Patents

Literature

56results about How to "Reduce the number of taps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

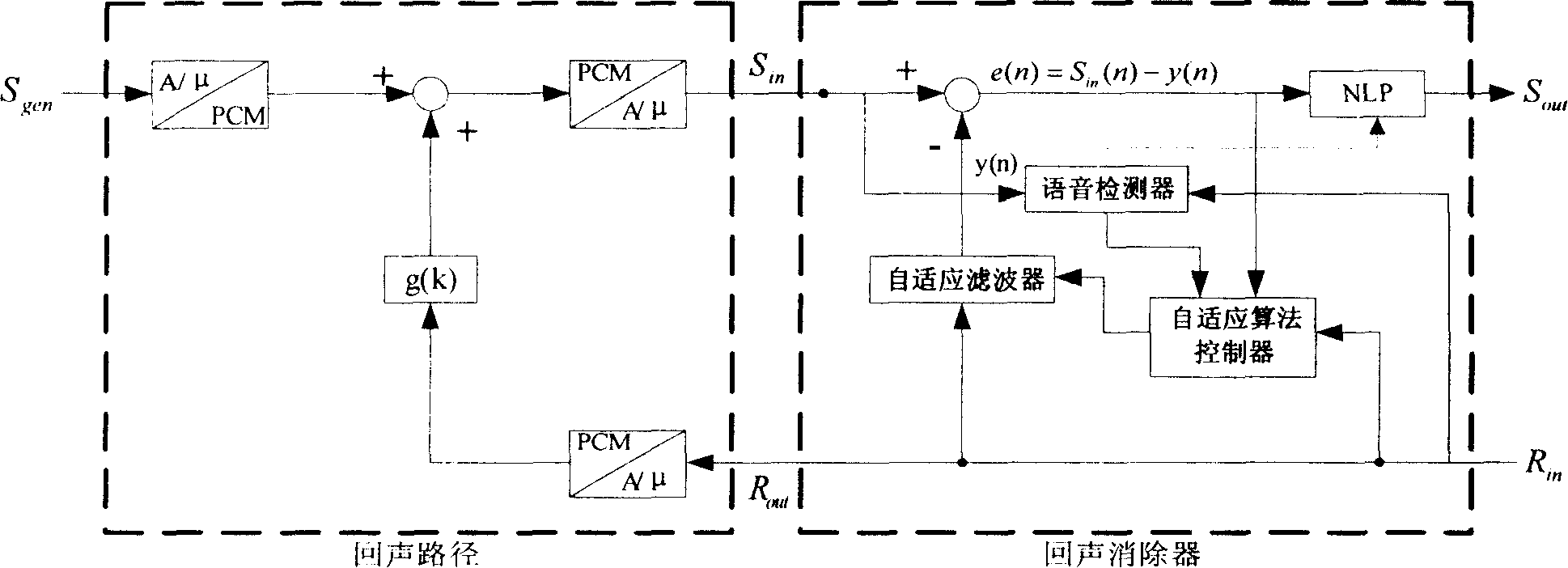

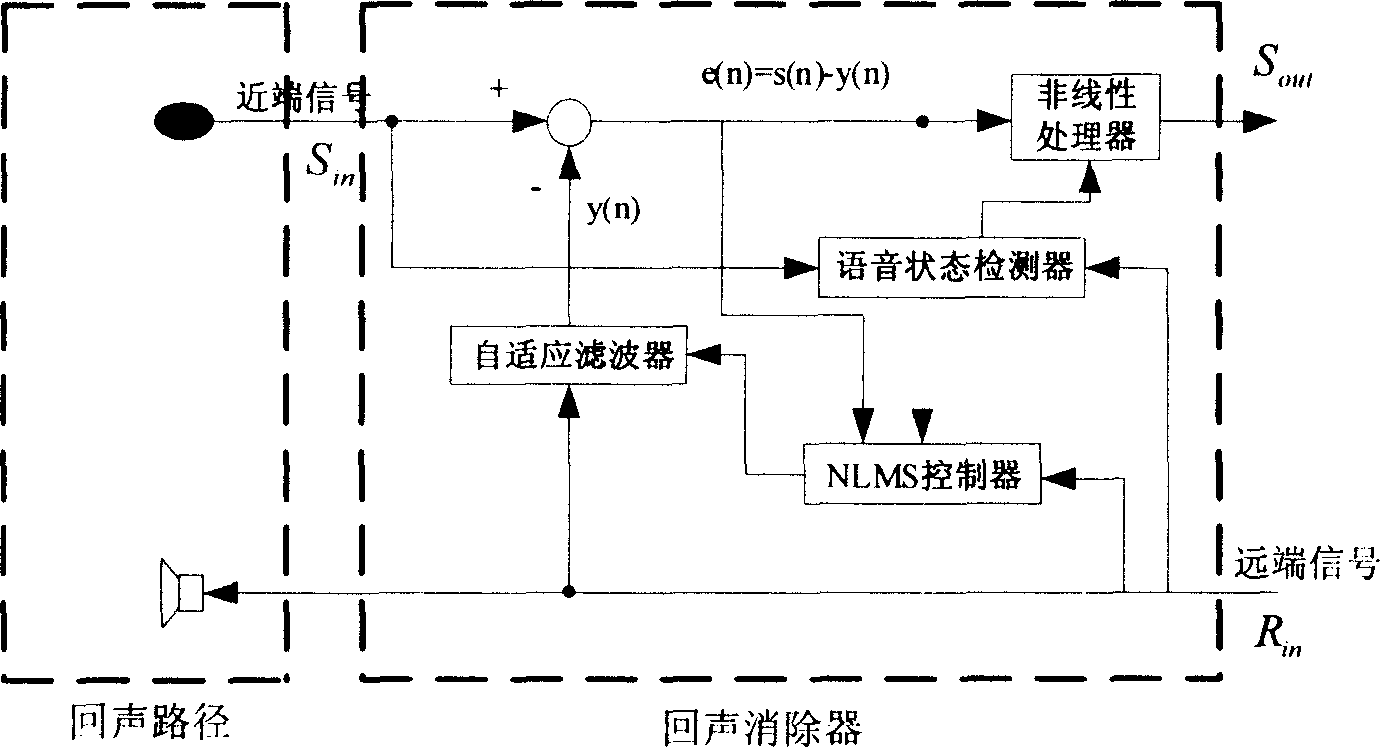

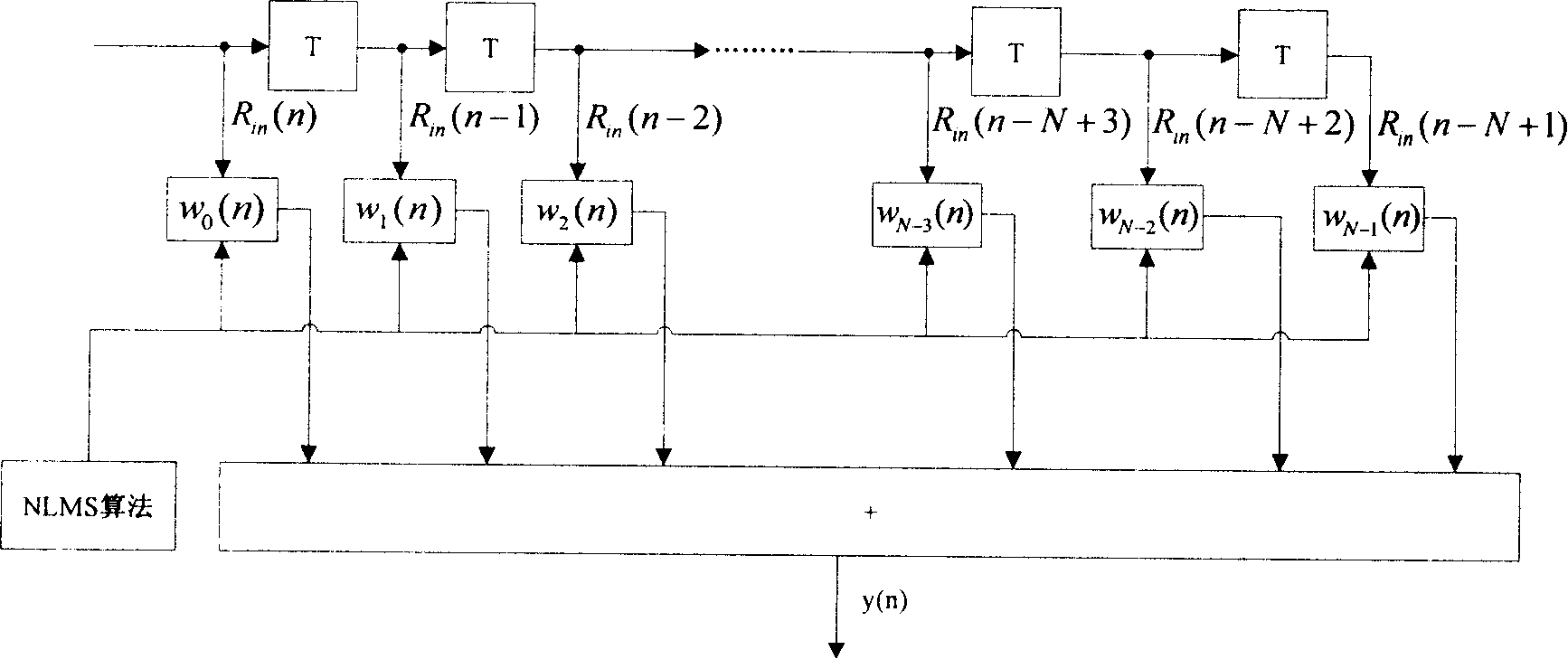

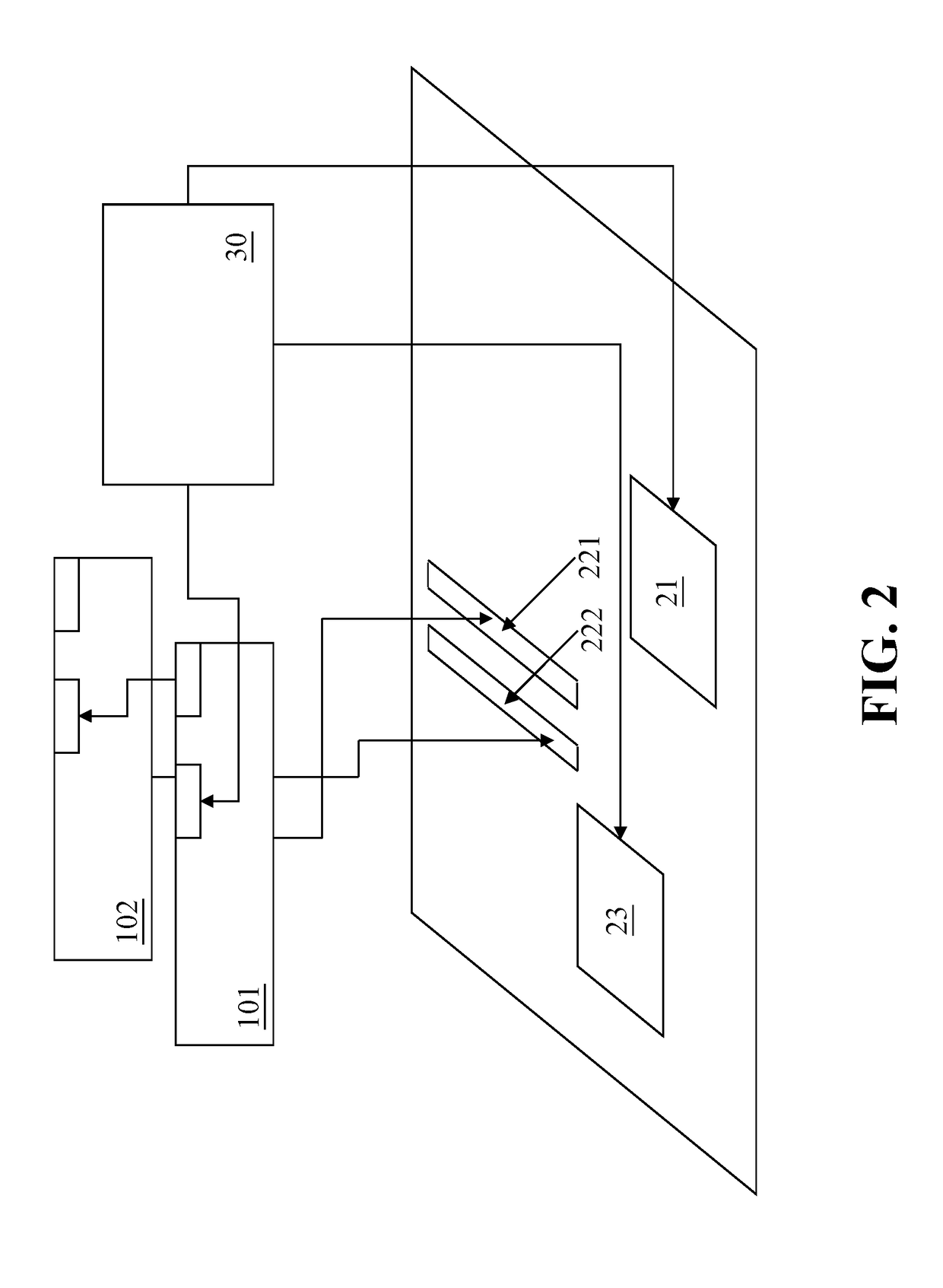

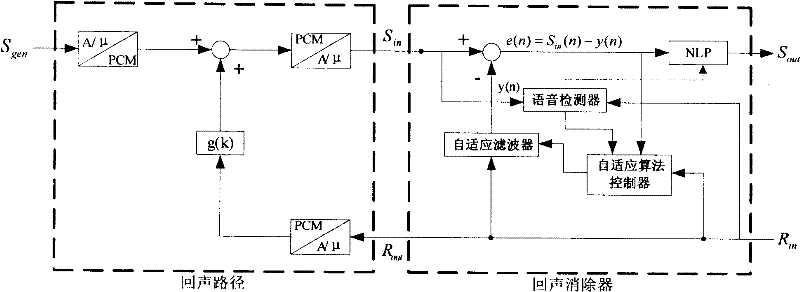

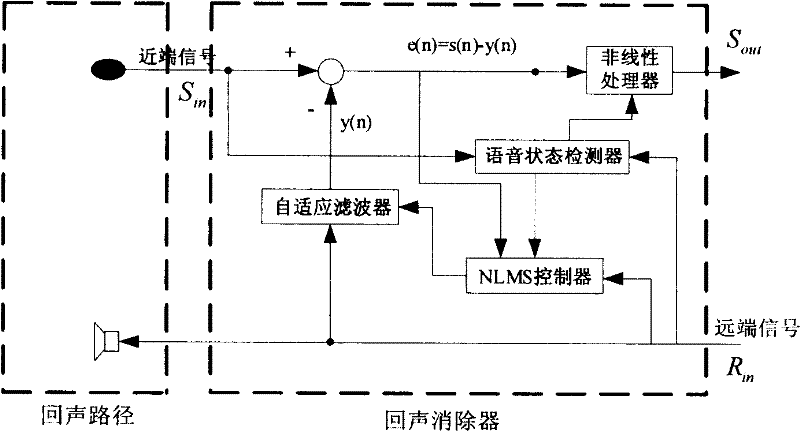

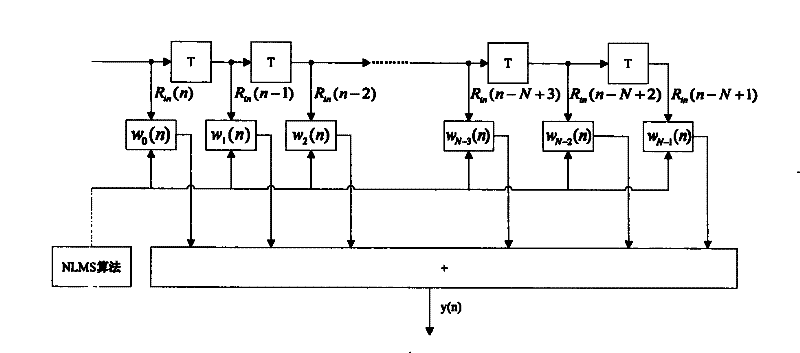

Self-adaptive echo eliminator and echo eliminating method thereof

InactiveCN101179294AReduce the number of tapsLow steady state misalignmentTwo-way loud-speaking telephone systemsLine-transmissionCommunications systemProximal point

The invention provides an adaptive echo eliminator and the echo eliminating method thereof; wherein the device consists essentially of a voice state detector, an NLMS (energy normalized least mean square error) controller and a sliding window FIR filter. The method mainly includes the following steps: sampling both a far-end voice signal and a near-end voice signal, and confirming the speaking status information of the current network according to the estimated values of the short-time energy of the sampled far-end speech signal sample and the near-end speech signal sample. Then, the coefficient of a sliding window FIR filter is configured according to the speaking status information of the current network, and the sliding window FIR filter step-by-step filters the near-end speech signal and the far-end speech signal filled into the buffer area according to the mobile length set by the configured coefficient. Utilizing the invention, the echo of the digital hands-free speaking system can be effectively eliminated, thereby effectively eliminating the echo of the digital communication system based on the embedded system.

Owner:APLUS COMM TECH BEIJING

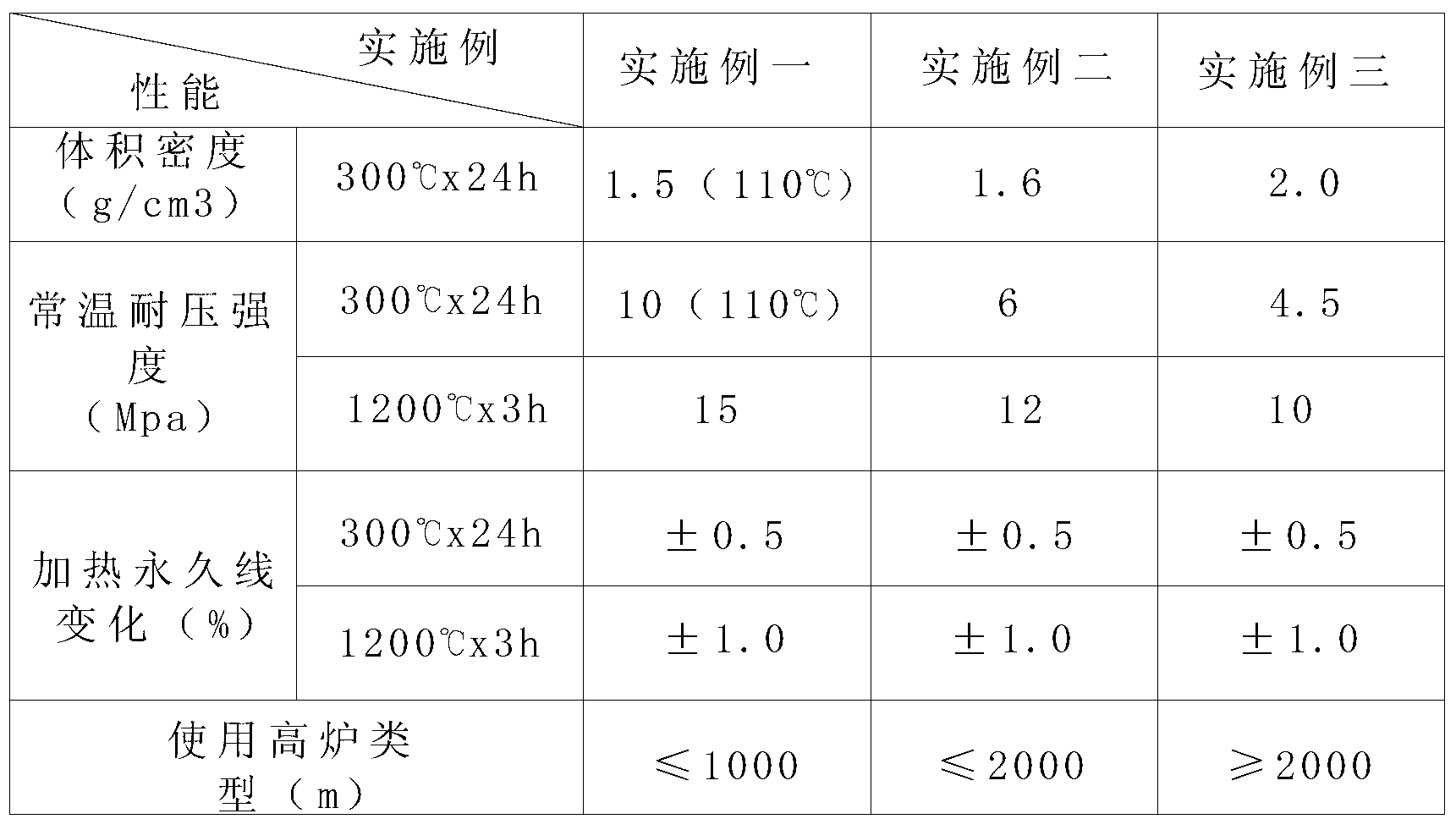

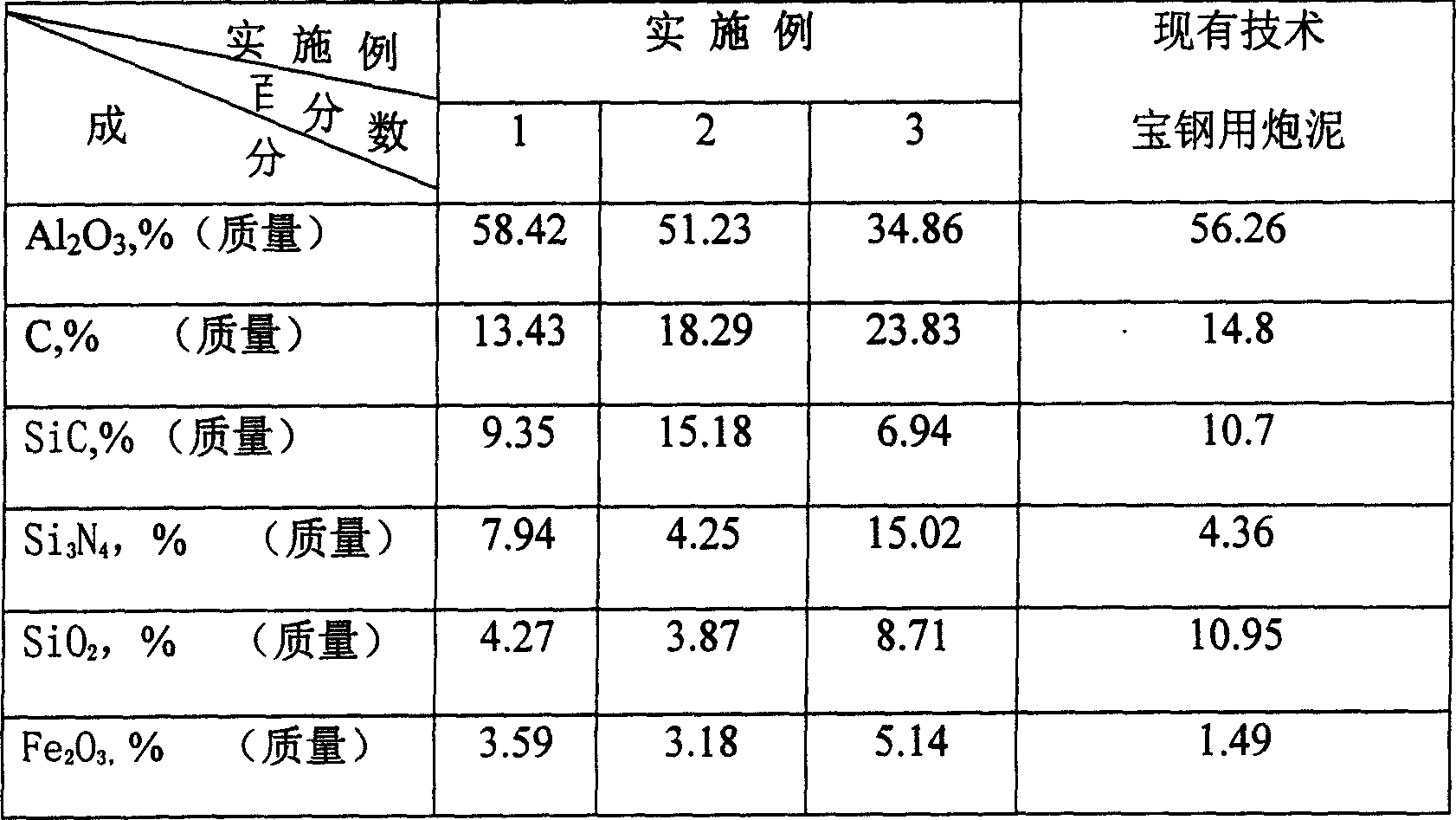

Bleed hole stemming and method for producing the same

ActiveCN101219900AGood sintered strengthEasy to openBlast furnace componentsBlast furnace detailsPyrophylliteGraphite

The invention relates to a stemming at a taphole; the weight percentages of the components are the following: 20 to 40 of corundum, 10 to 20 of silicon carbide, 3 to 10 of silicon nitride, 10 to 23 of coke powders, 1 to 5 of graphite powders, 3 to 10 of sericite, 1 to 5 of active alumina micropowders, 5 to 15 of clay, 5 to 10 of pyrophyllite, 1 to 3 of metal powders, and +15 to 25 of water-free binder. The stemming adds a plurality of materials with plasticity and good cohesiveness to cause the stemming to easily block the hole and fill interspaces, with good binding performance of new stemming and old stemming; materials with medium and high temperature expansion are added to reduce the size of the stemming contraction at high temperature, and cracks can be avoided; materials with sintering function within different temperature areas are added, so the stemming has good sintering strength in different temperature scopes; materials with high-temperature resistance and good erosion resistance are added, and thus the stemming has high strength at high temperature, washing resistance and erosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

Novel stemming at tap hole

The invention discloses novel stemming at a tap hole. The stemming comprises the components in parts by weight as follows: 5-25 parts of corundum, 5-25 parts of high aluminum aggregate, 10-30 parts of silicon nitride combined with silicon carbide, 2-3 parts of silicon nitride iron, 5-15 parts of coke powder, 8-20 parts of clay, 1-5 parts of crystalline flake graphite, 5-10 parts of pyrophyllite, 4-7 parts of sericite, 5-10 parts of magnesium-aluminum spinelle, 2-4 parts of active alumina micro powder, 1-3 parts of metal powder and 15-20 parts of external composite binding agent. The composite binding agent comprises tar, modified phenolic resin and an organic solvent. The volume ratio of tar, modified phenolic resin to the organic solvent in the composite binding agent is 1:3:1. According to the invention, with the adoption of the composite binding agent formed by mixing tar and modified phenolic resin, smoke generated is less, the same plasticity to be combined with tar is met, the opening performance is good, the pressure resisting thermal shock resistance is good, and the adhesion strength is high. The depth of the tap hole can be prolonged and the furnace cylinder can be protected, the tapping time is prolonged, and the number of casts every day is reduced.

Owner:长兴云峰炉料有限公司

Al*O*-SiC-C system waterless taphole mix containing ferrosilicon nitride

InactiveCN1544660AGood medium temperature strengthReduce operating proceduresBlast furnace componentsBlast furnace detailsChemical compositionFerrosilicon

The invention provides a silicon iron nitride-containing Al2O3-SiC-C system anhydrous tamping plug, composed of Al2O3, SiC, C, Si3N4, SiO2, Fe2O3 and other components in mass percents (m%) of 30-60%, 5-17%, 10-25%, 5-20%, 2-10%, 2-7% and 2-7%, respectively; adding 3-20m% silicon iron nitride to these raw materials, and during detecting course, silicon iron nitride is calculated in Fe2O3 form. Other components include: CaO, MgO, TiO2, K2O and NaO. Its advantages: solving the problems of slowly sintering of tamping plug and difficultly making holes, improving the property of the tamping plug; and at the same time reducing production cost.

