Leaf surface resistance control agent and preparation method and applications thereof

A kind of inhibitor and foliar technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Select the waste rice husk charcoal from the industrial fixed bed pyrolysis rice husk to produce bio-oil as raw material for crushing and grinding, after passing through a 100-mesh sieve, put it into a polytetrafluoroethylene container equipped with a constant temperature magnetic stirring device in sequence for each liter of water 200g of waste rice husk charcoal and 30g of potassium hydroxide passed through a 100-mesh sieve, and then turn on the constant temperature stirring device to stir evenly, control the stirring time for 50-60min, the stirring speed of 350-400rpm and the temperature of the reaction device at 80-90°C, and finally pass through the suction filtration The device passes through a 0.45μm PES material filter membrane, and the filtrate is used as a foliar inhibitor for reducing cadmium content in brown rice. After the preparation is completed, it is measured by silicon molybdenum yellow spectrophotometry and atomic absorption spectrophotometry that each ...

experiment example 2

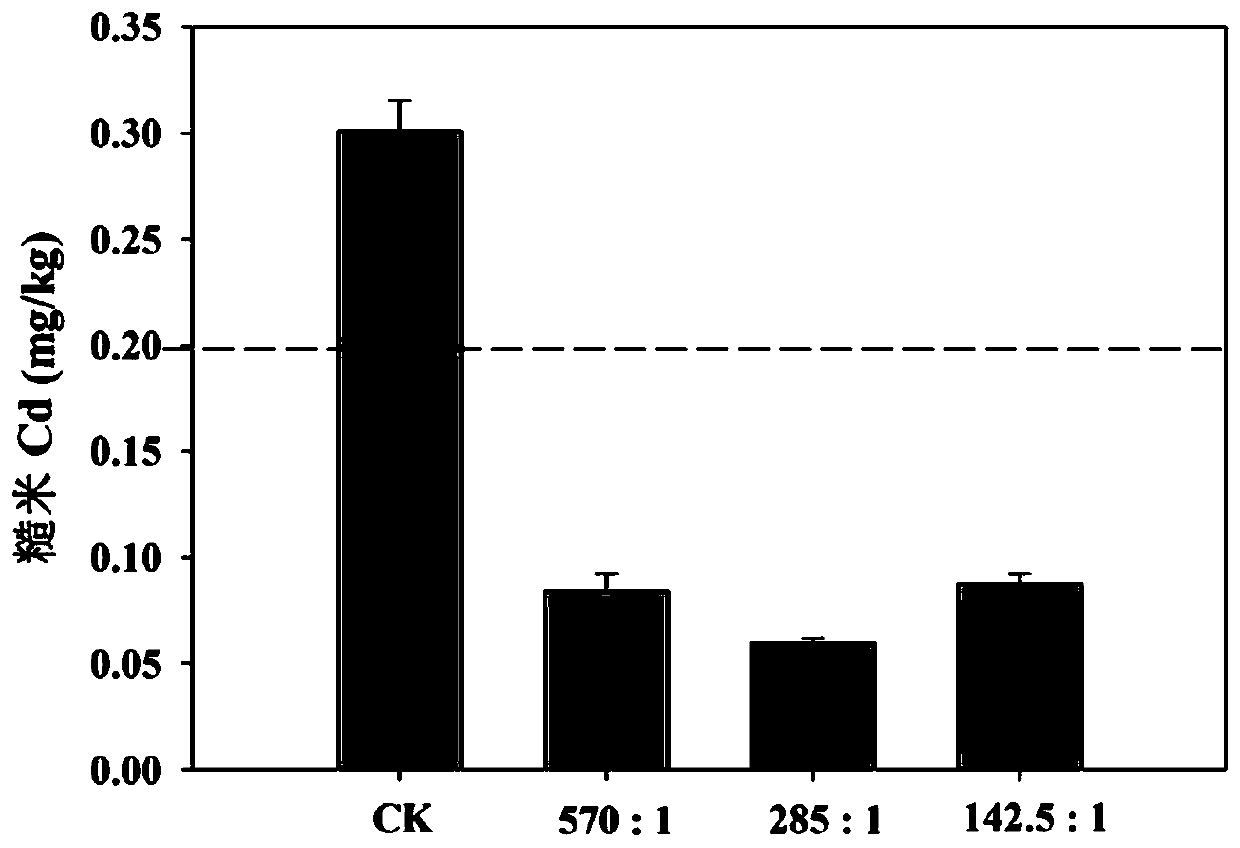

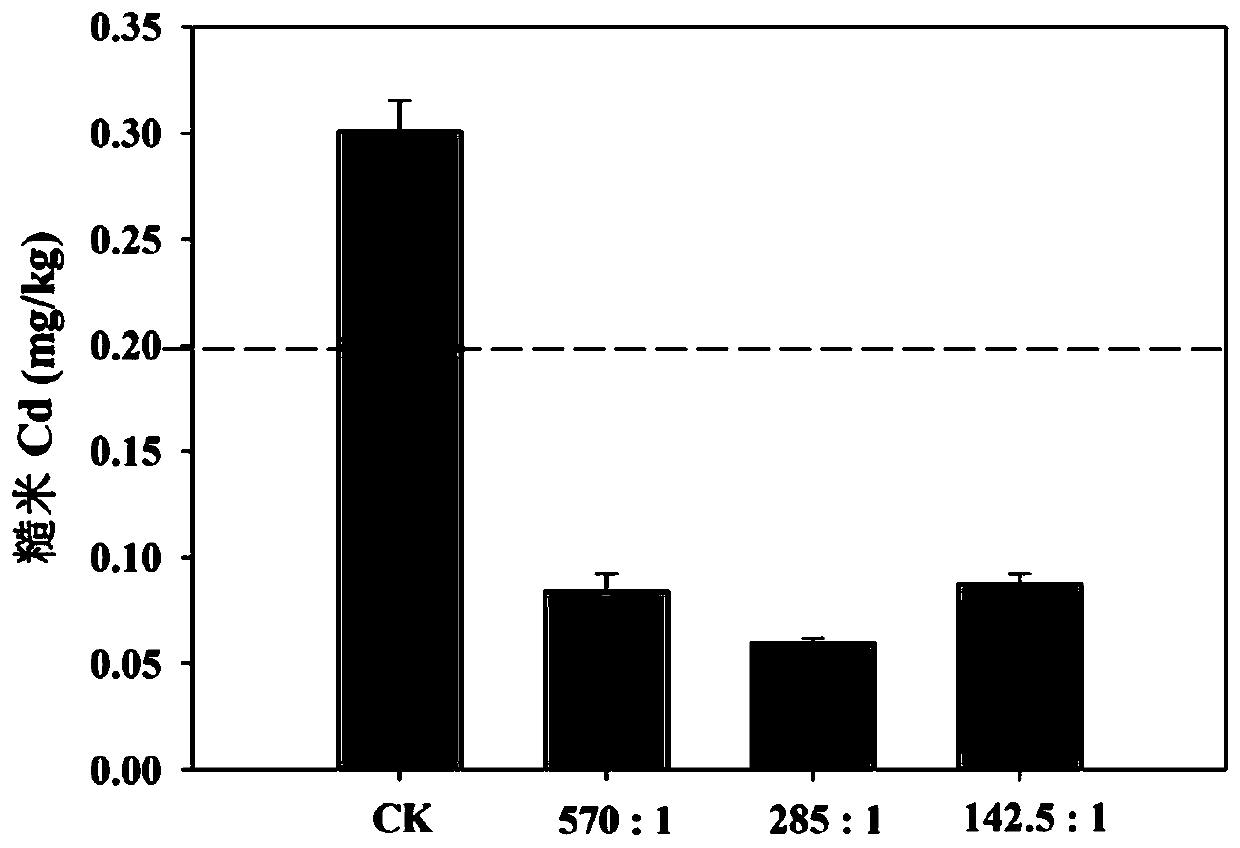

[0028] Experimental example 2: Screening for the optimal dilution ratio

[0029] Pot experiments were used to preliminarily investigate the effect of the volume ratio of dilution of the stock solution of the foliar inhibitor control agent of the present invention with surfactants on the effect of reducing the cadmium content of rice in polluted soil, in order to screen out the best dilution ratio.

