Patents

Literature

114results about How to "Meet the requirements of industrial mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nutrient release rate adjustable plant oil coated controlled-release fertilizer and preparation method thereof

ActiveCN104447026ARegulating nutrient release periodUniform coatingLayered/coated fertilisersFertilizer mixturesVegetable oilPtru catalyst

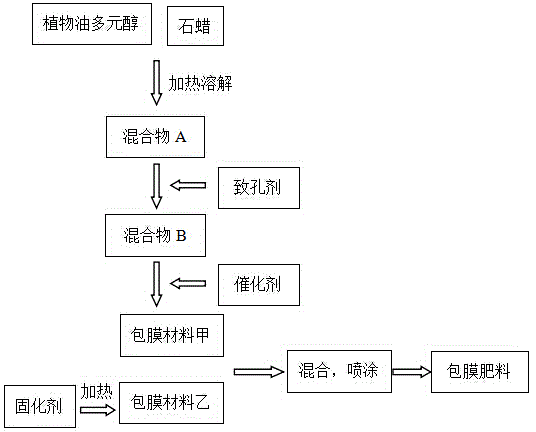

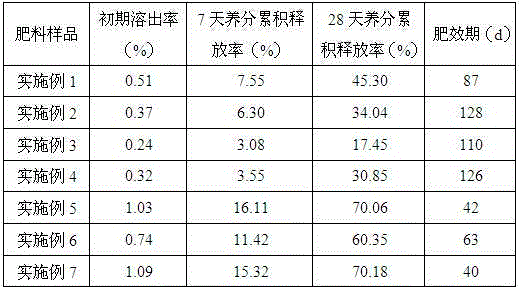

The invention discloses a nutrient release rate adjustable plant oil coated controlled-release fertilizer and a preparation method thereof. The preparation method comprises the following step: base on total weight of a coating frame substances, firstly co-mixing and polymerizing 1-10 percent of a pore-foaming agent, 1-18 percent of a film forming aid paraffin, 0.01-0.6 percent of an organic metal catalyst and plant oil polyol to prepare a coating material A; uniformly and simultaneously spraying the coating material A and polyisocyanate on the surface of a core fertilizer in a rotational flow-spraying fluidized bed on the bottom side; performing an in-situ polymerization reaction to generate a uniform high-molecular coating layer on the surface of the core fertilizer, wherein the coating frame substances are the plant oil polyol and the polyisocyanate of which the weight ratio is 1:(0.5-1.5). The preparation method disclosed by the invention has innovation in coating material selection, coated fertilizer nutrient release performance regulation, coating material co-mixing and polymerization process and coating process; the prepared controlled-release fertilizer is stable in quality, complete in coating, controllable in nutrient release rate, low in energy consumption in the coating process and simple and easy to operate in process.

Owner:SOUTH CHINA AGRI UNIV

Vanalium preparation method

The invention belongs to the field of metallurgy and particularly relates to a vanalium preparation method. The vanalium preparation method provided by the invention is low in cost and ensures high purity of obtained alloy. The technical scheme provided by the invention is as follows: in the vanalium preparation method, vanadium pentoxide and metallic aluminium are used as raw materials and are subjected to ignition reduction in a reaction device to obtain vanalium and furnace clinker; and a continuous feeding manner is adopted for the reaction device during feeding, and the feeding speed is 5-40kg / min. Compared with the prior art, the vanalium preparation method provided by the invention has the advantages that no coolant is added for controlling heat so that the cost is lower and the requirement for mass industrial production is completely met; and the produced vanalium is low in impurity content, the finished vanalium contains 65-91wt% of V, 9-35wt% of Al, not more than 0.3wt% of Fe and not more than 0.3wt% of Si, and the obtained vanalium has higher purity and meets the requirement of subsequent further processing.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

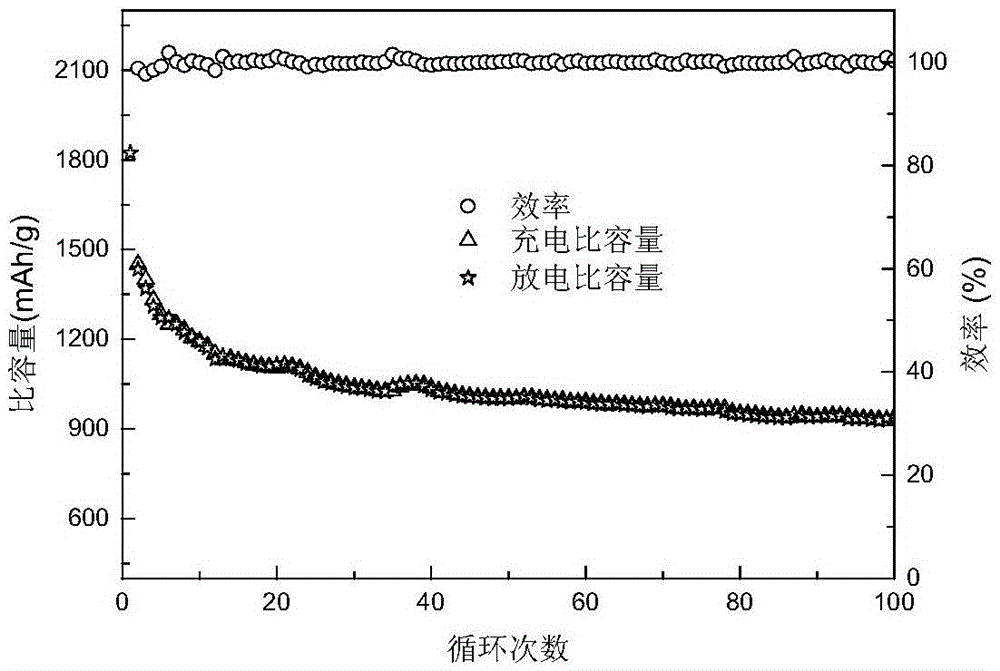

Lithium-sulfur battery containing barrier layer

InactiveCN105428616AImprove electrochemical performancePrevent collapseCell electrodesSecondary cellsFiberCarbon fibers

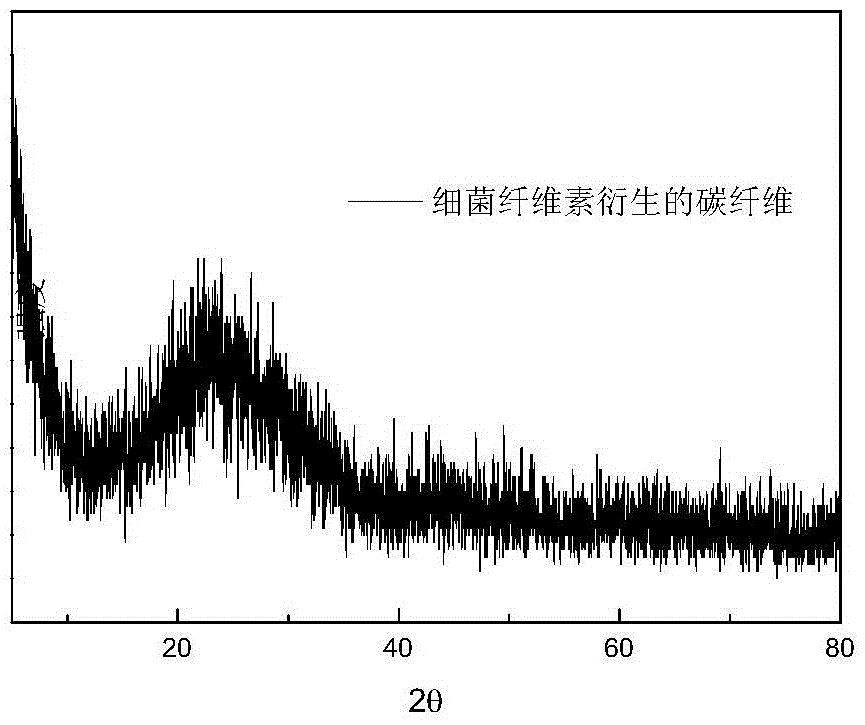

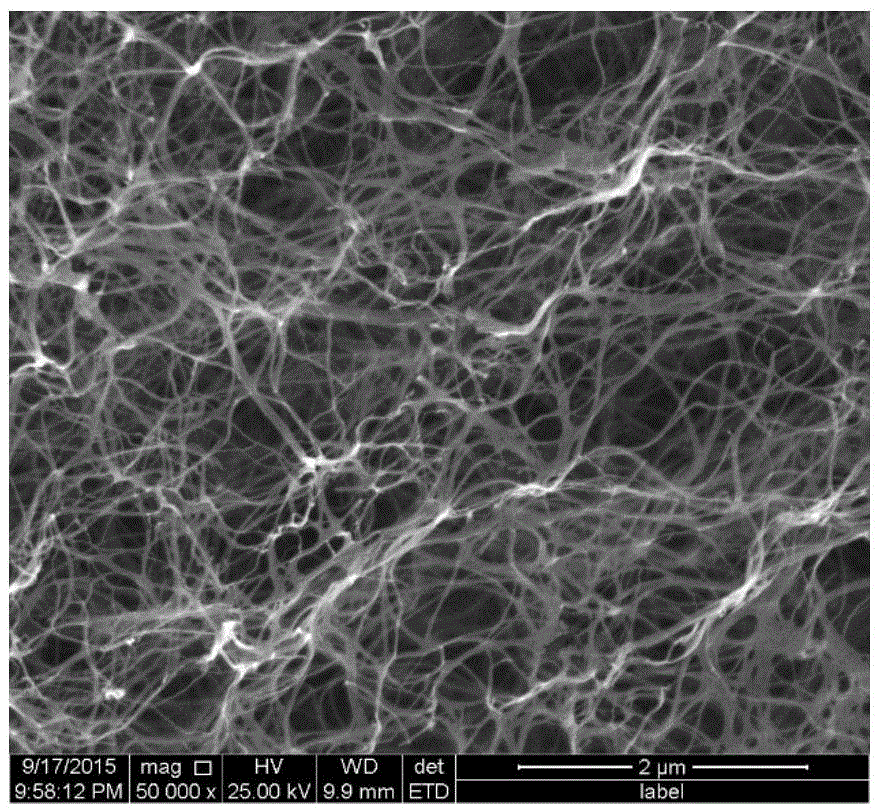

The invention relates to a lithium-sulfur battery containing a barrier layer, and belongs to the field of electrochemical batteries. The surface of the positive electrode of a conventional lithium-sulfur battery is coated with a bacterial cellulose derived carbon fiber barrier layer, so that the dissolution, shuttling and battery negative electrode corrosion of polysulfide in an electrolyte solution of the lithium-sulfur battery during charging / discharging are inhibited. According to the lithium-sulfur battery containing the barrier layer, a carbon material is directly pressed on the surface of a membrane by utilizing external pressure through using an ultra-filtration cup, and the membrane is directly used after being dried without the need for stripping the carbon-containing barrier layer, so that the material waste is avoided and the effectiveness and completeness of the barrier layer are ensured. The bacterial cellulose derived carbon fiber barrier layer improves the conductive problem of sulfur as an active substance of the positive electrode of the lithium-sulfur battery, and the three-dimensional space structure of carbon fibers also provides a buffer space for volume expansion during charging / discharging, so that the electrode collapse is prevented and the electrochemical performance of the lithium-sulfur battery is improved. Under the current density of 0.5C, the initial discharge specific capacity of the battery is 1,823.2mAh / g, and the specific discharge capacity of the battery after being cycled for 100 times is 939.4mAh / g.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

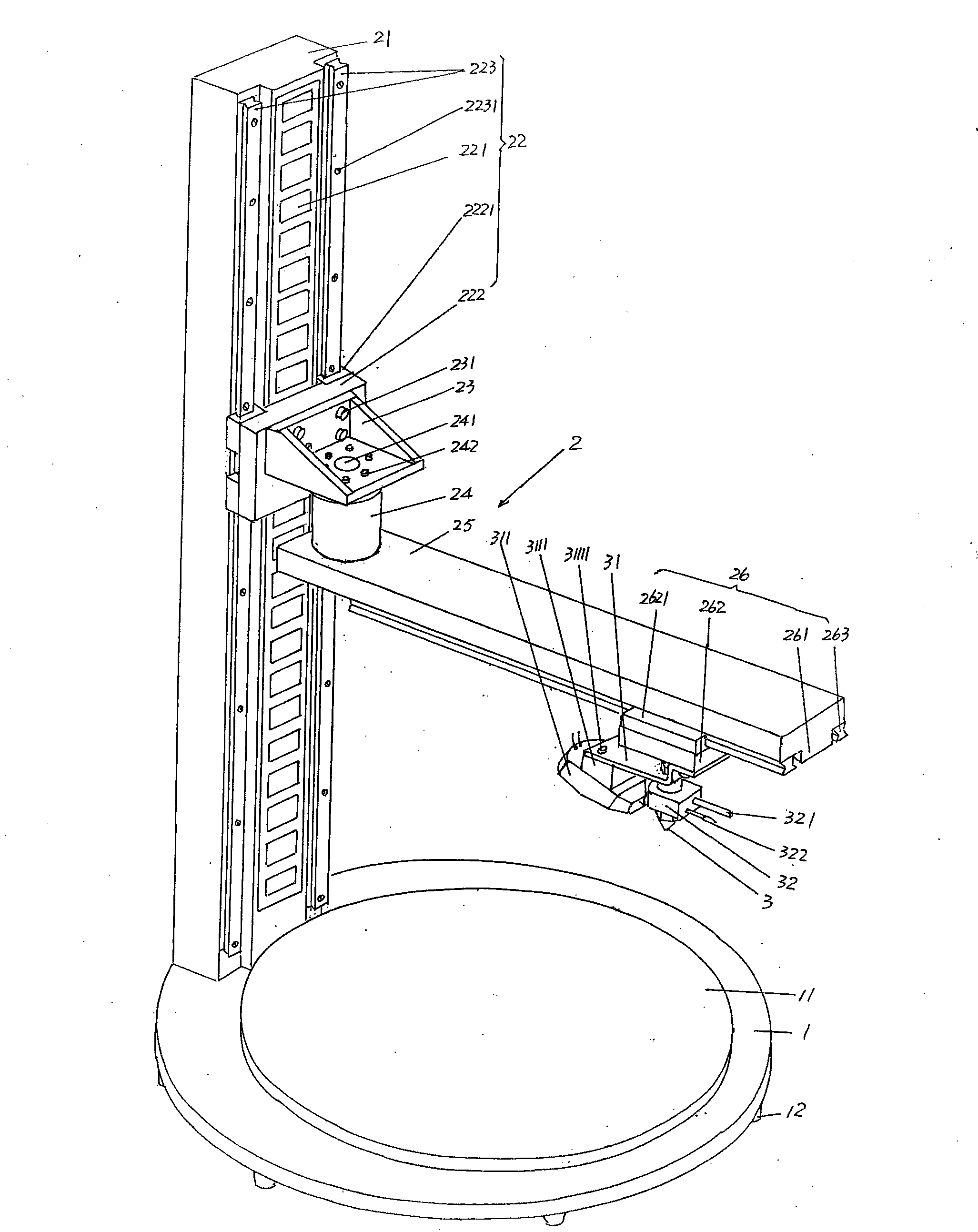

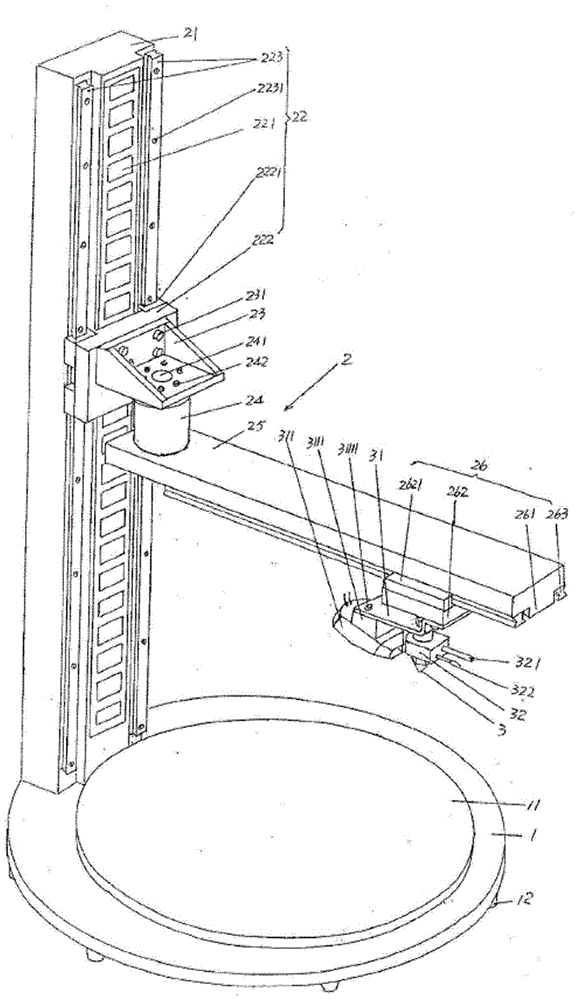

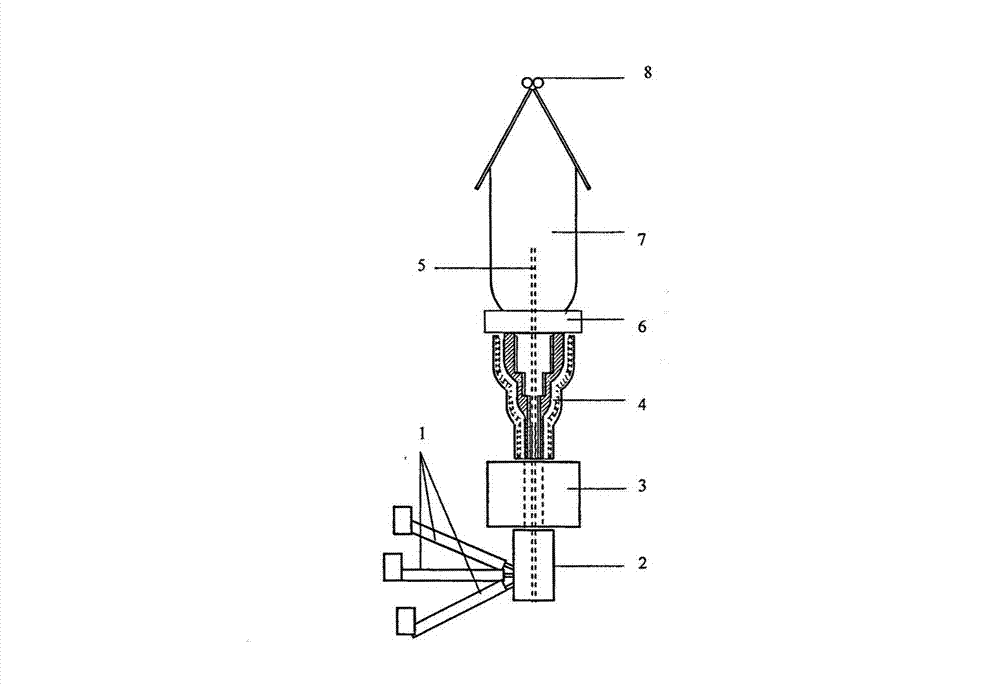

Rotary type 3D (three-dimensional) printer

ActiveCN104369383AEasy to printIncrease printing speedAdditive manufacturing apparatusCeramic shaping apparatusLinear motor3d printer

The invention discloses a rotary type 3D (three-dimensional) printer, belonging to the quick fused deposition molding equipment. The rotary type 3D (three-dimensional) printer comprises a base, a printing head platform drive mechanism and a printing head, wherein an objective table is arranged on the base; the printing head platform drive mechanism is arranged on the base; the printing head is arranged on the printing head platform drive mechanism which comprises a linear motor base, a linear motor, a rotary motor base, a rotary motor, a rotary arm and a printing head platform horizontal moving motor, wherein the linear motor is fixed on the base and arranged at one side, towards the rotary arm, of the linear motor base, the rotary motor base is fixed on the linear motor, the rotary motor is fixed on the rotary motor base, a rotary motor shaft is fixed with one end, towards the linear motor, of the rotary arm, the other end of the rotary arm is corresponding to a position above the objective table, the printing head platform horizontal moving motor is arranged at one side, towards the objective table, of the rotary arm, and the printing head is fixed on the printing head platform horizontal moving motor. The rotary type 3D printer disclosed by the invention can be used for improving the printing speed, printing high-precision components and precisely controlling the radius, the angle and the height, and is high in space utilization rate.