Owner:UNIV OF SCI & TECH BEIJING

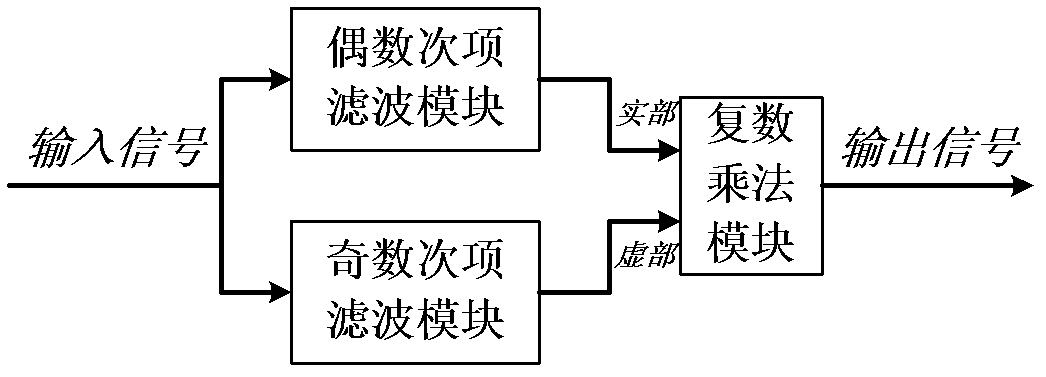

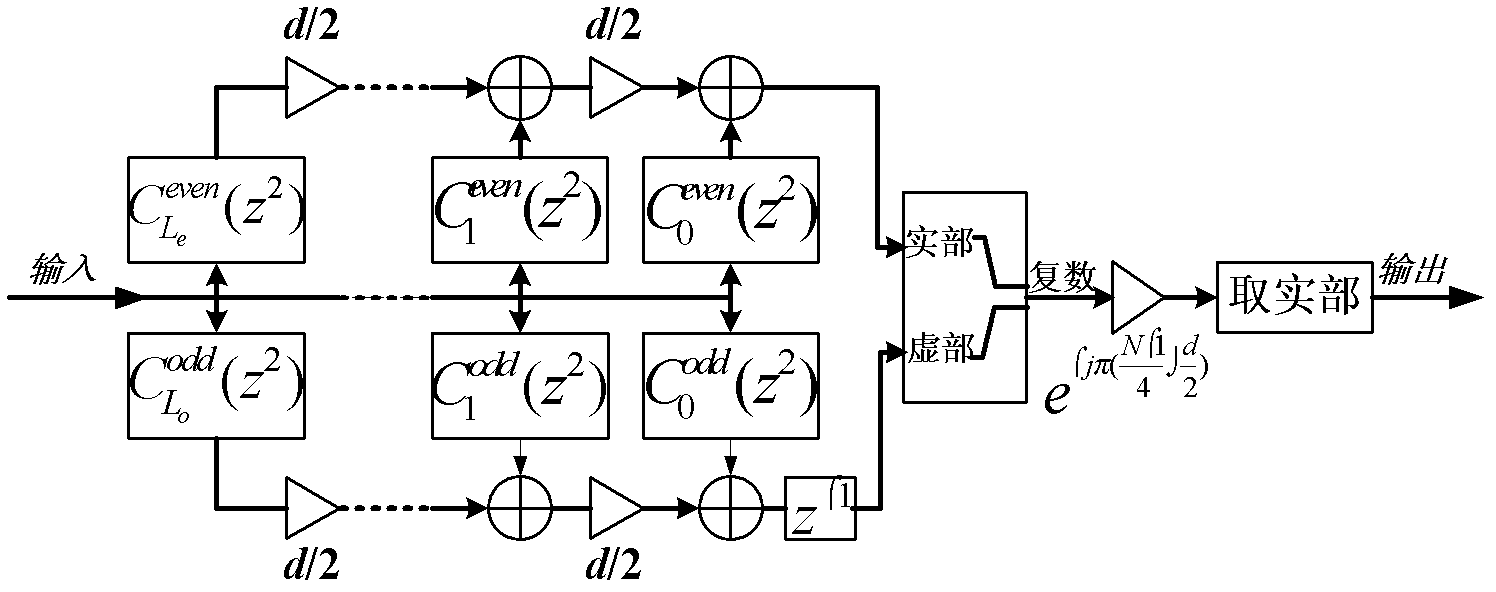

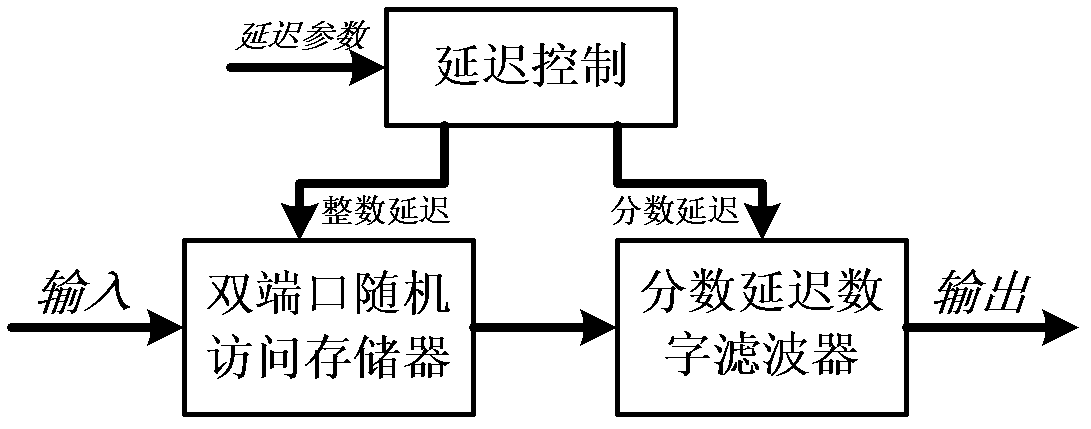

Implementation structure of fractional delay digital filter

InactiveCN102624357ASmall range of variationReduce the order of fitDigital technique networkCurve fittingDigital filter

The invention provides an implementation structure of a fractional delay digital filter. By factorizing odd term and even term of independent variable z in the frequency response function of the fractional delay digital filter, a high-level fractional delay digital filter operation can be factorized into two low-level fractional delay digital filter operations and one complex multiplication operation, thus the variation range of the target fitting curve which takes the delay parameter as the independent variable can be narrowed, the curve fitting orders can be lowered, the number of taps of the filter can be decreased, and hardware resources required for realizing the fractional delay digital filter can be reduced on the premise of not reducing the delay precision.

Owner:SHANGHAI JIAO TONG UNIV

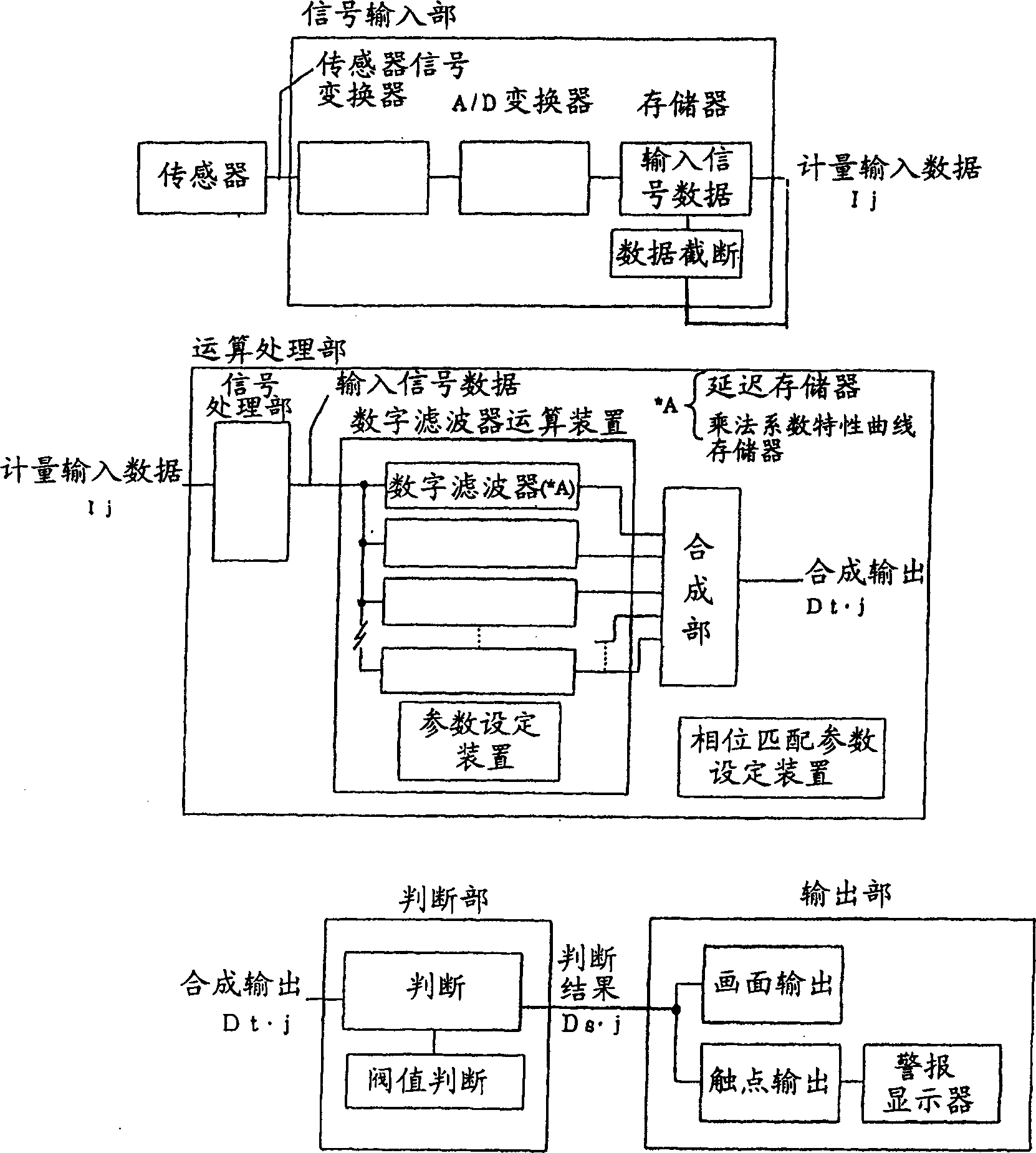

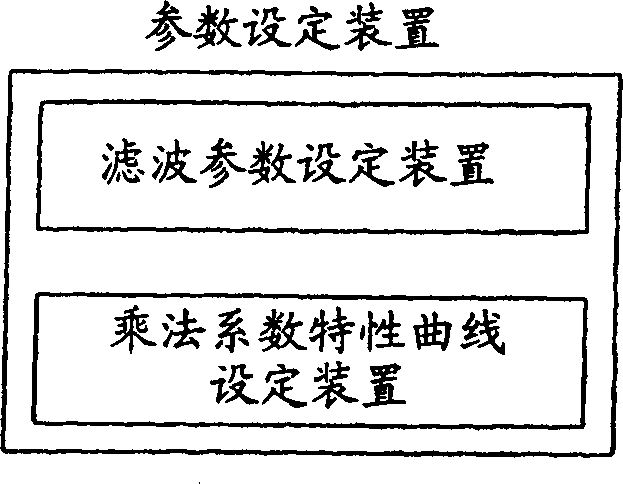

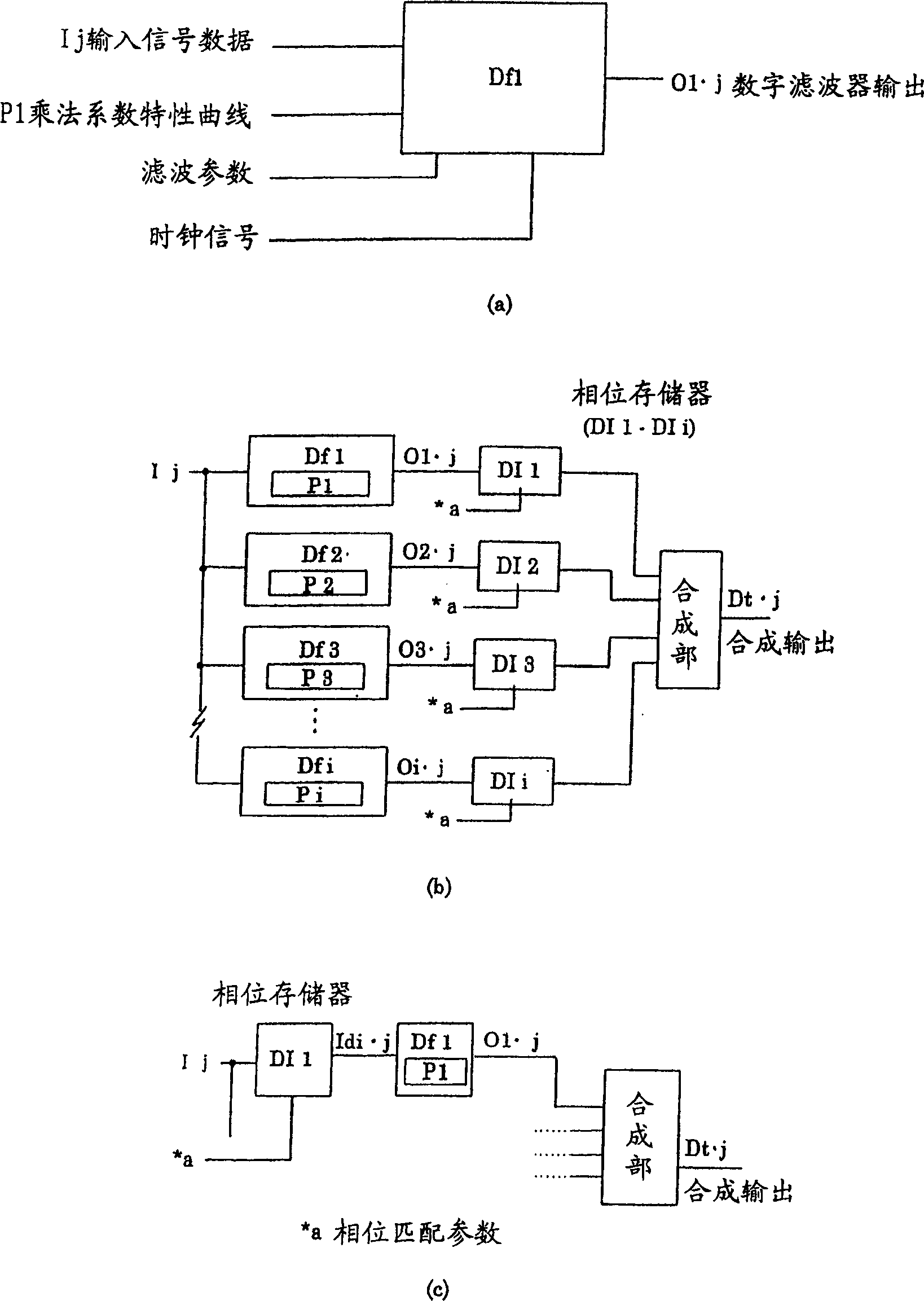

Wave form detector and state monitoring system using it

InactiveCN1441906AReduce the number of tapsReduce processing burdenSpectral/fourier analysisDigital technique networkTransient stateFeature extraction

A waveform detector having a signal processing function for producing an output waveform by detecting, by characterizing, a transient state variation having no periodic repetition or by subjecting an input waveform to 1 / f fluctuation conversion, and a state monitoring system utilizing the waveform detector. The waveform detector characterizing the characterization of the sign of state variation, chracterized in that a digital filter operating means of a processing section is provided with a plurality of digital filters, and means (phase matching parameter means) for altering the phase of any of, the elementary pattern of multiplication coefficient pattern defined by the coefficient pattern derived from a nonintegral-n-times integration expression, the input signal data, and the digital filter output is provided.

