Batch dyeing method to dye cotton fabrics with vat dyes under enhanced oxidation and zero soaping

A technology for cotton fabrics and dyes, applied in the field of printing and dyeing, can solve the problems of high consumption and achieve the effects of reducing emissions, improving efficiency, and shortening the process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

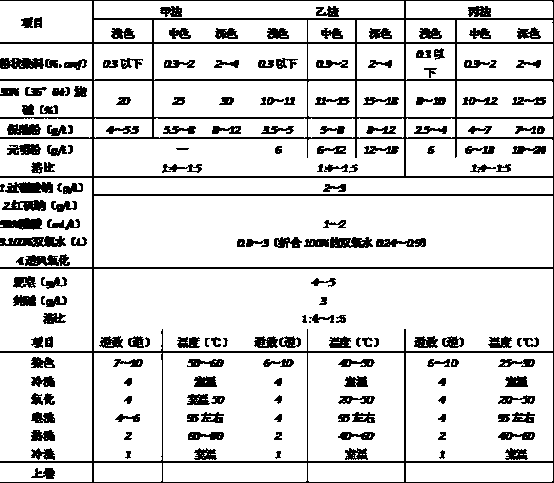

[0060] A method for intermittent dyeing of cotton fabric vat dyes to strengthen oxidation and remove soaping, comprising the following steps: after mercerizing, dry cloth is restored in a full bath before dyeing, jigger dyeing, vat passing, oxidation, cold washing, hot washing, cold washing, rolling up ;

[0061] Oxidation working solution includes: 100% hydrogen peroxide 4g / L.

[0062] The dyeing solution includes: diffusing agent 1.5g / L, vat dye 0.26%owf;

[0063] The reducing solution includes: 100% caustic soda 5g / L, 85% hydrosulfite 5g / L;

[0064] The remainder is water;

[0065] Bath ratio: 1:4.

[0066] The jigger temperature is 62±0.5°C.

[0067] The oxidation temperature was 40°C.

[0068] The hot wash temperature is 88°C.

Embodiment 2

[0070] A method for intermittent dyeing of cotton fabric vat dyes to strengthen oxidation and remove soaping, comprising the following steps: after mercerizing, dry cloth is restored in a full bath before dyeing, jigger dyeing, vat passing, oxidation, cold washing, hot washing, cold washing, rolling up ;

[0071] Oxidation working solution includes: 100% hydrogen peroxide 6g / L.

[0072] The dyeing solution includes: diffusing agent 1g / L, vat dye 1.94%owf;

[0073] The reducing solution includes: 100% caustic soda 8g / L, 85% sodium hydrosulfite 8g / L, sodium sulfate 12g / L;

[0074] The remainder is water;

[0075] Bath ratio: 1:5.

[0076] The jigger temperature is 62±0.5°C.

[0077] The oxidation temperature was 40°C.

[0078] The hot washing temperature is 90°C.

Embodiment 3

[0080] A method for intermittent dyeing of cotton fabric vat dyes to strengthen oxidation and remove soaping, comprising the following steps: after mercerizing, dry cloth is restored in a full bath before dyeing, jigger dyeing, vat passing, oxidation, cold washing, hot washing, cold washing, rolling up ;

[0081] Oxidation working solution includes: 100% hydrogen peroxide 7g / L.

[0082] The dyeing solution includes: dispersant 0.5g / L, vat dye 4.14%owf;

[0083] The reducing solution includes: 100% caustic soda 11g / L, 85% sodium hydrosulfite 11g / L, sodium sulfate 24g / L;

[0084] The remainder is water;

[0085] Bath ratio: 1:4.

[0086] The jigger temperature is 62±0.5°C.

[0087] The oxidation temperature was 40°C.

[0088] The hot wash temperature is 85°C.

[0089] A production line is calculated based on 12 sets of 180 dyeing jiggers in large rolls using the intermittent production method of vat dyes. Each dyeing machine produces 4 large rolls of cloth every day. The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com