Owner:广州市文搏智能科技有限公司

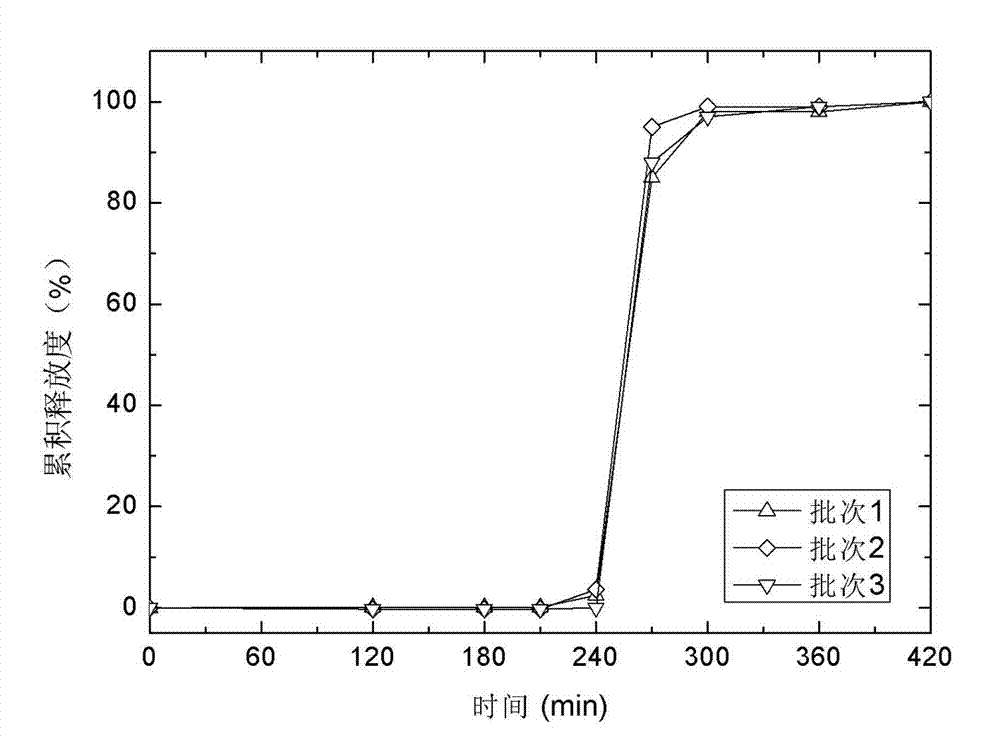

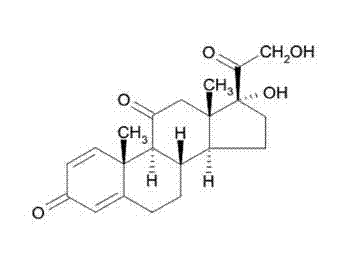

Oral prednisone time-selecting release preparation and preparation method thereof

InactiveCN103690545AGive full play to the therapeutic effectImprove balanceOrganic active ingredientsAntipyreticCelluloseFormulary

The invention discloses an oral prednisone time-selecting release preparation and a preparation method thereof. The oral prednisone time-selecting release preparation provided by the invention mainly consists of 0.3-5 parts of prednisone and derivatives thereof, 10-50 parts of glyceryl behenate and 3-30 parts of hydroxypropyl cellulose, and can further contain a disintegrating agent and other pharmaceutically acceptable excipients. The preparation method is as below: extruding tablet cores or granules containing the drug according to the formula by a tablet press or a dry granulator; and coating the tablet cores or particles containing the drug by a coating pan or a fluidized bed to attach the coating film to the tablet cores or particles containing the drug, so as to obtain the oral prednisone time-selecting release preparation. The oral prednisone time-selecting release preparation provided by the invention can achieve a good balance between the biological rhythm of the patients and the curative effects, and is safer, more convenient and effective compared with a traditional preparation. The oral prednisone time-selecting release preparation is prepared by an extrusion-coating process, which is simple for operation, and the obtained time-selecting release preparation has the advantages of drug stability and high reproducibility.

Owner:ZHONGSHUAI PHARMA SCI & TECH CO LTD

Method for preparing metal vanadium

The invention relates to a method for preparing metal vanadium, and belongs to the field of metallurgy. The technical problem to be solved is to provide a method for preparing the metal vanadium with low production cost. The method for preparing the metal vanadium comprises the following steps of: a, preparing crude vanadium, namely igniting and reducing vanadium trioxide and vanadium pentoxide serving as raw materials by using Al powder as a reducing agent to obtain the crude vanadium and slag, wherein the weight ratio of the vanadium trioxide to the vanadium pentoxide is 1:1-2, and the using amount of the Al powder is 0.6 to 0.9 time the theoretical using amount of the raw materials when the raw materials are completely reduced into vanadium (V) (the theoretical using amount is the using amount of the Al powder required for completely reducing the vanadium trioxide and the vanadium pentoxide serving as the raw materials into the metal vanadium); and b, refining, namely performing vacuum refining to obtain the metal vanadium.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Preparation method of vanadium-aluminum alloy

The invention discloses a preparation method of a vanadium-aluminum alloy, which can lower the producing cost of the vanadium-aluminum alloy. In the method, vanadium trioxide and vanadium pentoxide are taken as raw materials, Al powder is taken as a reducing agent and the vanadium-aluminum alloy and slag are obtained by igniting and reducing, wherein the weight ratio of the vanadium trioxide to the vanadium pentoxide is 1:1-2; and the using amount of the Al powder is 1.2 to 1.5 times of V ideal using amount (namely, the using amount of the Al powder needed for fully reducing the vanadium trioxide and the vanadium pentoxide into metal vanadium) of fully reduced raw materials. Compared with the conventional process, the method has lower cost and is fully accordant with the requirement on mass industrial production; moreover, the produced vanadium-aluminum alloy has low impurity content; a final vanadium-aluminum alloy comprises the following components in percentage by weight: 75 to 85 percent of V, less than or equal to 0.3 percent of Fe and less than or equal to 0.3 percent of Si; and the requirements on further subsequent processing are met.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Rotary-type 3D (three-dimensional) printer

ActiveCN105984150AEasy to printIncrease printing speedAdditive manufacturing apparatusCeramic shaping apparatusLinear motor3d printer

The invention discloses a rotary-type 3D (three-dimensional) printer, and belongs to the fused deposition quick molding equipment. The rotary-type 3D printer comprises a base, a printing head platform drive mechanism and a printing head, wherein an objective table is arranged on the base, the printing head platform drive mechanism is arranged on the base, and the printing head is arranged on the printing head platform drive mechanism. The printing head platform drive mechanism comprises a linear motor base, a linear motor, a rotary motor base, a rotary motor, a rotary arm and a printing head platform horizontal moving motor, wherein the linear motor is fixed on the base and arranged at one side, towards the rotary arm, of the linear motor base, the rotary motor base is fixed on the linear motor, the rotary motor is fixed on the rotary motor base, a rotary motor shaft is fixed with one end, towards the linear motor, of the rotary arm, the other end of the rotary arm is corresponding to a position above the objective table, the printing head platform horizontal moving motor is arranged at one side, towards the objective table, of the rotary arm, and the printing head is fixed on the printing head platform horizontal moving motor. The rotary type 3D printer disclosed by the invention can be used for improving the printing speed, printing high-precision components and precisely controlling the radius, the angle and the height, and is high in space utilization rate.

Owner:南通三聚知识产权服务有限公司

Enzymatic production technology of chitosan oligosaccharide

The invention discloses an enzymatic production technology of chitosan oligosaccharide. The technology comprises steps as follows: a, chitosan is added to an acetate solution, and a chitosan solution is prepared; b, a hydrogen peroxide solution is added to the chitosan solution and stirred uniformly, a mixed solution is subjected to a degradation reaction, and a degraded solution is obtained after degradation; c, the degraded solution is cooled to the room temperature, pH value is regulated to 6.2-6.5, then beta-glucosidase is added for primary enzymolysis, and a primary enzymatic hydrolysate is obtained; d, alpha-1, 4-glucan glucohydrolace is added to the primary enzymatic hydrolysate for secondary enzymolysis, and a secondary enzymatic hydrolysate is obtained; e, pH value of the secondary enzymatic hydrolysate is regulated to 6-6.5, the secondary enzymatic hydrolysate is subjected to rough filtration, ultrafiltration, nanofiltration, spray drying and sterilization sequentially, and a finished chitosan oligosaccharide product is obtained. According to the enzymatic production technology of chitosan oligosaccharide, the yield of chitosan oligosaccharide is greatly increased, molecular weight of the finally prepared chitosan oligosaccharide product can be smaller than 1500, the size is relatively uniform, and besides, the product contains no monosaccharide, therefore, the quality of the chitosan oligosaccharide product is effectively improved.

Owner:赵景卫

Vanadium-aluminum alloy and preparation method thereof

The invention belongs to the field of metallurgy, in particular relates to a vanadium-aluminum alloy and a preparation method thereof and aims at solving the technical problem of providing the preparation method of the vanadium-aluminum alloy. The preparation method comprises the following steps: with vanadium pentoxide and aluminum as raw materials, carrying out ignition to carry out reduction reaction, and preparing the vanadium-aluminum alloy, wherein the weight ratio of the vanadium pentoxide to the aluminum is (1.15-1.8) to 1, a graphite crucible with a cover is taken as a smelting furnace, fused magnesia cement is coated on the whole inner wall of the graphite crucible, and a hole is formed in the cover. The preparation method is low in cost and is capable of preparing the vanadium-aluminum alloy with low impurity and high quality.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

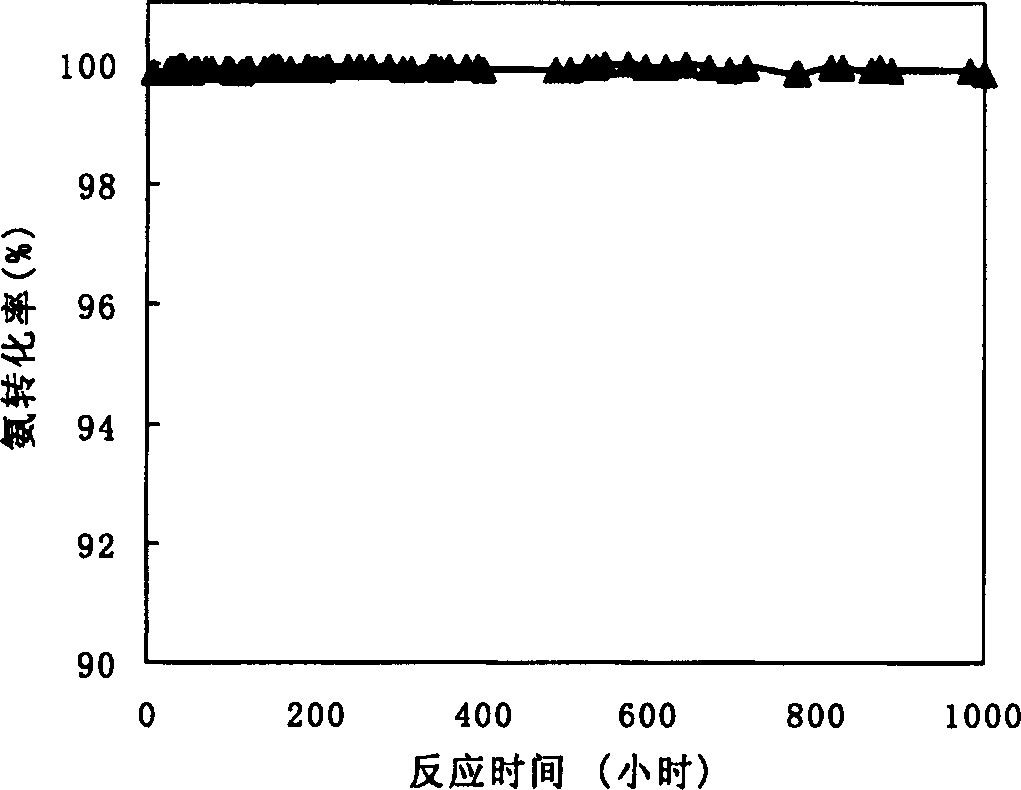

Prepn of nickel-base catalyst for decomposing ammonia

InactiveCN1772614AHigh activityStrong processing abilityCatalyst activation/preparationAlkali metal chloridesIonChemical measurement

Owner:大连华海制氢设备有限公司

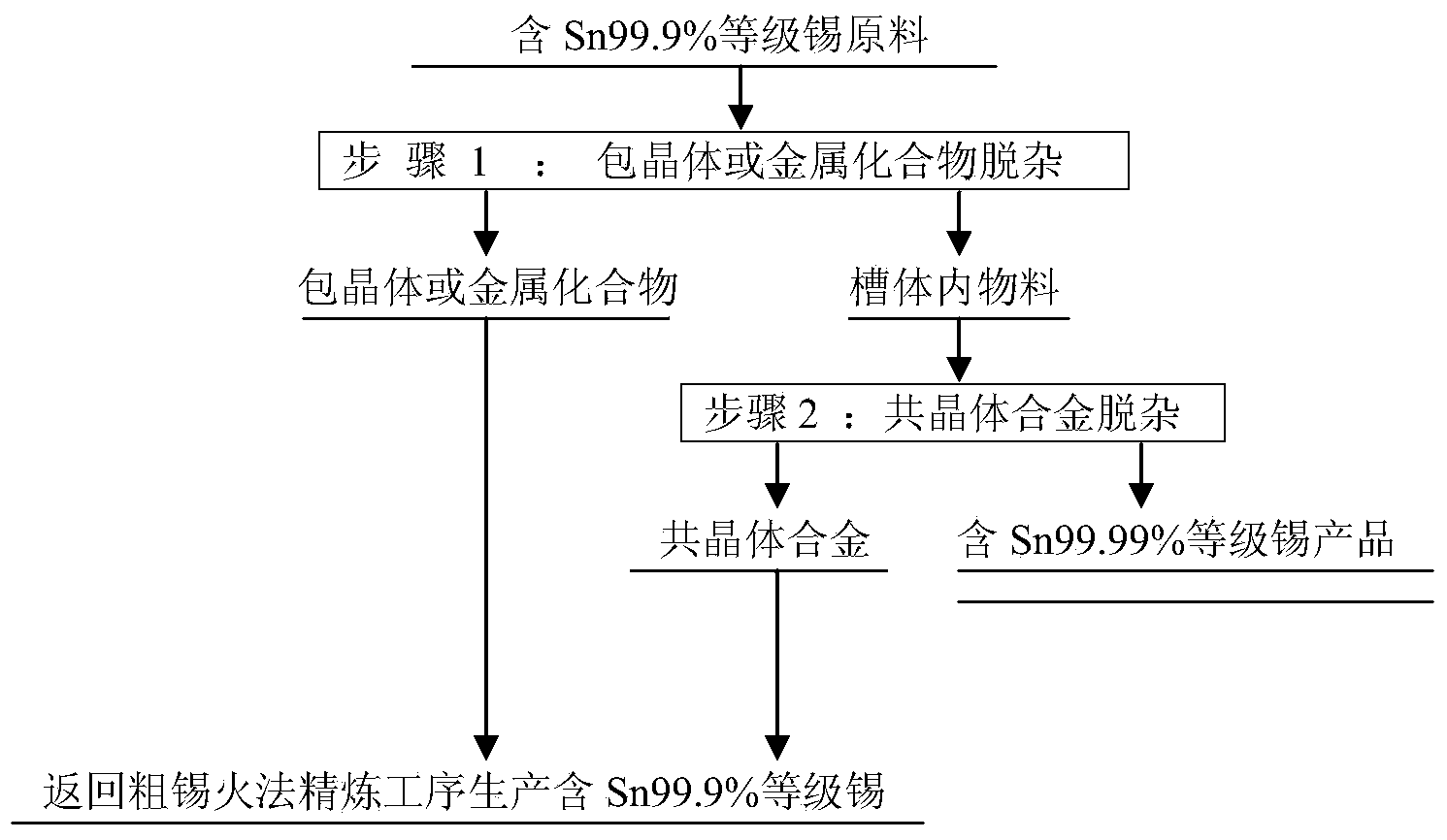

Production method of grade tin containing 99.99% of Sn

A production method of grade tin containing 99.99% of Sn comprises steps as follows: the grade tin containing 99.99% of Sn is added into helical blade crystallization equipment with six temperature control sections, and the temperature and the temperature gradient are controlled, so that a material can be continuously and repeatedly crystallized and smelt, and a tin alloy rich in arsenic, copper, ferrum, silicon, aluminum, magnesium, nickel, thallium and sulfur elements is produced at a high-temperature section outlet of the crystallization equipment; and then, the temperature and the temperature gradient of the inside of the crystallization equipment are changed, so that the material can be continuously crystallized and smelt, a tin alloy rich in silver, tin, lead, bismuth, cadmium and zinc elements is produced at a low-temperature section outlet of the equipment, and the grade tin containing 99.99% of Sn is obtained at the high-temperature section outlet of the crystallization equipment.

