Patents

Literature

96results about "Titanium suboxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanostructured titanium oxide material and its synthesis procedure

ActiveUS20060078726A1Stable nanotubular structureLarge specific surface areaMaterial nanotechnologyLayered productsFiberNanowire

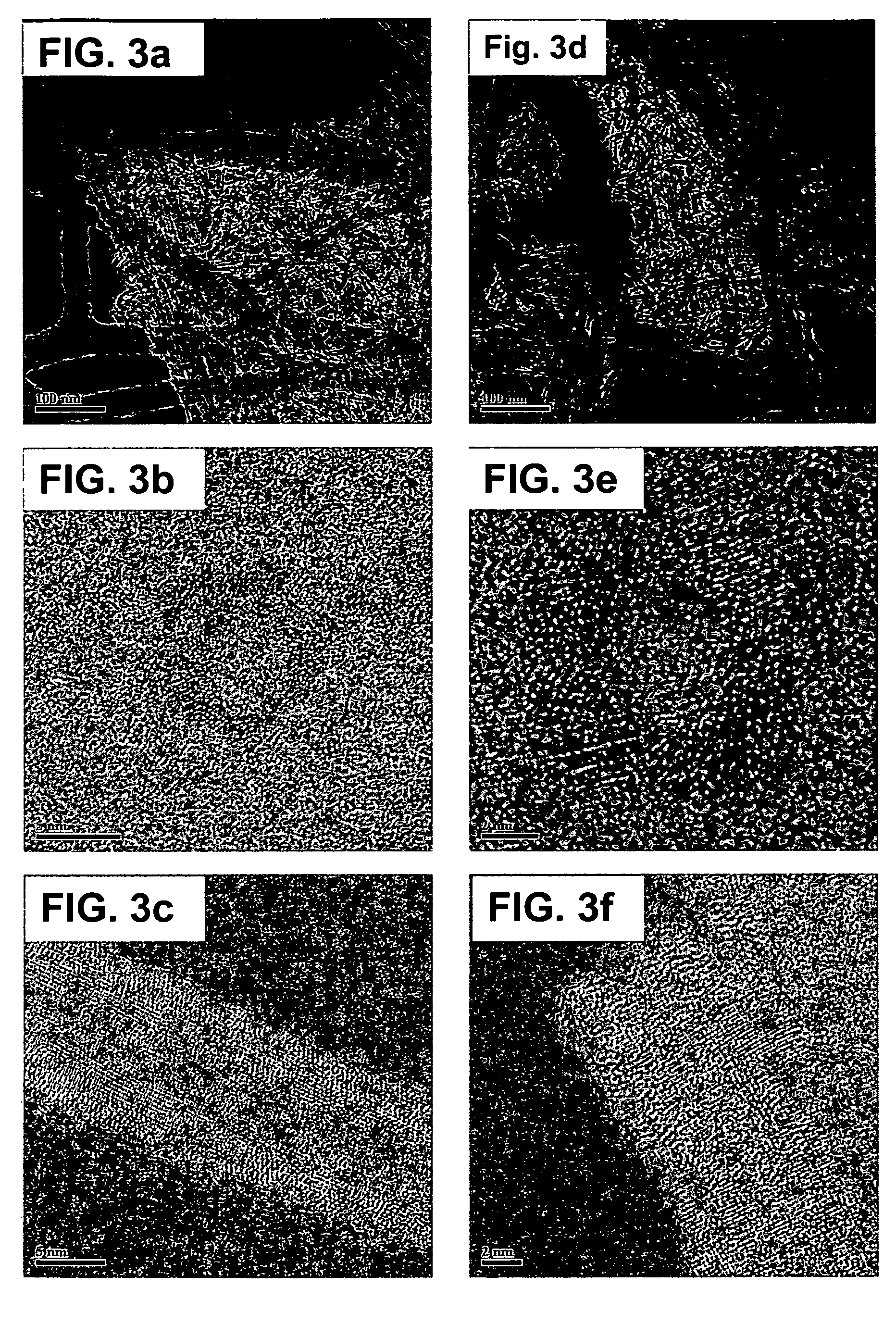

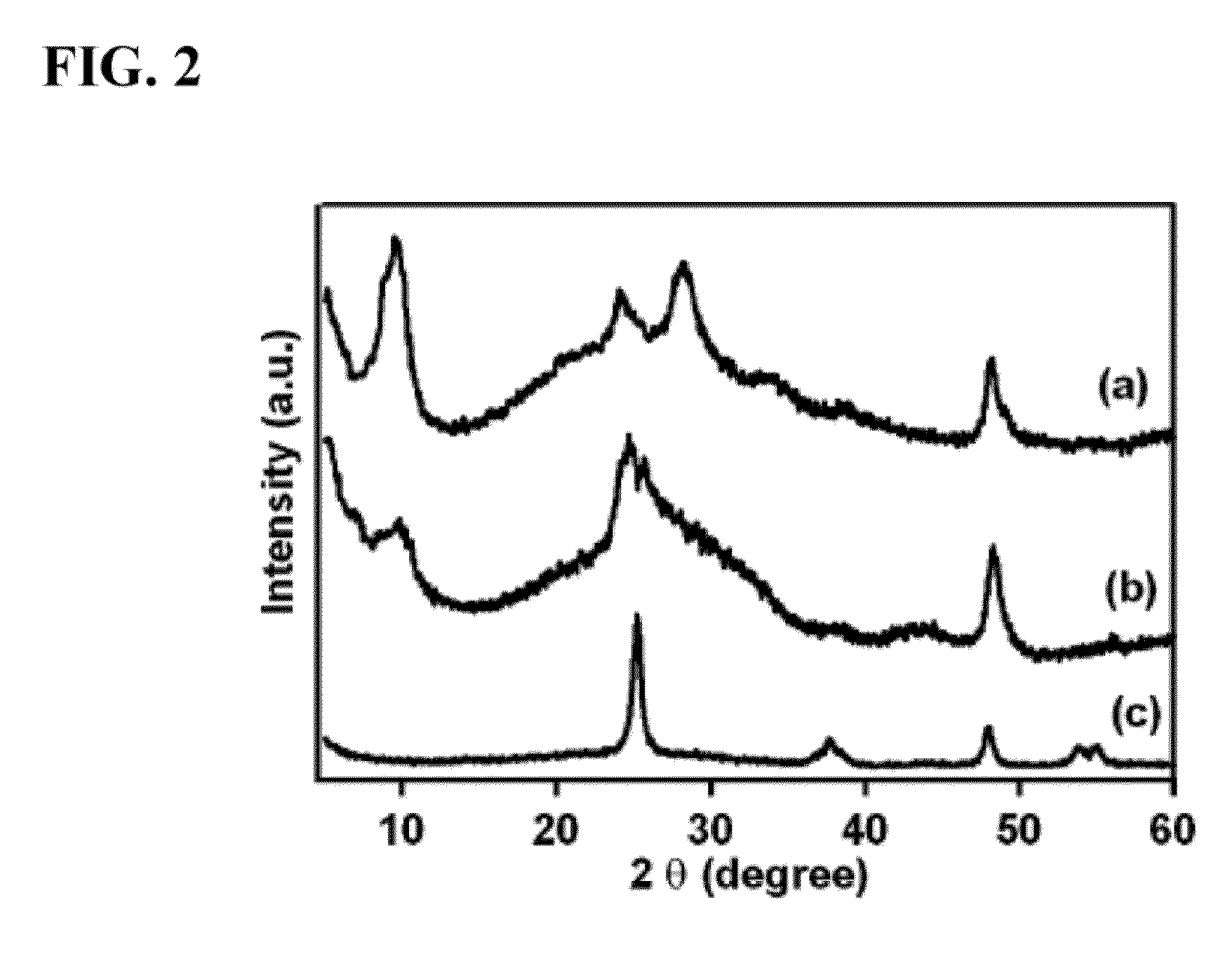

Nanomaterials of the JT phase of the titanium oxide TiO2-x, where 0≦x≦1 having as a building block a crystalline structure with an orthorhombic symmetry and described by at least one of the space groups 59 Pmmn, 63 Amma, 71 Immm or 63 Bmmb. These nanomaterials are in the form of nanofibers, nanowires, nanorods, nanoscrolls and / or nanotubes. The nanomaterials are obtained from a hydrogen titanate and / or a mixed sodium and hydrogen titanate precursor compound that is isostructural to the JT crystalline structure. The titanates are the hydrogenated, the protonated, the hydrated and / or the alkalinized phases of the JT crystalline phase that are obtained from titanium compounds such as titanium oxide with an anatase crystalline structure, amorphous titanium oxide, and titanium oxide with a rutile crystalline structure, and / or directly from the rutile mineral and / or from ilmenite. The titanates are submitted to dynamic thermal treatment in an inert, oxidizing or reducing atmosphere to produce the JT phase of the TiO2-x, where 0≦x≦1 with an orthorhombic structure.

Owner:INST MEXICANO DEL GASOLINEEO

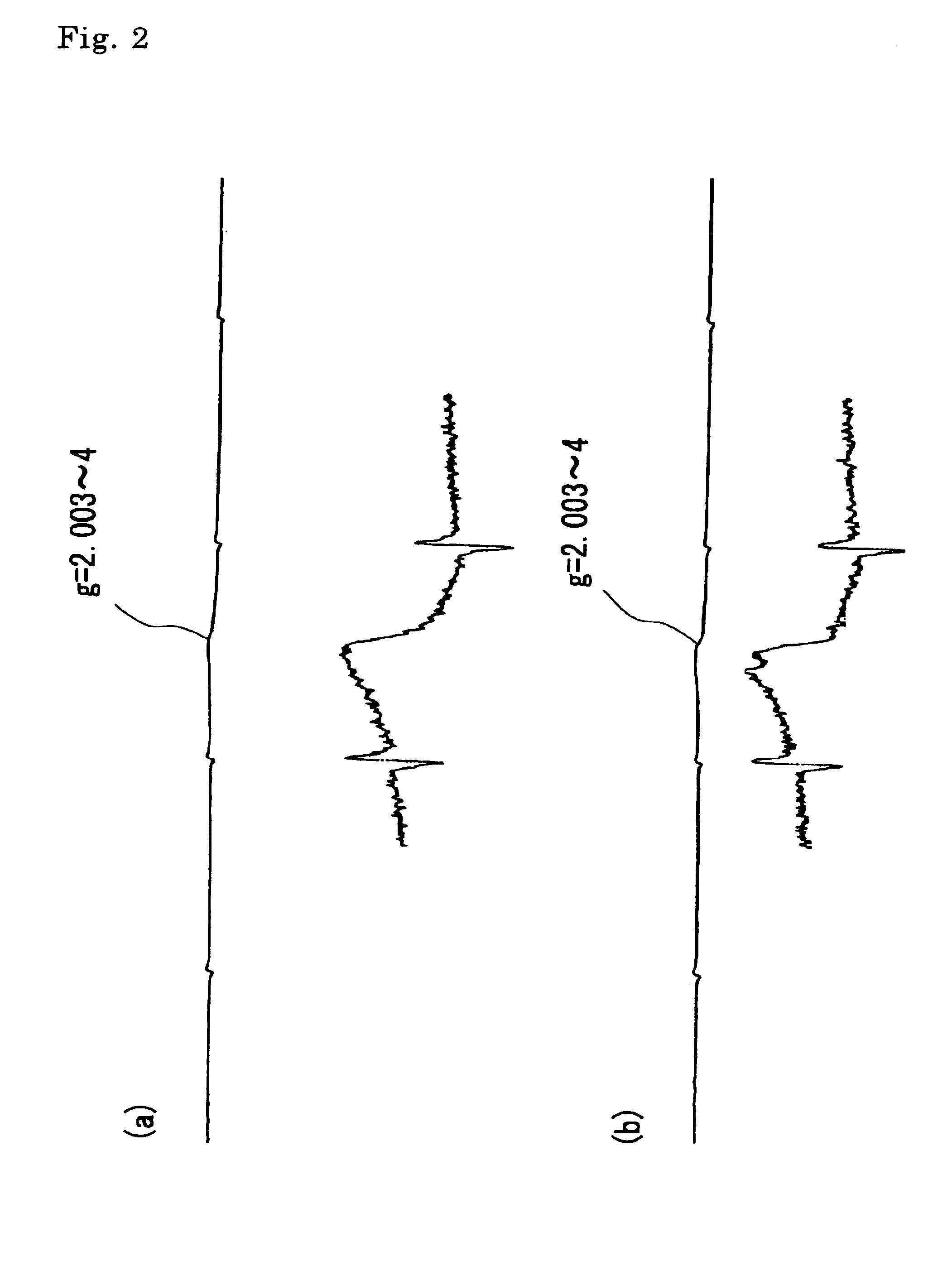

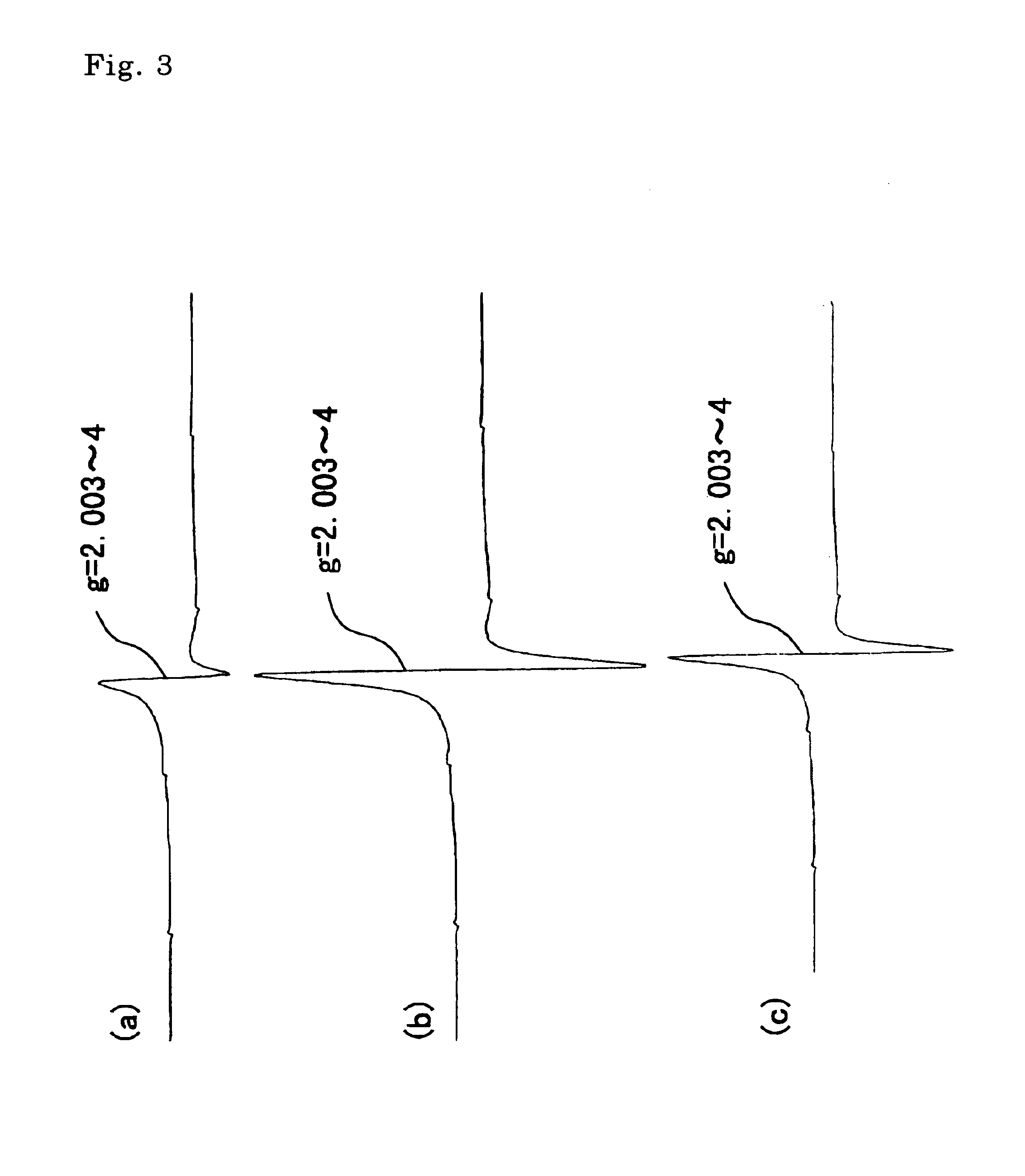

Visible radiation type photocatalyst and production method thereof

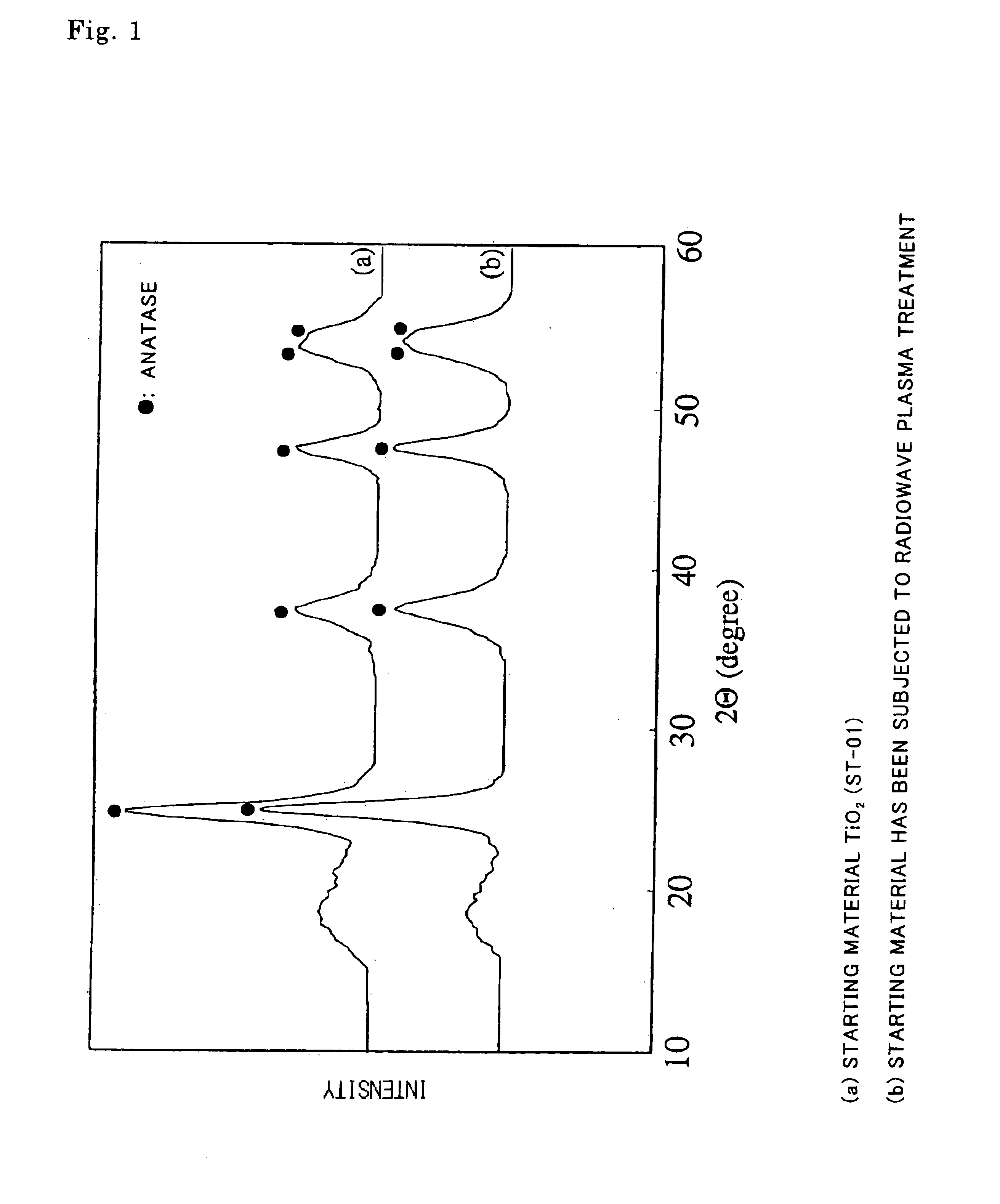

The invention is directed to a catalyst having activity under the irradiation of a visible light, the catalyst being an oxide semiconductor such as an anatase type titanium dioxide, having stable oxygen defects. A method for producing a catalyst having activity under the irradiation of a visible light which comprises treating an oxide semiconductor with hydrogen plasma or with a plasma of a rare gas element, comprising performing the treatment in a state substantially free from the intrusion of air into the treatment system is also provided. An article comprising a base material having the catalyst above provided on the surface thereof and a method for decomposing a substance, comprising bringing an object to be decomposed into contact with the catalyst above under the irradiation of a light containing at least a visible radiation are disclosed. A novel photocatalyst which enables use of a visible radiation is provided, as well as a method utilizing the photocatalyst for removing various substances containing an organic matter or bacteria by photodecomposition.

