Patents

Literature

44results about How to "Uniform outflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

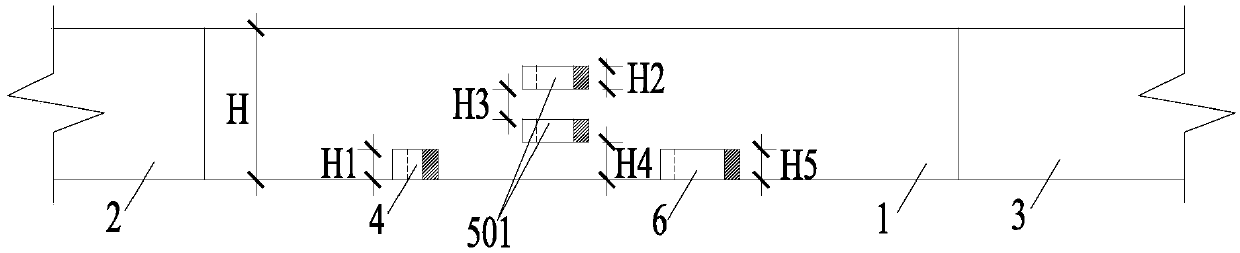

Bleed hole stemming and method for producing the same

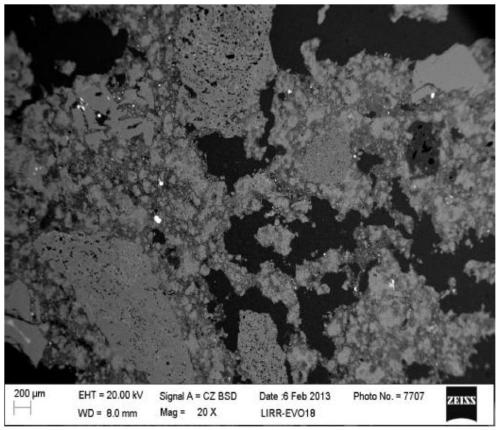

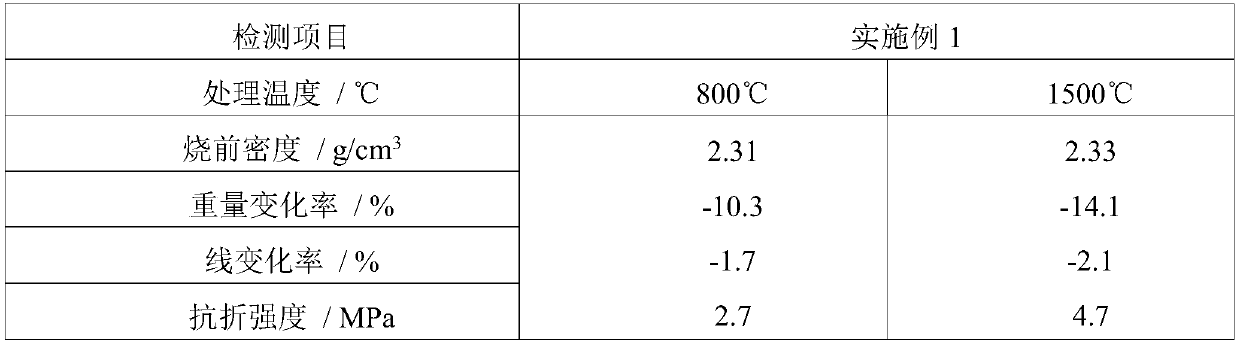

ActiveCN101219900AGood sintered strengthEasy to openBlast furnace componentsBlast furnace detailsPyrophylliteGraphite

The invention relates to a stemming at a taphole; the weight percentages of the components are the following: 20 to 40 of corundum, 10 to 20 of silicon carbide, 3 to 10 of silicon nitride, 10 to 23 of coke powders, 1 to 5 of graphite powders, 3 to 10 of sericite, 1 to 5 of active alumina micropowders, 5 to 15 of clay, 5 to 10 of pyrophyllite, 1 to 3 of metal powders, and +15 to 25 of water-free binder. The stemming adds a plurality of materials with plasticity and good cohesiveness to cause the stemming to easily block the hole and fill interspaces, with good binding performance of new stemming and old stemming; materials with medium and high temperature expansion are added to reduce the size of the stemming contraction at high temperature, and cracks can be avoided; materials with sintering function within different temperature areas are added, so the stemming has good sintering strength in different temperature scopes; materials with high-temperature resistance and good erosion resistance are added, and thus the stemming has high strength at high temperature, washing resistance and erosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