Owner:SYNCHRO

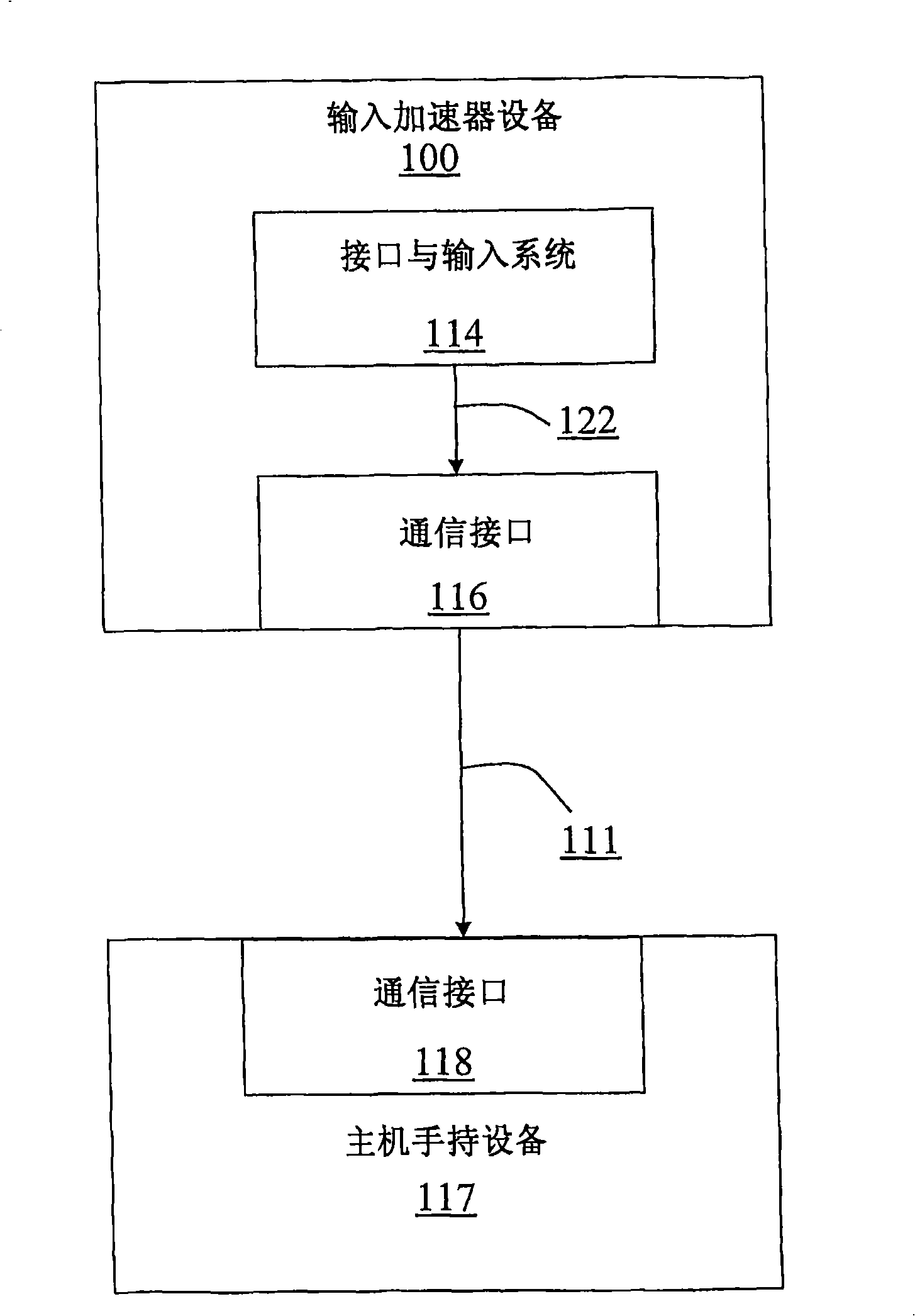

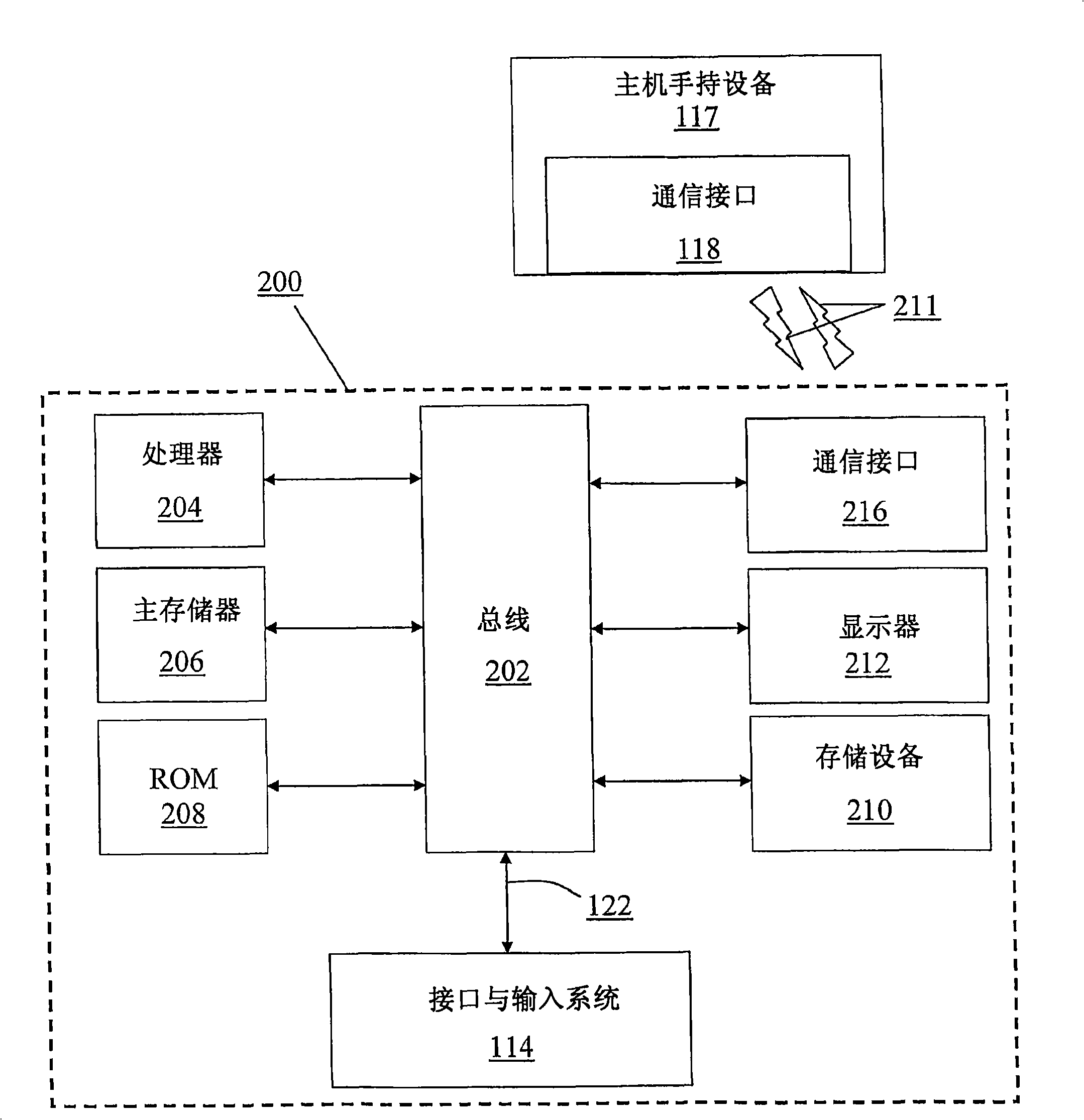

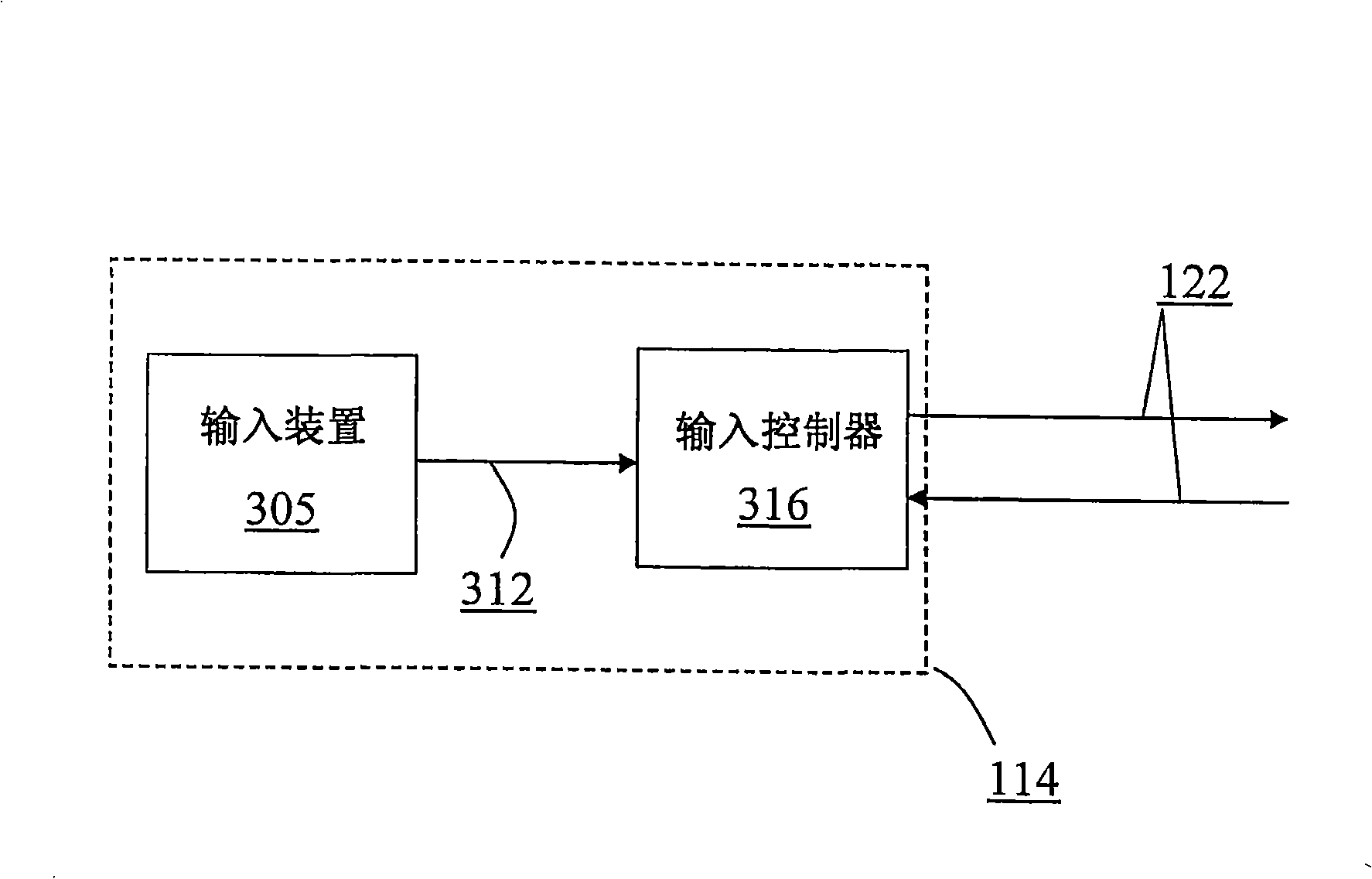

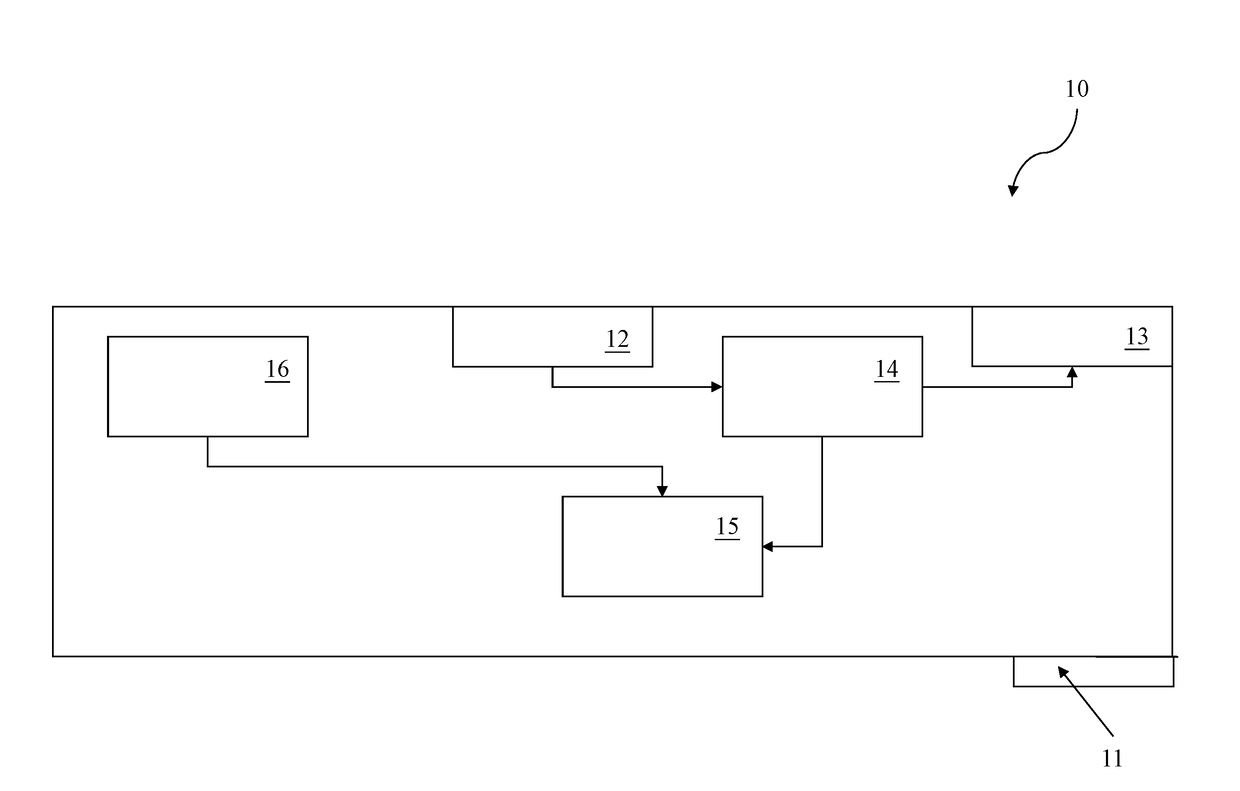

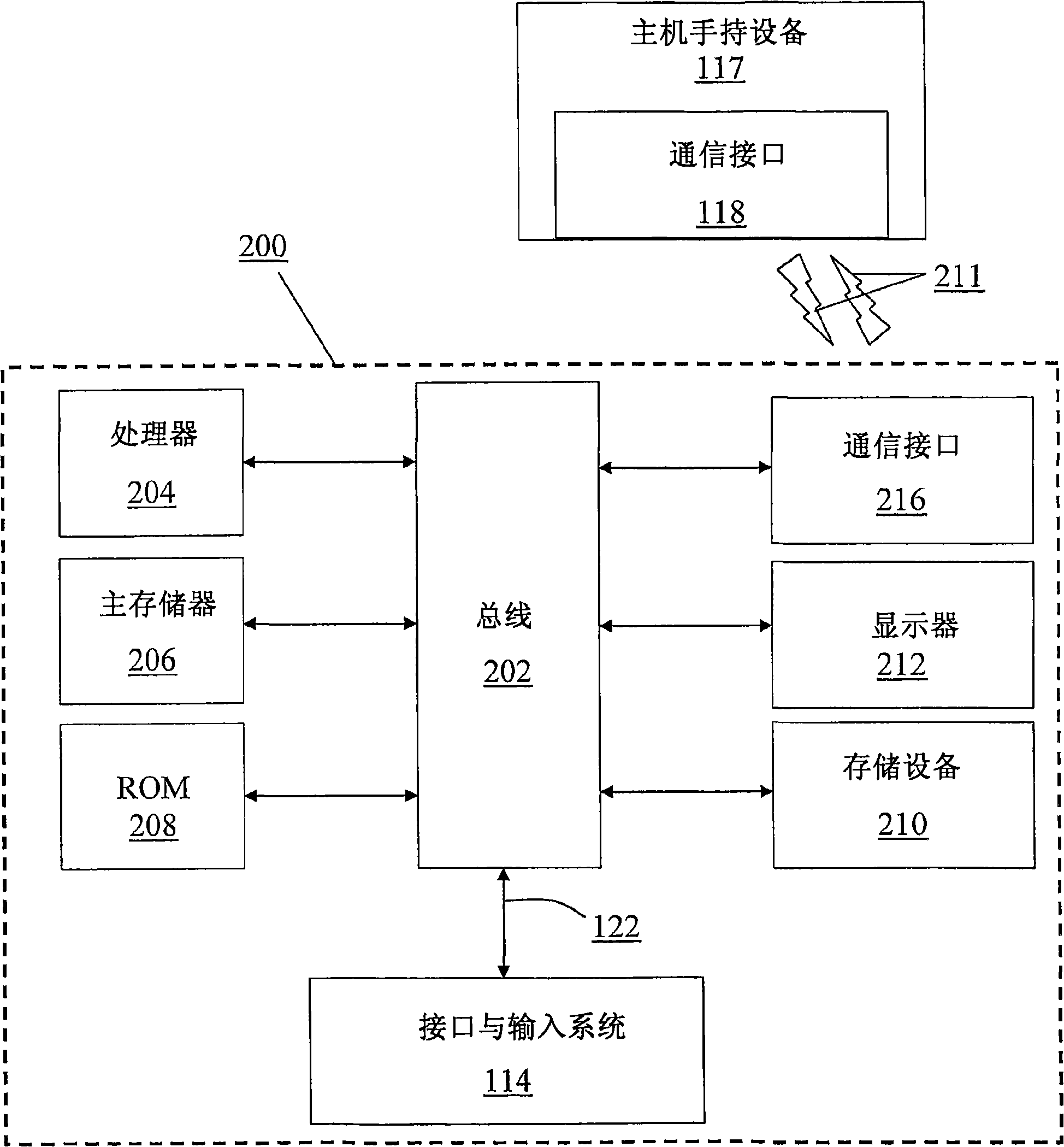

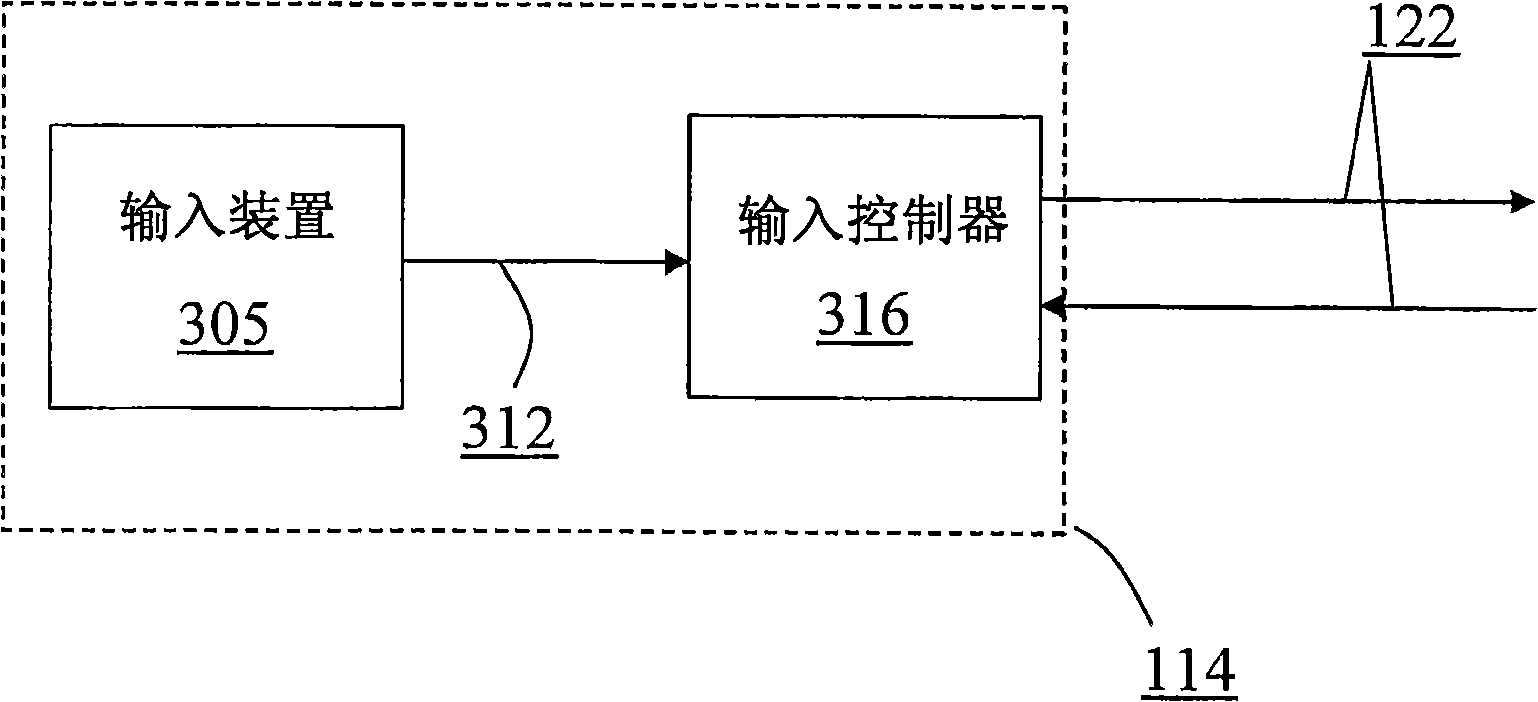

Mobile device customizer

InactiveCN101326479AIncrease the areaIncrease the number ofInput/output for user-computer interactionComputer hardwareCommunication link

A method and system for customizing a mobile host device is disclosed. An accessory device for interfacing with and customizing a mobile host device includes a communication channel designed to establish a bi-directional communication link between the accessory device and the host device. The accessory device also includes a processor communicatively coupled to the communication channel. The processor is designed to execute a plurality of applications. In addition, the accessory device includes an input assembly communicatively coupled to the processor. The input assembly is designed to minimize a total number of input elements included in the input assembly. Further, at least a first input element being selectively mapped to one or more input functions of the host device based on a user selection.

Owner:泽蒙特责任有限公司

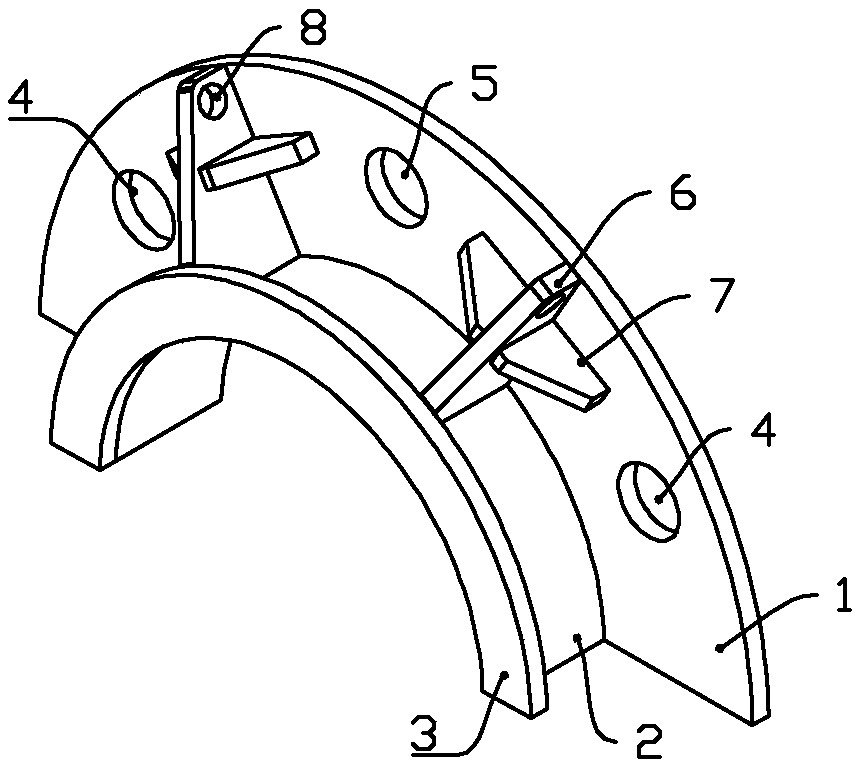

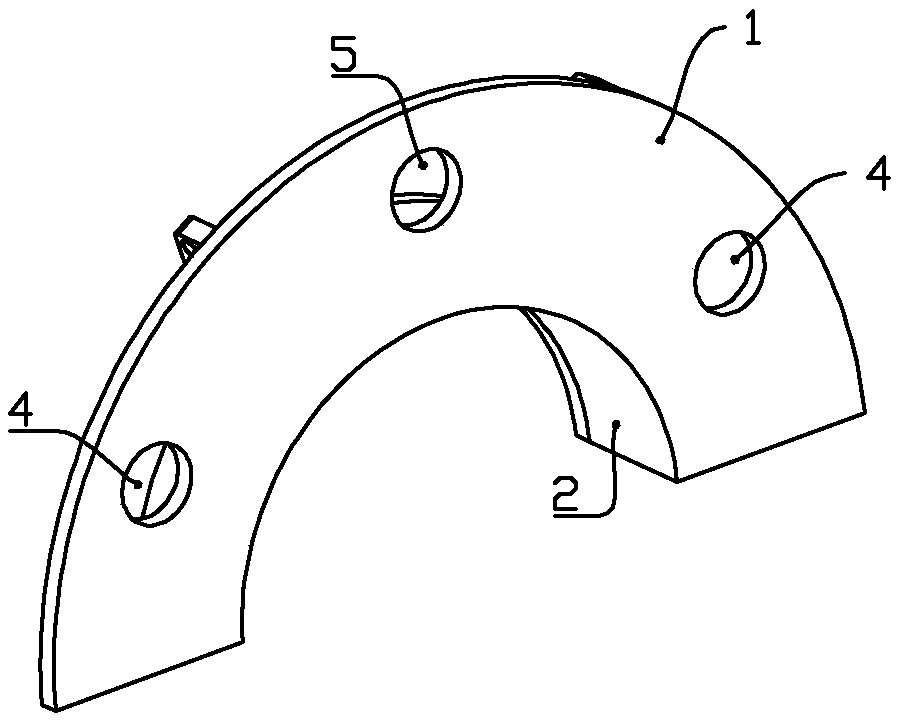

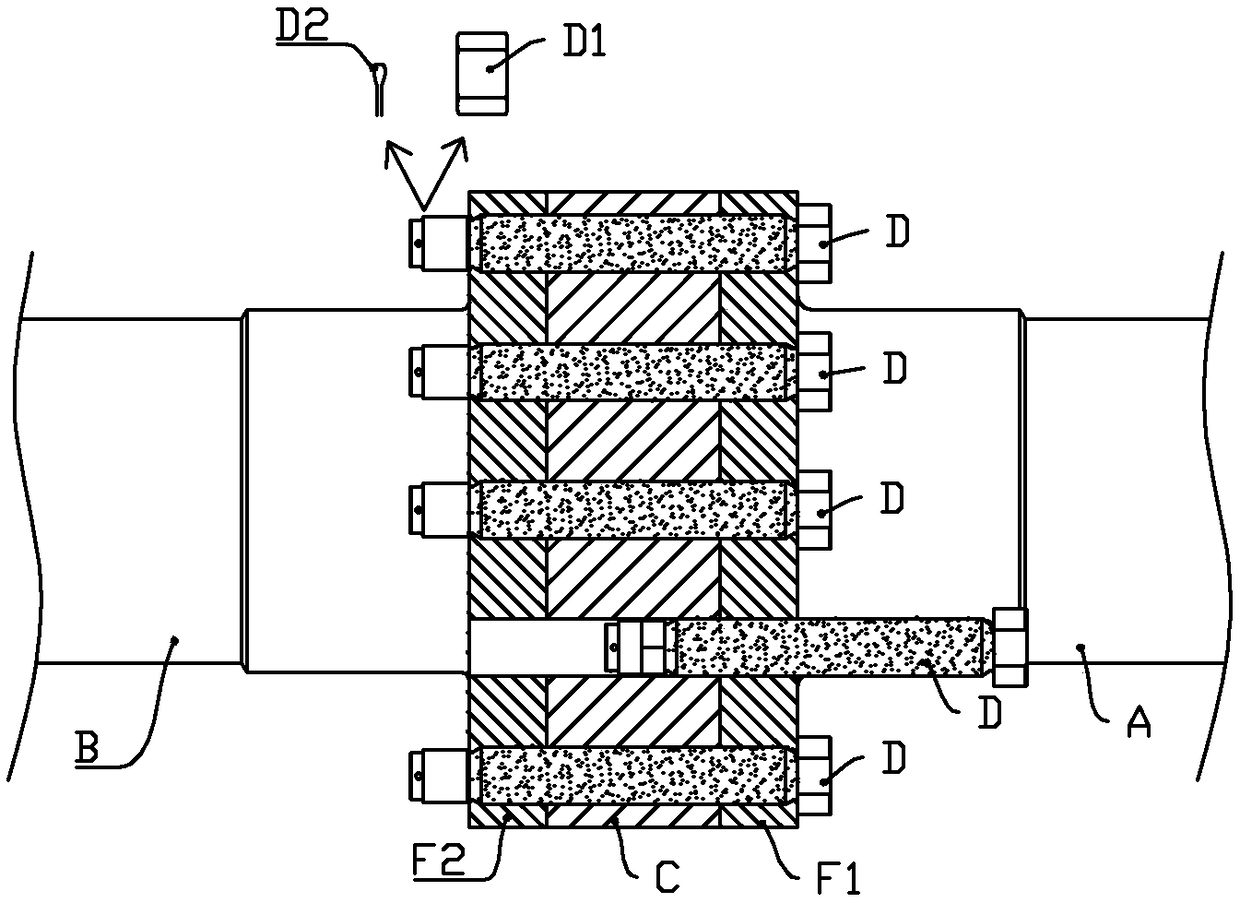

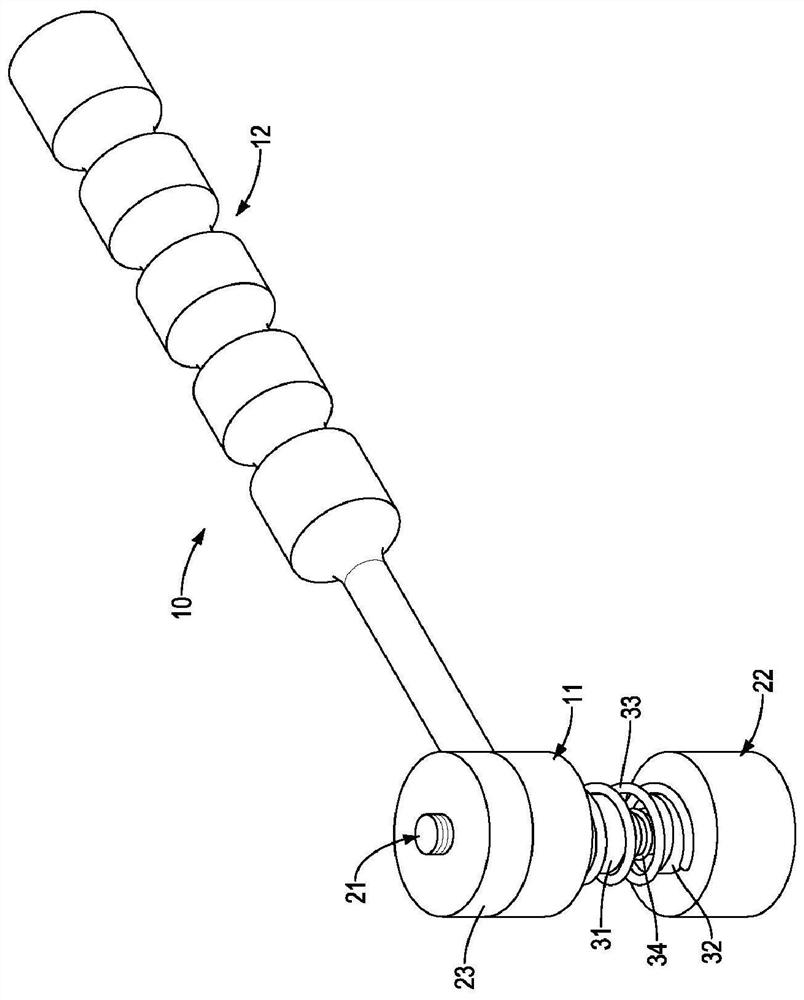

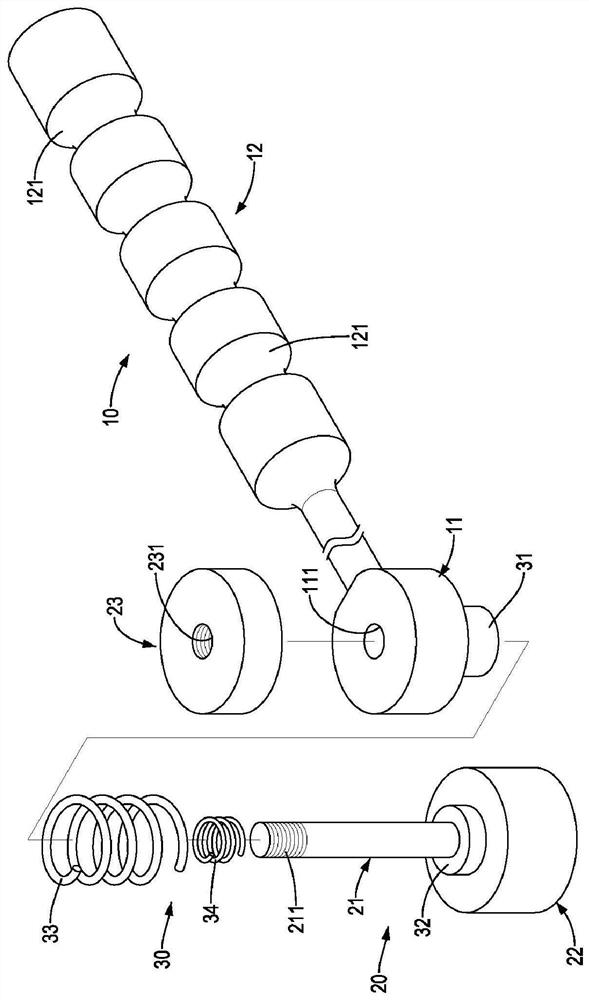

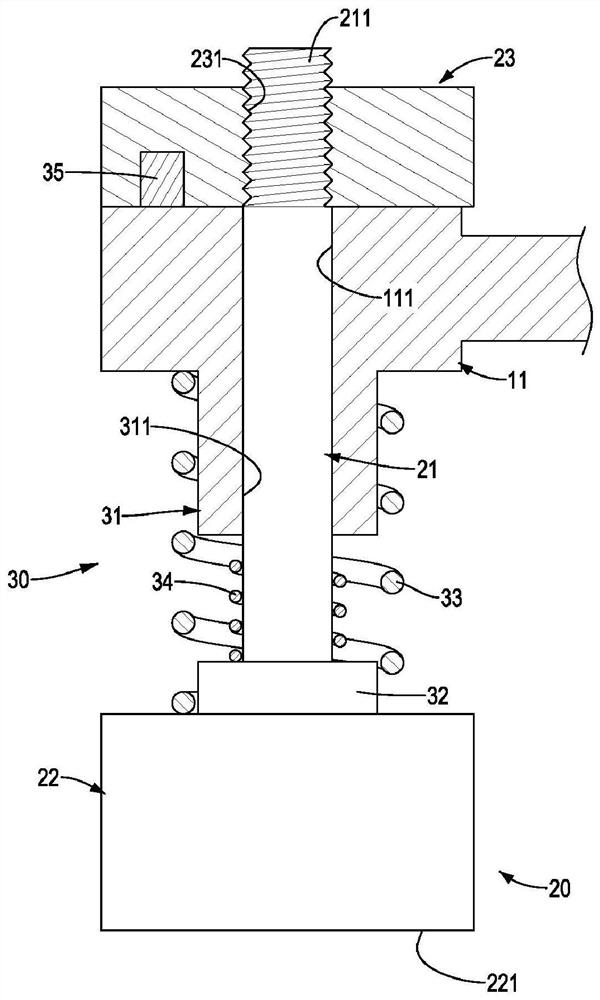

Removal tool and method of marine shafting adjusting ring bolts

ActiveCN108857367AAvoid situations that take more than four hoursReduce the number of tapsMetal working apparatusPulp and paper industryScrew thread

The invention belongs to the technical field of ship maintenance and particularly relates to a removal tool of marine shafting adjusting ring bolts. The removal tool comprises a drum plate in arc shape; one end of the drum plate is provided with a retaining plate perpendicular to the drum plate; the retaining plate is provided with more than two mounting holes mating with shafting adjusting ring bolt holes; a two-start bolt is fitted in each mounting hole and includes a first thread segment and a second thread segment, the first thread segment is passed through the corresponding mounting holeand is in screwed connection with two positioning nuts, and the two positioning nuts are positioned on the two sides of the retaining plate respectively; each second thread segment is in screwed connection with a connection nut. The removal tool provided herein enables shafting adjusting ring bolts to be removed more safely and more reliably, adjusting ring bolts can be removed from bolt holes more conveniently, and damage to bolt holes is decreased.

