Method for preparing nano titanium sub-oxide by utilizing high-temperature plasma

A high-temperature plasma, titanium oxide technology, applied in the direction of titanium oxide/hydroxide, nanotechnology, low-value titanium oxide, etc., can solve the problem of long preparation time, and achieve the effect of controllable process and short process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: The method for preparing nano-titanium suboxide by this high-temperature plasma, the specific operations are as follows:

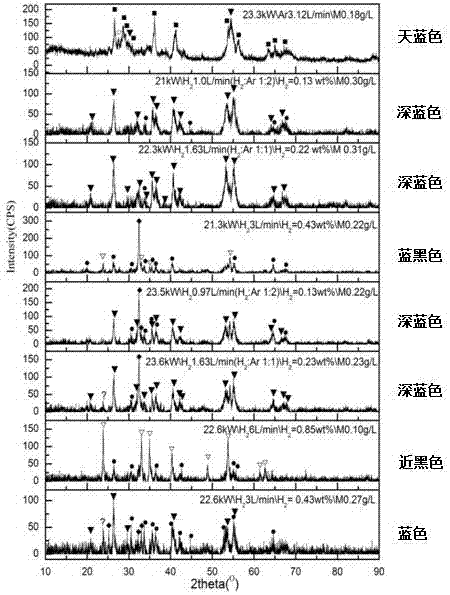

[0021] Using argon as the carrier gas with a flow rate of 3.12L / min, transport 15g of nano-scale rutile-type metatitanic acid powder into the plasma reaction device, and turn on the argon excitation gas source to excite high-temperature plasma, metatitanic acid powder After passing through the plasma high-temperature flame area within 1 second, the powder enters the powder condensation collection system driven by the airflow, and quickly obtains titanium dioxide powder with a particle size of 50-100nm. Using the same method, the carrier gas is exchanged For different proportions of argon and hydrogen, titanium dioxide powders with different colors are obtained. The color of the sample and the corresponding phase are as follows figure 1 As shown, with the increase of the hydrogen content in the carrier gas, the Ti n o 2n-1 The smaller...

Embodiment 2

[0022] Embodiment 2: The method for preparing nano-titanium suboxide by this high-temperature plasma, the specific operations are as follows:

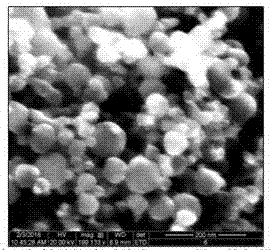

[0023] Use a carrier gas with a volume flow ratio of hydrogen and argon of 1:1 and a flow rate of 6L / min to transport 20g of anatase nanoscale metatitanic acid into the plasma reaction device, and turn on the argon excitation gas source to excite high-temperature plasma , after the metatitanic acid powder passes through the plasma high-temperature flame area within 1 second, it enters the powder condensation collection system under the drive of the airflow, and quickly obtains dark blue spherical Ti 4 o 7 Powder, its particle size is 50~100nm, its appearance is as figure 2 shown.

Embodiment 3

[0024] Embodiment 3: The method for preparing nano-titanium suboxide by this high-temperature plasma, the specific operation is as follows:

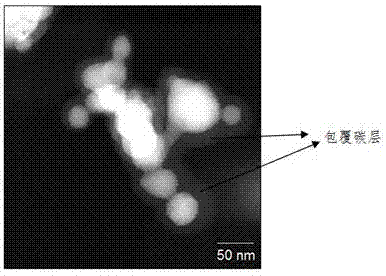

[0025] Graphite tubes are used as the lining around the high-temperature plasma flame area in the high-temperature plasma generation system, and the mixed gas of hydrogen and argon with a volume flow ratio of 1:2 is used as the carrier gas, and 20g of rutile nanoscale is used at a flow rate of 4L / min. The metatitanic acid is delivered to the plasma reaction device, and the helium excitation gas source is turned on to excite the high-temperature plasma. After the metatitanic acid powder passes through the plasma high-temperature flame area within 1 second, it enters the powder to condense and collect under the drive of the airflow. system, quickly obtain carbon-coated spherical Ti 4 o 7 Powder, its particle size is 50~80nm, its appearance is as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com