Binder for blast furnace clay and blast furnace clay

A technology of binder and clay, which is applied in the field of high-temperature refractory materials, can solve the problems of poor quality of blast furnace clay, and achieve the effects of reducing porosity, promoting mutual fusion, and improving compactness of blast furnace clay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

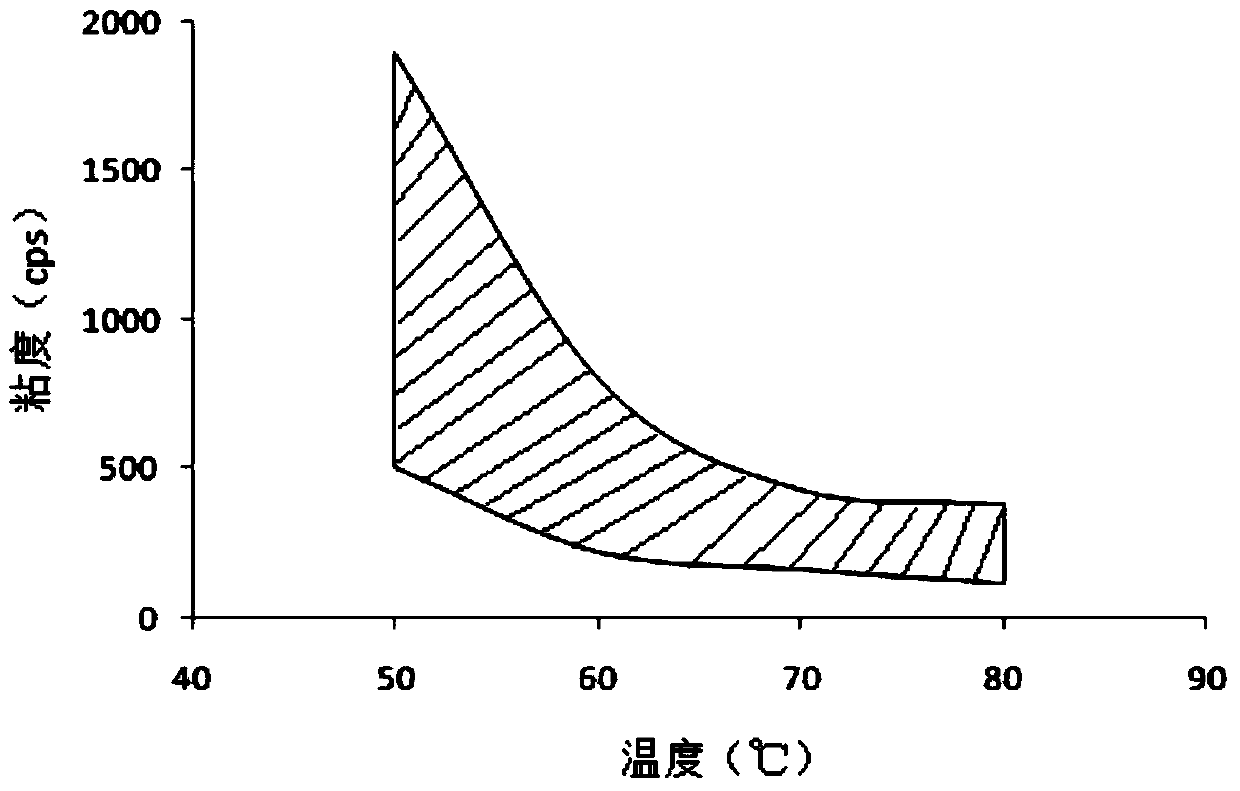

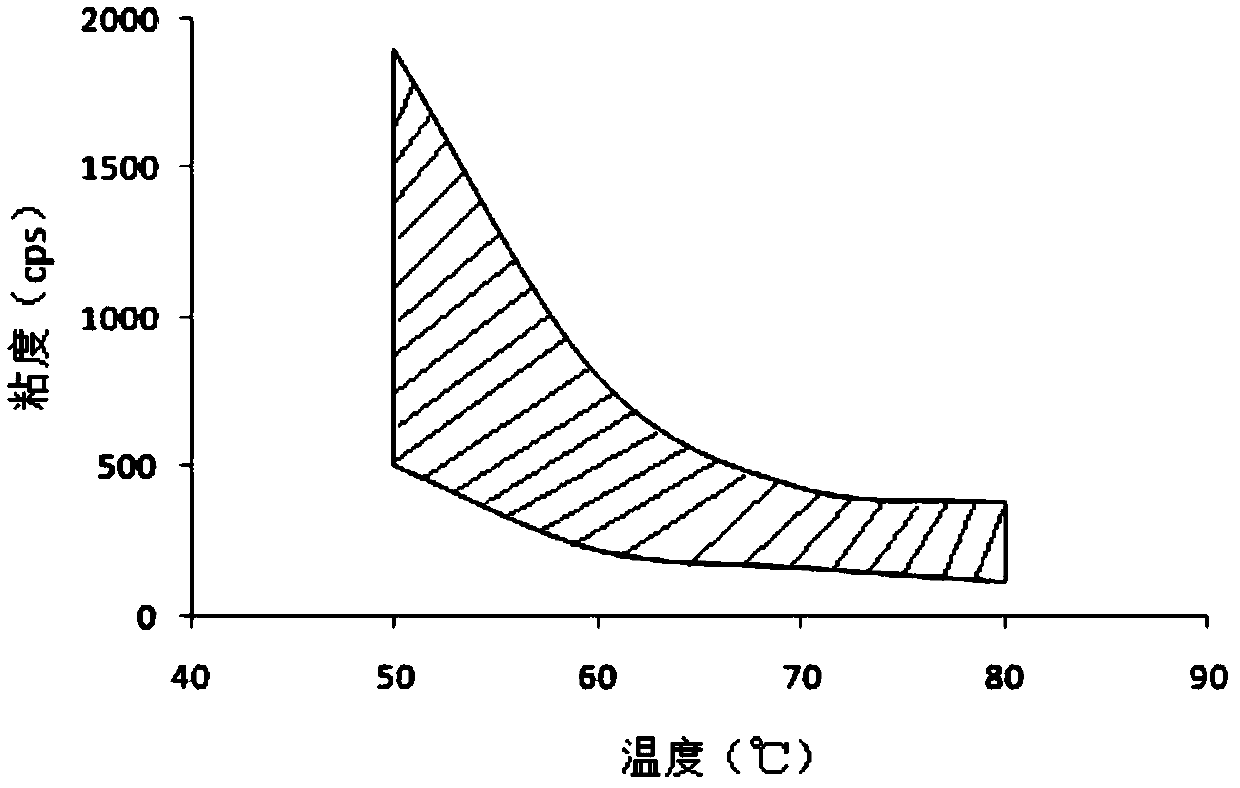

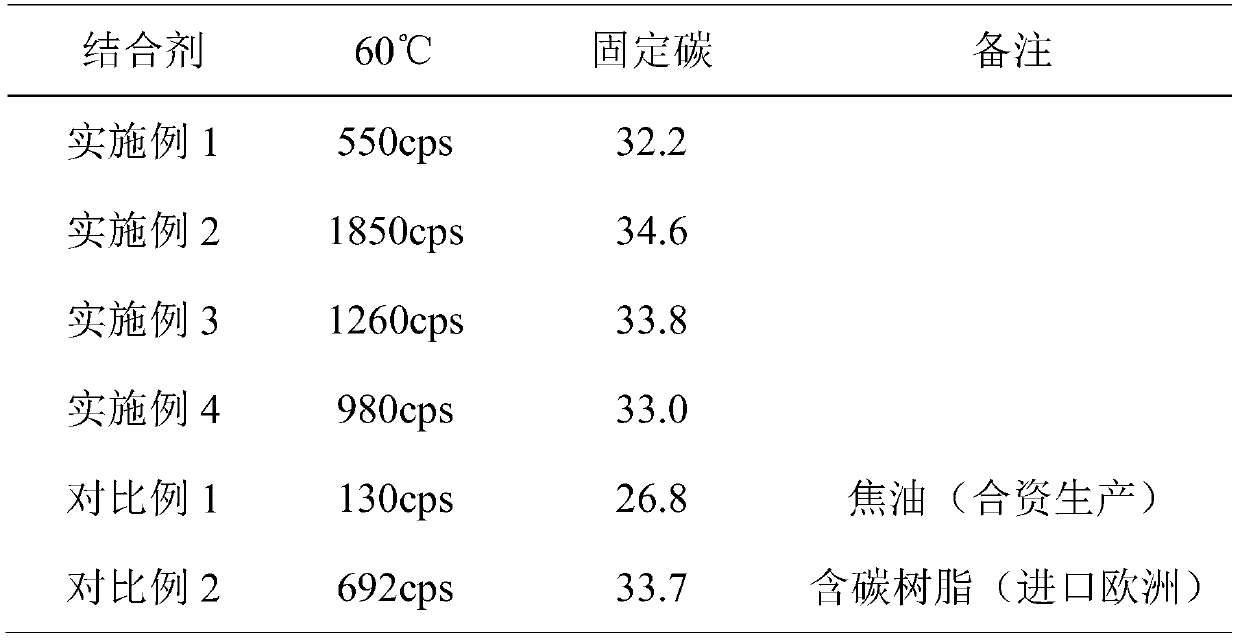

[0021] The binder for blast furnace mud of the present invention comprises the following components by mass: 40 parts of coal tar still bottoms, 60 parts of phenolic novolac resin, and 2 parts of external surfactants, wherein the method for obtaining the coal tar still bottoms The method is as follows: add coal tar to a high-temperature ceramic reaction kettle, heat and stir at 230° C. for 1.5 hours, and obtain the bottom of the coal tar distillation kettle after reaction and degassing. The coking value of the coal tar still bottoms was 37%. The free phenol content of the novolac resin is less than 9%, the coking value is greater than 29%, and the moisture content is less than 3%. Surfactant is made up of active agent and alcohols, and active agent is stearic acid, and alcohols is ethylene glycol.

