Method for reducing tapping frequency of blast furnace

A technology of blast furnace tapping and times, applied in blast furnace, blast furnace details, blast furnace parts, etc., can solve the problem of reducing the service life of taphole mud, opening machine, affecting the depth of furnace door, and the consumption of iron and mud size rods. High-level problems, to achieve the effect of slow mud erosion, increase the length of a single tap, and reduce the number of blast furnace taps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

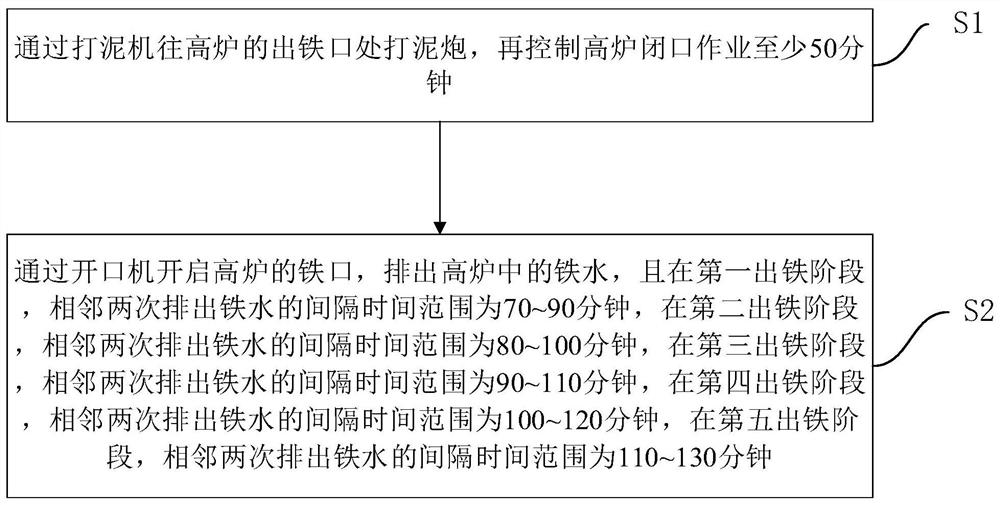

[0036] The invention provides a method for reducing the number of blast furnace tapping times, such as figure 1 As shown, the method includes:

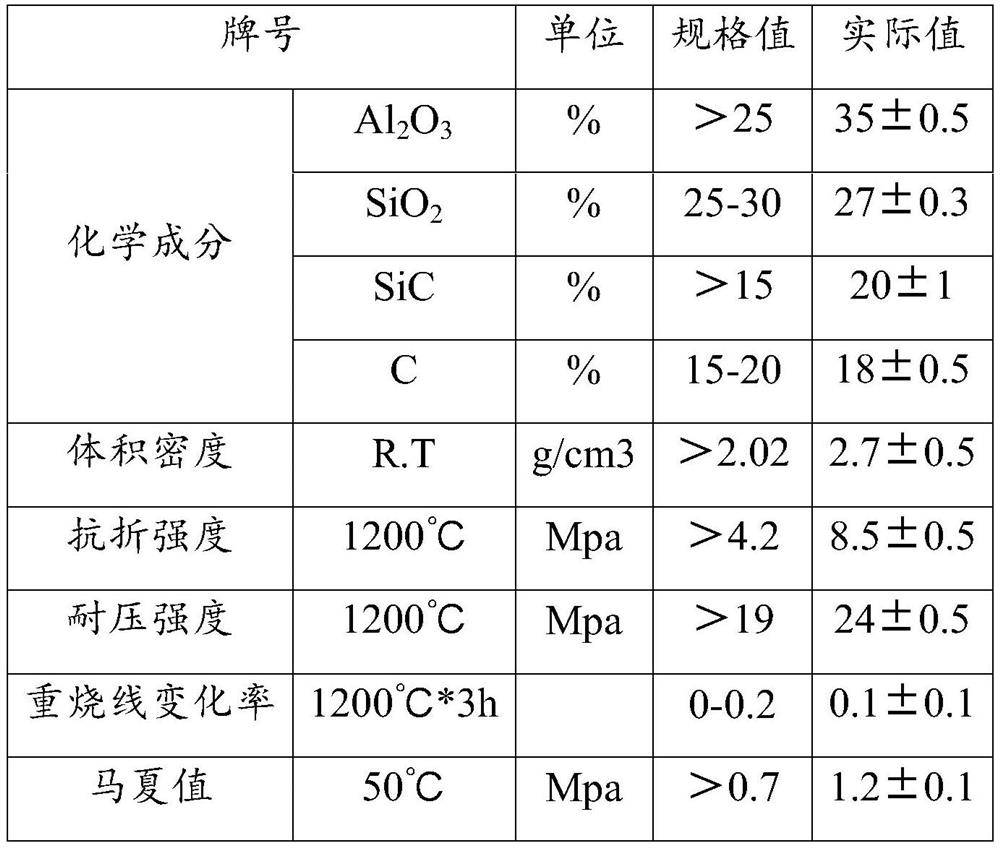

[0037] S1. Use a dredger to hit the blast furnace at the taphole, and then control the closed operation of the blast furnace for at least 50 minutes; among them, the mud required for the mud gun contains Al 2 o 3 (alumina), SiO 2 (silicon dioxide), SiC (silicon carbide) and C (carbon), Al 2 o 3 The mass proportion is greater than 25%, SiO 2 The mass proportion of SiC is in the range of 25%-30%, the mass proportion of SiC is greater than 15%, and the mass proportion of C is in the range of 15%-20%;

[0038] S2. Open the taphole of the blast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com