Removal tool and method of marine shafting adjusting ring bolts

A technology for marine shafting and disassembly tooling, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting ship repair progress, high labor costs, large impact force of bolts, etc., to reduce repair workload and improve. Work efficiency, the effect of reducing the number of strokes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

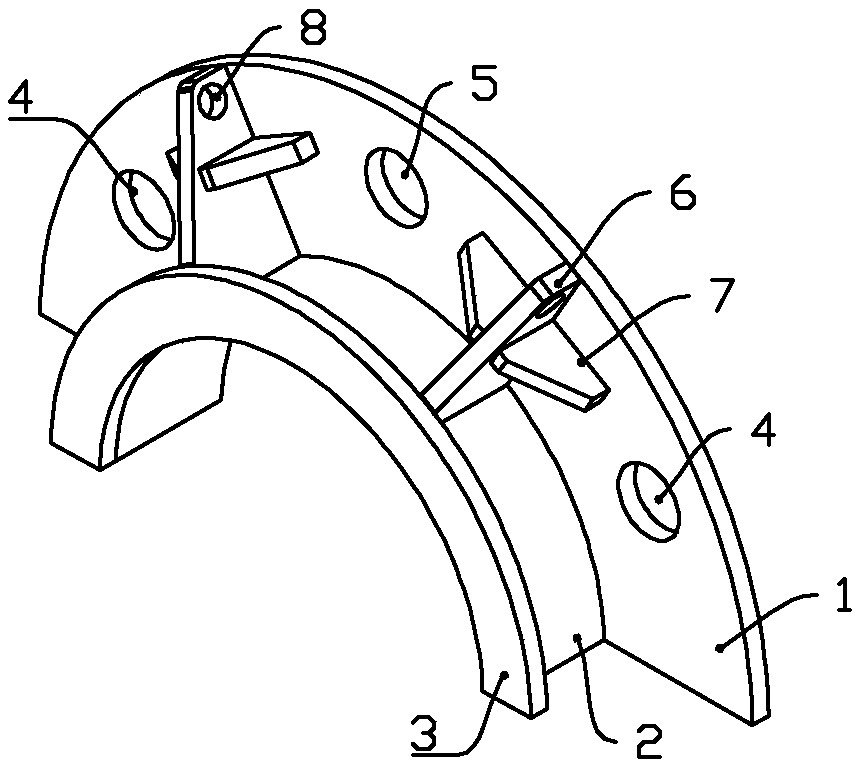

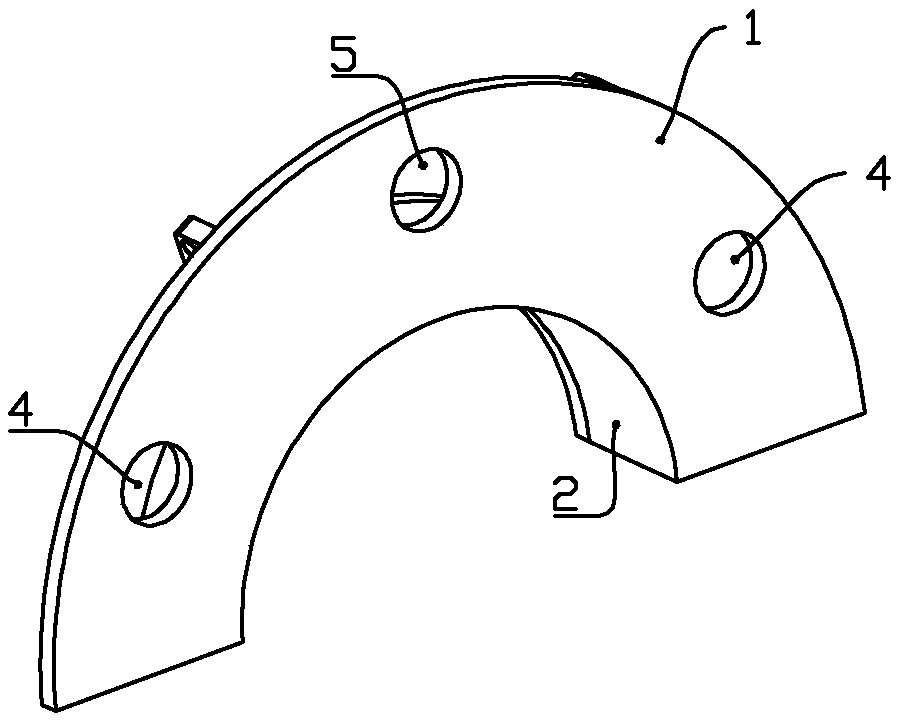

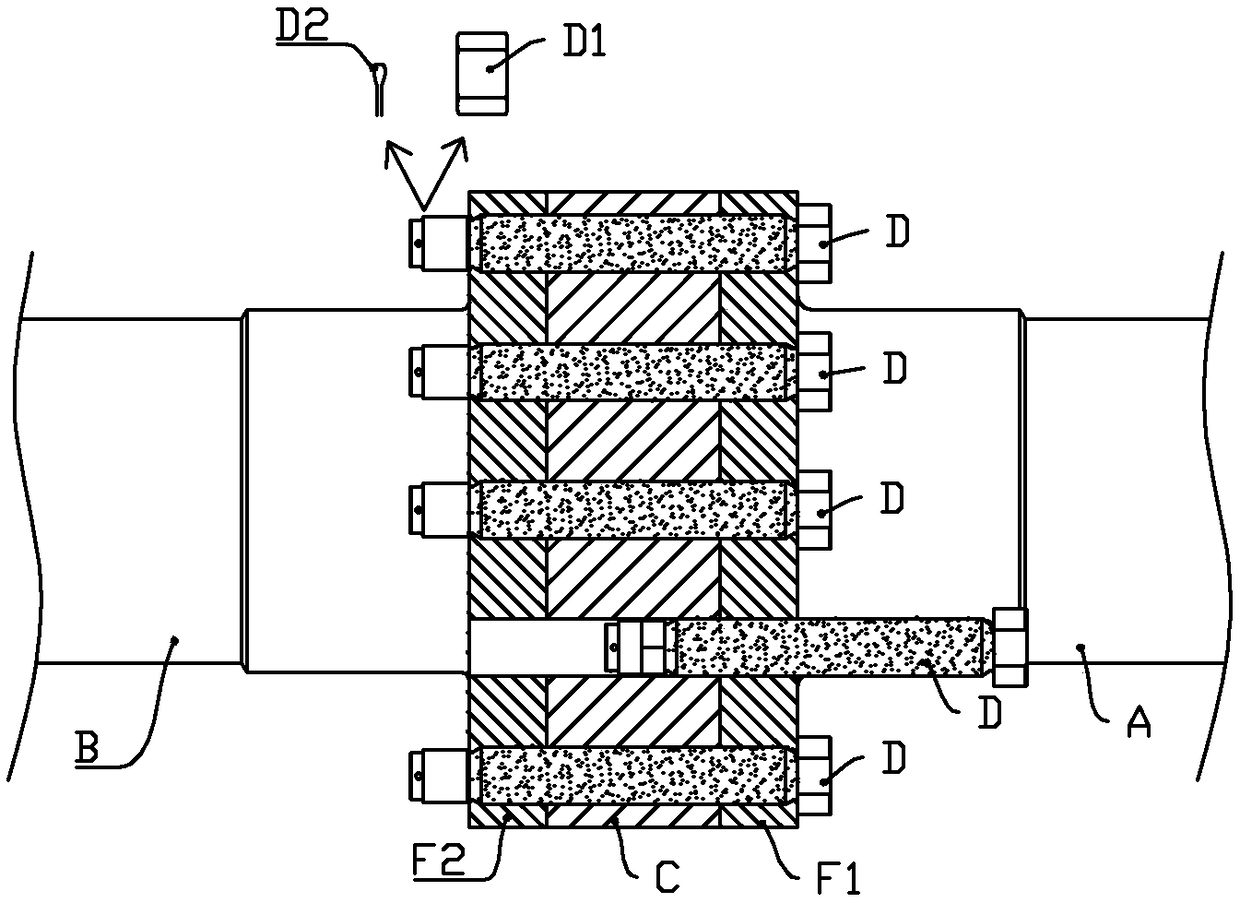

[0031] The utility model relates to a ship shaft adjustment ring bolt removal tool, which is mainly used for such as image 3 The shaft adjustment ring structure shown in the figure mainly includes No. 1 intermediate shaft A, No. 2 intermediate shaft B and shaft adjustment ring C. The end of No. 1 intermediate shaft A is equipped with No. 1 flange F1, and No. 2 intermediate shaft B The second flange F2 is installed at the end; when the ship is built, the shafting adjustment ring C is connected between the first flange F1 and the second flange F2 through the adjustment ring bolt D. When repairing the ship, when removing the oil pipes in the two intermediate shafts, the shafting adjusting ring C must be removed first, therefore, the adjusting ring bolt D used to fix the shafting adjusting ring C must also be removed.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com