Cloth dyeing machine capable of effectively recycling dye

A cloth dyeing machine and dyeing technology, which is applied in the processing of textile materials, mechanical cleaning, equipment configuration for processing textile materials, etc., can solve the problems of nozzle blockage, affecting the quality and efficiency of dyeing cloth, and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

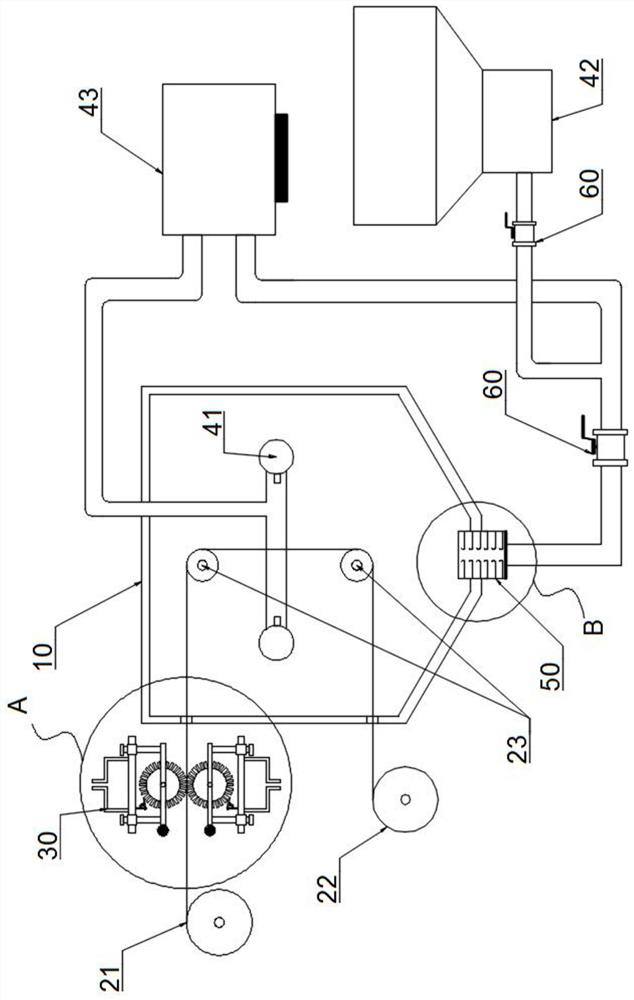

[0039] see Figure 1 to Figure 3 , a kind of dyeing machine that can effectively recycle dyestuff in the present embodiment, comprises body 10, unwinding roller 21, winding roller 22, two guide rollers 23, two groups of pre-cleaning devices 30, spray dyeing device, filter 50 and two discharge valves 60;

