Polyester/sorona mixed fabric disperse dye one-bath process dyeing method

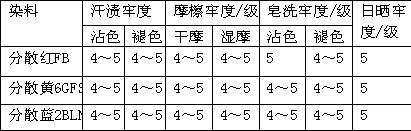

A technology of disperse dyes and dyeing methods, which is applied in the field of one-bath dyeing of polyester/sorona blended fabrics with disperse dyes, can solve the problems of homochromaticity and difference in dyeing performance, and achieve high product quality, low production cost, and various color fastnesses high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention relates to polyester / sorona blended fabric disperse dye one-bath method dyeing method, described method comprises the following processing steps:

[0017] Put the polyester / sorona interwoven fabric in water with a bath ratio of 1:10 at room temperature, add dispersant NNO 0.5 g / l and self-made carrier solution, circulate for 10 minutes, then add disperse dyes, and adjust the dye ratio according to different color requirements , when the pH value is adjusted to 5.5 with HAC, the cycle runs for 5 minutes, and then the temperature is raised to 110°C at 2°C / min, and the holding time is 50min. After dyeing, wash with water, wash with reducing cleaning solution (composed of 1.5g / L soda ash and 1.5g / L sodium hydrosulfite), and treat at 70°C for 20min.

[0018] The present invention adopts the method of adding self-made carriers in the dye liquor, and the above-mentioned dyeing process that takes, only the consumption of self-made carriers in the dye liquo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com