Chemical fiber cloth fabric suspension device

A hanging device and cloth fabric technology, which is applied in the processing of textile materials, textile material carriers, textiles and papermaking, etc., can solve the problems of low hanging and drying rate of fabrics, reduced production efficiency of fabrics, and inability to process dyes, etc., to achieve The effects of protecting water sanitation, improving efficiency, and reducing occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

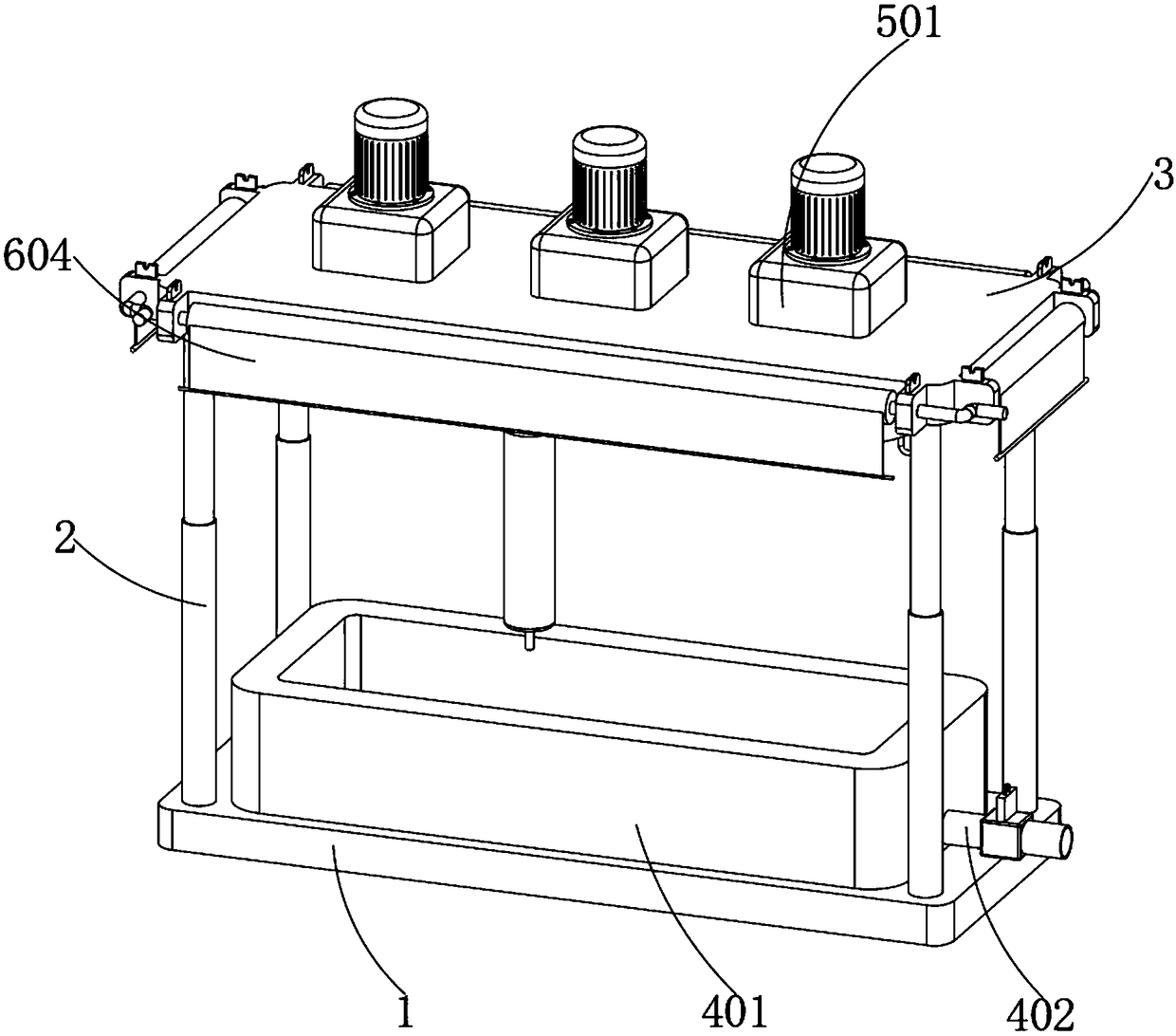