Owner:ASUKATEC

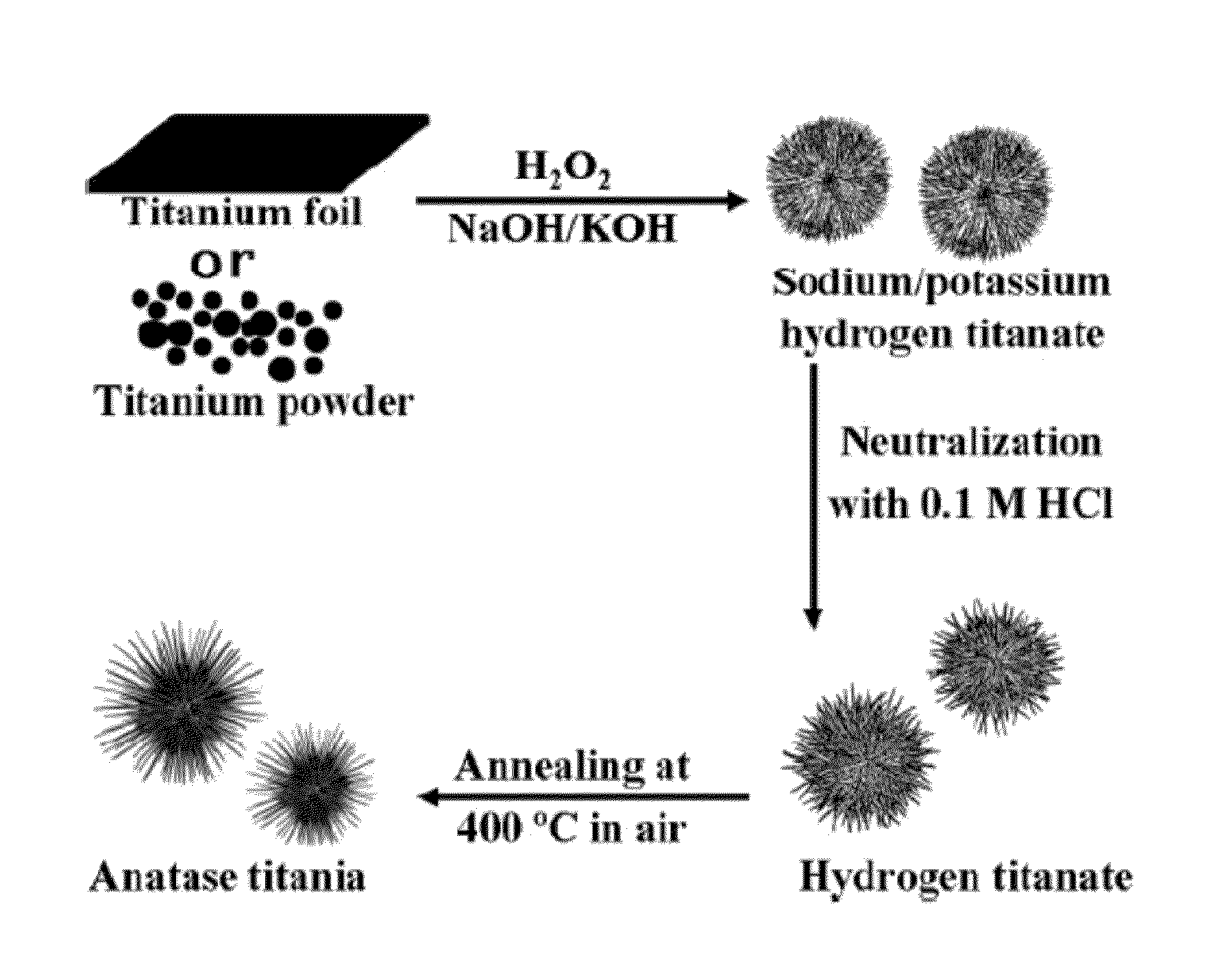

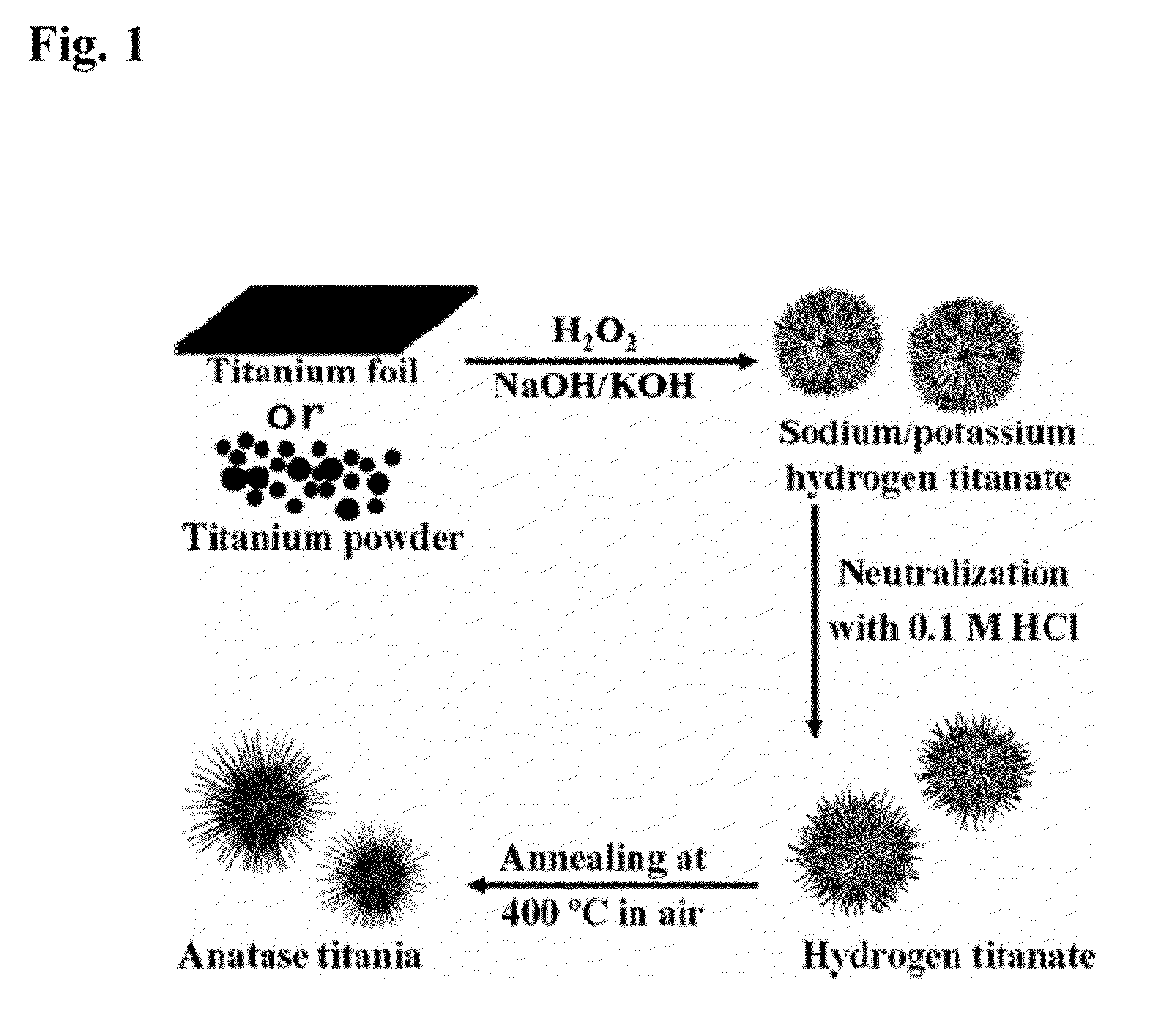

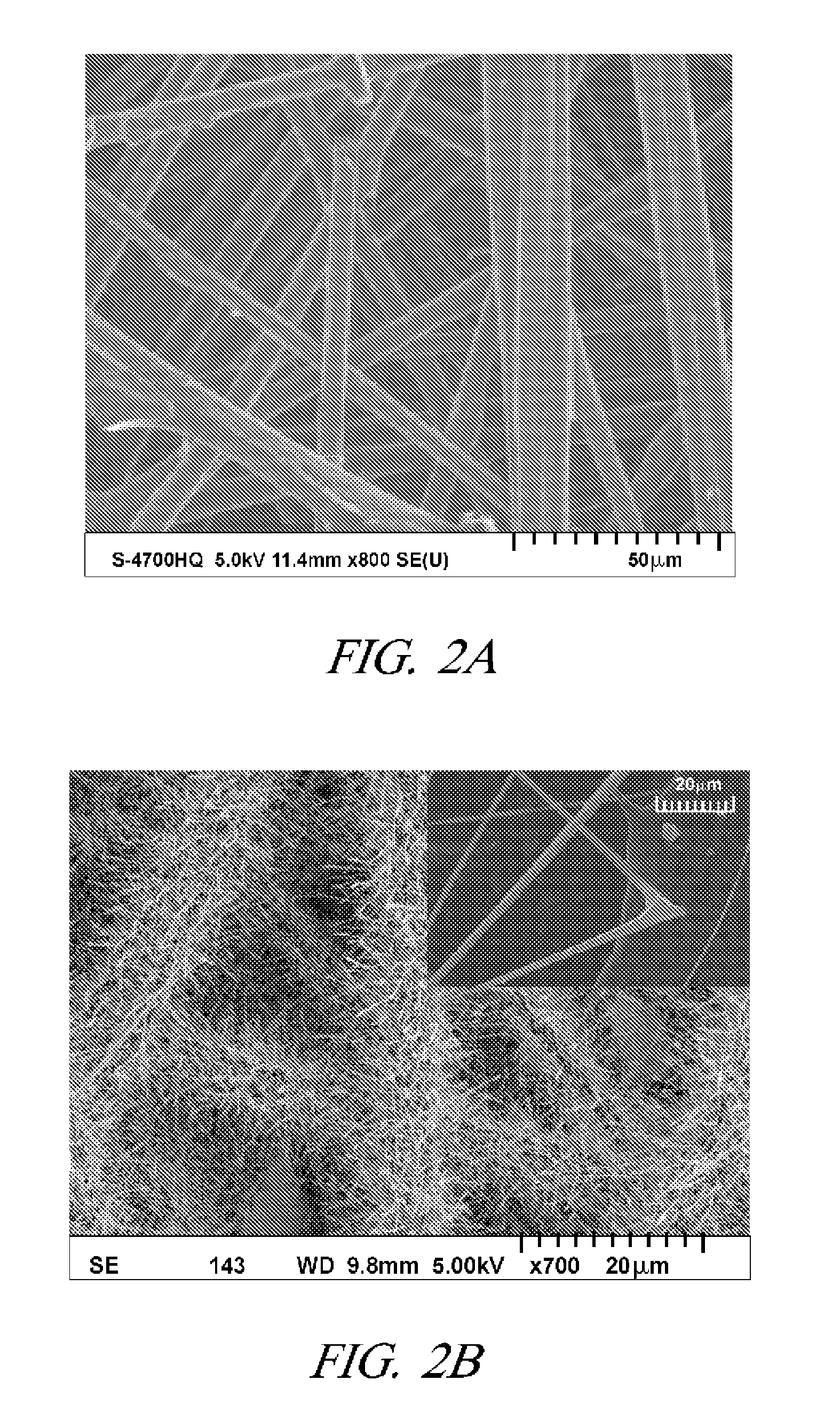

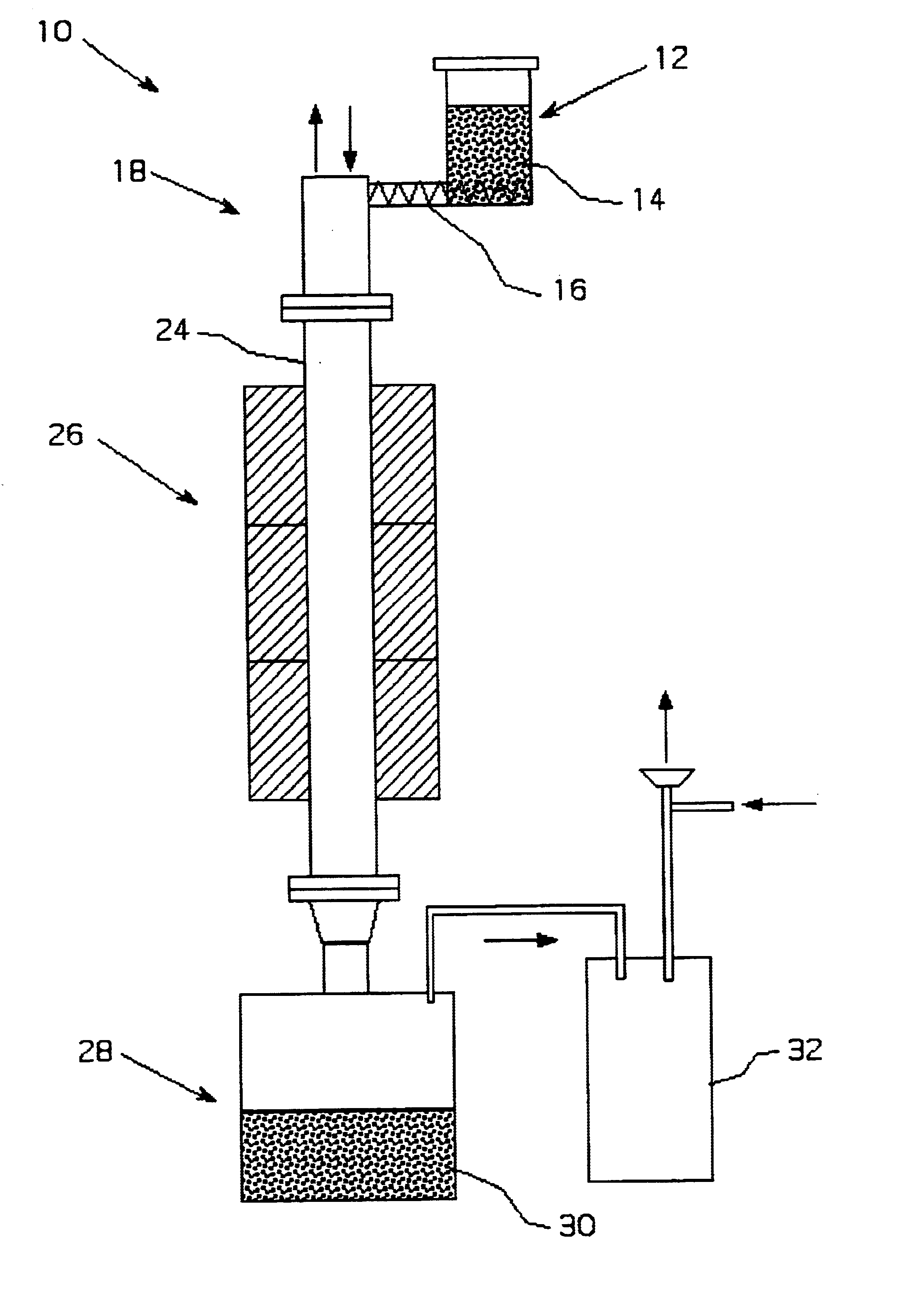

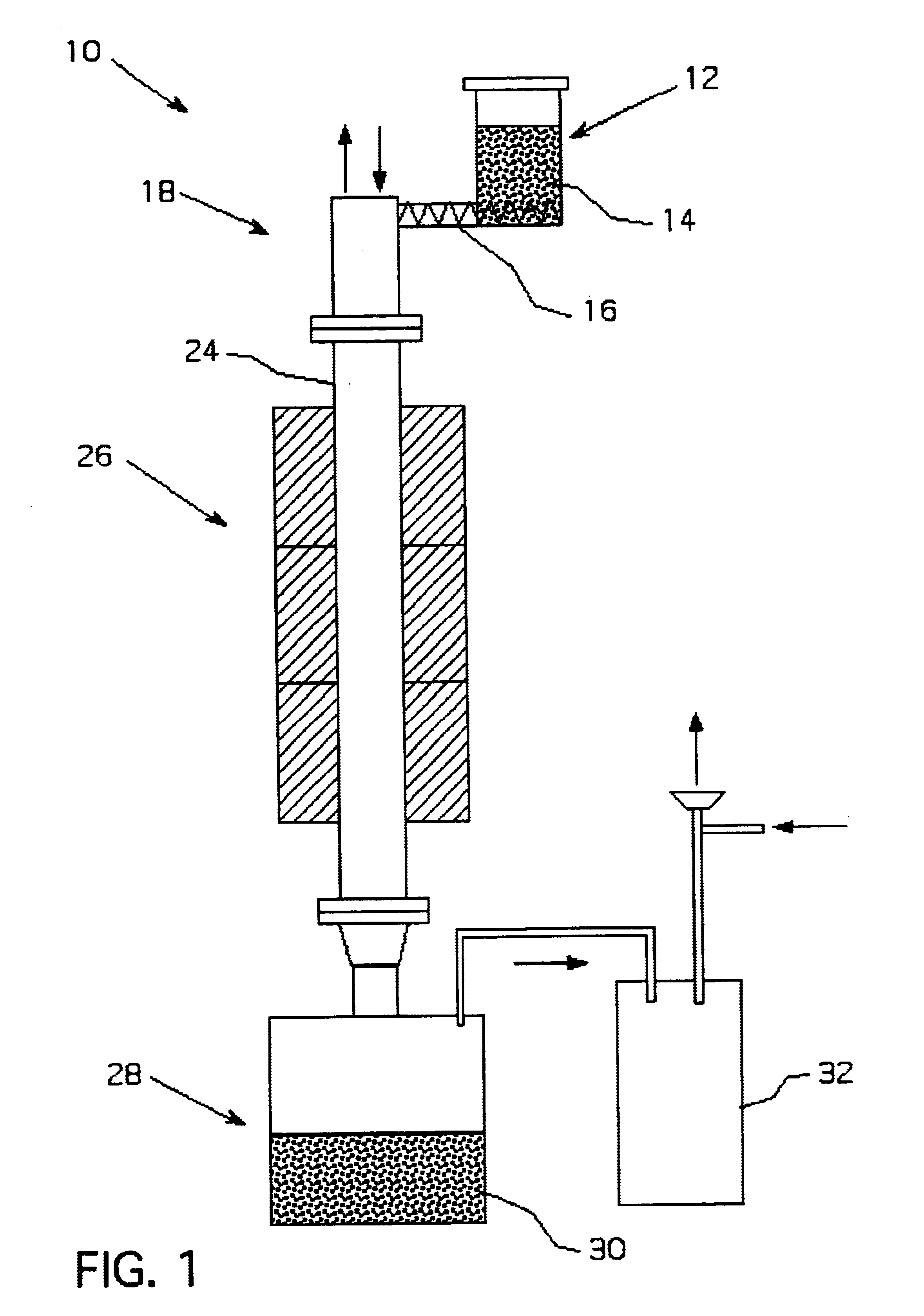

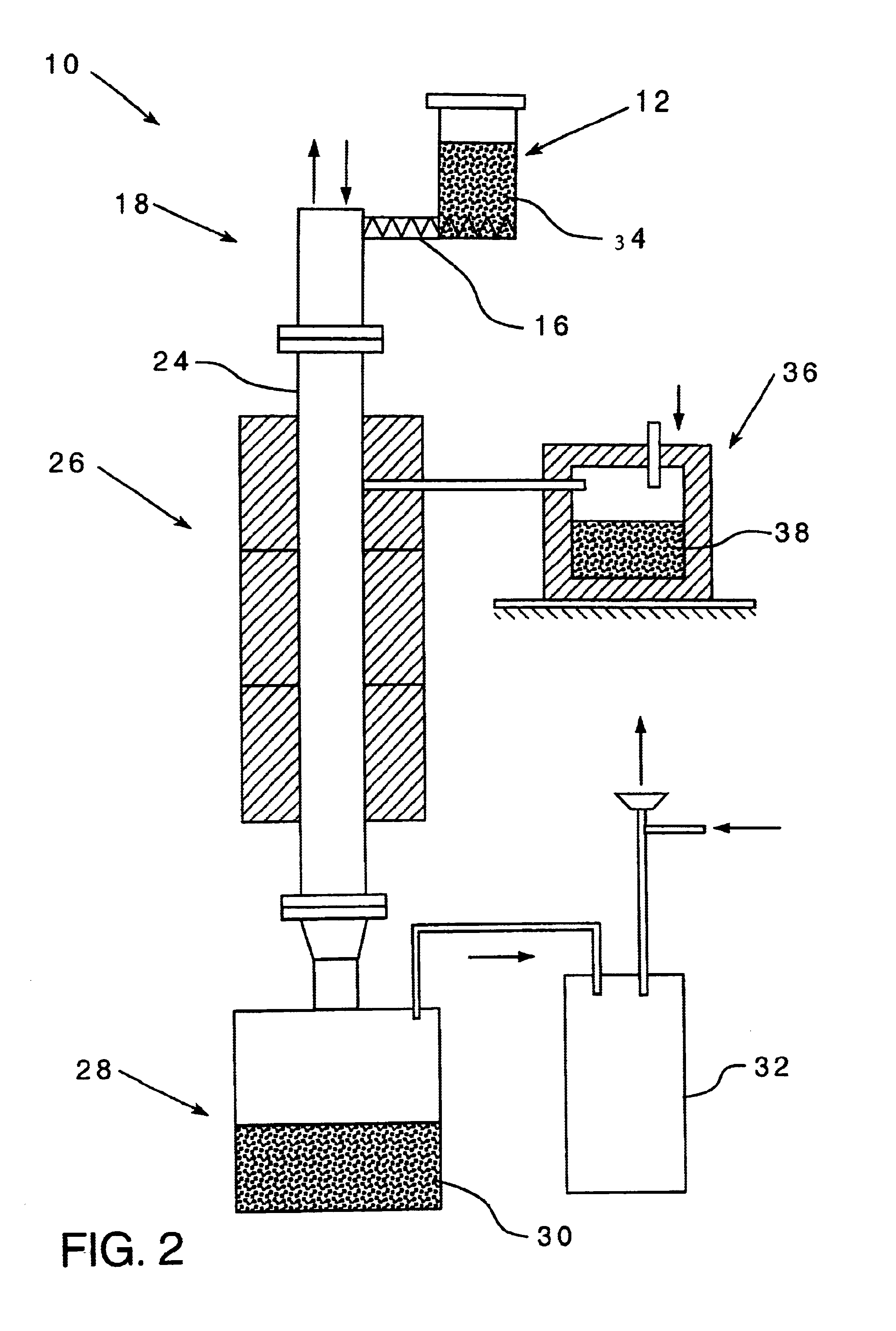

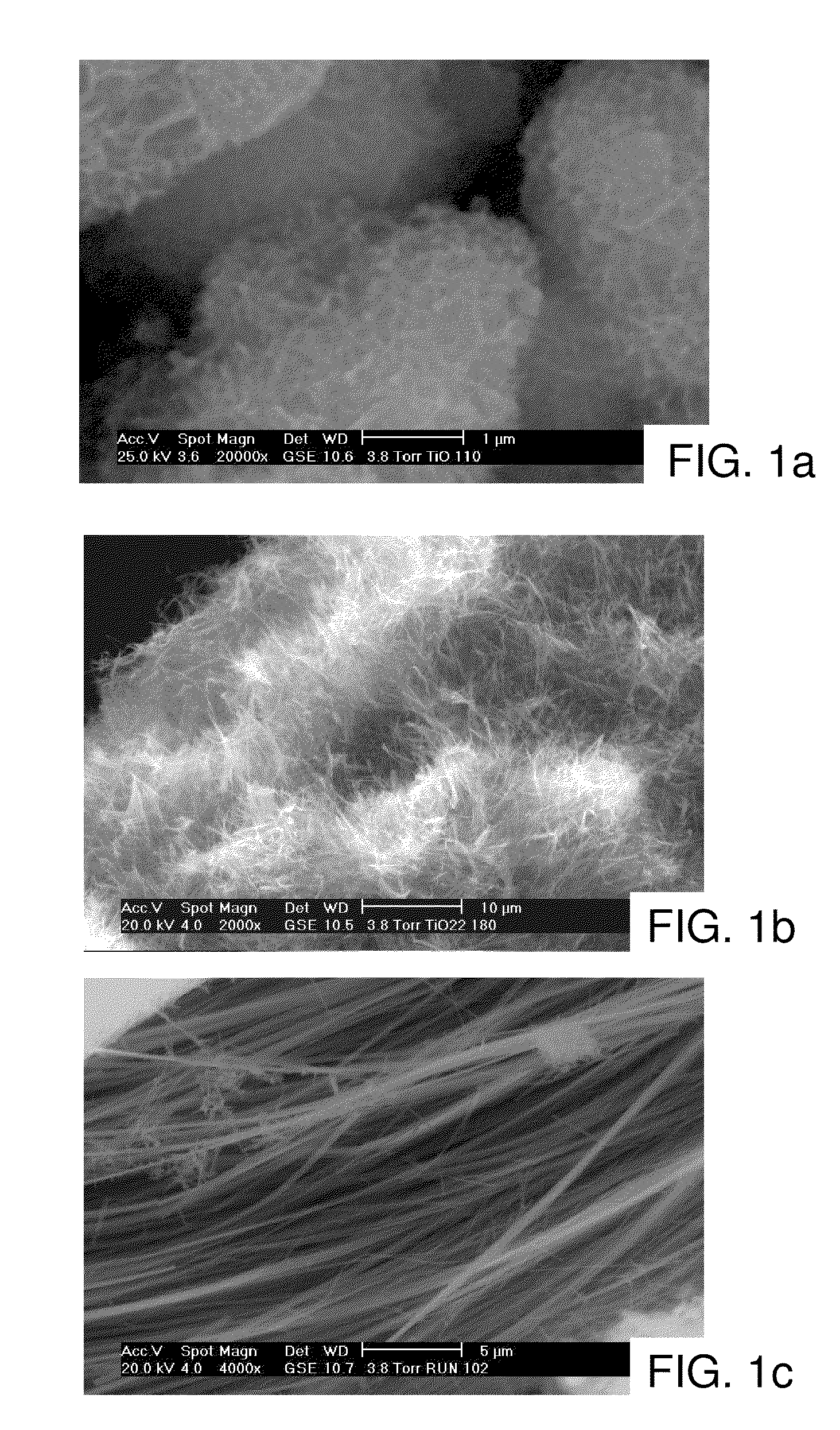

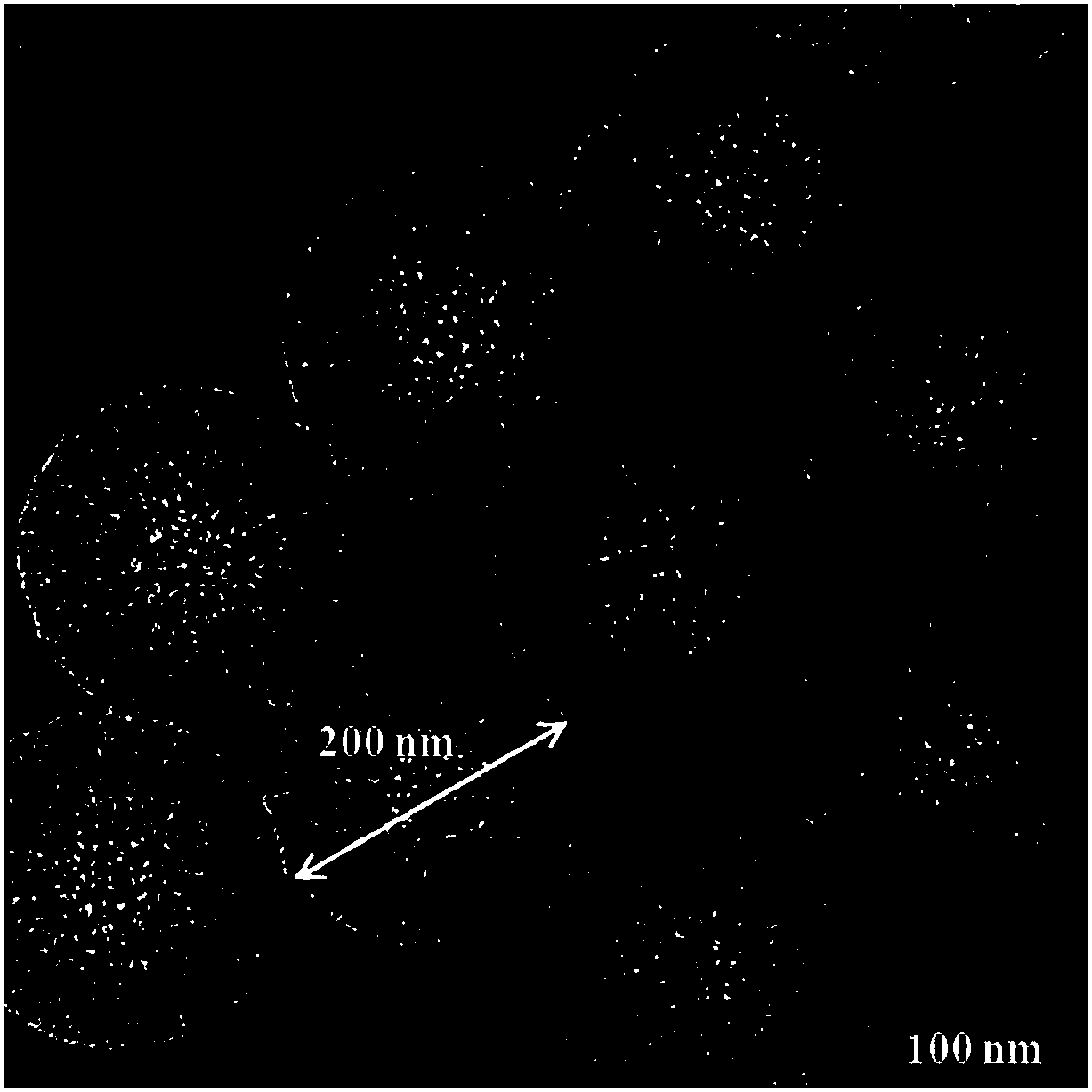

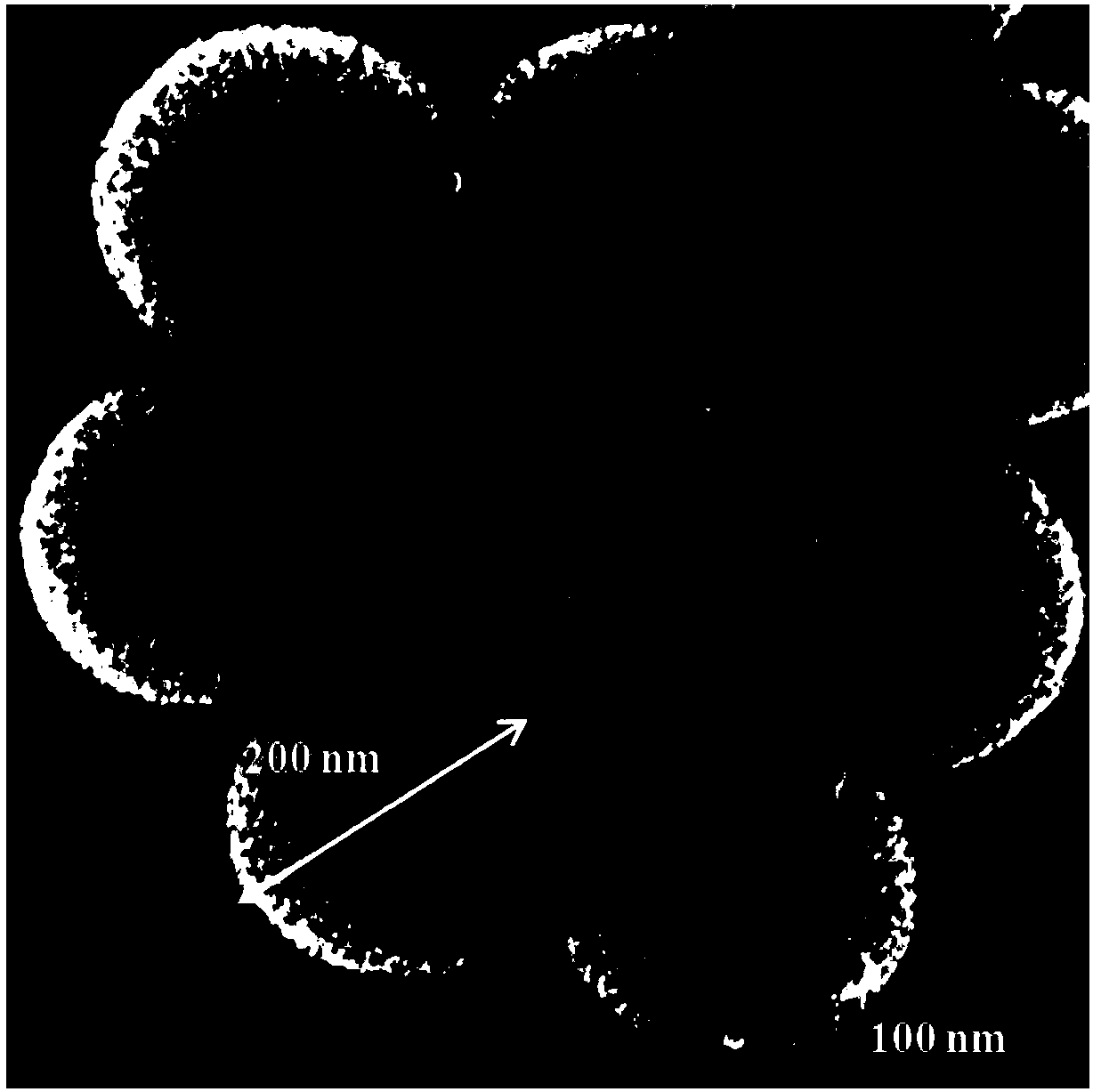

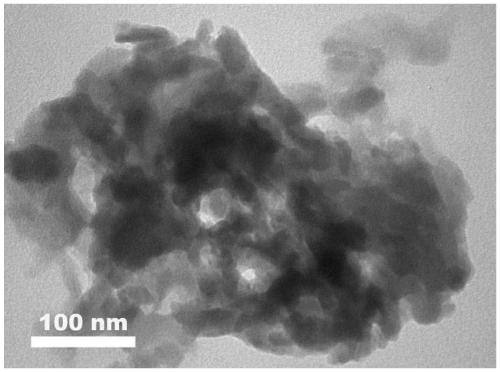

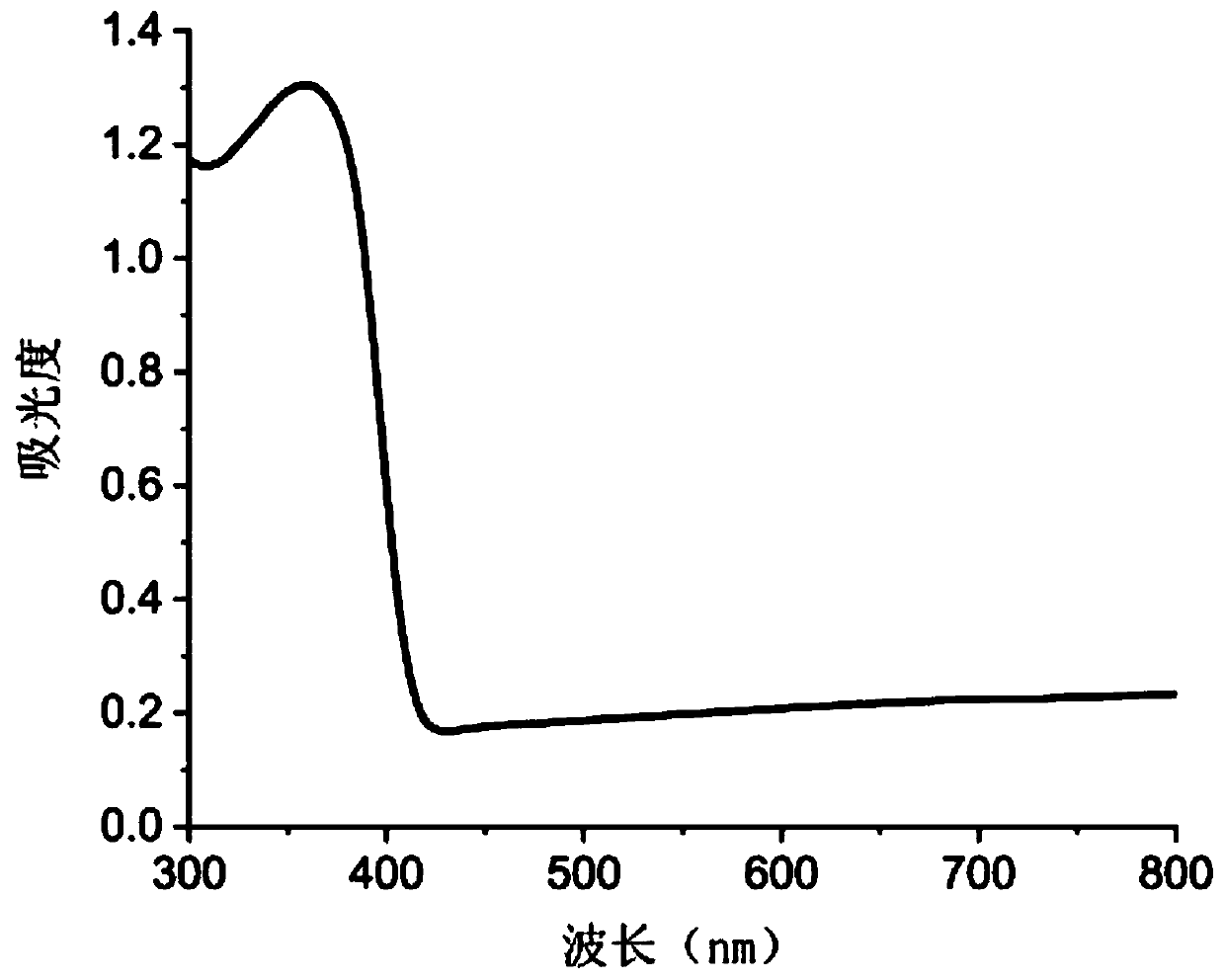

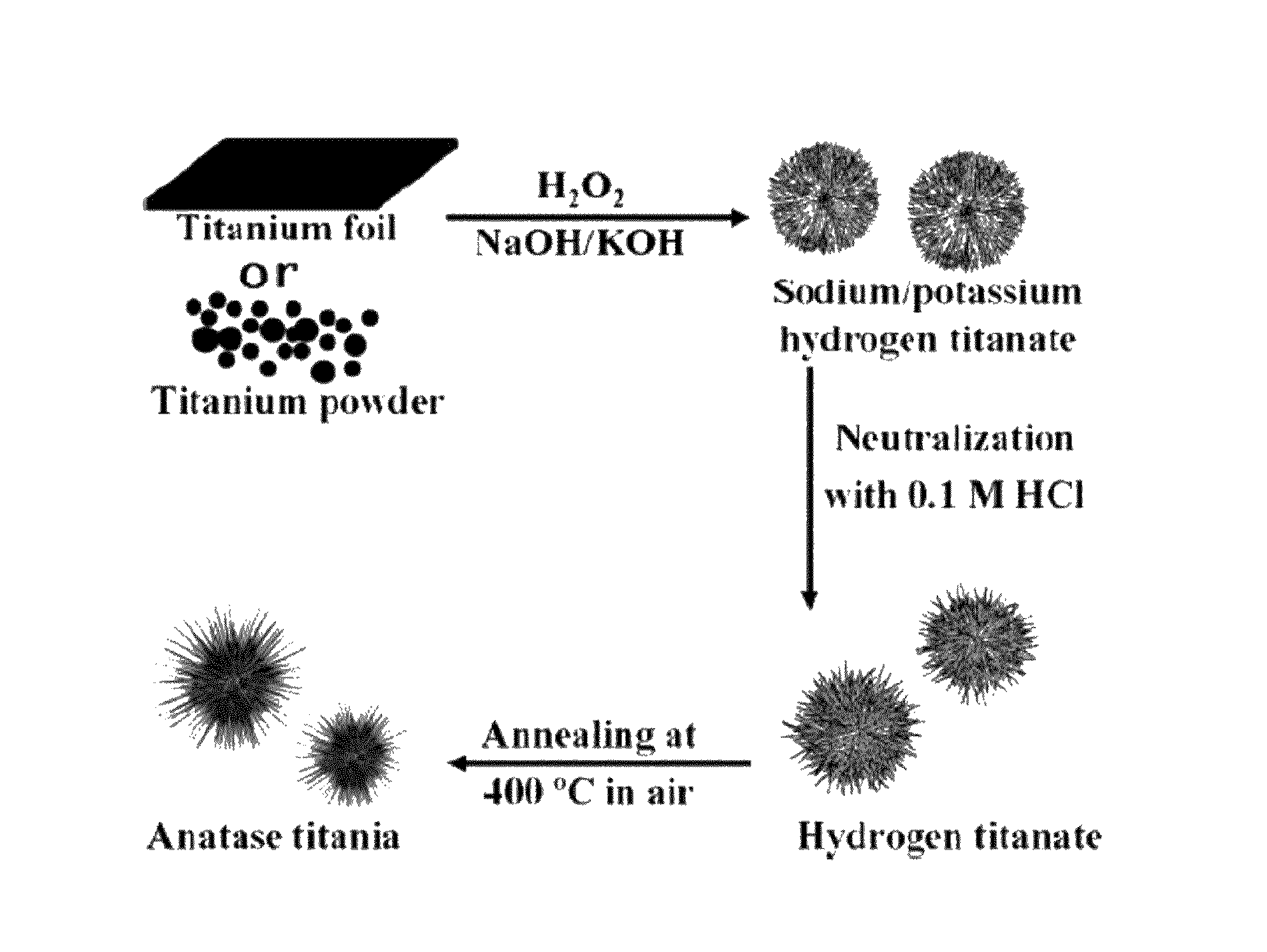

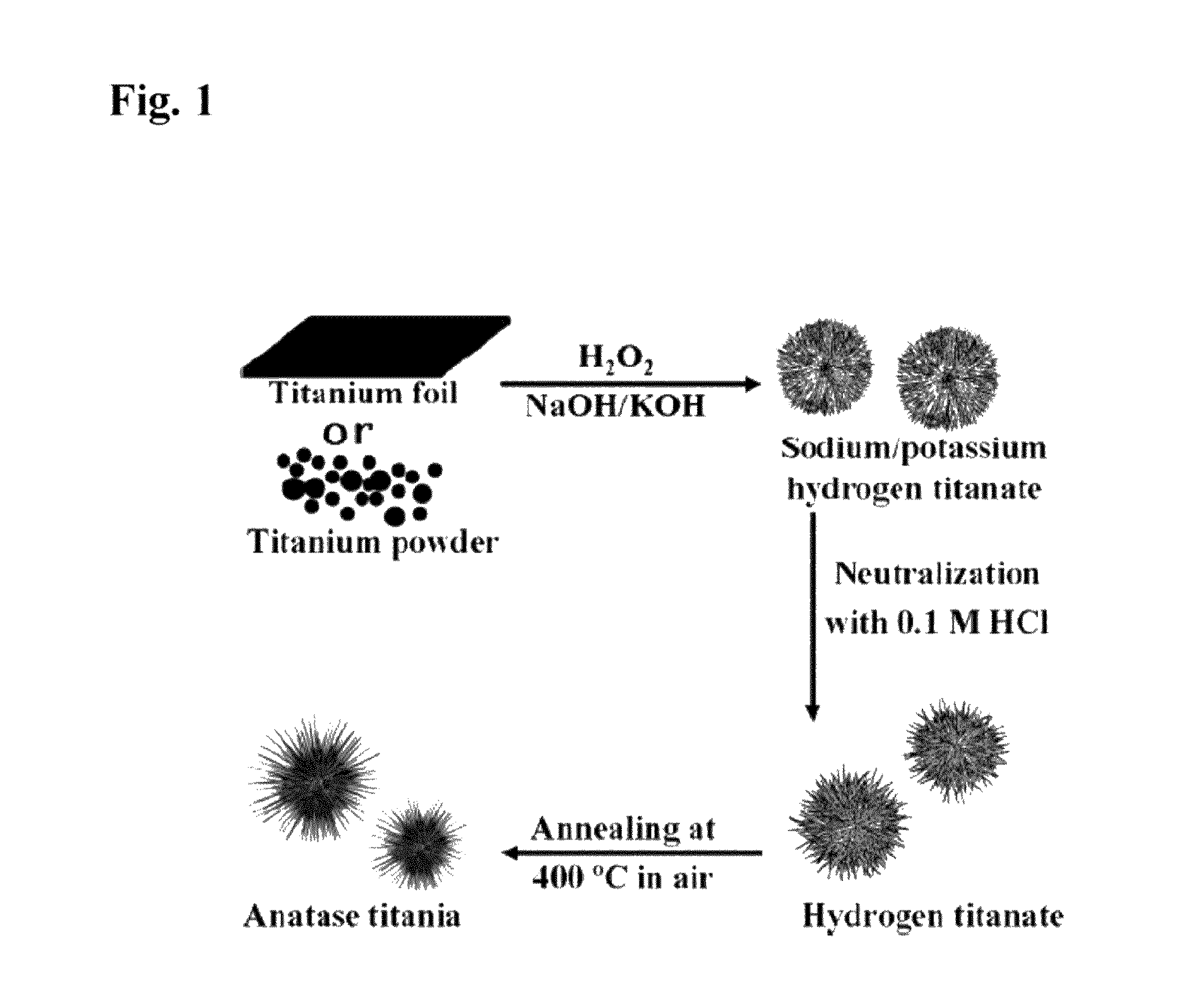

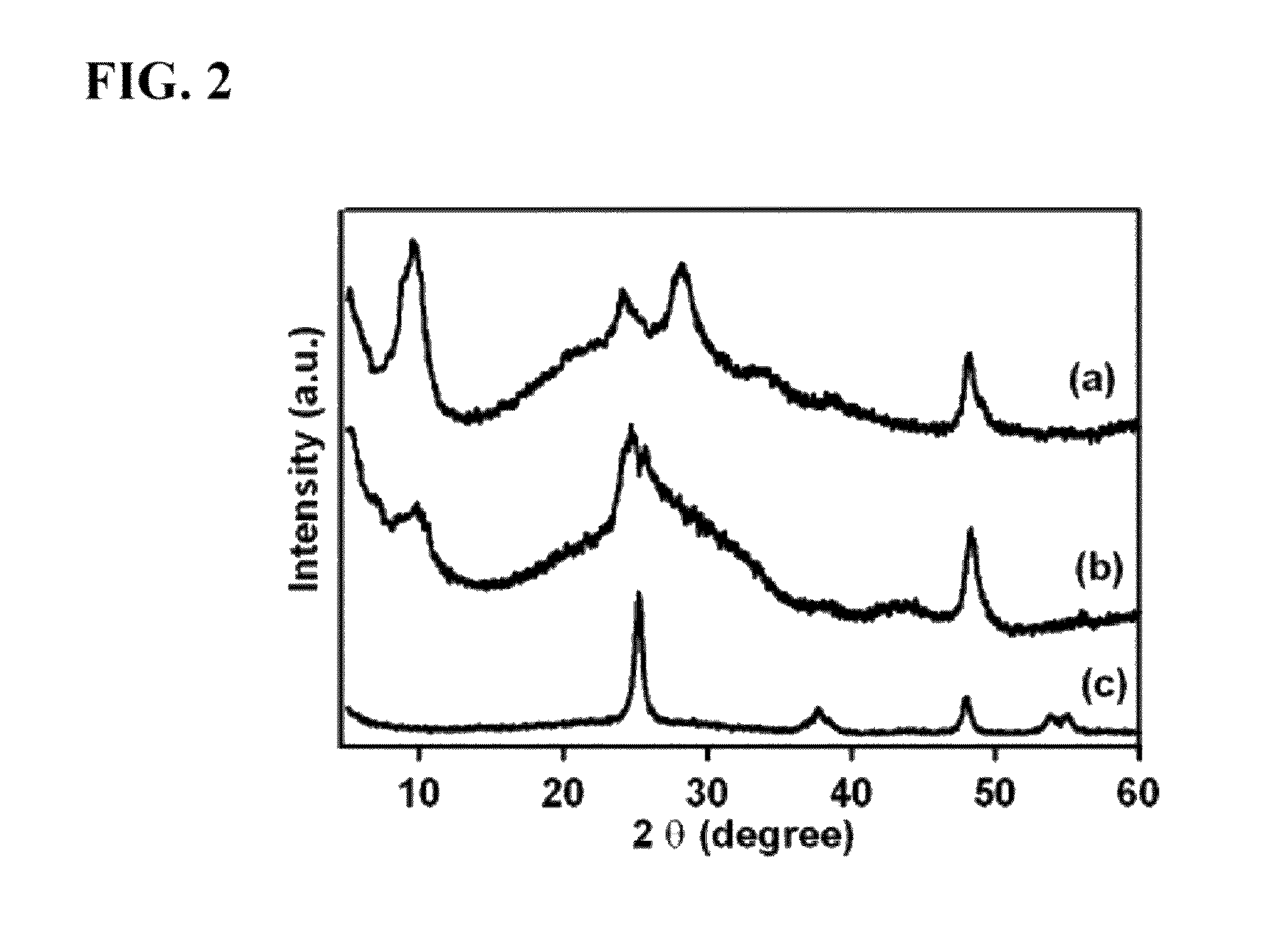

Titanate and titania nanostructures and nanostructure assemblies, and methods of making same

ActiveUS20130102458A1Improve scalabilityImprove photocatalytic performanceMaterial nanotechnologyHydrogenMicrometer scaleTitanium

The invention relates to nanomaterials and assemblies including, a micrometer-scale spherical aggregate comprising: a plurality of one-dimensional nanostructures comprising titanium and oxygen, wherein the one-dimensional nanostructures radiate from a hollow central core thereby forming a spherical aggregate.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

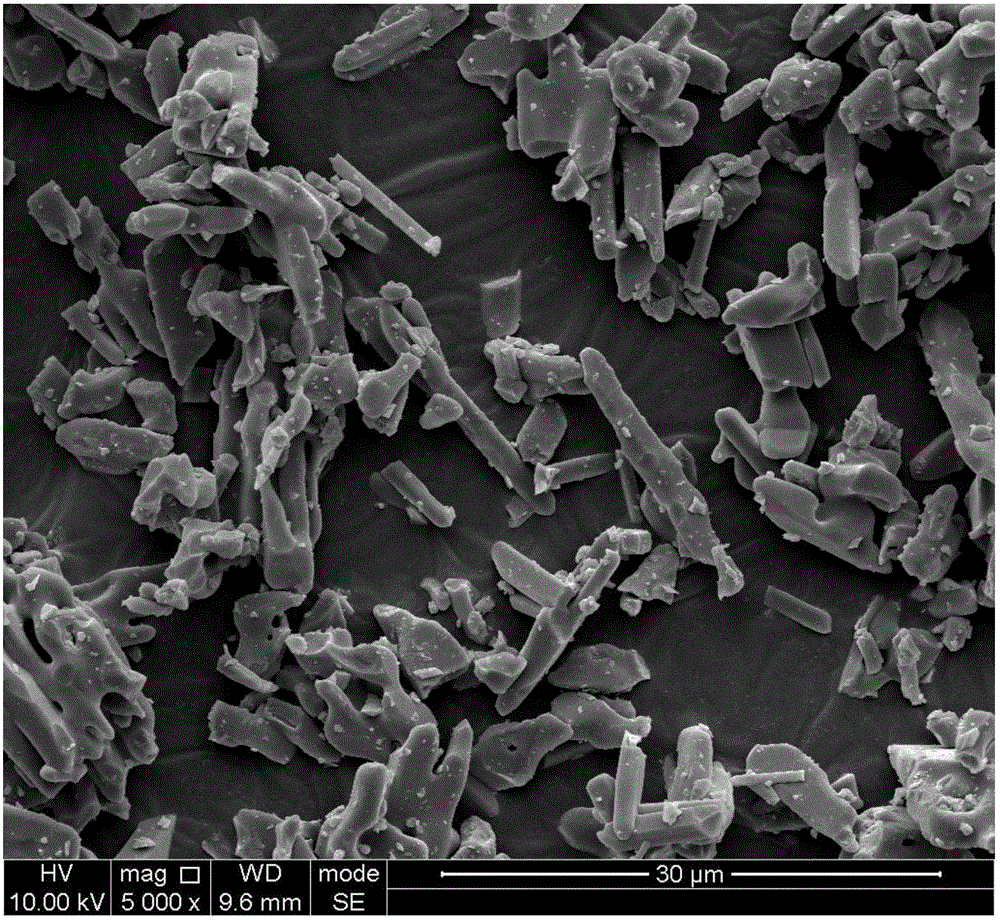

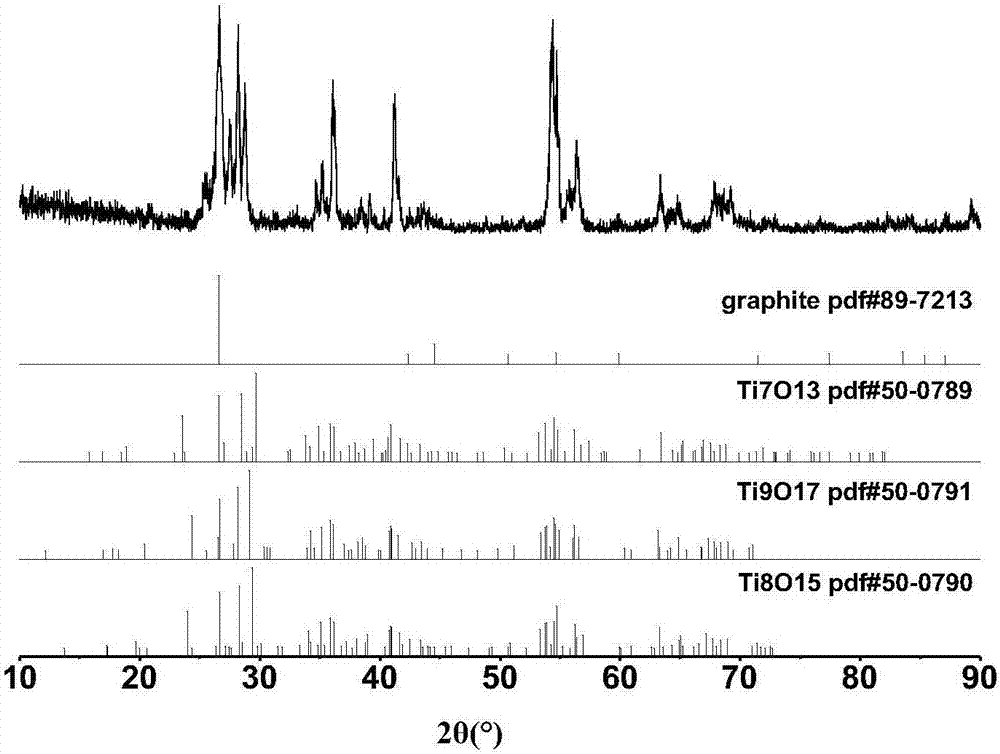

Rod-like titanium protoxide powder and preparation method thereof

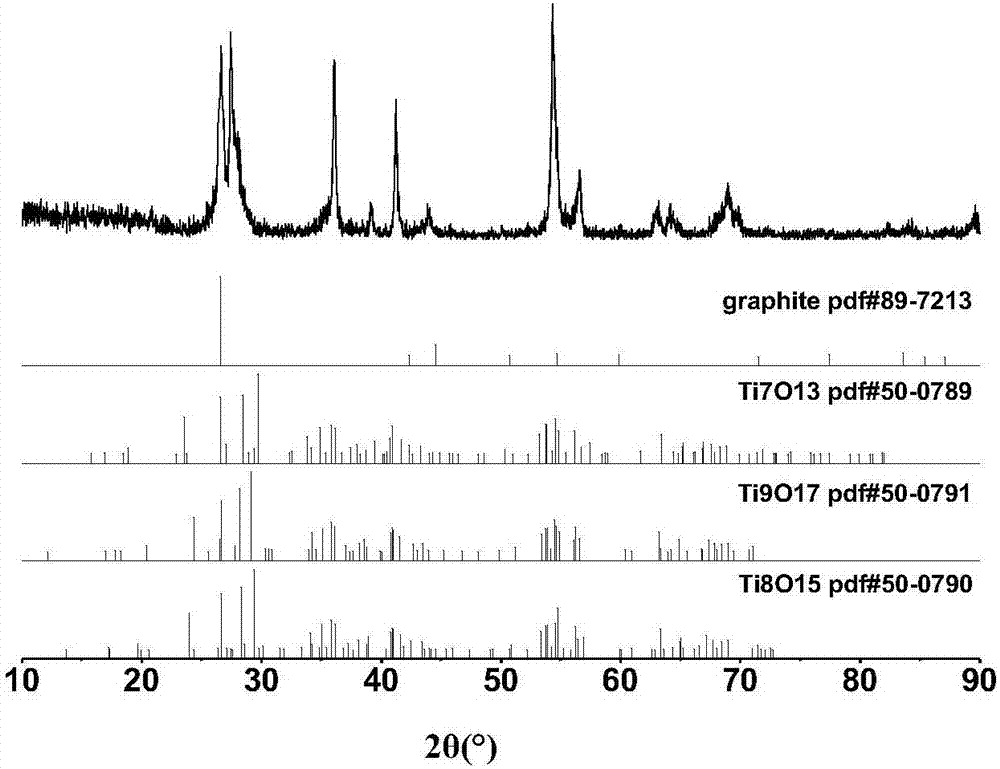

The invention relates to a rod-like titanium protoxide powder and a preparation method thereof, wherein the titanium protoxide powder is Ti3O5 powder, Ti4O7 powder, Ti5O9 powder, Ti6O11 powder, Ti7O13 powder, Ti8O15 powder or Ti9O17 powder. The preparation method comprises: (1) material preparing, wherein raw materials comprise titanium dioxide powder, a carbon reducing agent and a chlorine salt, and according to the chemical formulas of each titanium protoxide powder and the chemical reactions among the used raw materials, the mold ratios of the raw materials for preparing various titanium protoxide powders are calculated; (2) material mixing and drying; (3) sintering, wherein the mixed powder obtained in the step (2) is loaded into a heating furnace, heating is performed at a heating speed