Owner:JIANGNAN SHIPYARD GRP CO LTD

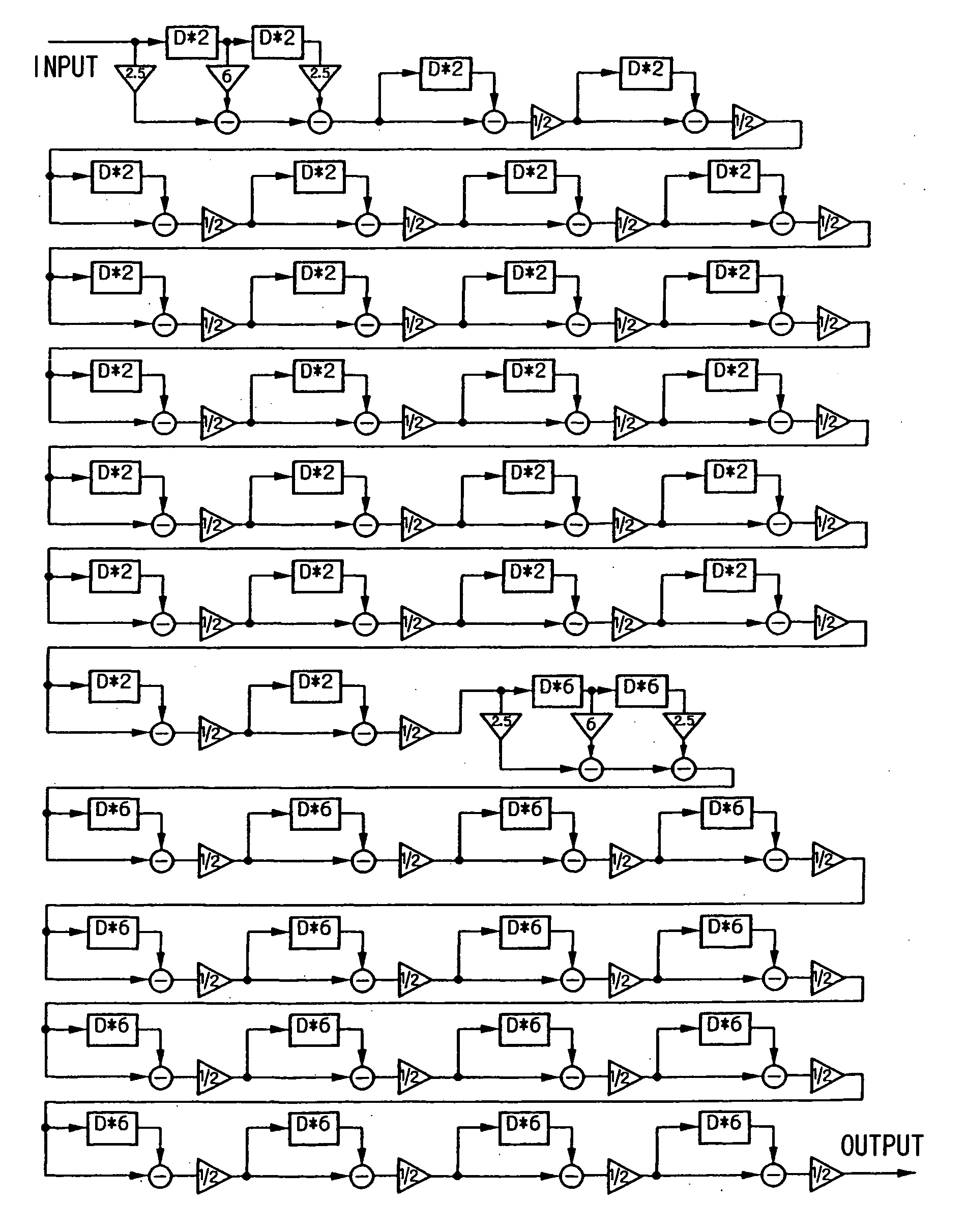

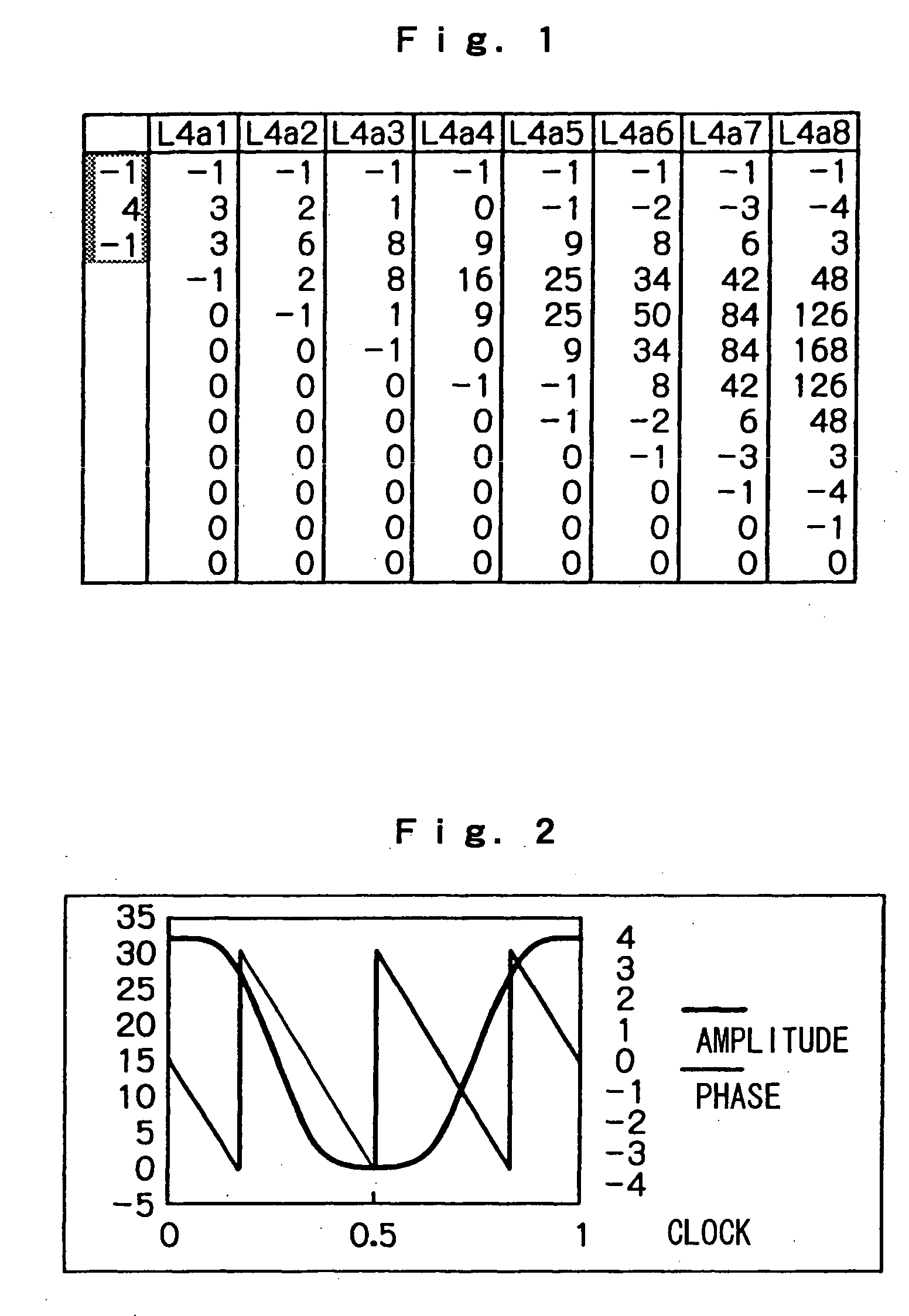

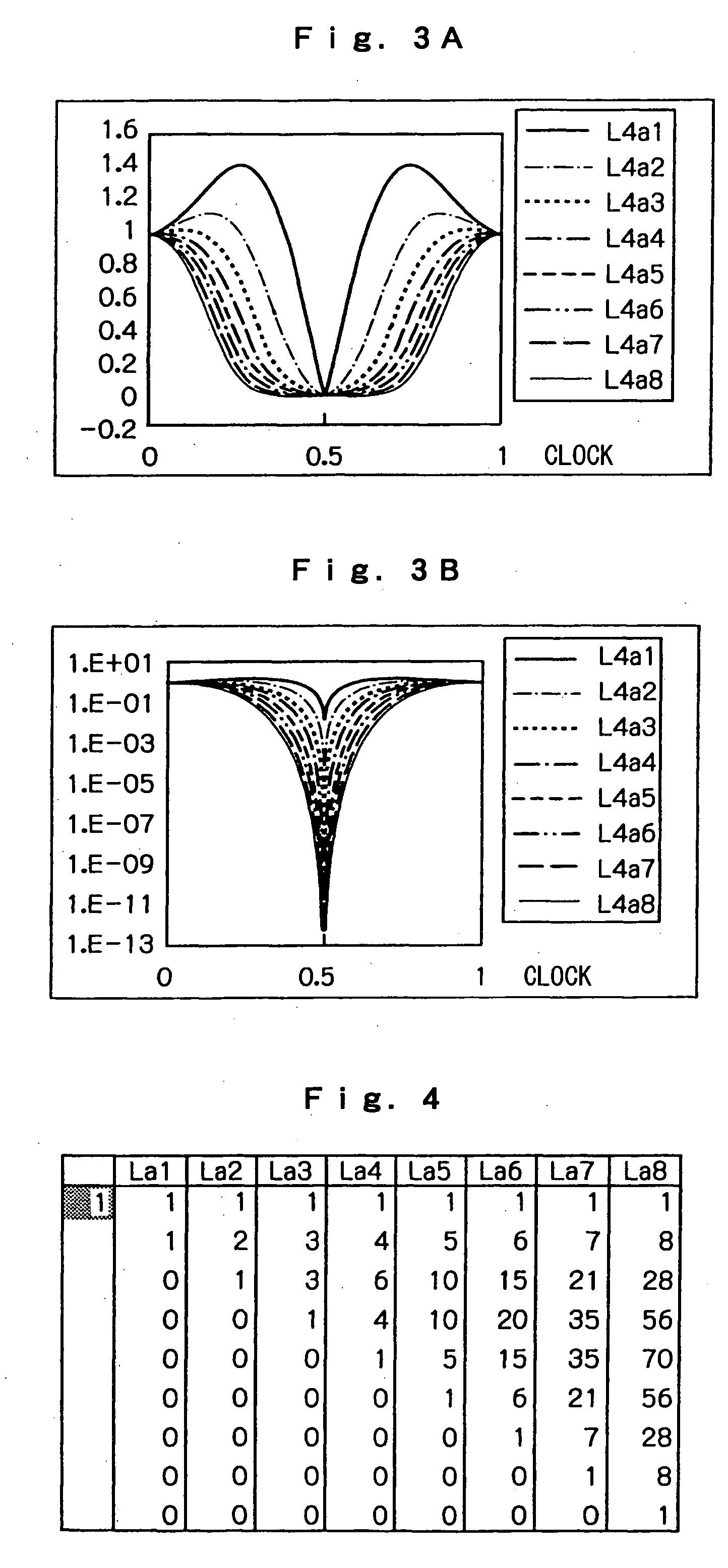

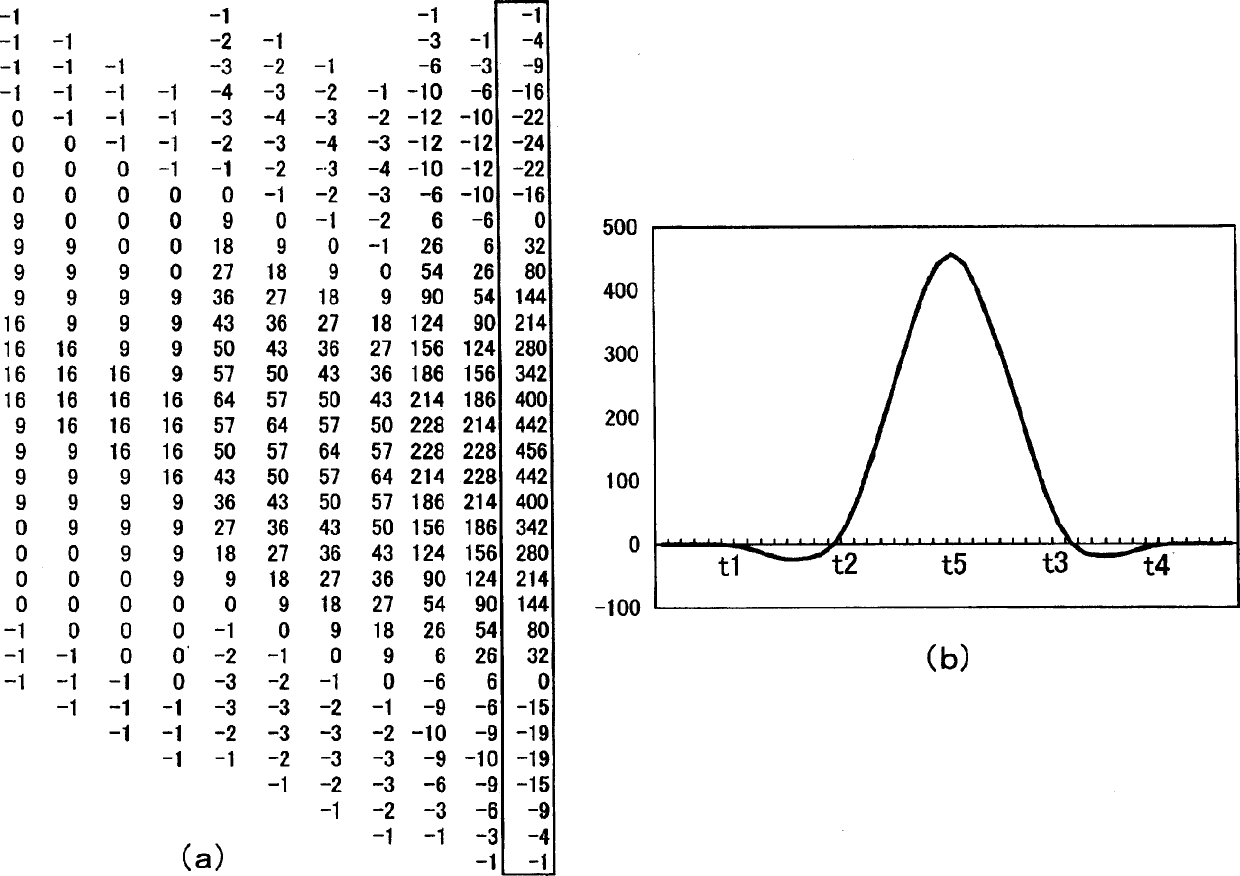

Digital filter design method and device, digital filter design program, digital filter

InactiveUS20050289206A1Reduce the number of tapsSimple structureDigital technique networkComplex mathematical operationsMoving averageUltrasound attenuation

A numerical string consisting of a ratio of “−1, m, −1” or “1, m, 1” is subjected to a predetermined moving average calculation n times. A numerical string thus obtained is used as filter coefficients of a basic filter and at least one basic filter is combined in an arbitrary way for cascade connection, thereby calculating the filter coefficients of the digital filter to be obtained. This significantly reduces the number of taps and the number of multipliers used as compared to the conventional FIR filter. Moreover, by using the numerical strings “−1, m, −1” and “1, m, 1” so that the filter impulse response becomes a finite-base function, it is possible to obtain a preferable frequency characteristic having no discretization error and having a great attenuation amount out of band.

Owner:NSC CO LTD

Test circuit board adapted to be used on universal serial bus connector

InactiveUS20170184671A1Improve stabilityEasy to useError detection/correctionPrinted circuit testingUSBEmbedded system

A test circuit board adapted to be used on USB connector is provided. Two test circuit boards can be seriously connected with each other through a first JTAG connection interface and a second JTAG connection interface. Therefore, the efficiency of reducing TAPs of TAP controller and providing test signal coverage of all of test signals may be achieved.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

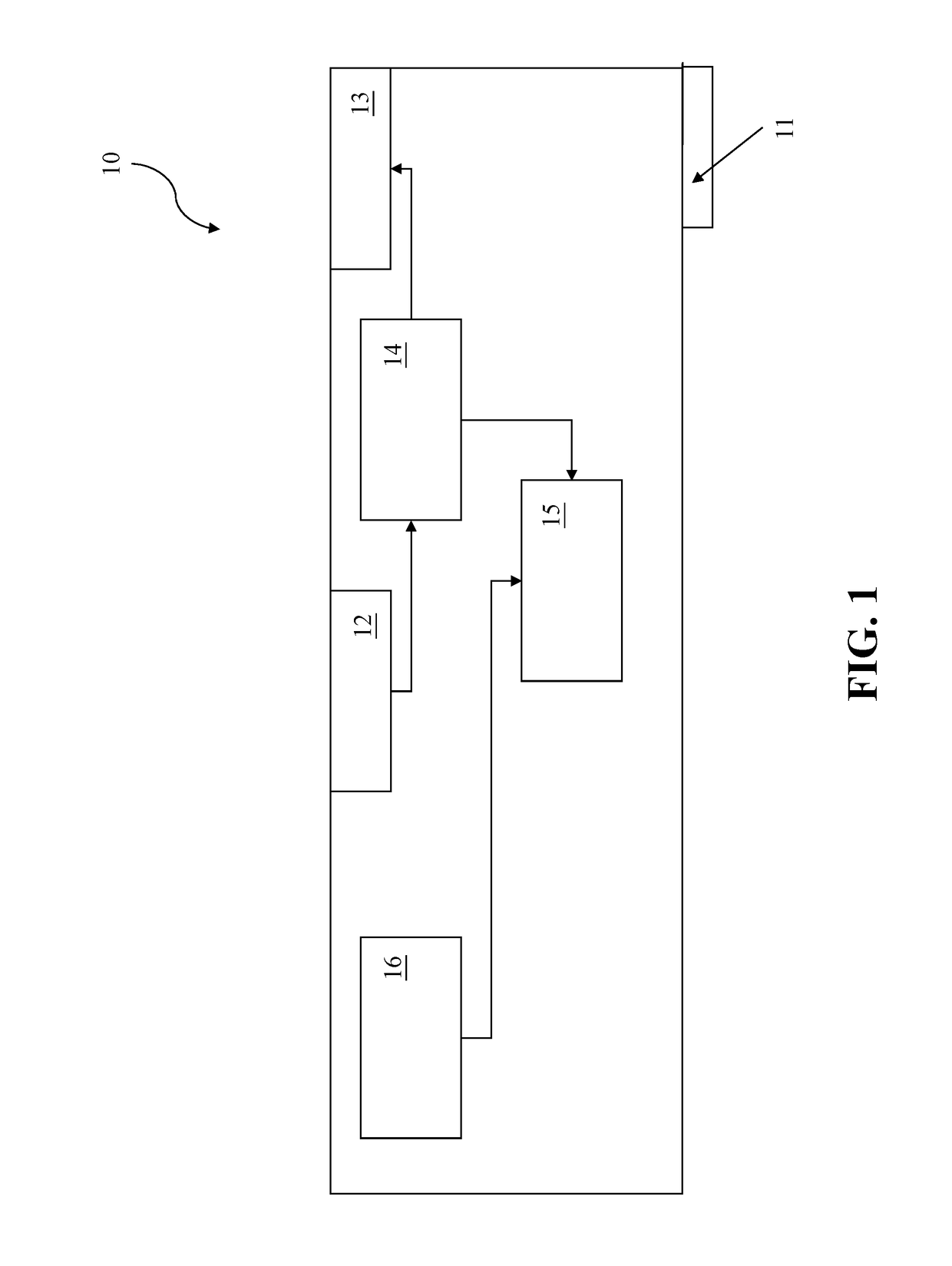

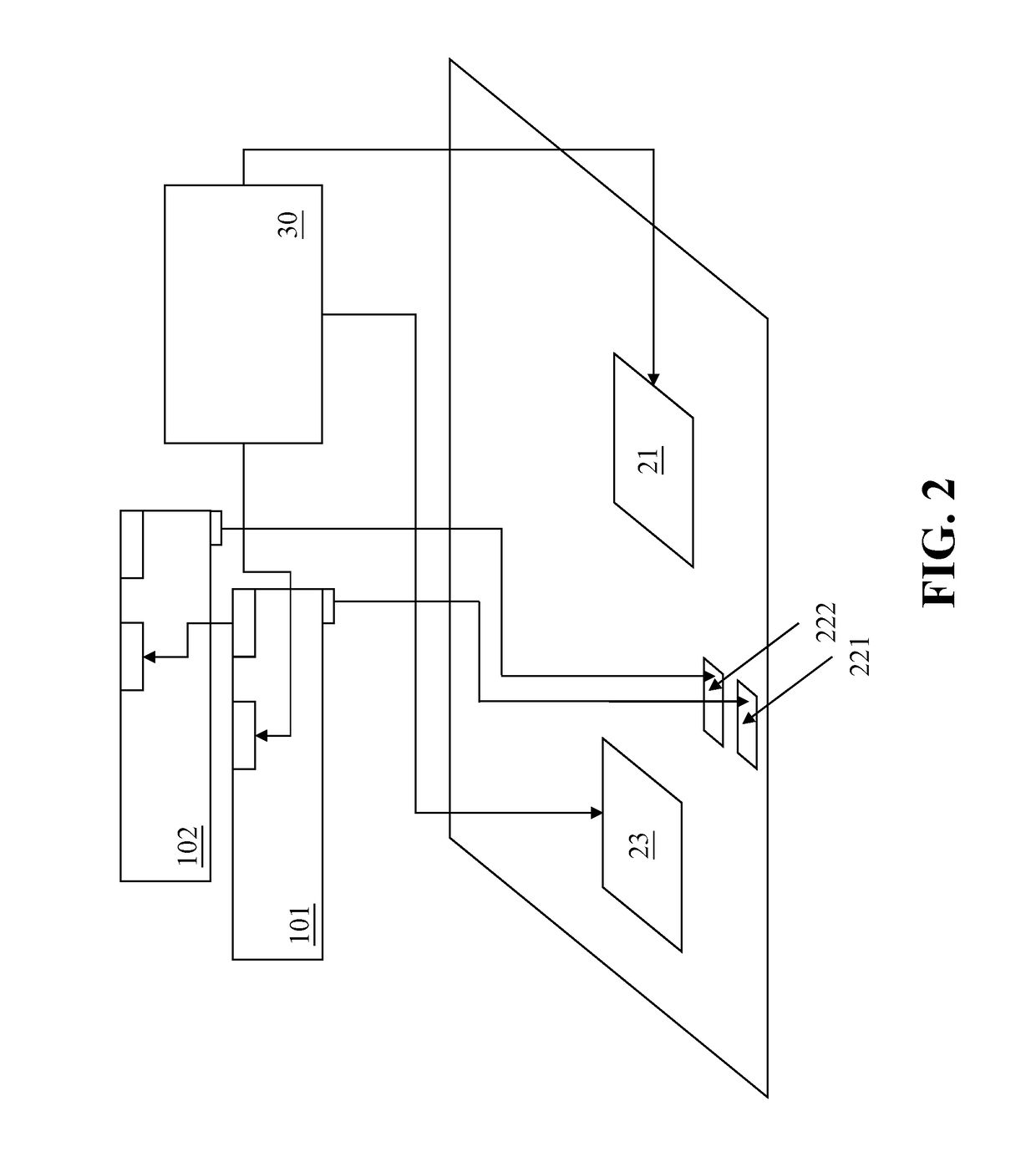

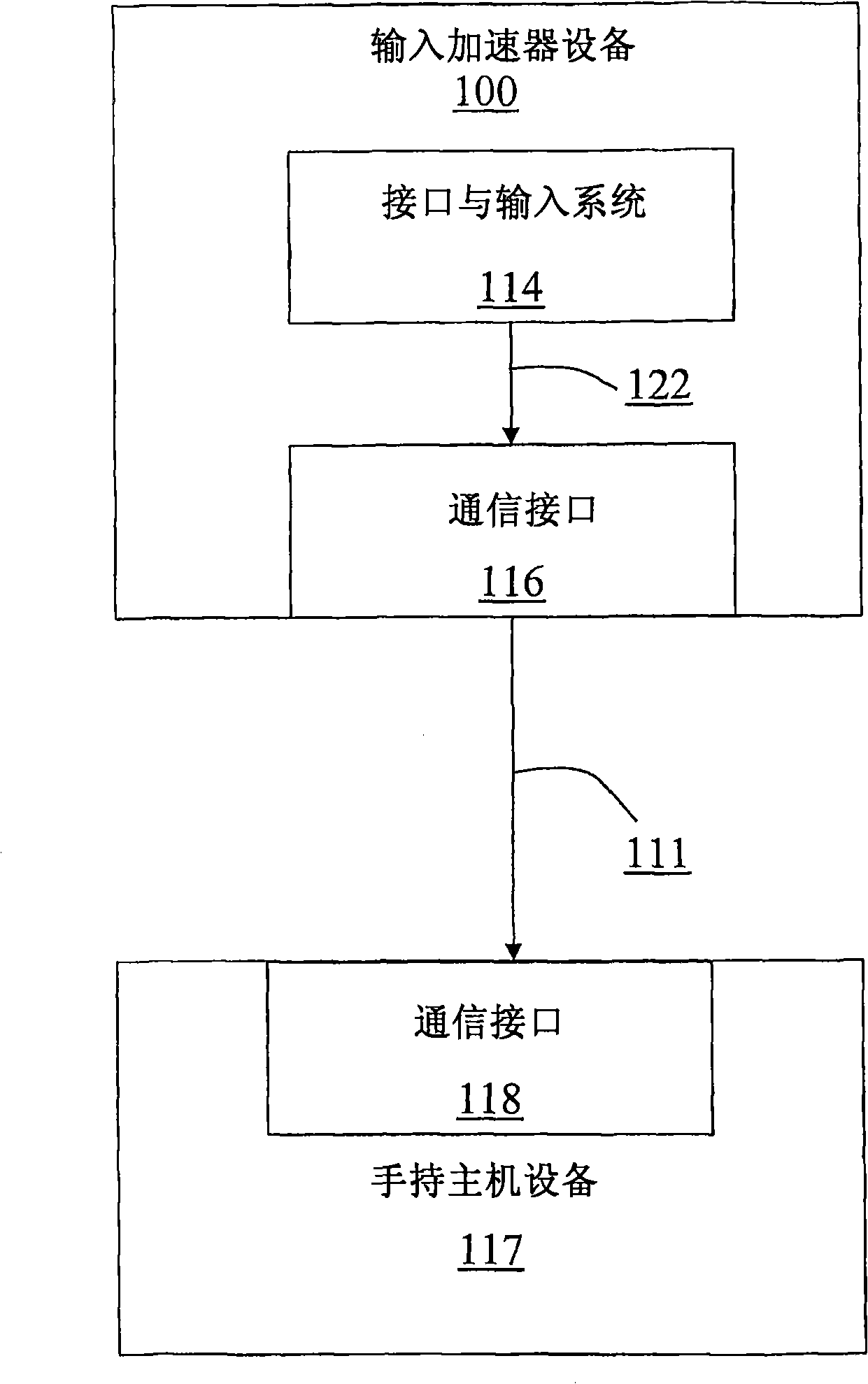

Human interface input acceleration system

InactiveCN101326480AIncrease the areaIncrease the number ofInput/output for user-computer interactionComputer hardwareHand held

A method and system for transmitting data to and from a hand-held host device are disclosed. An accessory device for interfacing with a host device includes a communication channel designed to establish a bidirectional data link between the accessory device and the host device. The accessory device also includes a storage unit communicatively coupled to the communication channel. The storage unit is designed to store various data. In addition, at least a first data is selectively transmitted from the stored data of the accessory device to the host device through the established bidirectional data link.

Owner:泽蒙特责任有限公司

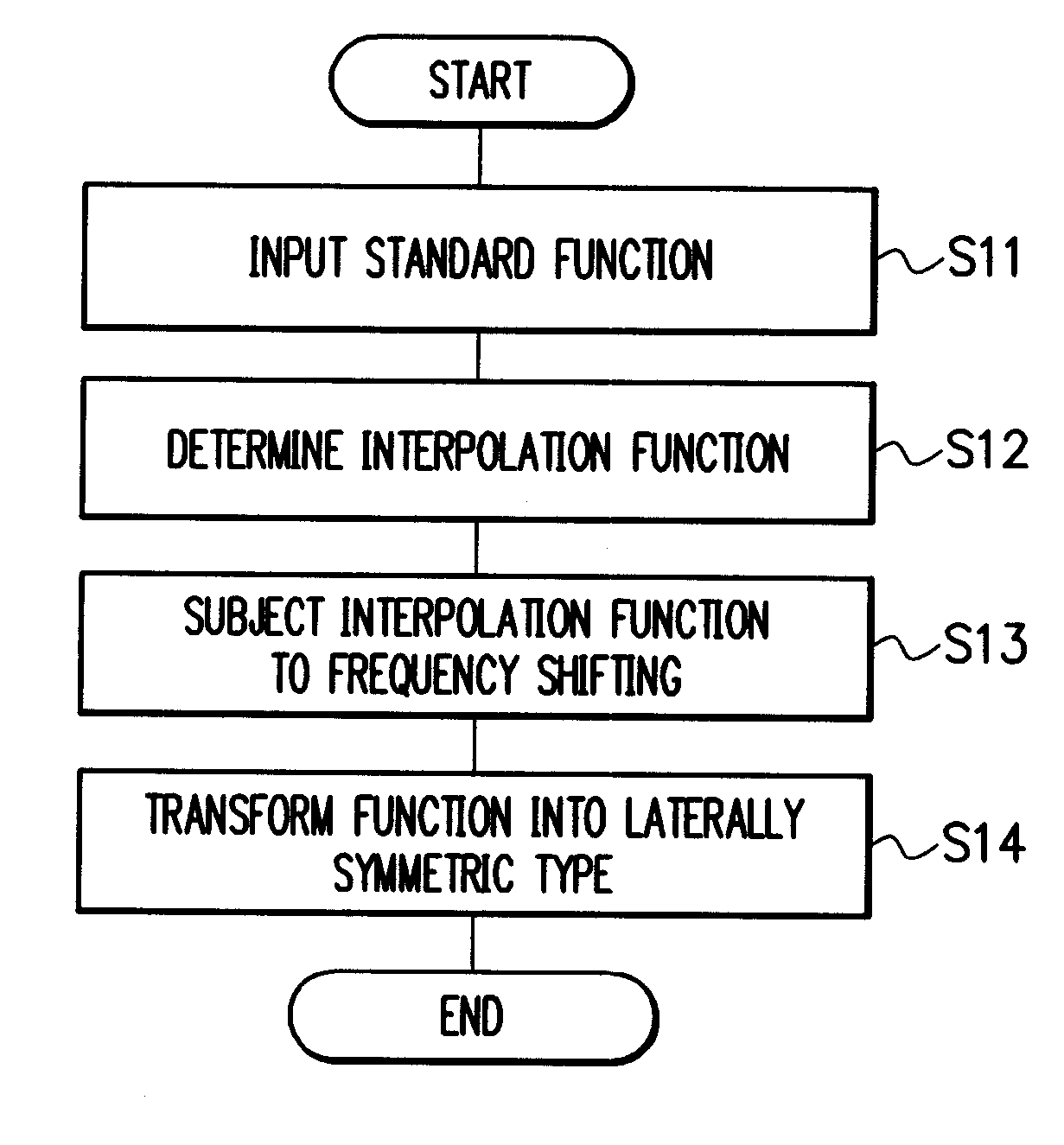

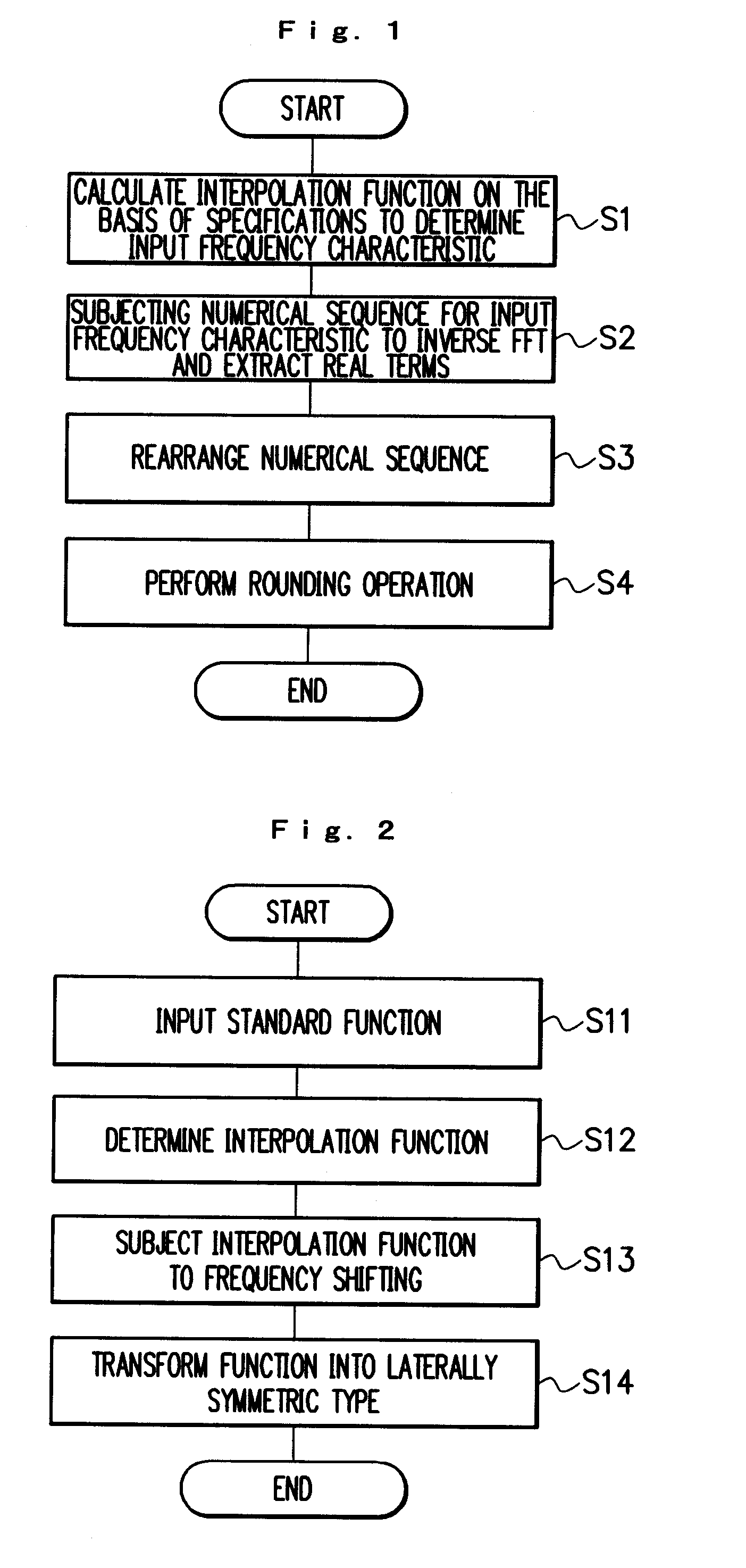

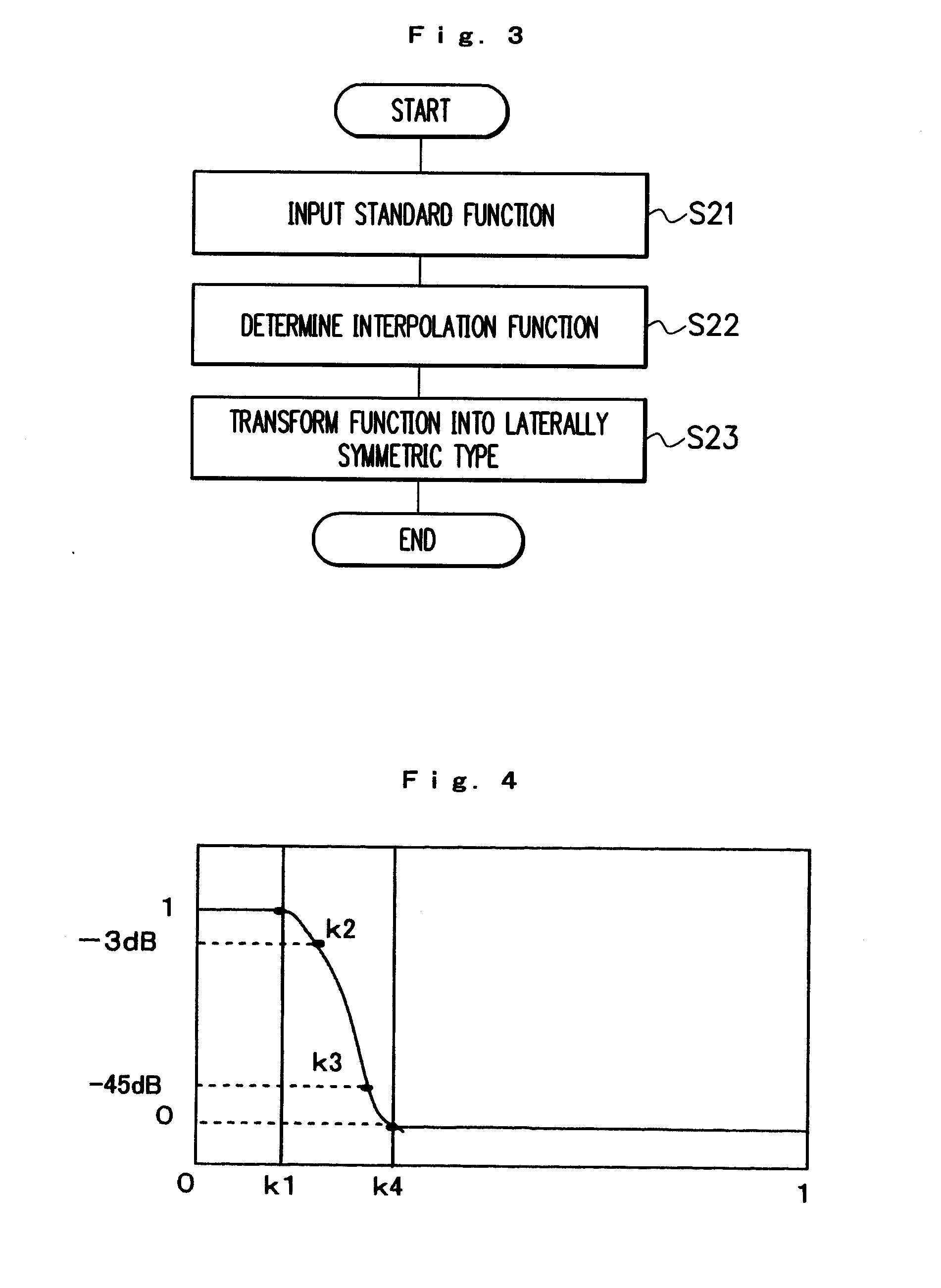

Methods, devices, and programs for designing a digital filter and for generating a numerical sequence of desired frequency characteristics

InactiveUS20070067377A1Simple designReduce in quantityDigital technique networkComplex mathematical operationsRoundingDigital filter

A standard function is inputted and an interpolation function of finite length is calculated therefrom. Then, the frequency characteristics of the interpolation function is shifted by a desired amount in the frequency axis direction, thereby determining input frequency characteristics based on specification. Filter coefficients are determined by performing inverse FFT of a numerical sequence representative of the input frequency characteristics and rounding is performed according to the coefficient values in order to obtain a smaller number of filter coefficients. Thus, it is possible to eliminate the need for windowing as an operation for decreasing the number of filter coefficients and easily design an FIR filter having desired frequency characteristics.