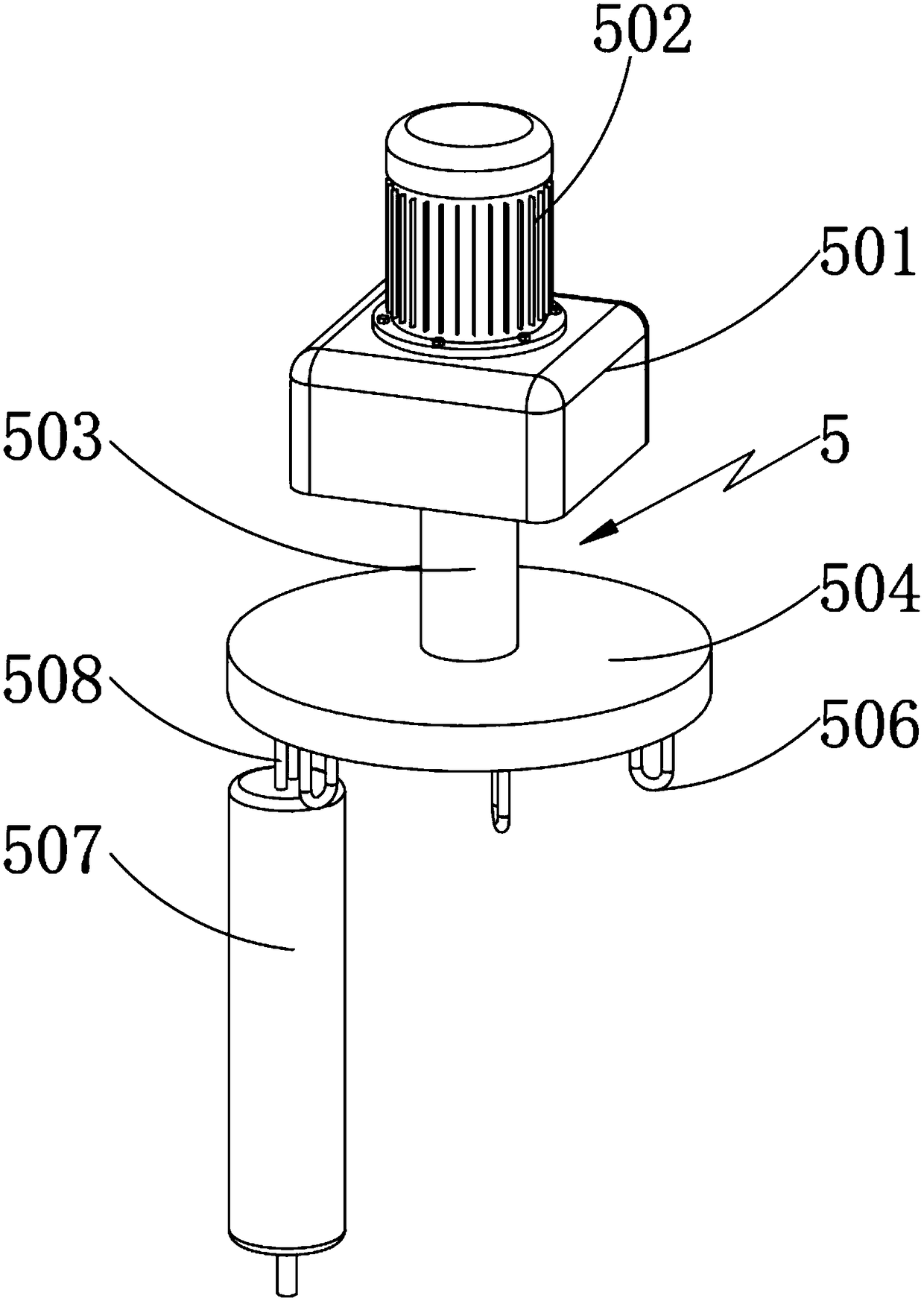

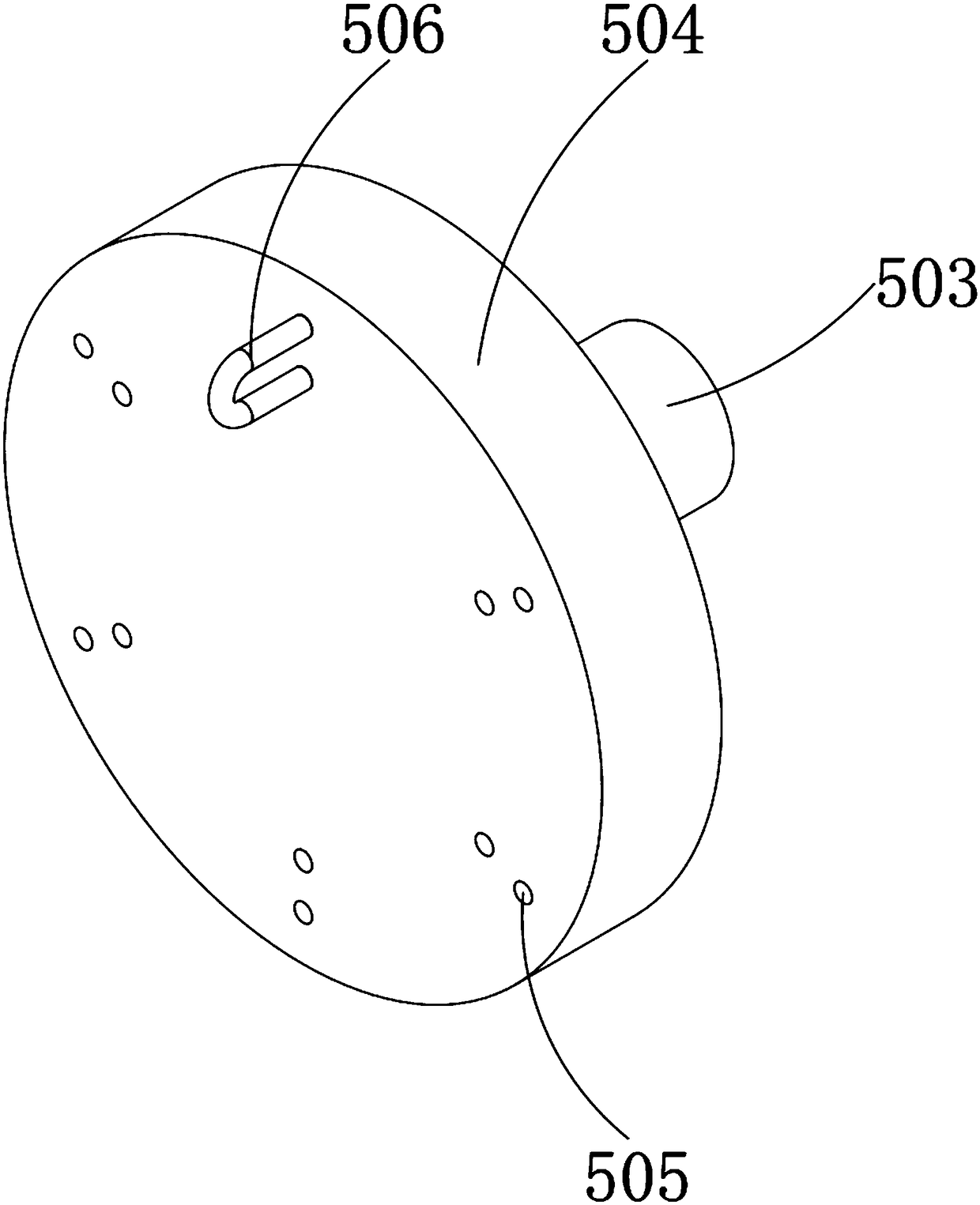

[0026] Example: such as Figure 1-6 As shown, the present invention provides a technical solution, a chemical fiber cloth fabric suspension device, including a bottom plate 1, and electric telescopic rods 2 are installed at each top corner of the upper surface of the bottom plate 1, and the model of the electric telescopic rod 2 is JF-TGA-50 , The top plate 3 is welded on the top of the electric telescopic rod 2 .

[0027] A dye recovery assembly 4 is installed in the middle of the upper surface of the bottom plate 1. The dye recovery assembly 4 includes a dye recovery tank 401, a sewage pipe 402, a filter box 403, a dye filter plate 404, and a handle 405. The base plate 1 and the dye recovery tank 401 are connected by welding , the bottom end of one end of the dye recovery tank 401 is equipped with a sewage pipe 402, the middle part of the sewage pipe 402 is equipped with a filter box 403, and the inside of the filter box 403 is interspersed with a dye filter plate 404. Leak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com