Preparation of Y-Ba-Cu-O high temperature superconductive film

A high-temperature superconducting, yttrium barium copper oxide technology, which is applied in the usage of superconductor elements, the manufacture/processing of superconductor devices, superconducting devices, etc. Slow speed, increased preparation difficulty, etc., to achieve the effect of improving the weak connection of grain boundaries, low cost, and increasing critical current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

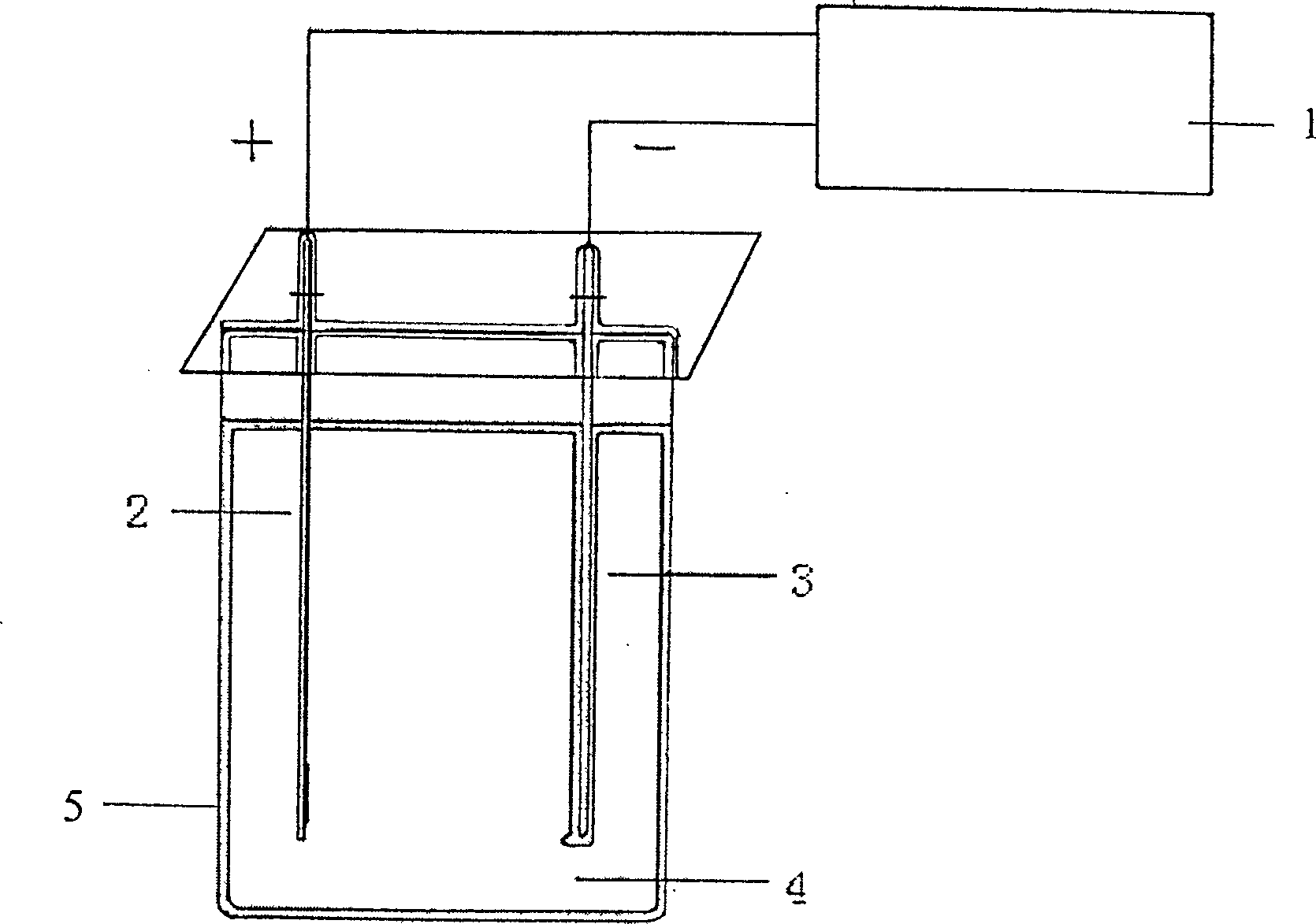

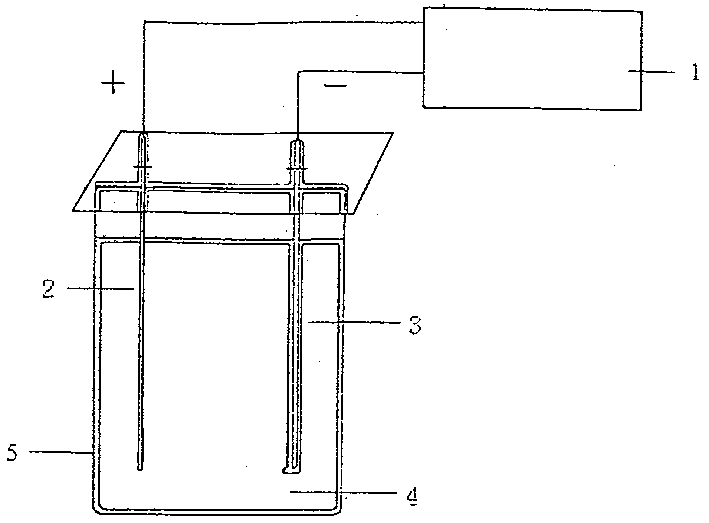

[0027] This embodiment is to prepare YBa on the MgO substrate of 5mm * 10mm 2 Cu 3 o 7-δ Nano superconducting film, using the battery 5, such as figure 1 As shown, the metal silver with a thickness of 0.3 mm, a width of 1.5 cm and a length of 5 cm is used as the positive and negative electrodes of the battery pool 5 after cleaning. The MgO substrate 6 of 10mm * 0.5mm is fixed on the negative electrode 3 after steaming a layer of Ag; Then, 2.45 grams of YBa 2 Cu 3 o 7-δ The powder is fully ground to make the particle size less than 2 μm, and then the ground YBa 2 Cu 3 o 7-δ The powder is prepared with a high-energy ball milling method to prepare nanoparticles with a particle size between 1-60nm, and mix it with 500 milliliters of acetone (purity 99.99%) with a glass rod and pour it into the electric pool 5; the negative electrode 3 with the baseband and the positive Electrode 2 is put into electric swimming pool, connects 900 volts of direct currents on electrode and ke...

Embodiment 2

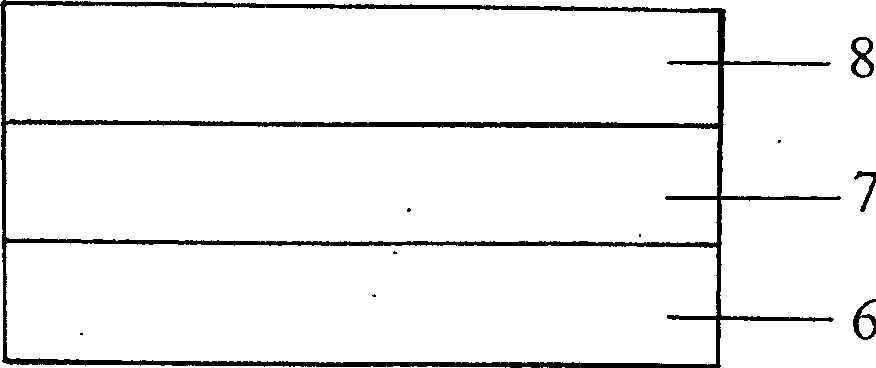