[0022] The binder for blast furnace clay is prepared by the following method: mix the above-mentioned coal tar distillation still bottom, novolac resin, and surfactant in a set ra...

Embodiment 2

[0026] The binder for blast furnace clay of the present invention comprises the following components by mass: 70 parts of coal tar still bottoms, 30 parts of phenolic novolac resin, and 3 parts of external surfactants, wherein the method for obtaining the coal tar still bottoms The method is as follows: add coal tar to a high-temperature ceramic reaction kettle, heat and stir at 230° C. for 2 hours, and obtain the bottom of the coal tar distillation kettle after reaction and degassing. The coking value of the coal tar still bottoms was 40%. The free phenol content of the novolac resin is less than 9%, the coking value is greater than 29%, and the moisture content is less than 3%. Surfactant is made up of active agent and alcohols, and active agent is sodium dodecylbenzene sulfonate, and alcohols is glycerol.

[0027] The binder for blast furnace mud is prepared by the following method: mix the above-mentioned coal tar distillation still bottom, novolak resin, and surfactant i...

Embodiment 3

[0031] The binder for blast furnace clay of the present invention comprises the following components by mass: 60 parts of coal tar still bottoms, 40 parts of phenolic novolak resin, and 3 parts of external surfactants, wherein the method for obtaining the coal tar still bottoms The method is as follows: add coal tar to a high-temperature ceramic reaction kettle, heat and stir at 230° C. for 2 hours, and obtain the bottom of the coal tar distillation kettle after reaction and degassing. The coking value of the coal tar still bottoms was 42%. The free phenol content of the novolac resin is less than 9%, the coking value is greater than 29%, and the moisture content is less than 3%. Surfactant is made up of active agent and alcohols, and active agent is lecithin, and alcohols is ethylene glycol.

[0032] The binder for blast furnace mud is prepared by the following method: mix the above-mentioned coal tar distillation still bottom, novolak resin, and surfactant in a set ratio by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com