Preparation method of lithium cobaltate material

A technology of lithium cobalt oxide and lithium carbonate, applied in chemical instruments and methods, cobalt compounds, inorganic chemistry, etc., can solve the problems of increasing liquid and solid mixing procedures, increasing the length and difficulty of the process, hidden dangers of organic matter, etc., to avoid safety Hidden dangers and environmental problems, perfect crystal growth, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

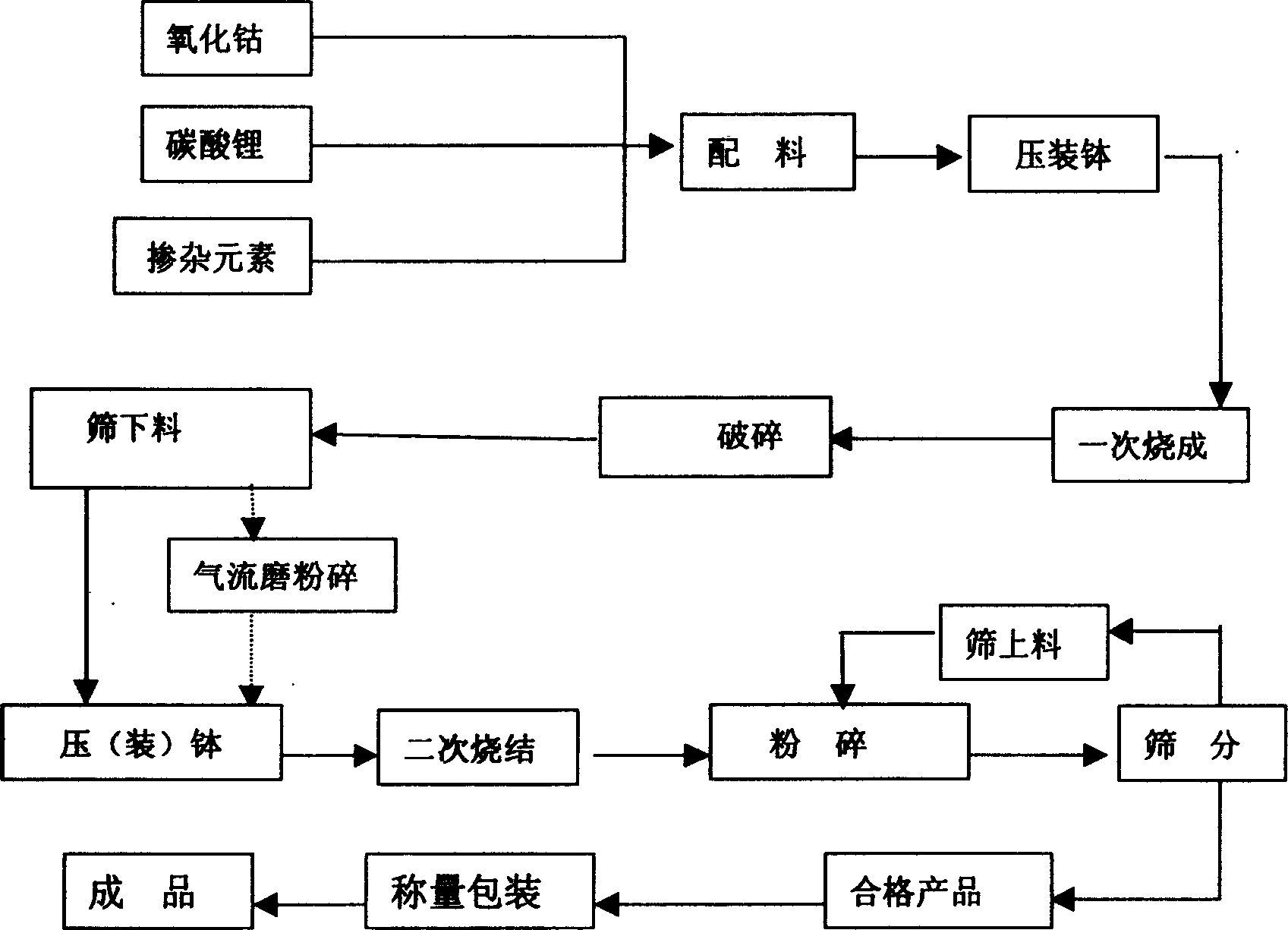

[0024] refer to figure 1 A kind of preparation method of lithium cobalt oxide material of the present invention, its step comprises:

[0025] 1) 317.35 grams of lithium carbonate, 681.30 grams of cobalt tetroxide, and 1.9 grams of zirconium dioxide are uniformly mixed;

[0026] 2) Compact the above-mentioned mixture with a bowl press, and the compacted density is 0.8-2.0g / cm 3 , and then put the compacted mixture into the sagger;

[0027] 3) After energizing the kiln and adjusting the temperature in the high-temperature zone of the kiln to 900°C, stack the above-mentioned saggers after filling the bowls and place them on the push plate of the outer push plate frame, and perform a sintering for 16 to 22 hours;

[0028] 4) Using a jaw crusher and a combined crushing system to crush the compacted mixture after primary sintering, and the particle size of the output material is D50=3-15um;

[0029] 5) After the above-mentioned pulverized mixture is compacted with a bowl press, i...

Embodiment 1

[0035] Mix 317.35 grams of lithium carbonate, 681.30 grams of tricobalt tetroxide, and 1.9 grams of zirconium dioxide evenly, compact the above-mentioned mixture with a bowl press, and then put the compacted mixture into the sagger; Constant temperature sintering for 16 hours. After being processed by the crushing system, it was sintered again at 900°C for 16 hours. After crushing, the particle size of the product was 7.09um, and the tap density was 2.36g / cm 3 .

Embodiment 2

[0037] Mix 373.15 grams of lithium carbonate with 808.28 grams of cobalt tetroxide evenly, compact the above mixture with a bowl press, and then put the compacted mixture into a sagger; sinter at a constant temperature of 900 degrees in the kiln for 22 hours. After being processed by the combined crushing system, it is sintered again at 900°C for 18 hours. After crushing, the particle size of the product is 7.78um and the tap density is 2.51g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com