Owner:NSC CO LTD

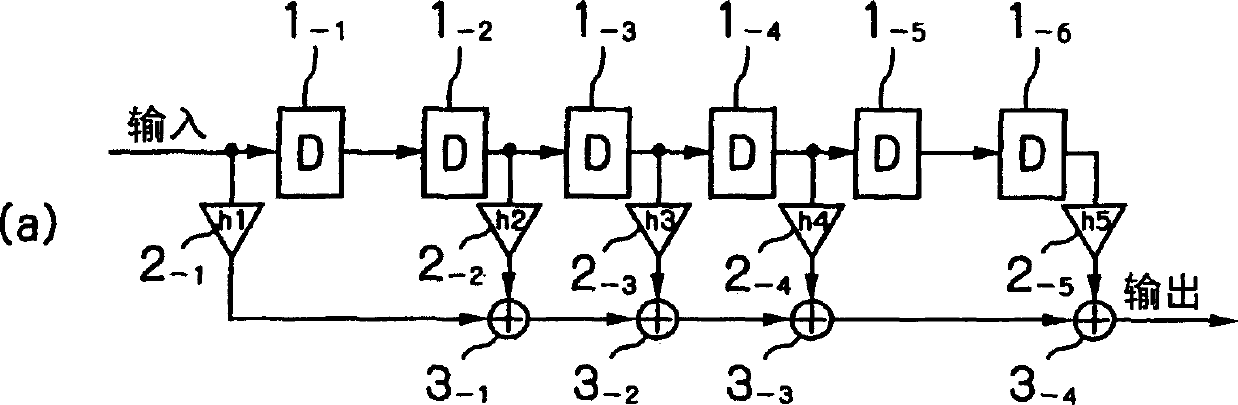

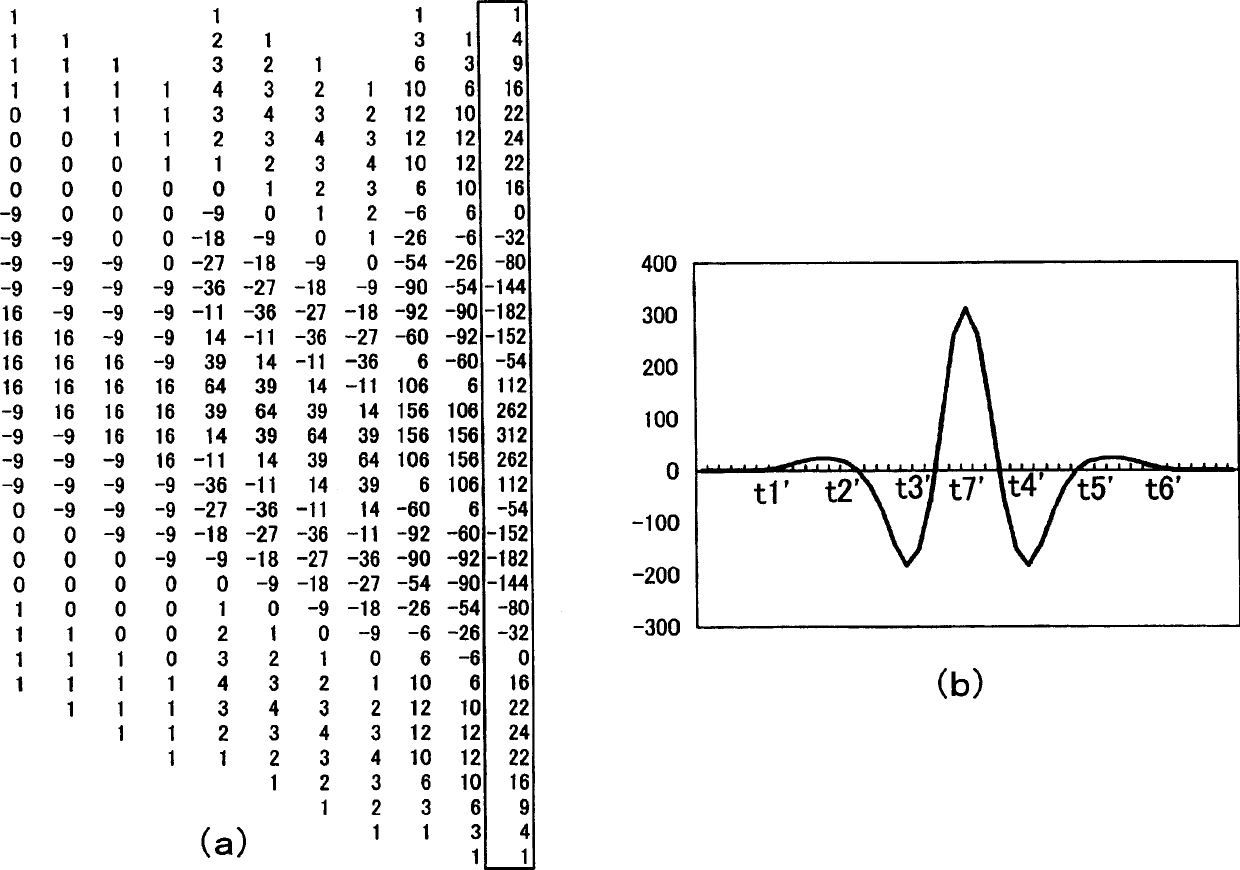

Digital filter design method and device, digital filter design program, and digital filter

InactiveCN1706101ASimple designAchieve frequency characteristicsDigital technique networkDigital filter designWindow function

A symmetric unit filter (L10') is designed by combining in series two unit filters (1L10, 2L10) having asymmetric numerical sequences as filter coefficients (H1 to H3 and H4 to H6). Thus, by designing a filter by series connection, it is possible to automatically obtain a desired digital filter coefficient only by combining one type of unit filter (L10') in series. Moreover, a symmetric numerical sequence {-1, 0, 9, 16, 9, 0, -1} / 32 is divided at the center into two parts and one of them is used as the asymmetric filter coefficients (H1 to H3 and H4 to H6). This reduces the number of necessary taps, eliminates use of a window function, and prevents generation of a discretization error in the filter characteristic obtained.

Owner:NEURO SOLUTION CORP

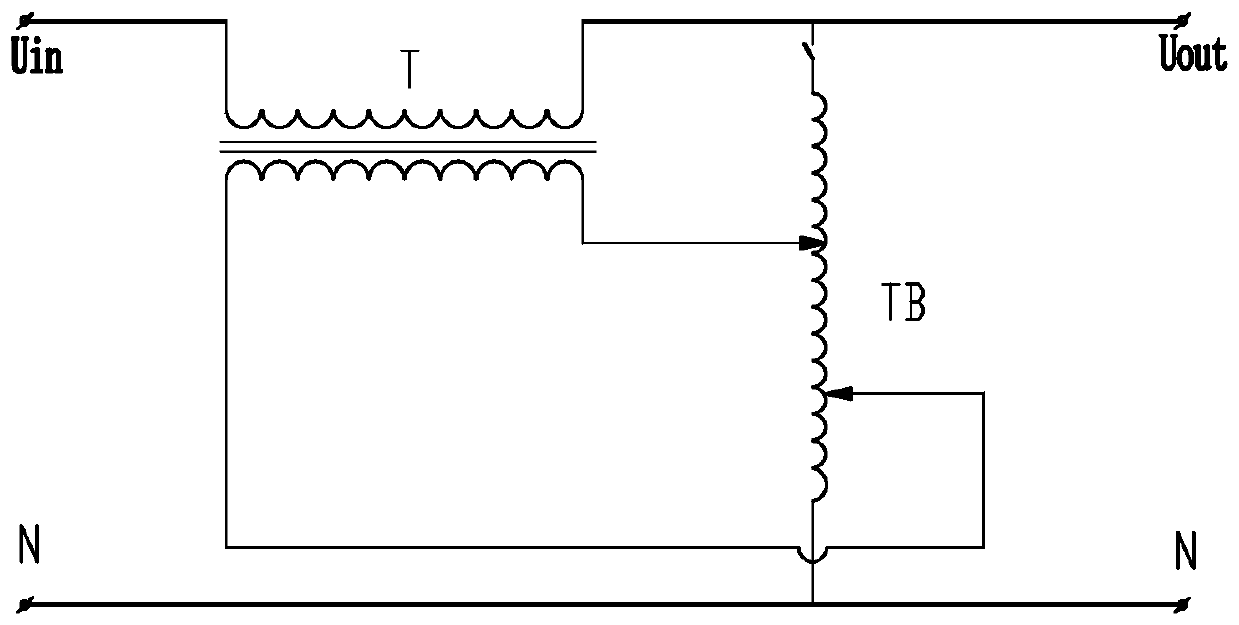

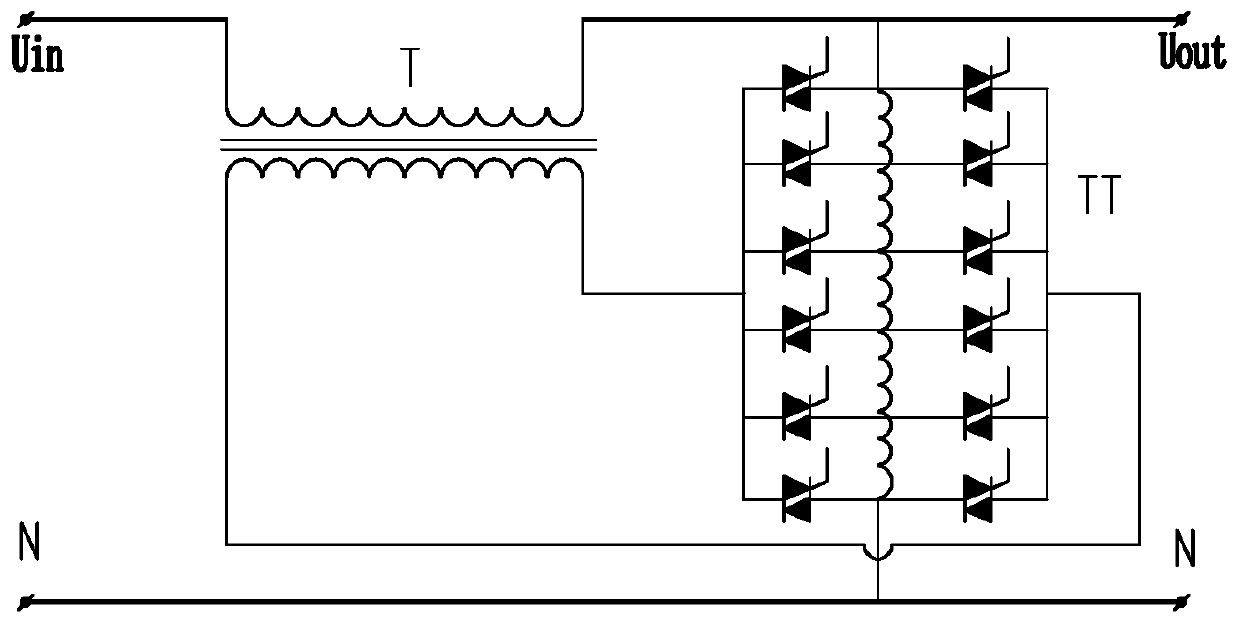

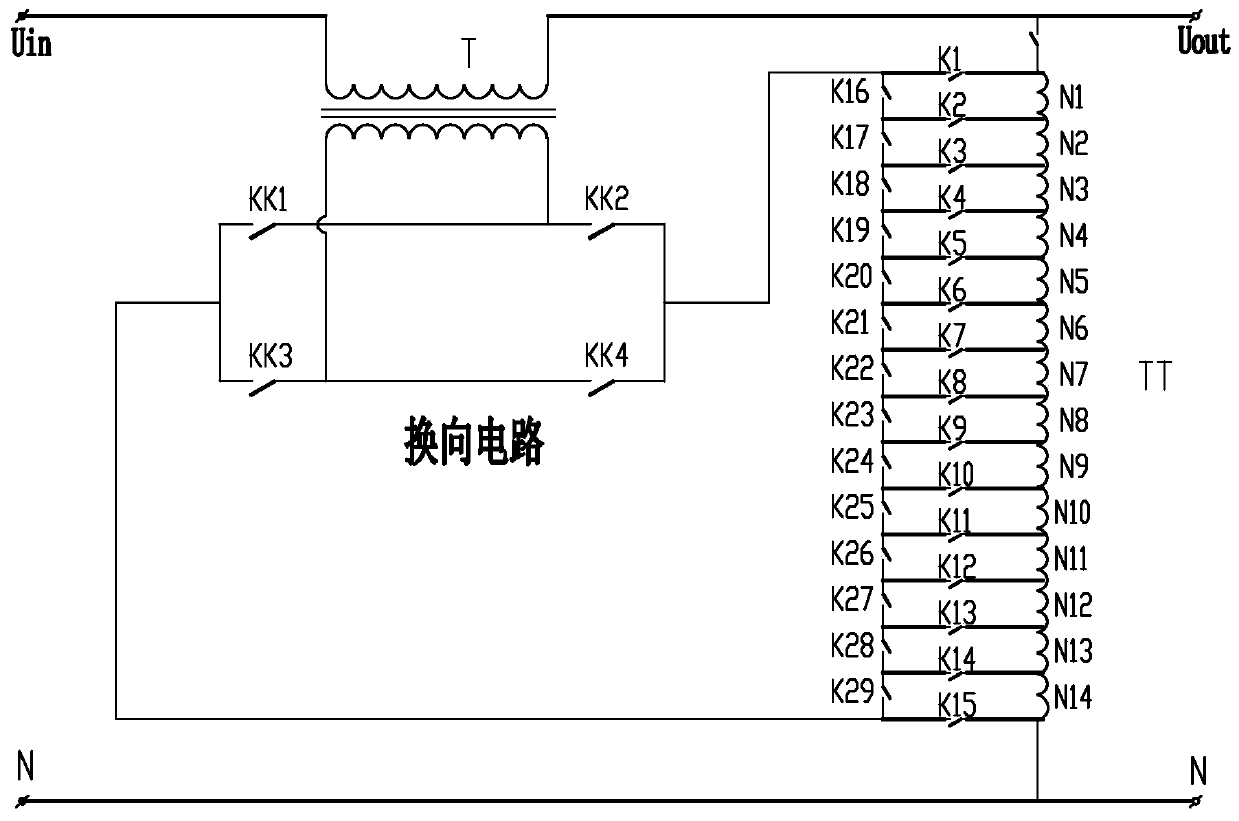

Contactless voltage stabilizer main circuit with high voltage stabilization precision and contactless voltage stabilizer

PendingCN110247556AFast adjustmentImprove reliabilityConversion without intermediate conversion to dcVariable inductancesAutotransformerTransformer

The invention discloses a contactless voltage stabilizer main circuit with high voltage stabilization precision. The contactless voltage stabilizer main circuit comprises a compensation transformer, an autotransformer and a reversing circuit. The two lead-out terminals and the n taps of the autotransformer are connected in parallel to be connected with a parallel wire through first contactor switches. Second contactor switches are arranged between every two adjacent connection points on the parallel wire. Both ends of the parallel wire are connected to the primary winding of the compensation transformer through the reversing circuit. The contactless voltage stabilizer main circuit has high voltage stabilization precision and a wide voltage stabilization range. The invention also discloses a contactless voltage stabilizer, which comprises a contactless voltage stabilizer main circuit, an output sampling circuit, a comparator and a control circuit, wherein the output sampling circuit acquires the voltage at the output end of a circuit to be subjected to voltage stabilization; the comparator is connected to the output sampling circuit; the control circuit is connected to the comparator, the reversing circuit, the first contactor switches and the second contactor switches. The contactless voltage stabilizer achieves high precision and voltage stabilization in a wide range.

Owner:PEARL ELECTRIC +1

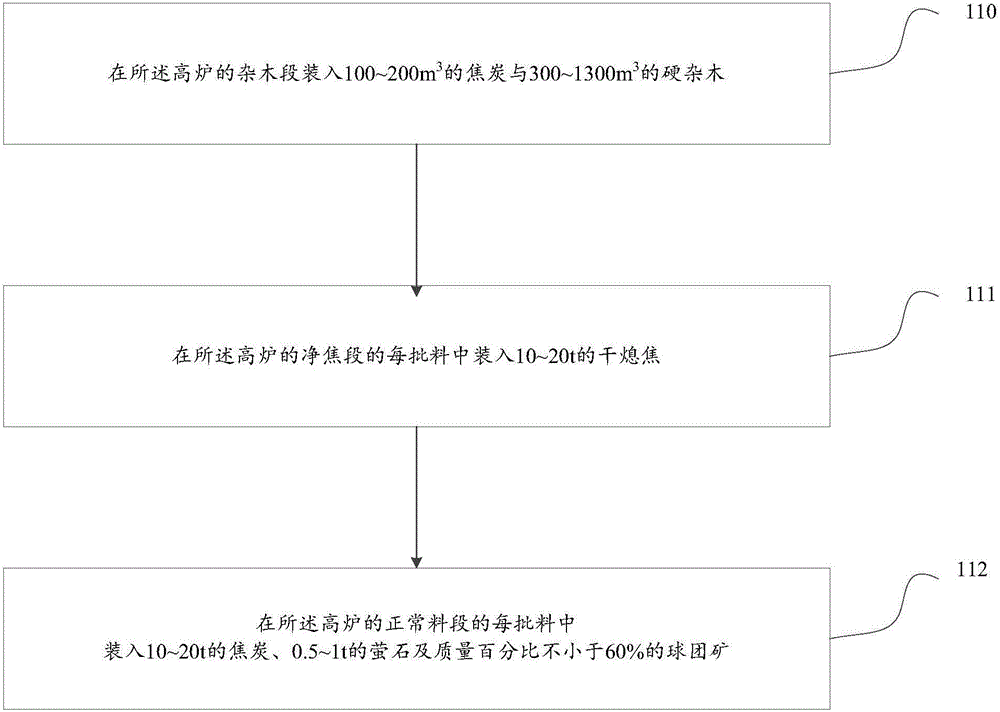

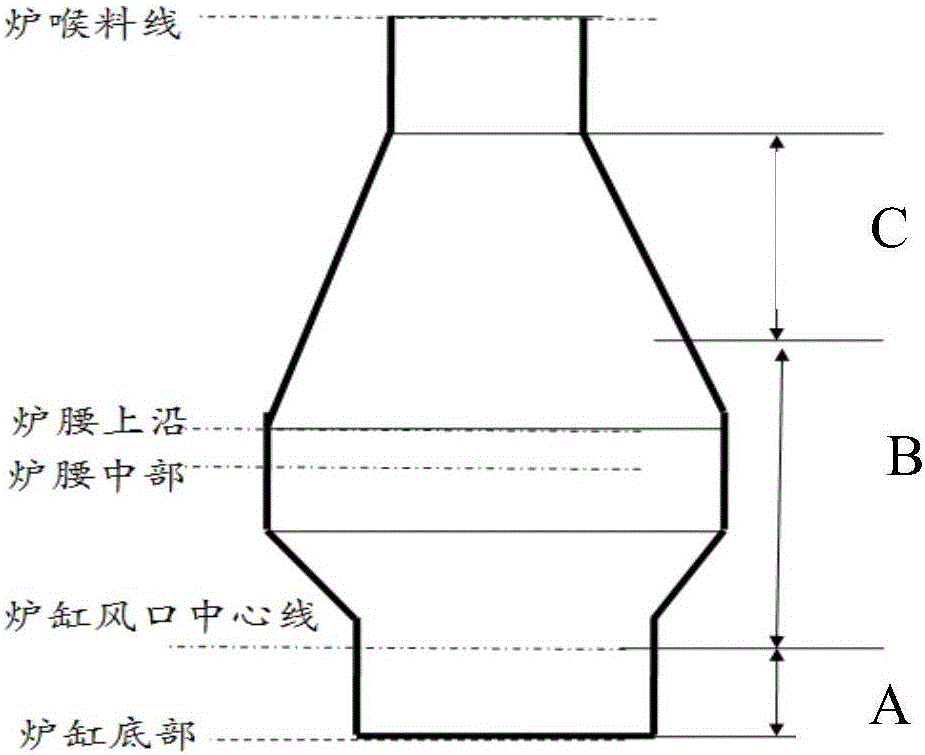

Blow-in burdening method for blast furnace

The invention provides a blow-in burdening method for a blast furnace. The method comprises the steps that 100 m<3>-200 m<3> of coke and 300 m<3>-1,300 m<3> of hardwood are arranged in a miscellaneous tree section of the blast furnace; 10 t-20 t of dry extinction coke is arranged in each batch of materials of a net coke section of the blast furnace; 10 t-20 t of coke, 0.5 t-1 t of fluorite and pellet ores with the mass percent not smaller than 60% are arranged in each batch of materials of a normal material section of the blast furnace; and the content of CaF2 in material slag in the normal material section is 2%-6%, the content of Si in molten iron is 2.5%-4%, and the iron charge load level is not larger than 2.5. Thus, the blow-in cost can be reduced by adopting the hardwood for blow-in operation, by adoption of a large proportion of pellet for the blow-in operation, the furnace slag generation amount can be reduced, the ventilation performance of a soft melting belt is improved, the blow-in progress is accelerated, and the direct motion state of the blast furnace is stabilized; and the number of tapping times can be reduced through few-slag or ultralow-slag ratio blow-in, the tapping time is delayed, it is guaranteed that iron in the furnace obtains the sufficient physical heat, and more qualified pig iron can be better recycled.

Owner:SHOUGANG CORPORATION

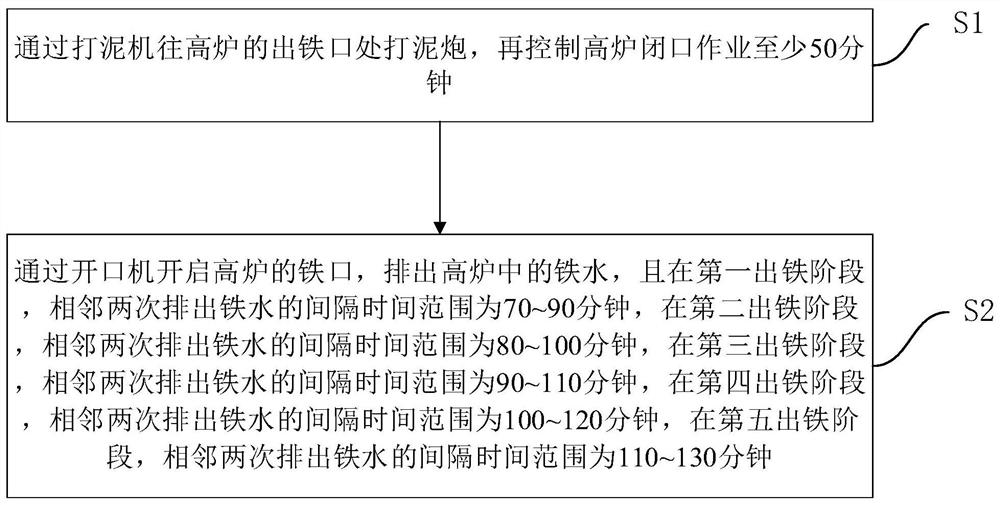

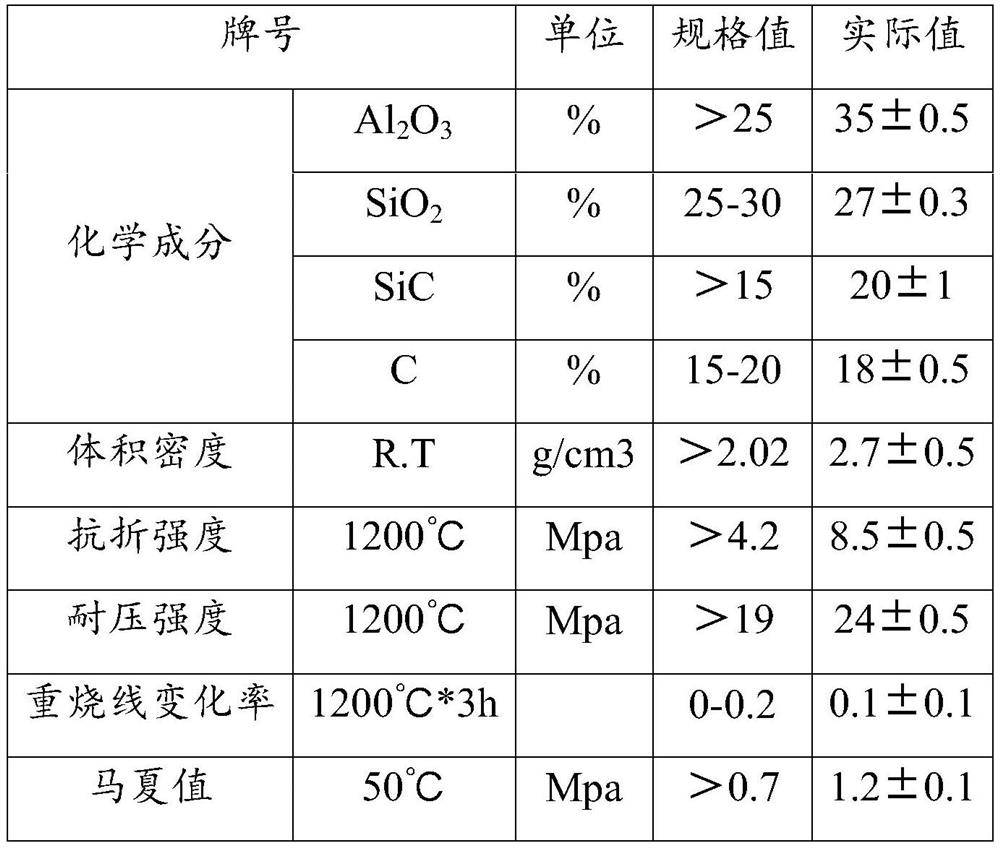

Method for reducing tapping frequency of blast furnace

ActiveCN112501369AReduce consumptionInfluence intensityBlast furnace componentsBlast furnace detailsEngineeringMaterials science