of 5-15 DEG C / min under a flowing inert gas to achieve a temperature of 700-1300 DEG C, a reduction reaction is performed for 2-8 h at the temperature of 700-1300 DEG C, and cooling is performed along with the furnace to a room temperature after the reduction time is achieved; and (4) washing and drying, wherein the titanium protoxide-salt mixed powder obtained in the step (3) is washed with deionized water 3-10 times, and then drying is performed to obtain the rod-like titanium protoxide powder.

Owner:SICHUAN UNIV

Highly reflective interference pigments with dark absorption color

InactiveUS7014700B2Reduced titanium oxideAbsorption colorPigmenting treatmentInksAutomotive paintSolvent

Highly reflective interference effect pigments with dark absorption color are obtained by reducing platy titanium dioxide.The present effect pigments may be used in cosmetics, plastics, inks, and coatings including solvent and water borne automotive paint systems.

Owner:ENGELHARD CORP

Highly reflective interference pigments with dark absorption color

InactiveUS20050154082A1Reduced titanium oxideAbsorption colorPigmenting treatmentInksAutomotive paintSolvent

Highly reflective interference effect pigments with dark absorption color are obtained by reducing platy titanium dioxide. The present effect pigments may be used in cosmetics, plastics, inks, and coatings including solvent and water borne automotive paint systems.

Owner:ENGELHARD CORP

Electrically conductive thin films

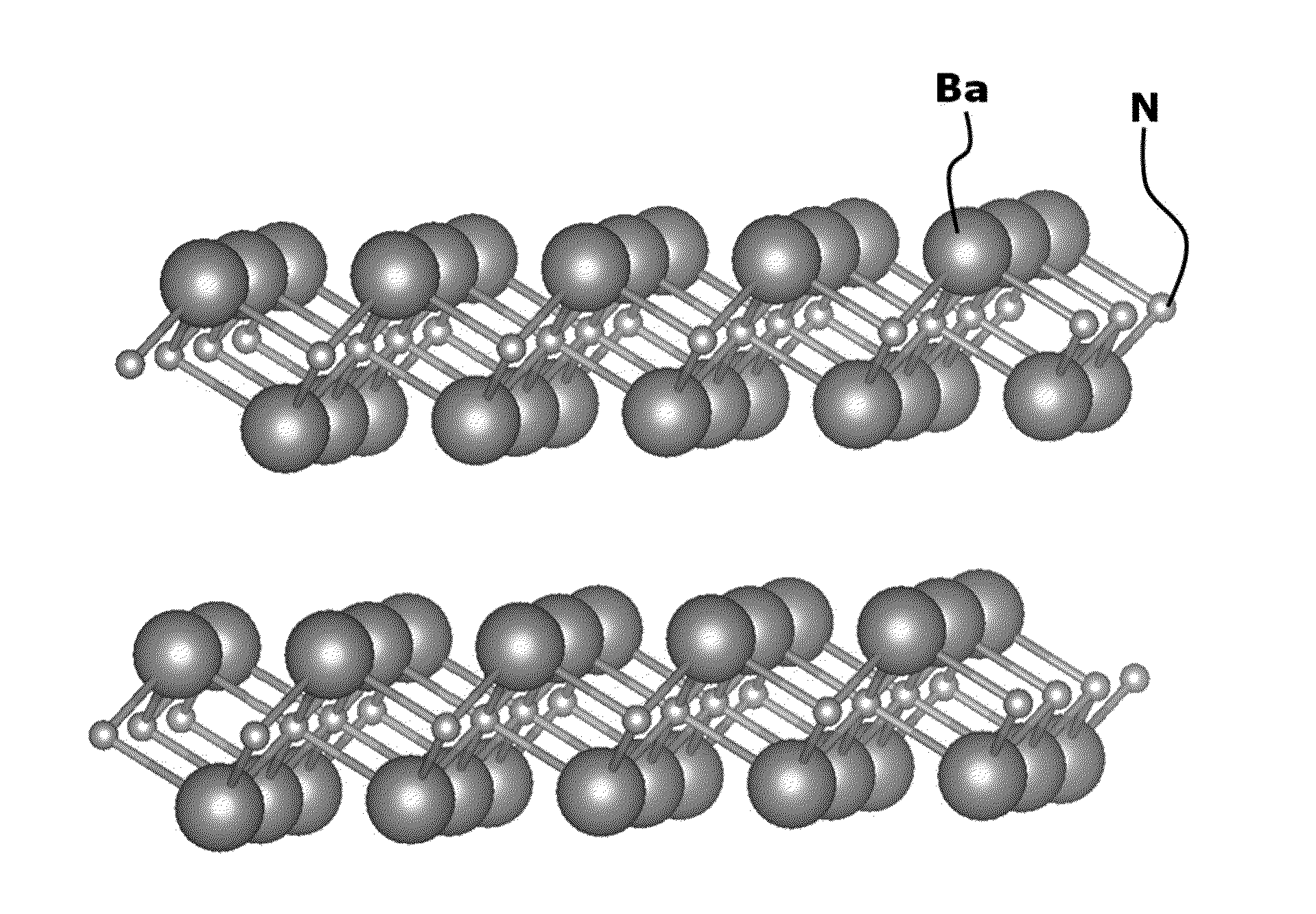

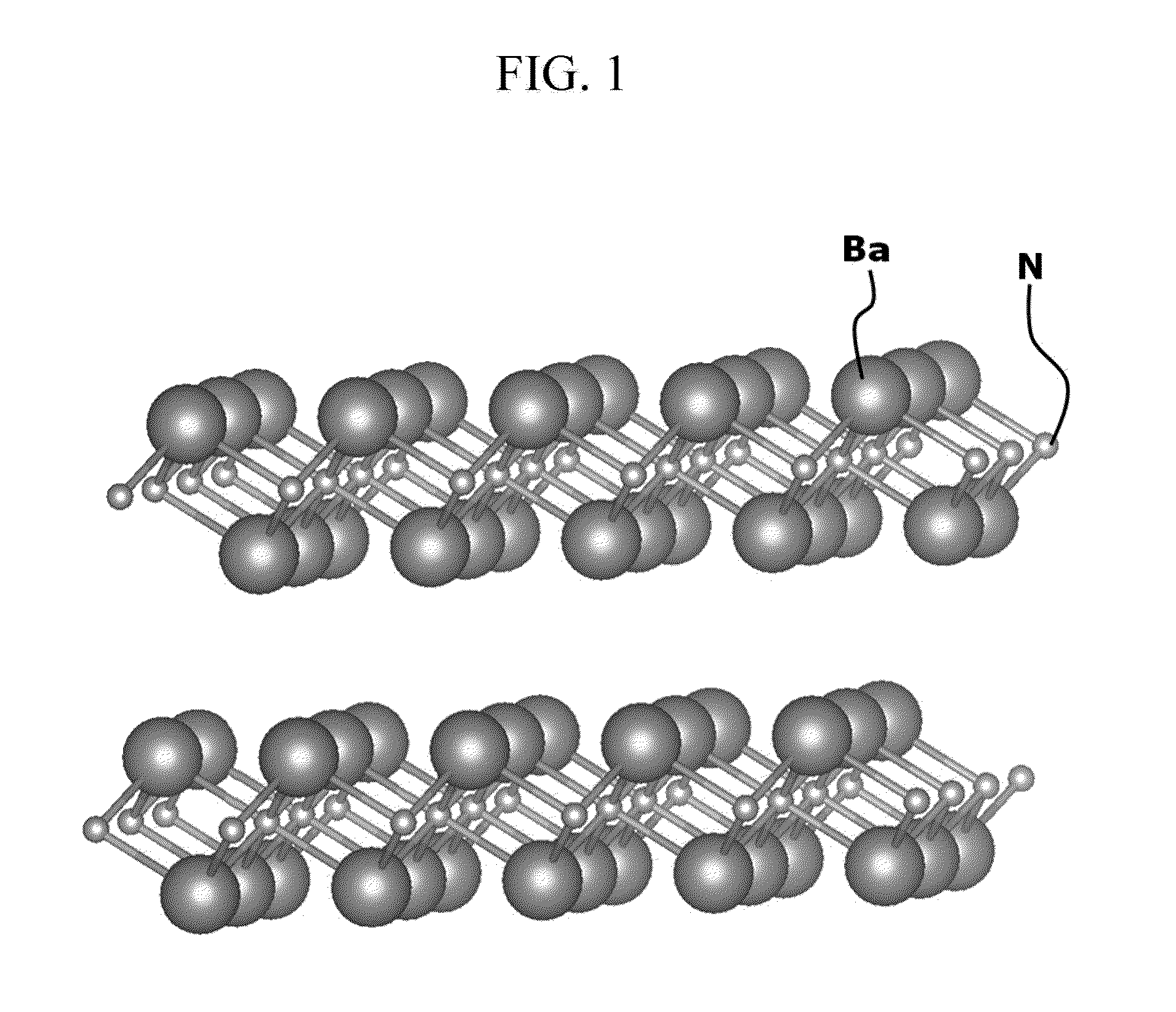

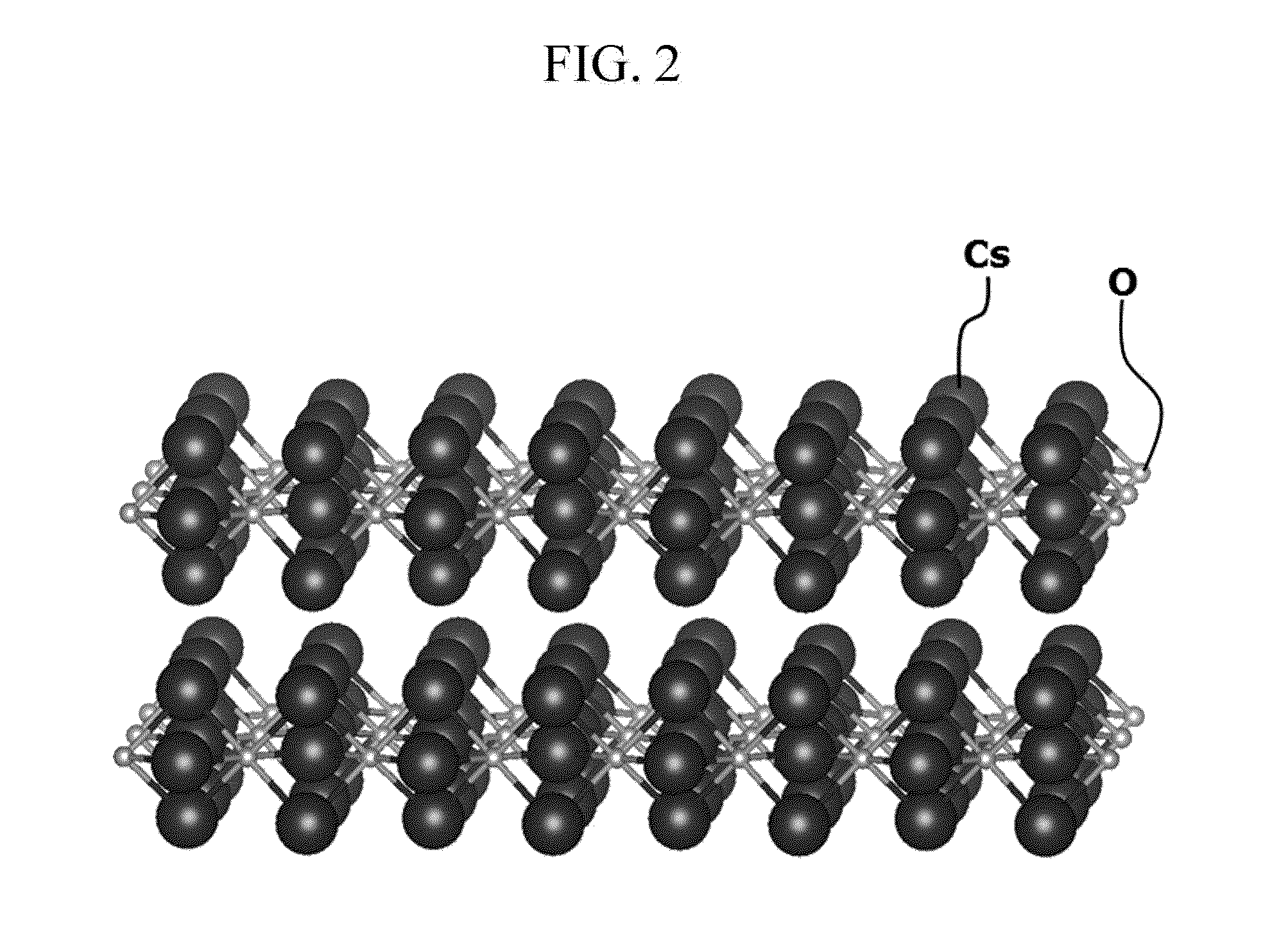

ActiveUS20150166340A1High light transmittanceGood flexibilitySynthetic resin layered productsTitanium suboxidesLamellar crystalsThin membrane

According to example embodiments, a transparent electrically conductive film including a compound that has a two-dimensional electron gas layer, and has a product of an absorption coefficient (α) for light having a wavelength of about 550 nm at 25° C. and a resistivity value (ρ) thereof of less than or equal to about 30 Ω / sq is provided. The electrically conductive film may be a layered crystal structure of the compound.