Owner:LAIBIN CHINA TIN SMELTING

Equipment for continuous extraction of fish protein

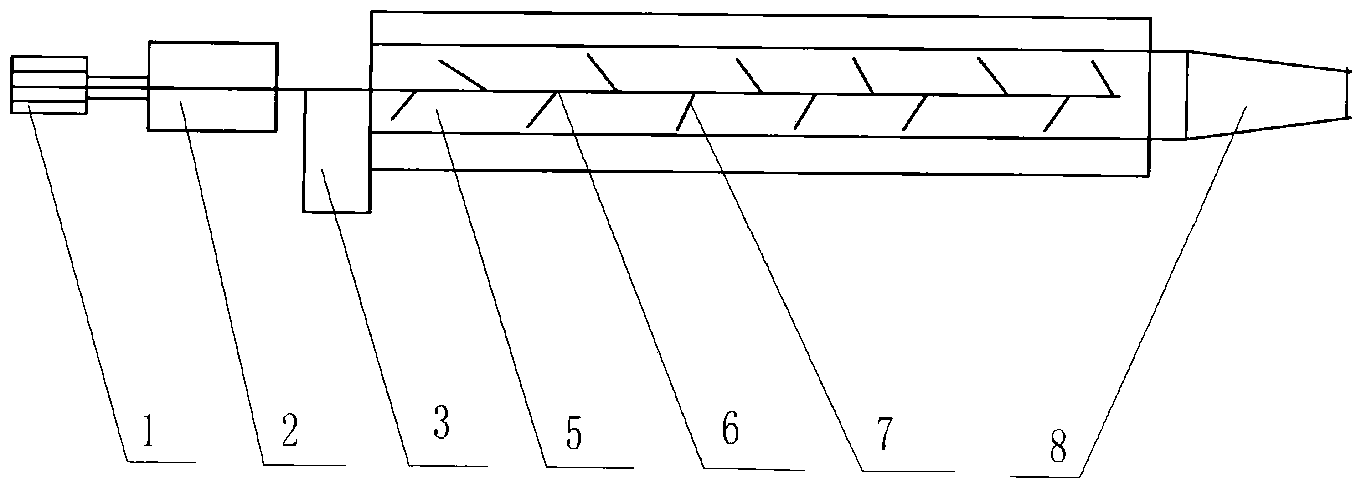

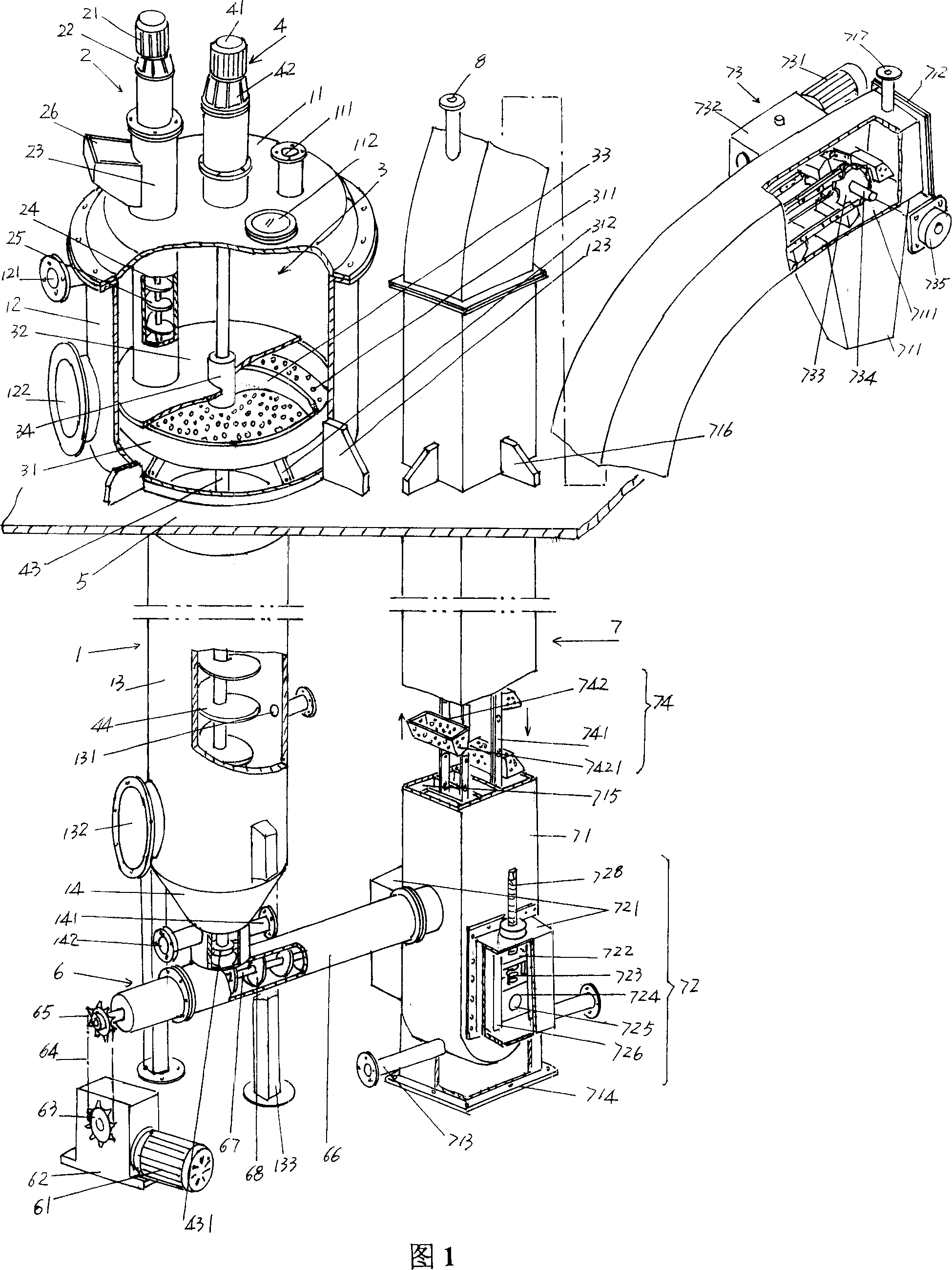

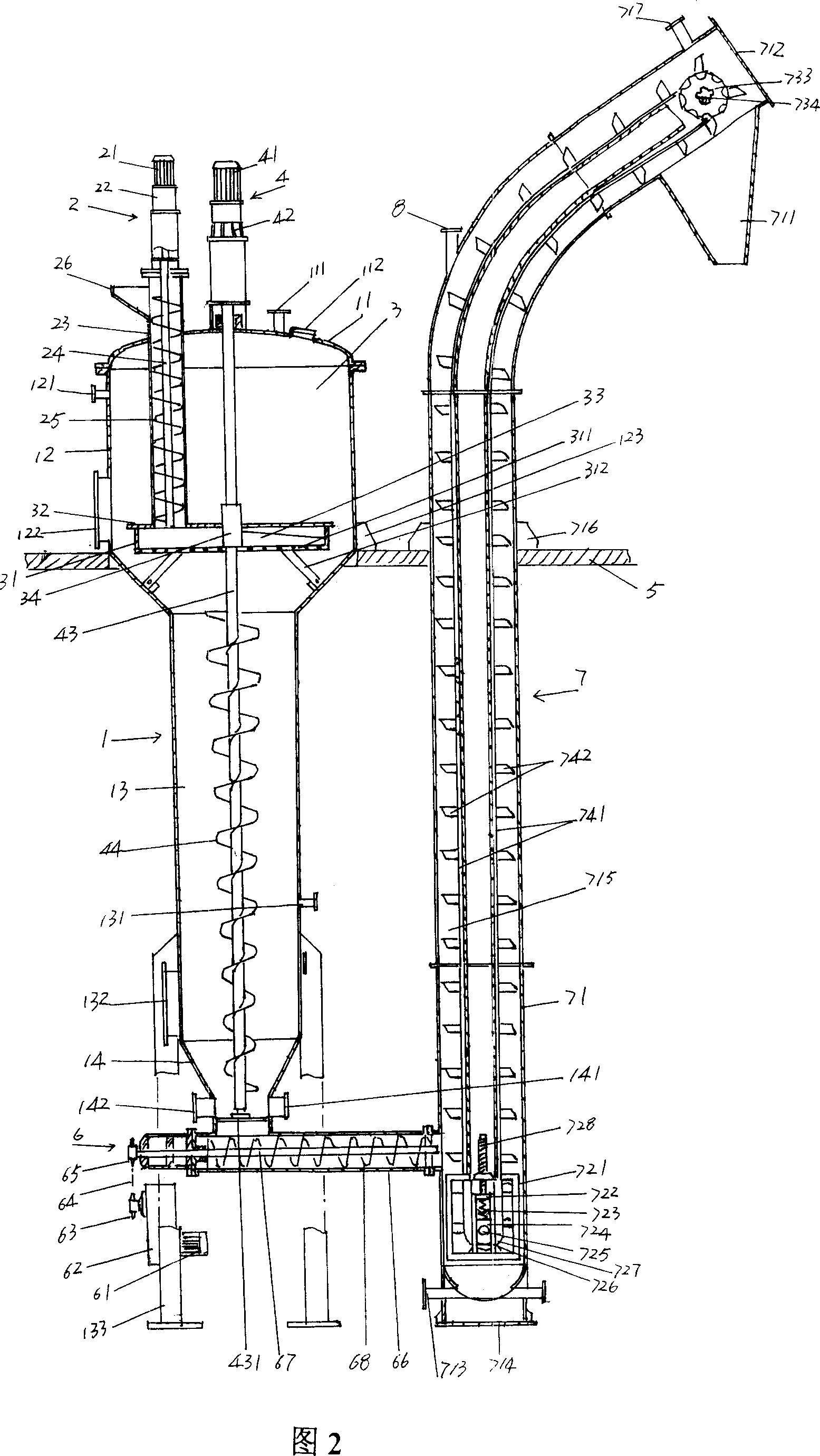

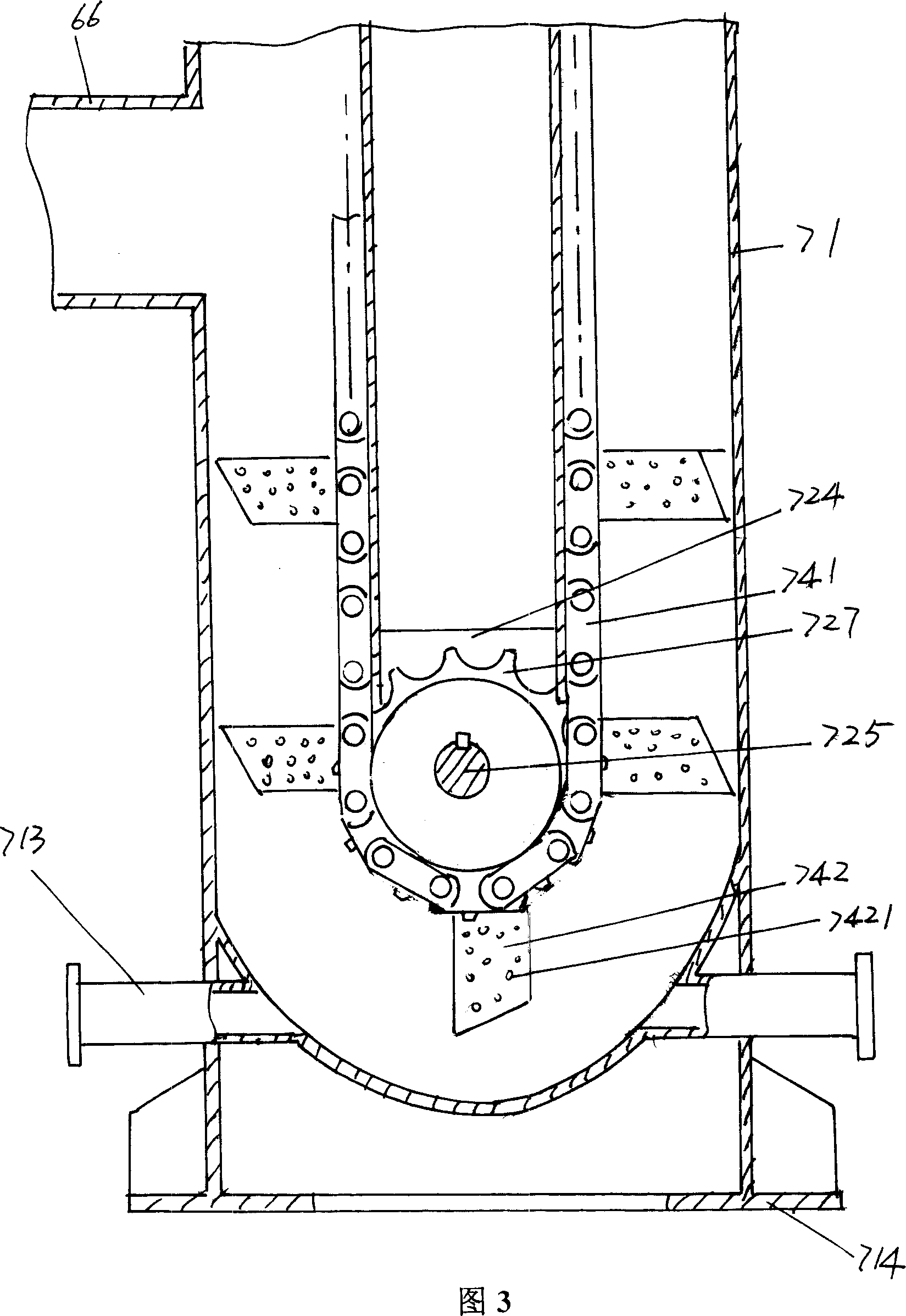

ActiveCN100998366AHas saving effectReduce work intensityProtein composition from fishMarine fishPropeller

An apparatus for continuously extracting fish protein from marine fish is composed of a working platform, an impregnating drum, a material distributor, a feeder mechanism, a stirring mechanism, an extracting chain-bucket unit, a material transfer unit and a solvent inlet. Said material transfer unit consists of motor, speed reducer, drive and driven chain wheels, drive chain, delivering pipe, axle and propeller.

