Modification method of polyvinyl alcohol capable of being subjected to thermoplastic processing

A polyvinyl alcohol and modification technology, applied in the field of thermoplastic processable polyvinyl alcohol modification, can solve the problems of small molecule overflow, excessive microporous structure, affecting profiles, etc., and achieves reduced dosage, simple process, and easy operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

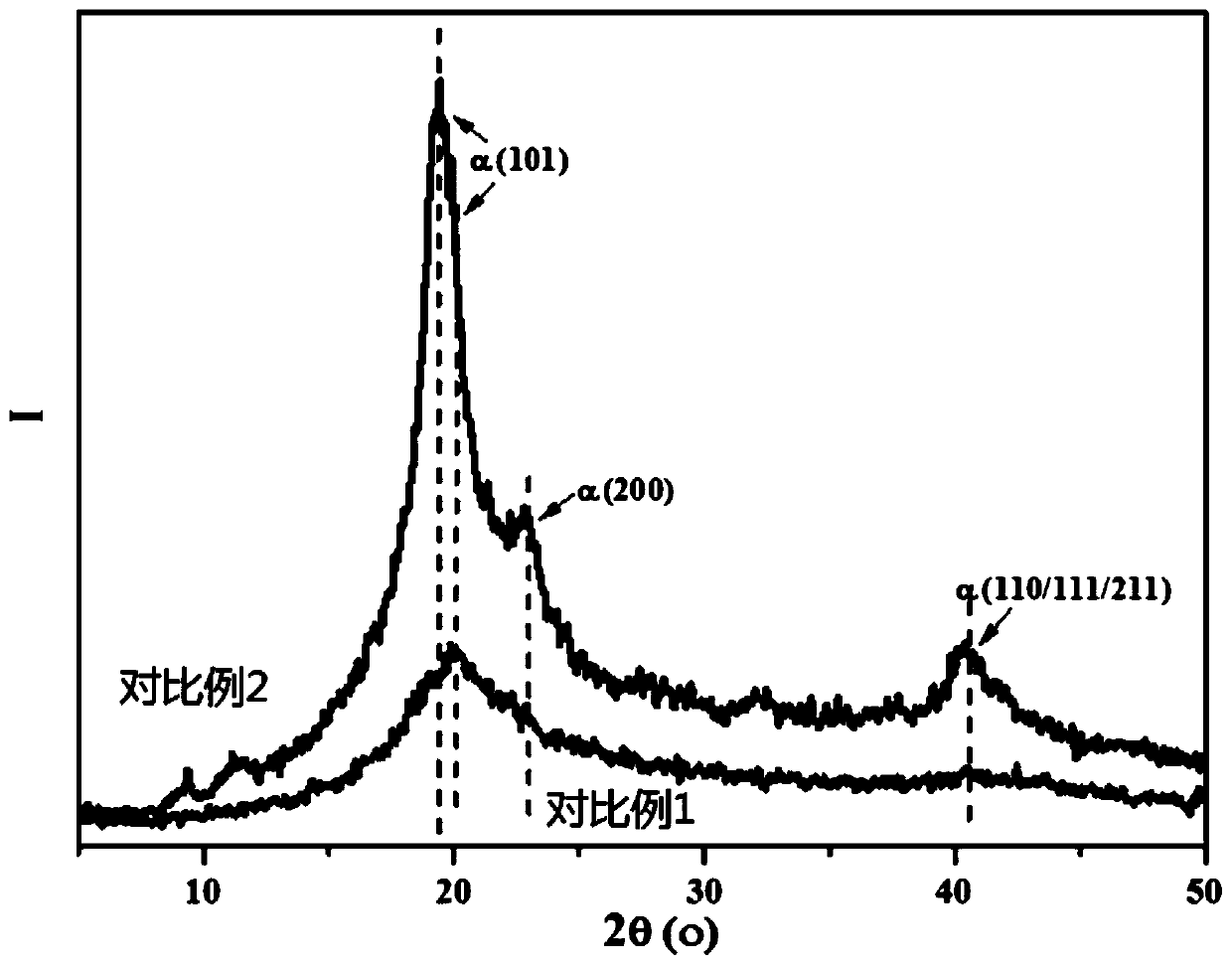

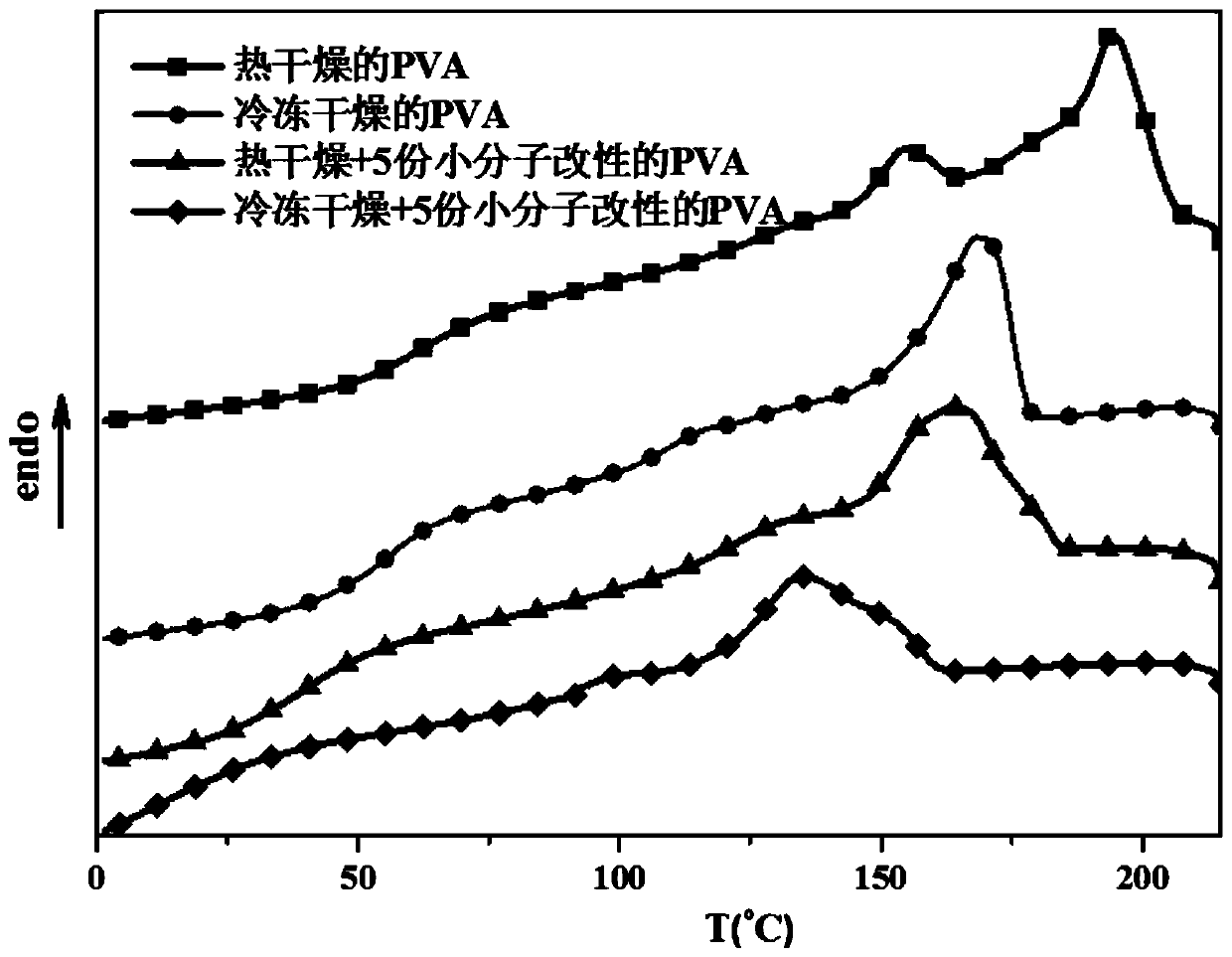

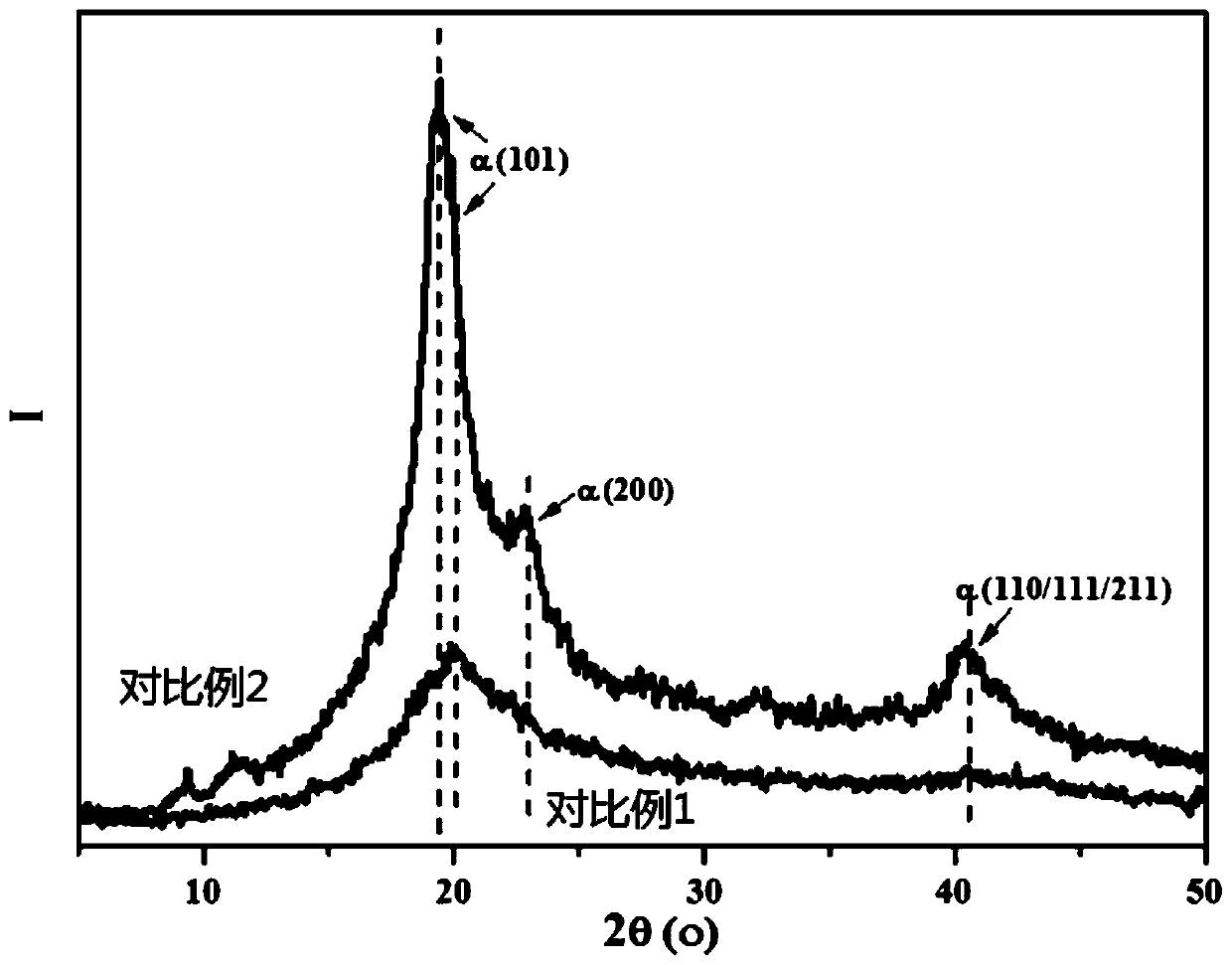

[0025] The grade of polyvinyl alcohol used in this embodiment is PVA1798, its degree of alcoholysis is 98%, and polyhydroxy small molecule D-sorbitol.

[0026] (1) Mix D-sorbitol, polyvinyl alcohol and water at a mass ratio of 5:40:100, and dissolve at 60°C until the polyvinyl alcohol is completely dissolved in the aqueous solution to obtain a homogeneous solution.