Owner:SAMSUNG ELECTRONICS CO LTD

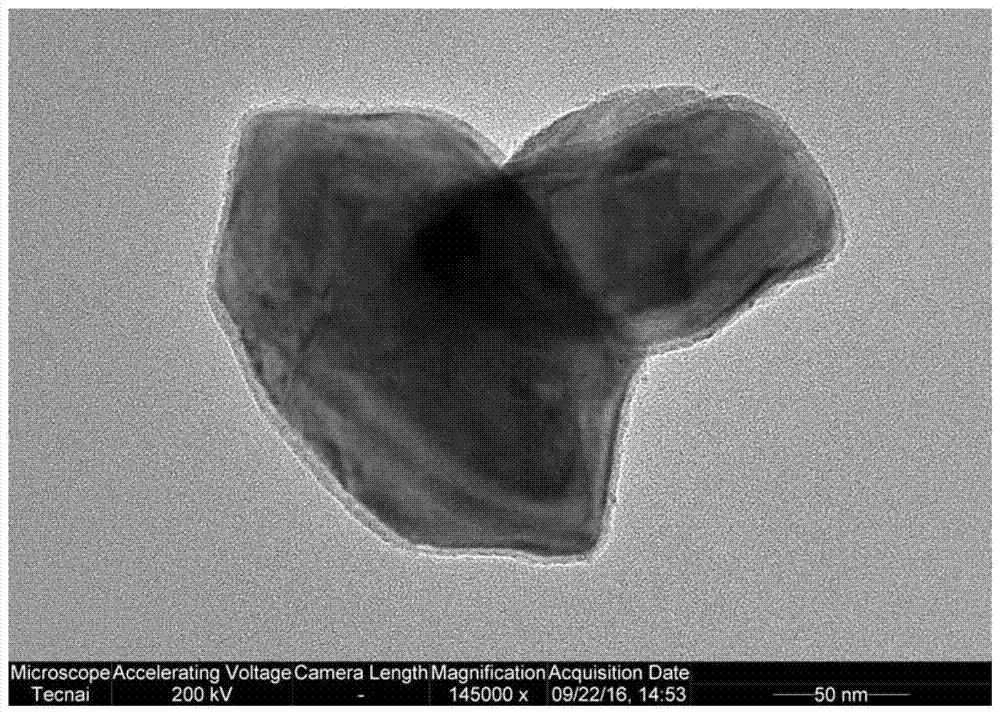

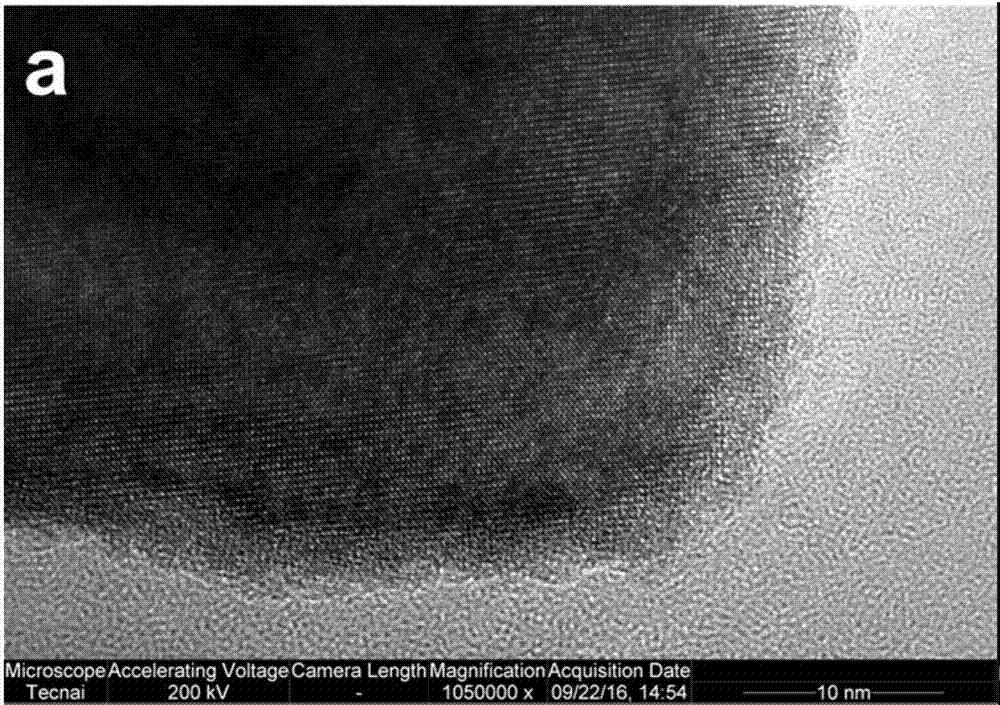

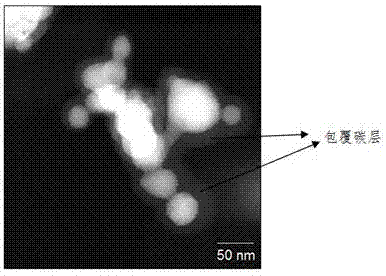

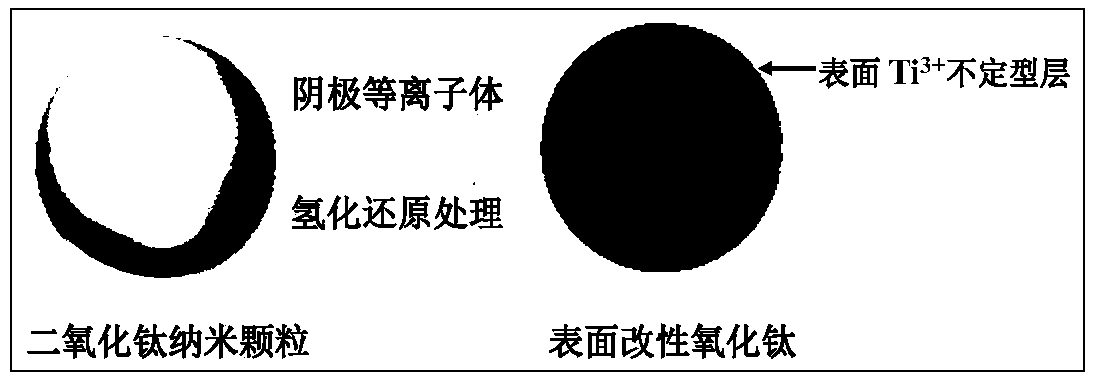

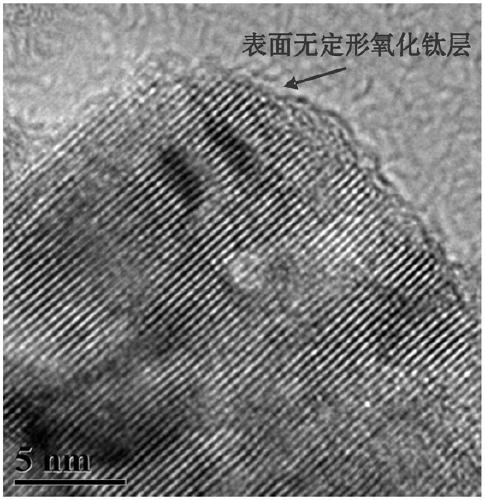

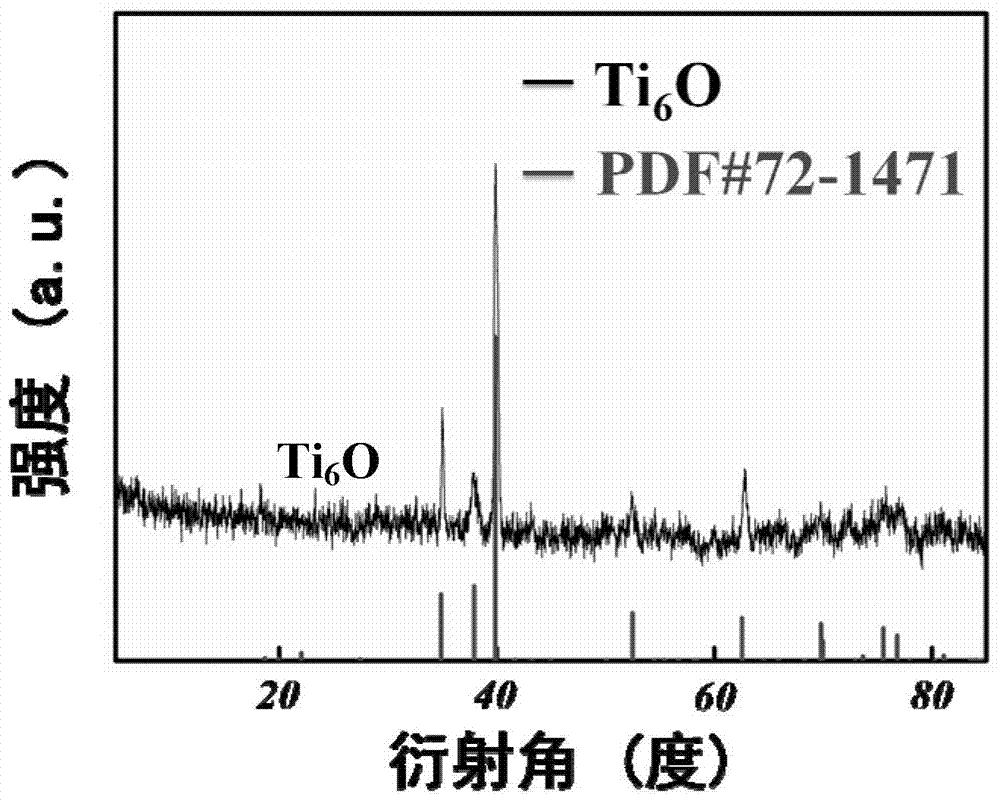

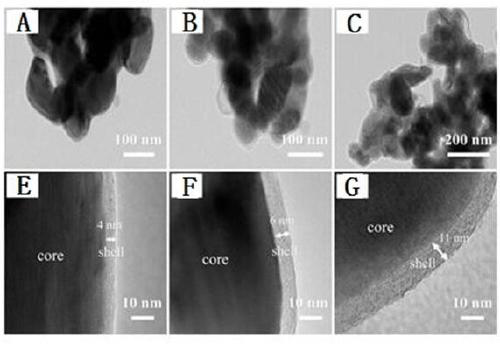

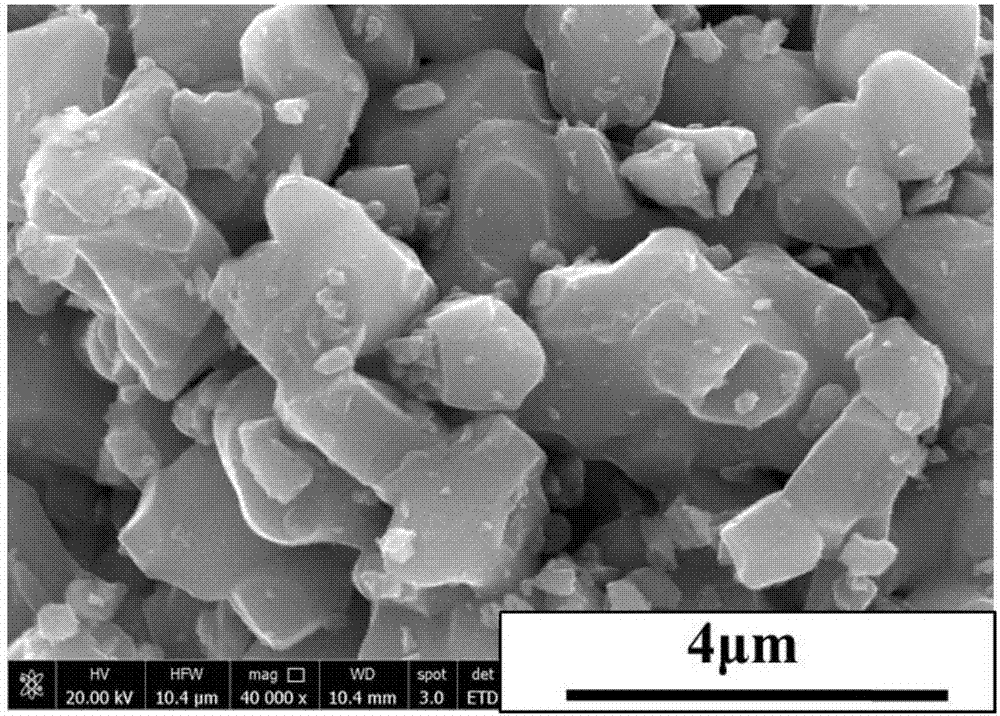

Core-shell structure titanium sub-oxide and controllable preparation method thereof

ActiveCN106976905AUnique electricityUnique optical propertiesPhysical/chemical process catalystsTitanium suboxidesConductive materialsTitanium oxide

The invention relates to core-shell structure titanium sub-oxide and a controllable preparation method thereof. The titanium sub-dioxide has a core shell structure, and the surface is coated with an amorphous titanium sub-oxide layer. The titanium sub-dioxide has the special core shell structure, and the surface of the special core shell structure is coated with an amorphous titanium sub-oxide layer, so that the core-shell structure titanium sub-oxide has unique electrical and optical properties of the titanium sub-oxide, excellent thermal stability and super-high conductivity, also has small particle size, high specific surface area, controllable micro structure units and other good performances, and can be used for catalysts and catalyst carriers, high conductive materials and preparation of effective rechargeable batteries and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

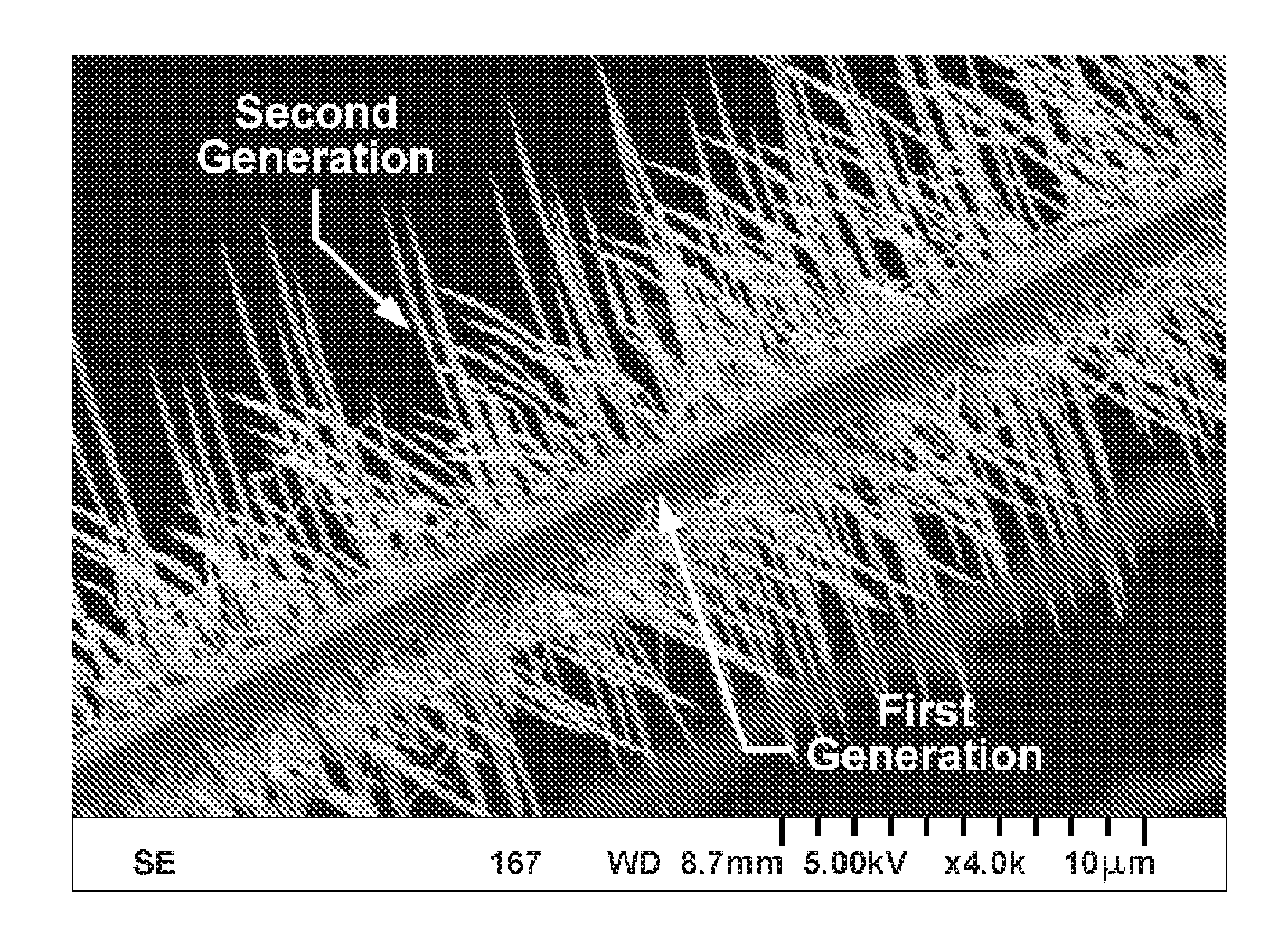

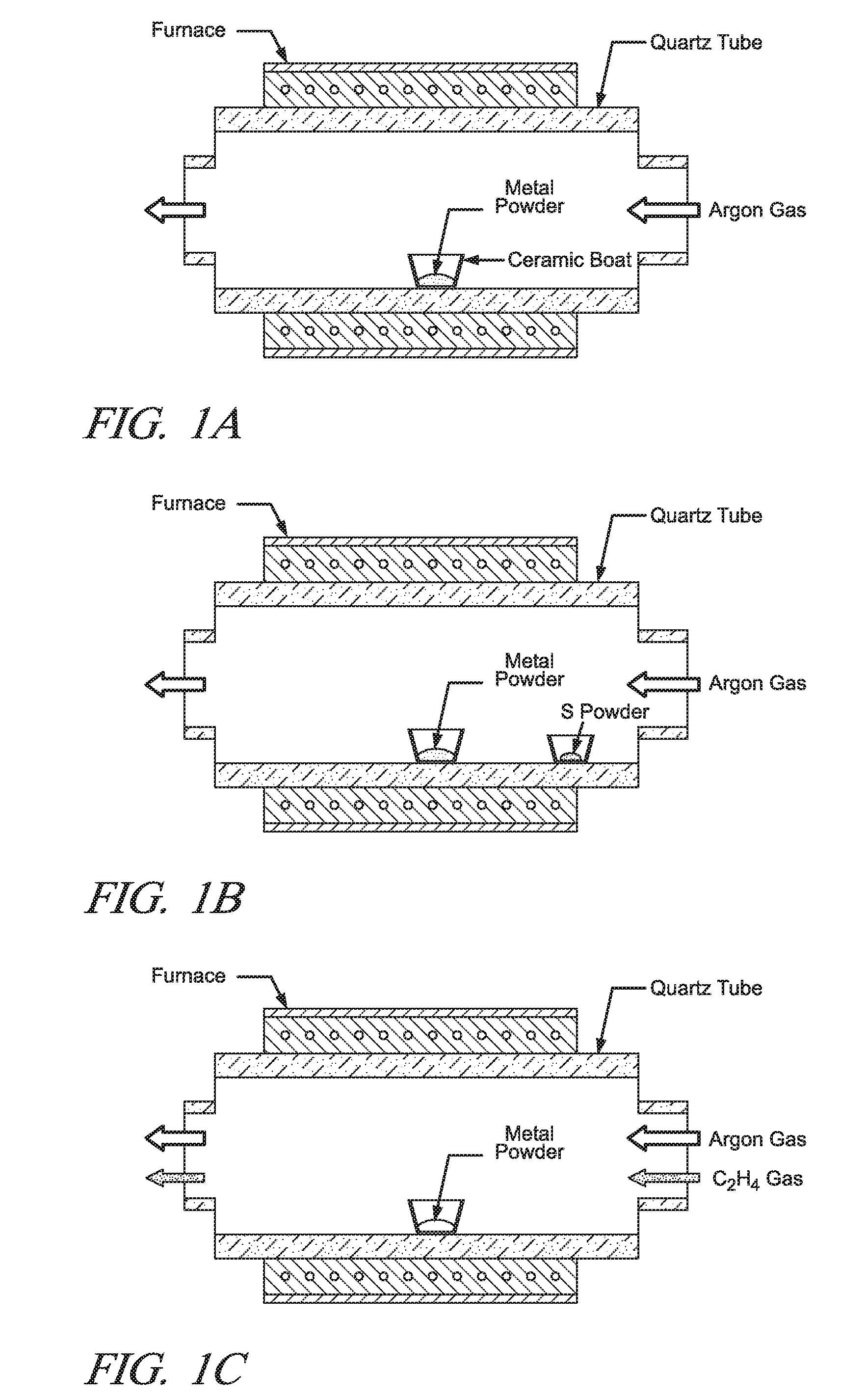

One-dimensional metal and metal oxide nanostructures

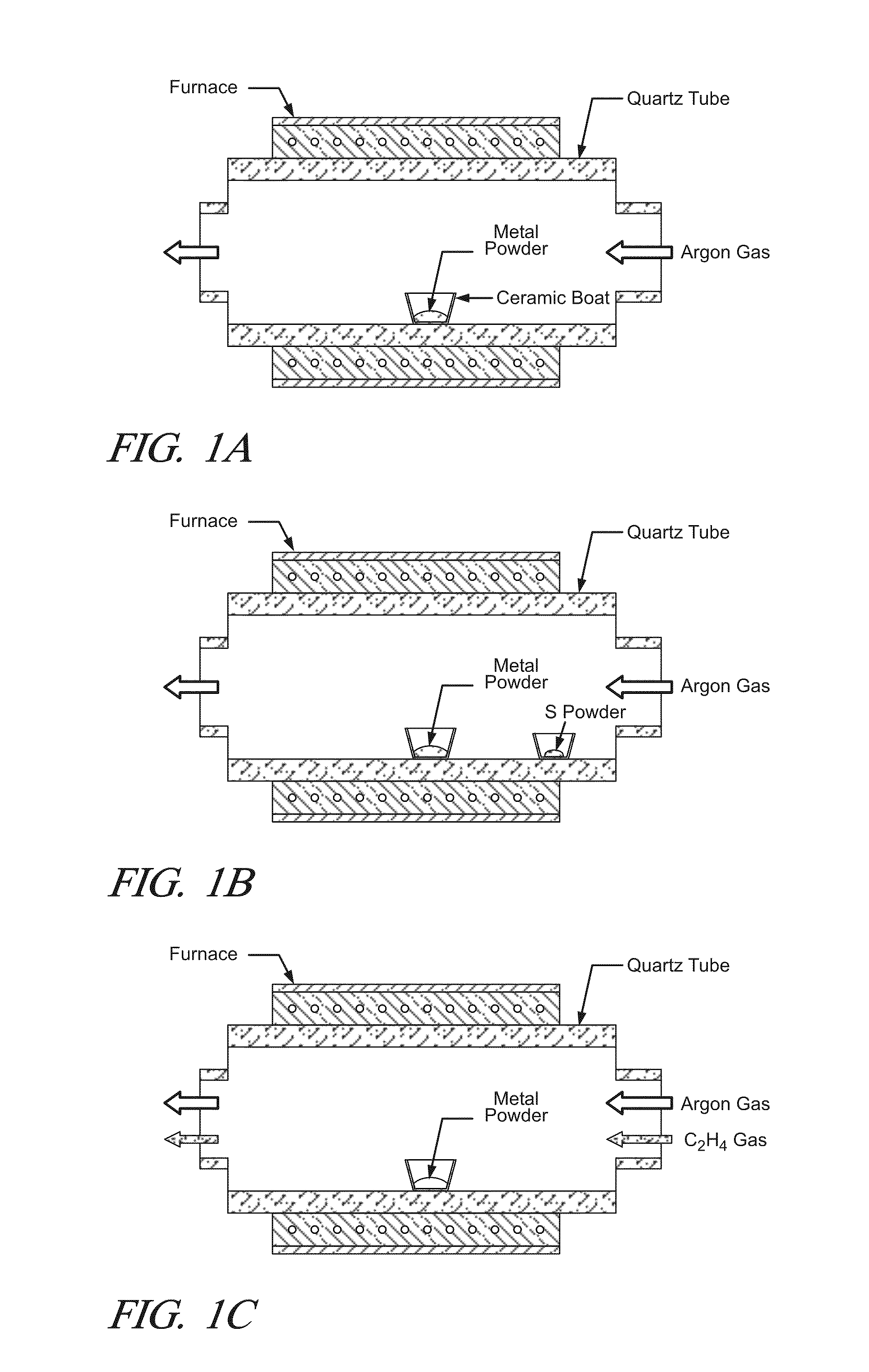

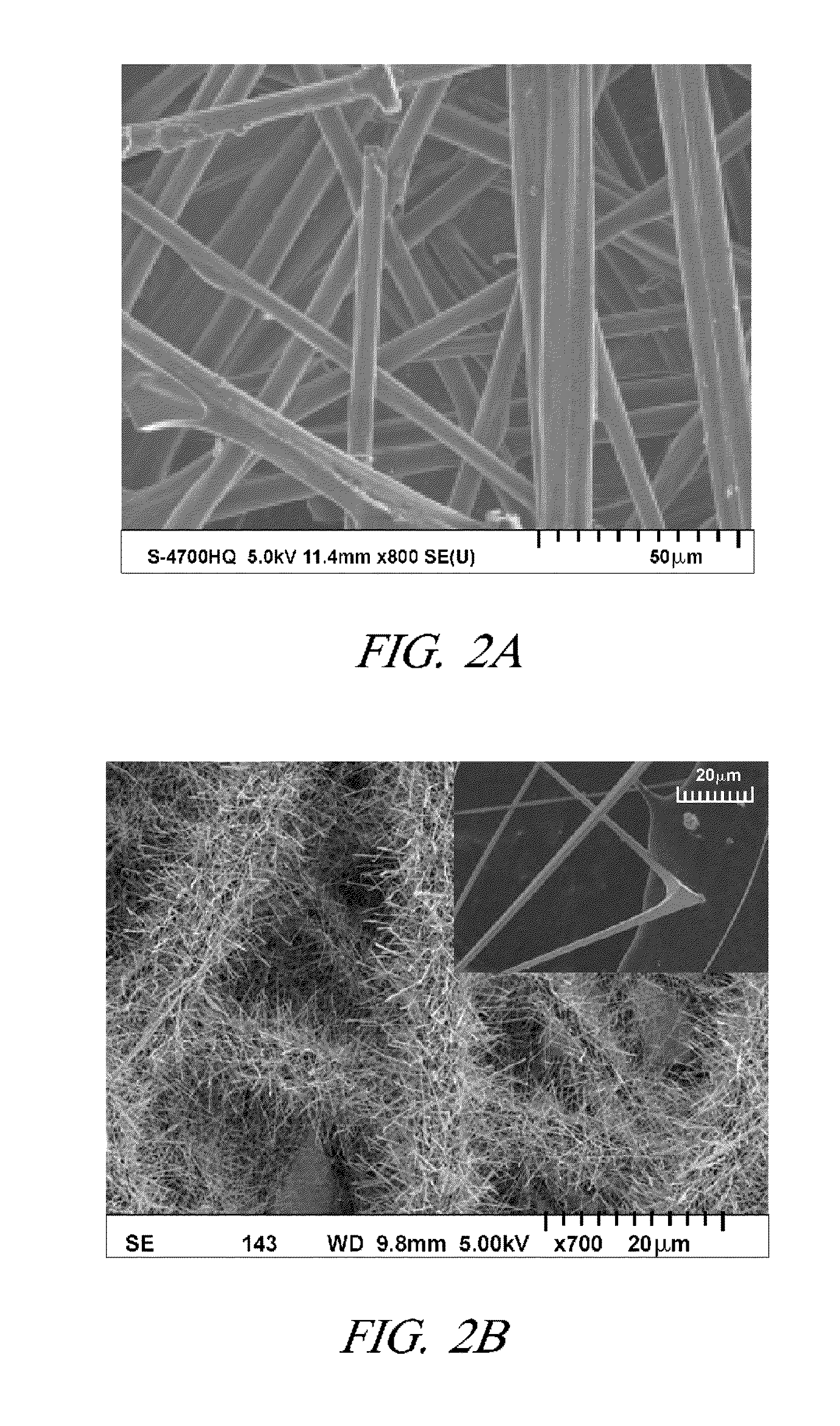

ActiveUS20080292789A1Material nanotechnologyLiquid surface applicatorsNanostructureChemical measurement

Metal powder (such as tin, titanium, or tungsten powder) is heated in a flowing stream of an inert gas, such as argon, containing a small abundance of oxygen at a temperature to produce metal vapor. The metal reacts with the oxygen to form and deposit one-dimensional nanostructures of oxygen-containing metal on the metal powder (in the case of Ti and W) or on a suitable nearby substrate in the case of the lower melting tin. The metal oxides are not necessarily stoichiometric compounds. Water may be introduced into the flowing inert gas to increase or control the oxygen content. Sulfur vapor or a carbon source may be introduced to dope the nanostructures with sulfur or carbon. Reaction conditions may be modified to vary the shapes of the one-dimensional nanostructures.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Metalothermic reduction of refractory metal oxides

InactiveUS6849104B2Quality improvementEliminate the problemOxide/hydroxide preparationTungsten oxides/hydroxidesAlloyExothermic reaction

High purity refractory metals, valve metals, refractory metal oxides, valve metal oxides, or alloys thereof suitable for a variety of electrical, optical and mill product / fabricated parts usages are produced from their respective oxides by metalothermic reduction of a solid or liquid form of such oxide using a reducing agent that establishes (after ignition) a highly exothermic reaction, the reaction preferably taking place in a continuously or step-wise moving oxide such as gravity fall with metal retrievable at the bottom and an oxide of the reducing agent being removable as a gas or in other convenient form and unreacted reducing agent derivatives being removable by leaching or like process.