[0029] In this embodiment, YBa is prepared with chloroform as the electrophoretic solvent on the nickel sheet 6 with MgO as the isolation layer 10 mm × 40 mm in texture. 2 Cu 3 o 7-δ Nano-superconducting thin film. The electric pool 5 used, such as figure 1 As shown, first, a dense and uniform magnesium oxide film 7 is prepared on the nickel sheet 6, and then a layer of Pt is evaporated on the base tape and fixed on the negative electrode 3; YBa with a particle size of less than 0.5 μm 2 Cu 3 o 7-δ The powder is prepared by high-energy ball milling to prepare nanoparticles with a particle size in the range of 1-10nm, and mix with 1000 milliliters of chloroform (purity 99.99%), stir with a glass rod and pour into the electric pool; two electrodes are put into the electric pool 5, and the Connect the voltage of 900 volts between the positive and negative poles and keep it for 5 seconds. In this way, a layer of YBa with a thickness of about 100nm is deposited on the baseband...

Embodiment 3

[0031] In this embodiment, on a textured 20mm×80mm nickel sheet 6, MgO is used as an isolation layer 7 to grow YBa 2 Cu 3 o 7-δ Nano-superconducting thin film8. The electric pool 5 used, such as figure 1 As shown, first, a dense and uniform magnesium oxide film 7 is prepared on the nickel sheet 6, and then a layer of Al is evaporated on the MgO substrate; YBa with a particle size of less than 8 μm 2 Cu 3 o 7-δ The powder is prepared by high-energy ball milling method to prepare nanoparticles with a particle size between 1-60nm; fix the Al / MgO / Ni baseband on the negative electrode 3 and put it into the electric pool, and there is a voltage of 900 volts between the positive and negative electrodes, and keep 20 In this way, a layer of YBa with a thickness of about 300nm is deposited on the baseband 2 Cu 3 o 7-δ Nano superconducting film; finally, the deposited YBa 2 Cu 3 o 7-δ The nano-superconducting film is placed in a sintering furnace, and the temperature of the fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com