Owner:中海海洋(荣成)健康产业有限公司

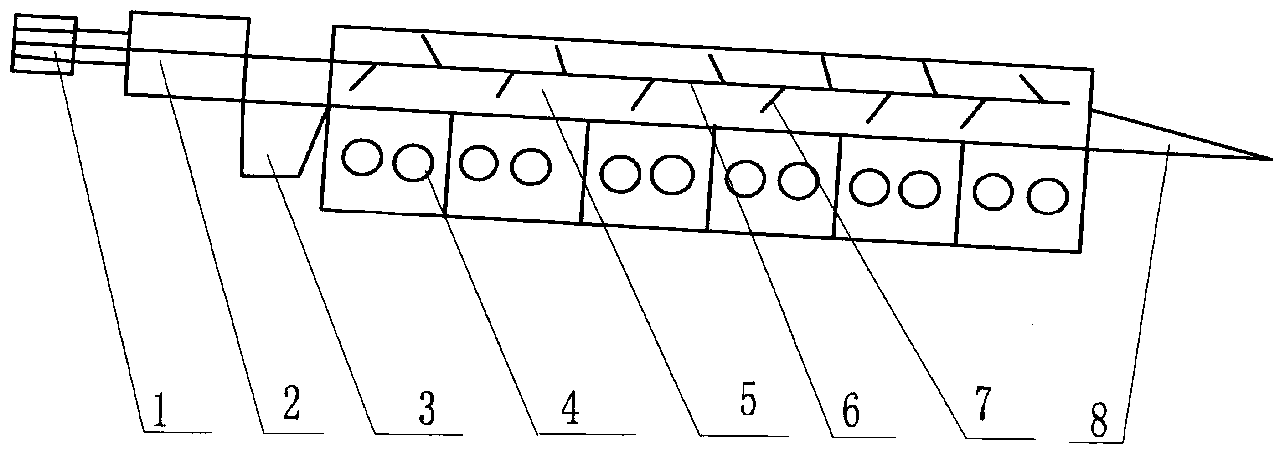

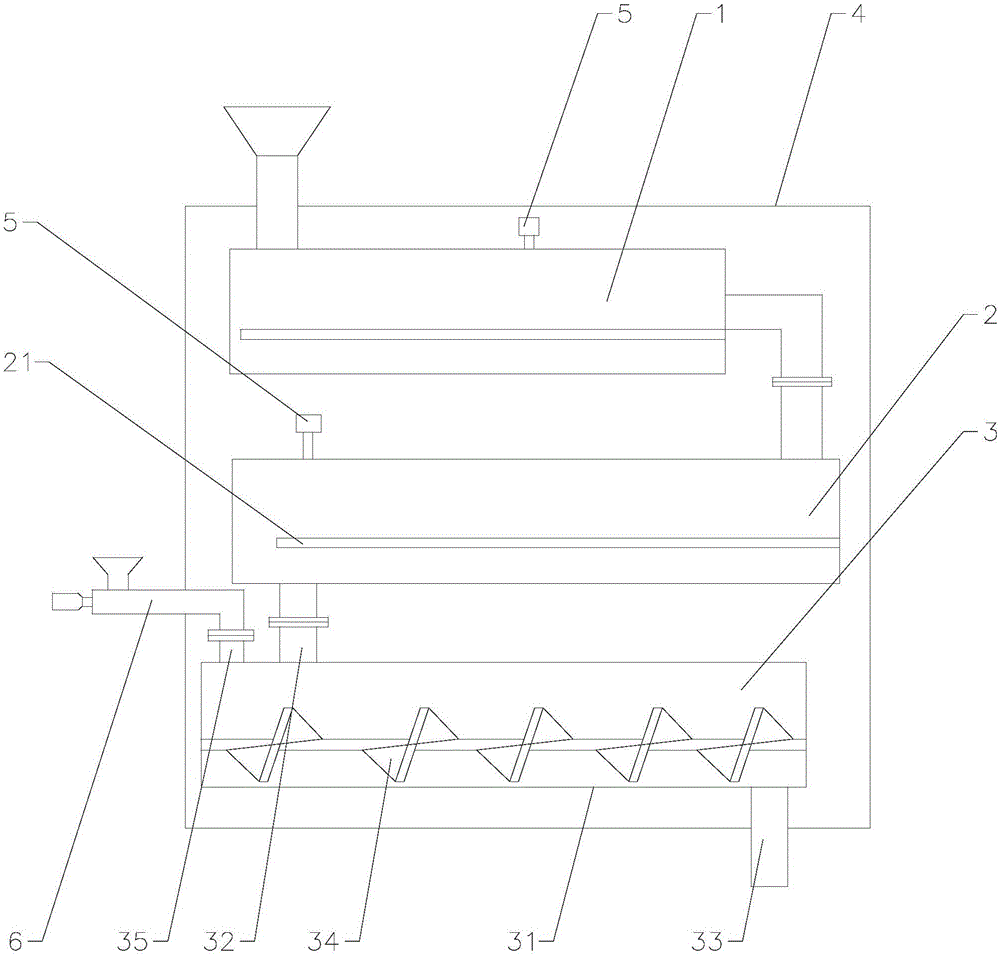

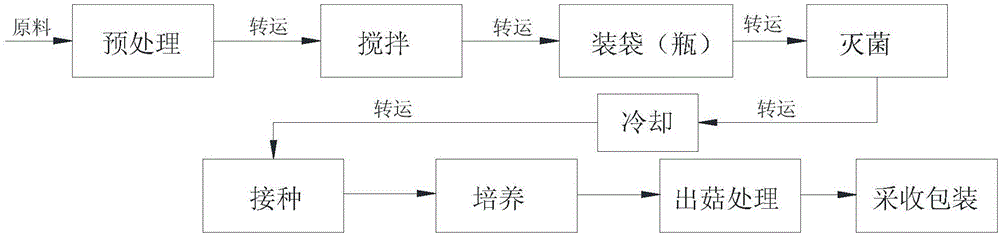

Production equipment for edible mushroom inoculation

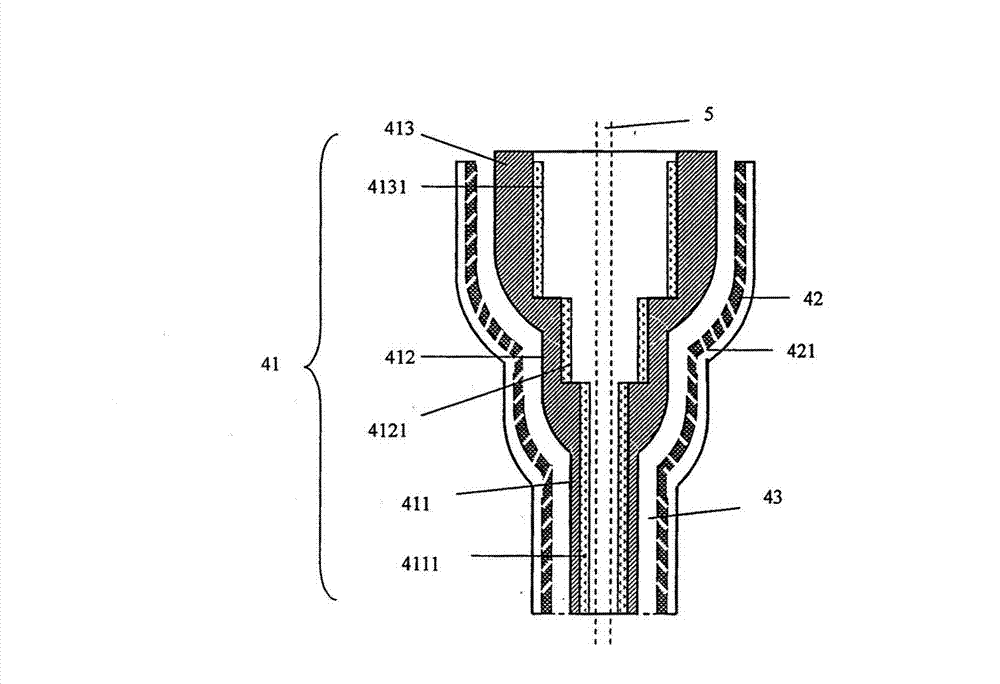

InactiveCN105075661AMeet the requirements of industrial mass productionReduce occupancyCultivating equipmentsMushroom cultivationBiotechnologyAnimal science

The invention relates to the technical field of edible mushroom inoculation and especially relates to a kind of integrated production equipment for the edible mushroom inoculation. The production equipment for the edible mushroom inoculation comprises a sterilization device, a cooling device, an inoculation device, a control device and a box body, wherein the inoculation device comprises a shell body, a feeding connecting hole, a discharge connecting hole and a first transmission mechanism used to stir and convey a solid culture medium, the shell body is equipped with a feeding hole used to add edible mushroom bacteria into the solid culture medium, and the feeding connecting hole and the discharge connecting hole are disposed in the shell body and firmly connected to the shell body; and the sterilization device, the cooling device and the inoculation device are disposed inside the box body, an outlet of the sterilization device is firmly connected to an inlet of the cooling device, an outlet of the cooling device is firmly connected to the feeding connecting hole, and the control device is connected to the first transmission mechanism by signals. In this way, problems such as that an existing edible mushroom inoculation device cannot realize automatic and continuous production can be effectively solved.

Owner:JIANGSU TIAN DE POWER EQUIP

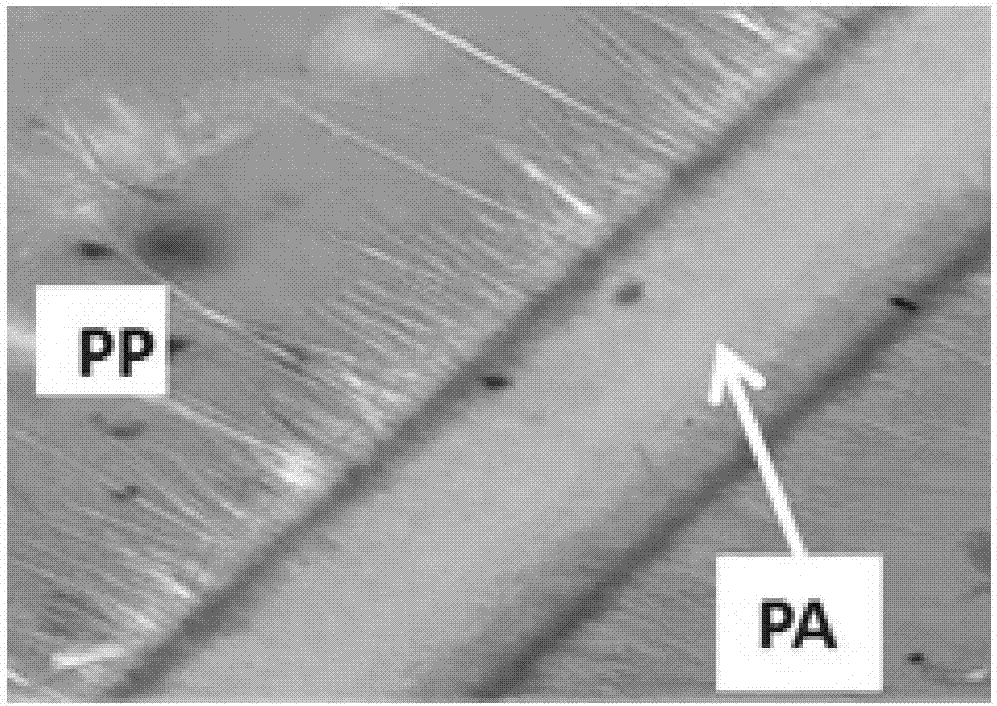

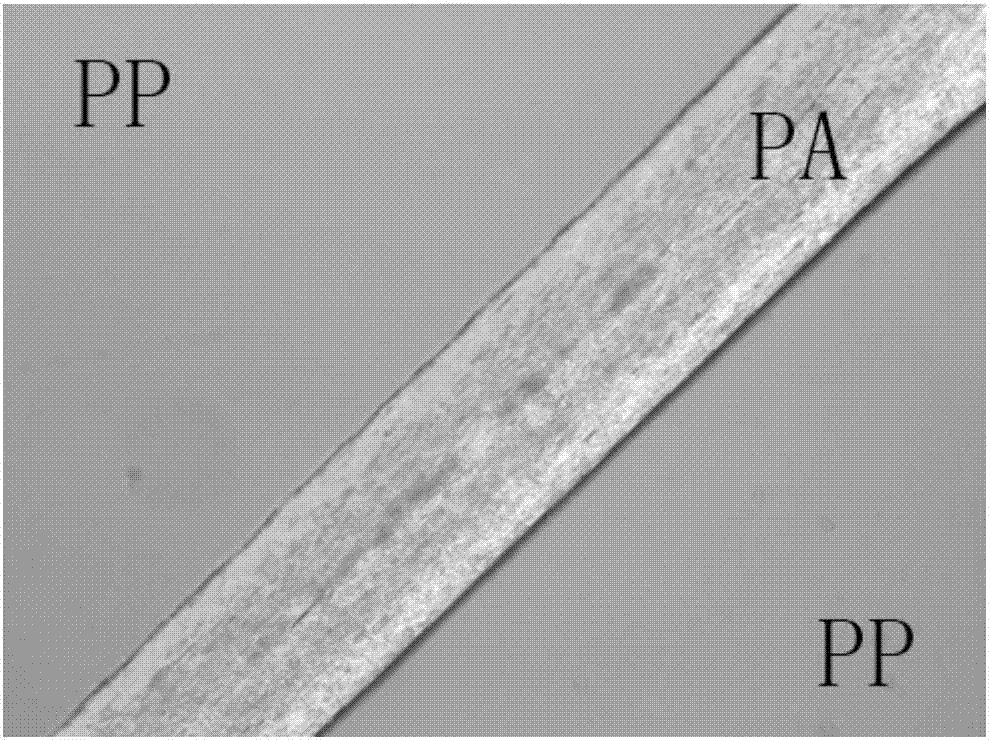

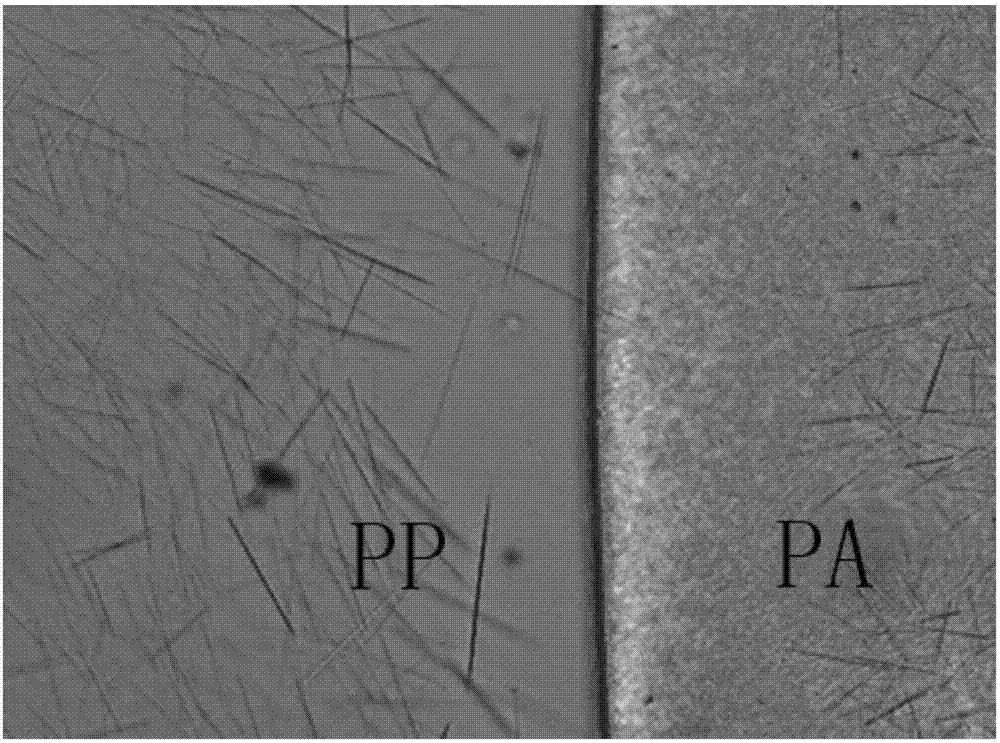

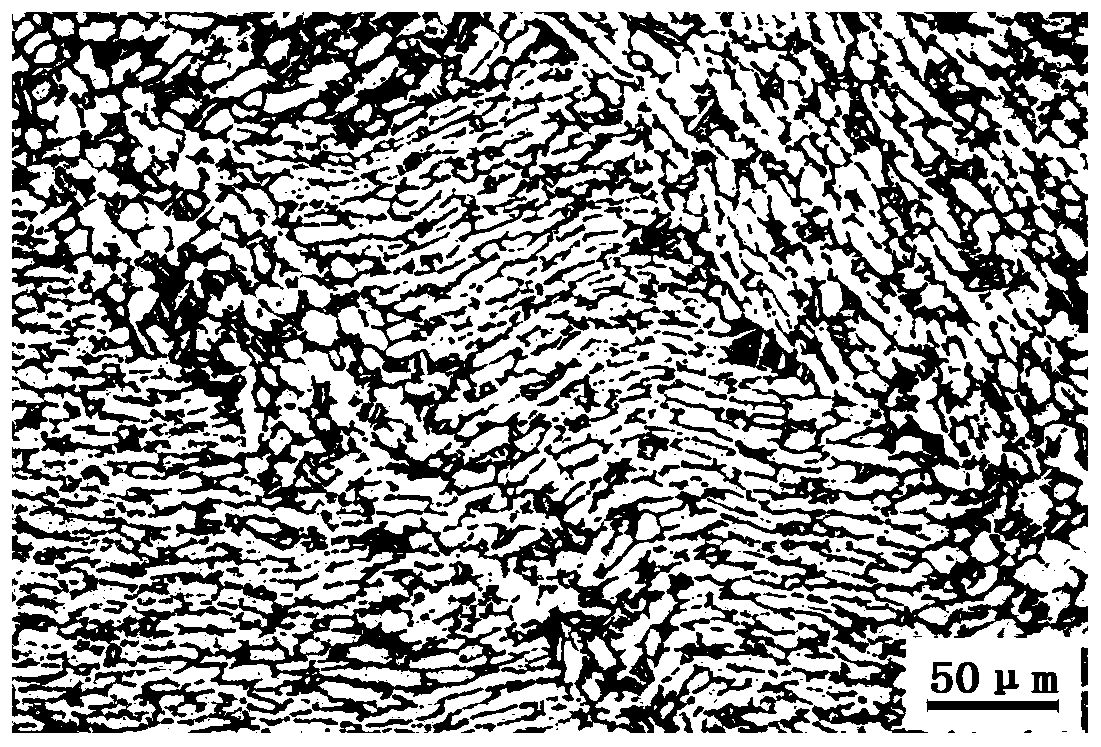

Preparation method of interface interlocked polyphase polypropylene-based polymer blending composite material

ActiveCN106967252AImprove interface compatibilityAdd lessSpinning head liquid feederMelt spinning methodsTemperature controlPolymer science

The invention provides a preparation method of a polypropylene-based polymer blending composite material, which can be used for constructing two phases or more than two phases of interlocked interfaces by self-assembly of polypropylene-based molecular interfaces and improving the interfacial strength of a polyphase polymer system. The preparation method comprises the following steps: firstly, carrying out melting and preblending extrusion on one or more plastic polymer materials except polypropylene and a nucleating agent capable of realizing melting-self-assembly; secondly, premixing an obtained substance with the polypropylene; thirdly, carrying out first-stage polyphase melting and blending and second-stage temperature control until self-assembly with at least 2s within a self-assembly temperature section of the nucleating agent in sequence, and carrying out treatment, namely obtaining a finished product. According to the preparation method provided by the invention, overall performance of the polypropylene-based polymer blending composite material is greatly improved, and a novel method is provided for interface design and optimization of a weak interface polyphaser polymer system; in addition, the preparation method has the advantages of wider application range and suitability for popularization.

Owner:SICHUAN UNIV

Preparation method of cinnamon polyphenol extract

InactiveCN103372056AEasy to prepareLow cost of preparationMetabolism disorderPlant ingredientsChemistryBatch production

The invention discloses a preparation method of a cinnamon polyphenol extract. The method comprises the following steps of: extracting cinnamon with ethanol water or acetone water; removing ethanol or acetone in the extracting solution by a reduced pressure distillation method, then adding a proper amount of water and diluting concentrated liquor to obtain crude extract; extracting the crude extract with petroleum ether, diethyl ether or methylene dichloride and collecting a water layer obtained from extraction; and extracting the collected water layer with ethyl acetate, combining an ethyl acetate layer obtained from extraction, removing the ethyl acetate by a reduced pressure distillation method, and drying to obtain solid powder of the cinnamon polyphenol extract. The preparation method is simple, does not need special equipment or complex technological condition, is low in preparation cost, and accords with the requirement of industrial batch production. The content of total polyphenol in the cinnamon polyphenol extract is as high as 30-40wt%, and hypoglycemic drug preparation can be developed so as to sufficiently guarantee application research of the cinnamon polyphenol extract.

Owner:SHANGHAI UNIV OF T C M

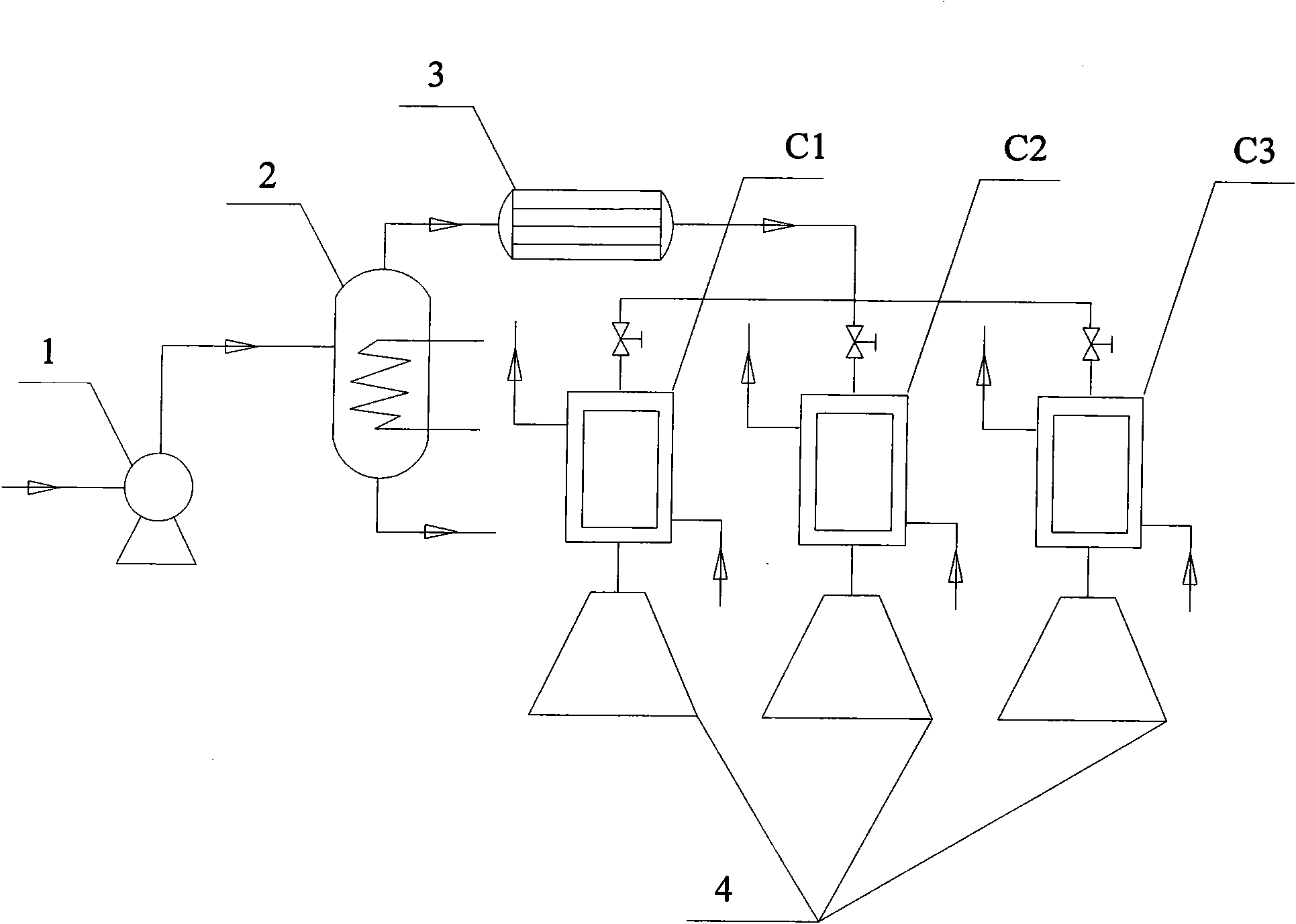

Method for refining isosorbide by distillation and melt crystallization coupling technology

InactiveCN101665497AHigh purityMeet purity requirementsOrganic chemistrySteam condensationDistillation

The invention discloses a method for refining isosorbide by a distillation and melt crystallization coupling technology. The method comprises the following steps: dehydrated mixed liquor of sorbitol is introduced to a distillation retort for reducing pressure and distilling; low-boiling isosorbide vaporization flows out from the upper part and enters a heat exchanger, high-boiling sorbitol, 1.4-dehydrated sorbitol and other dehydrated products remain at the bottom of a kettle, and are discharged from the bottom of the kettle. Vapor from the upper part enters the heat exchanger by introductionfor heat exchanging and condenses into liquid state after heat is exchanged by the heat exchanger; low-boiling distillate after heat exchanging is directly introduced into a crystallizer for reducingtemperature and crystallizing. The processes of temperature reducing and crystallization are melt crystallization, comprising four steps: hanging membrane, crystallizing, sweating and melting. In theinvention, the distillation and melt crystallization technologies are coupled and adopted to refine the isosorbide, in the melt crystallization process, 3-8 crystallizers are used for cycle use in turn, and the distillation and crystallization can be carried out continuously. The method of the invention has simple operation, less pollution to environment and low power consumption and the like; andthe ultimate purity of isosorbide can reach over 99.5%.