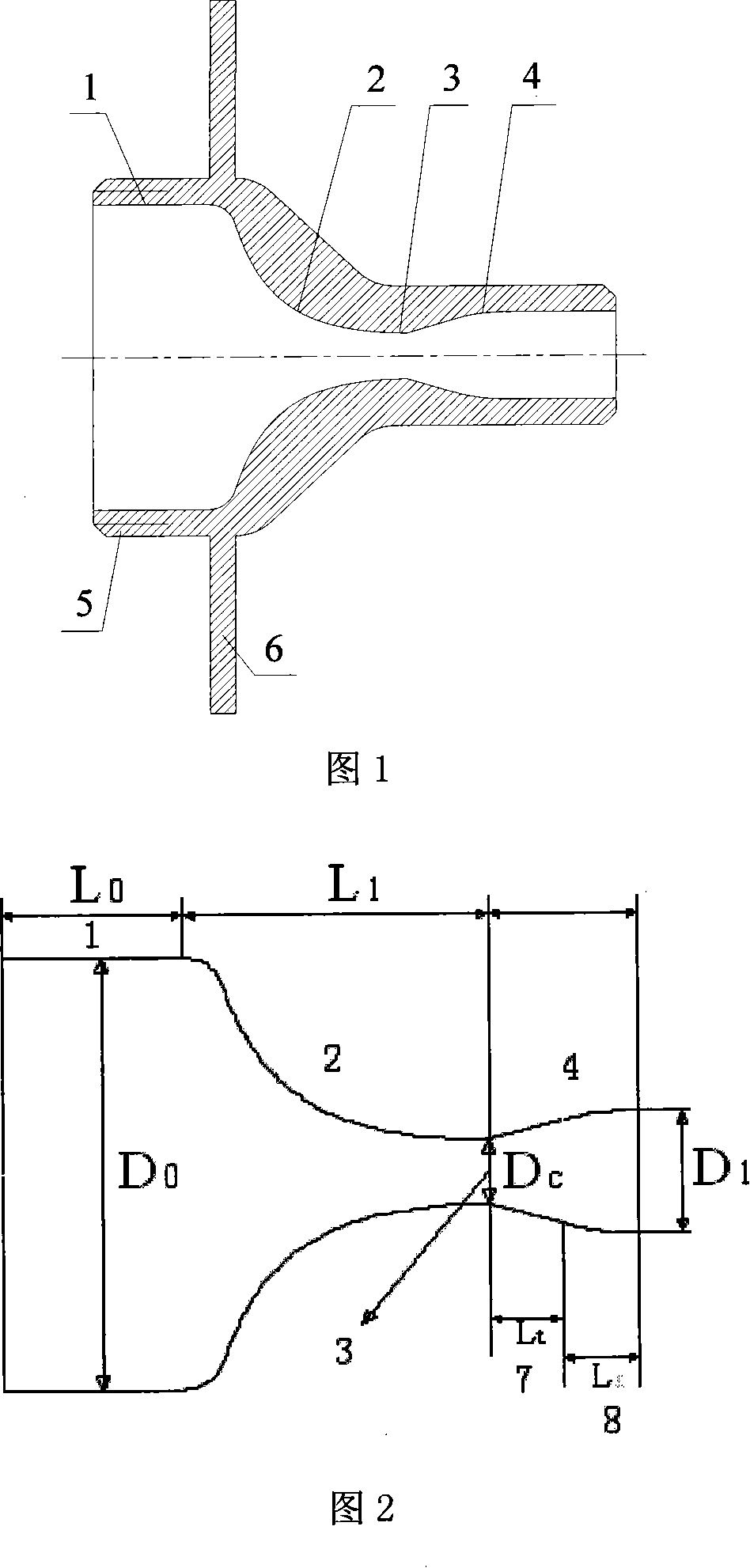

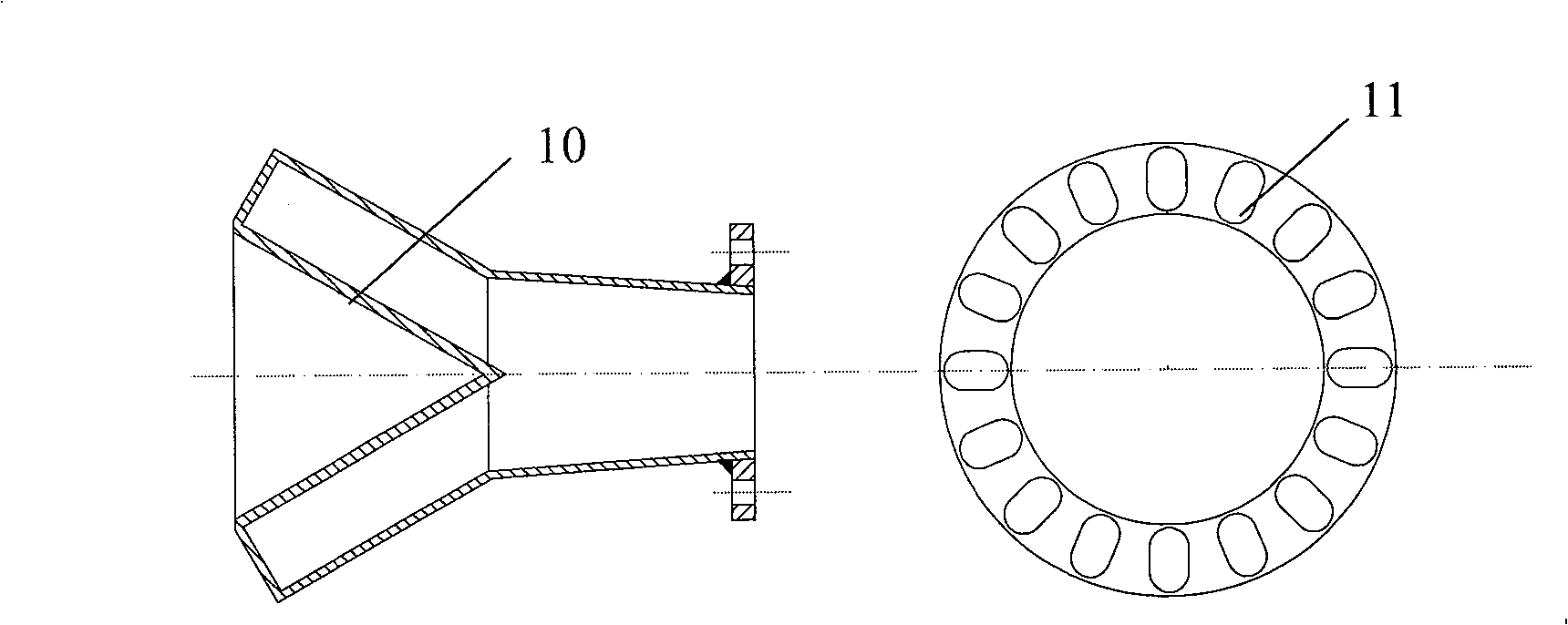

Supersonic speed nozzle for laser cutting

Owner:SHANGHAI JIAO TONG UNIV

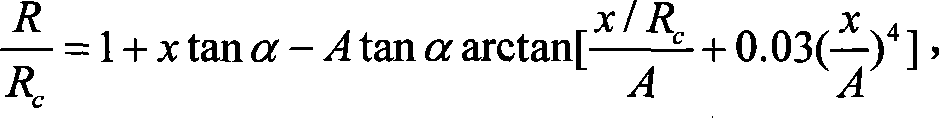

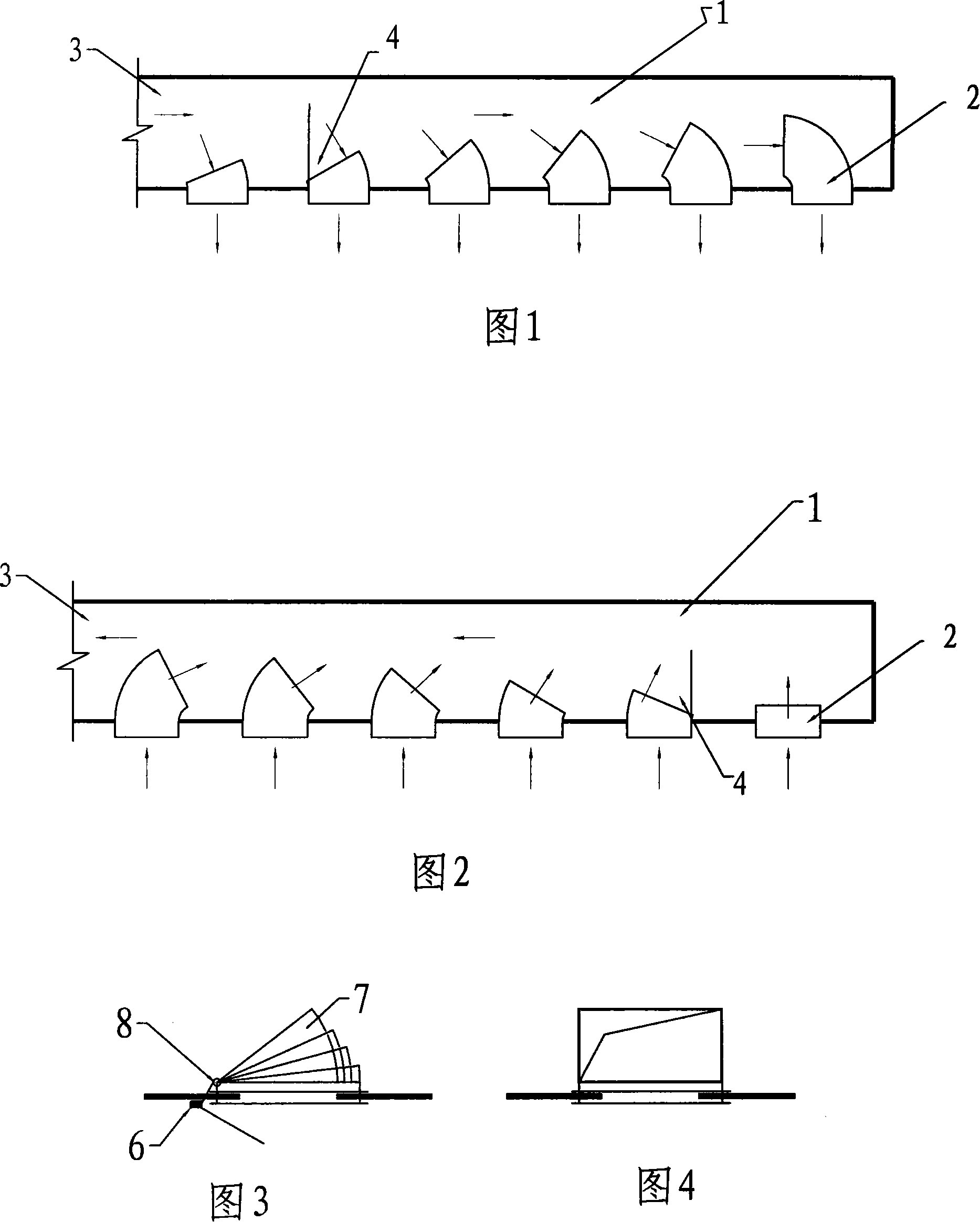

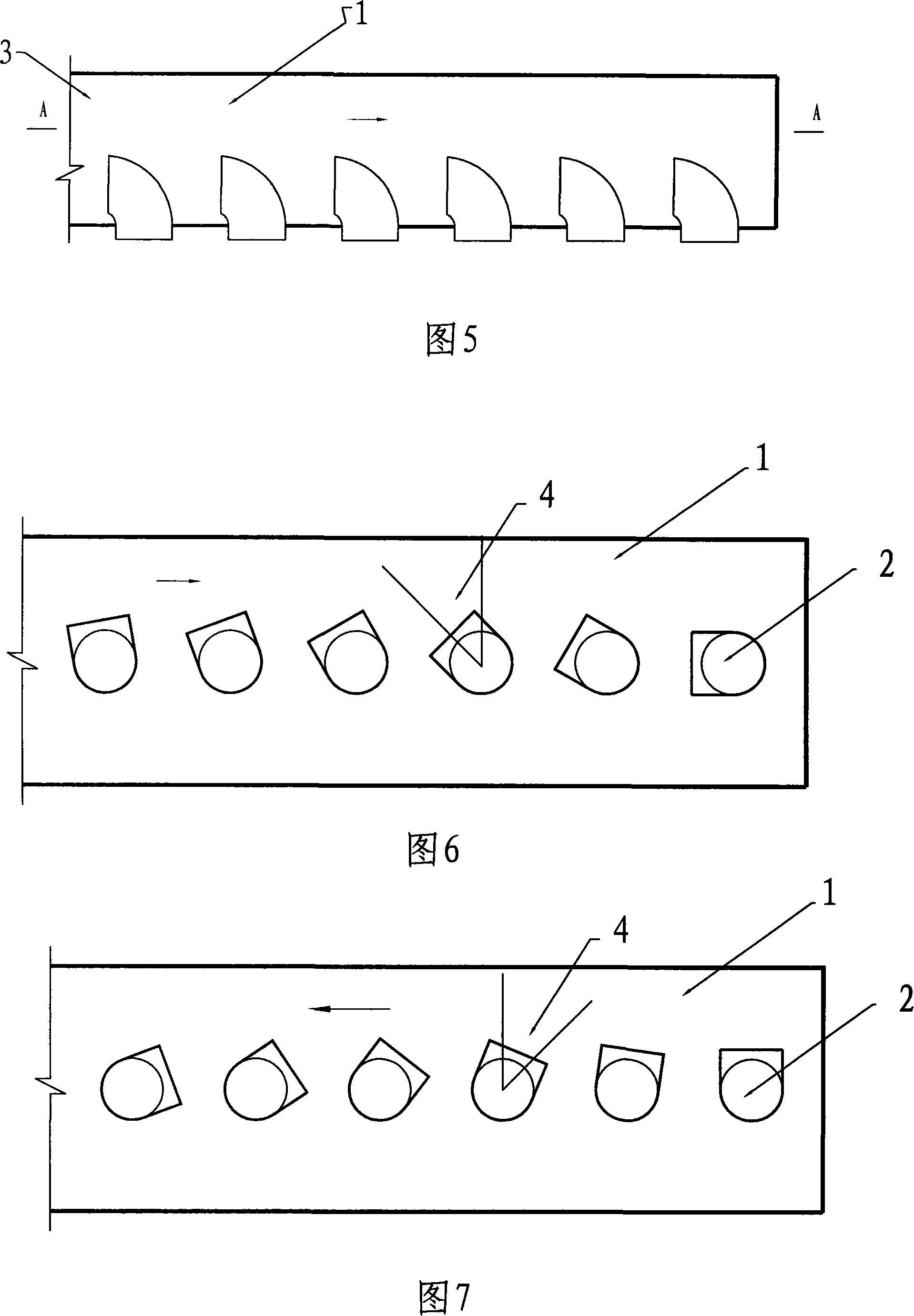

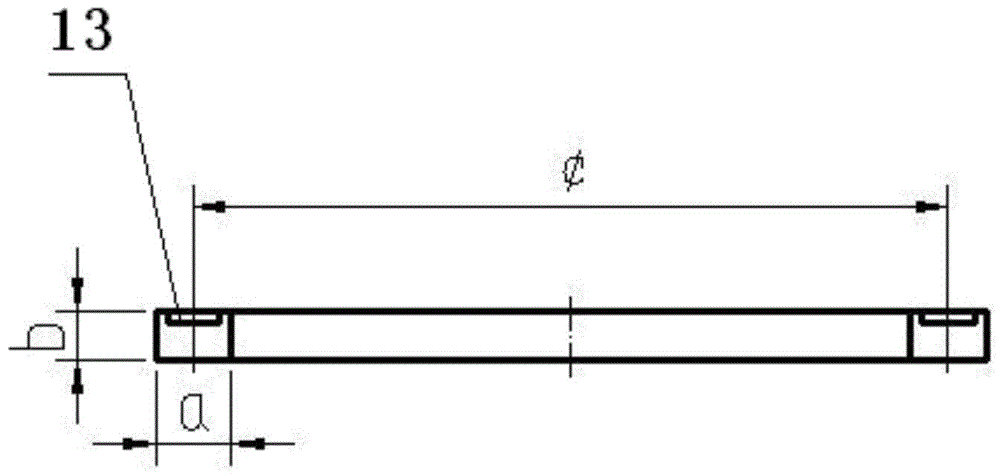

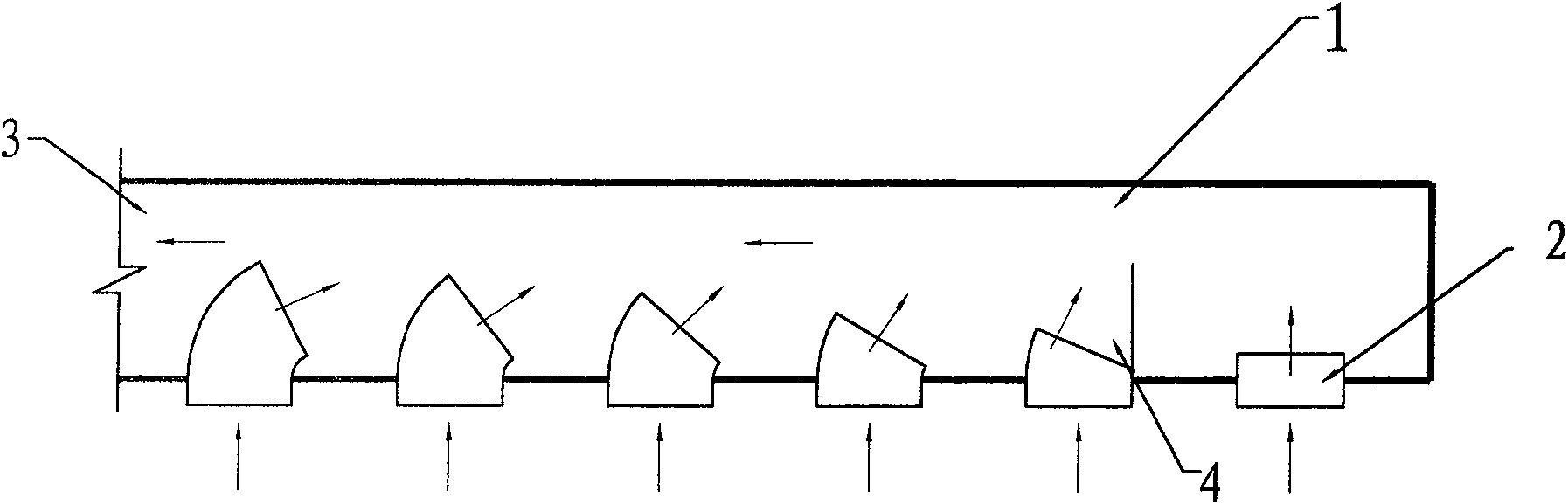

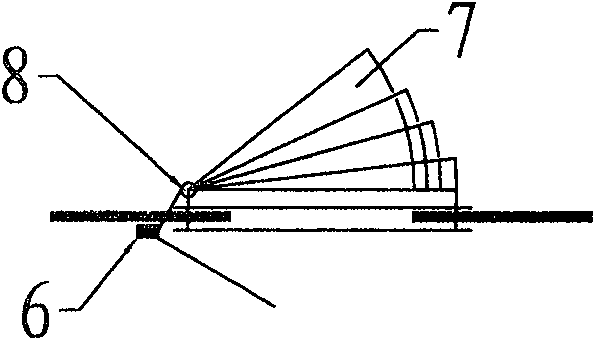

Ventilating current equalizer

ActiveCN101149177ASimple structureLow costLighting and heating apparatusSpace heating and ventilation detailsEngineeringStreamflow

This invention discloses a air supplying and discharging pipeline, especially an evenly absorbing and discharging pipeline that is adequate for long distance air supplying and discharging pipeline. It includes a simple and convenient ventilation flow equalizer, which is composed of several air ports arranged on the ventilation pipeline. The projecting area of the air port windward sections on air supplying pipeline section are increased or decreased successively. The flow rate and pressure of air port can be adjusted according to the position of air port, in order to realize evenly discharging or absorbing of the air supplying pipeline. This invention is easy to assemble too.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