The invention discloses a method for reducing the tapping frequency of a blast furnace. The method comprises the following steps that a clay gun is beaten to a tapping hole of the blast furnace through a clay beater, and the blast furnace is controlled to conduct closing operation for at least 50 minutes; gun clay comprises the components of, by mass, more than 25% of Al2O3, 25%-30% of SiO2, and more than 15% of SiC and 15%-20% of C; and a tapping machine is used for opening an iron notch of the blast furnace, molten iron in the blast furnace is discharged, in the first tapping stage, the interval time range of two adjacent times of molten iron discharging is 70-90 minutes, in the second tapping stage, the interval time range of two adjacent times of molten iron discharging is 80-100 minutes, in the third tapping stage, the interval time range of two adjacent times of molten iron discharging is 90-110 minutes, in the fourth tapping stage, the interval time range of two adjacent times of molten iron discharging is 100-120 minutes, and in the fifth tapping stage, the interval time range of two adjacent times of molten iron discharging is 110-130 minutes. According to the method, thetapping frequency of the blast furnace can be reduced, and the gun clay consumption can also be reduced.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

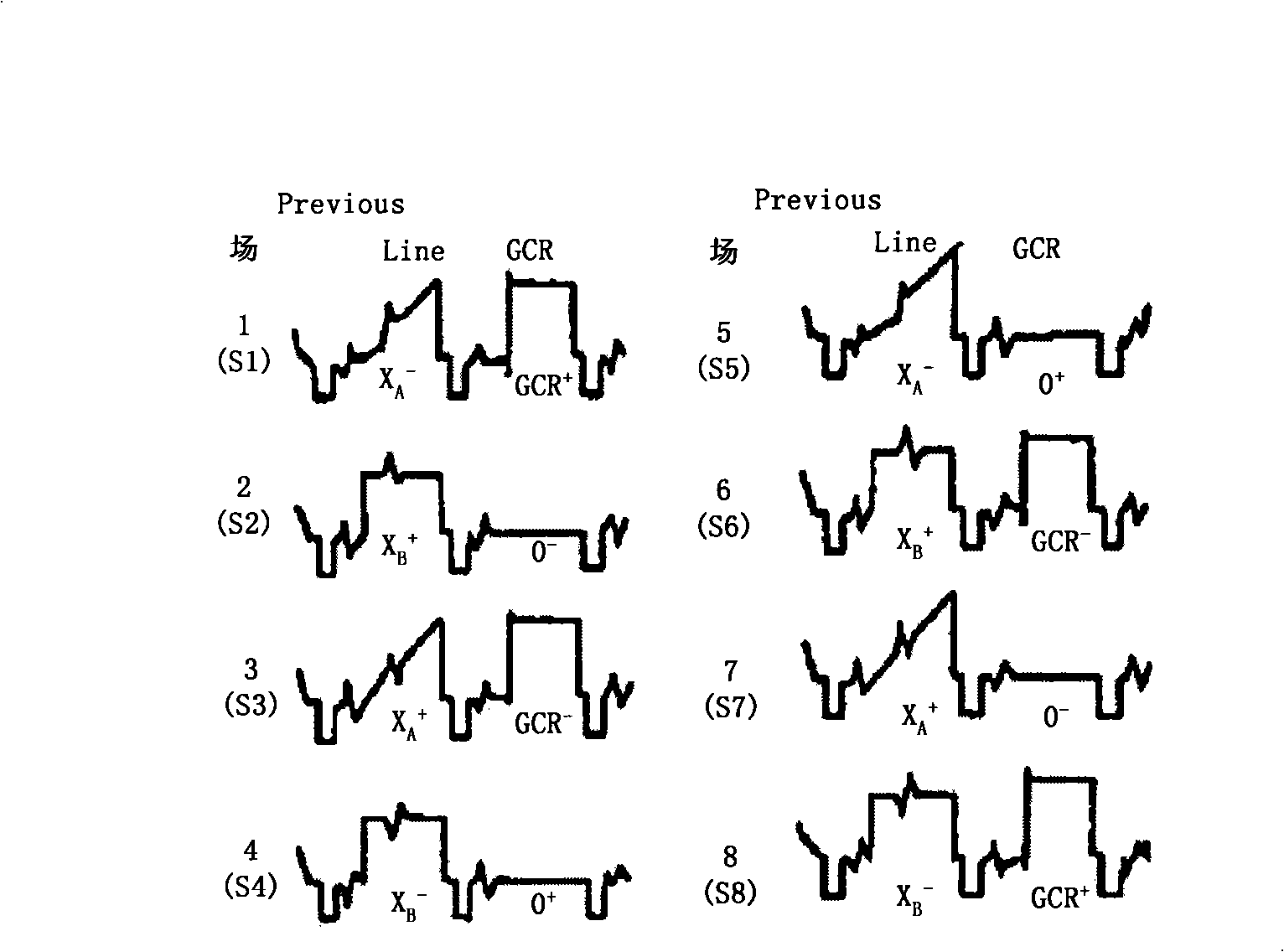

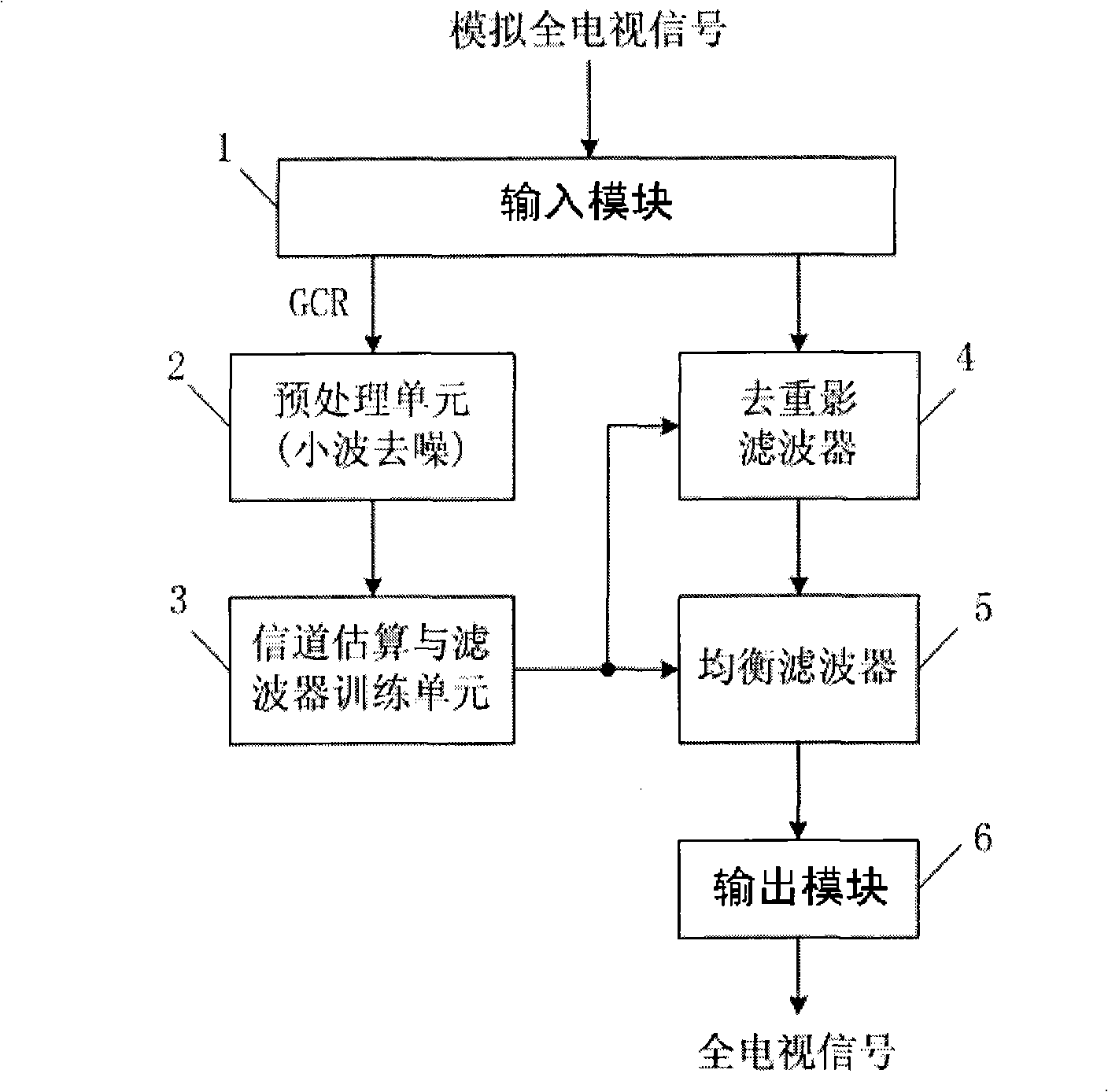

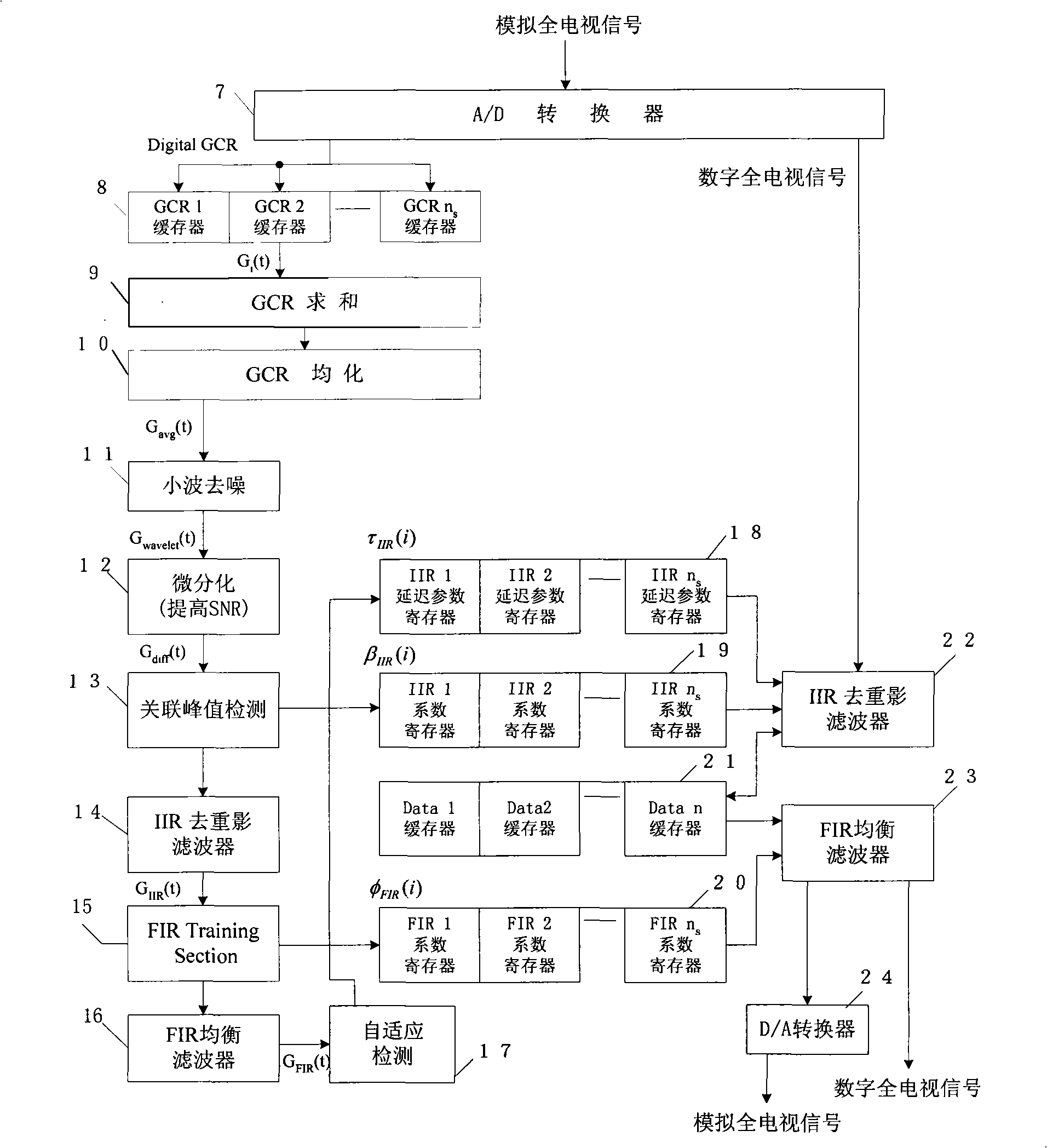

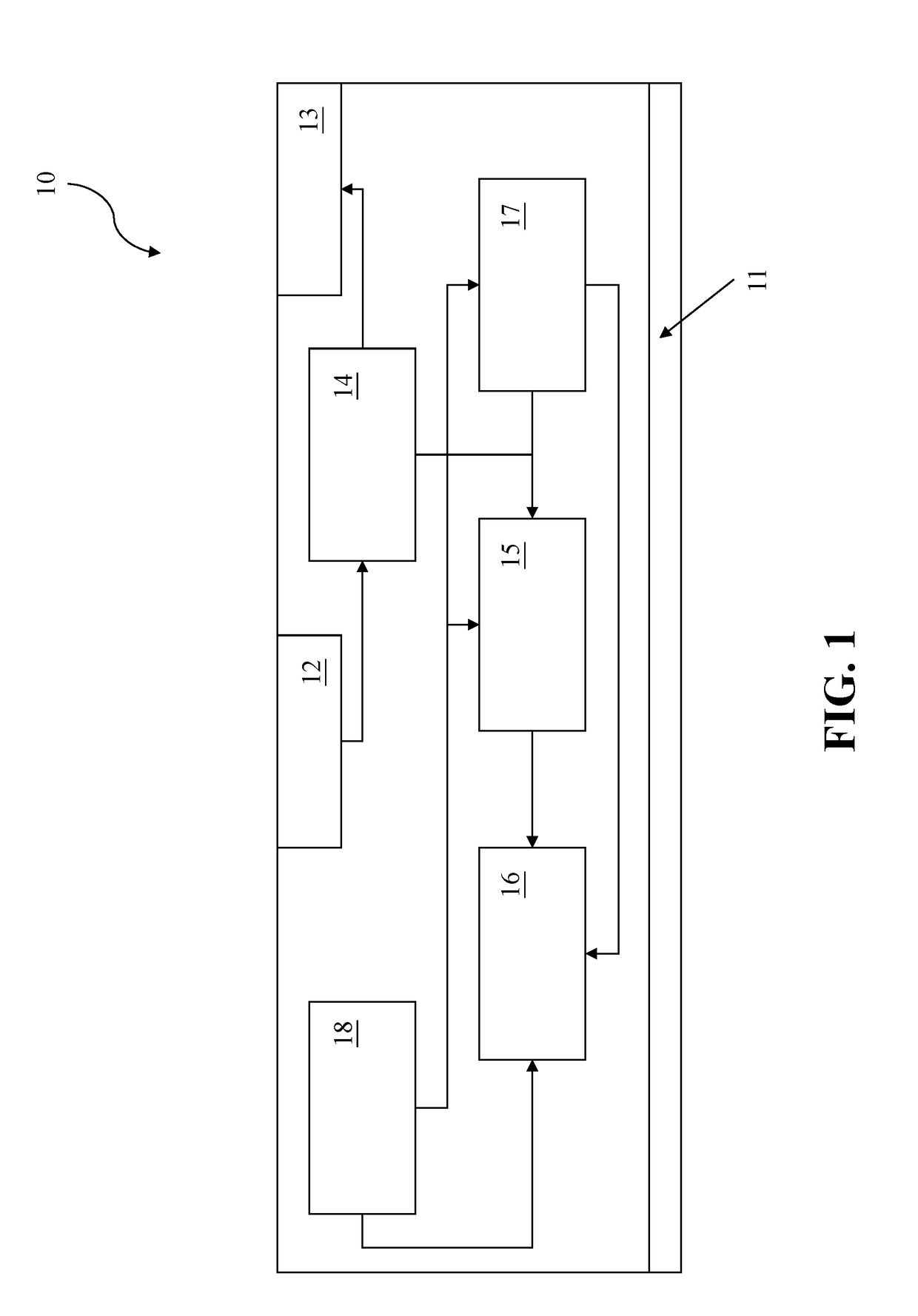

Method and system for eliminating ghost of television signal based on wavelet preprocessing GCR

InactiveCN101304480AReduce the number of tapsReduce ghostingTelevision system detailsEnergy efficient ICTElimination methodWave shape

The invention relates to a television signal ghost canceling method based on wavelet pretreatment GCR and a system thereof. The method comprises the following steps: the denoise of a received GCR signal is carried out by wavelet transformation, the channel feature is estimated according to the de-noised GCR signal waveform, an optimum coefficient of a ghost canceling filter and an equalization filter is obtained and ghost canceling to the digital television signal is carried out by the ghost canceling filter and the equalization filter. By adopting the method, the tap number of the filter can be reduced, thus reducing the hardware requirement of the ghost canceling system, and the power consumption of a chip reduces as MAC operation reduces. The method and the system provided by the invention can reduce the training time of the filter, track the time-varying channel rapidly and reduce the hardware requirement of the system, and have important theoretical meaning and practical meaning in digital mobile communication.

Owner:HUNAN UNIV

Test circuit board adapted to be used on peripheral component interconnect express slot

InactiveUS20170184669A1Easy to useReduce testing costsDigital circuit testingElectrical measurement instrument detailsJoint Test Action GroupEngineering

A test circuit board adapted to be used on PCI-E slot is provided. Two test circuit boards can be seriously connected with each other through a first JTAG connection interface and a second JTAG connection interface. Therefore, the efficiency of reducing TAPs of TAP controller and providing test signal coverage of all of test signals may be achieved.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

Self-adaptive echo eliminator and echo eliminating method thereof

InactiveCN101179294BReduce the number of tapsLow steady state misalignmentTwo-way loud-speaking telephone systemsLine-transmissionCommunications systemProximal point

The invention provides an adaptive echo eliminator and the echo eliminating method thereof; wherein the device consists essentially of a voice state detector, an NLMS (energy normalized least mean square error) controller and a sliding window FIR filter. The method mainly includes the following steps: sampling both a far-end voice signal and a near-end voice signal, and confirming the speaking status information of the current network according to the estimated values of the short-time energy of the sampled far-end speech signal sample and the near-end speech signal sample. Then, the coefficient of a sliding window FIR filter is configured according to the speaking status information of the current network, and the sliding window FIR filter step-by-step filters the near-end speech signal and the far-end speech signal filled into the buffer area according to the mobile length set by the configured coefficient. Utilizing the invention, the echo of the digital hands-free speaking system can be effectively eliminated, thereby effectively eliminating the echo of the digital communication system based on the embedded system.

Owner:APLUS COMM TECH BEIJING

Bleed hole stemming and method for producing the same

ActiveCN100575308CGood sintered strengthEasy to openBlast furnace componentsBlast furnace detailsPyrophylliteGraphite

The invention relates to a stemming at a taphole; the weight percentages of the components are the following: 20 to 40 of corundum, 10 to 20 of silicon carbide, 3 to 10 of silicon nitride, 10 to 23 of coke powders, 1 to 5 of graphite powders, 3 to 10 of sericite, 1 to 5 of active alumina micropowders, 5 to 15 of clay, 5 to 10 of pyrophyllite, 1 to 3 of metal powders, and +15 to 25 of water-free binder. The stemming adds a plurality of materials with plasticity and good cohesiveness to cause the stemming to easily block the hole and fill interspaces, with good binding performance of new stemming and old stemming; materials with medium and high temperature expansion are added to reduce the size of the stemming contraction at high temperature, and cracks can be avoided; materials with sintering function within different temperature areas are added, so the stemming has good sintering strength in different temperature scopes; materials with high-temperature resistance and good erosion resistance are added, and thus the stemming has high strength at high temperature, washing resistance and erosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

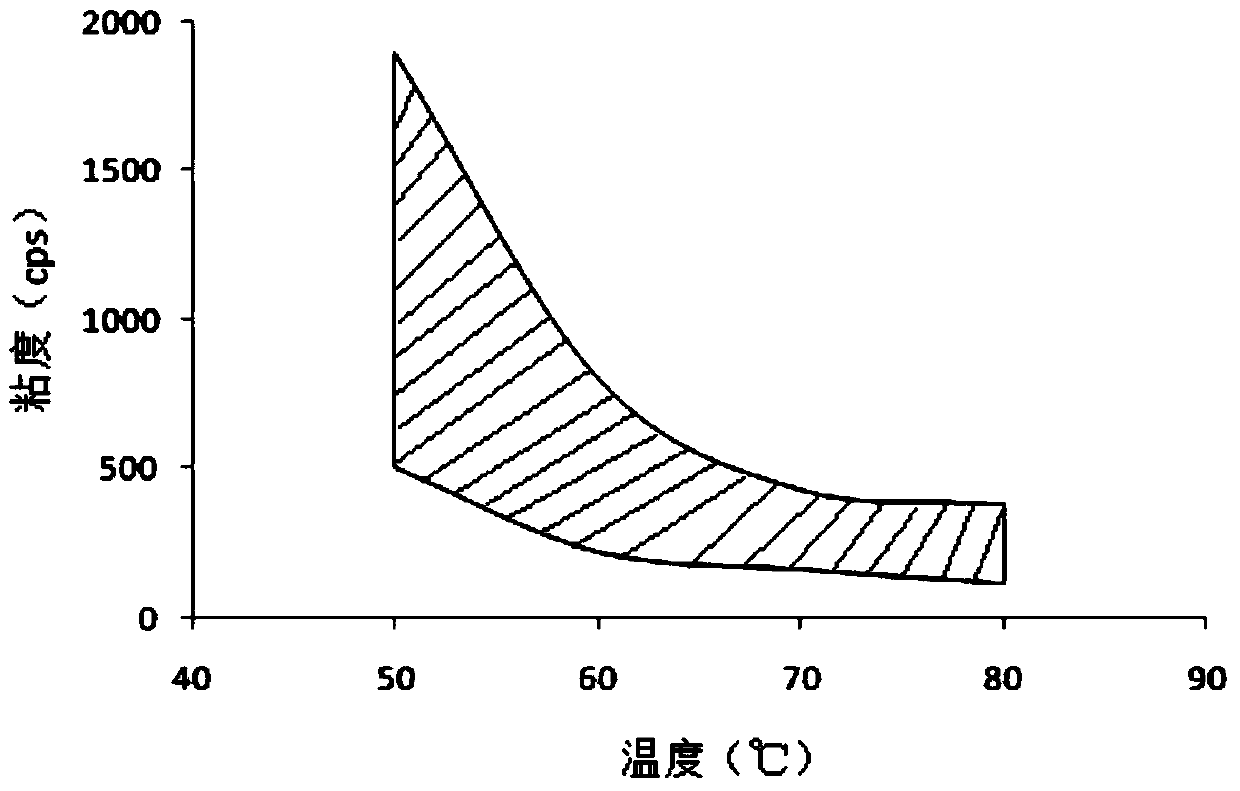

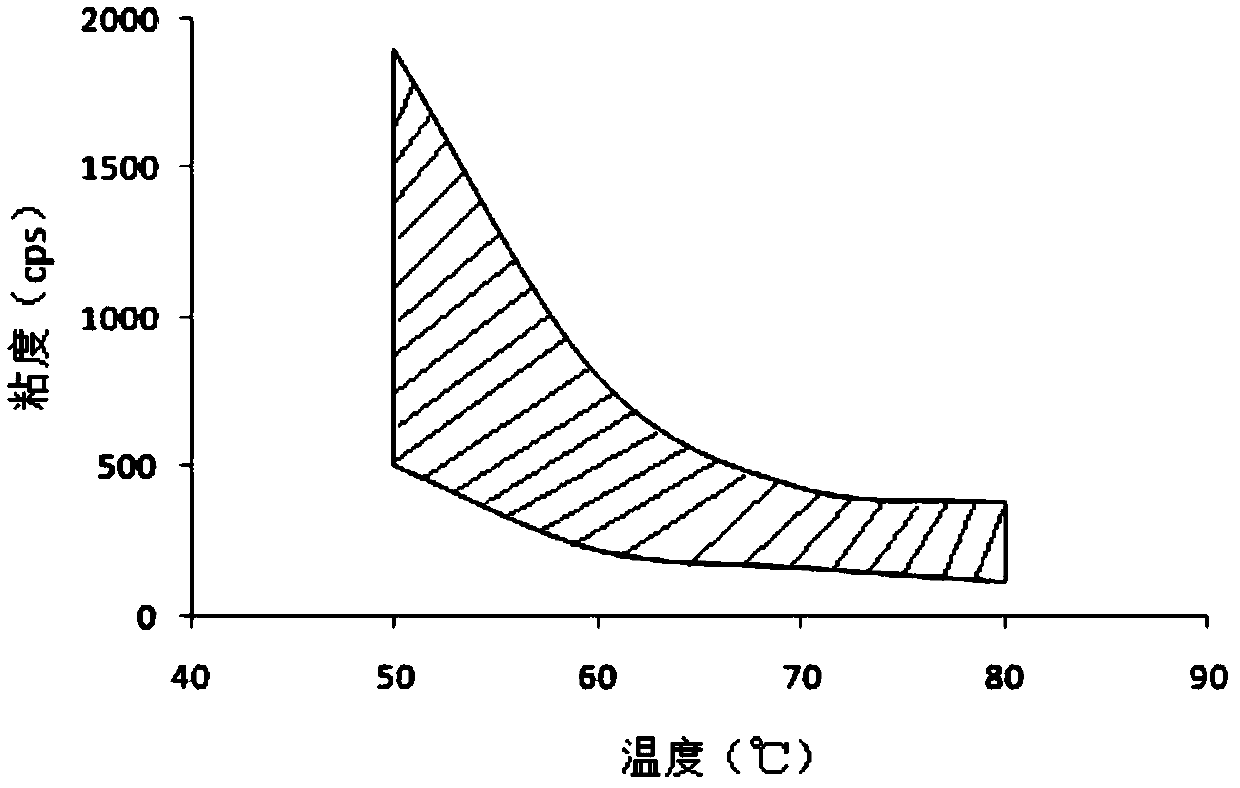

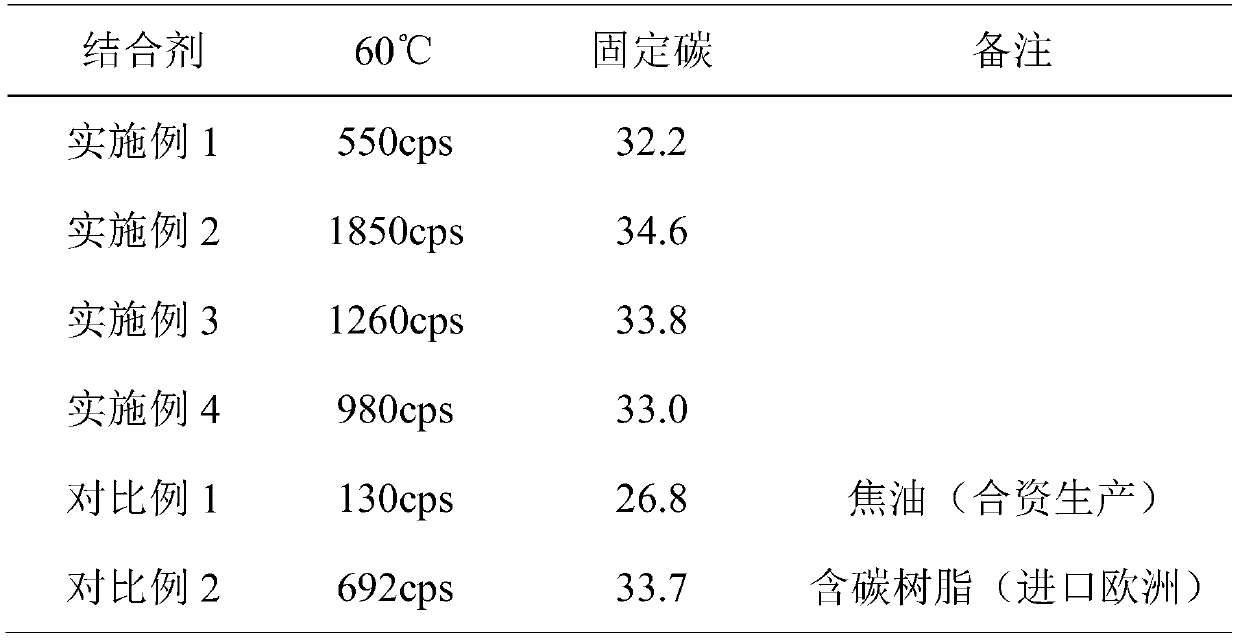

Binder for blast furnace clay and blast furnace clay

The invention discloses a binding agent for a blast furnace stemming and the blast furnace stemming. The binding agent is prepared from, by mass, 40-70 parts of coal tar distillation kettle substrate, 30-60 parts of novolac resin and 2-5 parts of surfactant, wherein a preparation method of the coal tar distillation kettle substrate is comprises the steps that coal tar is added to a high-temperature ceramic reaction kettle, heating and stirring are performed at the temperature of 230 DEG C for 1.5-2.5 hours, and the coal tar distillation kettle substrate is obtained after reaction and degassing. A blast furnace stemming material needs additional 12-17.5 parts of binding agent. The blast furnace stemming made from the binding agent and the blast furnace stemming material is environmentally friendly, smokeless and outstanding in durability effect, really protect refractory bricks at the lower portion of a tap hole, and accordingly the service life of a blast furnace is prolonged. The blast furnace stemming made from the binding agent and the blast furnace stemming material is high in sintering speed, is resistant to erosion and scouring, is environmentally friendly and smokeless, can completely replace imported products and has the important significance on supporting of energy saving and environmental protection of the iron-making industry in our country, prolonging of the service life of blast furnaces and technical progress.

