Hydrocracking catalyst and preparation method thereof

A hydrocracking and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as removing non-framework aluminum, affecting the distribution of B acid and L acid, and the cracking performance of difficult molecular sieves. Achieve the effects of increasing the specific surface, promoting the hydrogenation performance, and improving the activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Take 2000gNa 2 O content is 2.8wt% (dry basis 70.3wt%) raw material NH 4 NaY, put it into a flask with a reflux device and can be sealed, use 7800ml deionized water to make a slurry, and rapidly heat up to 95°C under stirring conditions, and then dropwise add 453 grams of six in 2 hours at a uniform speed Ammonium fluorosilicate and 3000 ml of deionized water are used to form an aqueous solution. After the addition, the slurry is kept at a constant temperature of 95° C. for 2 hours while stirring. Stop stirring, let it stand for 10 minutes, separate the molecular sieve in the upper part of the flask by decantation, wash and filter with water three times, and dry the filter cake in an oven at 120°C for 5 hours, and the code is SSY-1. The obtained SSY-1 molecular sieve is analyzed by X-ray diffraction (XRD) and plasma emission spectrum, and its unit cell parameter is 2.450nm, relative crystallinity 98%, Na 2 The O content is 0.1 wt%.

Embodiment 2

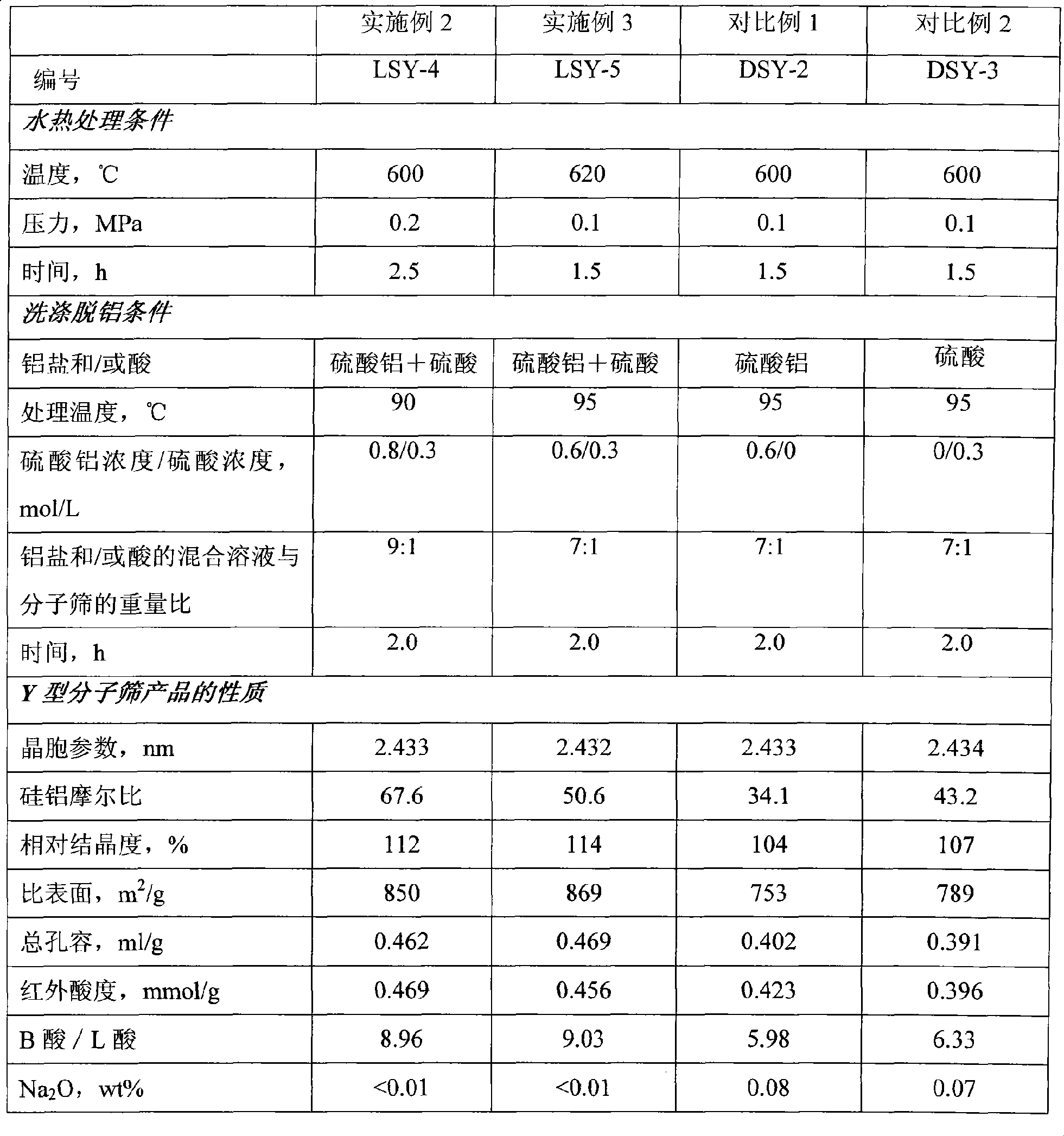

[0043] Weigh 200g of SSY-1 molecular sieve and put it into a tubular hydrothermal treatment furnace, raise the temperature to 600°C, and treat it at a gauge pressure of 0.2MPa for 2.5 hours, then put it into a closed flask with a reflux device, and add a concentration of 0.8mol / L aluminum sulfate and 0.3mol / L sulfuric acid mixed aqueous solution 1800ml, stirred at 90°C for 2 hours, filtered, and washed the filter cake with hot deionized water, and stopped washing when the pH value of the washing liquid was close to 7. The filter cake was dried in an oven at 120°C for 5 hours. No. LSY-4, see Table 1 for molecular sieve properties.

Embodiment 3

[0045] Weigh 200g of SSY-1 molecular sieve and put it into a tubular hydrothermal treatment furnace, raise the temperature to 620°C, and treat it at a gauge pressure of 0.1MPa for 1.5 hours, then put it into a closed flask with a reflux device, and add a concentration of 0.6mol / L aluminum sulfate and 0.3mol / L sulfuric acid mixed aqueous solution 1400ml, stir at 95°C for 2 hours, filter, and wash the filter cake with hot deionized water, stop washing when the pH value of the washing liquid is close to 7. The filter cake was dried in an oven at 120°C for 5 hours. No. LSY-5, molecular sieve properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell parameters | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com