[0030]The pot experiment was set up in the Wimbledon Room of the Red Soil Ecological Experiment Station of the Chinese Academy of Sciences in Yingtan City, Jiangxi Province. The soil used in the test is a paddy soil with excessive cadmium, and the basic physical and chemical properties of the soil are shown in Table 1. According to the Chinese Soil Environmental Quality Standard (GB 15618-2018), the cadmium content in the soil is between the farmland soil cadmium risk screening value and the control value, which belongs to the mild soil cadmium pollution, and more than 80% of the d...

experiment example 3

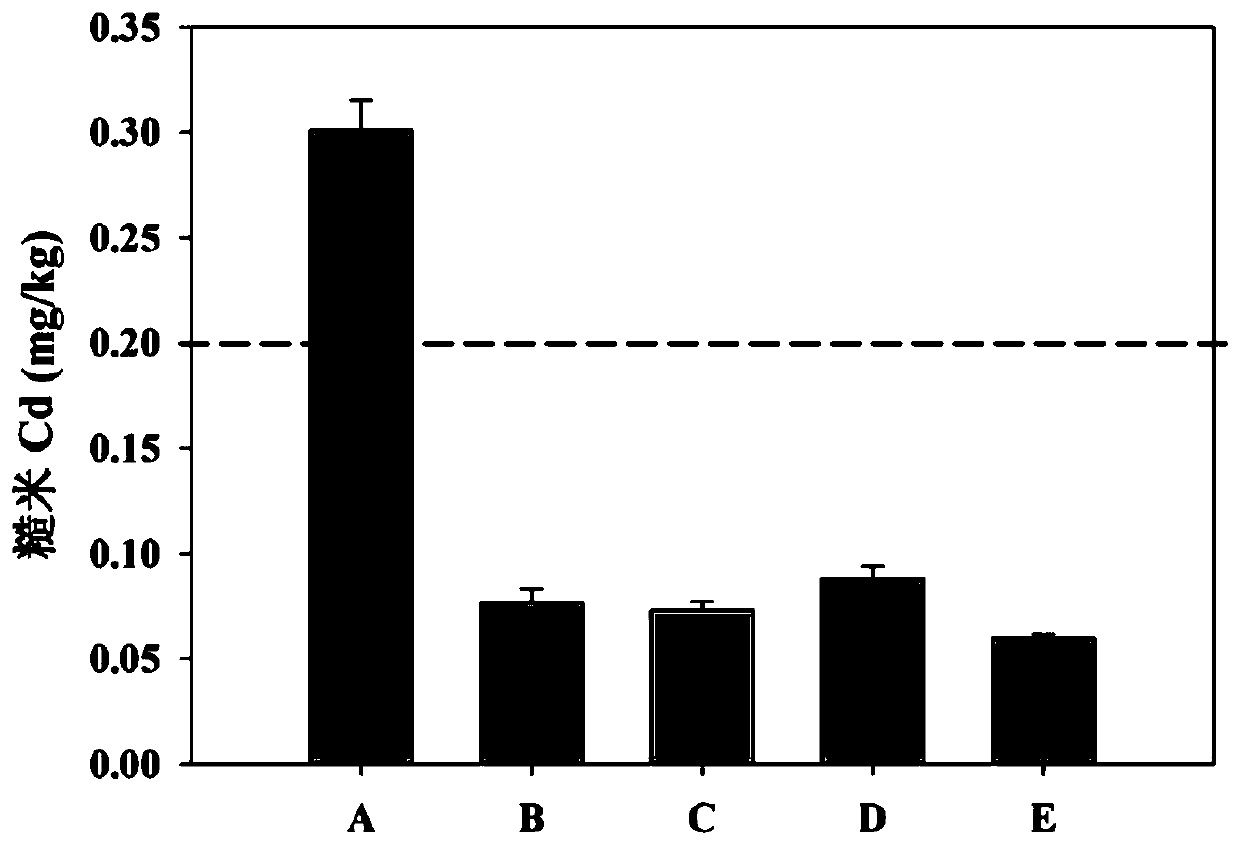

[0044] Experimental example 3: Application of potted plants

[0045] A potted method was used to preliminarily investigate the effect of the present invention on reducing cadmium in rice on polluted soil. The pH of the tested soil was 4.45, the organic matter was 29.5g / kg, the total cadmium was 0.78mg / kg, and the available cadmium was 0.17mg / kg.

[0046] Five treatments were set up in the pot experiment: (1) Control: no treatment was applied, and a certain amount of water (A) was sprayed; (2) Treatment 1: organosilicon reagent (positive Ethyl silicate) (B); (3) Treatment 2: Spraying Tubacon product (C) of the same quality (referring to elemental silicon); (4) Treatment 3: Spraying the same quality (referring to elemental silicon) (5) Treatment 4: Spray the foliage inhibitor dilution (E) of the same quality (referring to elemental silicon) and dilute 285 times with surfactant.

[0047] Before the pot experiment, the same seedling raising method in Experimental Example 2 was u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com