Owner:XUZHOU SUPAI HIGH TEMPERATURE NEW MATERIAL CO LTD

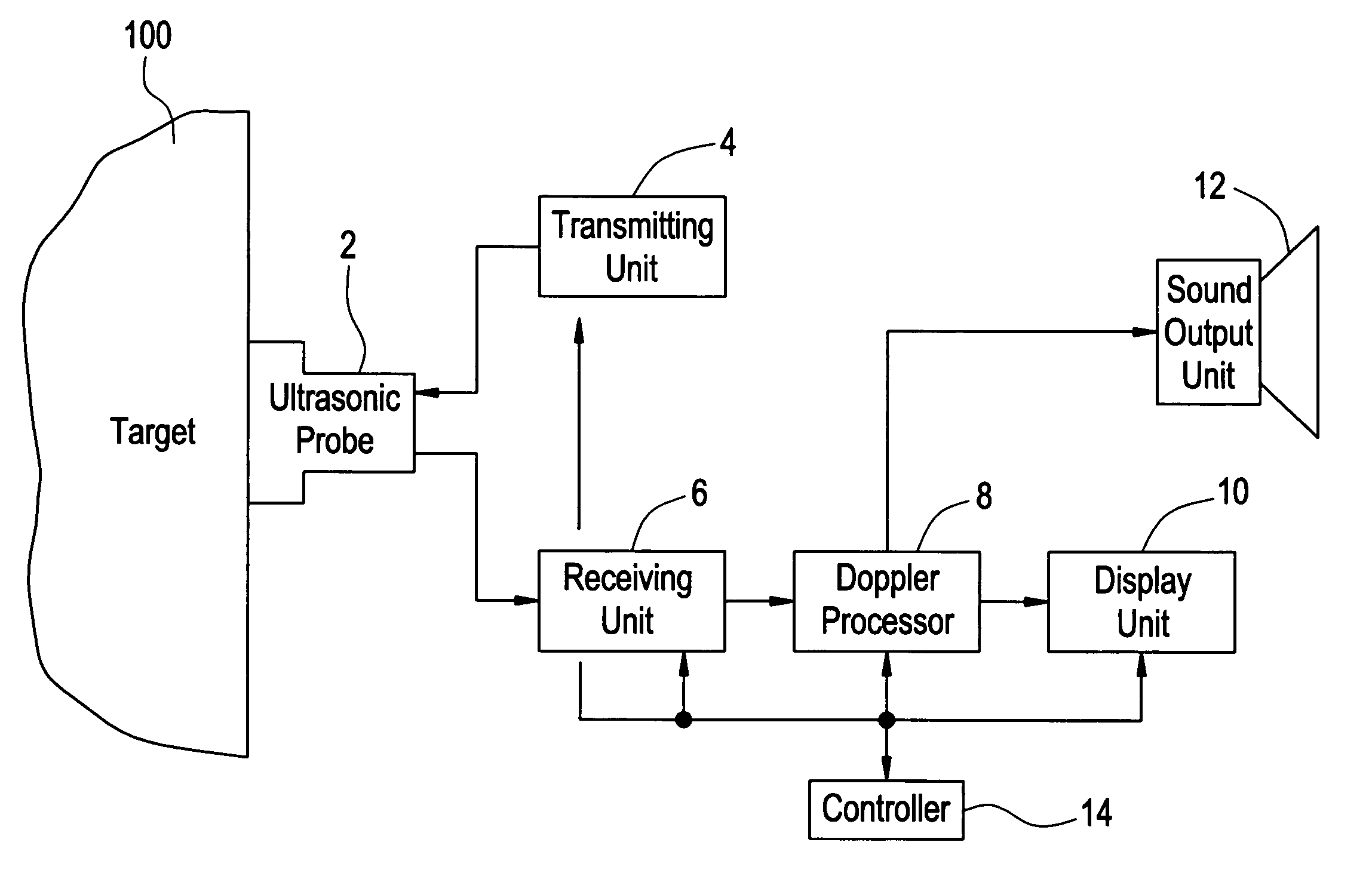

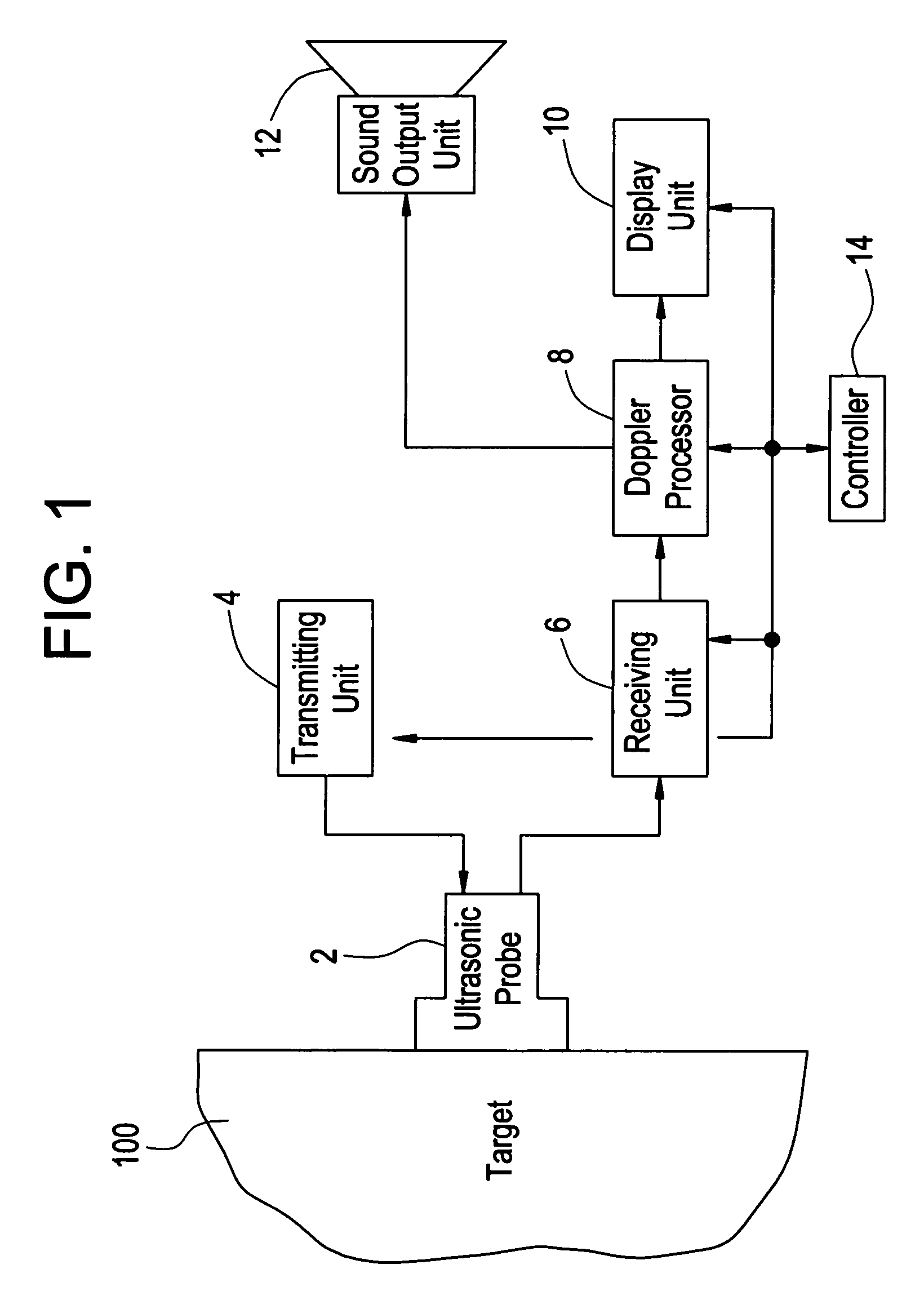

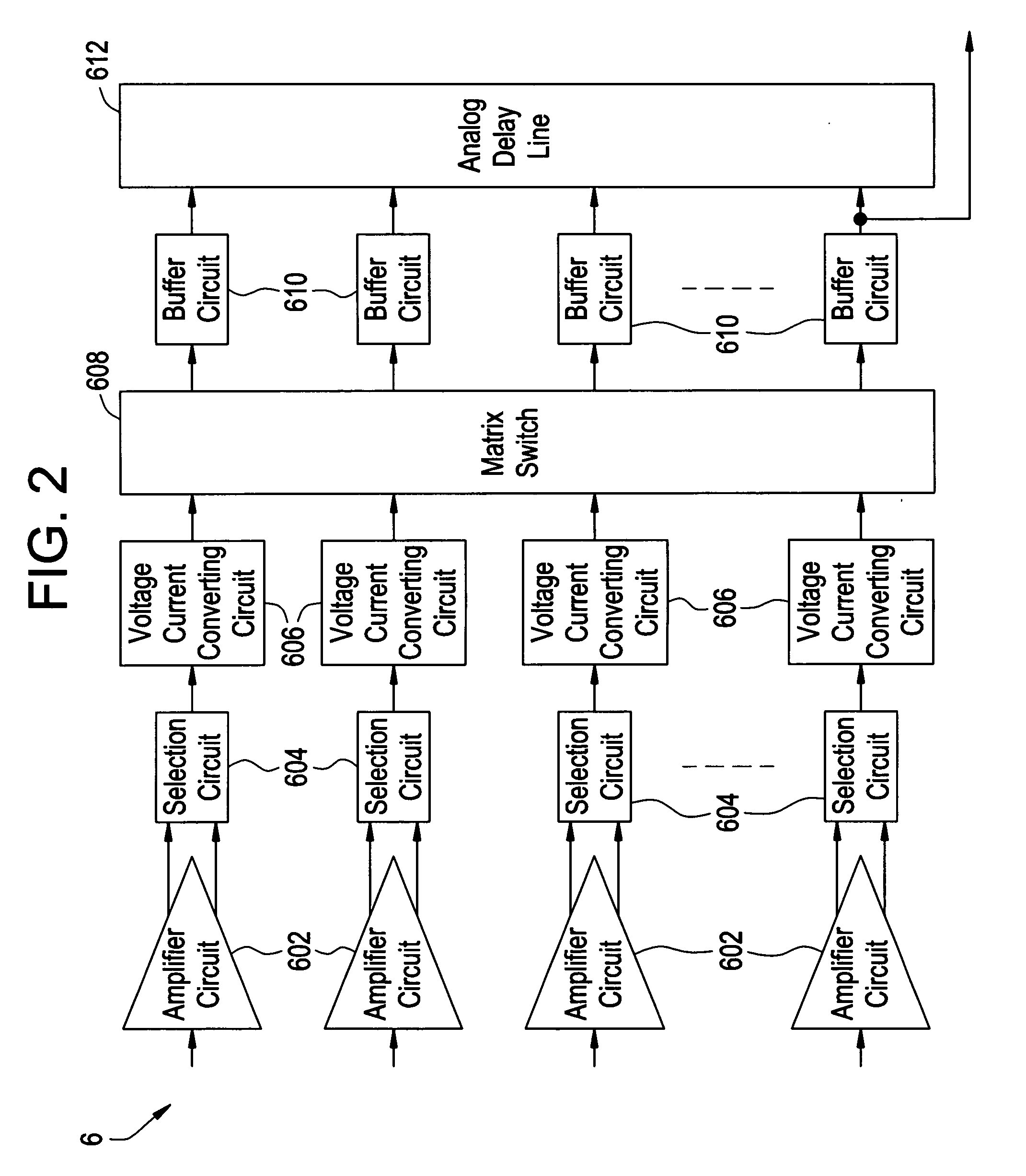

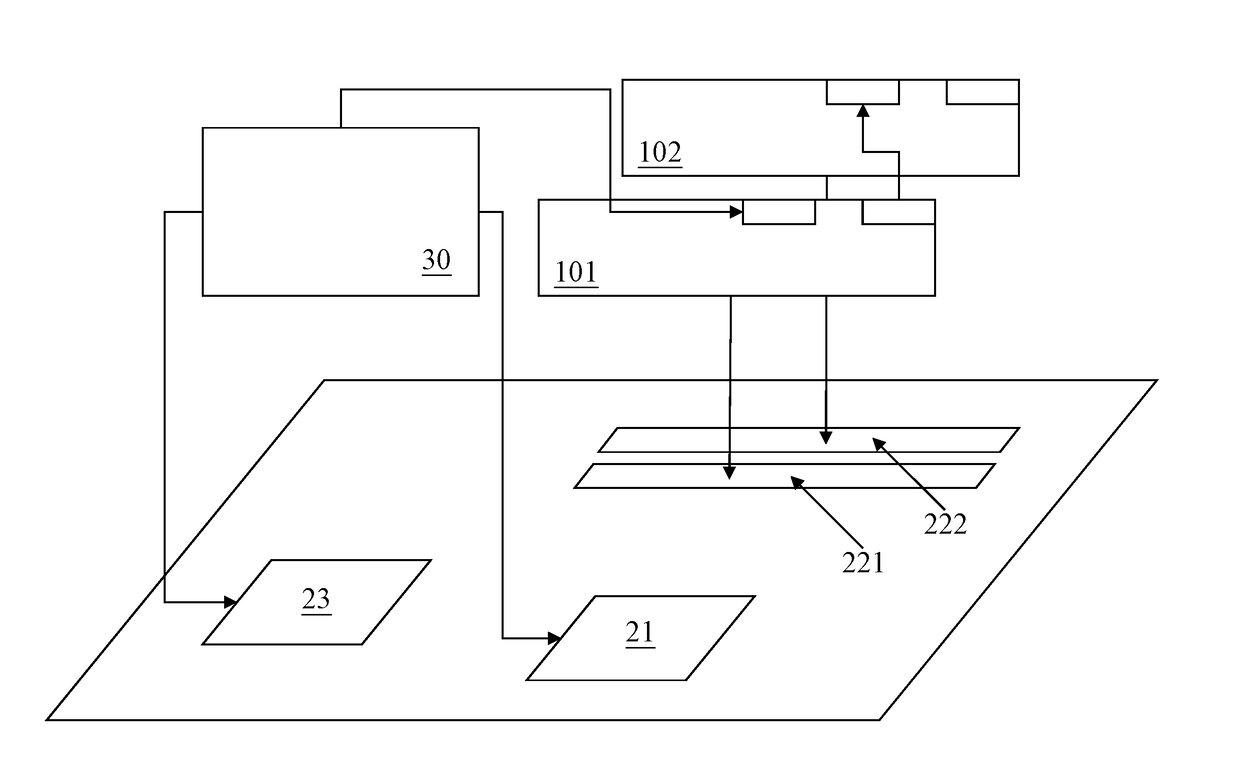

Delay adding device and ultrasonic diagnostic apparatus

InactiveUS20070038107A1Reduce the number of tapsReduce the numberMultiple-port networksFluid pressure measurementAnalog delay lineLength wave

The present invention aims to provide a delay device having an analog delay line adaptable to a plurality of frequencies with a less number of taps. The analog delay line has a maximum delay amount equivalent to a wavelength from over a ⅜ wavelength of a predetermined maximum wavelength of an input signal to under a 1 wavelength thereof. Tap intervals up to a delay point equivalent to ½ of a predetermined minimum wavelength of the input signal are different from tap intervals placed ahead of those. The maximum wavelength is a wavelength of a signal having a frequency of 2 MHz, for example, and the minimum wavelength is a wavelength of a signal having a frequency of 5 MHz, for example.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

Test circuit board adapted to be used on memory slot

ActiveUS20170184668A1Easy to useReduce testing costsDetecting faulty computer hardwareElectrical testingEngineeringJoint Test Action Group

A test circuit board adapted to be used on memory slot is provided. Two test circuit boards can be seriously connected with each other through a first JTAG connection interface and a second JTAG connection interface. Therefore, the efficiency of reducing TAPs of TAP controller and providing test signal coverage of all of test signals may be achieved.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

Force-limiting damping device

PendingCN112548952ASimple structureEasy to repair and replaceHand hammersMetal-working hand toolsPhysicsEngineering

Owner:施瑞源

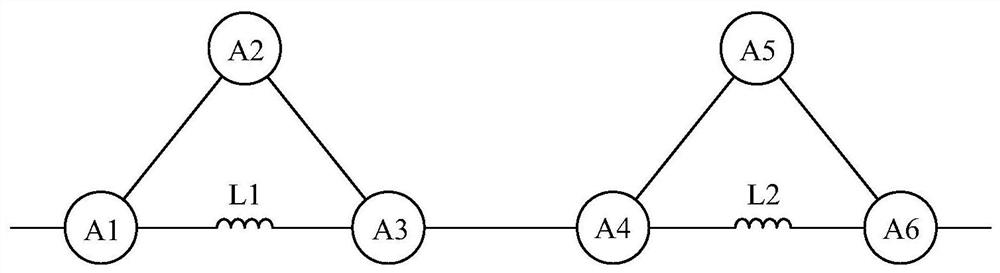

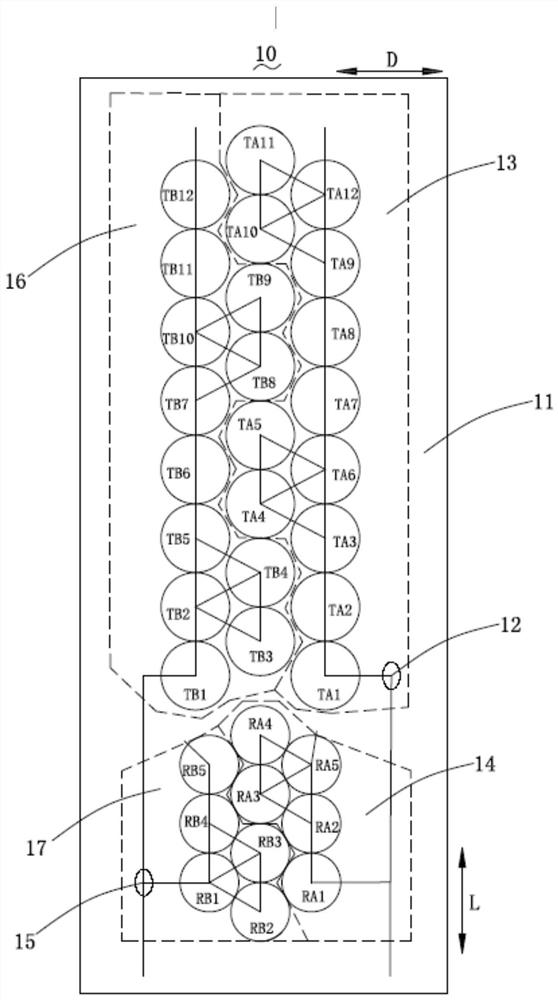

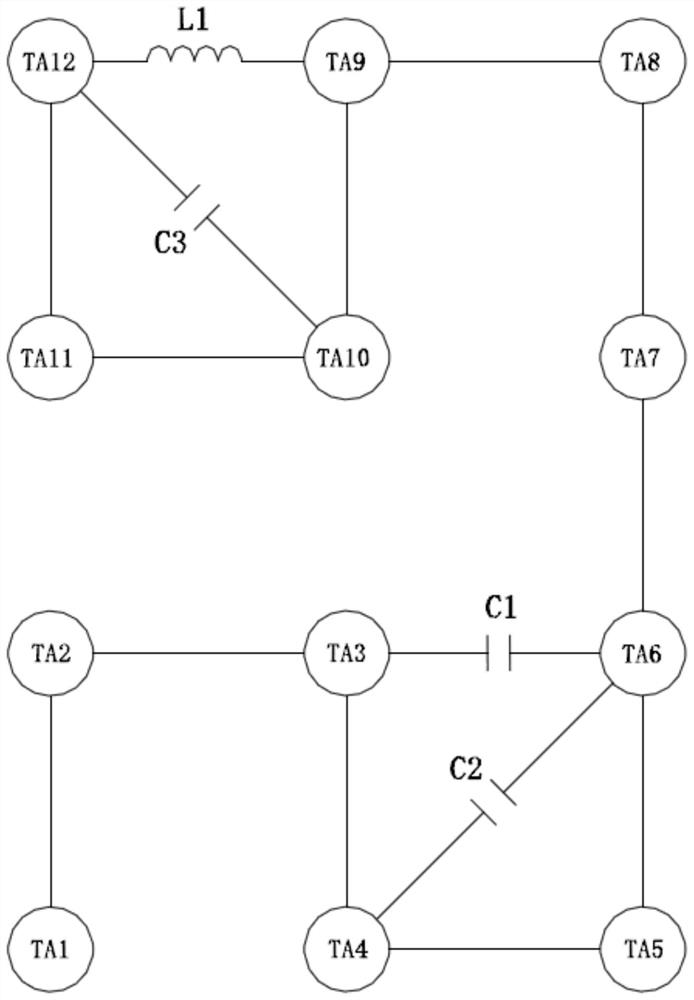

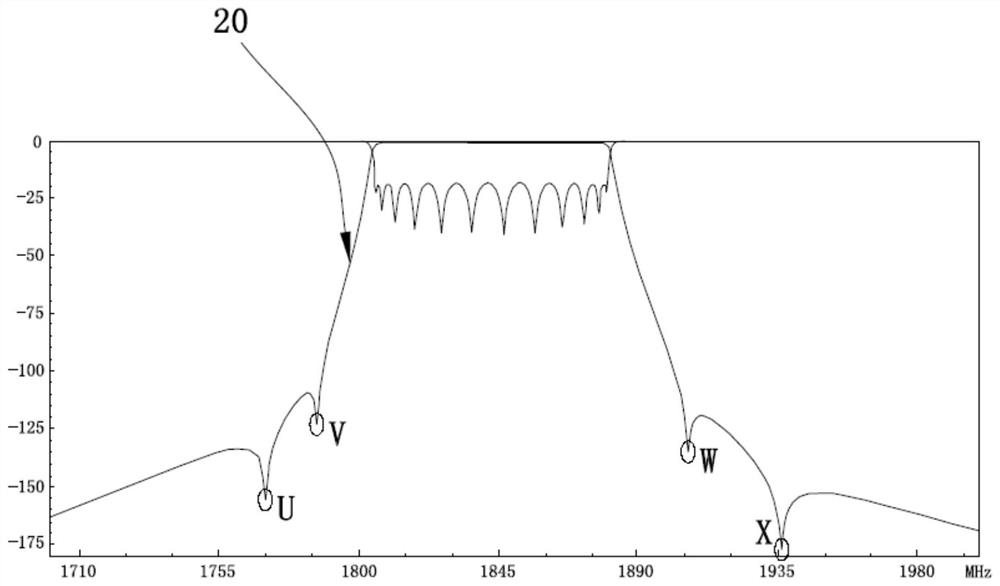

Communication equipment and filter thereof

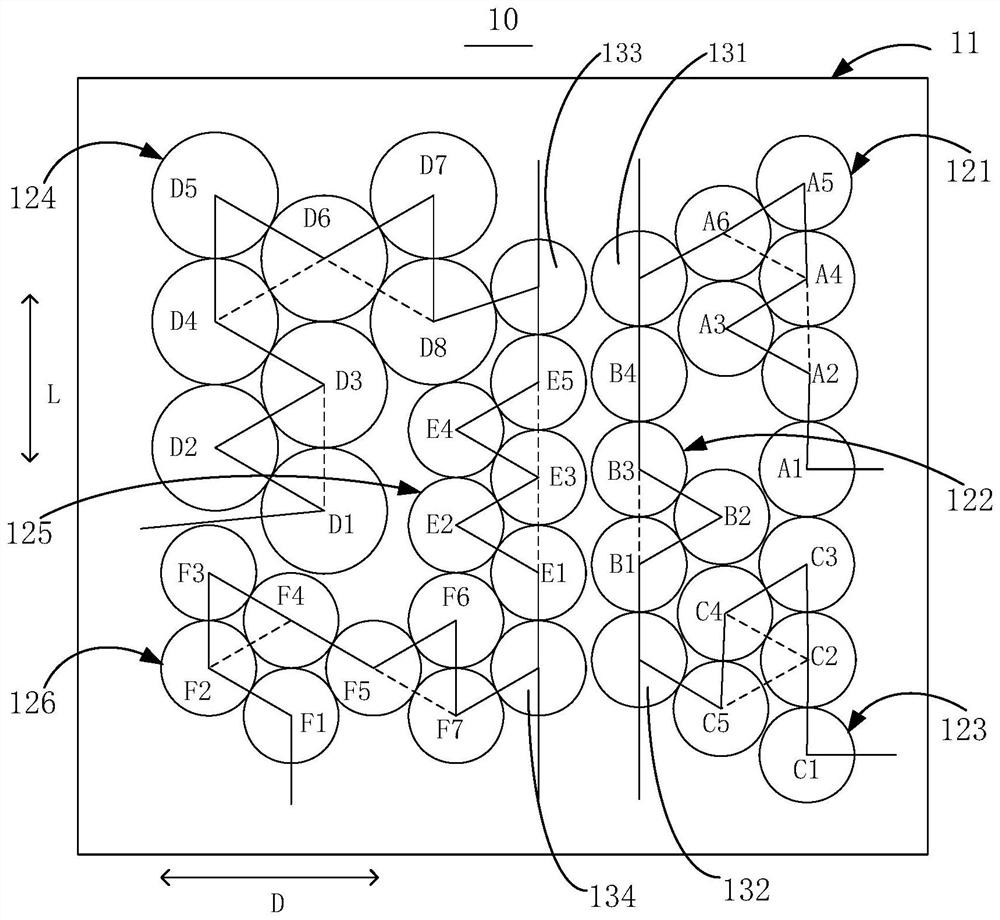

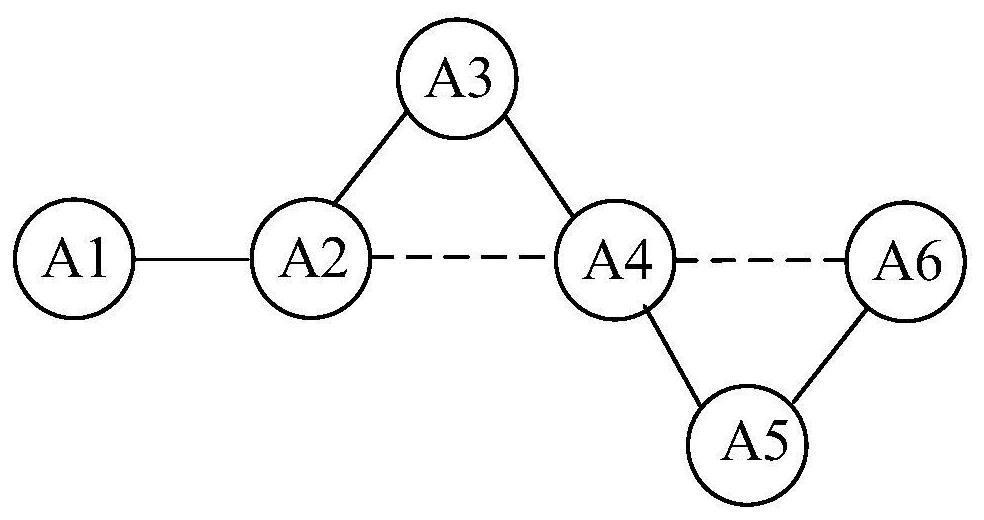

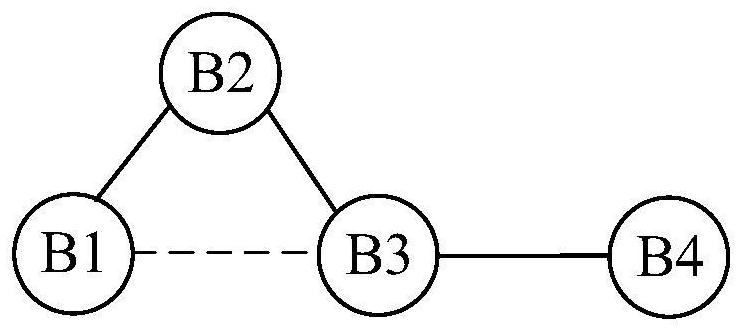

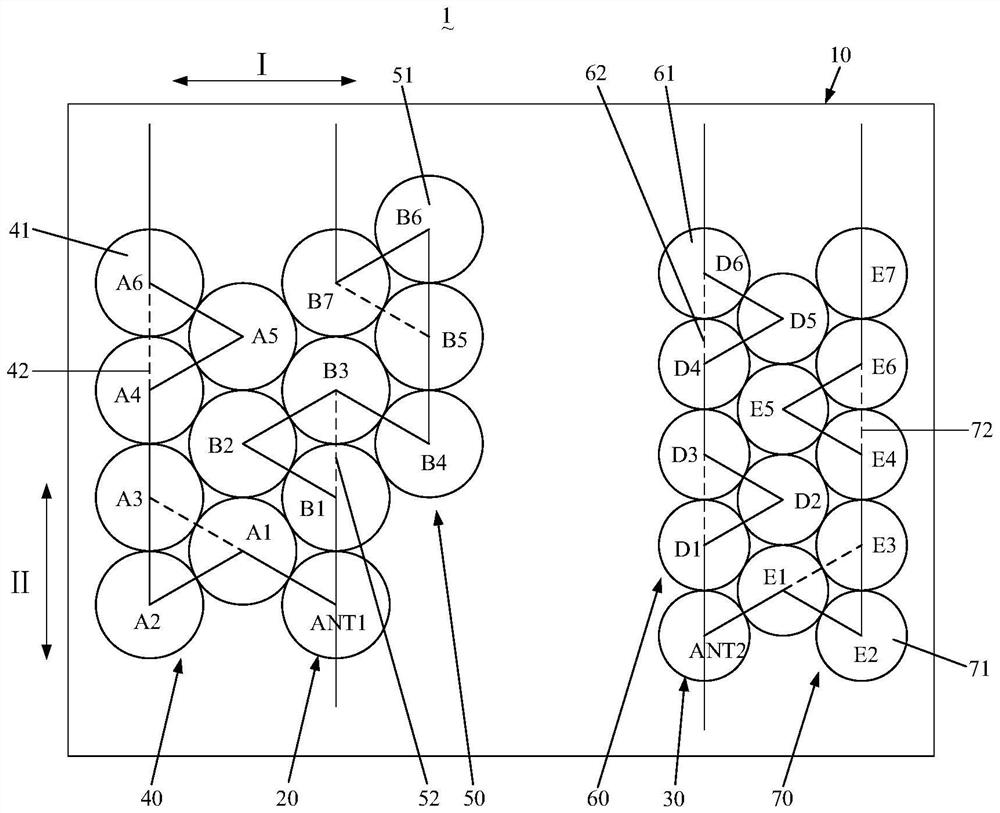

PendingCN113131121AEasy to debug indicatorsReduce the number of tapsWaveguide type devicesEngineeringMechanical engineering