Owner:NANJING UNIV OF TECH

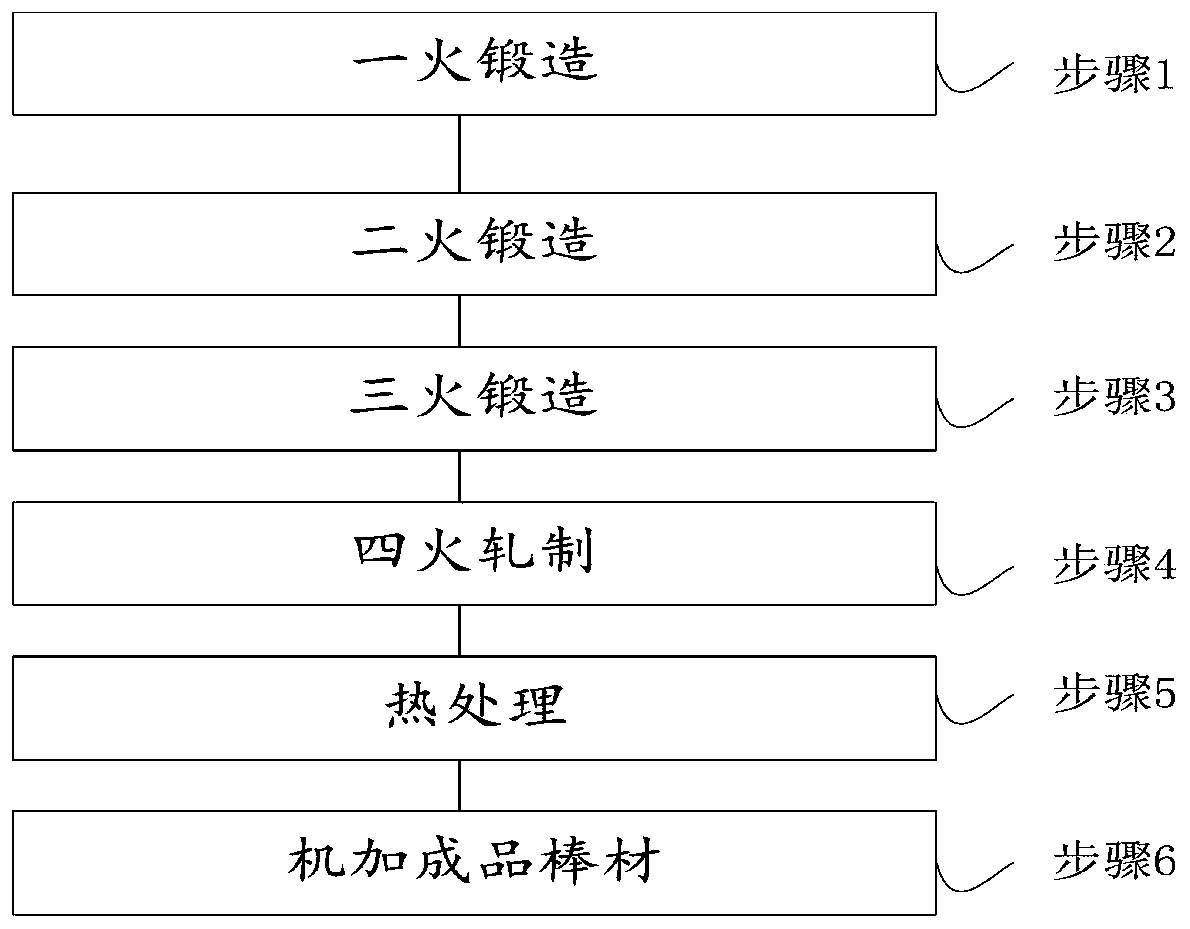

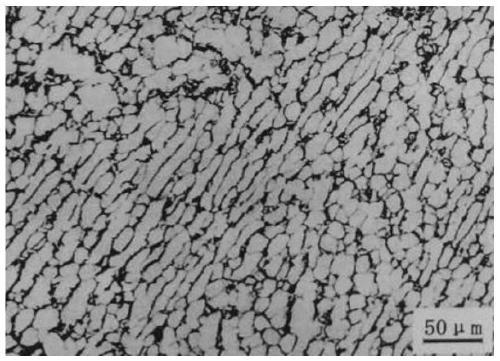

Low-cost efficient preparation method for two-phase titanium alloy round rod

PendingCN111136473AAvoid the disadvantages of unevennessImprove uniformityMetal-working apparatusOther manufacturing equipments/toolsSquare cross sectionLarge deformation

The invention provides a preparation method for a two-phase titanium alloy round rod, wherein three times of forging is realized according to a measured phase transformation point T[beta] of an ingotblank, and multi-directional thermo-plasticity forging deformation is realized according to heating temperature of three heating numbers in a high-to-low sequence; and forging with right-octagonal cross sections is used for two heating numbers under the phase transformation point. The forging mode avoids defects such as serious cracking caused by rapid cooling of corner angles of a forging blank with a right-square cross section as well as organizational unevenness caused by generation of deformation dead zones during forging with a right-square cross section can be avoided. Uniform and equal-axial alpha + beta two-phase processing organizations are obtained through polygonal multi-directional upsetting-stretching forging and large-deformation rolling under the phase transformation point Tbeta, so organizational evenness of the cross section of the round rod is improved; heating numbers of forging can be effectively reduced; surface cracking defects of forging can be reduced; intangible losses of materials are reduced; processing manufacturability and a yield are increased; production cost is reduced; production duration is reduced; production efficiency and a production capacity are increased; and requirements for industrial batched production can be better satisfied.

Owner:西安圣泰金属材料有限公司

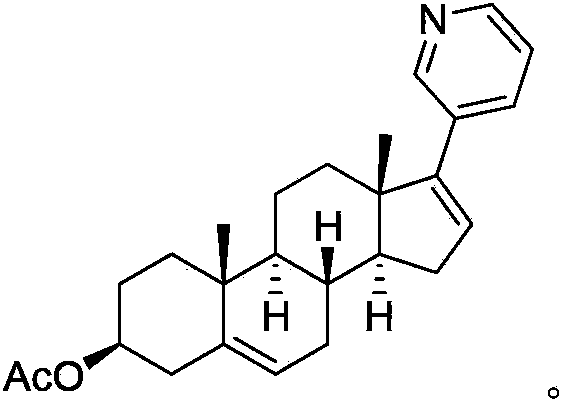

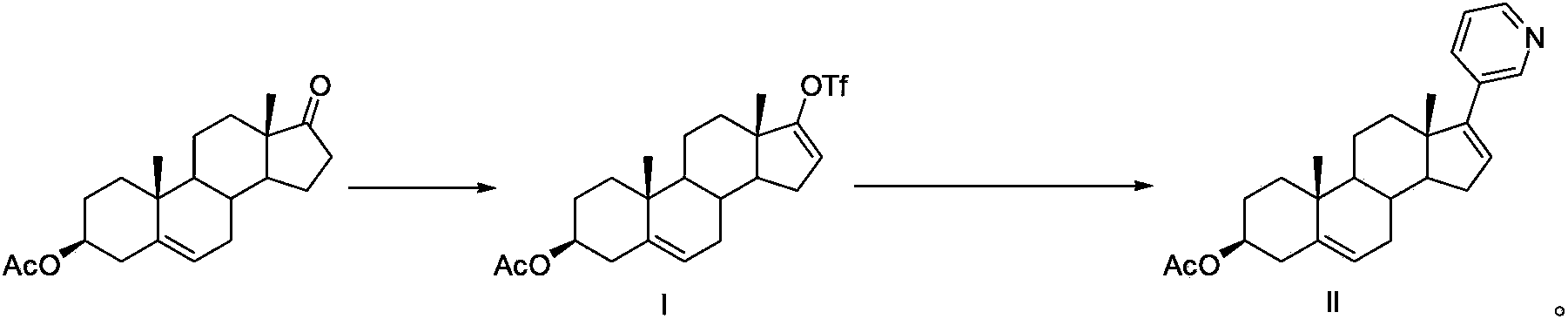

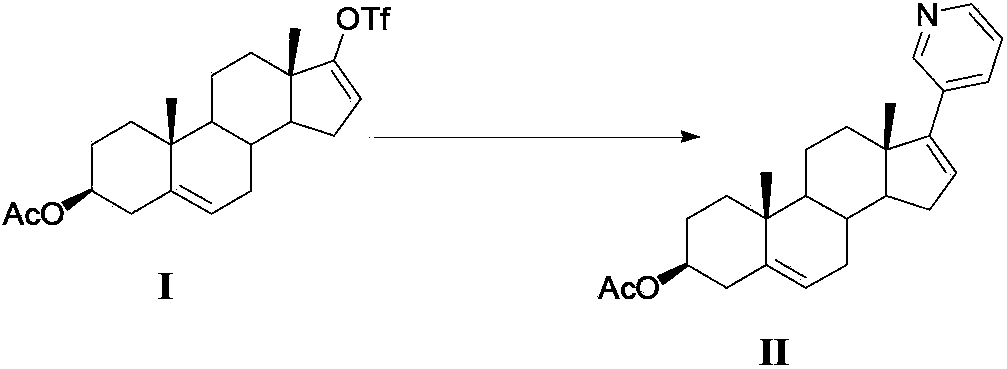

Method for preparing abiraterone acetate

The invention discloses a method for preparing abiraterone acetate. The method comprises the following steps of: (A) carrying out Suzuki coupling reaction on a formula I compound and 3-pyridineboric acid or a 3-pyridineboric acid derivative in a mixed solvent formed by an organic aprotic solvent and water under the action of a metal palladium catalyst and alkali; (B) after the reaction is finished, adding ethyl acetate and the water to a reaction system for liquid separation; collecting organic phases, sequentially washing by using the water and a saturated salt solution, drying and concentrating to obtain an oily crude product; (3) adding a crystallizing solvent to the oily crude product, and stirring for crystallization; (D) collecting solids for recrystallization. The method disclosed by the invention has the advantages of simple process, low cost and easiness for obtaining of raw materials, easiness for purifying treatment, high yield, low cost, high finished product purity, and the like, completely meets the requirement for industrialized batch production and has very high practical value.

Owner:重庆瑞泊莱医药科技有限公司

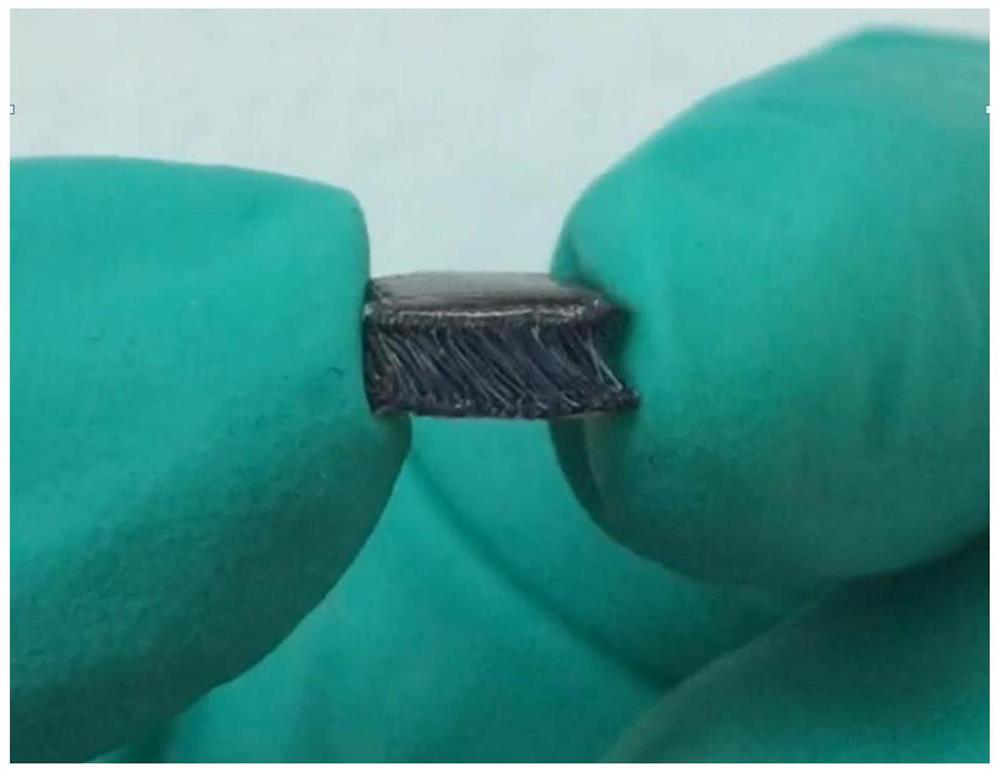

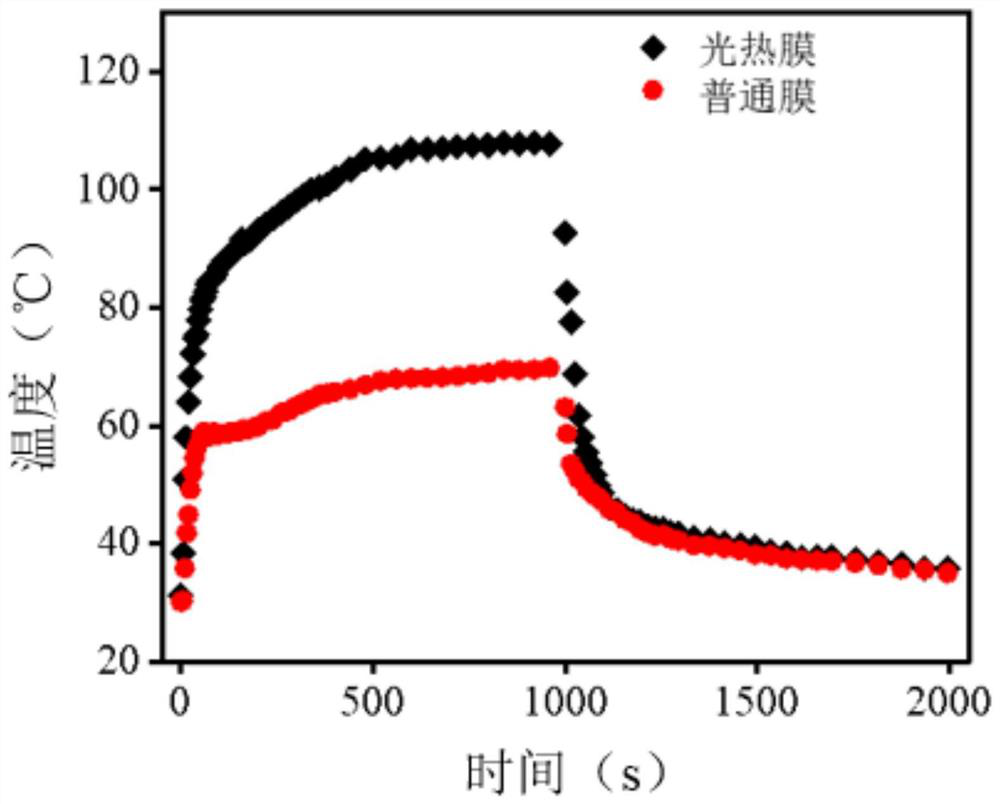

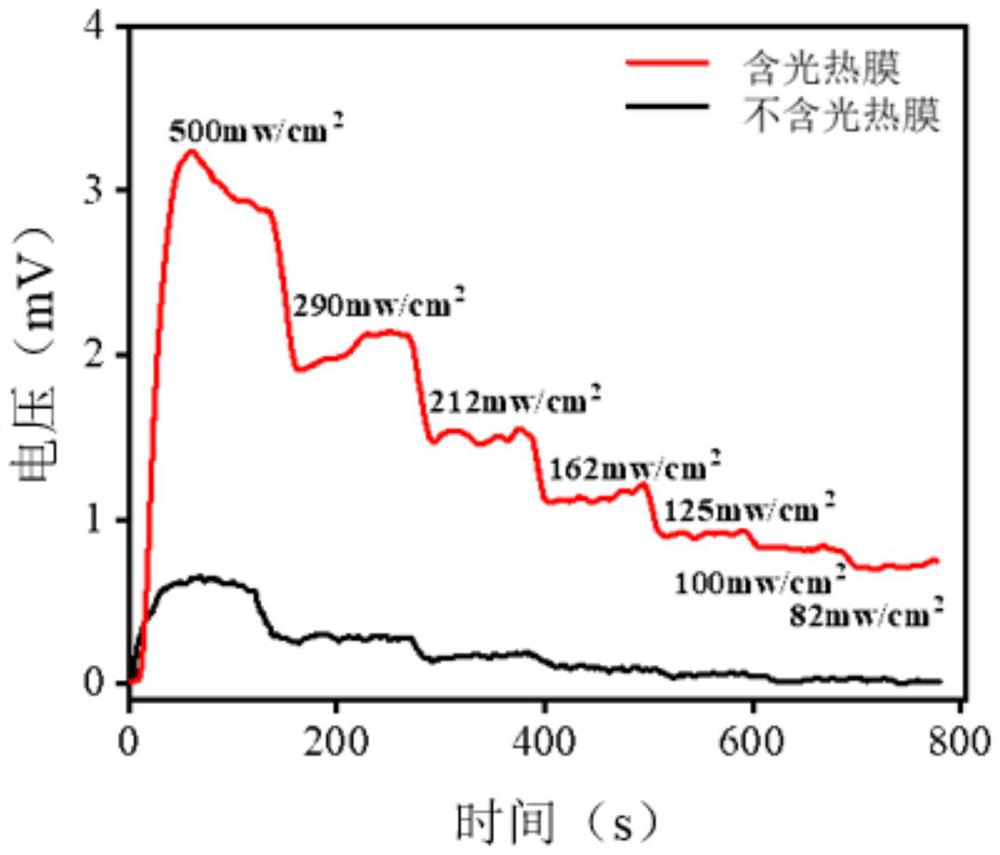

Efficient fiber-based thermoelectric energy supply material and preparation method thereof

PendingCN112234136ARealize self-generating functionNot easy to fall offThermoelectric device manufacture/treatmentFibre treatmentThermodynamicsNanoparticle

The invention provides an efficient fiber-based thermoelectric energy supply material and a preparation method thereof. The efficient fiber-based thermoelectric energy supply material comprises a fiber-based self-generating layer and a photo-thermal film arranged on an upper surface of the fiber-based self-generating layer, wherein the fiber-based self-generating layer is prepared by dipping the fiber base material in the thermoelectric solution and then arranging the electrodes on the upper surface and the lower surface of the dipped and dried fiber base material; and a colloidal photo-thermal material formed by mixing photo-thermal nanoparticles and a viscose solution is coated on the upper surface of the fiber-based self-generating layer to form the photo-thermal film. The material is advantaged in that the temperature of the upper surface of the fiber-based self-power-generation layer is increased through molecular thermal motion generated after the photo-thermal film absorbs solarrays and infrared rays emitted by a human body, a temperature difference is formed between the fiber-based self-power-generation layer and the lower surface of the fiber-based self-power-generation layer, the thermoelectric material is driven to generate voltage, and the self-power-generation function is achieved; and the efficient fiber-based thermoelectric energy supply material is excellent inthermoelectric performance, high in power generation efficiency and good in flexibility, and has relatively high application value.