Owner:TANIOBIS GMBH

Nanostructured titanium oxide material and its synthesis procedure

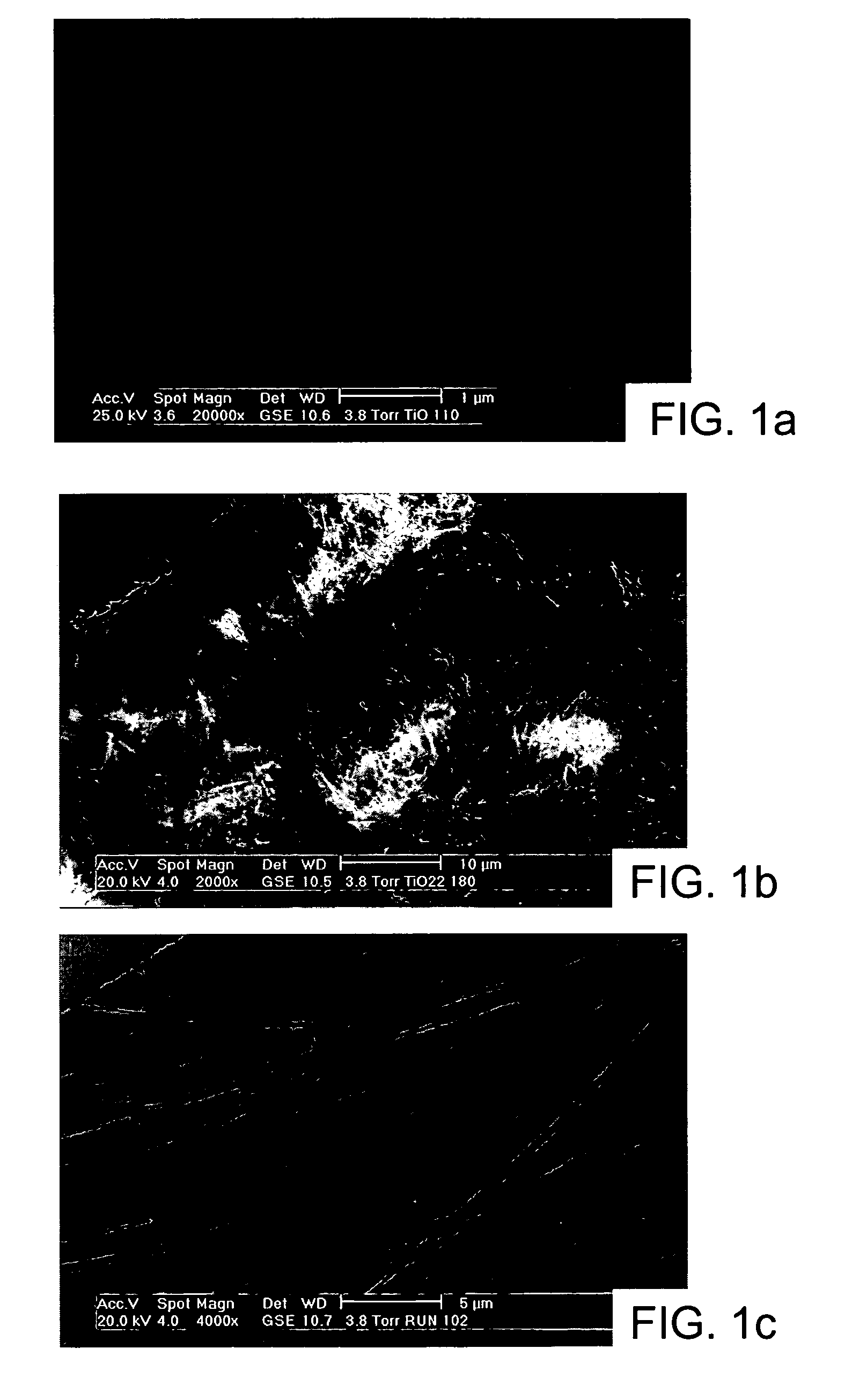

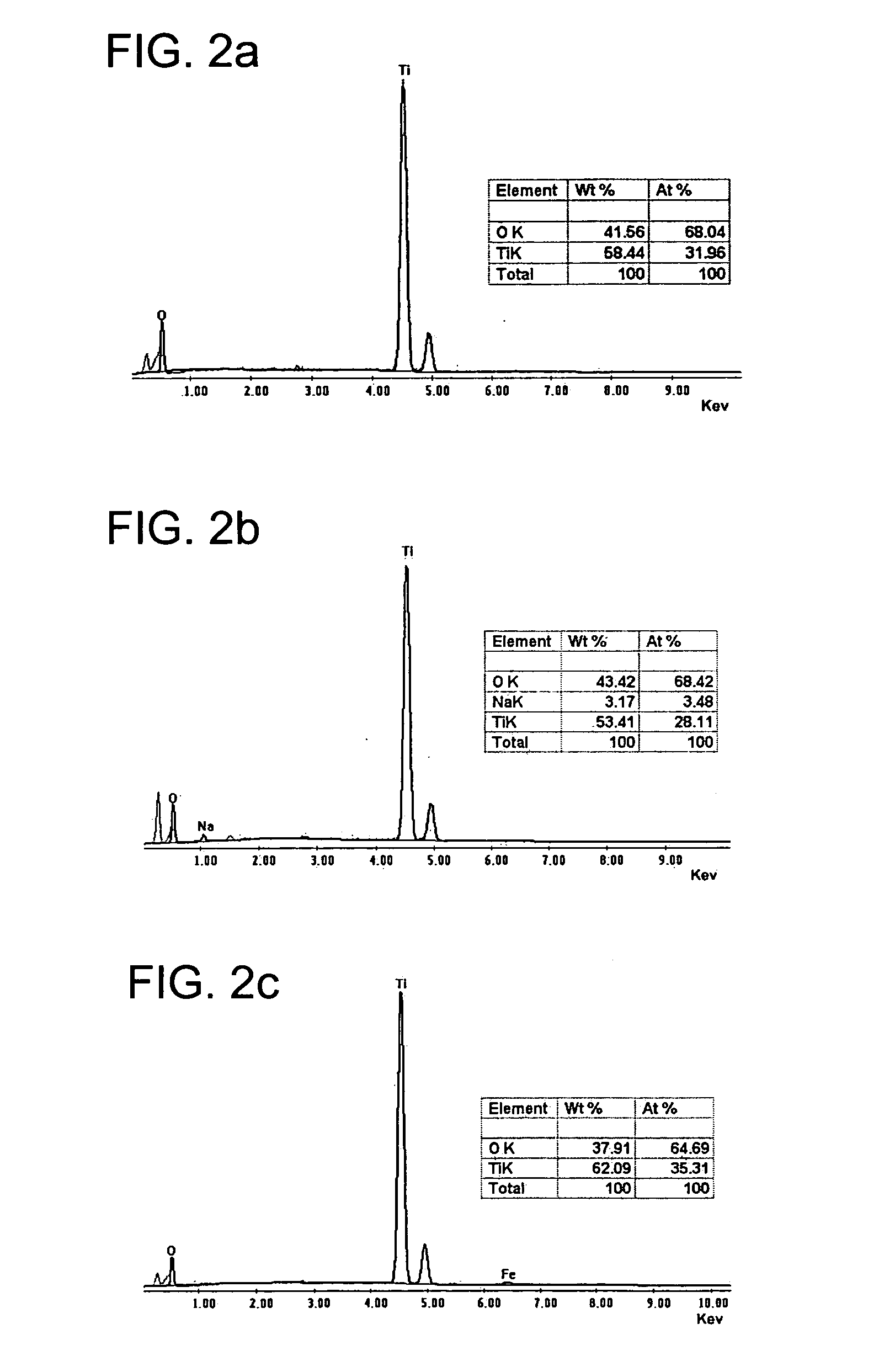

ActiveUS7645439B2Stable structureHigh areaMaterial nanotechnologyTitanium suboxidesNanowireNanostructure

Owner:INST MEXICANO DEL GASOLINEEO

Method for reducing metal oxide and method for producing photocatalyst using same

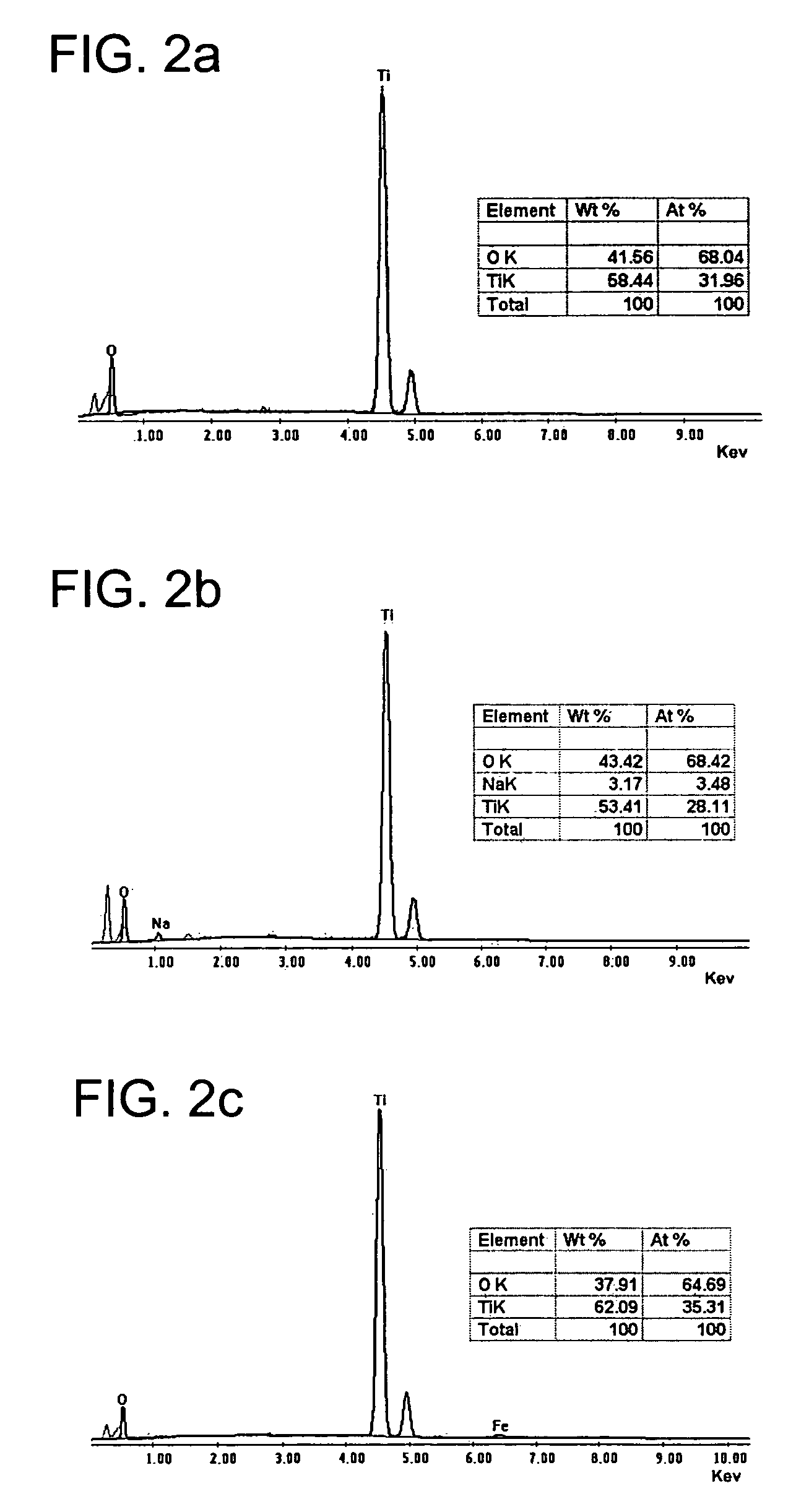

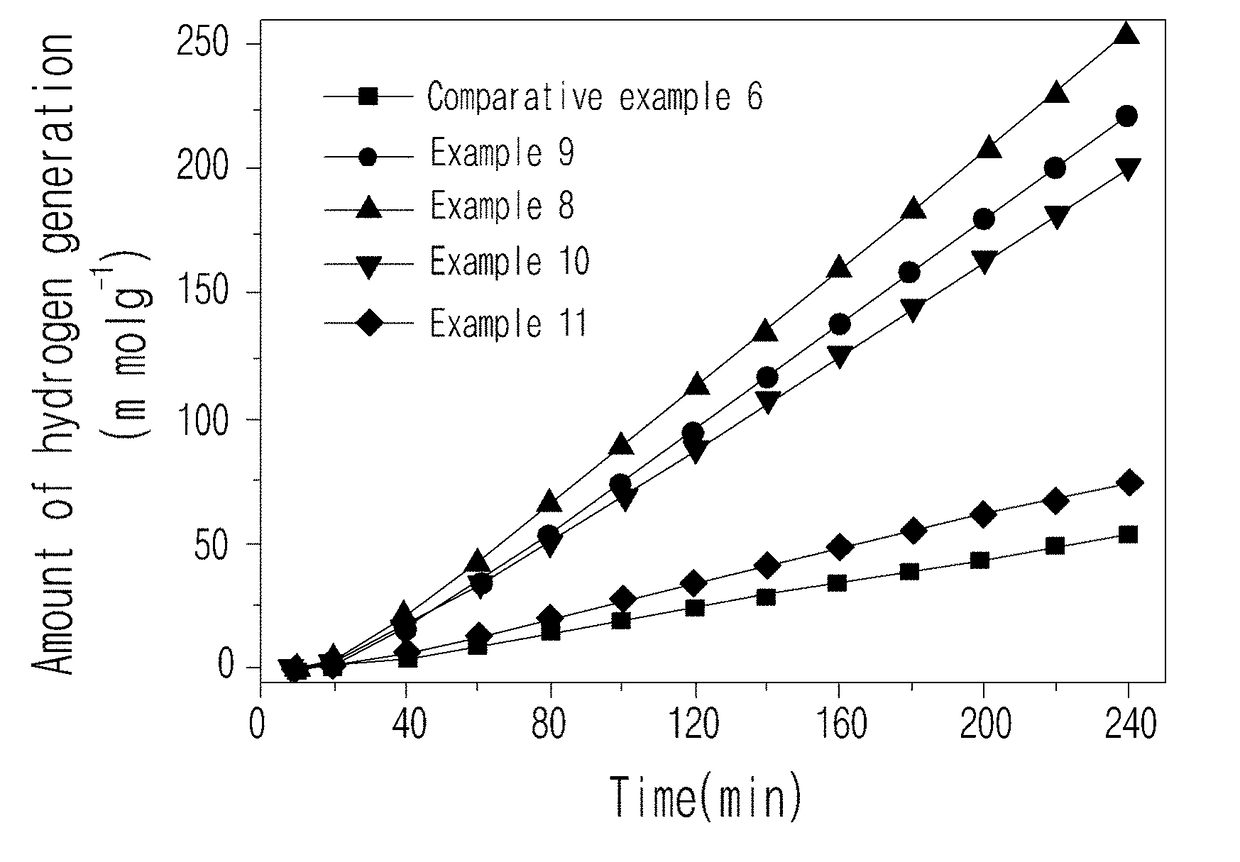

ActiveUS20180318795A1Improve photocatalytic efficiencyReduced titaniaZinc oxides/hydroxidesCatalyst activation/preparationMaterials scienceHeat treated

The present invention relates to a method of reducing a metal oxide comprising the steps of preparing a mixture by mixing a metal oxide and a metal hydride (step 1) and reducing the mixture by heat treatment (step 2) and a method of producing a photocatalyst using the same, and The method of reducing a metal oxide of the present invention can easily reduce such metal oxides as TiO2, ZrO2, V2O3, and Fe2O3.

Owner:DAEGU GYEONGBUK INST OF SCI & TECH

Metalothermic reduction of refractory metal oxides

InactiveUS7150776B2Eliminate the problemLimited physical propertyFixed capacitor electrodesTungsten oxides/hydroxidesAlloyMetal

High purity refractory metals, valve metals, refractory metal oxides, valve metal oxides, or alloys thereof suitable for a variety of electrical, optical and mill product / fabricated parts usages are produced from their respective oxides by metalothermic reduction of a solid or liquid form of such oxide using a reducing agent that establishes (after ignition) a highly exothermic reaction, the reaction preferably taking place in a continuously or step-wise moving oxide such as gravity fall with metal retrievable at the bottom and an oxide of the reducing agent being removable as a gas or in other convenient form and unreacted reducing agent derivatives being removable by leaching or like process.

Owner:TANIOBIS GMBH

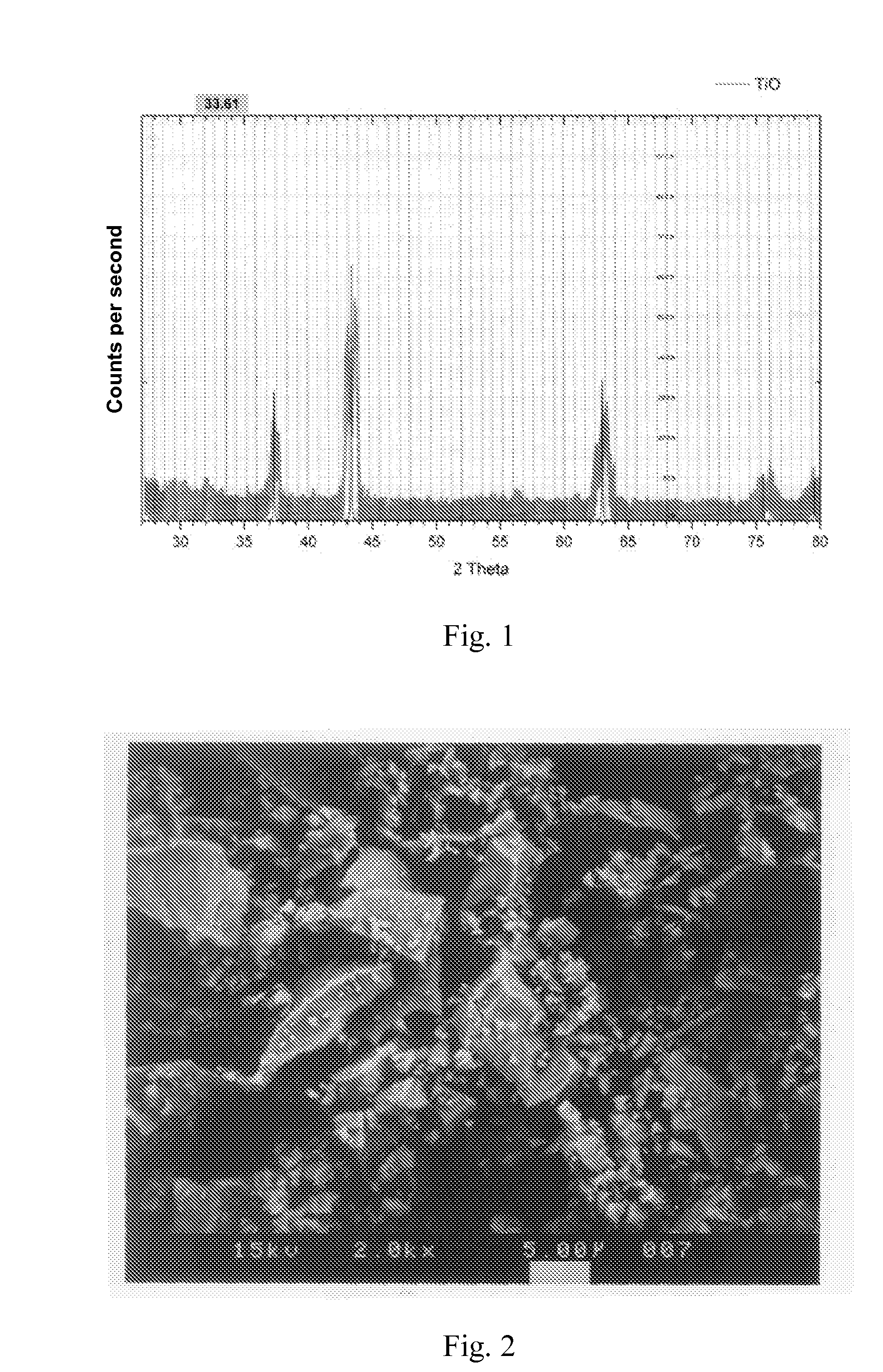

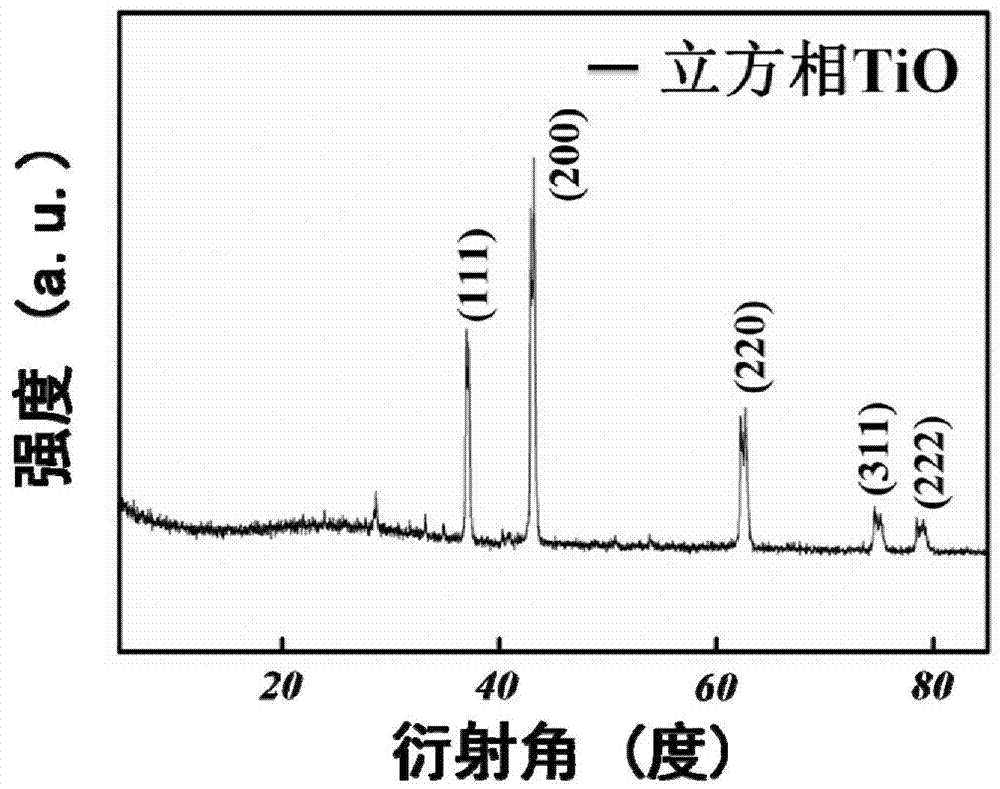

Production of high-purity titanium monoxide and capacitor production therefrom

The present invention relates to high-purity titanium monoxide powder (TiO) produced by a process of combining a mixture of titanium suboxides and titanium metal powder or granules; reacting the mixture at a temperature above about 1200° C.; and fragmenting the body to form TiO particles suitable for application as e.g., capacitors. The TiO product is unusually pure in composition and crystallography, highly dense, and can be used for capacitors and for other electronic applications. The method of production of the TiO is robust, does not require high-purity feedstock, and can reclaim value from waste streams associated with the processing of TiO electronic components.

