Numerical control laser engraving machine, control system, control method and computer

A technology of numerical control laser and control method, applied in laser welding equipment, manufacturing tools, welding equipment and other directions, can solve the problems of small calculation amount, inability to effectively improve production efficiency, poor accuracy of 3D-based CAD drawing data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

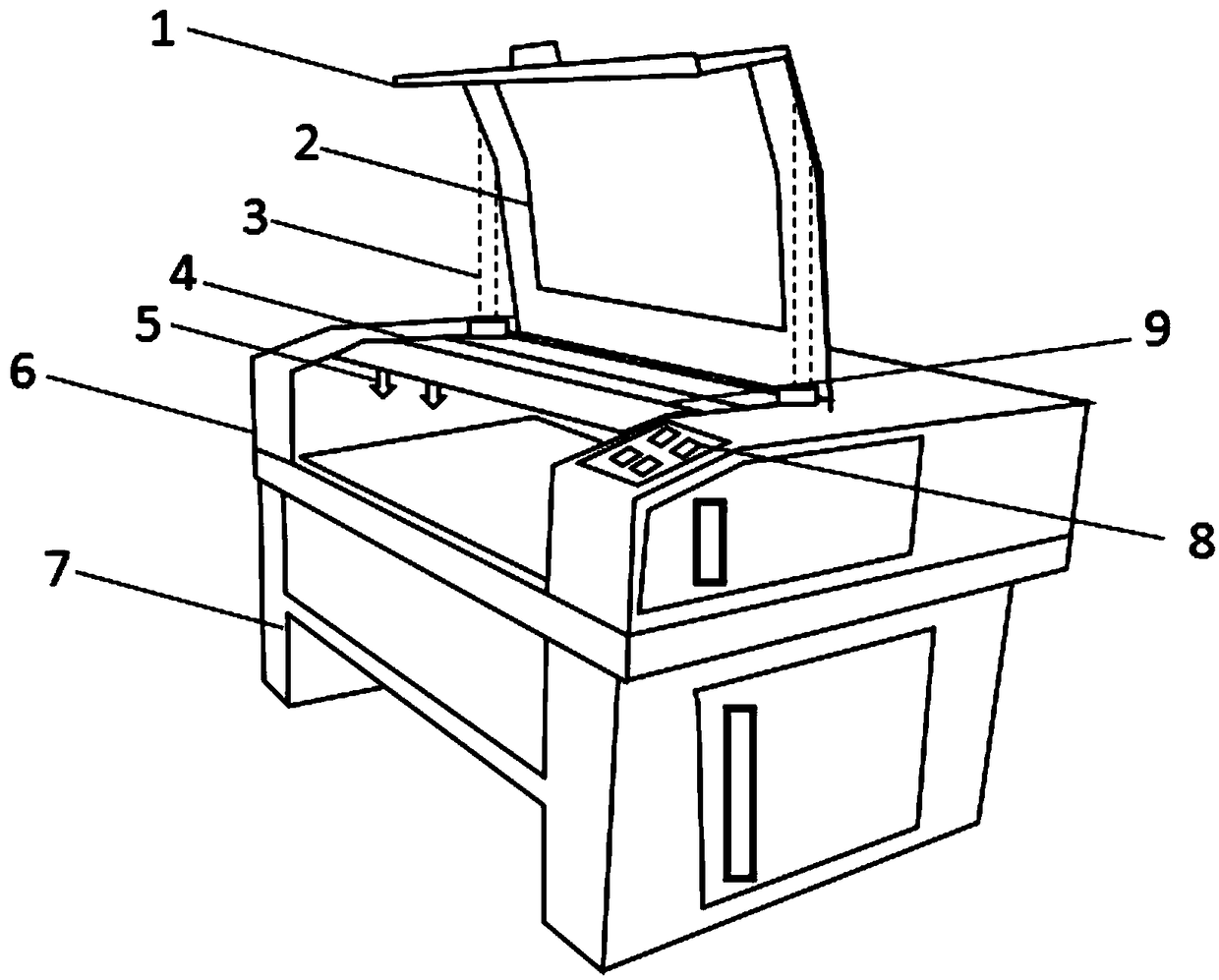

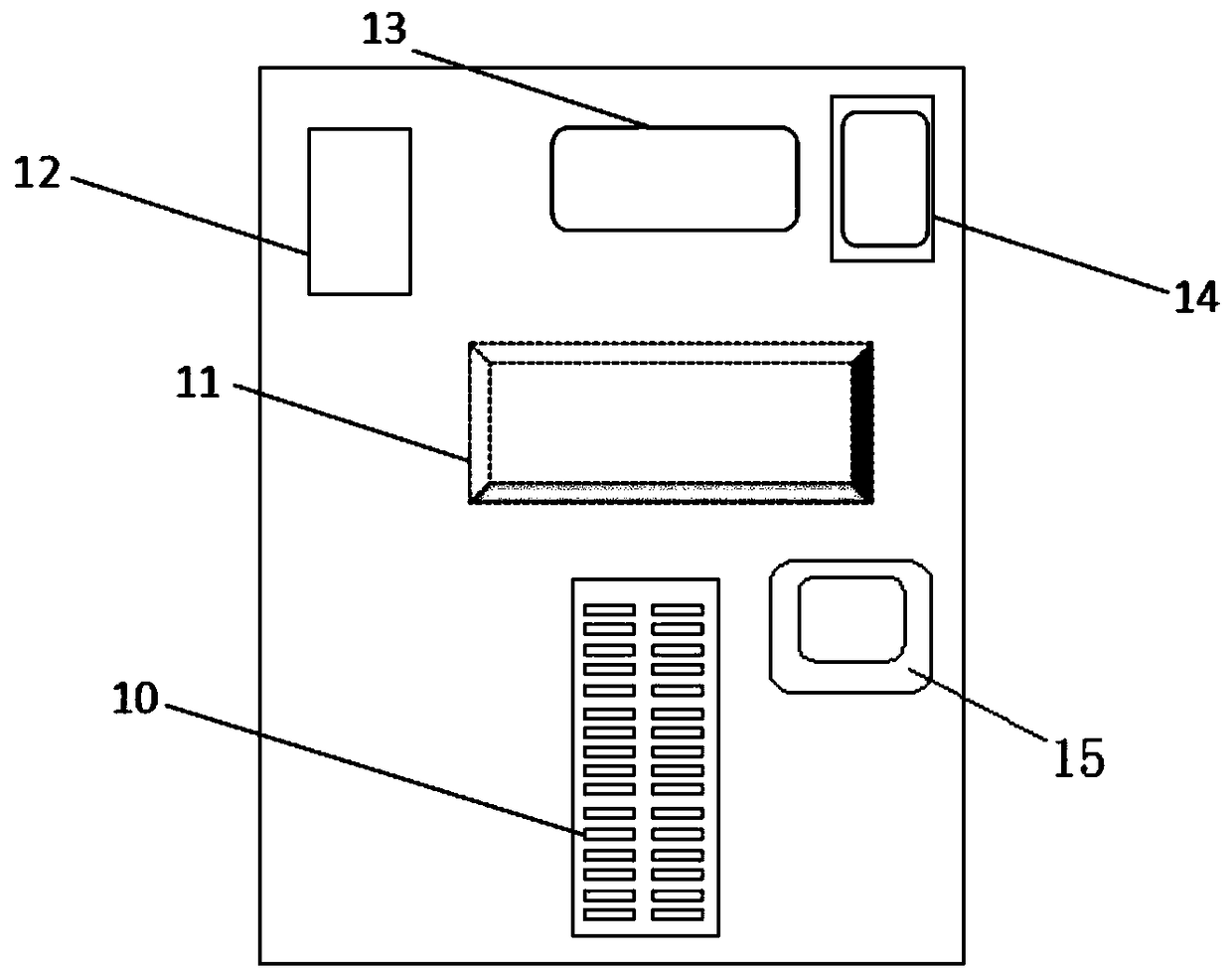

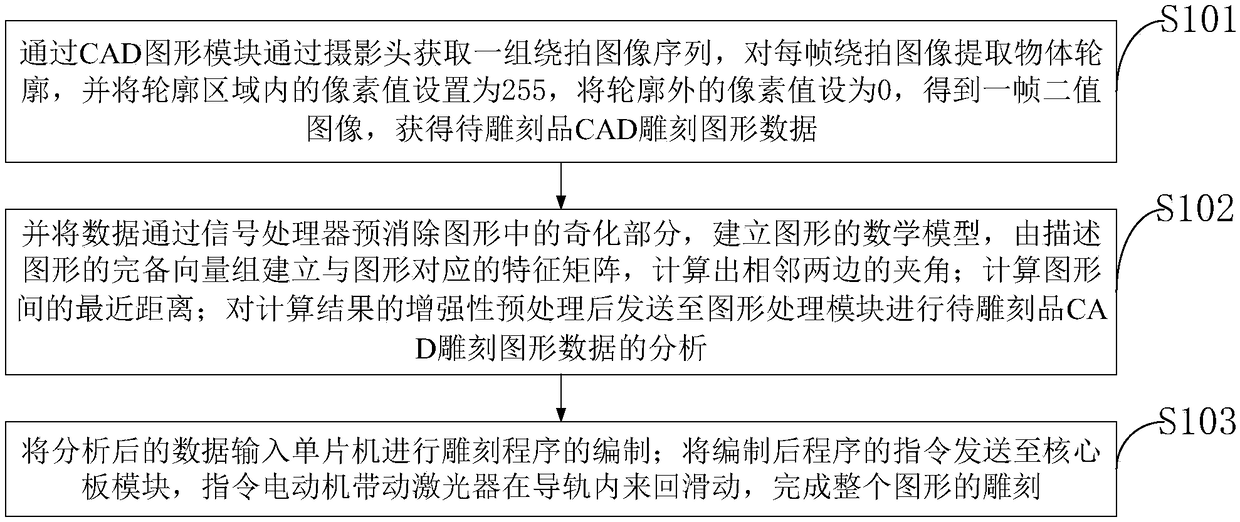

[0080] Such as figure 1 and figure 2 As shown, the CNC laser engraving machine provided by the embodiment of the present invention includes: a cover plate 1; a transparent baffle plate 2, a support rod 3, a guide rail 4, a laser device 5, a casing 6, a base 7, a control panel 8, and a horizontal bar 9 core board modules 10 (Arduino Uno R3 core board), signal processor 11, motor 12, graphics processing module 13, single-chip microcomputer 14.

[0081] The cover plate 1 is welded on the top of the shell 6 through the rotating shaft, the transparent baffle 2 is keyed in the middle of the cover plate 1, the head of the support rod 3 is welded on the cover plate 1, and the tail is welded on the top of the shell 6. In the recess, the two ends of the guide rail 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com