High active high medium oil selective hydrocracking catalyst and preparation thereof

A hydrocracking, high-medium oil technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low catalyst hydrocracking activity, high catalyst hydrocracking activity, and high medium oil selectivity , to achieve the effects of reducing metal loss, excellent performance, and improving medium oil selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

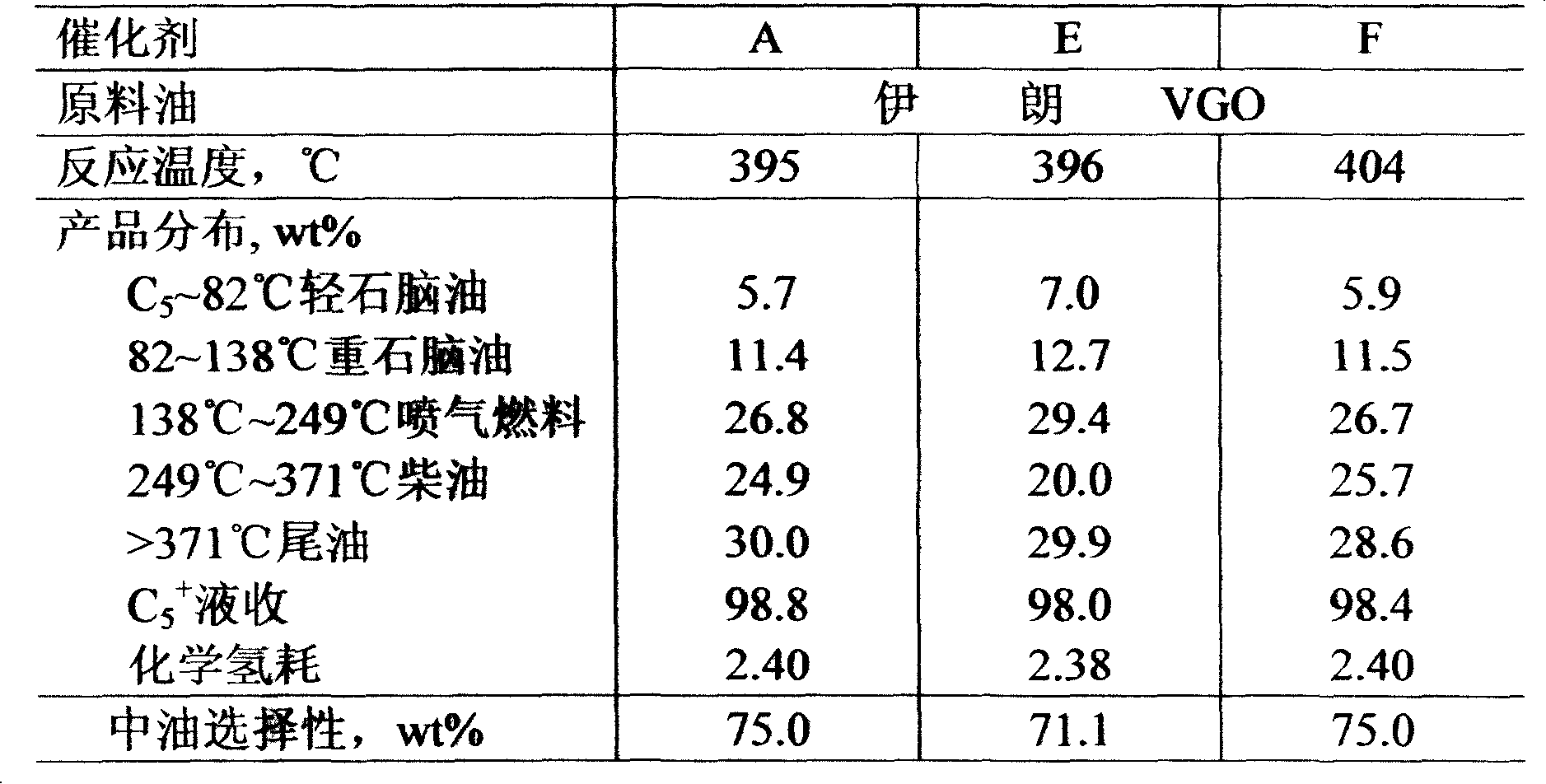

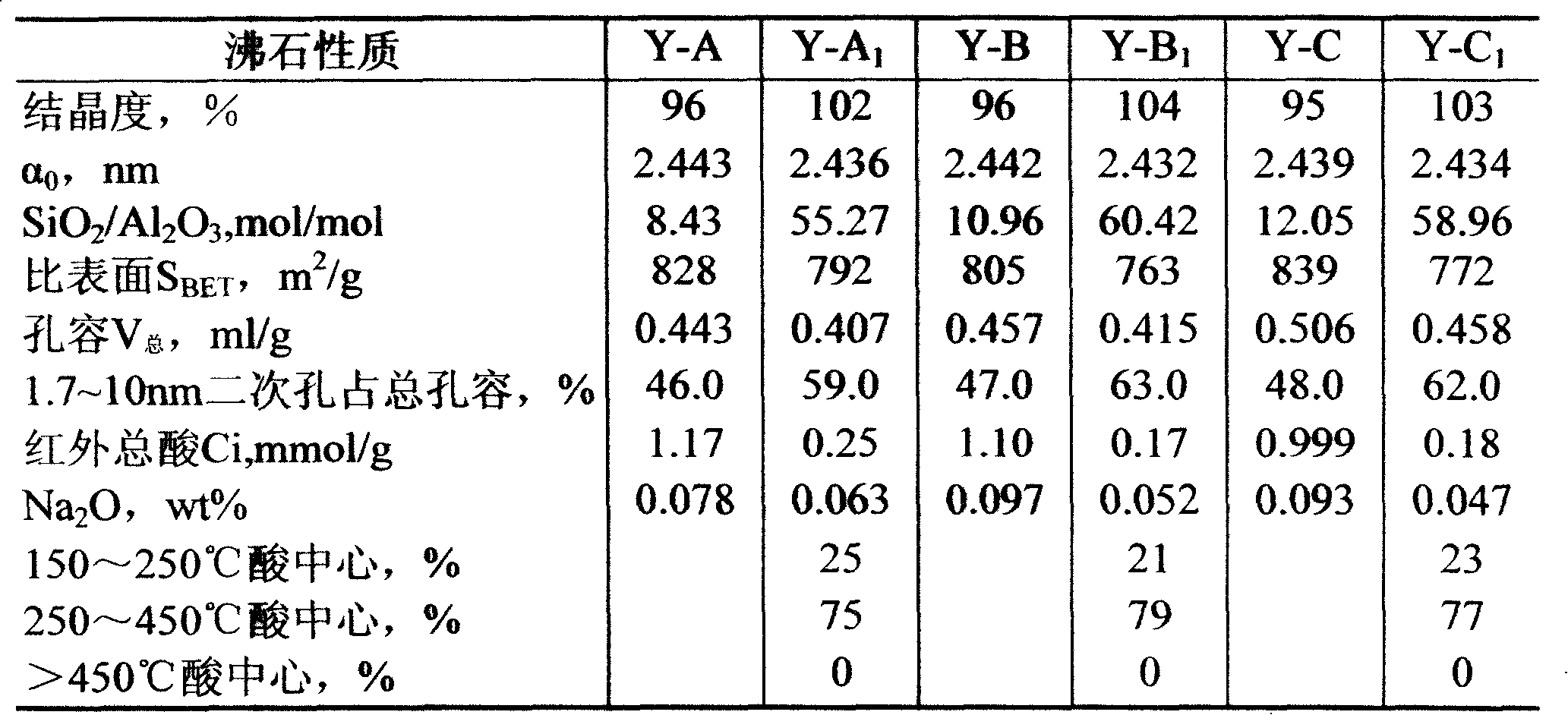

[0022] Catalyst A is the catalyst prepared by the inventive method, and catalyst weight is composed of: WO 3 22.0%, NiO 9.0%, ZrO 2 7% SiO 2 33%, Al 2 o 329%, of which the molecular sieve content is 20%, and the specific surface area is 240m 2 / g, the pore volume is 0.34ml / g.

[0023] Concrete preparation steps are as follows:

[0024] (1) Prepare Al-containing 2 o 3 600 ml of aluminum chloride solution with a concentration of 90 g / l, containing NiO 200 ml of nickel chloride solution with a concentration of 140 g / l, containing ZrO 2 150ml of 140g / l zirconium oxychloride solution was mixed in a 5 liter container and diluted with 2000ml of clean water.

[0025] (2) Prepare dilute water glass solution, containing SiO 2 550 milliliters of water glass solution of 75g / l, under stirring situation, (2) is added in (1);

[0026] (3) Add ammonia water to the mixture of (1) and (2) under stirring until the pH value is 5.2;

