Disperse grey dye composition

A technology of dye composition and disperse ash, which is applied in the field of disperse ash dye composition and dye products containing the composition, which can solve the problems of light-colored cloth blocking, shorten dyeing time, high success rate and small batch difference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

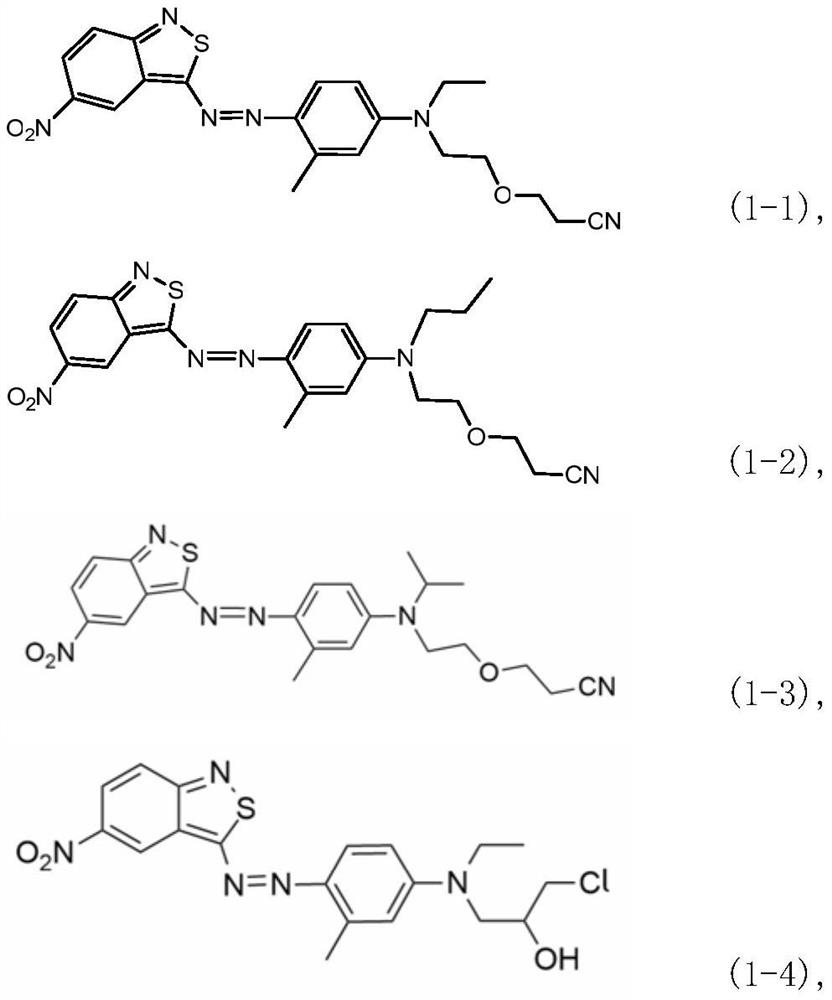

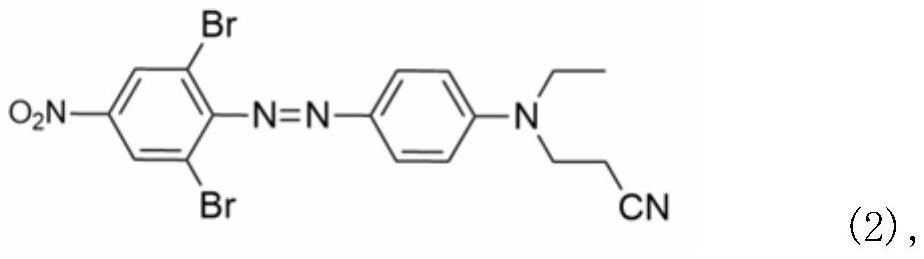

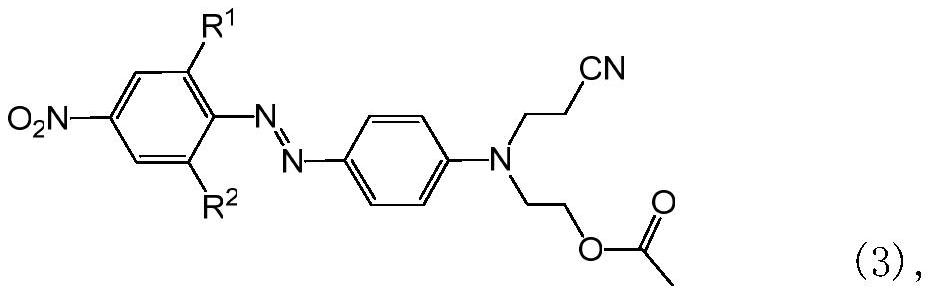

[0047] Component A shown in 26 grams of formula (1-1), component B shown in 31 grams of formula (2), component C shown in 18 grams of formula (3-1), 25 grams of formula (4- 1) The components D shown are mixed, crushed with a pulverizer, and mixed to obtain the disperse gray dye composition of the present invention.

[0048] 50 grams of the disperse gray dye composition of the present invention, 300 grams of dispersant MF and 300 grams of water are micronized with a sand mill (for dispersion treatment), and then spray-dried to obtain a solid dye product of the disperse gray dye composition. Based on the disperse gray dye composition used: the mass fraction of component A shown in formula (1-1) is 26%, the mass fraction of component B shown in formula (2) is 31%, and the mass fraction of component C shown in formula (3) The fraction is 18%, and the mass fraction of component D shown in formula (4) is 25%.

Embodiment 2~5

[0050] According to the dosage shown in Table 1, Component A, Component B, Component C, Component D, auxiliary agent, synergist and 200 grams of water are ground and dispersed with a sand mill, and then spray-dried to prepare Solid dye preparations for disperse dye compositions.

[0051] Table 1

[0052]

Embodiment 6

[0067] Imitate the phenomenon of cylinder blockage during dyeing, stop the machine during the dyeing process, and then heat up the dyeing after cooling down.

[0068] Experimental equipment: overflow double-cylinder mid-sample test machine

[0069] Normal dyeing: Weigh 1.226kg of white embryo polyester fiber, install it in the sample tank, put 12.3L of water, 5.4g of disperse dye in the machine tank, and add 18g of 0.5g / L glacial acetic acid. Raise the temperature at 3°C / min to 130°C, keep the temperature for 60 minutes, cool down and take samples. Described disperse dye is respectively with the dye product made in embodiment 1, the dye product made in comparative example 3, makes normal dyed cloth sample.

[0070] Shutdown of the tank during simulated dyeing: Weigh 0.68kg of white embryo polyester fiber and install it in the sample tank. Put 12.3L of water, 5.4g of disperse dye into the machine tank, and add 12.26g of 10g / L glacial acetic acid. Raise the temperature at 3°C / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com