Owner:READING ALLOYS

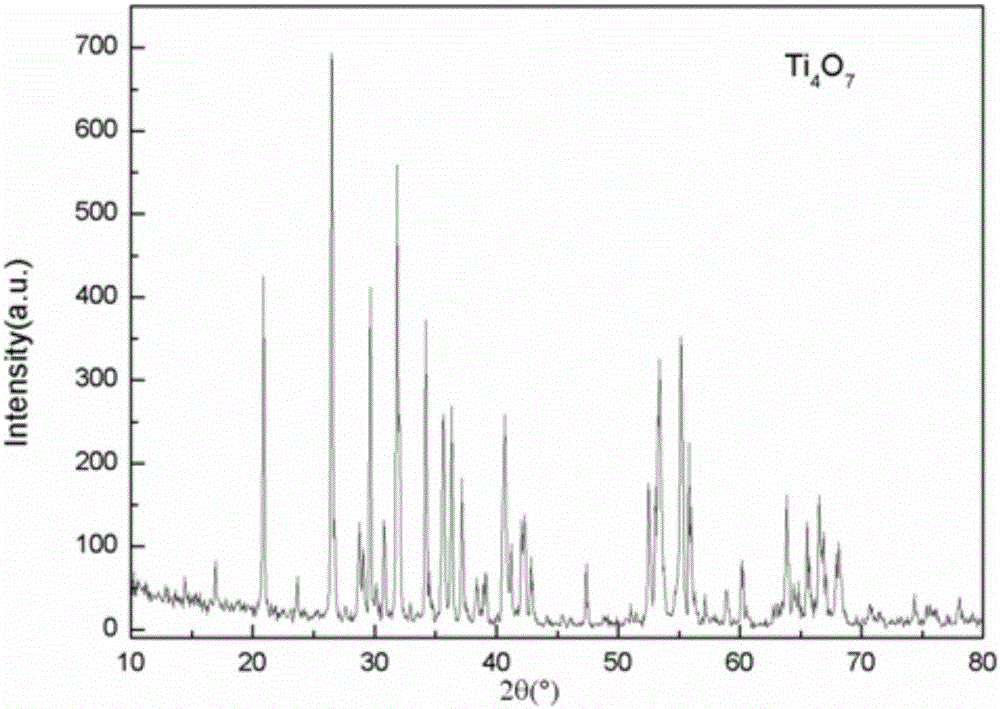

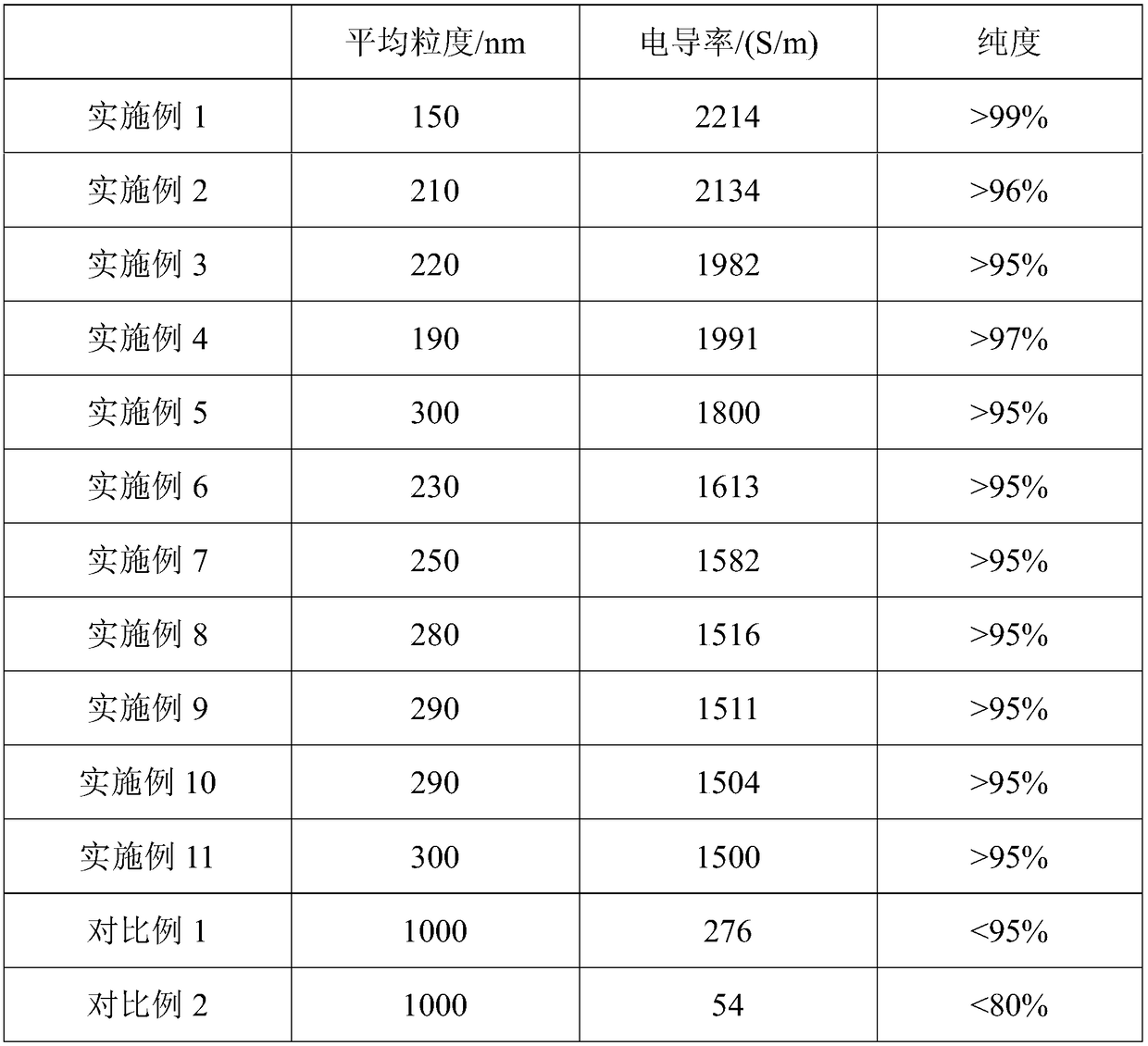

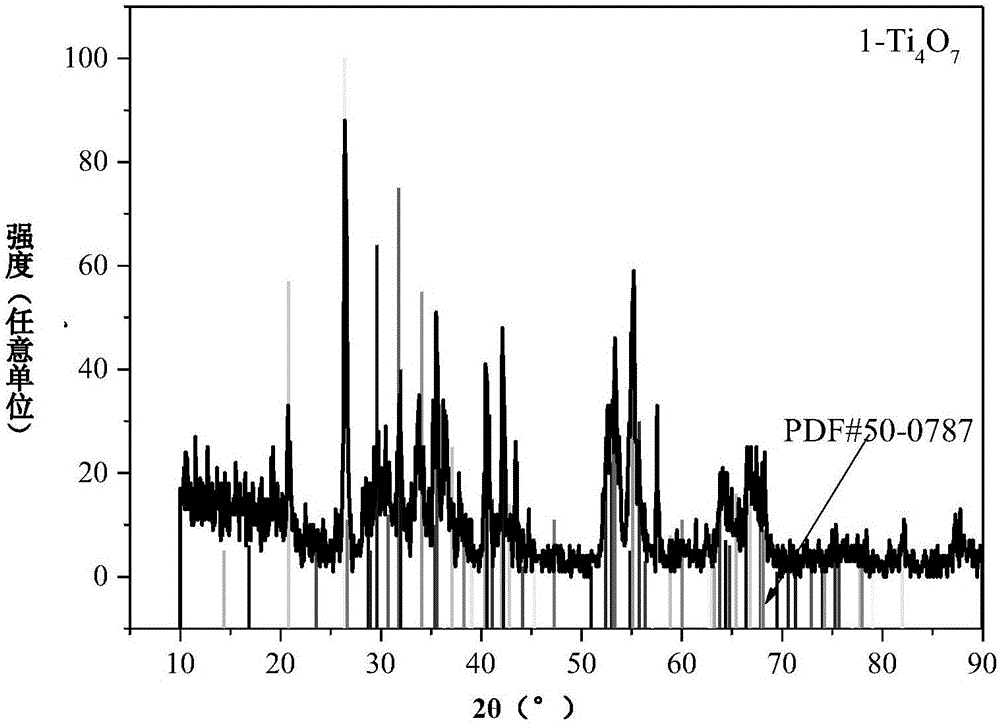

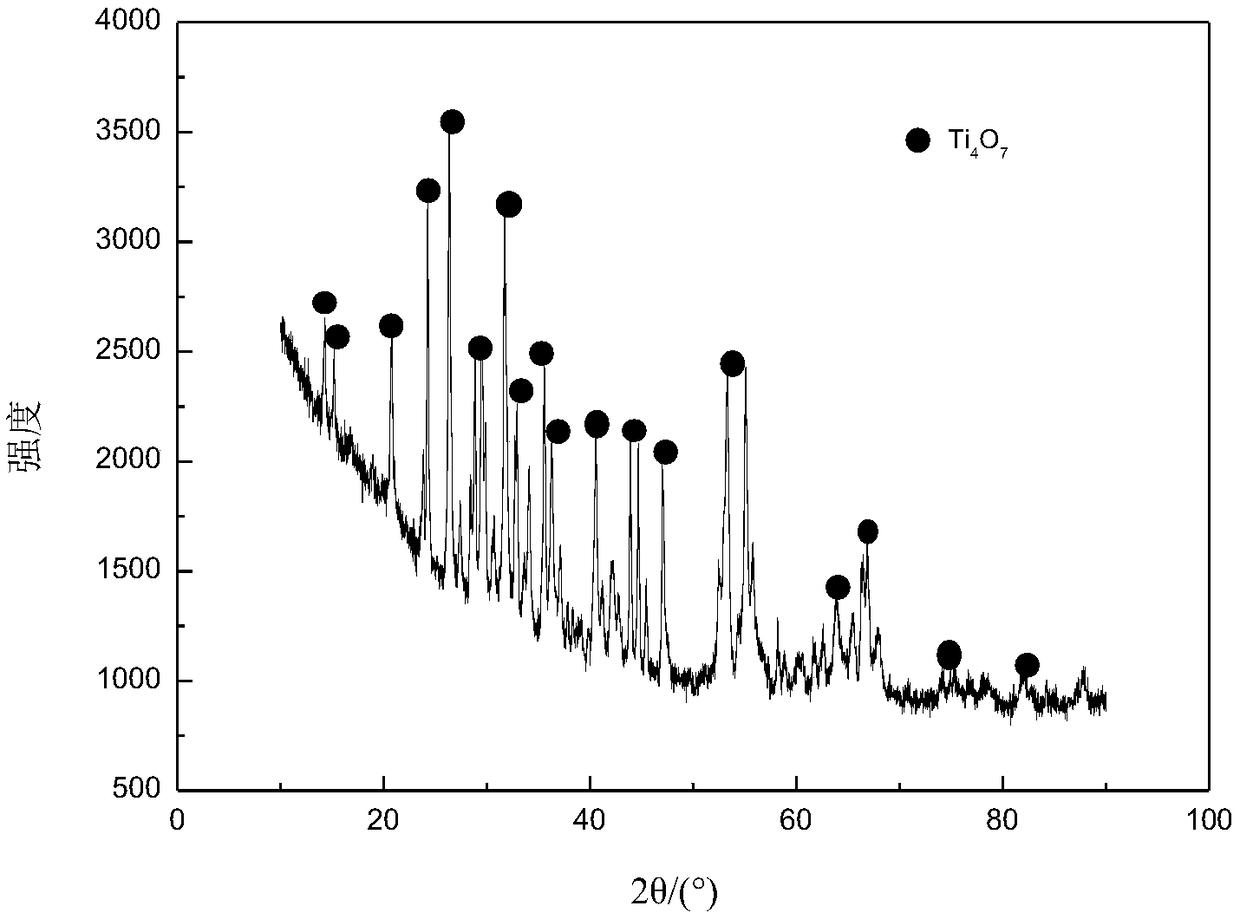

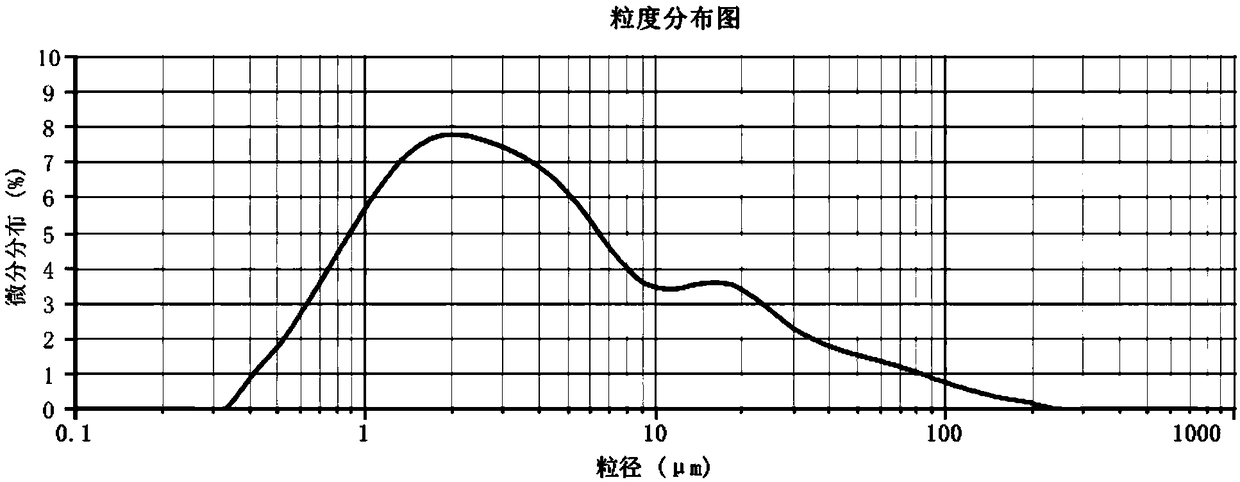

Ti4O7 nano material as well as preparation method thereof and use thereof

ActiveCN108862377AInhibit growthGuaranteed uniformityPhysical/chemical process catalystsTitanium suboxidesThermal treatmentElectrical resistivity and conductivity

The invention relates to a Ti4O7 nano material as well as a preparation method thereof and use thereof. The preparation method of the Ti4O7 nano material comprises the following steps: adopting nano titanium dioxide as a titanium source, adopting an inorganic carbon source and an inorganic carbon source as a reducing agent, and grinding and performing thermal treatment to obtain the Ti4O7 nano material. In a preparation process, the inorganic carbon source and the organic carbon source cooperatively act to realize controllable preparation of particle diameters and purity of product nano particles. The preparation method is simple in process flow, and is relatively low in cost; and the obtained Ti4O7 nano material is high in purity and conductivity, is small in particle diameter, and can beused as a catalysis material and an electrode material.

Owner:LANGFANG GREEN IND TECH CENT +1

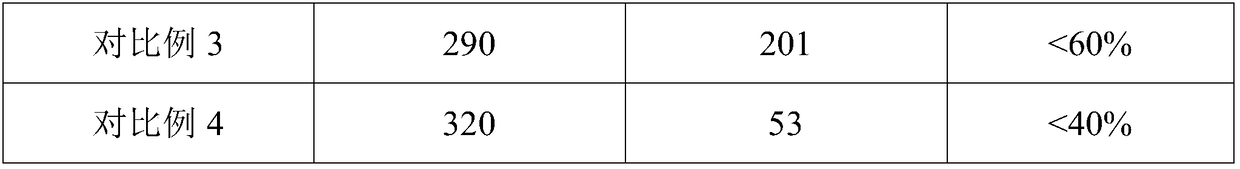

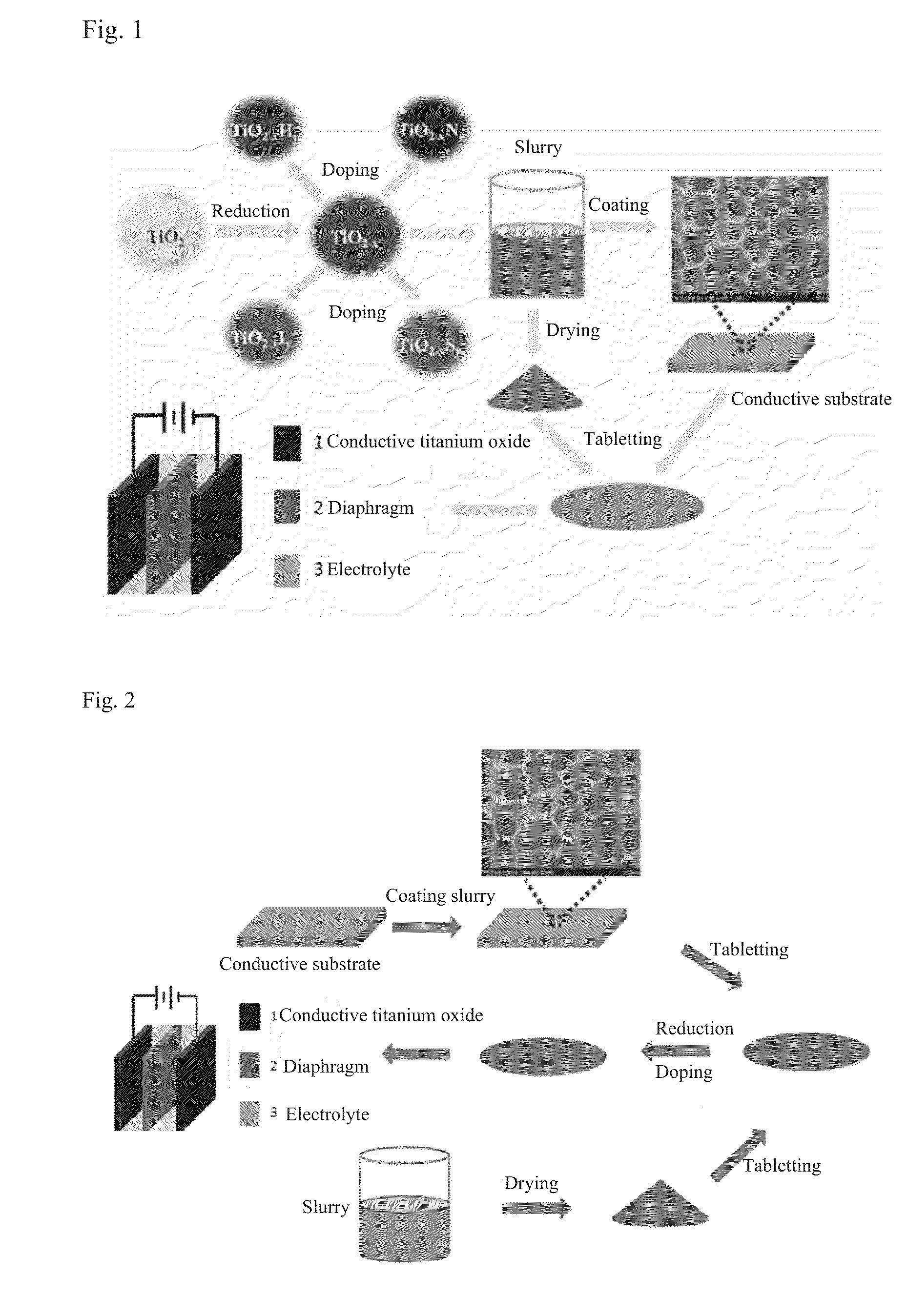

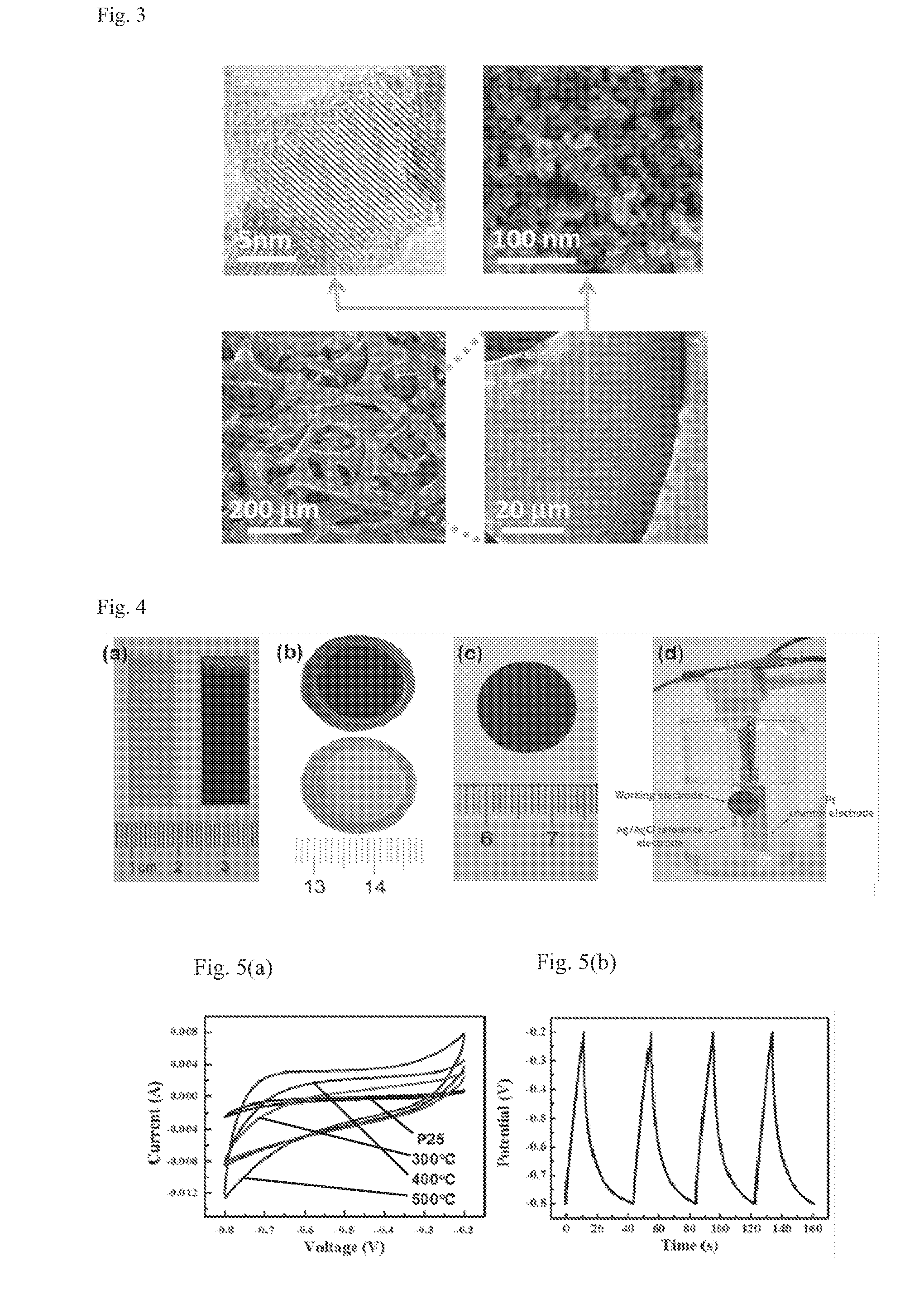

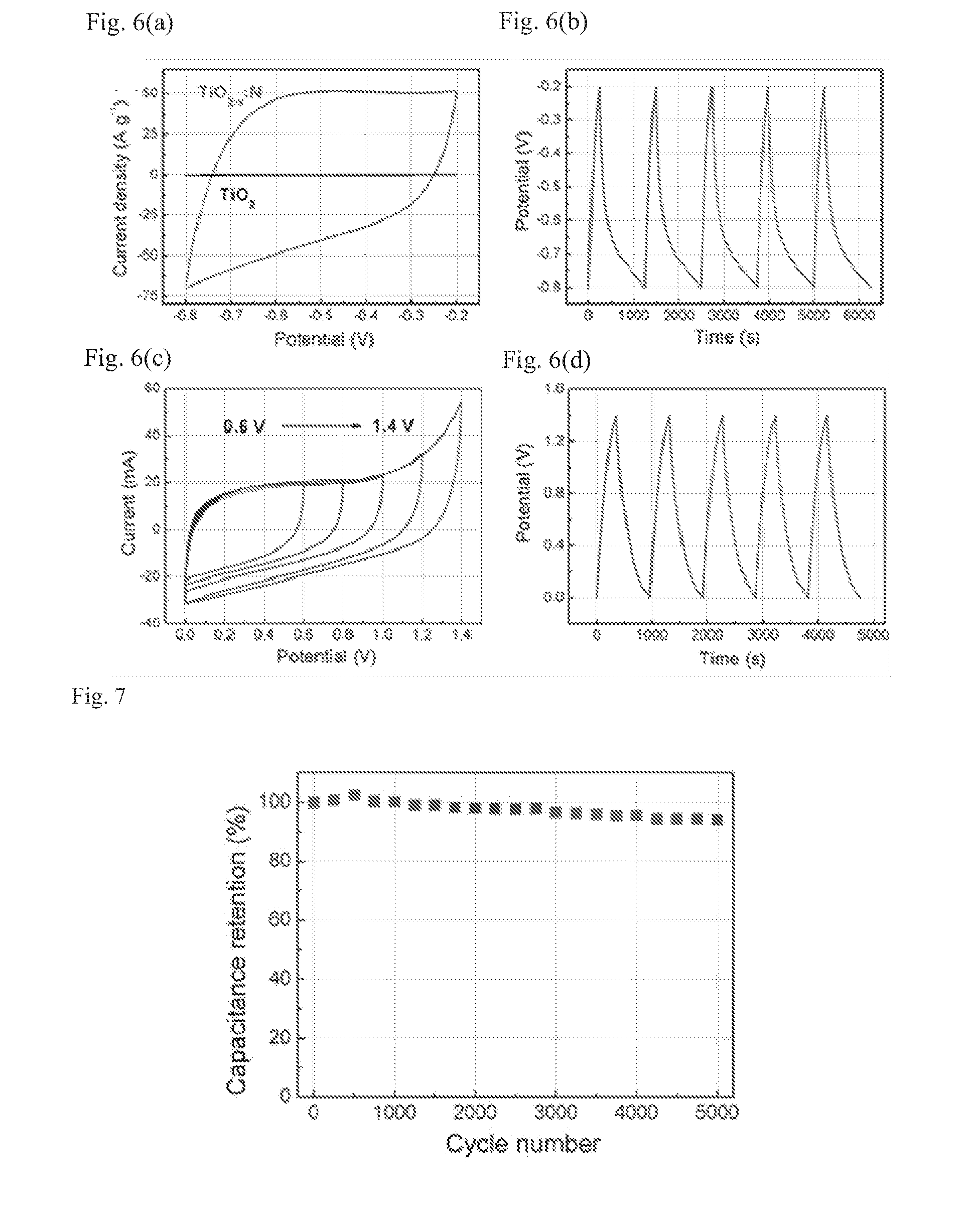

Titanium oxide-based supercapacitor electrode material and method of manufacturing same

ActiveUS20160240328A1Improve conductivityLow costHybrid capacitor electrodesTitanium suboxidesCapacitanceSupercapacitor

A titanium oxide-based supercapacitor electrode material and a method of manufacturing same. A reactive substance of the titanium oxide-based supercapacitor electrode material is a conductive titanium oxide. The conductive titanium oxide is a sub-stoichiometric titanium oxide, reduced titanium dioxide, or doped reduced titanium dioxide obtained by further doping an element in reduced titanium dioxide. The titanium oxide-based supercapacitor electrode material has a carrier concentration greater than 1018 cm−3, and the titanium oxide-based supercapacitor electrode material has a specific capacitance 20 F / g to 1,740 F / g at a charge / discharge current of 1 A / g.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

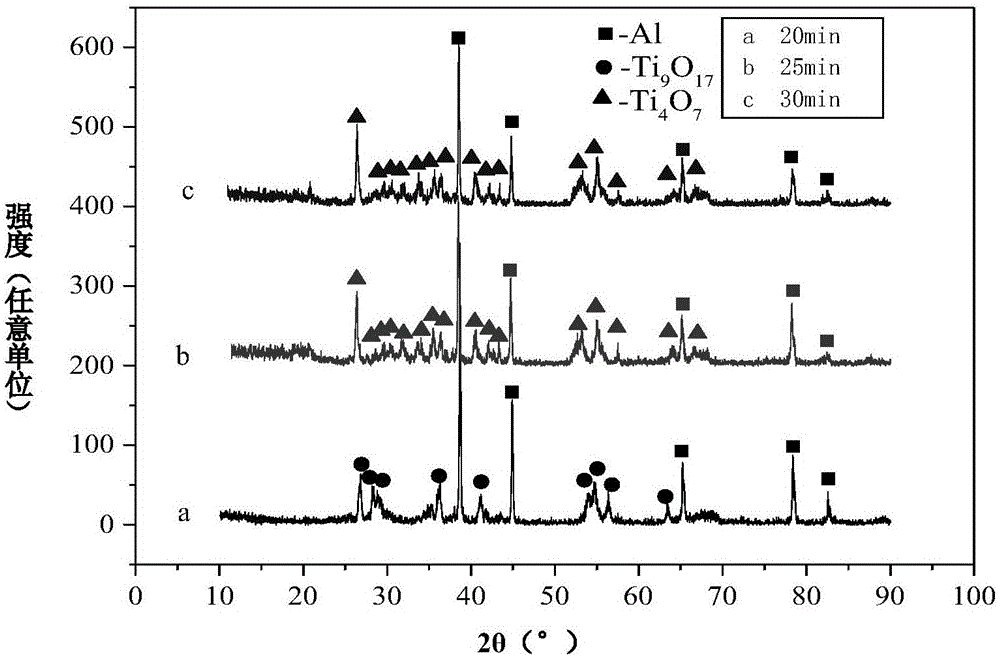

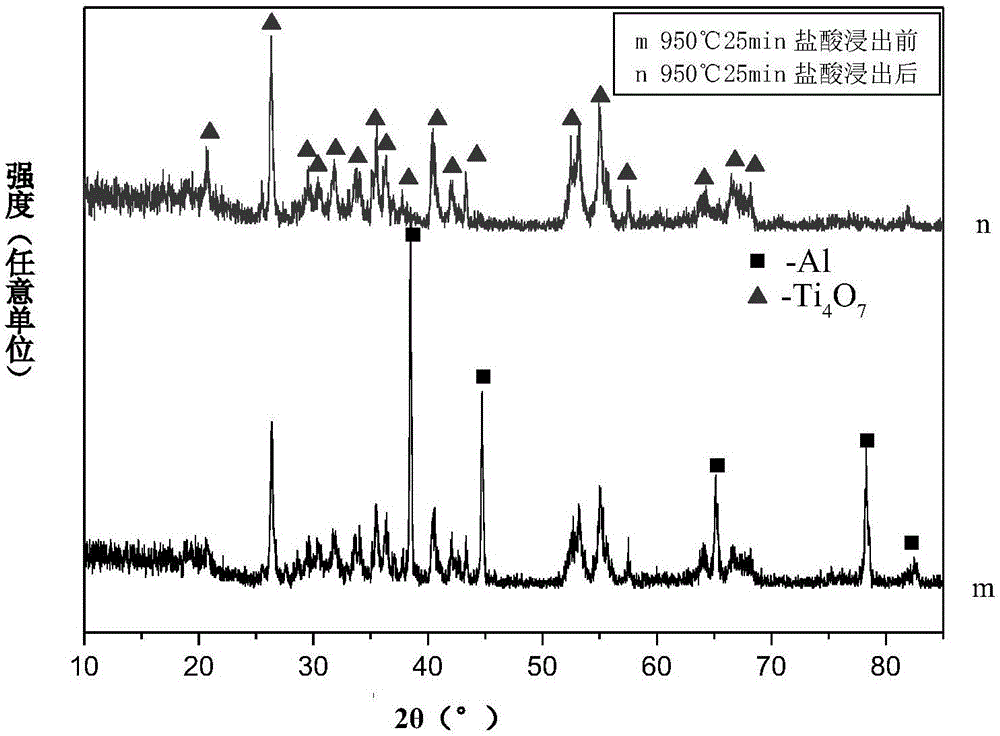

Preparation method of Magneli phase low valence titanium oxide

ActiveCN106830065ARealize large-scale preparationReduce manufacturing costTitanium suboxidesCrucibleMixed materials

The invention relates to the technical field of inorganic material preparation process, in particular to a preparation method of Magneli phase low valence titanium oxide. The method comprises the steps of uniformly mixing titanium pigment, aluminum powder and absolute ethanol in the mass and volume ratio of 0.4-0.8g: 1g: 0.5-0.8mL, adding the uniformly mixed material into a crucible to compaction, melting boron oxide with low melting point, using the boron oxide to cover the material surface, putting the crucible on an electric heating furnace for roasting to obtain the low valence titanium oxide. Because the Magneli phase low valence titanium oxide is stable in chemical property, the finally obtained material is leached in acid to obtain the pure Magneli phase (TinO2n-1) low valence titanium oxide. According to the Magneli phase low valence titanium oxide, the preparation in relatively low temperature, normal pressure and relatively short period of time is achieved, the cost is greatly reduced, and the method is beneficial to achieve the scale production and preparation.

