Method for controllably preparing oxide powder of titanium

A technology of oxide powder and titanium powder, applied in the direction of low-value titanium oxide, titanium oxide/hydroxide, etc., can solve the problems of difficult to quantify the amount of oxygen, increase the risk, unstable oxygen content, etc., and achieve the reaction time. Shortening, crystallinity and purity assurance, effect of accelerated diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The method for preparing titanium oxide powder provided by the present invention is exemplarily described below.

[0027] Mix titanium powder and perchlorate in a vacuum-tight quartz tube. Specifically, a certain mass of titanium powder and perchlorate was weighed according to different proportions, transferred to a quartz tube, and then vacuum-packed in the quartz tube. Among them, the vacuum sealing device should make the inside of the quartz tube in a vacuum state (the pressure should be less than 10 -3 Torr), and then use the oxyhydrogen flame device to complete the vacuum packaging of the quartz glass tube. The particle diameter of the titanium powder may range from 1 to 50 microns. The perchlorate described in the present invention can be selected from potassium perchlorate, lithium perchlorate, sodium perchlorate, etc. if it satisfies high decomposition of oxygen and halides.

[0028] The vacuum-encapsulated quartz tube is placed in a muffle furnace for high-t...

Embodiment 1

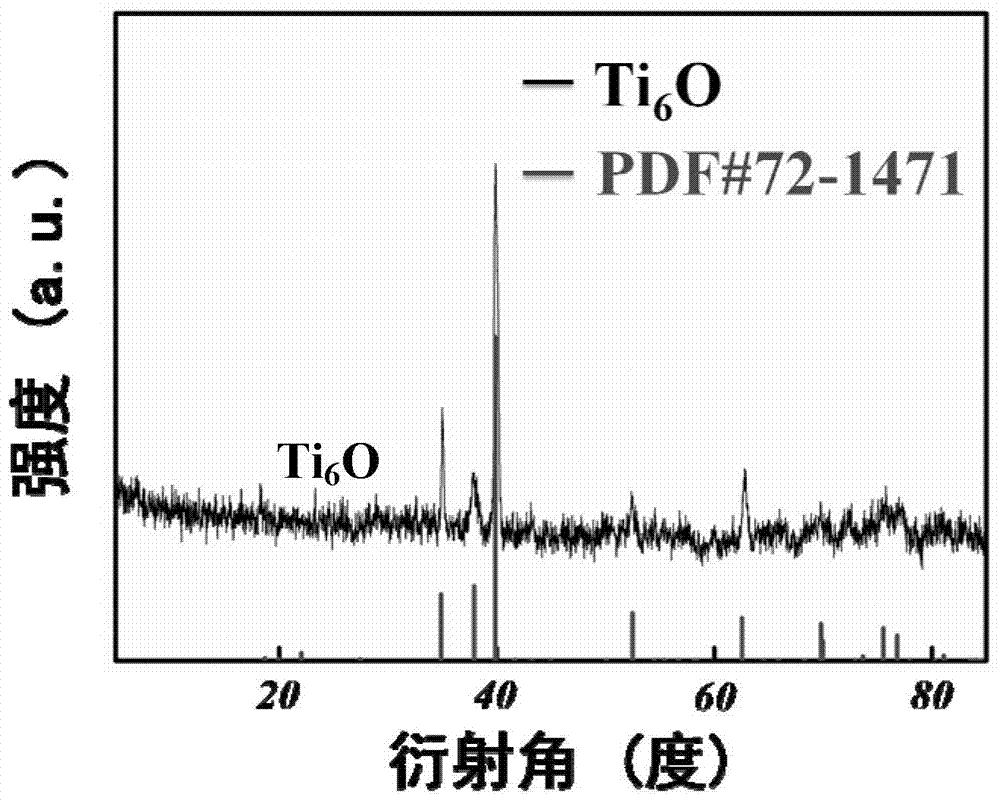

[0034] Weigh 22.8 mg of potassium perchlorate and 189.4 mg of titanium metal powder, mix well, transfer to the quartz tube, and then -3 Under the vacuum condition of Torr, the quartz glass tube was sealed with a hydrogen-oxygen flame gun tube sealing device. Then transfer the quartz tube to a muffle furnace, slowly raise the temperature to 450 degrees, and keep it warm for 20 hours. After the sintering is completed, it is cooled to room temperature with the furnace. After opening the tube, soak it in distilled water to dissolve the potassium chloride produced during the reaction. Then, filter, and finally, after vacuum drying in a 60-degree oven, you can get Ti 6 O powder.

