A transition metal phosphide MxPy oxygen reduction and hydrogen evolution bifunctional catalyst and preparation method and application thereof

A bifunctional catalyst and transition metal technology, applied in the field of electrochemical catalysis, can solve the problems of large grain size, small specific surface area, and weak catalytic activity, and achieve small grain size, large specific surface area, and high HER catalytic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

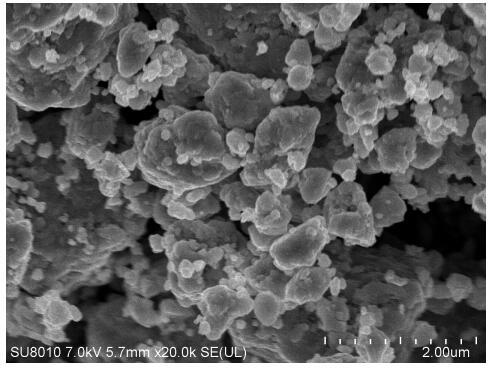

[0040] This embodiment provides several transition metal phosphides M x P y (MnP, FeP, CoP and Ni 5 P 4 ) Oxygen reduction and hydrogen evolution bifunctional catalyst, prepared by the following method.

[0041]Select metal elements Mn, Fe, Co with a particle size of 300nm, red phosphorus powder at a metering ratio of 1:1, Ni and red phosphorus powder at a metering ratio of 5:4 and mix them into a zirconia ball mill tank, add zirconia The mass ratio of the ball to the mixed powder is 15:1. Under the condition of inert gas, seal the zirconia ball mill jar, and perform high-energy ball milling at a speed of 400rpm for 12h to preliminarily prepare transition metal phosphides MnP, FeP, CoP and Ni respectively. 5 P 4 Material;

[0042] Then the MnP, FeP, CoP and Ni synthesized initially in the previous step 5 P 4 In the material, the ratio of the mass of the isopropanol dispersion to the mass of the powder is 2:1, wet ball milling at a speed of 100rpm for 2h, and then drying...

Embodiment 2

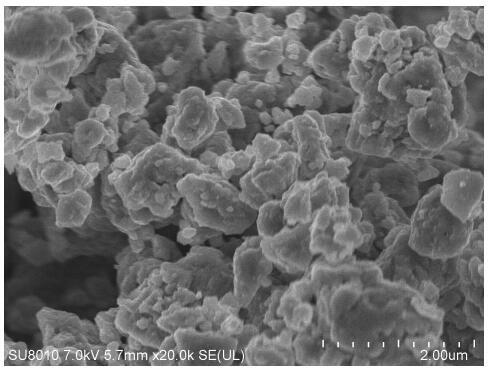

[0049] This embodiment provides several transition metal phosphides M x P y (MnP, FeP, CoP and Ni 5 P 4 ) Oxygen reduction and hydrogen evolution bifunctional catalyst, prepared by the following method.

[0050] Select metal elements Mn, Fe, Co with a particle size of 100nm, red phosphorus powder at a metering ratio of 1:1, Ni and red phosphorus powder at a metering ratio of 5:4 and mix them into a zirconia ball mill tank, add zirconia The mass ratio of the ball to the mixed powder is 10:1. Under the condition of inert gas, seal the zirconia ball mill jar, and carry out high-energy ball milling at a speed of 300 rpm for 15 hours to preliminarily prepare transition metal phosphides MnP, FeP, CoP and Ni respectively. 5 P 4 Material;

[0051] Then the MnP, FeP, CoP and Ni synthesized initially in the previous step 5 P 4 In the material, the ratio of the mass of the added aqueous dispersion to the mass of the powder is 3:1, wet ball milling at a speed of 150rpm for 3h, and ...

Embodiment 3

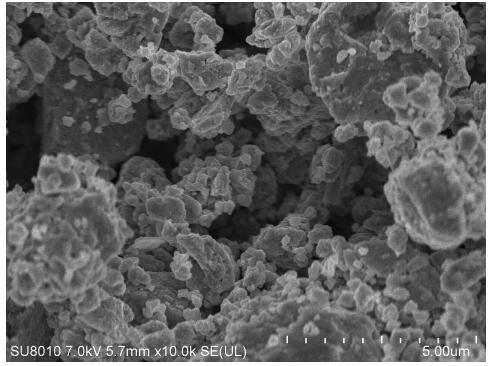

[0054] This embodiment provides several transition metal phosphides M x P y (MnP, FeP, CoP and Ni 5 P 4 ) Oxygen reduction and hydrogen evolution bifunctional catalyst, prepared by the following method.

[0055] Select metal elements Mn, Fe, Co with a particle size of 30nm, red phosphorus powder at a metering ratio of 1:1, Ni and red phosphorus powder at a metering ratio of 5:4 and mix them into a zirconia ball mill tank, add zirconia The mass ratio of the ball to the mixed powder is 5:1. Under the condition of inert gas, seal the zirconia ball mill jar, and perform high-energy ball milling at a speed of 200 rpm for 18 hours to preliminarily prepare transition metal phosphides MnP, FeP, CoP and Ni respectively. 5 P 4 Material;

[0056] Then the MnP, FeP, CoP and Ni synthesized initially in the previous step 5 P 4 In the material, the ratio of the mass of the ethanol dispersion to the mass of the powder is 4:1, wet ball milling at a speed of 100rpm for 4h, and then dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com