Owner:WUHAN TEXTILE UNIV

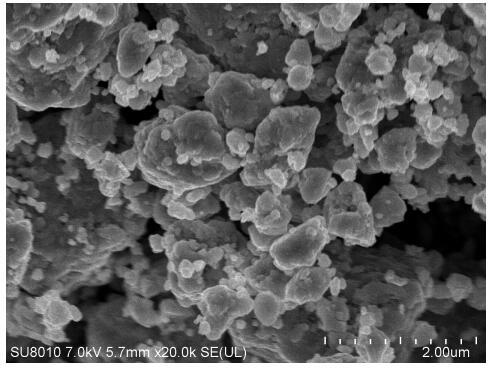

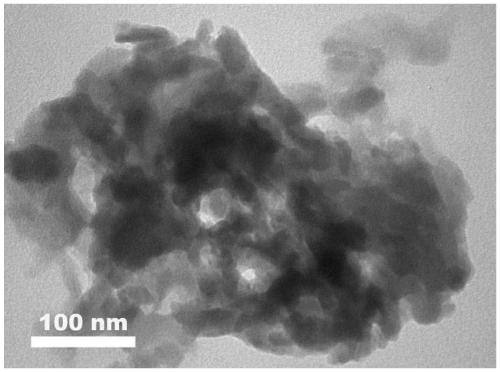

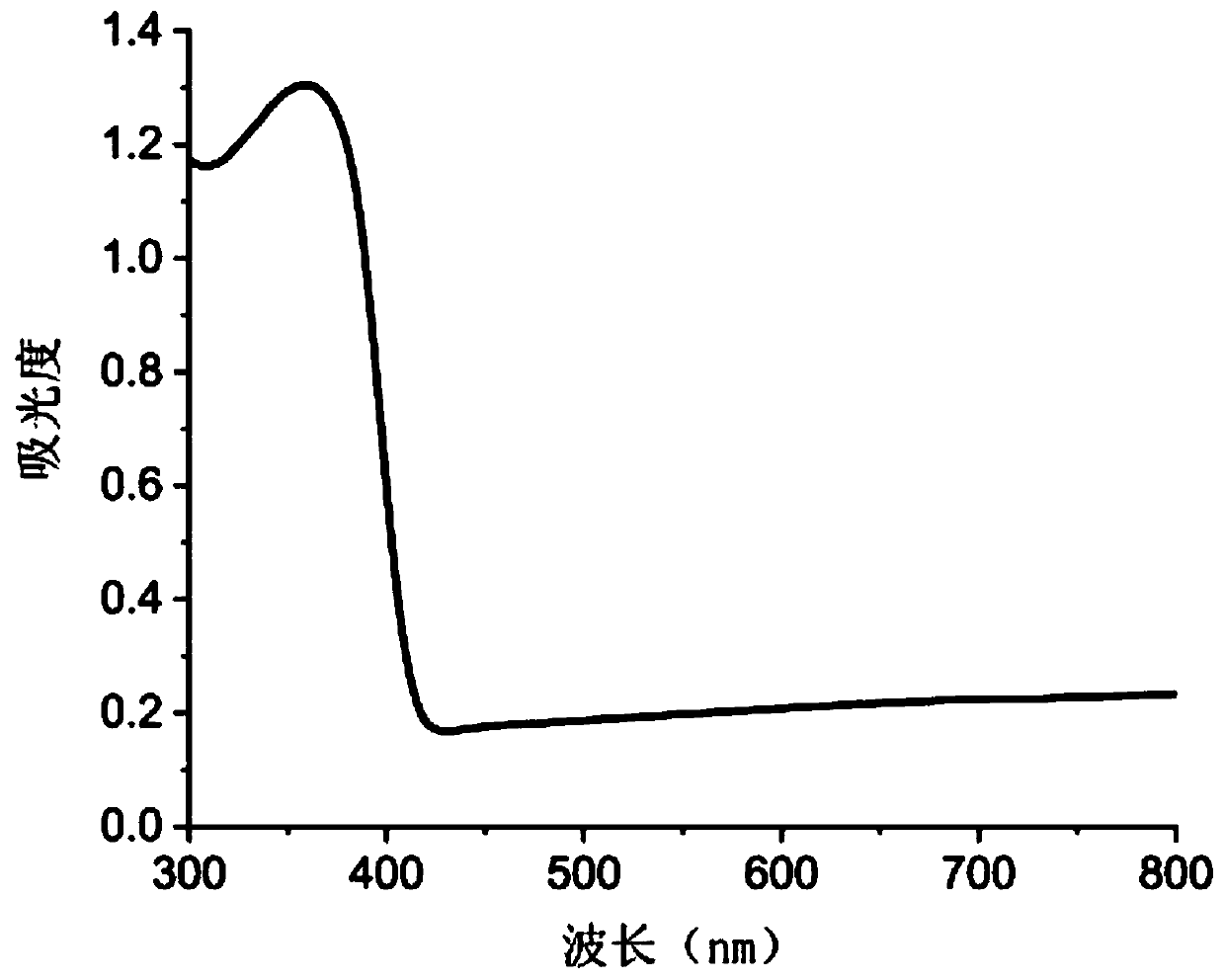

A transition metal phosphide MxPy oxygen reduction and hydrogen evolution bifunctional catalyst and preparation method and application thereof

InactiveCN109119647AEfficient oxygen reductionEfficient hydrogen evolution catalytic effectCell electrodesElectrodesHydrolysisPollution

The invention relates to a transition metal phosphide MxPy oxygen reduction and hydrogen evolution bifunctional catalyst and a preparation method and application thereof. The preparation method comprises the following steps: S1, mixing transition metal elementary substance M and red phosphorus powder, and ball milling to obtain transition metal phosphide MxPy material in an inert atmosphere; S2, adding a dispersing agent into the MxPy material, ball milling, and drying to obtain a transition metal phosphide MxPy bifunctional catalyst for oxygen reduction and hydrogen evolution. A metal transition phosphide with high purity, small crystal grain size and large specific surface area is prepared by a ball milling method, and has excellent ORR and HER catalytic performance and high stability, and can be widely applied to metal-air batteries, fuel cells or electrocatalytic hydrolysis to produce hydrogen; and the preparation method provided by the invention is simple and quick, the raw materials are cheap and easy to obtain and pollution-free, the production cost is low, and the requirement of industrialized mass production is met.

Owner:GUANGDONG UNIV OF TECH

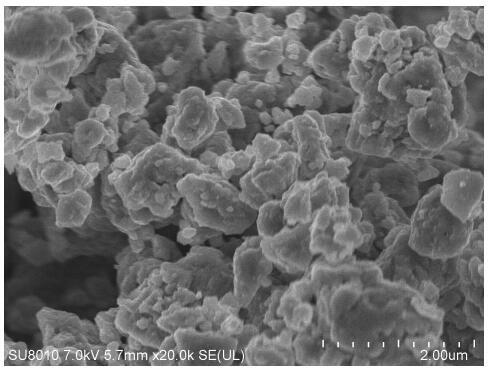

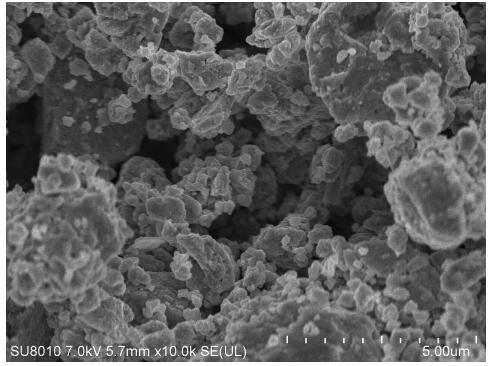

Preparation method of black rutile phase titanium dioxide

The invention discloses a preparation method of black rutile phase titanium dioxide, which comprises the following steps: taking an amorphous titanium oxide precursor, heating to 600 DEG C or above, and calcining for 2-4 hours to obtain white rutile phase titanium dioxide; adding white rutile phase titanium dioxide into a hydrochloric acid aqueous solution, carrying out ultrasonic dispersion, adding metal powder, stirring for 15 minutes or more, centrifuging, taking the precipitate, washing, and drying to obtain black rutile phase titanium dioxide. The process is simple, no toxic and hazary agents is related, production cost is low, the preparation method is simple in process and short in period, the requirement for industrial large-batch production can be met, the obtained black rutile phase titanium dioxide can strongly absorb ultraviolet light, visible light and infrared light in the whole solar spectrum, sunlight can be effectively utilized for a catalytic reaction, and the problemthat an existing rutile phase TiO2 is low in sunlight utilization rate is solved.

Owner:苏州机数芯微科技有限公司

Chitosan oligosaccharide/chito-oligomer single enzymatic production process

The invention is a chitooligosaccharide / chito oligomer production process by specific enzyme, firstly preparing 1-6% chitosan solution, adding in saturated sodium bicarbonate solution to regulate pH value, adding in endo-chitosanase for enzymic hydrolysis, then adopting macroporous weakly acidic cation resin chromatographic column to separate and purify the degraded product- chitooligosaccharide, and after reaction ends, adopting screen filter method to recover immobilized enzyme, adopting ultrafiltration membrane to recover dissociative enzyme, and able to use repeatedly. And the process can make high efficiency specific degradation on chitosan, extremely raising yield of chitooligosaccharide, having featuring of simple production process, largely reduced production cost, and effectively improved quality of chitooligosaccharide product. And the whole production process is a continous production process, which meets the requirements for industrialized large-scale production of chitooligosaccharide product.