Embodiment 2

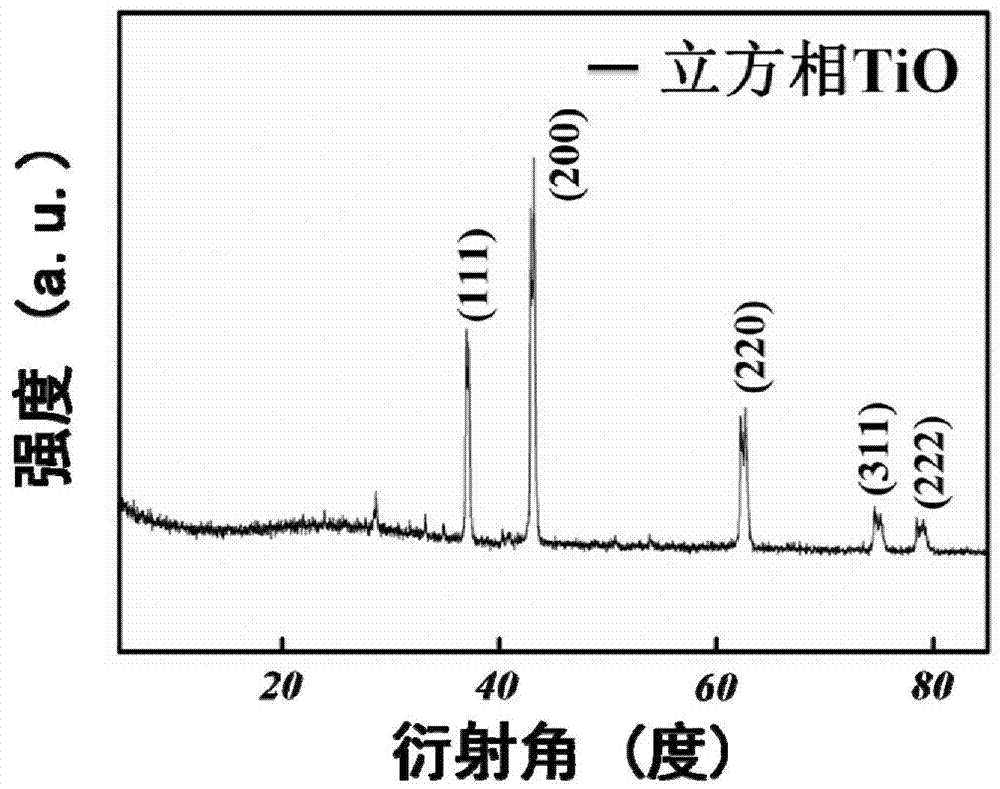

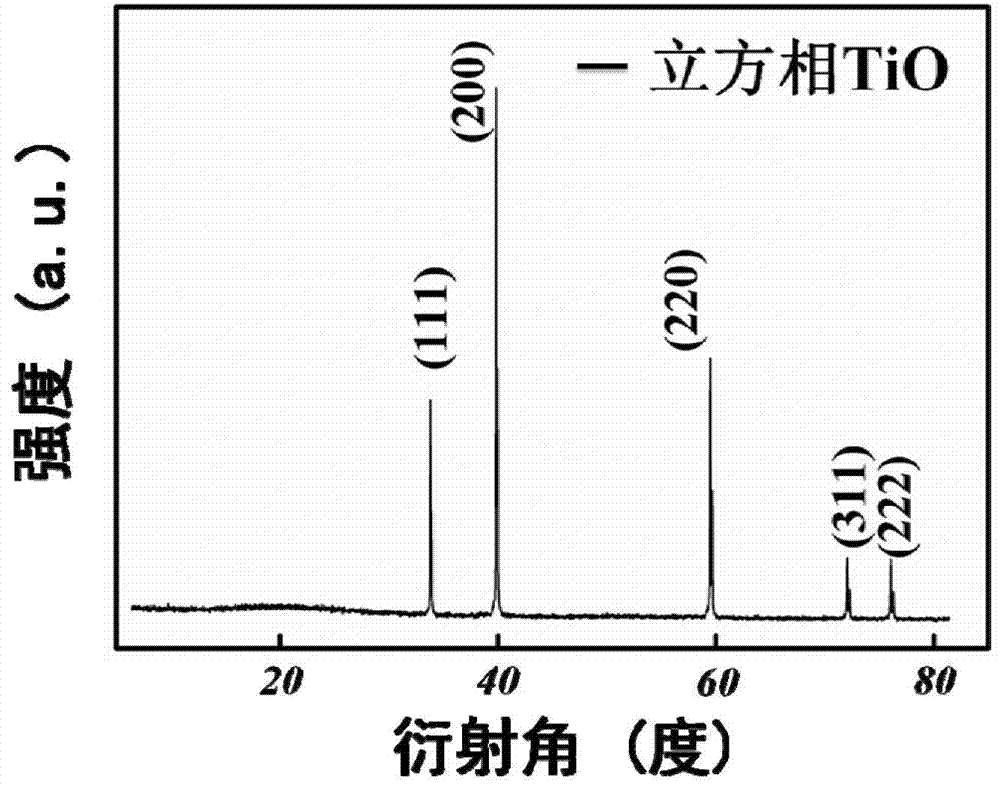

[0036] Weigh 43.4 mg of potassium perchlorate and 180 mg of titanium metal powder, mix well, transfer to a quartz tube, and then -3 Under the vacuum condition of Torr, the quartz glass tube was sealed with a hydrogen-oxygen flame gun tube sealing device. Then transfer the quartz tube to a muffle furnace, slowly raise the temperature to 450 degrees, and keep it warm for 20 hours. After the sintering is completed, it is cooled to room temperature with the furnace. After opening the tube, soak it in distilled water to dissolve the potassium chloride produced during the reaction. Then, filter, and finally, after vacuum drying in a 60-degree oven, you can get Ti 3 O powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com