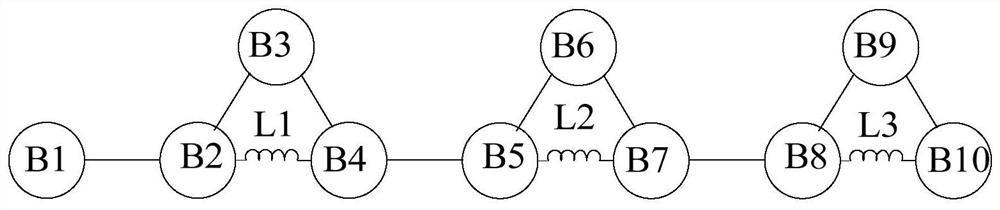

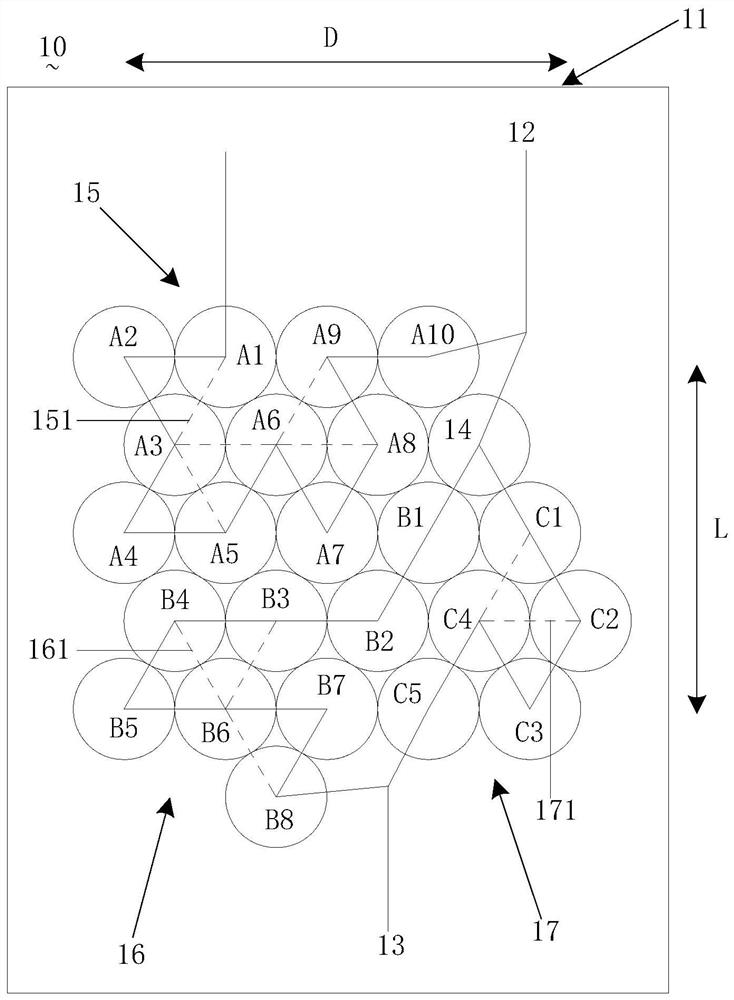

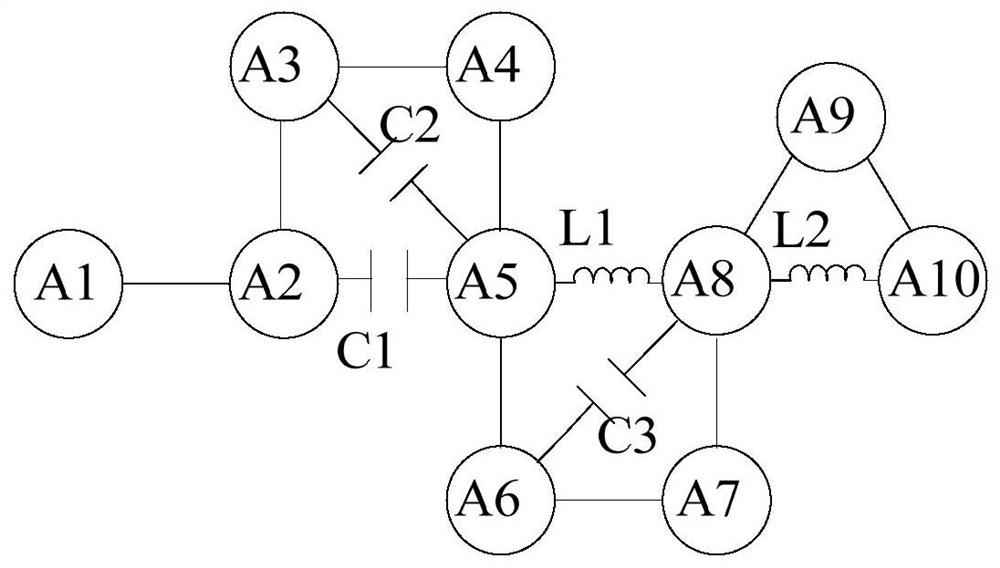

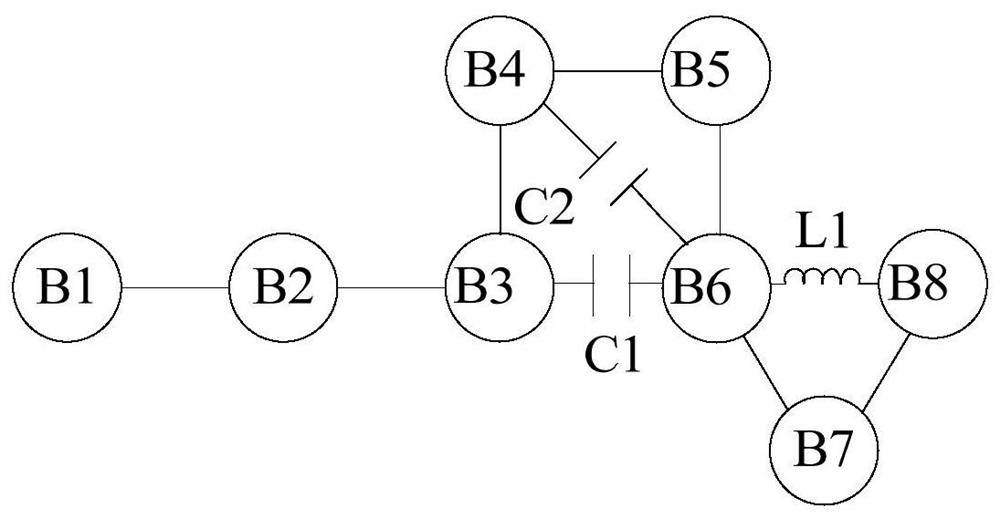

The invention discloses communication equipment and a filter thereof. The filter comprises a shell having a first direction and a second direction perpendicular to each other, afirst common cavity, a first filtering branch and a second filtering branch, wherein the first common cavity is arranged on the shell; the first filtering branch is coupled with the first common cavity, consists of six filtering cavities which are sequentially coupled and forms two cross coupling zero points of the first filtering branch; and the second filtering branch is coupled with the first common cavity, consists of four filtering cavities which are sequentially coupled, and forms a cross coupling zero point of the second filtering branch. In the way, the number of taps can be reduced, and the size of the filter is reduced.

Owner:ANHUI TATFOOK TECH CO LTD

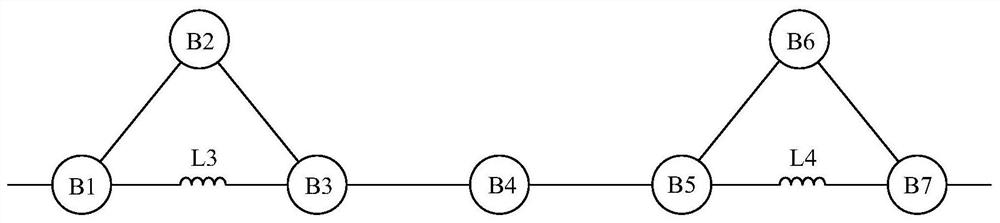

Communication equipment and filter

PendingCN113131122AReduce the number of tapsReduce volumeWaveguide type devicesSoftware engineeringMechanical engineering

The invention discloses communication equipment and a filter. The filter includes a shell, a first common cavity, a second common cavity, a firstfiltering branch, a secondfiltering branch, a fourthfiltering branch and a fifthfiltering branch, wherein the first common cavity and the second common cavity are arranged on the shell in a spaced mode in the first direction of the shell; the first filtering branch consists of six filtering cavities which are sequentially coupled, and is coupled with the first common cavity to further form two first inductive cross coupling zero points; the second filtering branch consists of seven filtering cavities which are coupled in sequence, and is coupled with the first common cavity to further form two second inductive cross coupling zero points; the fourth filtering branch consists of six filtering cavities which are sequentially coupled, and is coupled with the second common cavity to further form two fourth inductive cross coupling zero points; and the fifth filtering branch consists of seven filtering cavities which are coupled in sequence, and is coupled with the second public cavity to further form two fifth inductive cross coupling zero points. By means of the mode, the two common cavities are arranged, the number of taps can be reduced, the size of the filter is reduced, and the production cost is reduced.

Owner:ANHUI TATFOOK TECH CO LTD

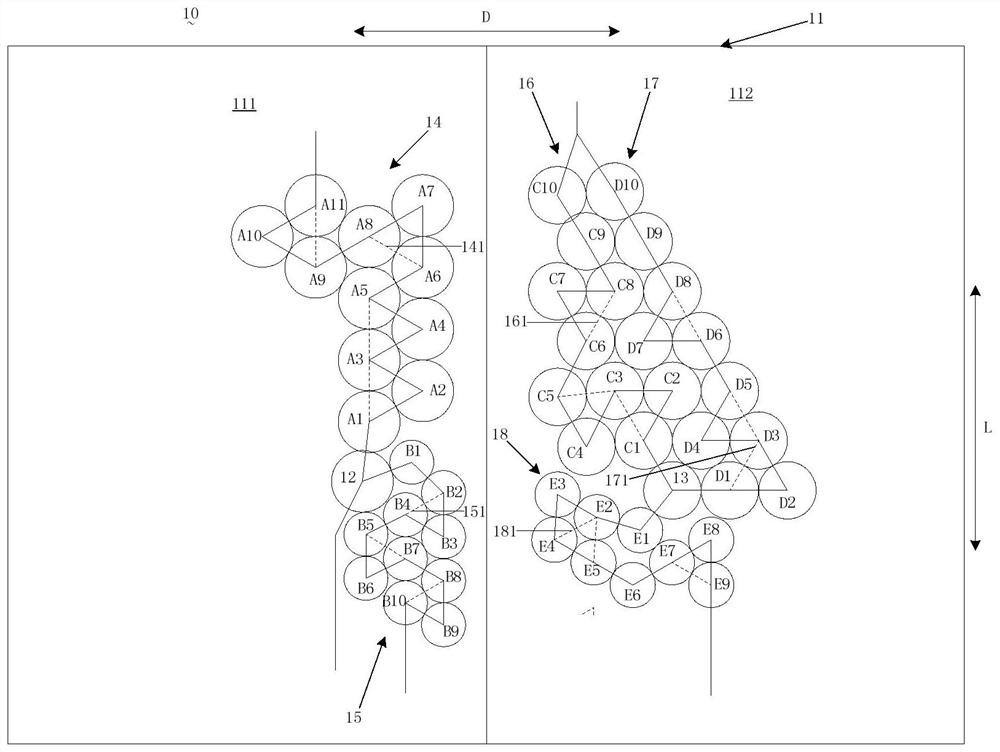

Communication equipment and filter thereof

InactiveCN113131149AReduce volumeReduce the number of tapsWaveguide type devicesEngineeringComputer science

The invention discloses communication equipment and a filter thereof. The filter comprises a first common cavity arranged on a first surface of a shell, a second common cavity arranged on a second surface of the shell, a first filtering branch arranged on the first surface and coupled with the first common cavity, a second filtering branch arranged on the first surface and coupled with the first common cavity, a third filtering branch arranged on the second surface and coupled with the second common cavity, a fourth filtering branch arranged on the second surface and coupled with the second common cavity, and a fifth filtering branch arranged on the second surface and coupled with the second common cavity. Through the mode, the number of taps can be reduced through the arrangement of the common cavity, and the size of the filter is reduced; the front and back arrangement reduces the size of the filter and reduces the cost.

Owner:ANHUI TATFOOK TECH CO LTD

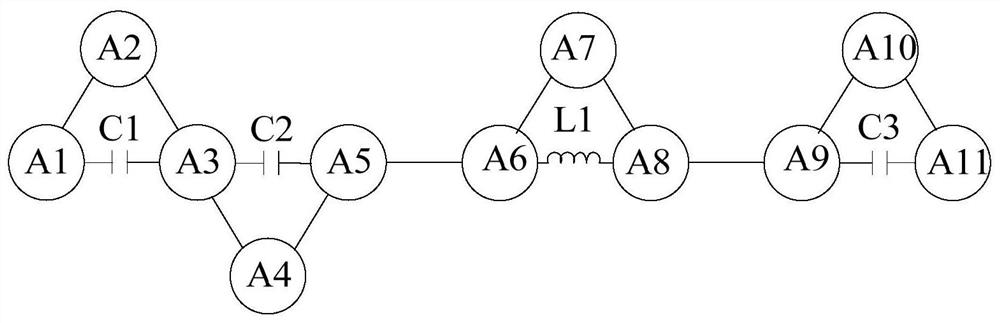

Communication system and filter thereof

InactiveCN113054348AReduce volumeImprove stabilityWaveguide type devicesCommunications systemCross coupled

The invention discloses a communication system and a filter thereof. The filter comprises: a first port, a second port and a first common cavity connected with the first port, which are arranged on a shell; a first filtering branch coupled with the first port and composed of ten filtering cavities which are coupled in sequence, wherein the ten filtering cavities of the first filtering branch further form five cross coupling zero points; a second filtering branch respectively coupled with the first common cavity and the second port and consisting of eight filtering cavities which are sequentially coupled, wherein the eight filtering cavities of the second filtering branch further form three cross coupling zero points; and a third filtering branch respectively coupled with the first common cavity and the second port and consisting of five filtering cavities which are sequentially coupled, wherein the five filtering cavities of the third filtering branch further form two cross coupling zero points. Through the above mode, the arrangement of the common cavity and the common port can reduce the number of taps and reduce the size of the filter, the cross coupling zero point can realize zero point suppression, and index debugging is facilitated.

Owner:ANHUI TATFOOK TECH CO LTD

Waveform equalizing device

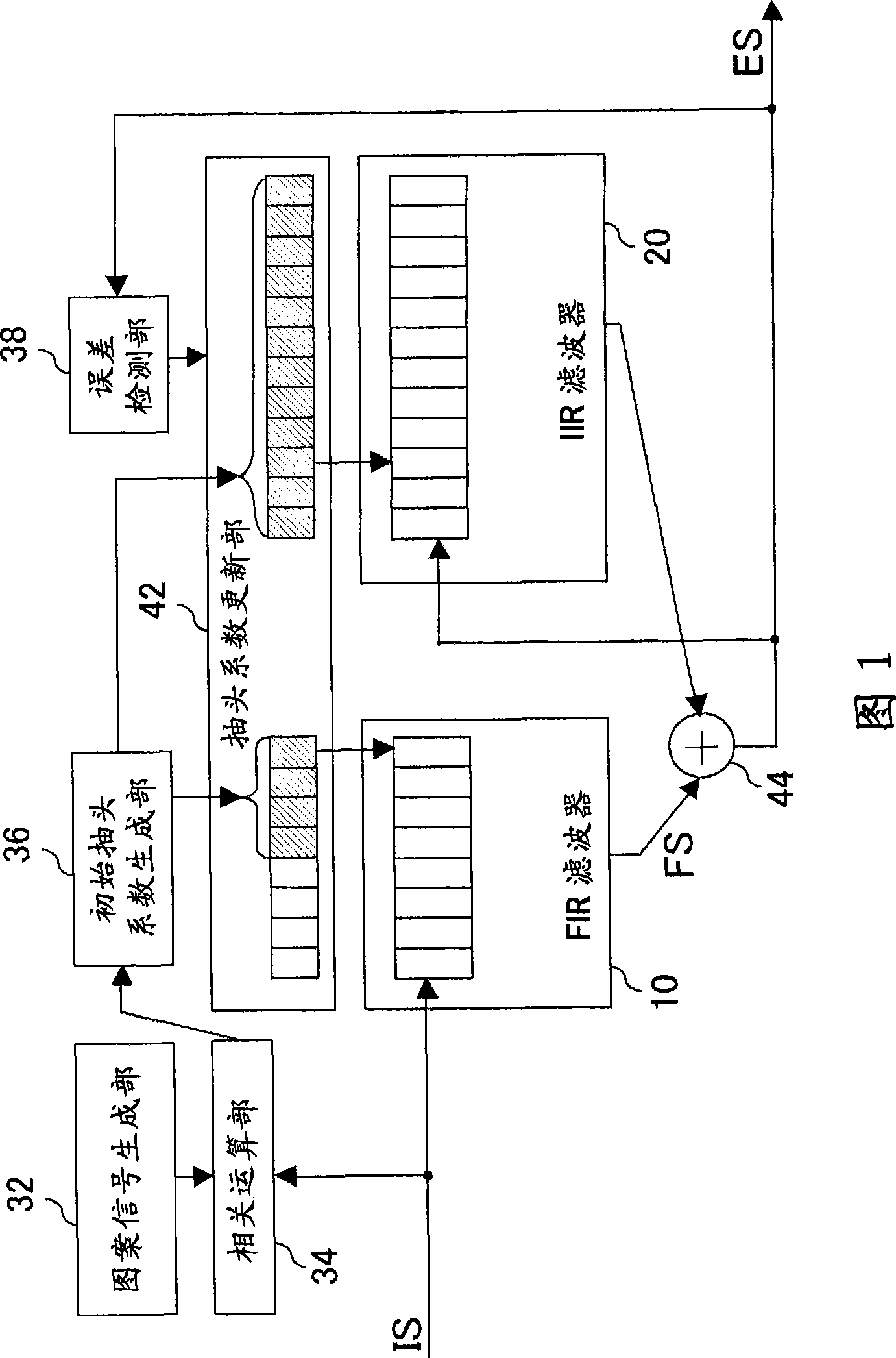

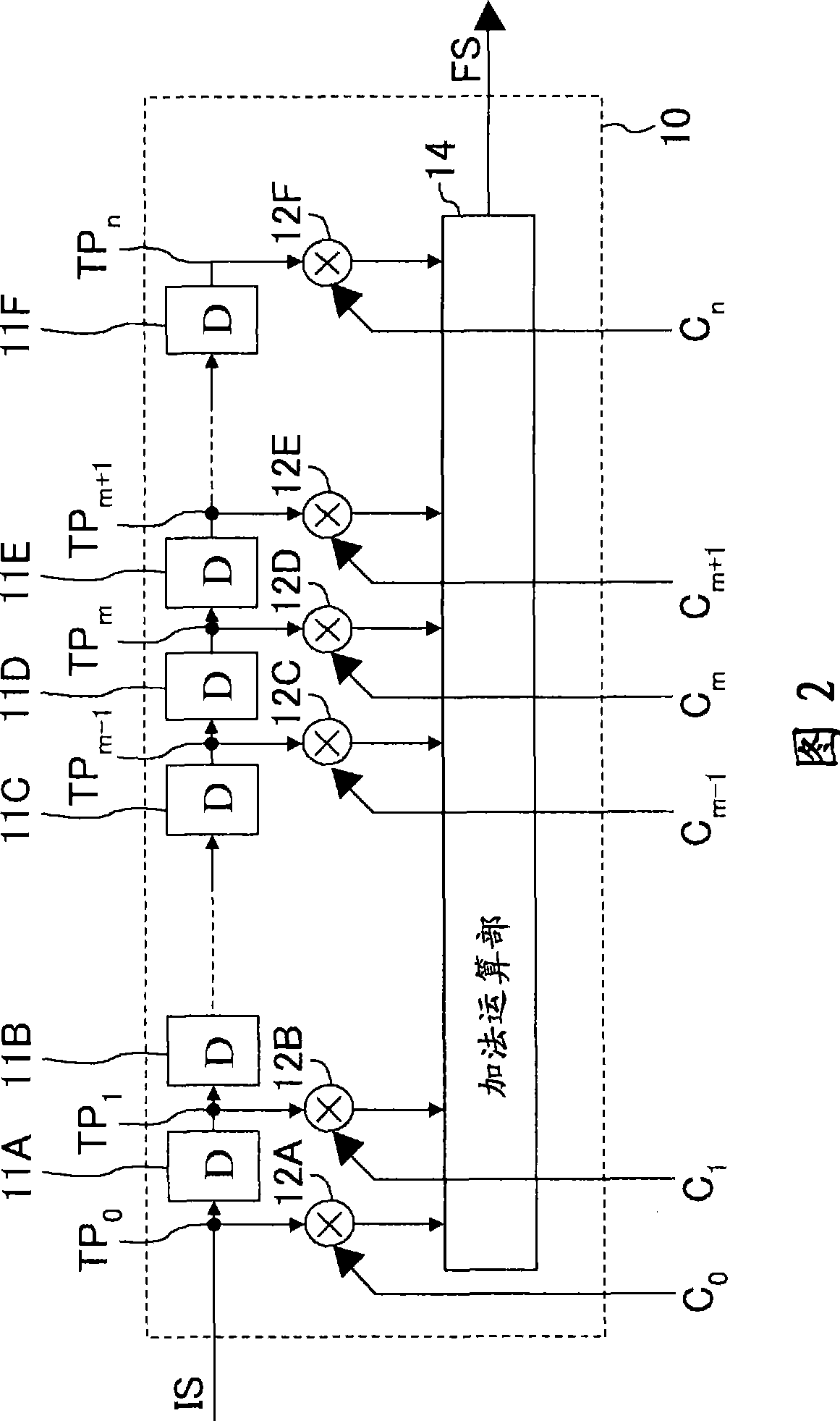

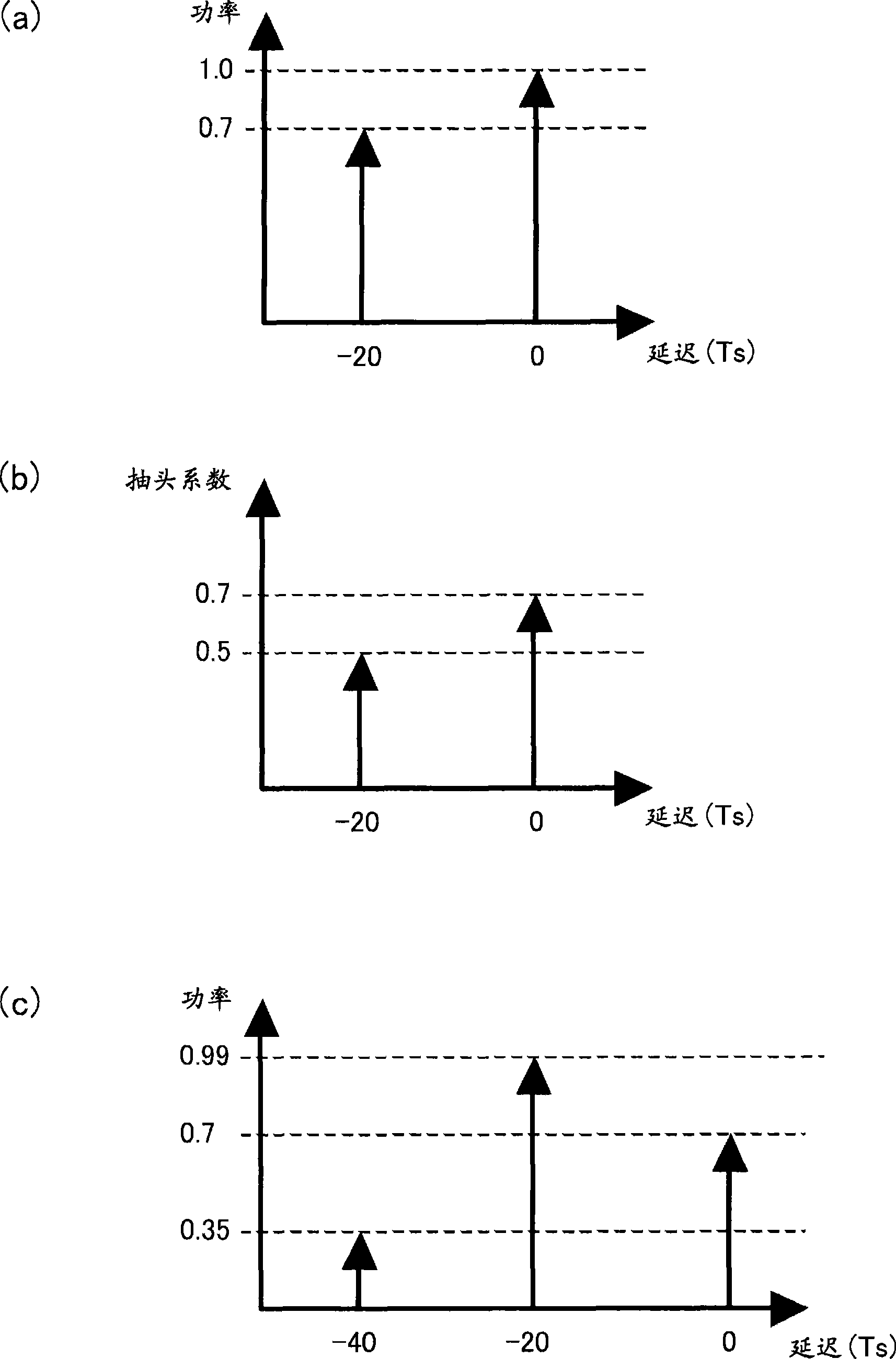

InactiveCN101454993AReduce the number of tapsReduce areaTelevision system detailsTransmission control/equlisationIir filteringEngineering

Tap coefficients for a filter for removing a ghost signal are converged to optimum values in a short time. The waveform equalizing device includes: an initial tap coefficient generation section for determining and outputting the initial values of tap coefficients for a FIR filter and an IIR filter based on a plurality of correlation values; and a tap coefficient updating section for outputting the initial values of tap coefficients for the FIR filter and the IIR filter to these filters and updating tap coefficients for these filters based on error information. The initial tap coefficient generation section reverses the order of values, among the plurality of correlation values, corresponding to delays within a predetermined range to determine the order-reversed values as the initial values of tap coefficients for the FIR filter corresponding to the delays within the predetermined range, and also reverses the signs of values, among the plurality of correlation values, corresponding to delays exceeding the predetermined range to determine the sign-reversed values as the initial values of tap coefficients for the IIR filter.

Owner:PANASONIC CORP

Communication equipment and filter thereof

InactiveCN113131124AReduce the number of tapsReduce volumeWaveguide type devicesControl theoryMechanical engineering

The invention discloses communication equipment and a filter thereof. The filter comprises a shell, a first port, a first filtering branch and a second filtering branch, wherein the shell has a first direction and a second direction which are perpendicular to each other; the first port is arranged on the shell; the first filtering branch is connected with the first port and is composed of twelve filtering cavities which are coupled in sequence, and four coupling zero points of the first filtering branch are formed; the second filtering branch is connected with the first port and is composed of five filtering cavities which are coupled in sequence, and two coupling zero points of the second filtering branch are formed; and the projection of the first filtering branch in the first direction is overlapped with the projection of the second filtering branch in the first direction. Through the mode, the first filtering branch and the second filtering branch can share the first port, each filtering branch is prevented from being independently provided with a tap, the number of the taps of the filter is reduced, the size of the filter is reduced, and the cost is reduced.

Owner:ANHUI TATFOOK TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com