Owner:泉州市科思生物科技有限公司

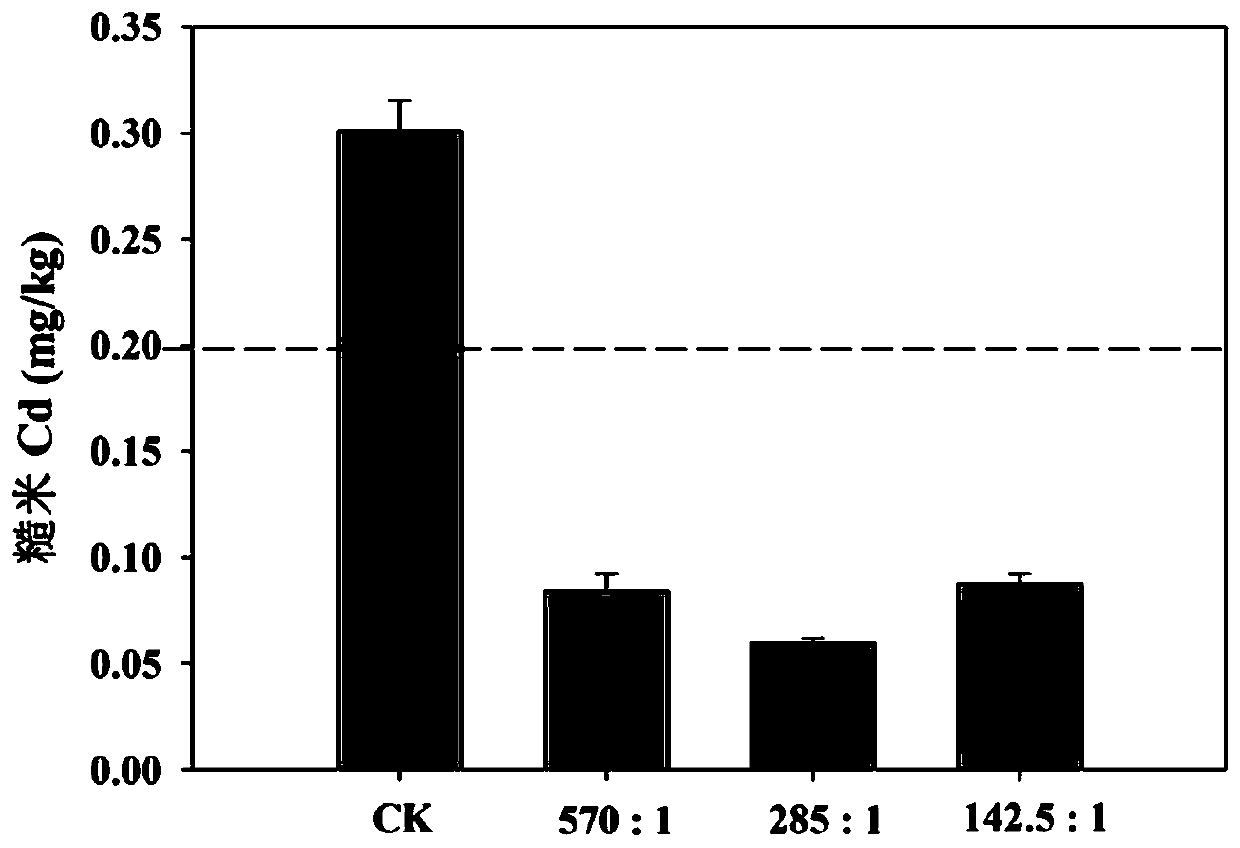

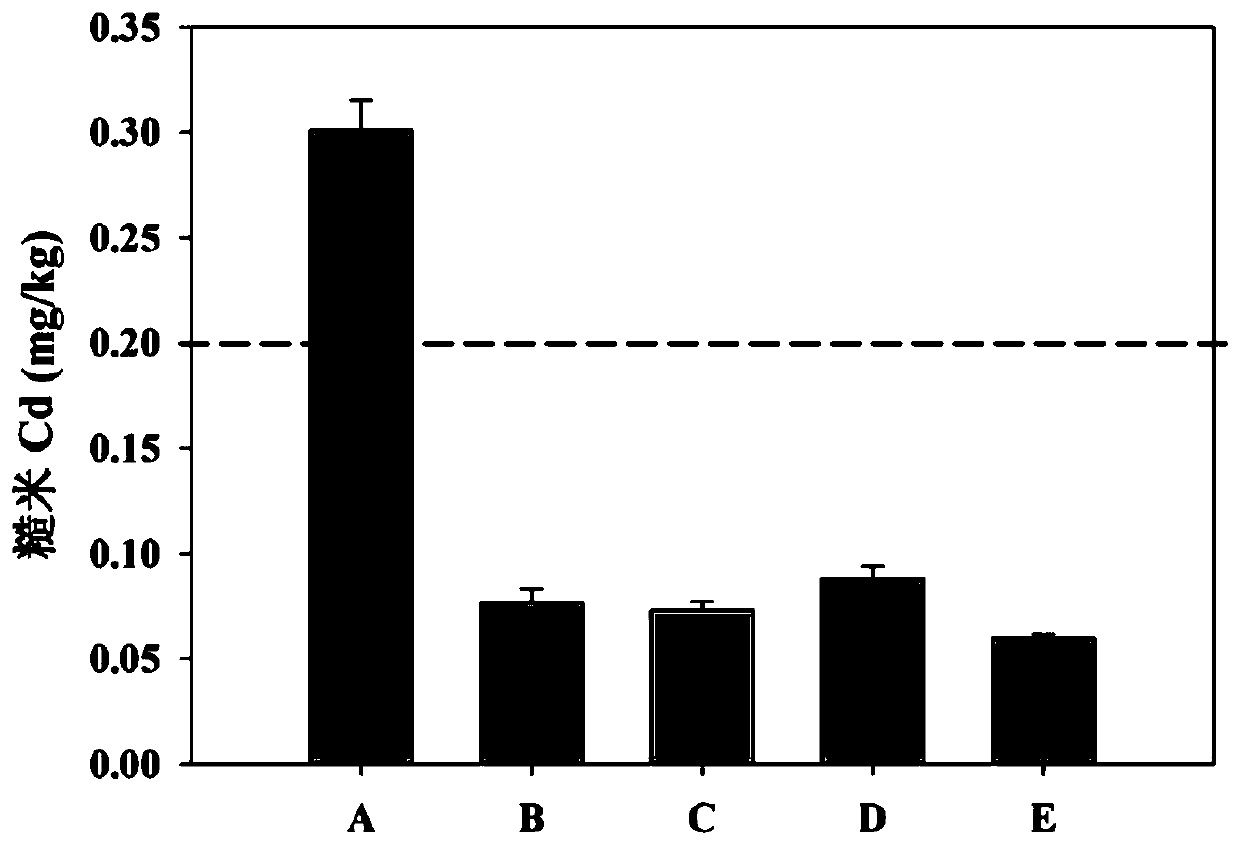

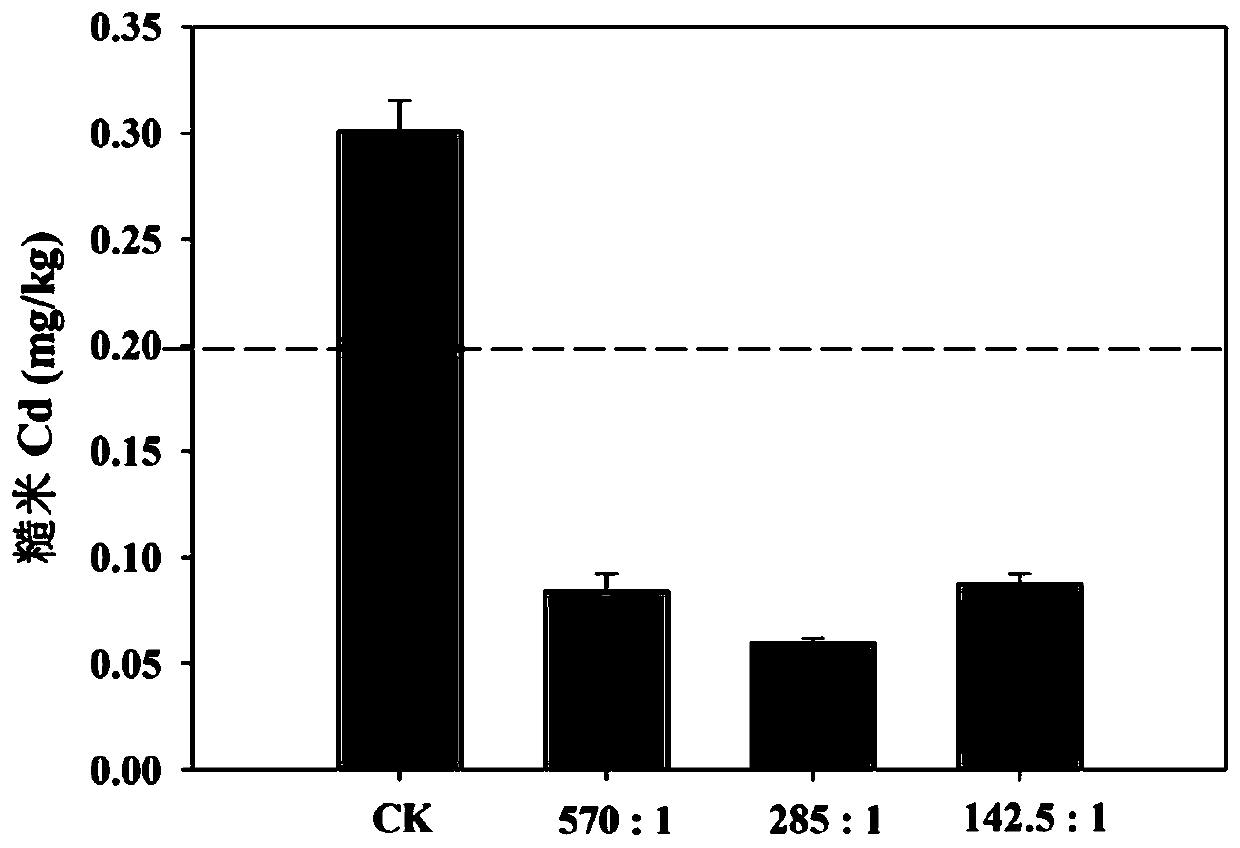

Leaf surface resistance control agent and preparation method and applications thereof

The invention discloses a leaf surface resistance control agent and a preparation method and applications thereof. The effective component of the leaf surface resistance control agent comprises a mainfunctional component namely water soluble silicon and water soluble potassium that assists the growth of crops. For each liter of stock solution of the leaf surface resistance control agent, there are 15 to 25 grams of water soluble silicon and 20 to 30 grams of water soluble potassium, and the pH of the stock solution of the resistance control agent is 10.5 to 11.5. The provided leaf surface resistance control agent can reduce cadmium pollution of paddy rice, is capable of increasing the paddy rice output, and can be used to control the heavy metal pollution of agricultural products such aspaddy rice.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

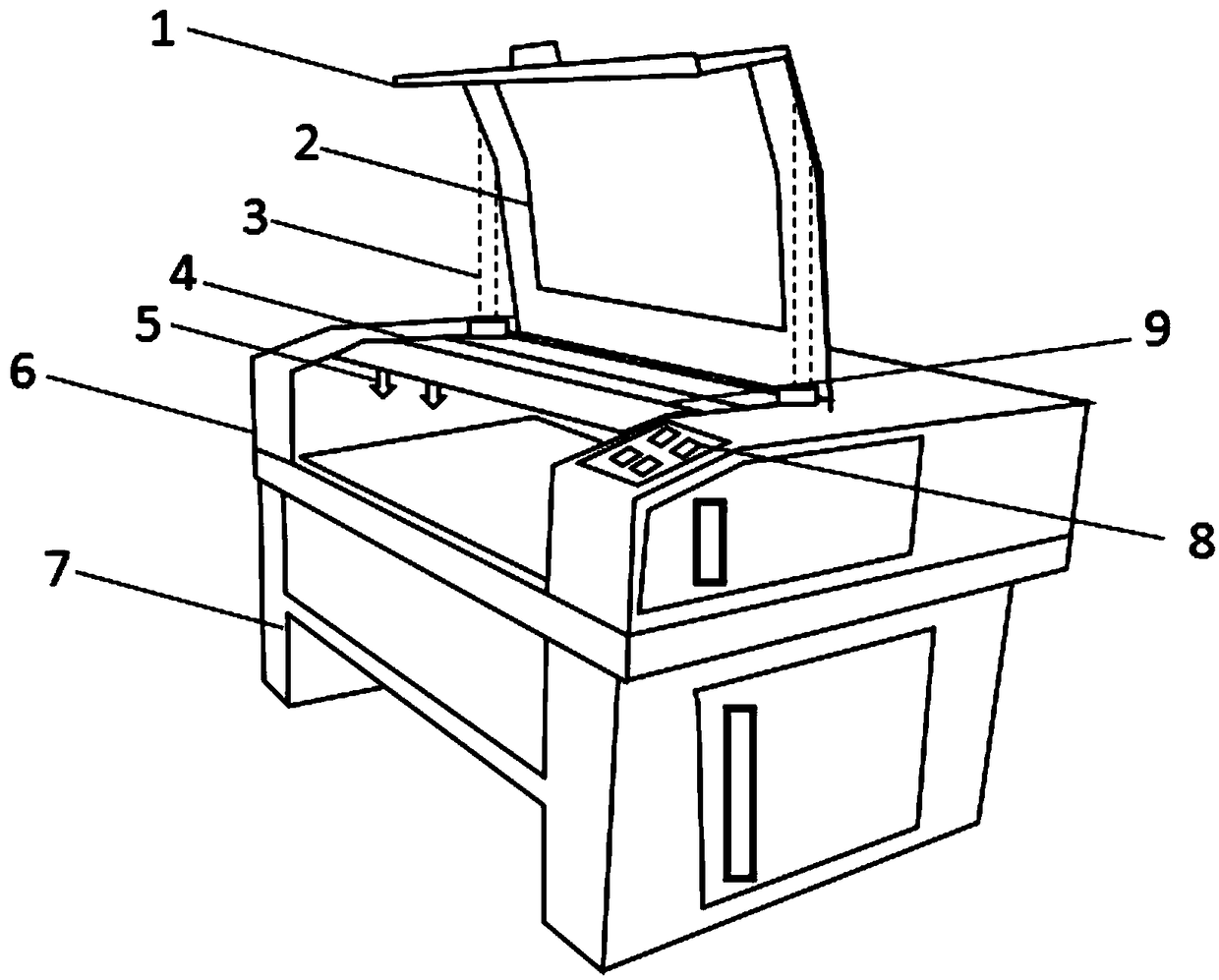

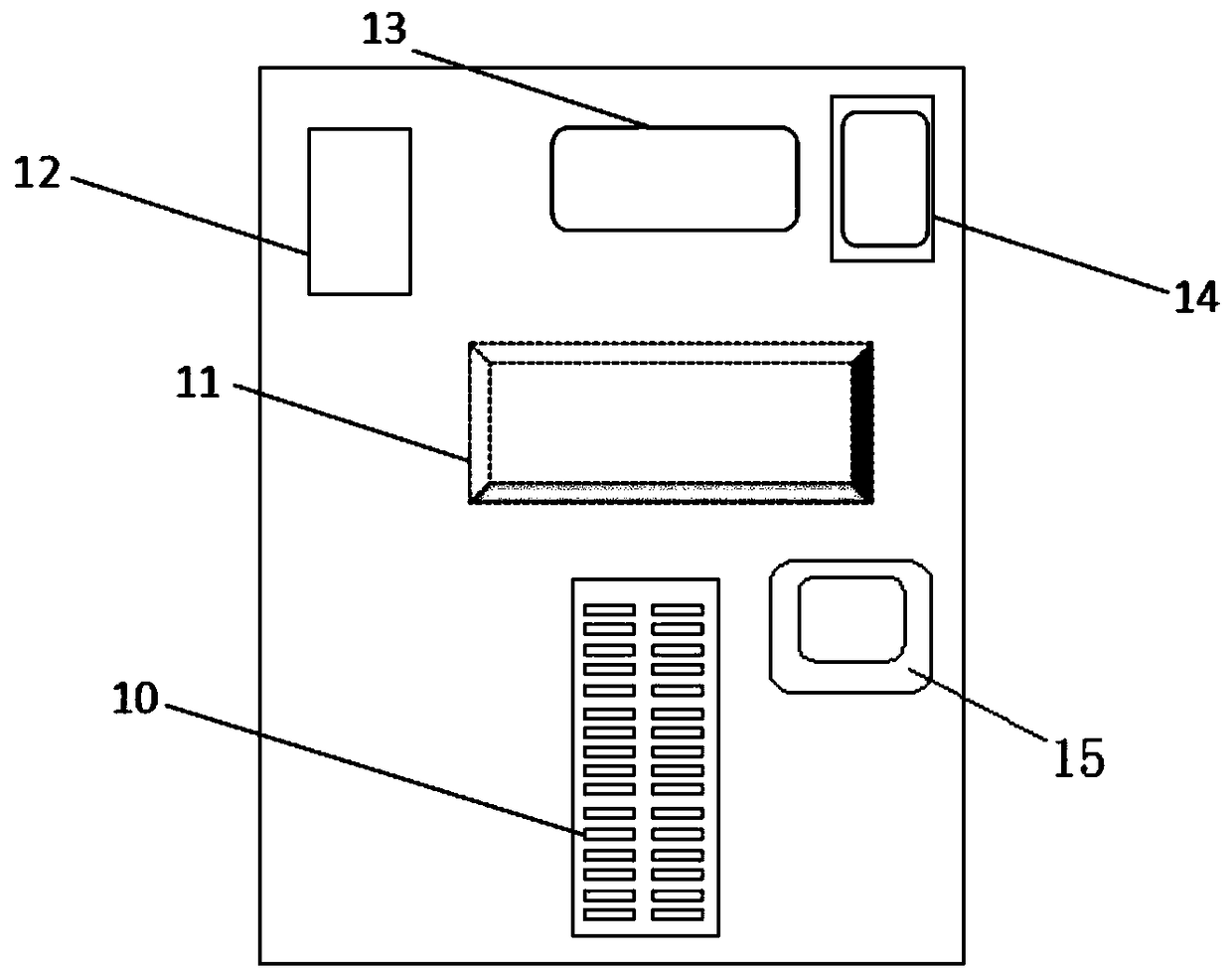

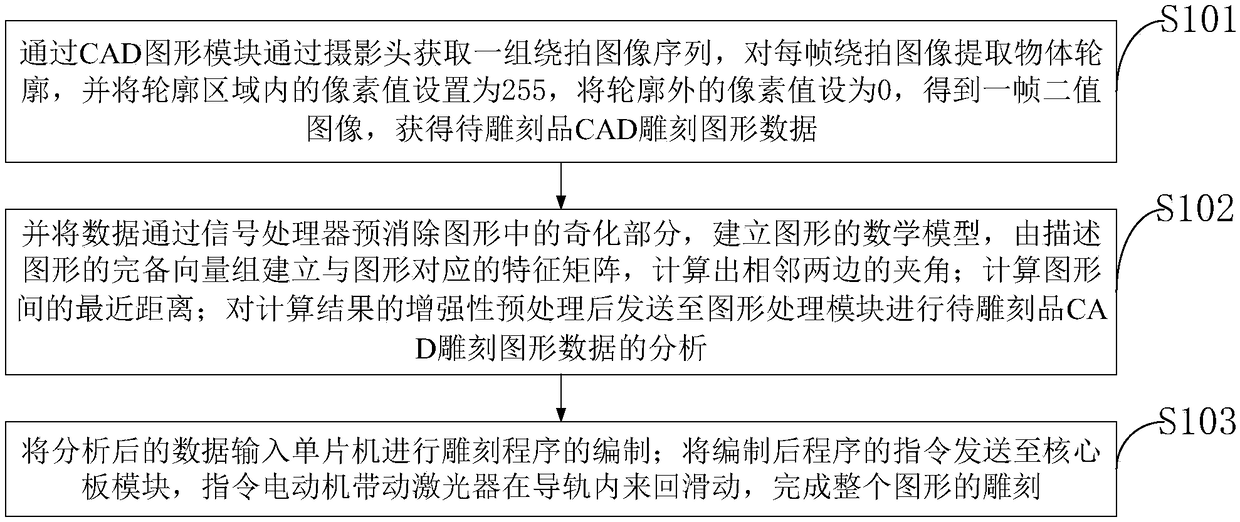

Numerical control laser engraving machine, control system, control method and computer

InactiveCN108655571AEasy to operateVersatileLaser beam welding apparatusMicrocontrollerNumerical control

The invention belongs to the technical field of numerical control engraving, and discloses a numerical control laser engraving machine, a control system, a control method and a computer. The control method comprises the steps that a set of circularly photographing graph sequences are obtained through a camera through a CAD graphic module, so that CAD engraving graphic data of a to-be- engraved product is obtained; moreover, the data are preprocessed through a signal processor and then are sent to a graphic processing module for analysis of the CAD engraving graphic data of the to-be-engraved product; the analyzed data is input into a single-chip microcomputer to be compiled by an engraving program; and an instruction of the compiled program is sent to a core board module, an instruction motor drives a laser to slide back and forth in a guide rail, and engraving of the whole graph is completed. According to the numerical control laser engraving machine, the control system, the control method and the computer, fine engraving can be carried out by utilizing laser, a computer numerical control technology is used and can be well combined with a laser processing system so that requirements for industrial mass production can be met, the production efficiency can be effectively improved, moreover, by using laser processing, the environment can be prevented from being polluted, and thepracticability and the generalization performance are good.

Owner:GUANGDONG TECHN COLLEGE OF WATER RESOURCES & ELECTRIC ENG

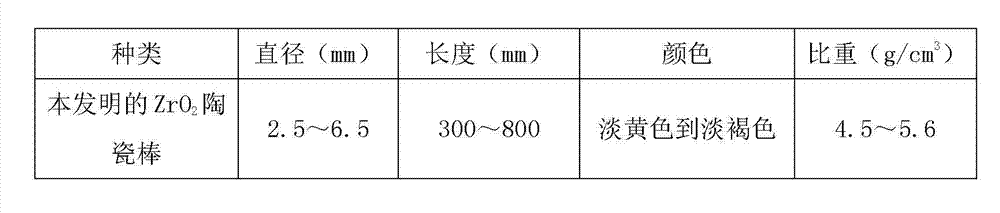

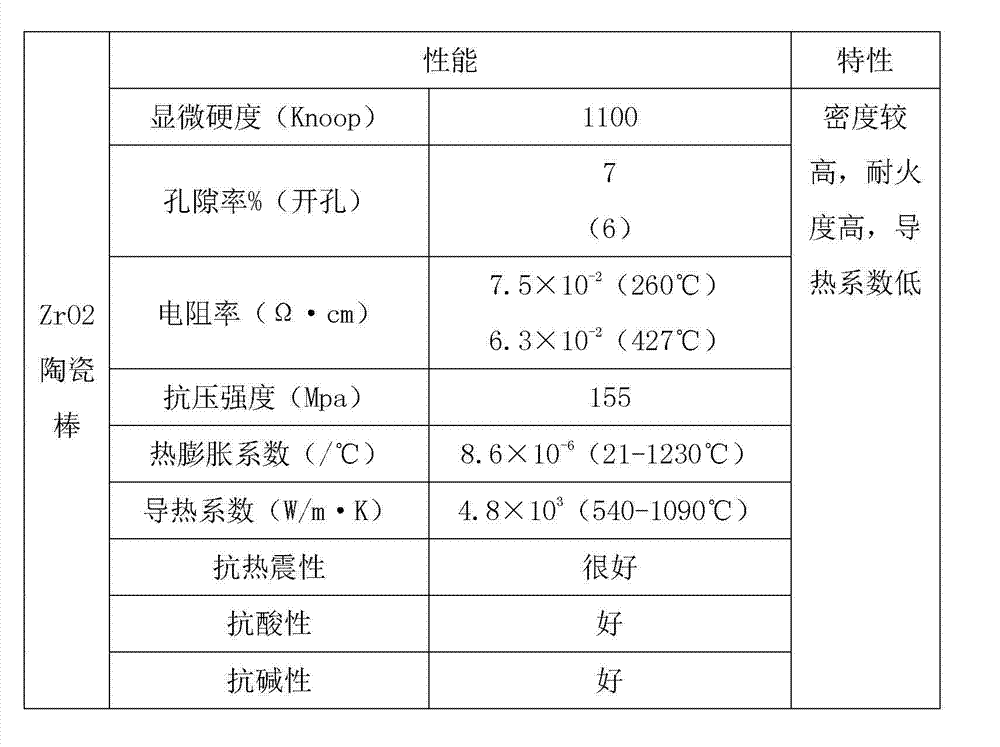

Preparation method of zirconia ceramic rod for flame spraying

The invention discloses a preparation method of a zirconia ceramic rod for flame spraying. The method comprises the steps of: first, weighing and proportioning a ceramic raw material; grinding and drying the raw material to obtain a mixed powder; then adding a modified styrene-acrylic emulsion into the mixed powder; conducting mixing and pugging; placing plastic clay into a vacuum extruder, and extruding for molding; using a horizontal burning method; heating for a degumming treatment; and finally sintering at a certain temperature to obtain the zirconia ceramic rod provided by the invention.The invention has the advantages of simple process, high rate of qualified products, greatly reduced production cost and improved efficiency, and is suitable for industrialized production; the produced ceramic rod has good spraying performance; and a ceramic coating formed after spraying has good mechanical properties, good thermal insulation, insulation and corrosion resistance, etc. The zirconia ceramic rod has good application prospects in the fields of tank, armored vehicle and aerospace.

