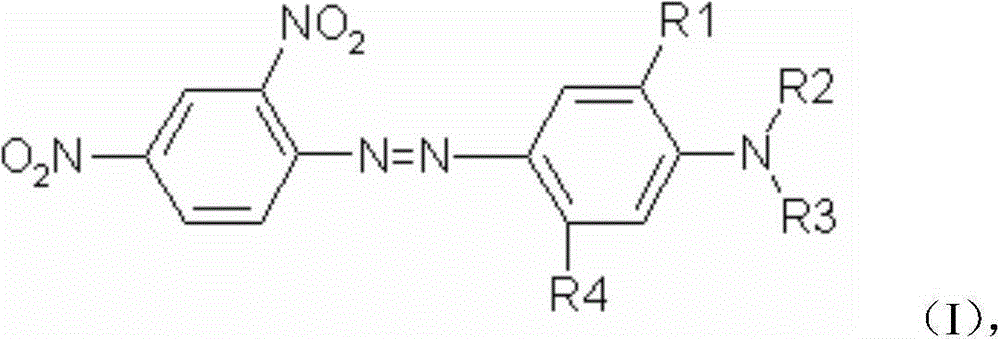

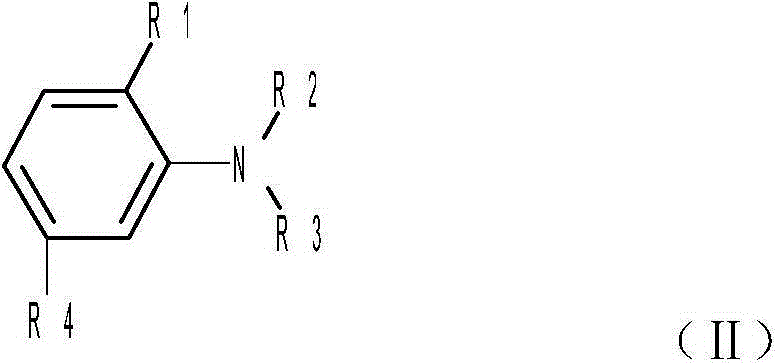

A kind of synthetic method of azo type disperse dye composition

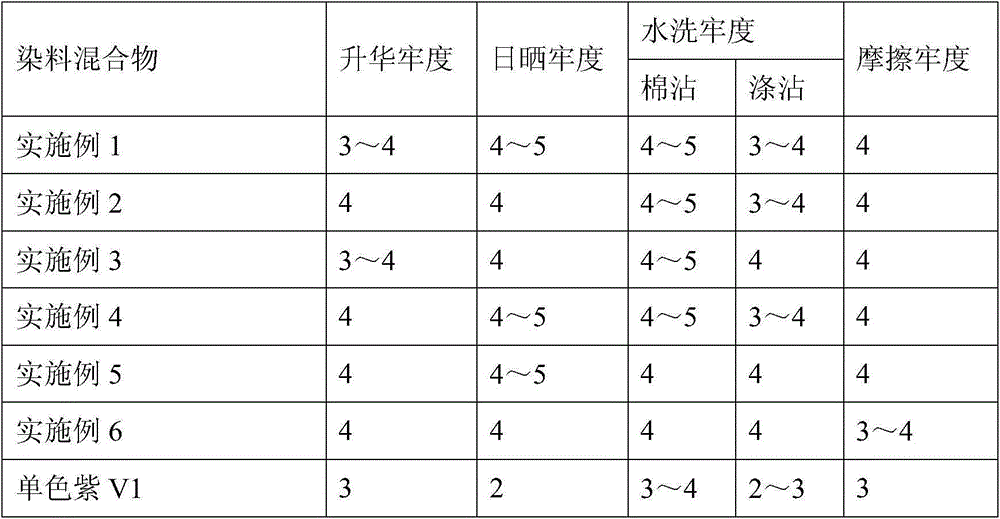

A technology for disperse dyes and a synthesis method, which is applied in the field of synthesis process of azo-type disperse dye compositions, can solve problems such as unsatisfactory light fastness of monochromatic varieties, reduce production costs and sewage discharge, and simplify individual production. process, eliminating the effect of the mixing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] According to the product is a mixture of disperse violet, the mol ratio of the coupling component N ethyl-N-cyanoethyl m-aminoacetanilide to N-allyl N-cyanoethyl o-methoxy m-acetanilide is reversed to be 3 :2.

[0033]Diazotize 0.2mol of 2,4-dinitroaniline by conventional methods to obtain 0.2mol of the diazo component of 2,4-dinitroaniline, and dilute it into 600g of ice water at about 0°C to synthesize the diazo component Liquid separation; add emulsifier OP-10 and dispersant sulfamic acid 1g each, then weigh 0.132mol of N-ethyl-N-cyanoethyl m-aminoacetanilide, and dissolve it in 10% dilute sulfuric acid solution below 10°C In the range of 0-10°C, add it dropwise to the above-mentioned diluted diazo component liquid to start the coupling reaction, keep it for 0.5-1 hour to obtain the reaction product, and then weigh N-allyl-N-cyanoethyl 0.088 mol of o-methoxy m-acetamidoaniline, dissolved in 10% dilute sulfuric acid, and then added dropwise to the above reaction prod...

Embodiment 2

[0034] According to the product being a mixture of disperse violet, the molar ratio of the coupling component N-cyanoethyl-N-benzyl-m-acetanilide to N,N-diallyl-o-methoxy-m-acetanilide is 59: 41.

[0035] 0.2mol of 2,4-dinitroaniline is diazotized by conventional methods to obtain 0.2mol of the diazo component of 2,4-dinitroaniline. In a 2000ml beaker, add 200ml of 10% dilute sulfuric acid and cool down to below 10°C , add 0.118mol N-cyanoethyl-N-benzyl-m-acetanilide and 0.082mol N,N-diallyl-o-methoxy-m-acetanilide under stirring to dissolve, add ice 400g after complete dissolution, and add disperse Add 1g of sulfamic acid and emulsifier OP-10, then add the above diazo component solution dropwise into the dissolved mixed azo component liquid, control the temperature at 0-10°C, keep it until the diazo component Disappearance is the end point. After the end point is reached, the temperature is raised to 40° C. for 1 hour, and filtered to obtain a mixture of disperse violet dyes...

Embodiment 3

[0037] According to the product being a mixture of disperse violet, the molar ratio of the coupling component N,N-diethyl-m-acetanilide to N-allyl-N-cyanoethyl o-methoxy-m-acetanilide is 3: 2.

[0038] 0.2mol2,4-dinitroaniline is diazotized by conventional methods to obtain 0.2mol of the diazo component of 2,4-dinitroaniline, which is divided into two parts of 50% and 50% by weight, and N,N- Dissolve 0.114mol of diethyl-m-aminoacetanilide in 10% sulfuric acid solution below 10°C, pour it into a 2000ml beaker after fully dissolving, add 400g of ice, and add dropwise to the above-mentioned portion at -5~5°C In the nitrogen component, obtain the reaction product, keep it for 1 hour, then dissolve 0.076mol of N-allyl-N-cyanoethyl-o-methoxym-acetaniline with 10% dilute sulfuric acid, dissolve completely, and pour it into the above-mentioned To the reaction product, add a small amount of ice and adjust the temperature of the coupling liquid to about 0°C, add another part of the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com