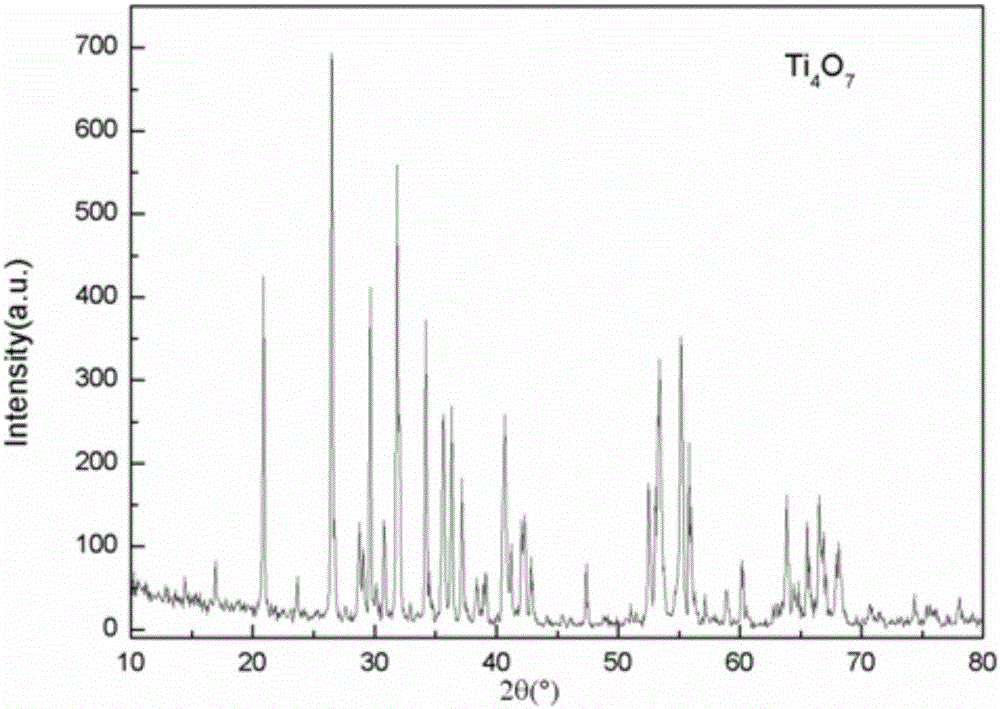

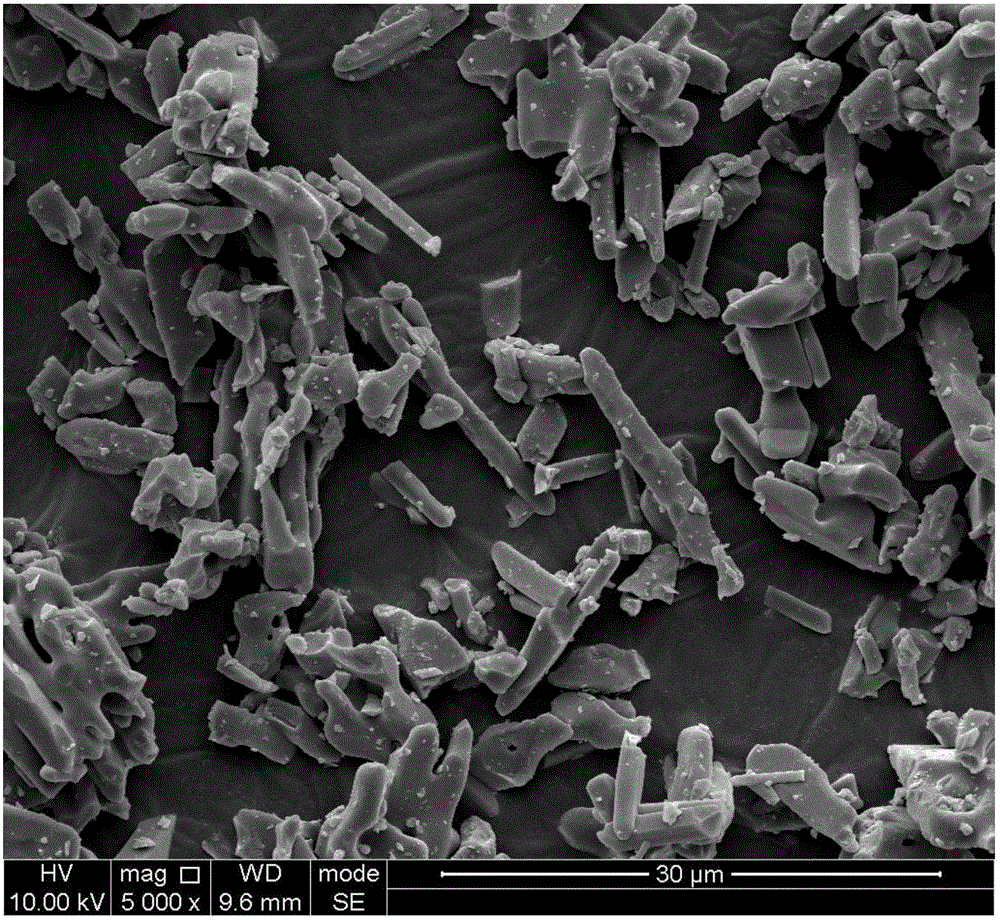

Rod-like titanium protoxide powder and preparation method thereof

A technology of titanium dioxide and titanium dioxide, which is applied in the field of rod-shaped titanium dioxide powder and its preparation, can solve the problems of battery stability and life reduction, Pt particle migration and growth, and application limitations, etc., and achieve just fast diffusion speed and abundant The effect of type and group ratio is accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of the sub-rod-shaped titanium oxide powder described in this embodiment is as follows:

[0043] (1) Ingredients

[0044] micron TiO 2 Powder, nano-carbon black, sodium chloride, and potassium chloride are used as raw materials, and the raw materials are measured according to the molar ratio of the following components and components:

[0045] Micron TiO 2 Powder: nano carbon black: sodium chloride: sodium chloride = 9:0.8:1.5:2.5

[0046] (2) Mixing and drying

[0047] The raw materials measured in step (1) are loaded into a ball mill, cemented carbide balls are added as grinding spheres, absolute ethanol is added as a ball milling medium, and ball milling is carried out for 72 hours to obtain a mixed wet material. The ball mass ratio of the balls is 6: 1, the addition of the wet grinding medium is limited to immerse the raw material and the grinding sphere;

[0048] (3) Sintering

[0049] Put the mixed powder obtained in step (2) into a he...

Embodiment 2

[0053] The preparation method of the sub-rod-shaped titanium oxide powder described in this embodiment is as follows:

[0054] (1) Ingredients

[0055] micron TiO 2 Powder, graphite powder, and sodium chloride are used as raw materials, and the raw materials are measured according to the molar ratio of the following components and components:

[0056] Micron TiO 2 Powder: graphite powder: sodium chloride = 9:1:2

[0057] (2) Mixing and drying

[0058] The raw materials measured in step (1) are loaded into a ball mill, cemented carbide balls are added as grinding spheres, deionized water is added as a ball milling medium, and ball milling is carried out for 12 hours to obtain a mixed wet material, and the ball milling mass ratio is 10: 1, the addition of the wet grinding medium is limited to immerse the raw material and the grinding sphere;

[0059] (3) Sintering

[0060] Put the mixed powder obtained in step (2) into a heating furnace, raise the temperature to 710°C at a...

Embodiment 3

[0064] The preparation method of the sub-rod-shaped titanium oxide powder described in this embodiment is as follows:

[0065] (1) Ingredients

[0066] micron TiO 2 Powder, charcoal powder, and zinc chloride are used as raw materials, and the raw materials are measured according to the molar ratio of the following components and components:

[0067] Micron TiO 2 Powder: graphite powder: zinc chloride = 9:1.2:6

[0068] (2) Mixing and drying

[0069] Put the raw materials measured in step (1) into the ball mill, add cemented carbide balls as grinding balls, add acetone as the ball milling medium, and ball mill for 36 hours to obtain a mixed wet material. , the addition of wet grinding medium is limited to immersing the raw material and grinding sphere;

[0070] (3) Sintering

[0071] Put the mixed powder obtained in step (2) into a heating furnace, raise the temperature to 700°C at a rate of 15°C / min under a flowing argon atmosphere and keep it warm for 4 hours. After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com