Owner:马根英

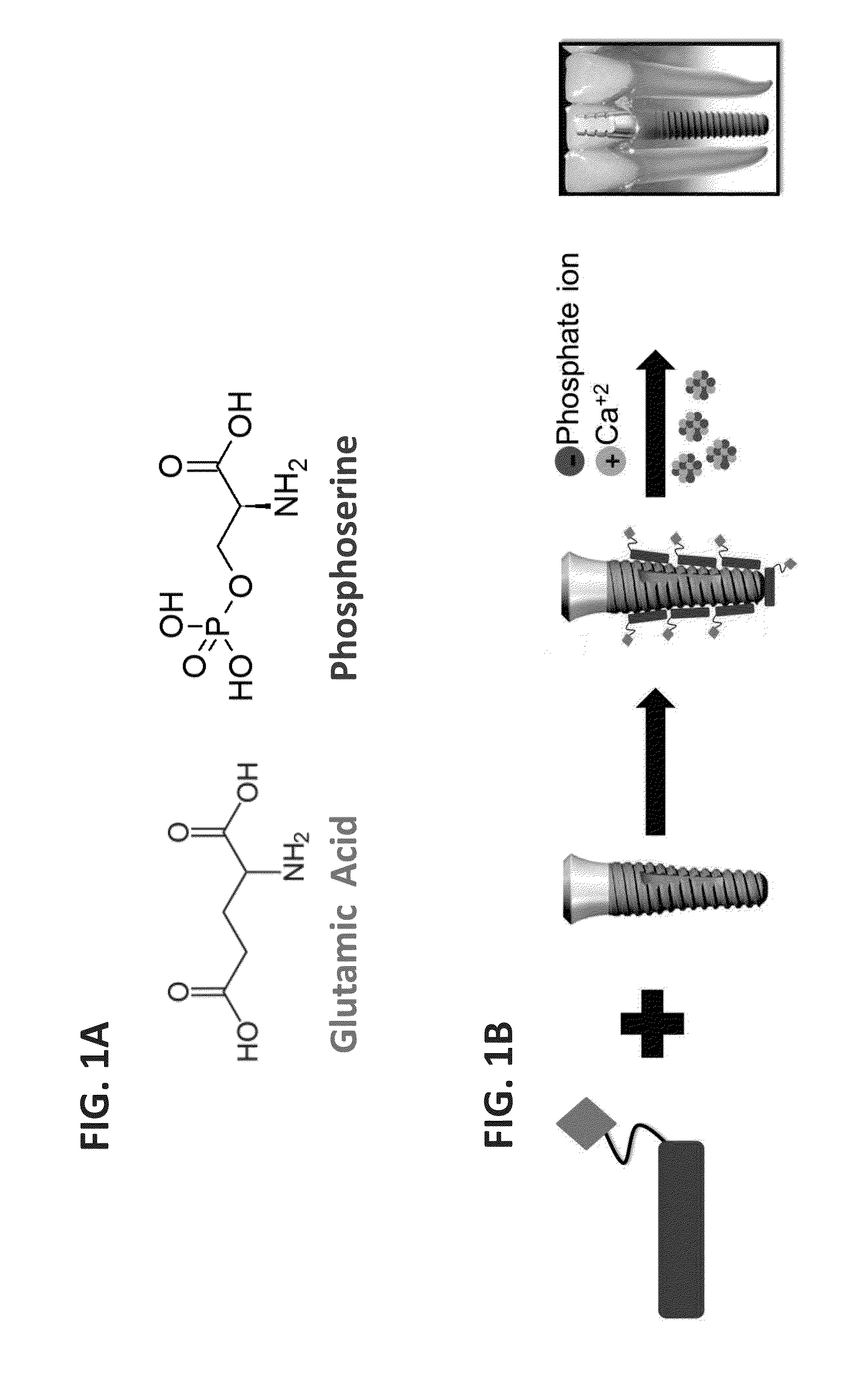

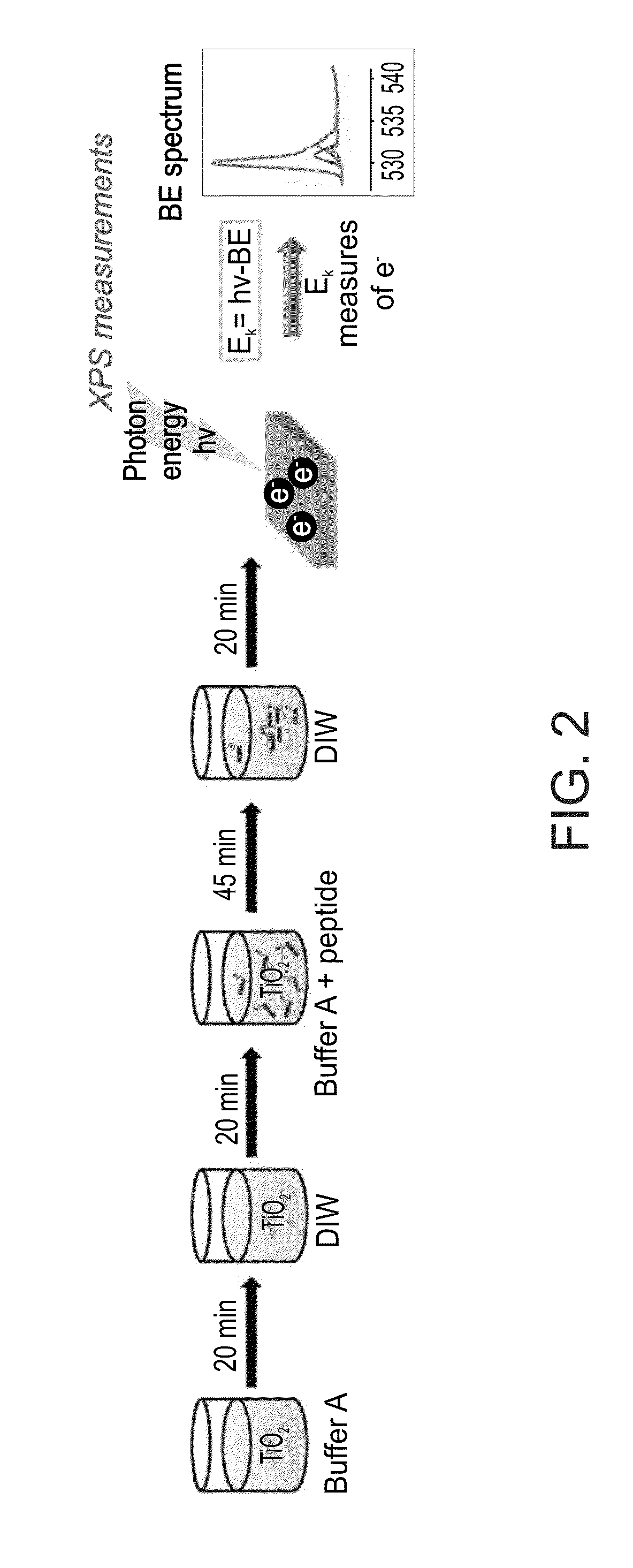

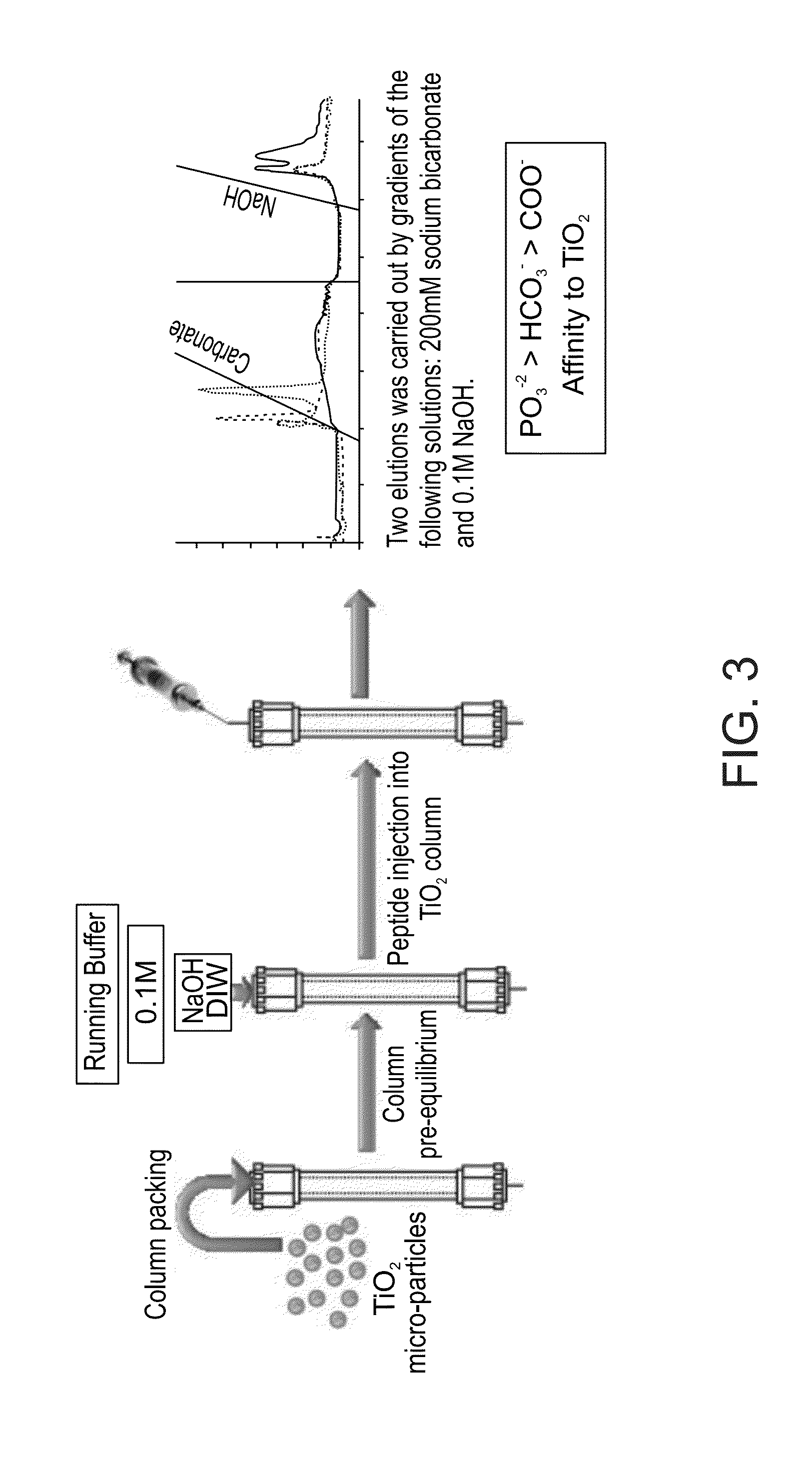

Functionalized titanium binding peptides and implants coated with same

Owner:BEN GURION UNIVERSITY OF THE NEGEV

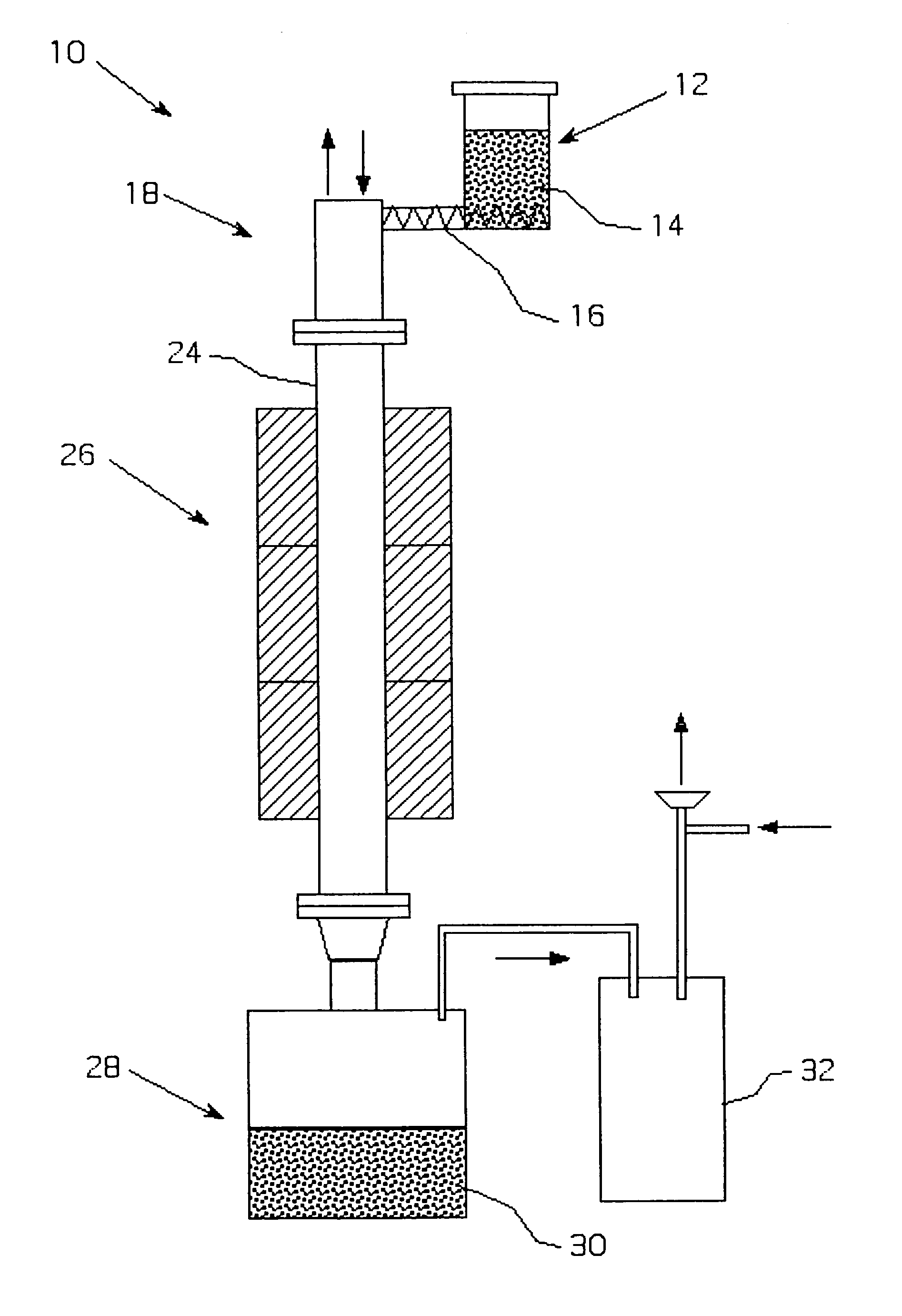

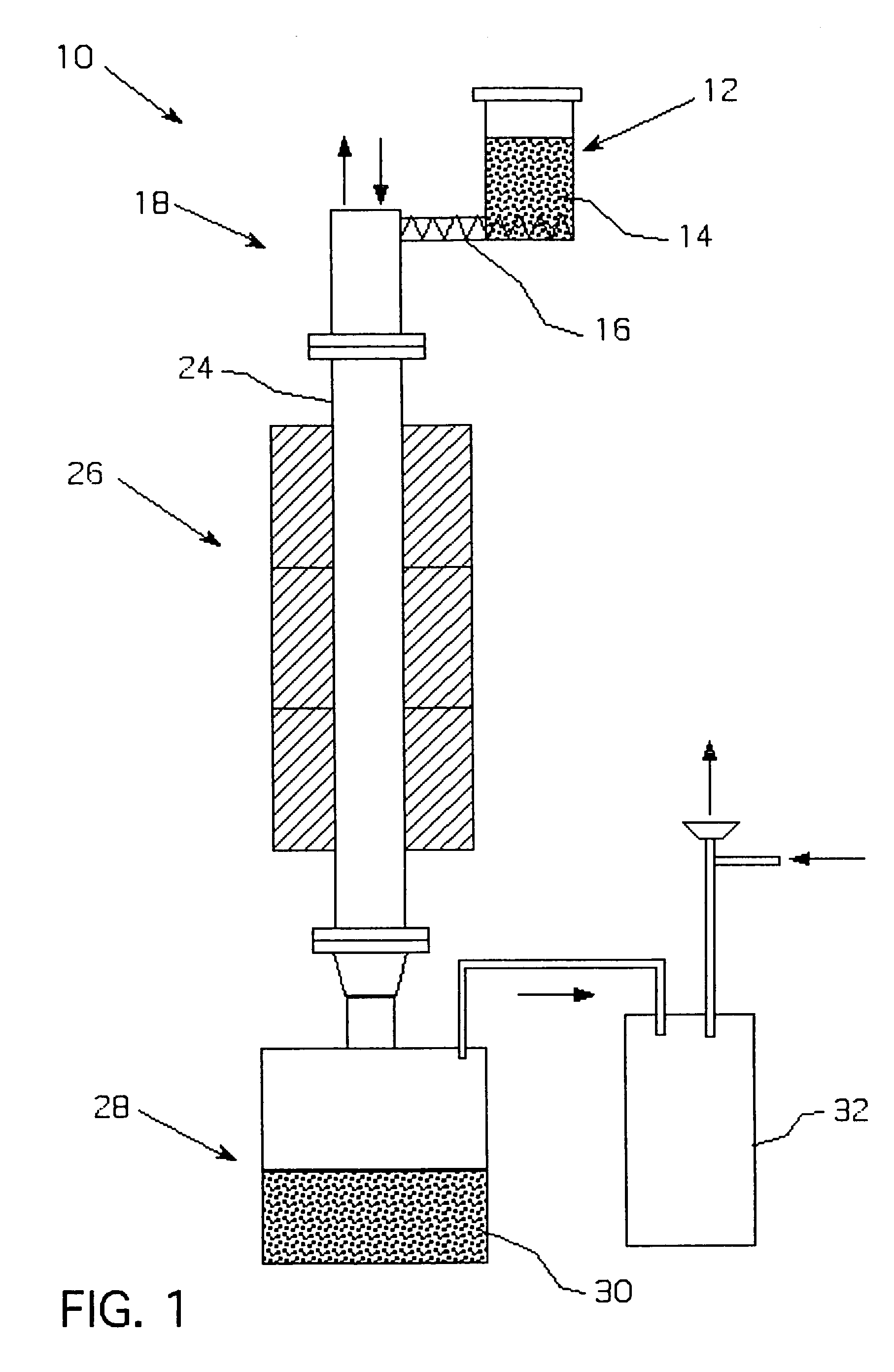

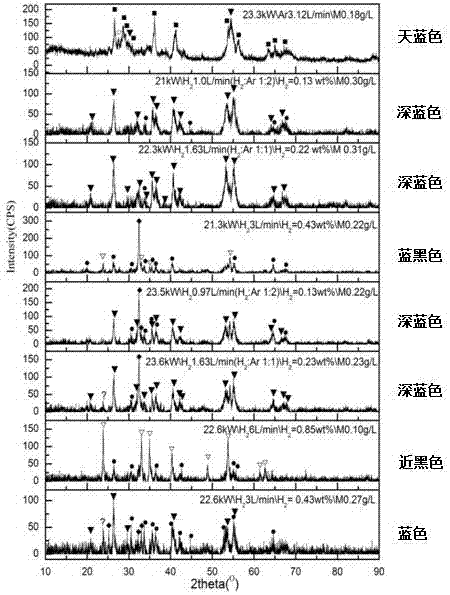

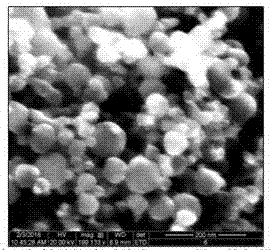

Method for preparing nano titanium sub-oxide by utilizing high-temperature plasma

ActiveCN107473264AShort processEasy to controlTitanium suboxidesNanotechnologyCollection systemTitanium

The invention discloses a method for preparing nano titanium sub-oxide by utilizing high-temperature plasma. The method comprises the following steps: firstly, conveying a nanoscale metatitanic acid powder body into a plasma reaction device by using carrier gas, wherein the plasma reaction device comprises a high-temperature plasma generation system and a power body condensation and collection system; enabling the metatitanic acid powder body to pass through a high-temperature plasma flame area of the high-temperature plasma generation system within 1 second; then enabling the metatitanic acid powder body to enter the power body condensation and collection system, and carrying out condensing settlement to finally obtain a titanium sub-oxide powder body of which the particle size is nanoscale. A preparation process of the method disclosed by the invention is simple and feasible, is less in time consumption, is high in efficiency, and has a wider application prospect.

Owner:KUNMING UNIV OF SCI & TECH

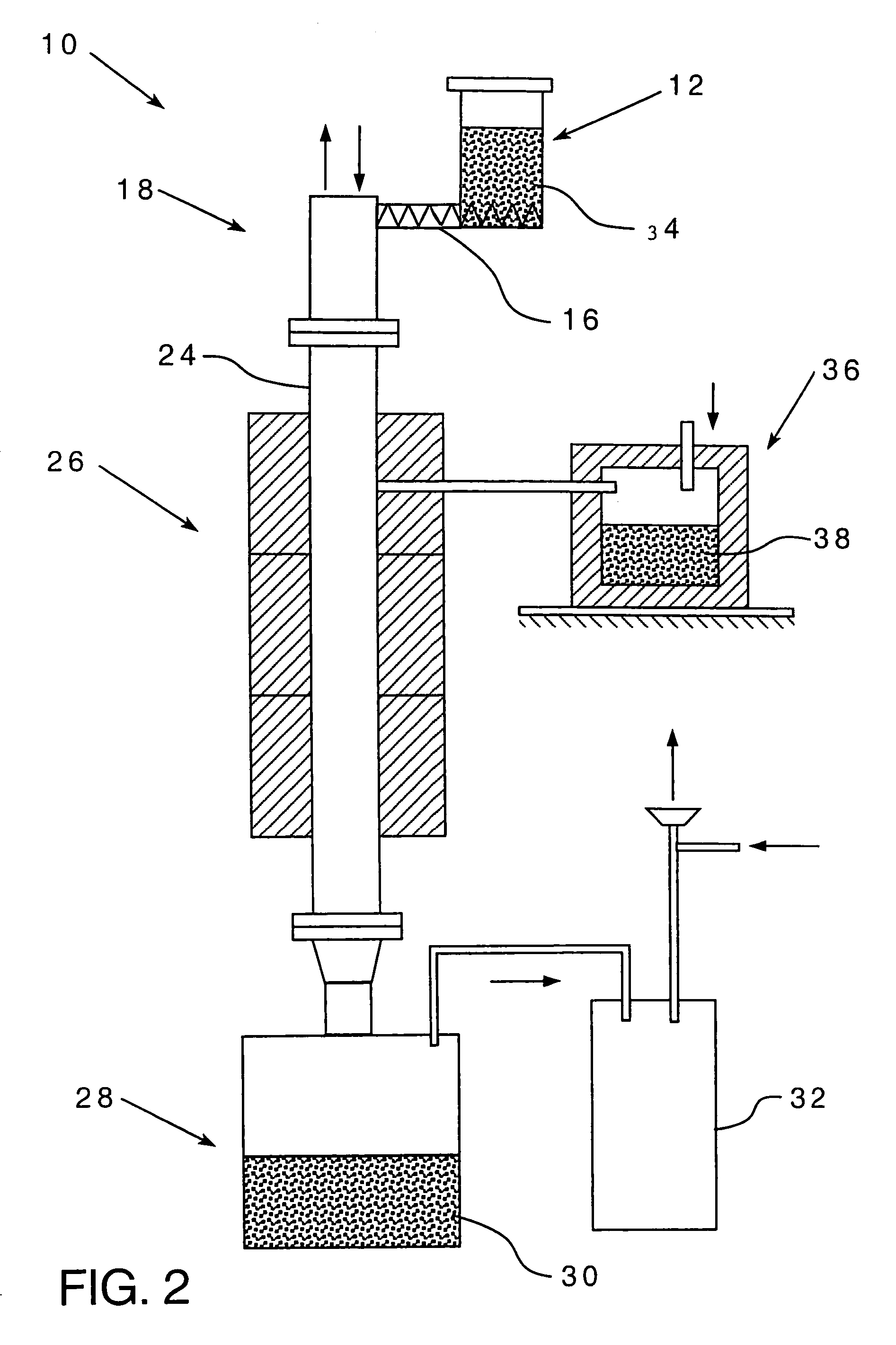

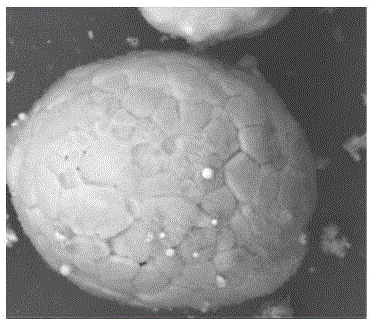

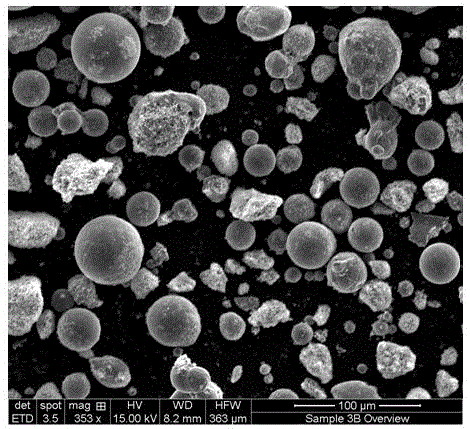

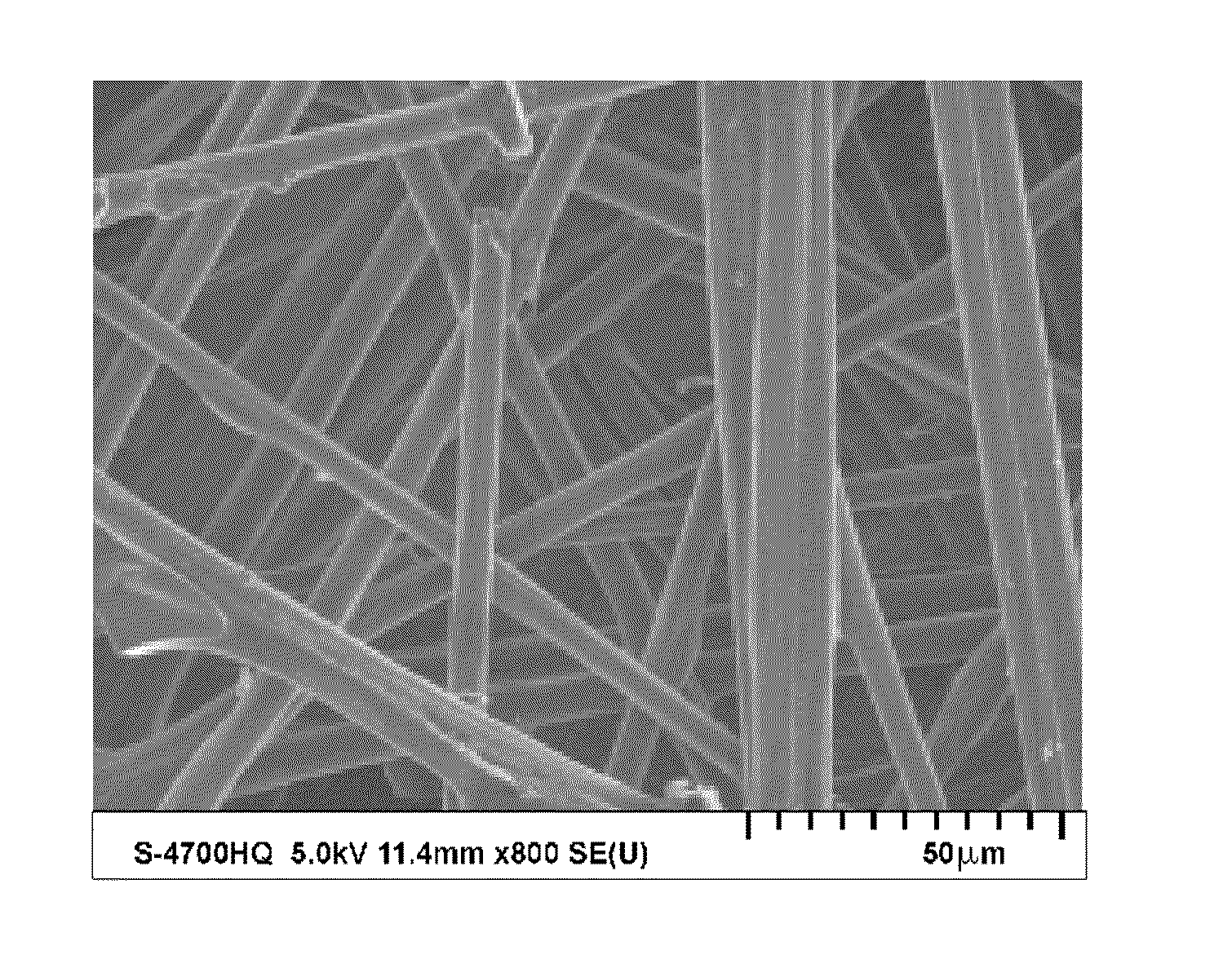

Method for preparing spherical TinO(2n-1) from plasma

The invention discloses a method for preparing spherical TinO(2n-1) from plasma and belongs to the technical field of preparation of powdery materials. According to the method, TiO2 powder is conveyed into a plasma flame area in a high-temperature plasma reactor through carrier gas, loses oxygen in the carrier gas atmosphere and is settled in a condensing area, and spherical TinO(2n-1) powder is obtained. Rapid preparation of TinO(2n-1) can be realized with the method, the technical process is short, and continuous production can be realized.

