Method for preparing spherical TinO(2n-1) from plasma

A technology of titanium dioxide and plasma, which is applied in the field of plasma preparation of spherical titanium dioxide, can solve the problems of long process flow and achieve the effects of good product uniformity, less agglomeration and fast preparation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

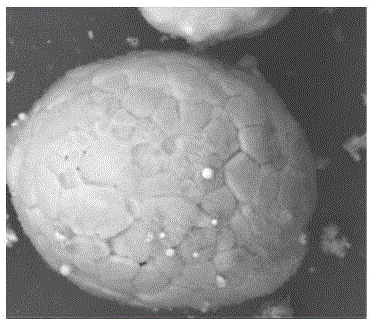

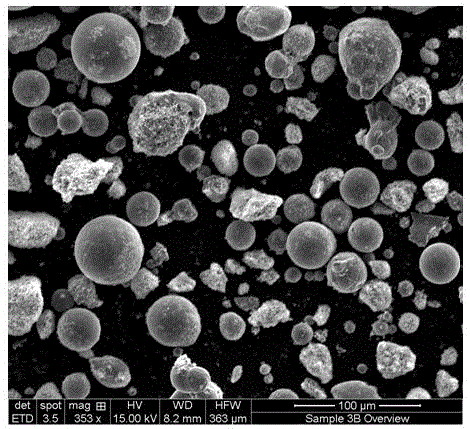

[0015] Example 1: A method for preparing spherical titanium dioxide by plasma: pass the titanium dioxide powder through a 200-mesh sieve, take the under-sieve, and then transport it to a high-temperature plasma reactor through a carrier gas (the carrier gas is argon) In the high-temperature plasma flame area, under the carrier gas (argon) atmosphere, the titanium dioxide powder undergoes a reduction reaction, and then is driven by the gas to settle through the condensation zone of the cooling device to obtain spherical titanium dioxide powder (Ti n o 2n-1 , 3≤n≤10); wherein the titanium dioxide powder is rutile, the flow rate of the carrier gas (argon) is 5L / min, and the ion excitation gas of the high temperature plasma reactor is argon;

[0016] The obtained spherical titanium oxide powder (Ti n o 2n-1 , 3≤n≤10) is blue titanium dioxide powder with a particle size of 30~150μm.

Embodiment 2

[0017] Example 2: A method for preparing spherical titanium dioxide by plasma: pass the titanium dioxide powder through a 300-mesh sieve, get its undersize, and then pass the carrier gas (the carrier gas is a mixture of argon and hydrogen, argon and The volume ratio of hydrogen (1:1) is transported to the high-temperature plasma flame area in the high-temperature plasma reactor. Under the atmosphere of carrier gas (a mixture of argon and hydrogen), the titanium dioxide powder undergoes a reduction reaction, and then driven by the gas After passing through the condensation zone of the cooling device, the spherical titanium dioxide powder (Ti n o 2n-1 , 3≤n≤10); wherein the titanium dioxide powder is anatase, the flow rate of the carrier gas (a mixture of argon and hydrogen) is 0.5L / min, and the ion excitation gas of the high temperature plasma reactor is argon and hydrogen the gas mixture;

[0018] The obtained spherical titanium oxide powder (Ti n o 2n-1 , 3≤n≤10) is a dar...

Embodiment 3

[0019] Example 3: A method for preparing spherical titanium dioxide by plasma: pass the titanium dioxide powder through a 400-mesh sieve, take the under-sieve, and then transport it to a high-temperature plasma reactor through a carrier gas (the carrier gas is hydrogen) In the high-temperature plasma flame area, under the carrier gas (hydrogen) atmosphere, the titanium dioxide powder undergoes a reduction reaction, and then is driven by the gas to settle through the condensation zone of the cooling device to obtain spherical titanium dioxide powder (Ti n o 2n-1 , 3≤n≤10); wherein the titanium dioxide powder is rutile type, the flow rate of the carrier gas (hydrogen gas) is 1.0L / min, and the ion excitation gas of the high temperature plasma reactor is hydrogen gas;

[0020] The obtained spherical titanium oxide powder (Ti n o 2n-1 , 3≤n≤10) is a dark black titanium oxide powder with a particle size of 10-50 μm. The titanium oxide powder obtained in this example (Ti n o 2n-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com