Nutrient release rate adjustable plant oil coated controlled-release fertilizer and preparation method thereof

A kind of technology of controlled release fertilizer and vegetable oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

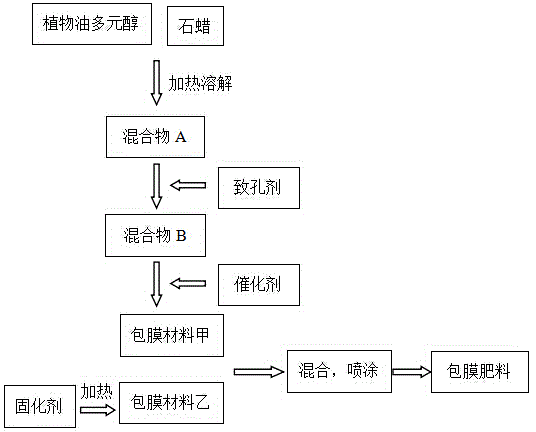

Image

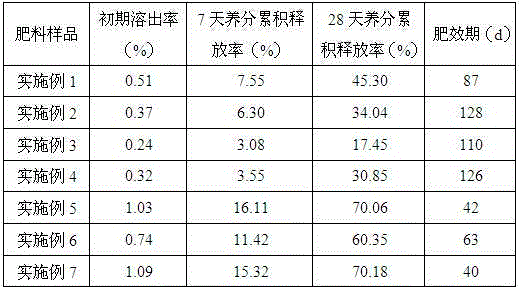

Examples

Embodiment 1

[0048] Add the catalyzer and the 5g porogen of the film-forming aid of 6% of total weight of coating framework material, coating framework material total weight 0.6%, and coating thickness is expressed as 4% with coating material station core fertilizer weight percent, so The coating skeleton material is vegetable oil polyol and curing agent, the weight ratio of the two is 1:0.6; the curing agent is polyisocyanate DMI 400.

[0049] Weigh each component by weight as follows:

[0050] Vegetable oil polyol (castor oil): 250 g

[0051] Curing agent (polyisocyanate DMI 400): 150 g

[0052] Magnesium carbonate (porogen): 5 g

[0053] Catalyst (stannous octoate): 2.4 g

[0054] Coalescent (paraffin): 24 g

[0055] Urea (3 mm≤d≤5 mm): 10 Kg.

[0056] The preparation technological process of coated controlled-release fertilizer of the present invention refers to attached figure 1 As shown, it specifically includes the following steps:

[0057] S1. Add paraffin wax to vegetable o...

Embodiment 2

[0069] Add the catalyzer and 5g porogen of 0.6% of the film-forming auxiliary agent of coating framework material gross weight 8% and coating framework substance total weight, and coating thickness is expressed as 4% with coating material station core fertilizer weight percent, The coating skeleton material is vegetable oil polyol and curing agent, the weight ratio of the two is 1:0.6; the curing agent is polyisocyanate DMI 400.

[0070] Weigh each component by weight as follows:

[0071] Vegetable oil polyol (castor oil): 250 g

[0072] Curing agent (polyisocyanate DMI 400): 150 g

[0073] Porogen (nano-bentonite): 5 g

[0074] Catalyst (stannous octoate): 2.4 g

[0075] Coalescent (paraffin): 32 g

[0076] Urea: 10 Kg (3 mm≤d≤5 mm)

[0077] The schematic diagram of the preparation process of the coated controlled-release fertilizer in this embodiment refers to the attached figure 1 Shown, step is with embodiment 1, and envelope thickness is 4%.

Embodiment 3

[0079] Add the film-forming aid (paraffin) of 6% of the total weight of the coating framework material, the catalyst of 0.6% of the total weight of the coating framework material and the 2g porogen, and the thickness of the coating is represented by the weight percentage of the core fertilizer of the coating material station, The coating skeleton material is vegetable oil polyol and curing agent, the weight ratio of the two is 3:2; the curing agent is polyisocyanate DMI 400.

[0080] Weigh each component by weight as follows:

[0081] Vegetable polyol (castor oil): 300 g

[0082] Curing agent (polyisocyanate DMI 400): 200 g

[0083] Magnesium carbonate (porogen): 2 g

[0084] Catalyst (stannous octoate): 3.0 g

[0085] Coalescent (paraffin): 30 g

[0086] Urea (3 mm≤d≤5 mm): 10 Kg

[0087] The schematic diagram of the preparation process of the coated controlled-release fertilizer in this embodiment refers to the attached figure 1 Shown, step is with embodiment 1, and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com