example 2

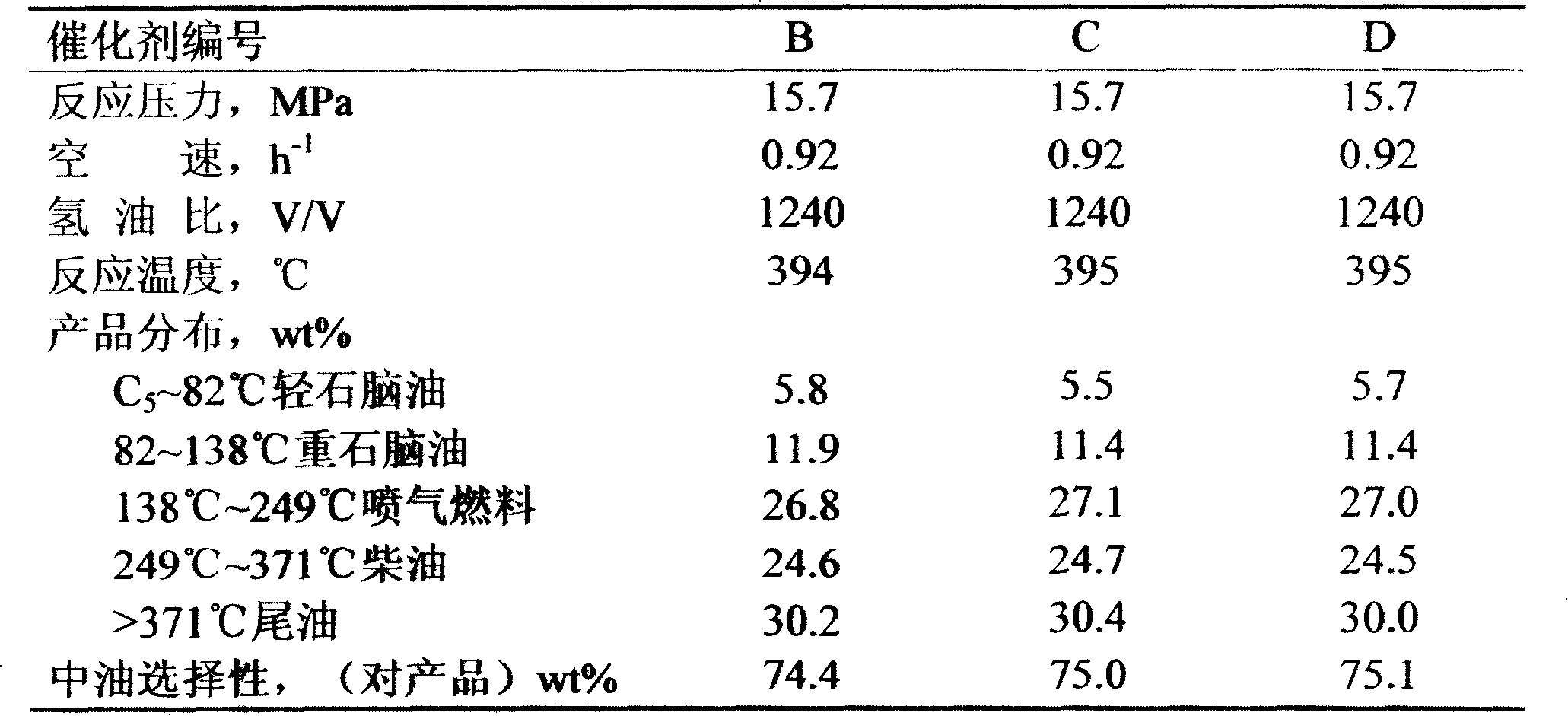

[0035] It is the hydrocracking catalyst B of the present invention, and the preparation method is the same as that of Example 1, except that 25% of the Y-type molecular sieve modified by hydrothermal treatment is added before aging, and the molecular sieve Y-B prepared by ZL96119840.0 Example 2 is used as a raw material for the molecular sieve, and the Hydrothermal treatment, hydrothermal treatment conditions are temperature 700 ° C, pressure 0.3 MPa, time 22 hours, then acid treatment, using 0.5M sulfuric acid 3000 ml, sulfuric acid and molecular sieve weight ratio is 1: 2, temperature 30 ° C, time 1 hour, Obtain modified molecular sieve Y-B 1 , Y-B and Y-B 1 The properties are shown in Table 3. Catalyst weight composition is: WO 3 21.0%, NiO 7.5%, ZrO 2 6.5% SiO 2 30%, Al 2 o 3 35%, the specific surface is 260m 2 / g, the pore volume is 0.36ml / g.

example 3

[0037] It is the hydrocracking catalyst C of the present invention, and the preparation method is the same as Example 1, except that the Y-type molecular sieve modified by hydrothermal treatment is added before aging to be 17%, and the molecular sieve Y-C prepared by ZL96119840.0 embodiment 3 is used as a raw material for the molecular sieve, and the Hydrothermal treatment, hydrothermal treatment conditions are temperature 650 ° C, pressure 0.2 MPa, time 28 hours, then acid treatment, use 3.0 M hydrochloric acid 8500 ml, hydrochloric acid and molecular sieve weight ratio is 1: 18, temperature 60 ° C, time 3 hours , to get modified molecular sieve Y-C 1 , Y-C and Y-C 1 The properties are shown in Table 3. Catalyst weight composition is: WO 3 23.6%, NiO 7.4%, ZrO 2 7% SiO 2 31%, Al 2 o 3 31%, the specific surface is 270m 2 / g, the pore volume is 0.31ml / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com