Owner:六安皖智知识产权运营有限公司

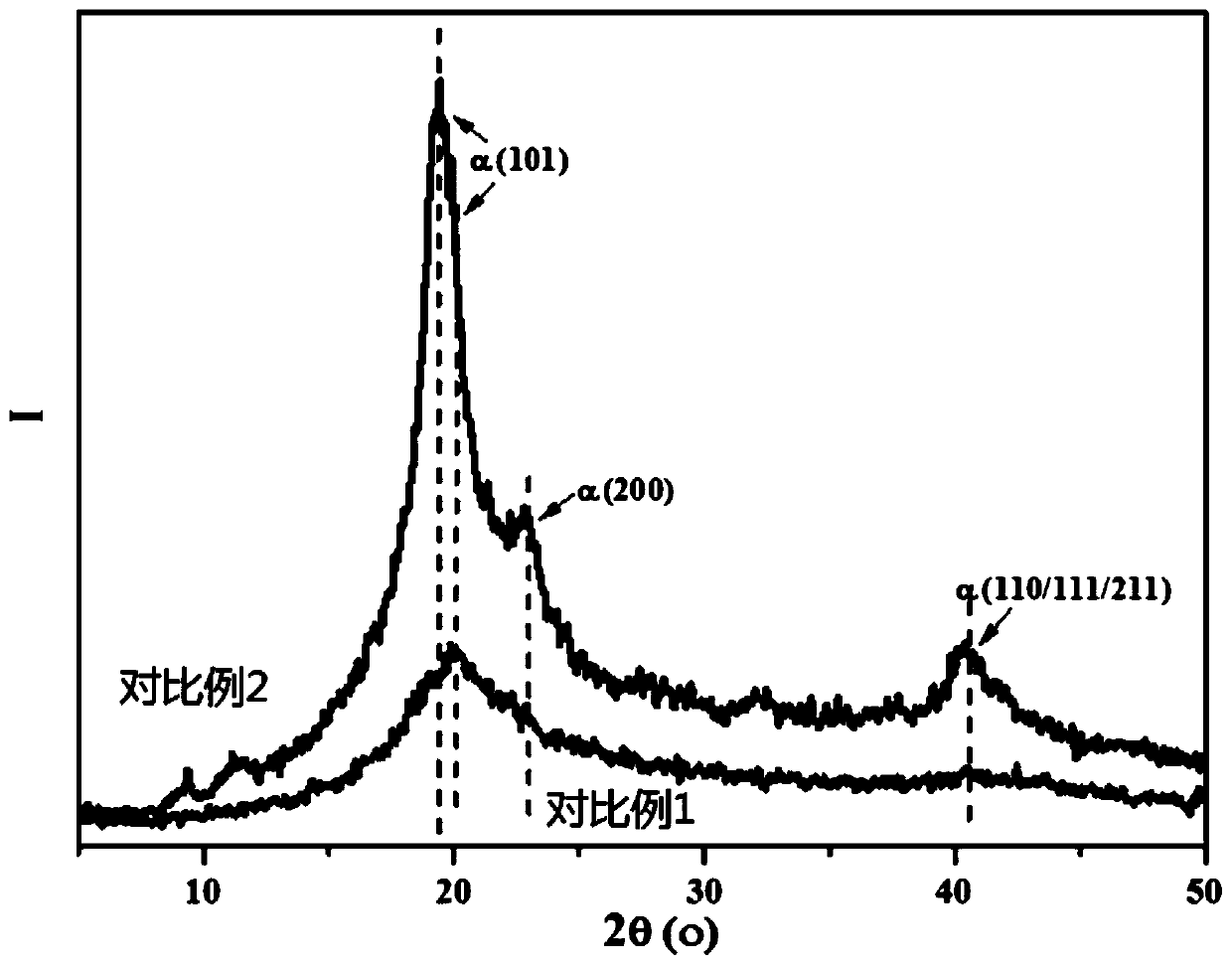

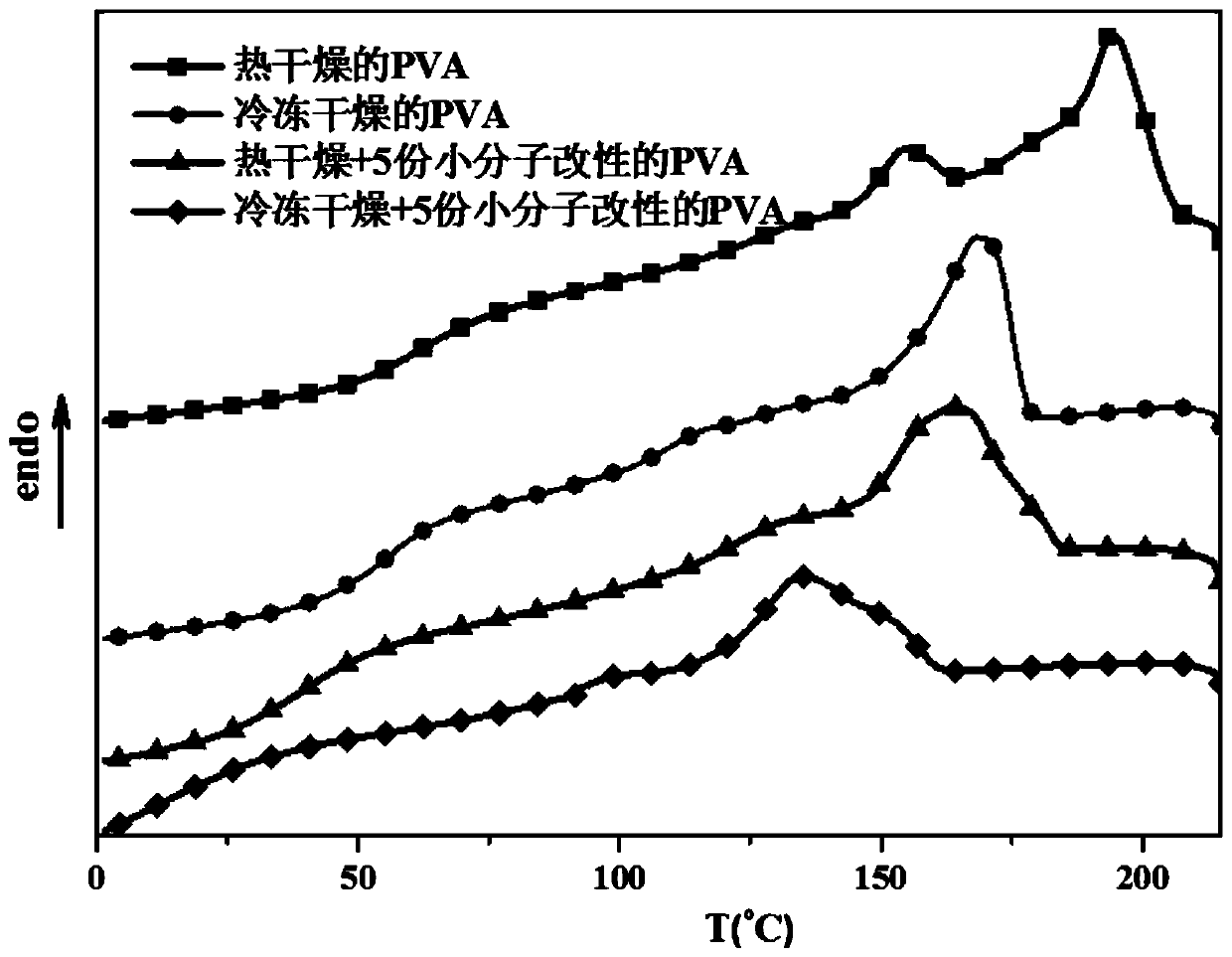

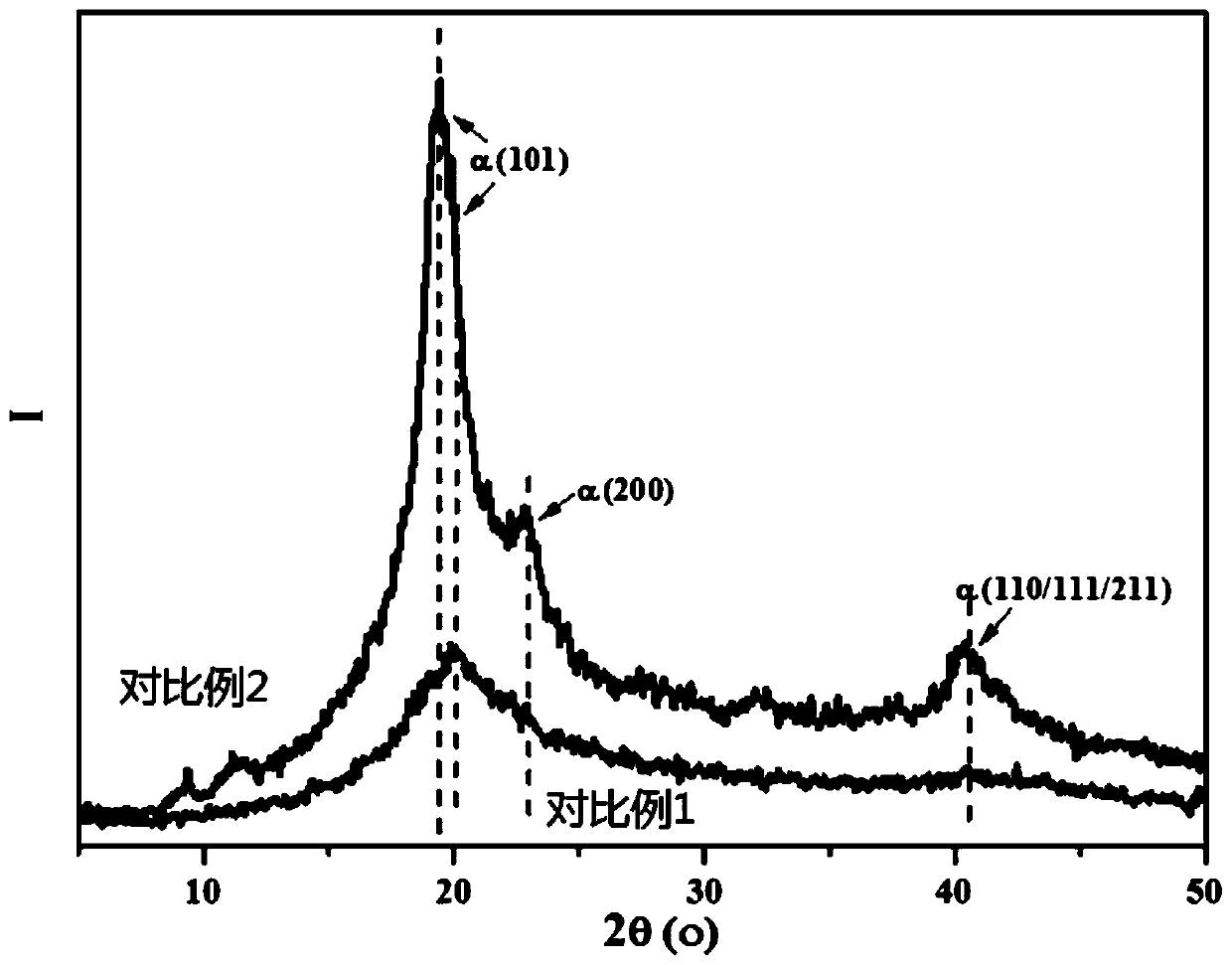

Modification method of polyvinyl alcohol capable of being subjected to thermoplastic processing

The invention relates to the technical field of thermoplastic processing of polyvinyl alcohol, and concretely relates to a modification method of polyvinyl alcohol capable of being subjected to thermoplastic processing. The method comprises the following steps: (a) performing molecular modification: mixing a polyhydroxy small molecular compound with an aqueous polyvinyl alcohol solution to form ahomogeneous solution; and (b) performing physical modification: cooling the homogeneous solution in step (a) to form an ice crystal mixture, and freeze-drying the ice crystal mixture. The polyvinyl alcohol is firstly subjected to molecular modification, and then is subjected to physical modification, and molecular modification and physical modification are combined to achieve synergistic effects,so the melting temperature of the polyvinyl alcohol is reduced greatly, and meanwhile, the temperature interval of melting processing is increased, thereby the polyvinyl alcohol is conveniently subjected to melting processing to prepare various profiles, such as pipes.

Owner:KANGTAI PLASTIC SCI & TECH GRP +1

Method for preparing polyvinylidene fluoride film

ActiveCN103203879AImproved bidirectional tensile strengthImprove performanceFlat articlesPolyvinylidene difluoridePolyvinylidene fluoride

The invention discloses a method for preparing a polyvinylidene fluoride film, and belongs to fields of preparation and application of novel macromolecule functional materials. The method comprises the following steps of: selecting materials of a first blending component, a second blending component and a third blending component; respectively feeding the first material, the second material and the third material into a respective mixer and mixing the materials; feeding, melting and extruding the first mixture, the second mixture and the third mixture into a double-screw extruder; feeding, melting and extruding a first aggregate, a second aggregate and a third aggregate into a single-screw extruder unit; cooling and crystallizing the obtained annular melt; leading the obtained annular material into a finalized drawing system, and carrying out longitudinal and transverse stretching; lifting the obtained cylinder pipe for stretching in two ways upwards to obtain cylindrical bubbles; and leading the cylindrical bubbles into a pair of pinch rolls, obtaining a flat dual-layer film after discharging from the pair of pinch rolls; and carrying out corona treatment, trimming and rolling. The two-way stretching strength of the polyvinylidene fluoride can be obviously improved to enhance the property of the film; the method has the advantages that the method is convenient to operate, concise in equipment, and fewer in technological links; and energy sources are saved.

Owner:CHANGSHU TOP SOLAR MATERIAL

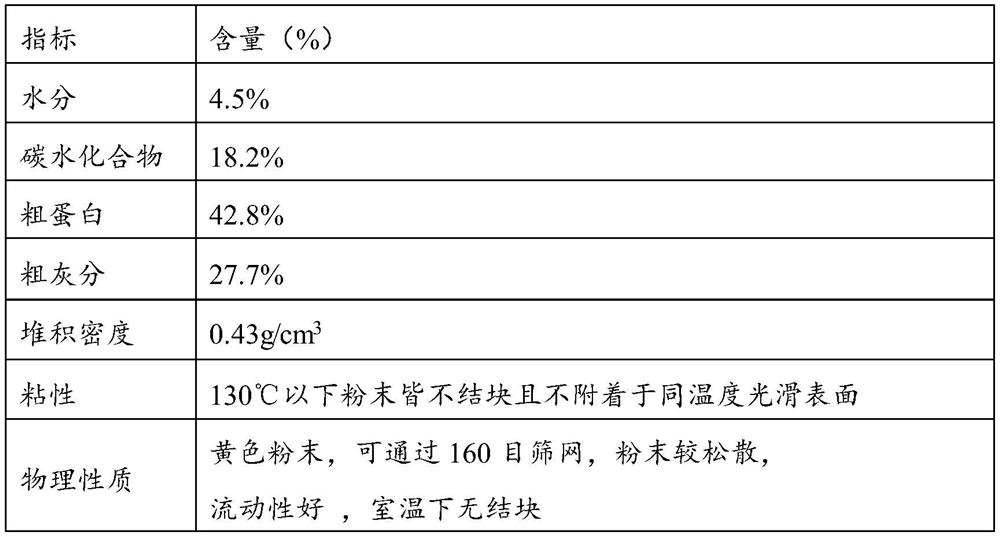

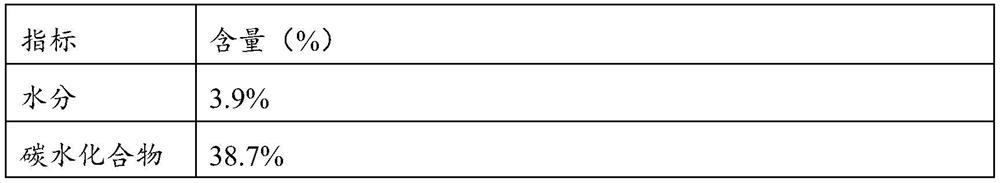

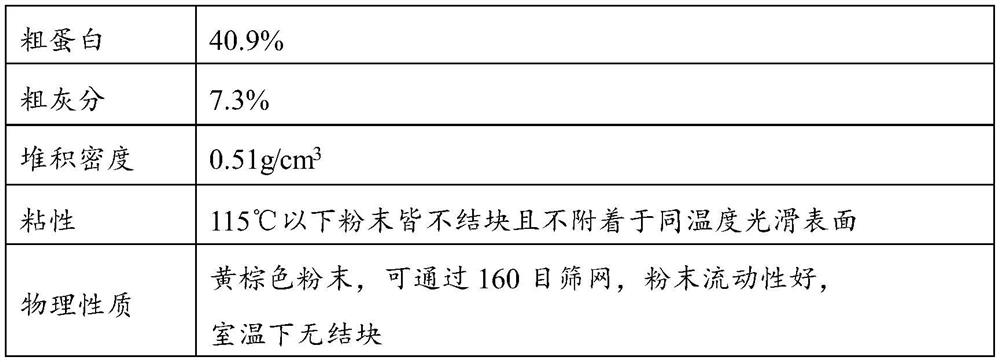

Feed with threonine mother liquor as raw material and preparation method of feed

PendingCN111758840AGood liquiditySimple methodFood processingAnimal feeding stuffMother liquorThreonine

The invention relates to the technical field of reutilization of threonine mother liquor, in particular to feed with the threonine mother liquor as a raw material and a preparation method of the feed.The threonine mother liquor produced by a fermentation method is used as the raw material, a multi-effect evaporator is used for evaporating and concentrating the threonine mother liquor, then concentrated mother liquor is mixed with auxiliary materials according to different proportions, and a mixture is processed by spray-drying or slurry-spraying granulation equipment to obtain the feed; and the obtained feed has the moisture content of less than 5%, good product flowability and no caking. The method solves the problem that the threonine mother liquor cannot be granulated due to too high viscosity in the prior art, avoids the problem of waste or pollution caused by discarding or burning the threonine mother liquor, is simple, and can meet the requirements of industrial mass production.

Owner:MEIHUA BIOTECH LANGFANG CO LTD

Vanadium-aluminum alloy production method

The invention discloses a vanadium-aluminum alloy production method, and belongs to the technical field of metallurgy. The technical effects that the rate and quality of finished products of vanadium-aluminum alloy are improved, the impurity content of the vanadium-aluminum alloy is reduced, the production scale of the vanadium-aluminum alloy is broadened, and the cost of the vanadium-aluminum alloy is reduced are achieved. The vanadium-aluminum alloy production method comprises the steps that the first batch of vanadium oxide and the first batch of aluminum are added into a graphite crucibleprovided with a drilled cover, ignition is conducted for aluminothermic reduction reaction, after reaction is completed, the follow-up batch of vanadium oxide and the follow-up batch of aluminum are added in sequence, aluminothermic reduction reaction is conducted till all vanadium oxide and aluminum are added and reacted completely, slag is separated from the alloy, and the vanadium-aluminum alloy is obtained. According to the method, the batched adding mode is adopted, the graphite crucible provided with the drilled cover is used as a smelting furnace body, the production scale is expanded,the vanadium yield is increased, a slagging cooling agent does not need to be added, the cost is lower, the obtained alloy is higher in purity and quality, and the industry large scale production requirements are completely met.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com