Owner:KUNMING UNIV OF SCI & TECH

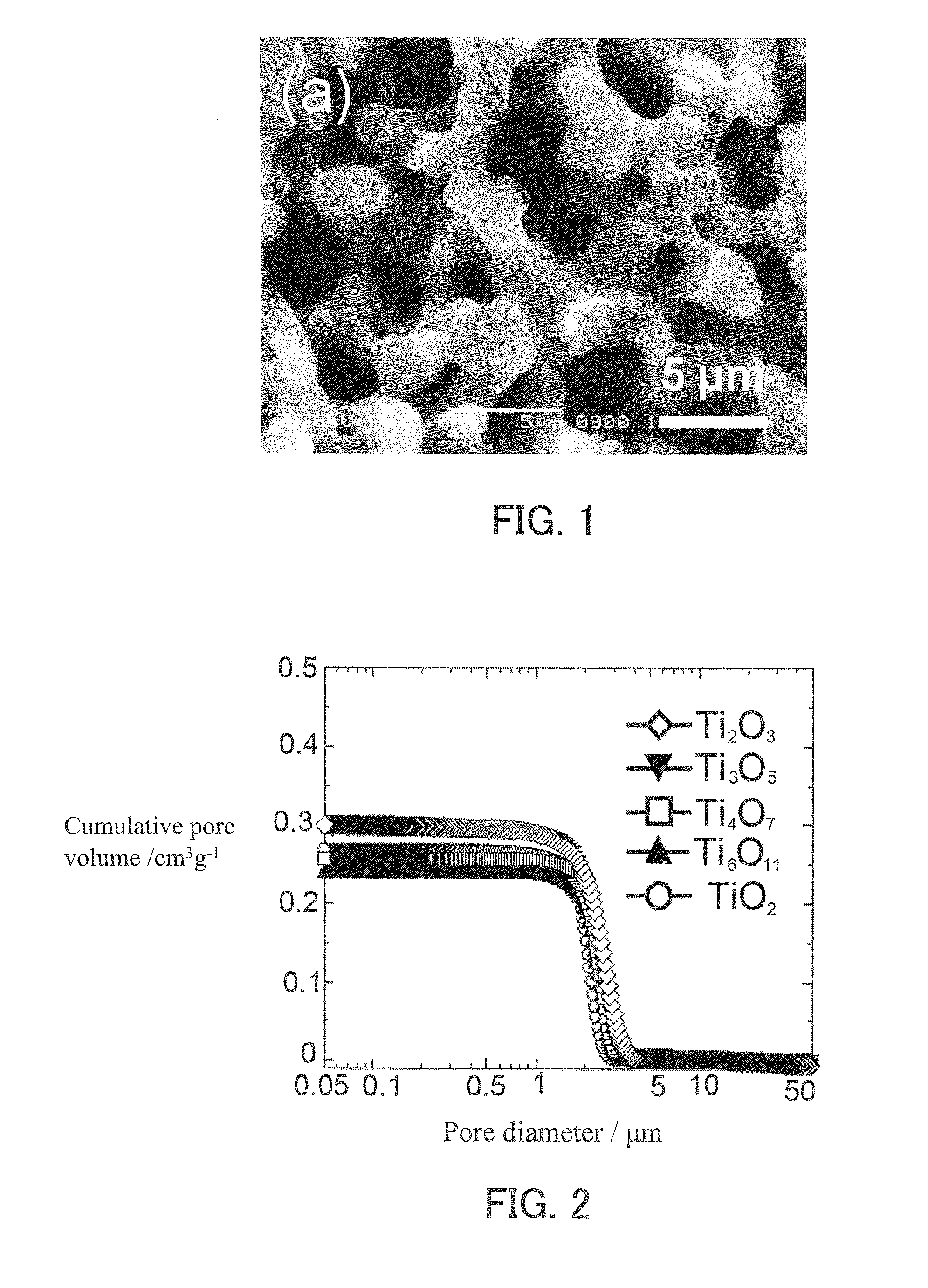

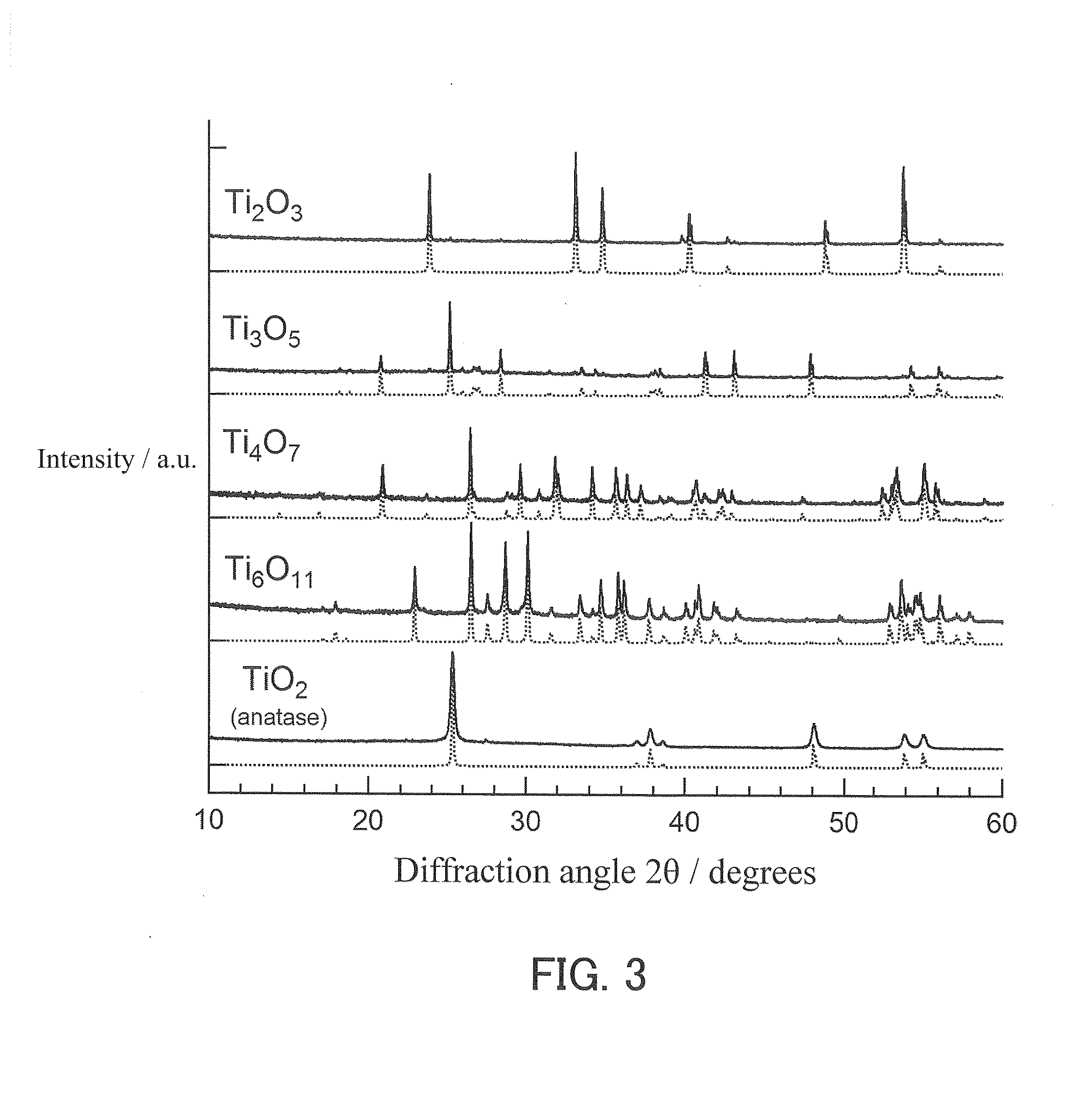

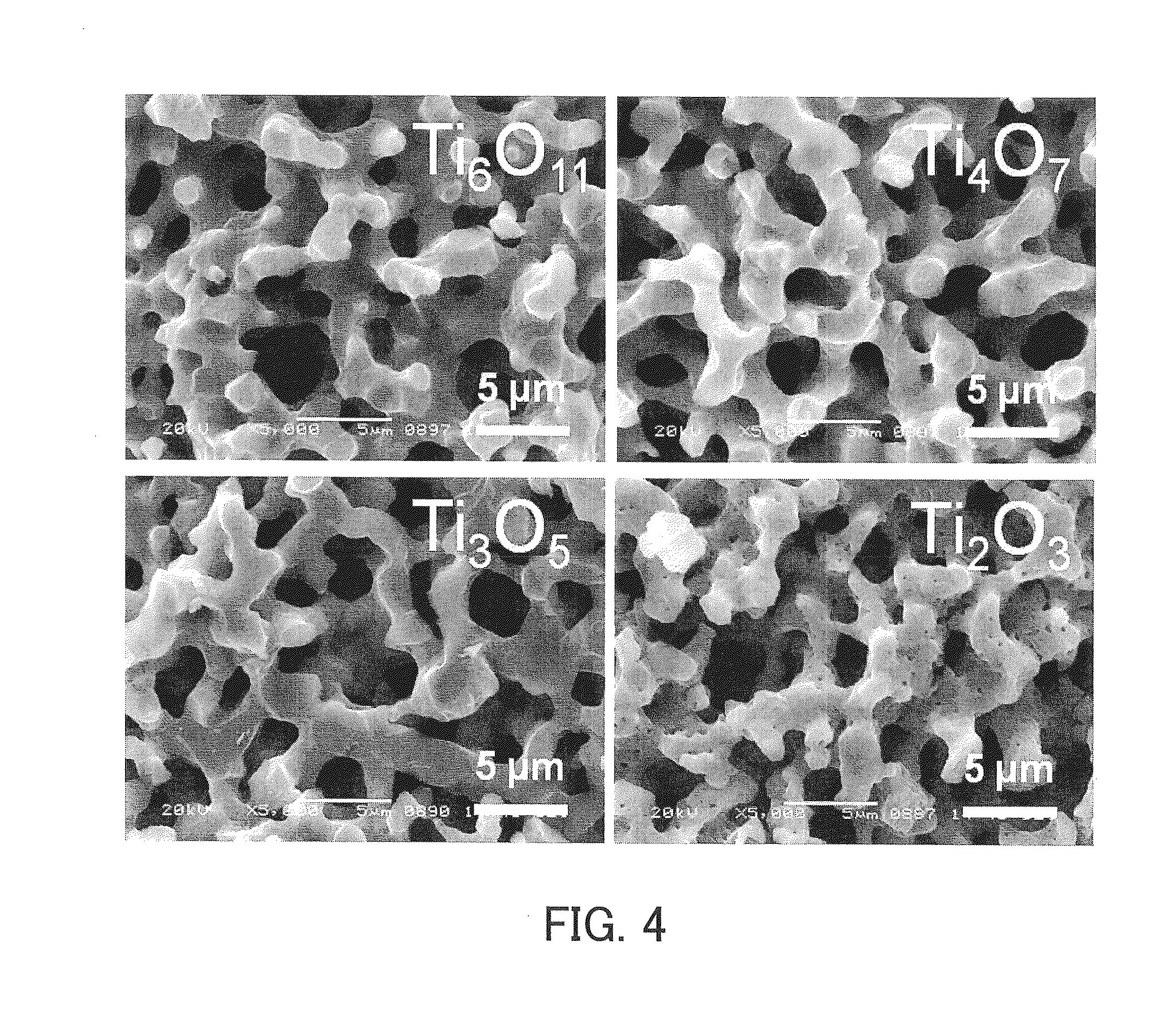

Macroporous titanium compound monolith and method for producing same

Provided are a macroporous titanium compound monolith and a production method thereof, the macroporous titanium compound monolith having a framework that is composed of a titanium compound other than titanium dioxide, having controlled macropores, and having electron conductivity, the titanium compound being oxygen-deficient titanium oxide, titanium oxynitride, or titanium nitride. Provided is a method including: placing a macroporous titanium dioxide monolith and a metal having titanium-reducing ability in a container, the macroporous titanium dioxide monolith having a co-continuous structure of a macropore and a framework that is composed of titanium dioxide; creating a vacuum atmosphere or an inert gas atmosphere within the container; and heating the monolith and the metal to cause gas-phase reduction that removes oxygen atom from the titanium dioxide composing the monolith by the metal acting as an oxygen getter, thereby obtaining a macroporous oxygen-deficient titanium oxide monolith having a co-continuous structure of the macropore and a framework that is composed of oxygen-deficient titanium oxide, the macroporous oxygen-deficient titanium oxide monolith having electron conductivity derived from the oxygen-deficient titanium oxide.

Owner:JAPAN SCI & TECH CORP

Preparation method of hollow mesoporous Ti4O7@C nanospheres with large specific surface areas

ActiveCN108383154AIncrease reaction rateSuppress coarseningMaterial nanotechnologyTitanium suboxidesLithium–sulfur batteryLithium sulfur

The invention discloses a preparation method of hollow mesoporous Ti4O7@C nanospheres with large specific surface areas. The method comprises the steps of enabling amorphous TiO2 to grow in an in-situway by taking hollow mesoporous carbon spheres as a template, and coating the surface of the amorphous TiO2 with a layer of p-phenylenediamine (PDA) to form PDA@ TiO2@C nanospheres having sandwich structures; then, calcining for 15-30min at the temperature of 950 DEG C in an argon environment to obtain the hollow mesoporous Ti4O7@C nanospheres. The preparation method provided by the invention issimple, short in needed reaction time and low in temperature, and can effectively inhibit the grain coarsening of Ti4O7; the obtained Ti4O7@C nanospheres are large in specific surface areas, and havea wide application prospect in the field of lithium-sulfur batteries.

Owner:SHAANXI NORMAL UNIV

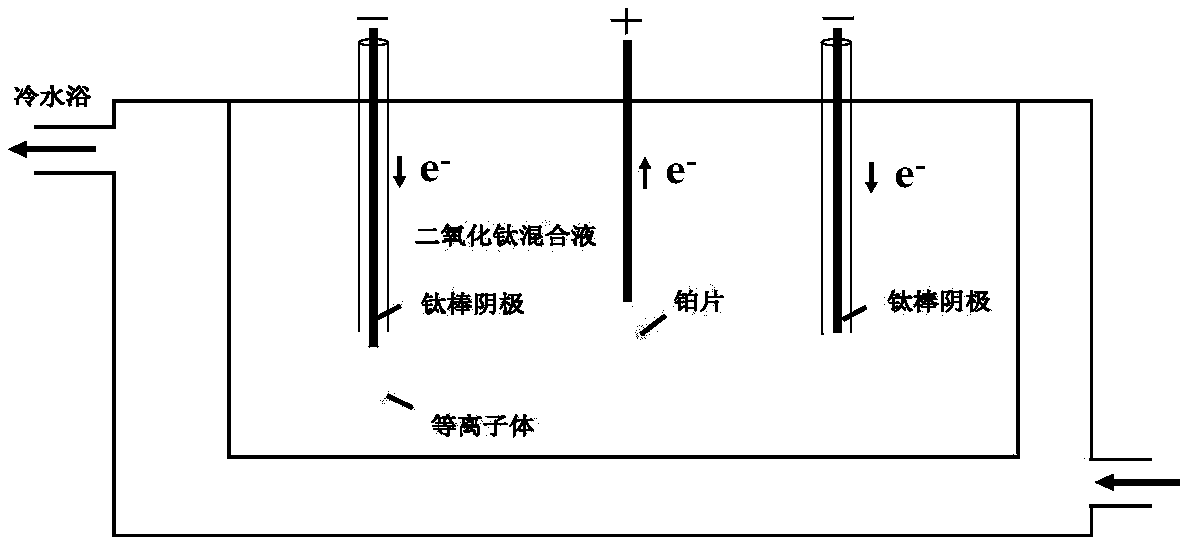

Titanium dioxide surface modifying method

ActiveCN109678201AImprove securityEase of industrial productionElectrolysis componentsCatalyst activation/preparationEnvironmental resistanceHydrogen atmosphere

The invention relates to the technical field of synthesis of photocatalysts and particularly relates to a titanium dioxide surface modifying method. A titanium dioxide powder is dispersed in an electrolyte, a cathode glow discharge plasma is produced in the electrolyte and electrolyzes water to produce a hydrogen atmosphere, the titanium dioxide is subjected to hydrogenation reduction in the hydrogen atmosphere, and the titanium oxide with a core-shell structure is obtained after finishing discharging. The cathode glow discharge plasma is used for rapidly preparing the visible-light response reductive titanium oxide in one step, no chemical reducing agent is added in the preparation process, and the method is a green environmentally-friendly preparation technique; the preparation process is simple, only the electric energy and a small quantity of liquid are consumed, the raw material of the titanium dioxide is not self-made, the surface of the titanium dioxide is directly modified, andthe mass production is implemented conveniently. By using the titanium dioxide surface modifying method, the titanium oxide is not required to be reduced at the high temperature in the hydrogen atmosphere, so that the safety of the preparation process is improved, and the industrial production is facilitated.

Owner:GUANGDONG ROI OPTOELECTRONICS TECH CO LTD +2

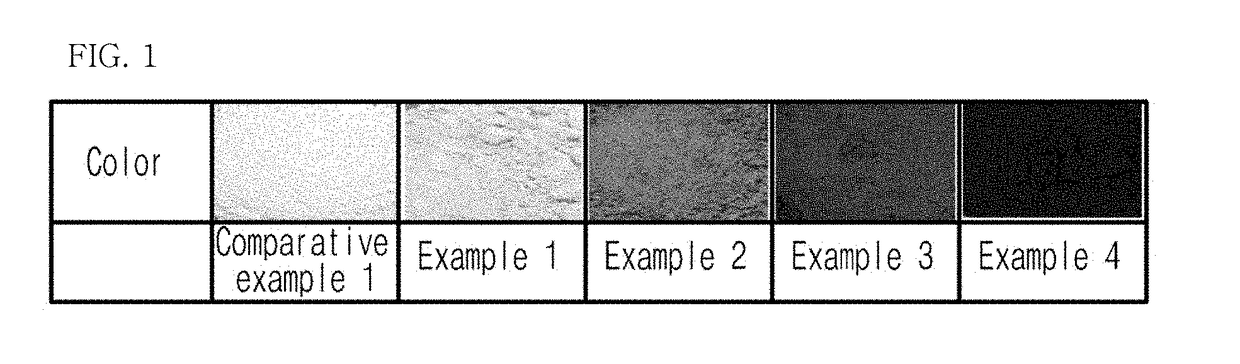

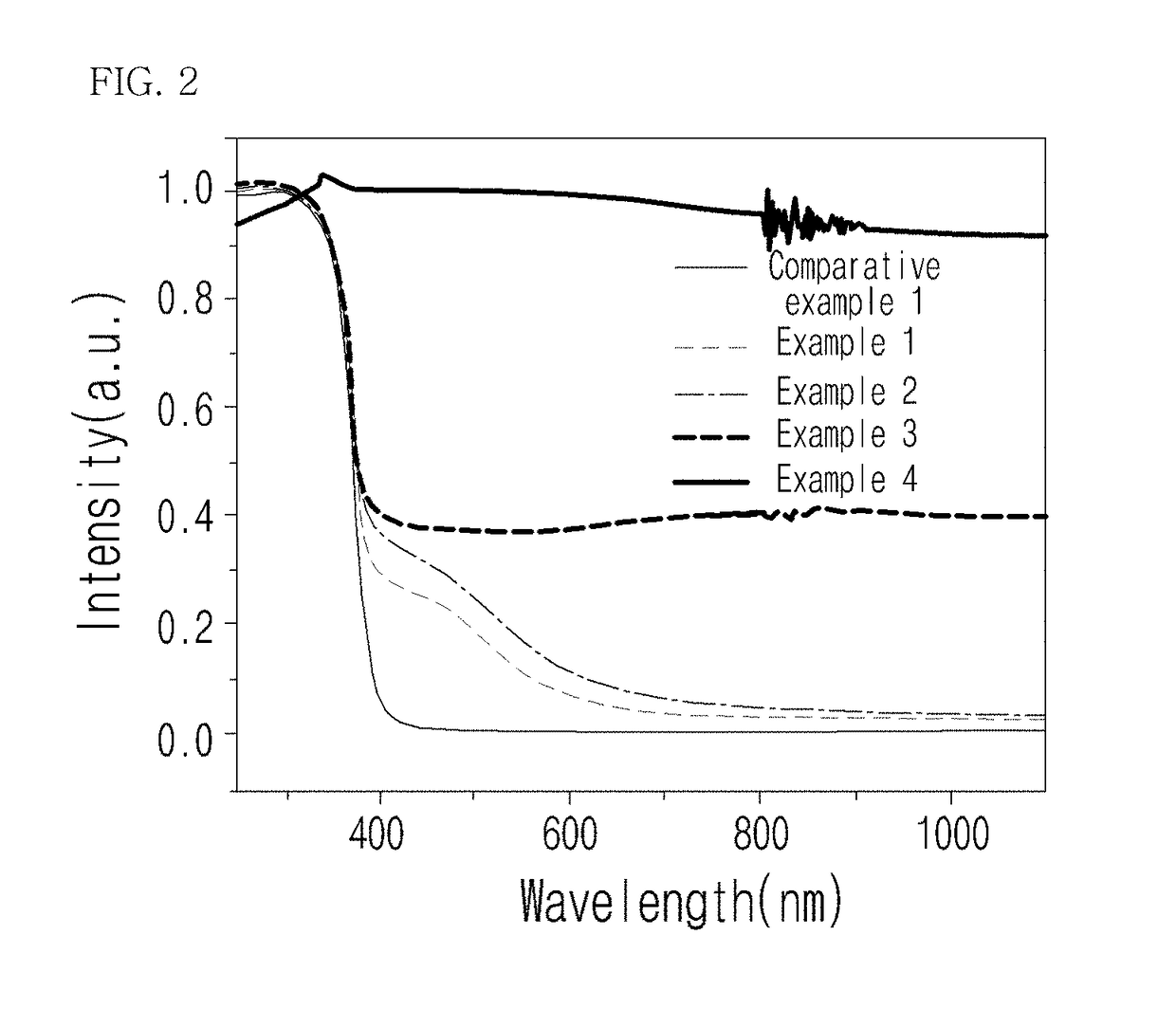

Preparation method of black rutile phase titanium dioxide

The invention discloses a preparation method of black rutile phase titanium dioxide, which comprises the following steps: taking an amorphous titanium oxide precursor, heating to 600 DEG C or above, and calcining for 2-4 hours to obtain white rutile phase titanium dioxide; adding white rutile phase titanium dioxide into a hydrochloric acid aqueous solution, carrying out ultrasonic dispersion, adding metal powder, stirring for 15 minutes or more, centrifuging, taking the precipitate, washing, and drying to obtain black rutile phase titanium dioxide. The process is simple, no toxic and hazary agents is related, production cost is low, the preparation method is simple in process and short in period, the requirement for industrial large-batch production can be met, the obtained black rutile phase titanium dioxide can strongly absorb ultraviolet light, visible light and infrared light in the whole solar spectrum, sunlight can be effectively utilized for a catalytic reaction, and the problemthat an existing rutile phase TiO2 is low in sunlight utilization rate is solved.

Owner:苏州机数芯微科技有限公司

Titanate and titania nanostructures and nanostructure assemblies, and methods of making same

ActiveUS8440162B1Improve photocatalytic performanceImprove scalabilityMaterial nanotechnologyHydrogenMicrometer scaleTitanium

The invention relates to nanomaterials and assemblies including, a micrometer-scale spherical aggregate comprising: a plurality of one-dimensional nanostructures comprising titanium and oxygen, wherein the one-dimensional nanostructures radiate from a hollow central core thereby forming a spherical aggregate.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

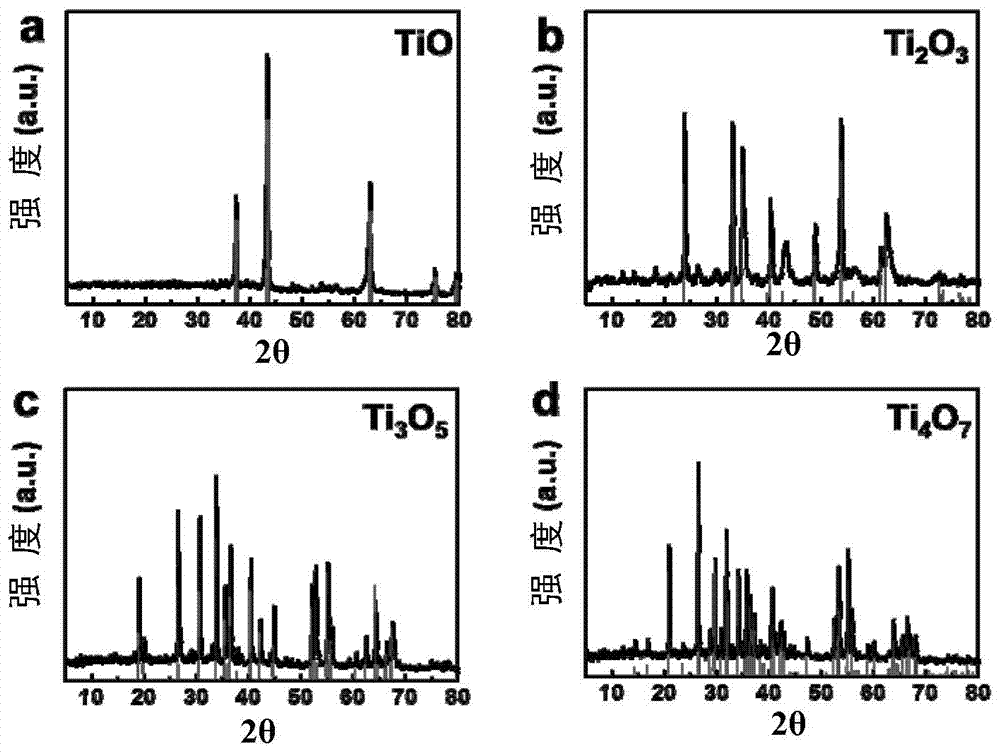

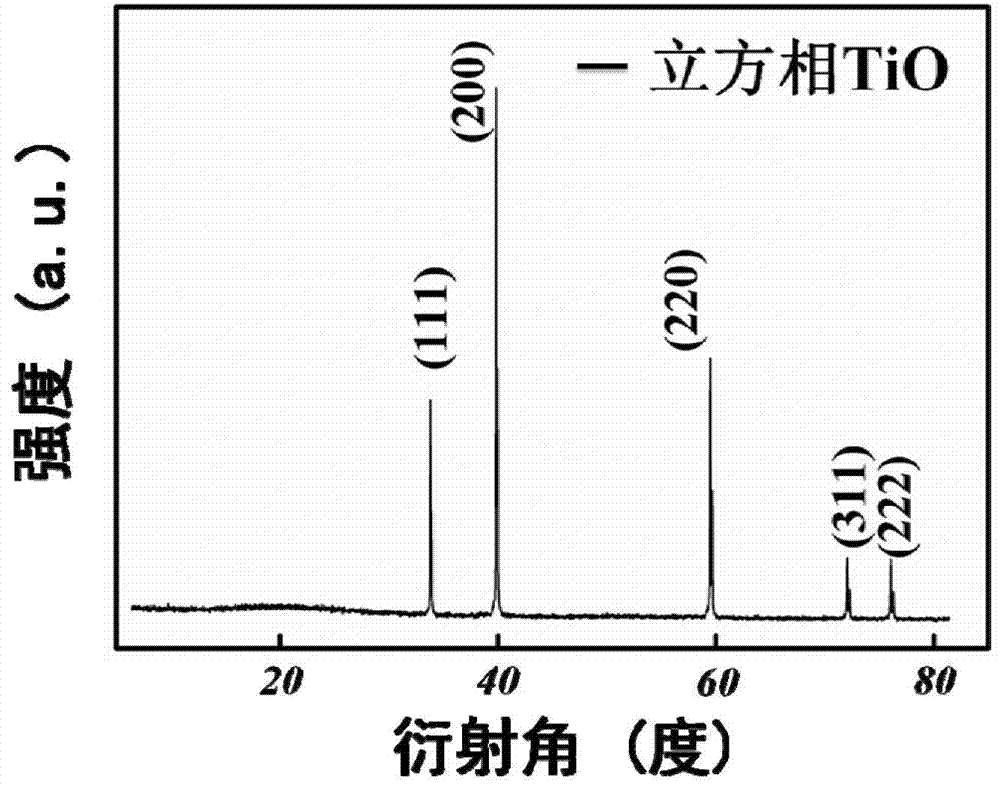

Method for controllably preparing oxide powder of titanium

ActiveCN107416896AControllable titania ratioControllable oxygen ratioTitanium suboxidesCrystallinityTitanium powder

The invention relates to a method for controllably preparing oxide powder of titanium. The method comprises the steps of weighing titanium powder and perchlorate, mixing the titanium powder and the perchlorate, then, putting the mixture into a vacuum-tight quartz tube, and carrying out a reaction for 10 to 30 hours at the high temperature of 400 DEG C to 1,100 DEG C, thereby obtaining the oxide powder of titanium. According to the method, a halide is produced during the reaction and can serve as a cosolvent of the reaction; and due to the addition of the halide cosolvent, the diffusion is accelerated, the reaction time is greatly shortened, and the crystallinity and purity of oxides of transition-metal titanium are guaranteed.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

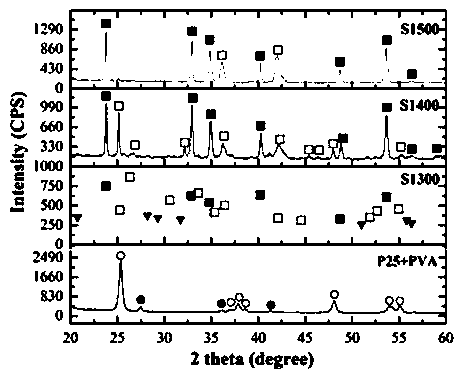

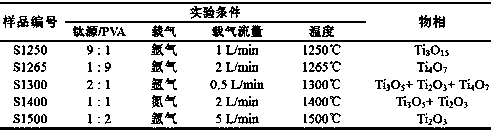

Method for rapidly preparing carbon-coated nano TinO2n-1@C nano powder

PendingCN110182842ARealize continuous preparationShort preparation cycleMaterial nanotechnologyTitanium suboxidesMaterials preparationPolyvinyl alcohol

The invention discloses a method for rapidly preparing carbon-coated nano TinO2n-1@C nano powder, and belongs to the technical field of powder material preparation. The method of the invention includes the steps of using a mixture of metatitanic acid or titanium dioxide and polyvinyl alcohol as raw materials, and using argon gas or nitrogen gas as carrier gas to be transported to a rapid heat treatment furnace at a gas flow rate of 0.5 L / min to 5 L / min; enabling the material to react at a high temperature reaction region and then to settle at a condensation region during the falling process inthe furnace, and then obtaining the carbon-coated nano TinO2n-1@C (n is an integer from 2 to 9) powder at a collection region, wherein the morphology is spherical or ellipsoidal; by adoption of the method, rapid preparation and short process of carbon-coated TinO2n-1@C can be realized.

Owner:KUNMING UNIV OF SCI & TECH

One-dimensional metal nanostructures

Tin powder is heated in a flowing stream of an inert gas, such as argon, containing a small concentration of carbon-containing gas, at a temperature to produce metal vapor. The tin deposits as liquid on a substrate, and reacts with the carbon-containing gas to form carbon nanotubes in the liquid tin. Upon cooling and solidification, a composite of tin nanowires bearing coatings of carbon nanotubes is formed.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for preparing graphite-titanium low-valence oxide composite material

ActiveCN106865602ALow requirements for production equipmentLow production environment requirementsTitanium suboxidesAir atmosphereCompression molding

The invention relates to the field of inorganic composite materials and in particular relates to a method for preparing a graphite-titanium low-valence oxide composite material. The preparation method disclosed by the invention mainly comprises the following steps: preparing materials, performing compression molding, performing high-temperature reduction, and performing ball-milling, thereby obtaining the graphite-titanium low-valence oxide (titanium black) composite material. According to the composite powder prepared by the invention, TiO2 (or metatitanic acid) and graphite are mainly taken as raw materials, a carbon thermal reduction method is adopted, and the graphite-titanium low-valence oxide (titanium black) composite material is prepared in an air atmosphere. The method has the characteristics that the process is simple, the requirements on production equipment and production environment are low, the raw materials are low in price and huge in storage capacity, and the process method is convenient for large-scale industrial production.

Owner:攀枝花市弘正钒钛科技有限公司

Method for preparing Ti4O7

InactiveCN109019677ALow equipment requirementsLow reaction conditionsTitanium suboxidesTitanium powderMicrowave sintering

The invention relates to a method for preparing Ti4O7 and belongs and belongs to the technical field of titanium materials, aiming at solving the technical problems that the quality of a product of anexisting preparation method of the Ti4O7 is not high and requirements on preparation conditions are high. Aiming at solving the technical problems, the invention provides the method for preparing theTi4O7; the method comprises the following steps: uniformly mixing prepared titanium powder and TiO2 according to the mol ratio of 1 to 7; carrying out microwave sintering at the sintering temperatureof 600 to 1200 DEG C, so as to obtain the Ti4O7. The method provided by the invention has the advantages that a technology is simple and easy to control, the quality of the product is high and an industrialization prospect is good.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com