Ti4O7 nano material as well as preparation method thereof and use thereof

A nano-material and nano-titanium dioxide technology, which is applied in the field of Ti4O7 nano-materials and its preparation, can solve problems such as difficult control of product quality, high operating cost, and complicated process, and achieve high degree of reduction, sufficient contact area, and improved product purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

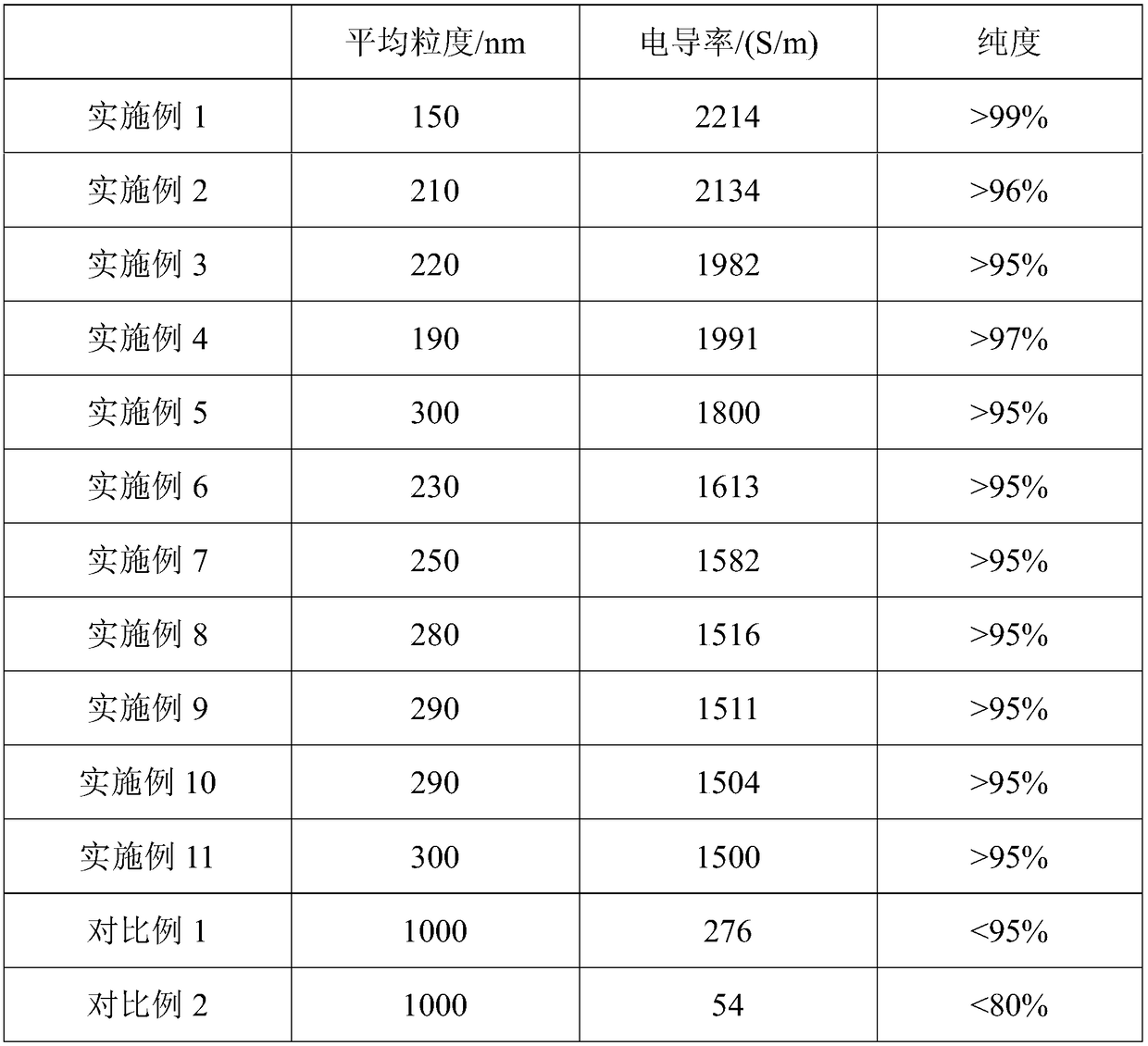

Embodiment 1

[0043] (1) Mix 70g of nano-titanium dioxide powder, 25g of activated carbon powder and 1g of glucose, place them in a ball mill jar, and perform ball milling for 10 hours with a ball-to-material ratio of 10:1 to obtain a mixed powder;

[0044] (2) Put the mixed powder in an atmosphere furnace, and heat treat the mixed powder under a nitrogen atmosphere. The heat treatment temperature is 1200°C, the heating rate is 8°C / min, and the holding time is 1h. After the reaction time expires, follow the furnace Cool down to get Ti 4 o 7 nanomaterials.

