Method for preparing high-purity small oxidized graphene

A graphene, small-scale technology, applied in the direction of single-layer graphene, etc., can solve the problems of high cost, complex process and high toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

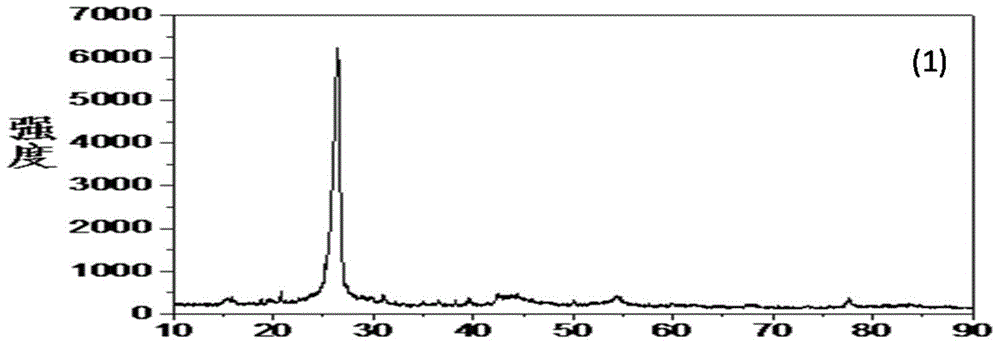

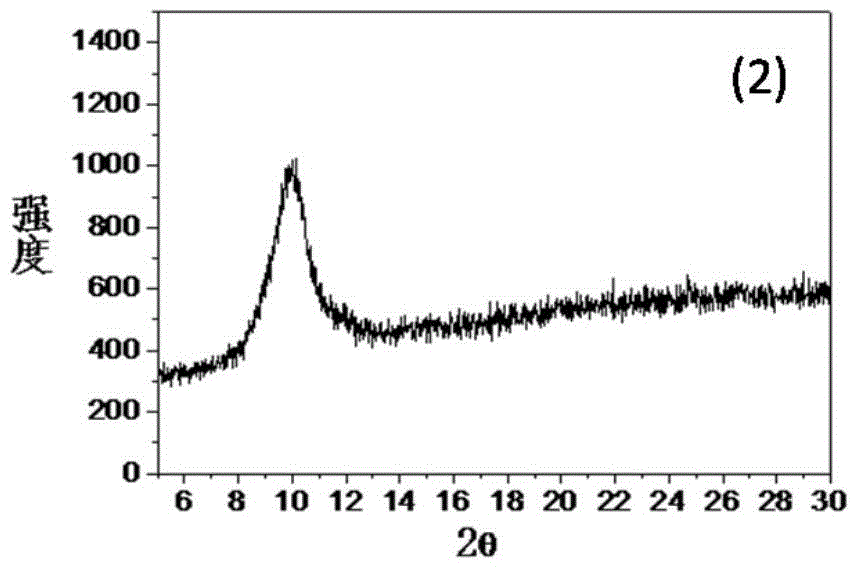

Image

Examples

Embodiment 1

[0021] First, place the aphanitic graphite in a 20% hydrofluoric acid solution (diluted with ethanol, that is, 40% HF and ethanol 1:1 to make a 20% HF solution), wash with hydrofluoric acid for 2 hours under stirring, and centrifuge. Use ethanol and water to wash and centrifuge, repeat several times until the pH is about 7, and dry at 80°C to obtain HF-purified aphanitic graphite. Add 0.6g of HF-purified aphanitic graphite and 3g of potassium permanganate Add 30mL concentrated sulfuric acid with a concentration of 98% to the lining of a 50mL polytetrafluoroethylene reactor and cool at 0°C for 12 hours. Cover, let stand at 0°C for 1.5h, then react in an oven at 90°C for 2h, after natural cooling, take out the polytetrafluoroethylene reactor from the stainless steel shell, and slowly pour the reaction mixture into 0.5L deionized In water, after stirring evenly, add 5mL aqueous hydrogen peroxide solution with a mass concentration of 25%, stir until the suspension is brownish yell...

Embodiment 2

[0024] The high-temperature melting method is mixed with a certain proportion of alkali, calcined at a high temperature of 400-600 ° C, washed to remove water-soluble substances, acid-washed to remove oxide impurities easily soluble in acid, and then washed and dried to obtain purified Aphanitic graphite, 6g of aphanitic graphite purified by high-temperature melting method, 60g of potassium ferrate were added to the lining of a 200ml polytetrafluoroethylene reactor and 150ml of concentrated phosphoric acid with a concentration of 85.5% were cooled at -2°C for 12h, After cooling, add concentrated phosphoric acid to the inner lining of the above-mentioned reaction kettle, place it in a stainless steel reaction kettle and cover it tightly, let it stand at 0°C for 4 hours, and then react in an oven at 90°C for 1 hour; after natural cooling, put the polytetrafluoroethylene Take out the ethylene reaction kettle from the stainless steel kettle shell, slowly pour the reaction mixture i...

Embodiment 3

[0027]Add 10g of aphanitic graphite purified by high-temperature melting method, 30g of potassium dichromate into the inner lining of 1000ml polytetrafluoroethylene reactor and 800ml of perchloric acid, respectively cool at -5°C for 24h, after cooling, add perchloric acid Put it into the lining of the above-mentioned reaction kettle, put it in a stainless steel reaction kettle and cover it tightly, let it stand at 0°C for 1h, and then react in an oven at 80°C for 4h; after natural cooling, remove the polytetrafluoroethylene reaction kettle from the stainless steel kettle Take out the shell, slowly pour the reaction mixture into 5L deionized water, stir evenly, add 50mL aqueous hydrogen peroxide solution with a mass concentration of 25%, stir until the suspension is brownish yellow or bright yellow, and dissolve the suspension solution, let it stand overnight, remove the supernatant, centrifuge, wash with 1M dilute hydrochloric acid for 5 times, and then wash with distilled wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com