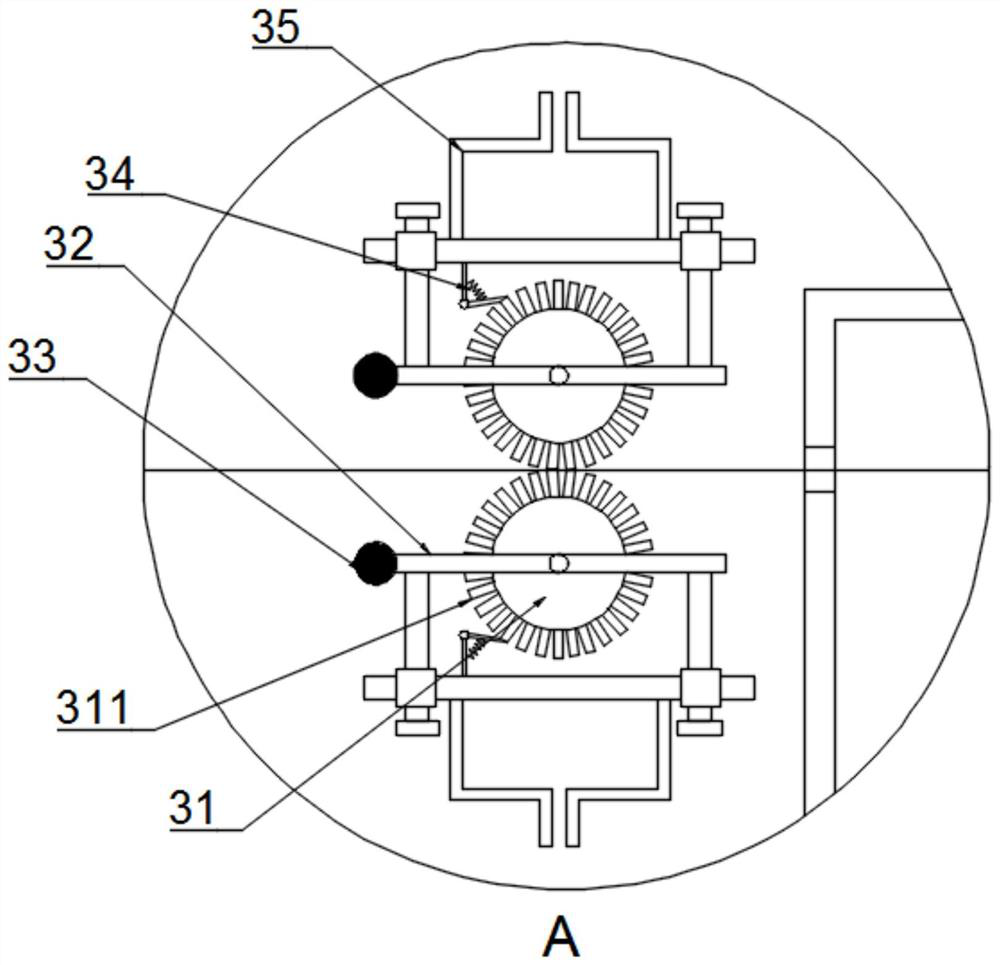

[0040] Specifically, the pre-cleaning device 30 includes a cleaning drum 31, a fixed bracket 32, a static elimination rod 33, an elastic scraper 34, a fan (not shown), an exhaust hood 35 and a collection box (not shown);

[0041] Specifically, the spraying device includes a spray pipe 41, a hopper 42 and a high-pressure pump 43;

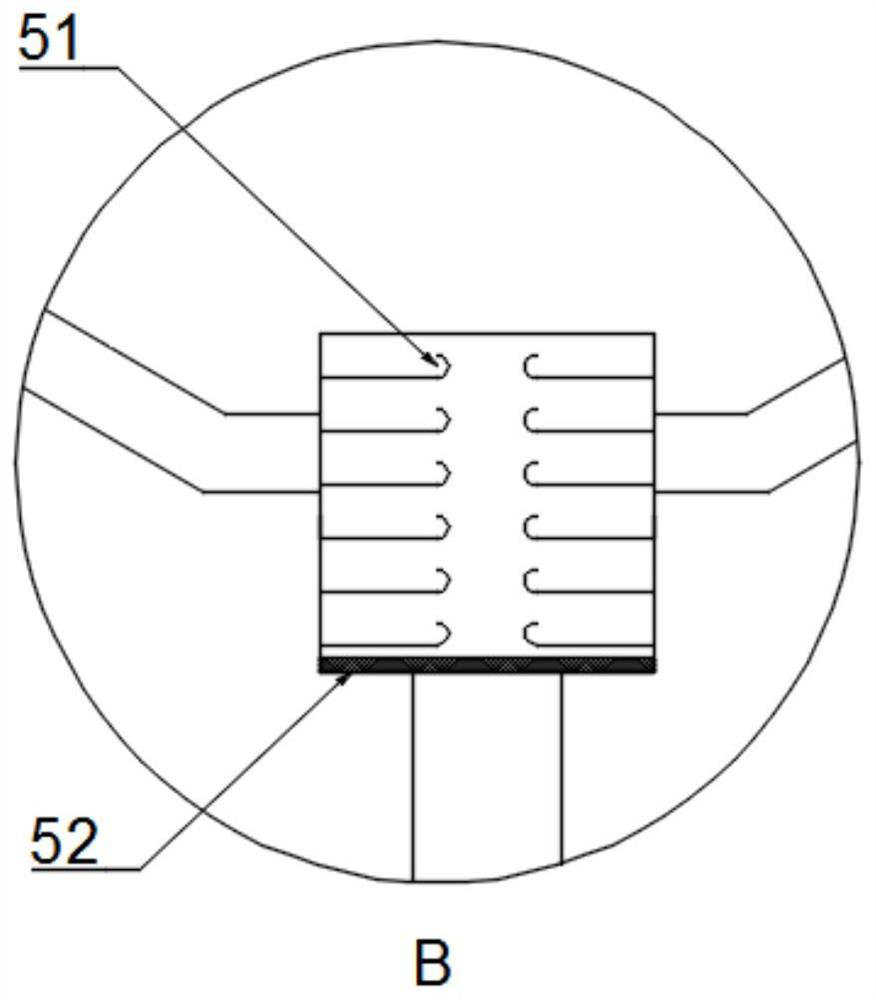

[0042] Specifically, a number of flexible hooks 51 are uniformly arranged on the inner wall of the filter 50; the flexible hooks 51 are all arranged horizontally; and a filter screen 52 is also provided at the bottom of the filter 50.

[0043] The connection mode of this embodiment:

[0044] The unwinding roller 21 is arranged on one side outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com