[0027] (2) Add the homogeneous solution prepared in step (1) into liquid nitrogen, and rapidly cool at a cooling rate of 80° C. / min to obtain a frozen mixture of polyvinyl alcohol ice crystals, and then quickly transfer the mixture to a freeze dryer, The modified polyvinyl alcohol was obtained by cooling and drying at -50°C. The melting temperature of the modified polyvinyl alcohol was 135°C.

Embodiment 2

[0029] The grade of polyvinyl alcohol used in this embodiment is PVA1788, its degree of alcoholysis is 88%, polyhydroxy small molecule glycerin.

[0030] (1) Mix glycerin, polyvinyl alcohol and water at a mass ratio of 2:40:100 and dissolve at 80°C until the polyvinyl alcohol is completely dissolved in the aqueous solution to obtain a homogeneous solution.

[0031] (2) Add the homogeneous solution prepared in step (1) into liquid nitrogen, and rapidly cool at a cooling rate of 100° C. / min to obtain a frozen mixture of polyvinyl alcohol ice crystals, and then quickly transfer the mixture to a freeze dryer, The modified polyvinyl alcohol was obtained by cooling and drying at -50°C. The melting temperature of the modified polyvinyl alcohol was 138°C.

Embodiment 3

[0033] The grade of polyvinyl alcohol used in this embodiment is PVA1797, its degree of alcoholysis is 97%, polyhydroxy small molecule glucose.

[0034] (1) Mix glucose, polyvinyl alcohol and water at a mass ratio of 1:10:100 and dissolve at 30°C until the polyvinyl alcohol is completely dissolved in the aqueous solution to obtain a homogeneous solution.

[0035](2) Add the homogeneous solution prepared in step (1) into liquid nitrogen, and rapidly cool at a cooling rate of 80° C. / min to obtain a frozen mixture of polyvinyl alcohol ice crystals, and then quickly transfer the mixture to a freeze dryer, The modified polyvinyl alcohol was obtained by cold dynamic drying at -80°C. The melting temperature of the modified polyvinyl alcohol was 132°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com