Active dye cold pad fixation method

A technology of reactive dyes and cold stacking, which is applied in the field of reactive dyes cold stacking color fixing process, can solve the problems of greater influence of shade, easy hydrolysis of reactive dyes, large batch difference of fabrics, etc., to achieve stable shade, smooth dyeing process, The effect of small batch difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

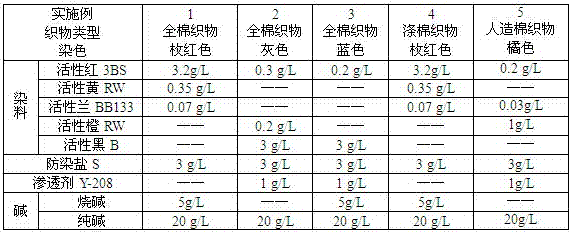

Embodiment 1

[0019] The reactive dye cold-batch color fixing process of dyeing cotton fabric into a red color, using Everzol C reactive dye (powder) and water to prepare a dye solution (the volume of the padding tank is 100L, and 3 g / L of Resist salt S (sodium 3-nitrobenzene sulfonate), wherein the dosage of reactive red 3BS is 3.2 g / L, the dosage of reactive yellow RW is 0.35 g / L, and the dosage of reactive blue BB133 is 0.07 g / L. Pad the above-mentioned dyeing solution to complete the pad dyeing (with a liquid rate of 65%), but add 10L of water to the padding tank before starting the pad dyeing, and then use hot air to dry the cotton fabrics after pad dyeing. Drying and drum drying, in which the hot air drying adopts a hot air drying box, and the drum drying adopts a drum dryer. Each drum dryer is equipped with 10 drying drums, and the pressure in each drying drum is The drying temperature is 2KG / cm2; the drying temperature of the hot air drying box is 80°C, and the drying temperature of...

Embodiment 2

[0021] The reactive dye cold-batch color-fixing process of dyeing cotton fabrics into gray, using Everzol C reactive dyes and water to prepare a dye solution (the volume of the padding tank is 100L, and 3 g / L of anti-staining salt S, 1g / L penetrant Y-208), wherein the dosage of reactive red 3BS is 0.3g / L, the dosage of reactive orange RW is 0.2g / L, and the dosage of reactive black B is 3g / L. Pad dyeing is completed with the dye liquor (liquid-carrying rate 62%), but 8L of water is added to the padding trough before the initial start-up of the pad dyeing, and then the cotton fabrics after pad dyeing are dried with hot air and then with a drying cylinder. Drying, wherein the hot air drying adopts a hot air drying box, and the drying drum drying adopts a drying drum dryer. Each drying drum dryer is equipped with 10 drying drums, and the pressure of each drying drum is 1KG / cm2; The drying temperature of the drying box is 80°C, and the drying temperature of the drum dryer is 100°C....

Embodiment 3

[0023] The reactive dye cold batch color fixing process of dyeing cotton fabrics blue, using Everzol C reactive dyes and water to prepare a dyeing solution (the volume of the padding tank is 100L, and 3 g / L of anti-staining salt S is added to the dyeing solution , 1g / L penetrating agent Y-208), wherein the dosage of reactive red 3BS is 0.2g / L, and the dosage of reactive black B is 3g / L, and padding the cotton fabric with the dye solution prepared above to complete the pad dyeing (with liquid rate of 58%), but add 9L of water to the padding trough before starting the pad dyeing, and then use hot air drying and drying drum drying for the cotton fabric after pad dyeing, of which hot air drying is hot air drying Drying box, drum drying adopts drum dryer, each drum dryer is equipped with 10 drying drums, and the pressure of each drying drum is 1.5KG / cm2; the drying temperature of the hot air drying box is 80°C, and the drying temperature of the drum dryer is 100°C. Then pad the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com