Preparation method of zirconia ceramic rod for flame spraying

A technology of zirconia ceramics and flame spraying, which is applied in the field of ceramic preparation, can solve the problems of unsatisfactory industrial production, increased processing costs, and low qualified rate of finished products, so as to save drying and sieving, reduce scrap rate, and good mechanics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

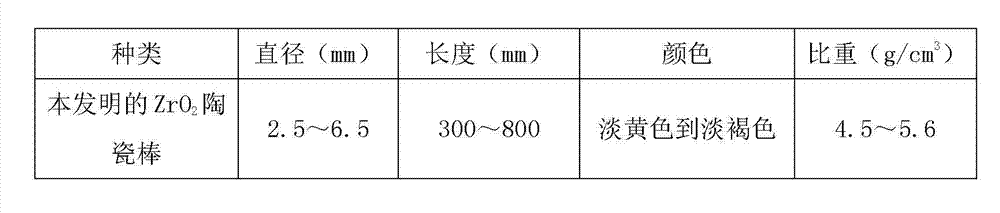

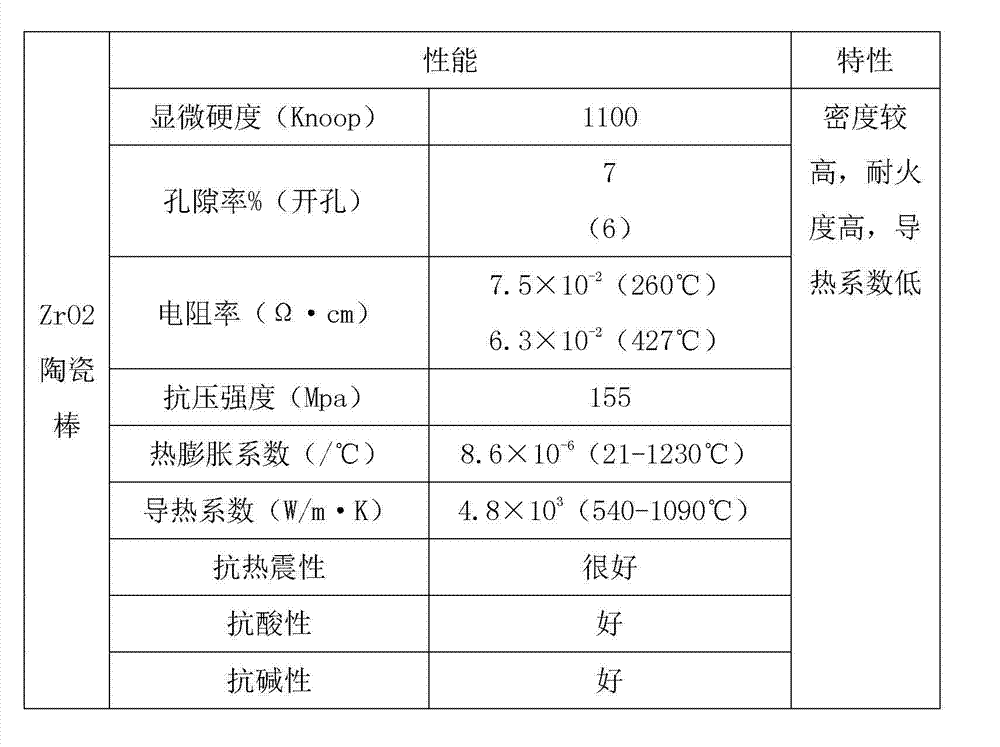

[0033] The selected formula is: 89.108% ZrO 2 + 2.42%Al 2 o 3 +3.715%SiO2 2 + 0.027% Fe 2 o 3 +0.8%TiO 2 + 3.93%CaO 2 Weigh the ingredients, put them into the ball mill tank and carry out dry mixing for 4 hours directly. After the mixed powder is discharged, it is directly added to the high-temperature box-type electric furnace, and it is sintered at 1600°C for 23 hours at a high temperature, and then it is crushed out of the furnace and passed through 280°C. mesh vibrating sieve; mix 75 parts of deionized water with 5 parts of allyloxy hydroxypropyl sodium sulfonate and 6.5 parts of polyethylene glycol 200, stir at high speed until the emulsification is sufficient, then heat up in a water bath until the temperature rises to 75 °C , add 18 parts of styrene, 8 parts of hydroxyethyl methacrylate and 0.4 parts of sodium persulfate completely dissolved in 5 parts of acrylic acid and 25 parts of deionized water, then raise the temperature to 88°C, keep it warm for about o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com