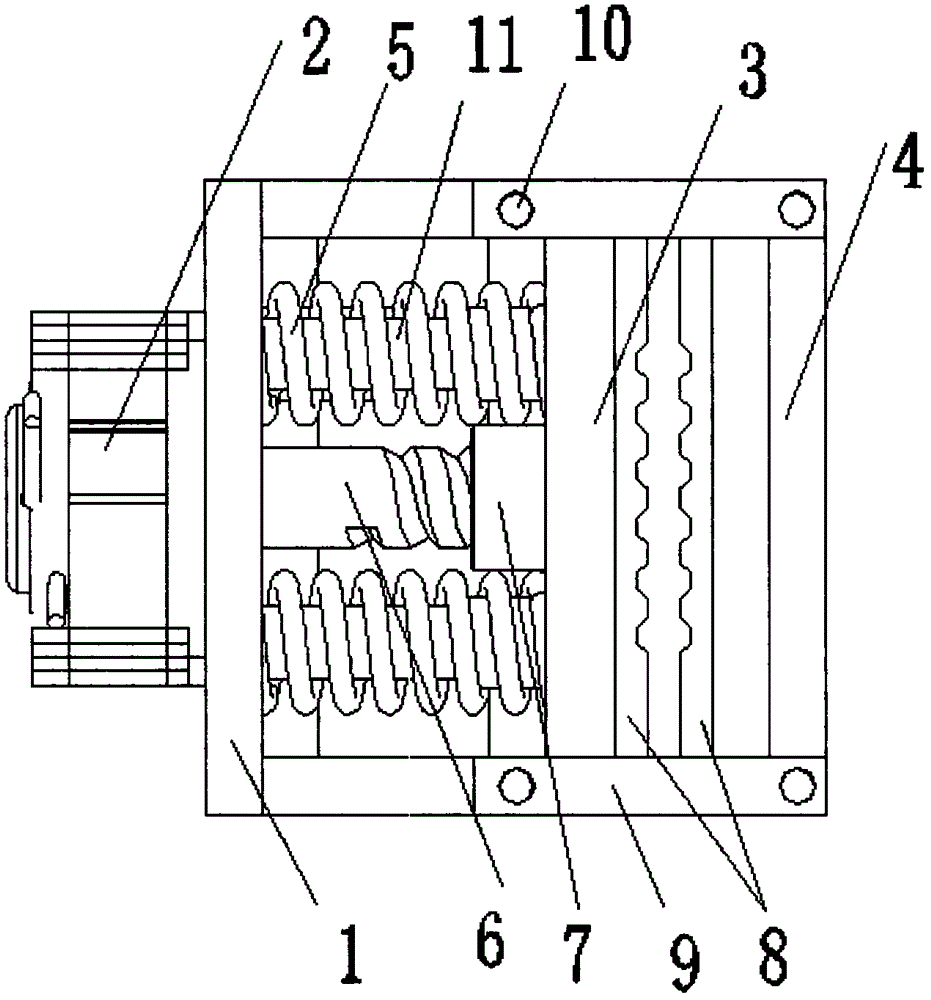

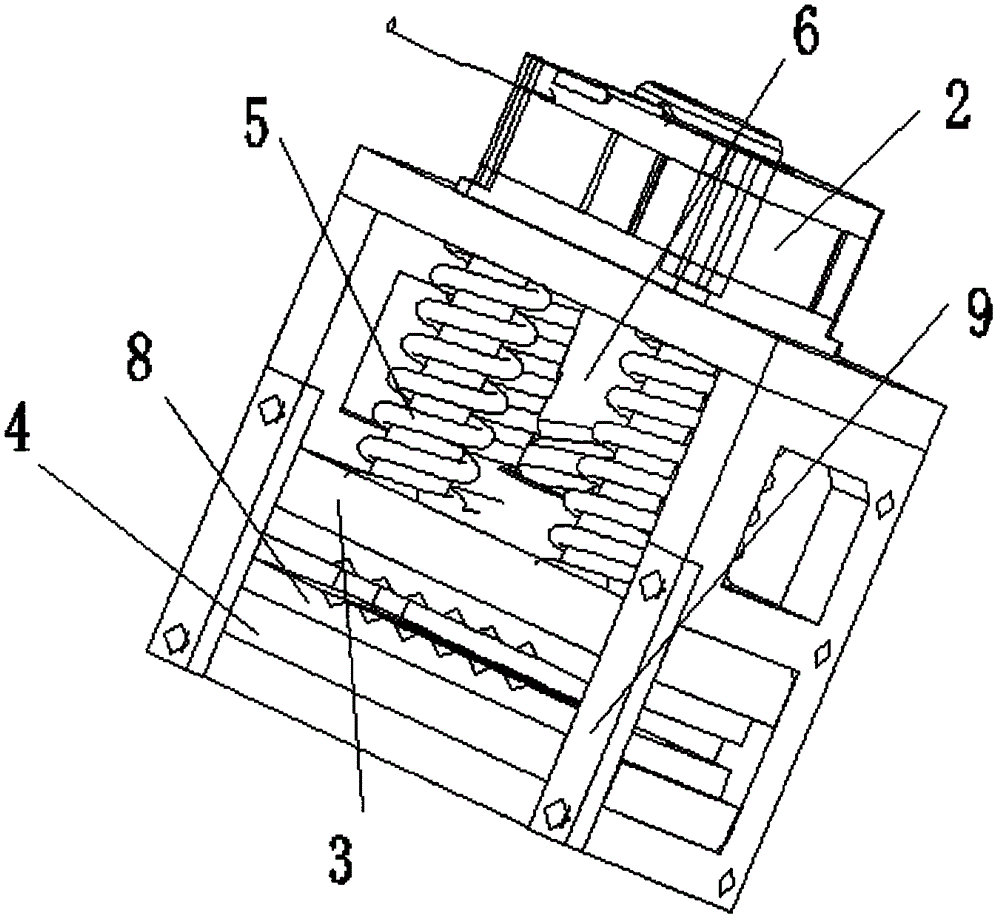

[0016] A motor-driven elevator rope clamping device with automatic reset will be described in detail below with reference to the accompanying drawings.

[0017] Such as figure 1 and figure 2 A motor-driven elevator rope clamping device with automatic reset shown includes a main body base 1, a driving motor 2 arranged on one side of the main body base 1, a driving moving plate 3 and a static plate 4 arranged in the main body base 1, It is characterized in that: a spring 5, a guide post, a lead screw 6 and a lead screw nut 7 are fixedly arranged between the main body seat 1 and the driving movable plate 3, the guide post 11 is arranged around the lead screw 6, and the guide post 11 is covered with a guide sleeve, a brake pad 8 is set between the driving moving plate 5 and the static plate 4, a brake pad baffle 9 is set on the main body seat 1, and the brake pad baffle 9 is fixed by bolts 10 , the static plate 4 is used to disengage from the wire rope of the elevator under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com