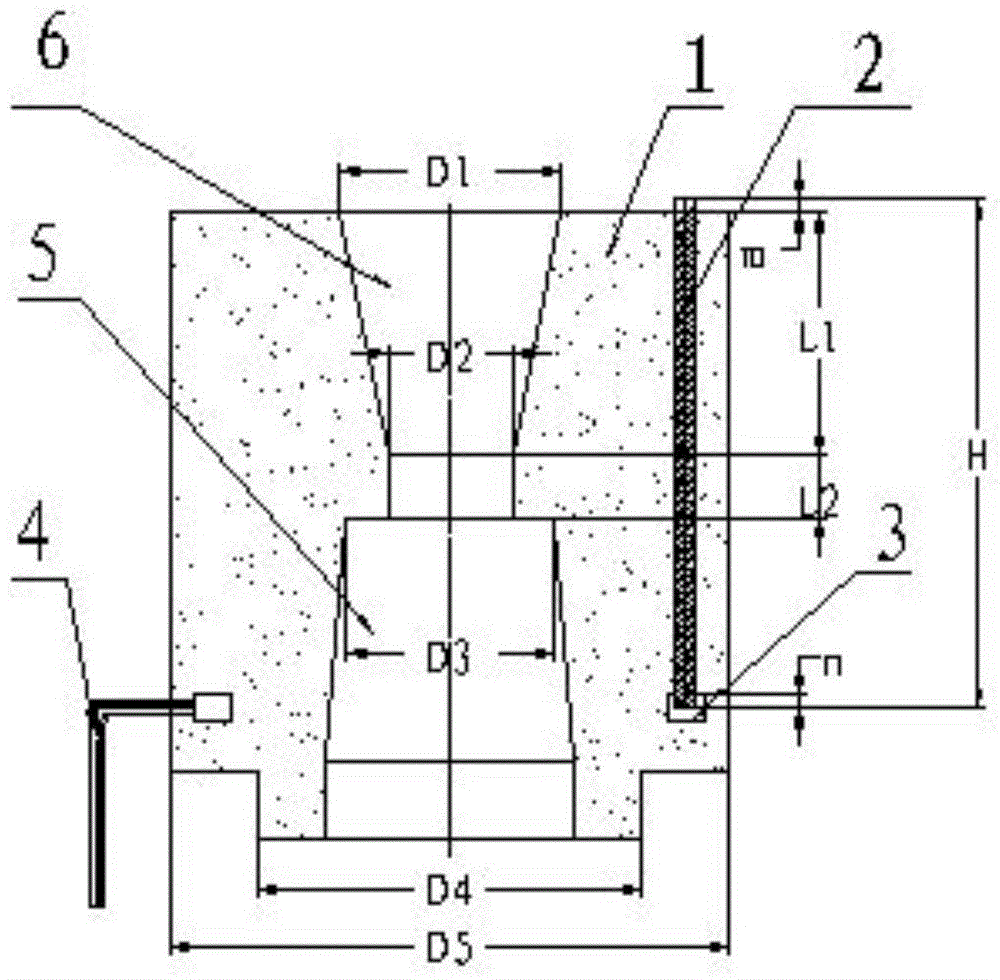

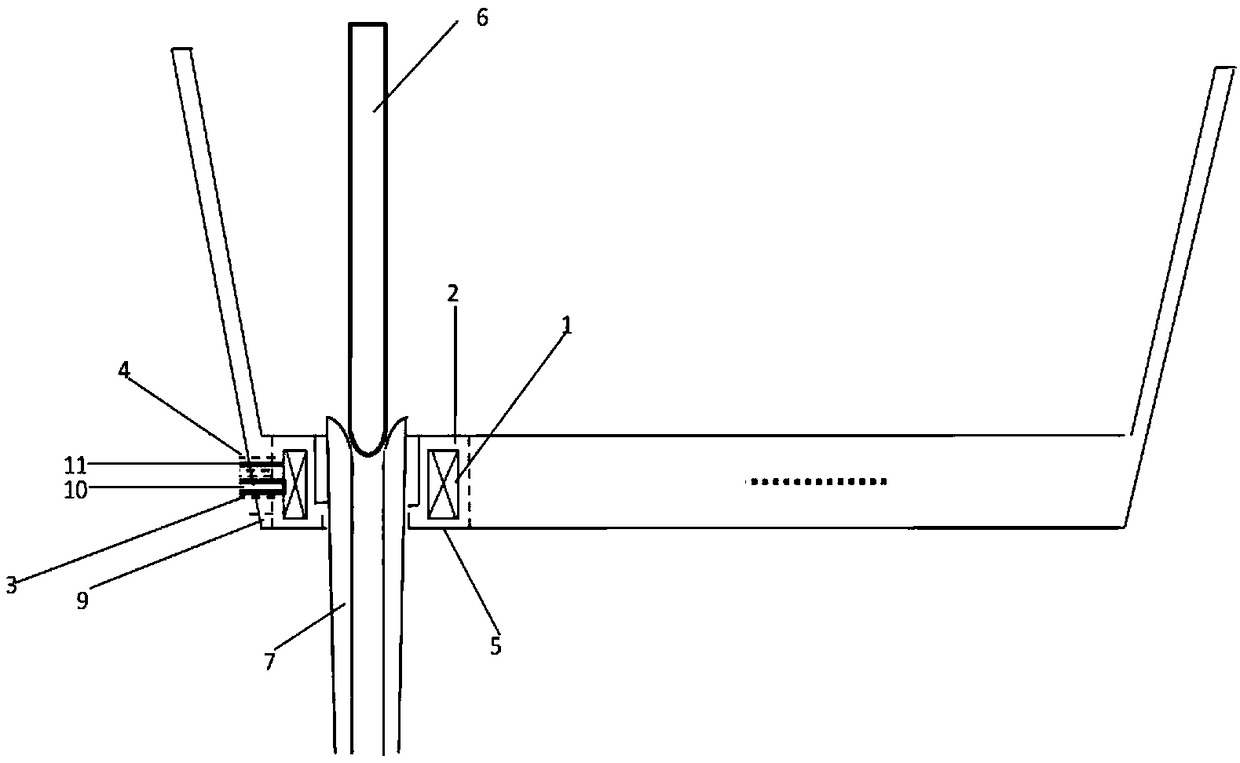

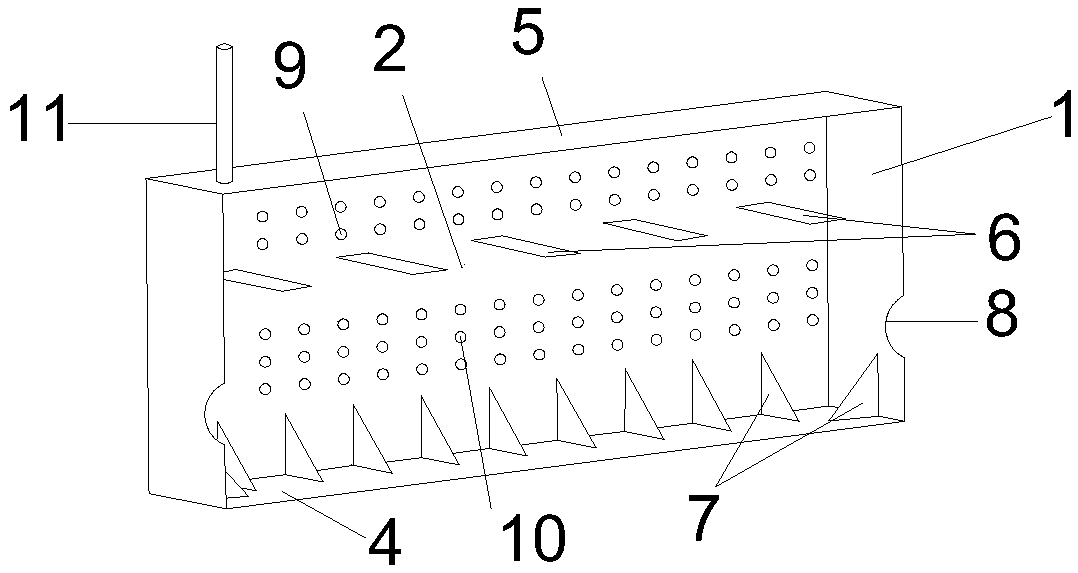

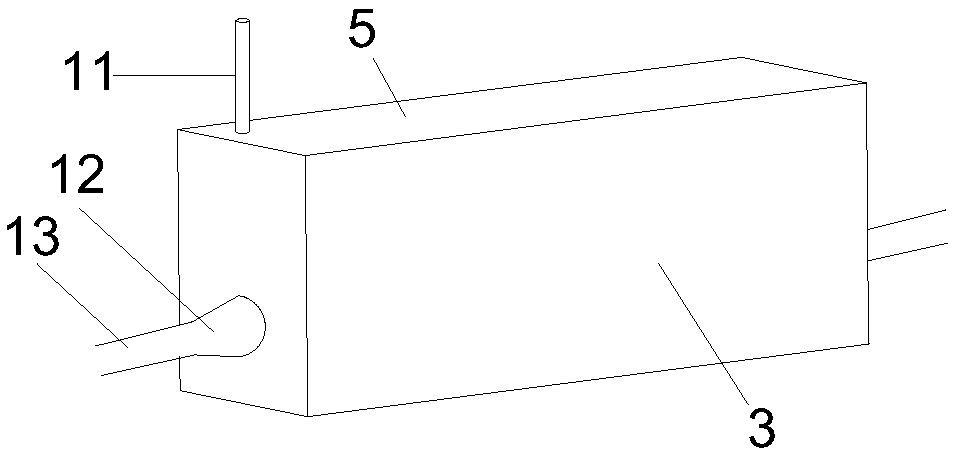

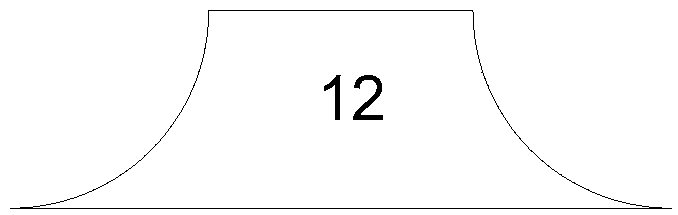

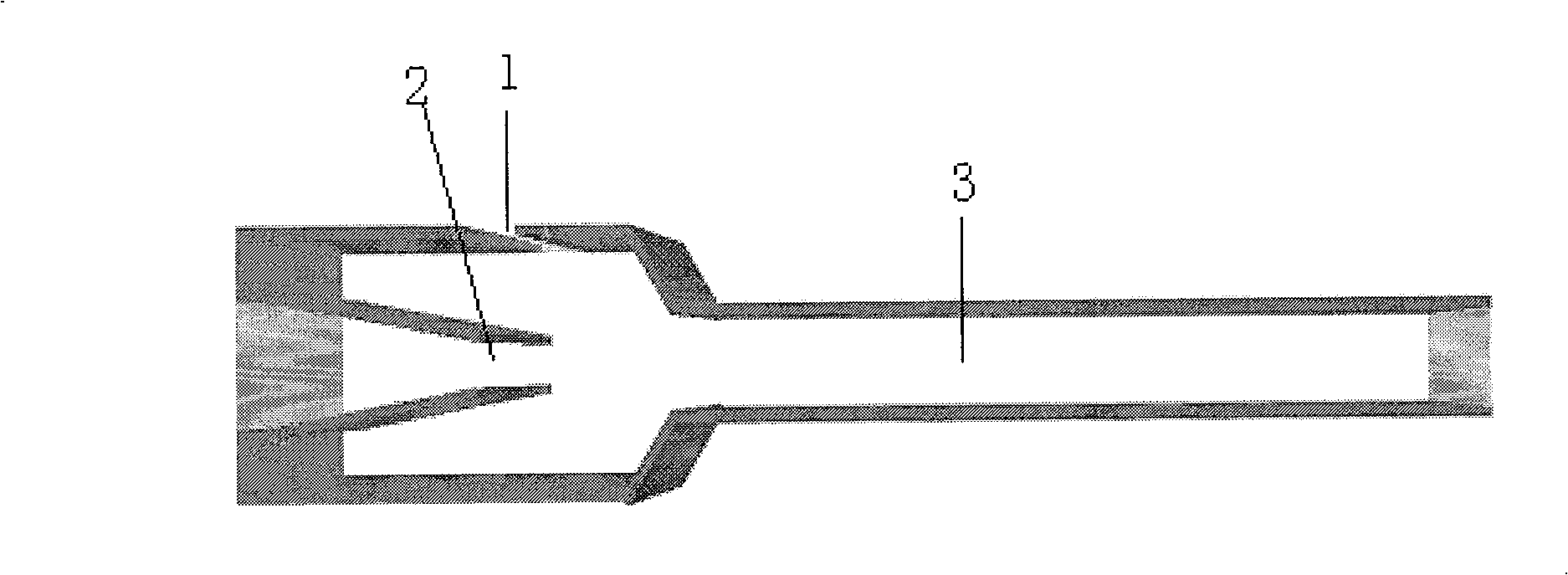

Ladle breathable upper nozzle seat brick and method for controlling nozzle slag entrainment

The invention relates to a ladle ventilating upper nozzle seat brick and a method for controlling nozzle slag volume, which comprises a ladle upper nozzle seat brick body, a ventilating ceramic rod and an air chamber box, the air chamber box is located at the bottom of the ventilating ceramic rod and connected with the ventilating ceramic rod Connected, there are a plurality of breathable ceramic rods, which are evenly arranged in the body of the upper nozzle block in a ring around the flow steel hole. The top of each breathable ceramic rod protrudes from the upper surface of the upper nozzle block body. A plurality of slots for fixing the air-permeable ceramic rods are provided, and the bottom end of each air-permeable ceramic rod extends into the slot of the air intake chamber box. When the molten steel in the ladle is at a low level, argon gas is blown in from the inlet pipe to form a ring-shaped air curtain barrier around the upper nozzle of the ladle to wash the molten steel that is about to enter the upper nozzle. The problem of eddy current slag entrainment at the nozzle not only improves the cleanliness of molten steel, but also reduces the amount of molten steel in the ladle injection surplus, a year-on-year decrease of more than 30%.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