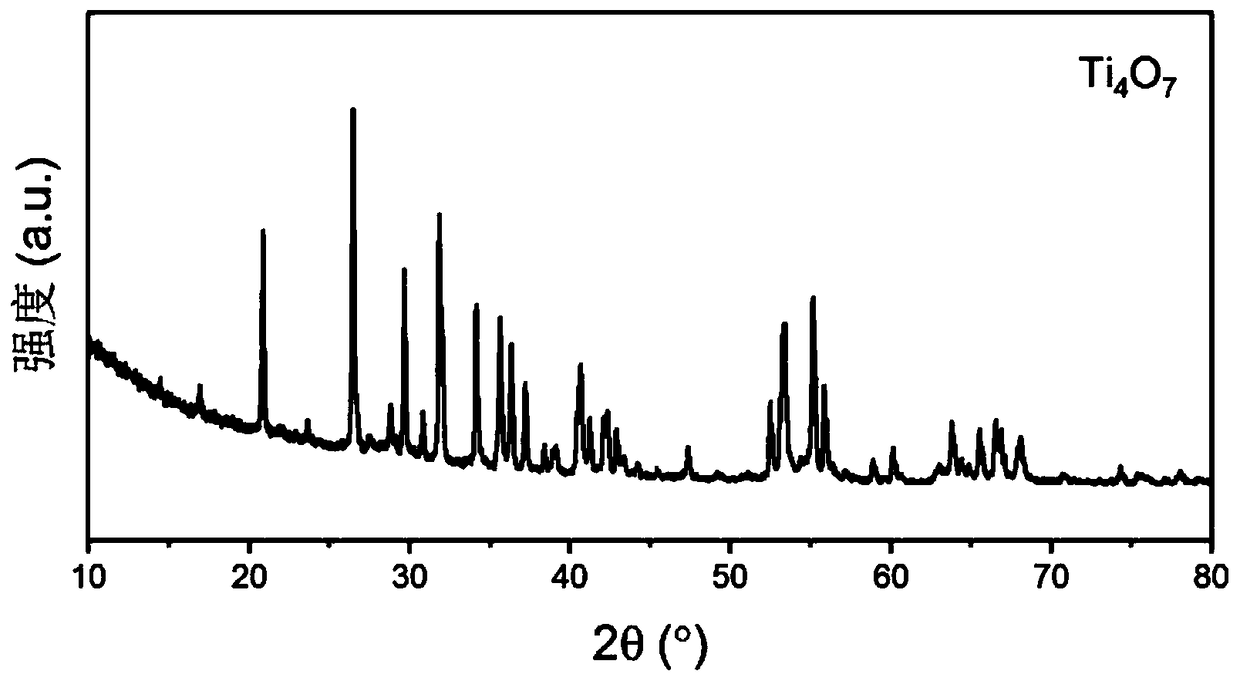

[0045] The Ti that the embodiment of the present invention 1 obtains 4 o 7 The X-ray diffraction pattern of the material is as figure 1 shown by figure 1 It can be seen that only Ti appears in the X-ray diffraction spectrum of the nanomaterial obtained by the preparation method of Example 1. 4 o 7 Diffraction peaks of the crystal structure, indicating that the main component of the nanomaterials is Ti 4 o 7 .

Embodiment 2

[0047] (1) Mix 60g of nano-titanium dioxide powder, 20g of carbon black powder and 0.3g of epoxy resin, place in a ball mill jar, and carry out ball milling for 40h with a ball-to-material ratio of 5:1 to obtain a mixed powder;

[0048] (2) Put the mixed powder in an atmosphere furnace, and heat treat the mixed powder under an argon atmosphere. The heat treatment temperature is 950°C, the heating rate is 15°C / min, and the holding time is 4h. Cool down the furnace to get Ti 4 o 7 nanomaterials.

Embodiment 3

[0050] (1) Mix 79.5g of nano-titanium dioxide powder, 20g of graphite powder and 0.5g of citric acid, place in a ball mill jar, and carry out ball milling for 20h with a ball-to-material ratio of 10:1 to obtain a mixed powder;

[0051] (2) Put the mixed powder in an atmosphere furnace, and heat-treat the mixed powder under a helium atmosphere. The heat treatment temperature is 1100°C, the heating rate is 10°C / min, and the holding time is 2h. Cool down the furnace to get Ti 4 o 7 Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com