Production method of grade tin containing 99.99% of Sn

A production method and grade technology, applied in the direction of improving process efficiency, can solve the problems of reduced equipment capacity, large amount of slag in the process, low recovery rate of smelting, etc., and achieve the effect of high production efficiency and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

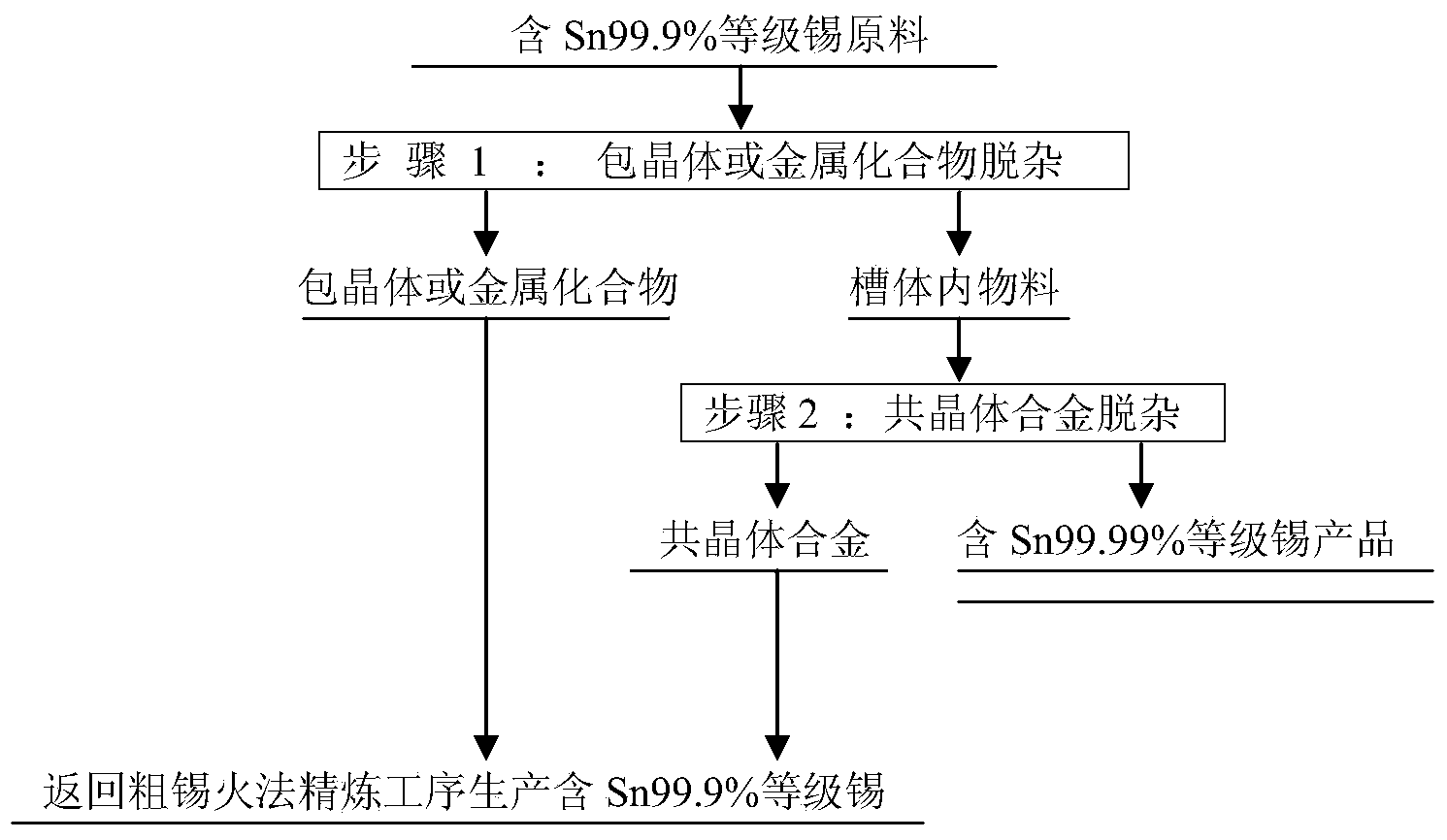

[0027] Present embodiment is the first example of the production method containing Sn99.99% grade tin of the present invention, comprises the steps:

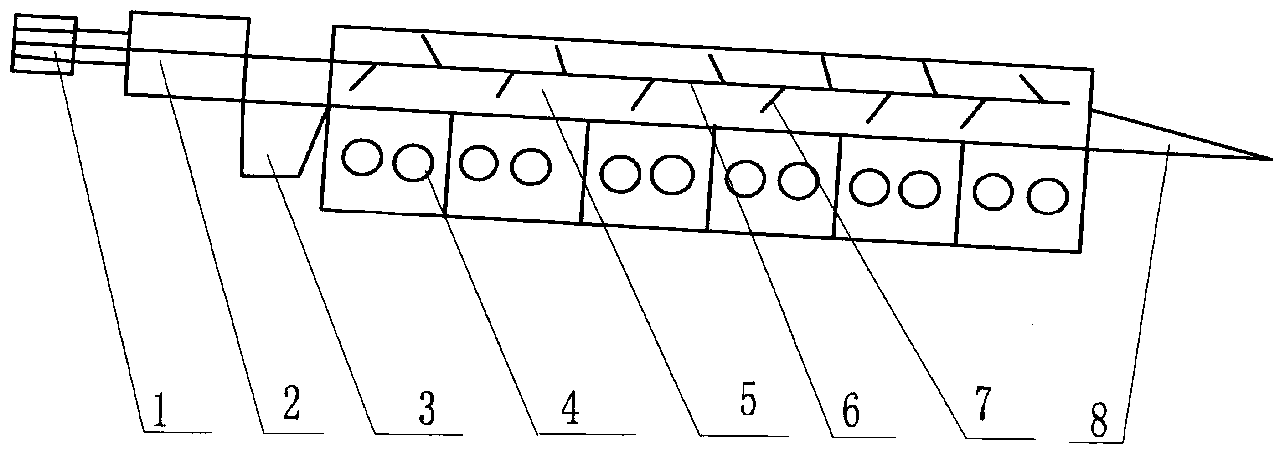

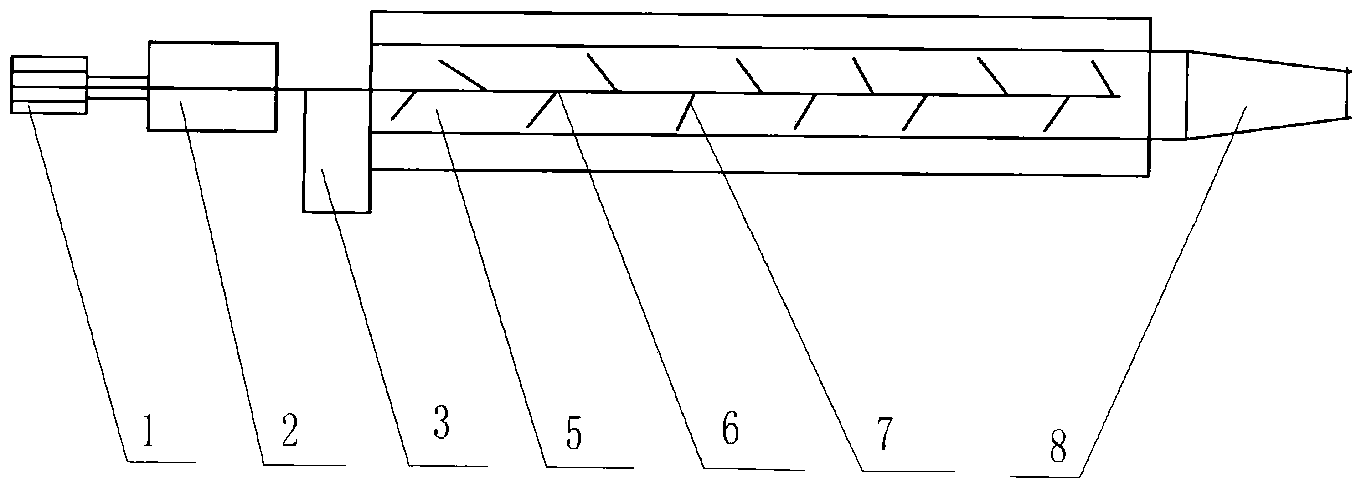

[0028] (1) Peritectic or metal compound removal: at a temperature of 250°C, gradually remove 1 ton of Sn99.92%, Fe0.005%, Cu0.0032%, Pb0.018%, Sb0.017%, As0.004%, Bi0.011%, S0.003%, Ag0.0005%, In0.018% Sn99.9% grade tin is added to the equipment, the tank size is Φ280mm×2000mm and there are 6 temperature control sections In the spiral blade crystallization equipment, the temperature of the six temperature sections of the crystallization equipment is controlled at the same time to be 180°C, 195°C, 205°C, 215°C, 225°C, and 235°C, and the rotation speed of the spiral blade shaft is 0.4n / min, so that the material is crystallized Continuous crystallization and melting are realized in the equipment. After 12 hours, at the outlet of the high temperature section of the crystallization equipment, the output contains Sn99.73%, Fe0.015%, C...

no. 2 example

[0031] Present embodiment is the second example of the production method containing Sn99.99% grade tin of the present invention, comprises the steps:

[0032] (1) Peritectic or metal compound removal: at a temperature of 270°C, gradually remove 9 tons of Sn99.93%, Fe0.006%, Cu0.0035%, Pb0.019%, Sb0.016%, As0.003%, Bi0.012%, S0.003%, Ag0.0005%, In0.0016% Sn99.9% grade tin is added to the equipment, the tank size is Φ650mm×6000mm and there are 6 temperature control sections In the spiral blade crystallization equipment, the temperature of the six temperature sections of the crystallization equipment is controlled at the same time to be 190°C, 200°C, 210°C, 220°C, 230°C, and 238°C, and the rotation speed of the spiral blade shaft is 0.35n / min, so that the material is crystallized Continuous crystallization and melting are realized in the equipment. After 16 hours, at the outlet of the high temperature section of the crystallization equipment, Sn99.76%, Fe0.017%, Cu0.011%, Pb0.003...

no. 3 example

[0035] Present embodiment is the 3rd example of the production method that contains Sn99.99% grade tin of the present invention, comprises the steps:

[0036] (1) Peritectic or metal compound removal: at a temperature of 300°C, gradually remove 12 tons of Sn99.96%, Fe0.004%, Cu0.002%, Pb0.010%, Sb0.010%, As0.002%, Bi0.008%, S0.002%, Ag0.0002%, In0.0018% Sn99.9% grade tin is added to the equipment, the tank size is Φ680mm×6400mm and there are 6 temperature control sections In the spiral blade crystallization equipment, the temperature of the six temperature sections of the crystallization equipment is controlled at the same time to be 195°C, 205°C, 215°C, 225°C, 235°C, and 240°C, and the rotation speed of the spiral blade shaft is 0.3n / min, so that the material is crystallized Continuous crystallization and melting are realized in the equipment. After 20 hours, at the outlet of the high temperature section of the crystallization equipment, the continuous output contains Sn99.88...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com