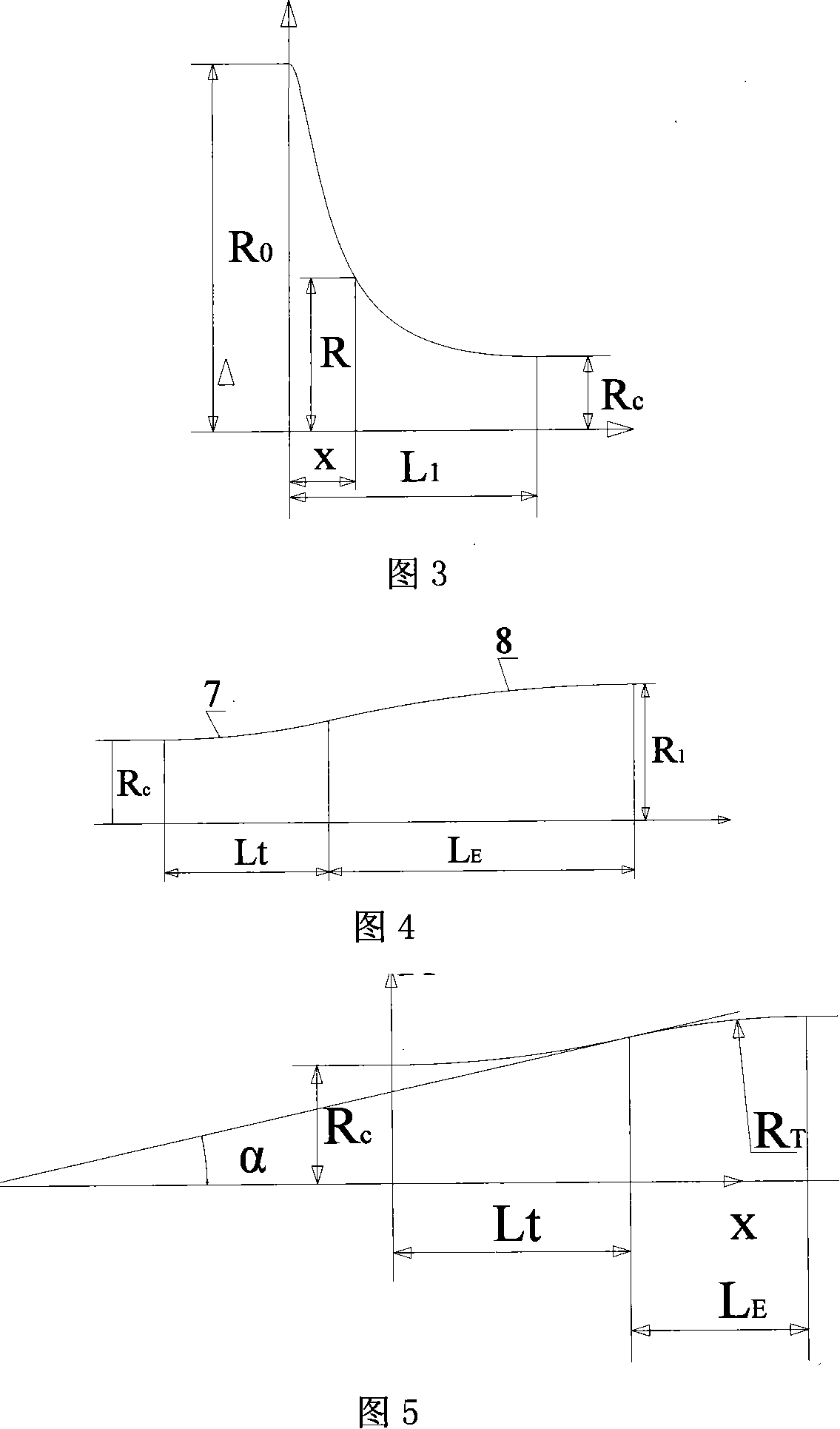

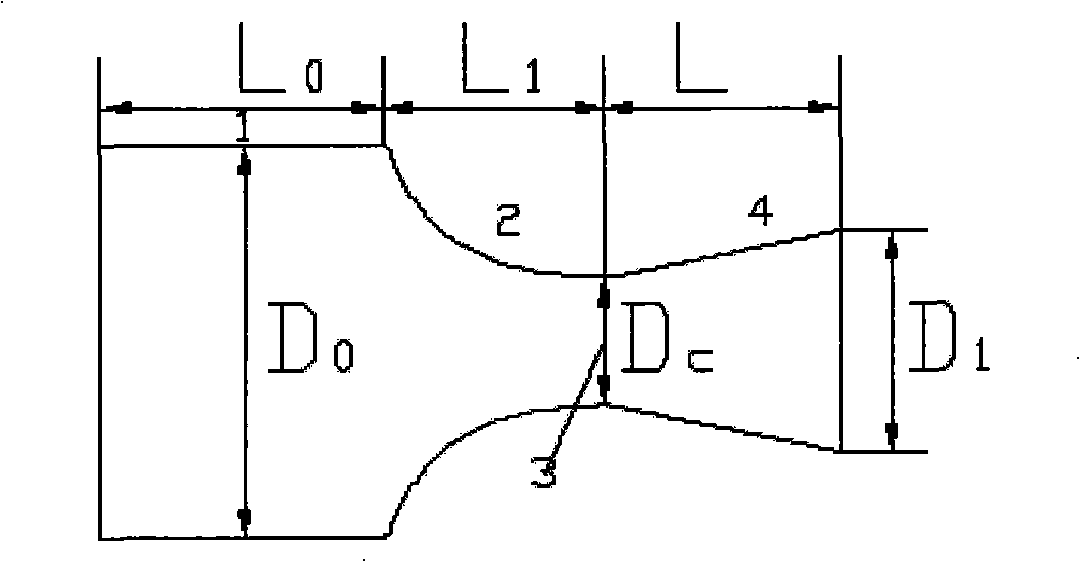

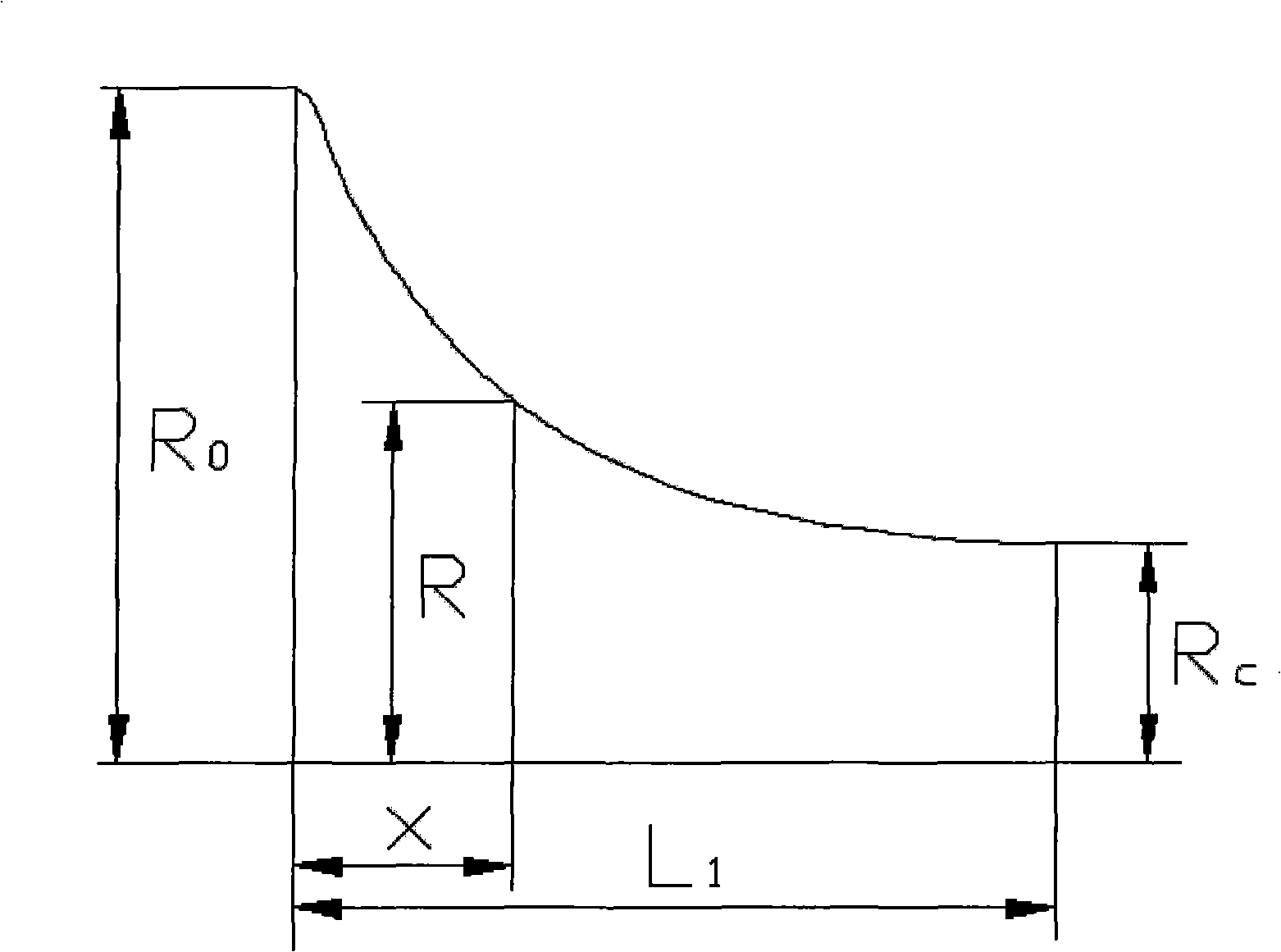

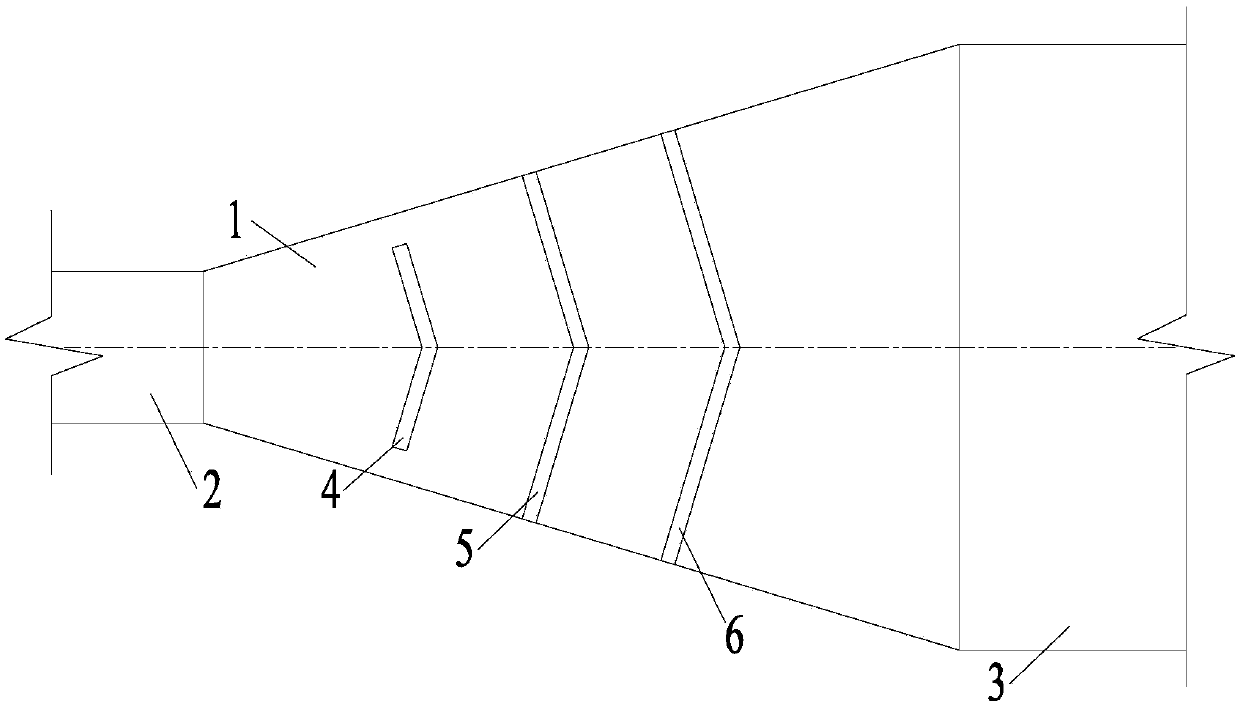

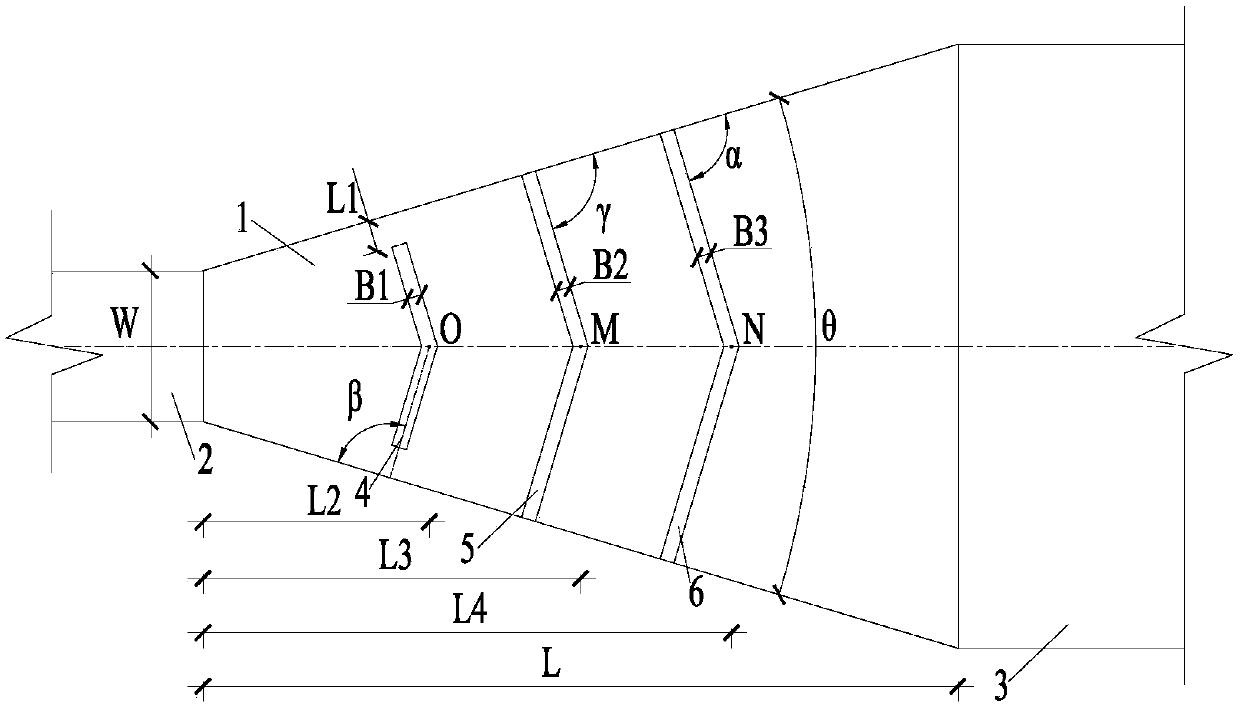

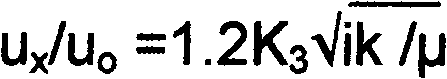

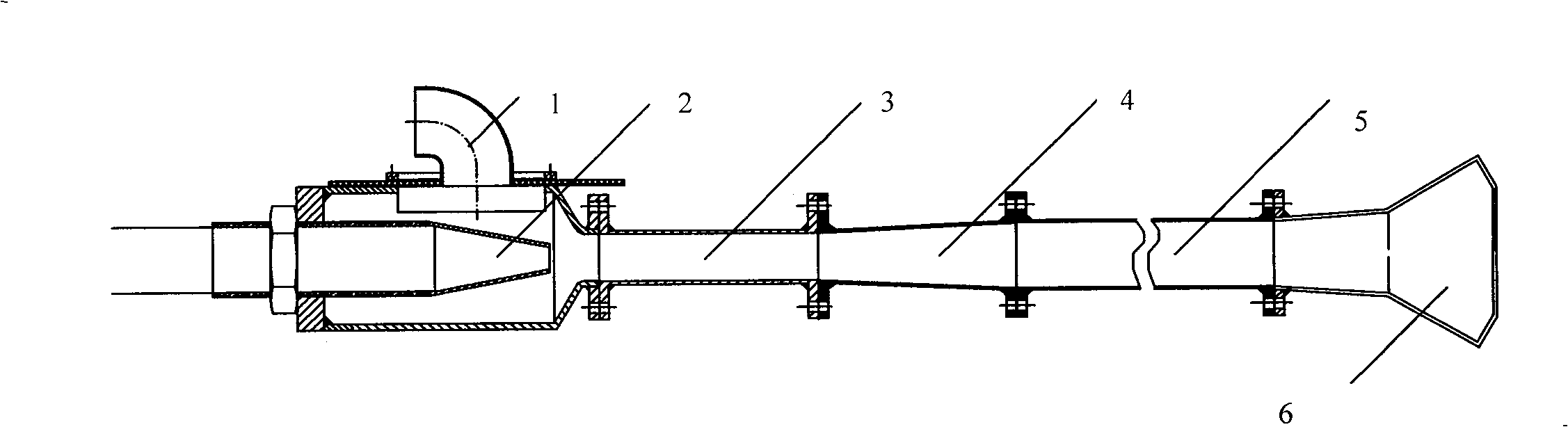

Simple fold line scaling supersonic nozzle for numerical control laser cutting

InactiveCN101284333AIncrease air velocityGuaranteed accuracyLaser beam welding apparatusNumerical controlMomentum

The invention relates to a simple broken-line scaling supersonic nozzle used for digital controlled laser cutting, which comprises a parallel segment, a shrinkage segment, a throat part and an extension segment. The extension part is a straight line segment; the ratio between the entry radius R0 of the shrinkage segment and the radius Rc of the throat part is determined by the entry mach number M0 of the shrinkage segment, the mach number Mc of the throat part and an aerothermodynamic factor K; the ratio between the exit radius R1 of the extension segment and the radius Rc of the throat part is determined by the exit mach number M1 of the extension segment, the mach number Mc of the throat part and the aerothermodynamic factor K; when R0 / Rc is equal to a constant, and R1 / Rc is equal to a constant, the exit mach number of the supersonic nozzle is kept as a fixed value under the action of gas pressure. When the supersonic nozzle conducts digital controlled laser cutting, the air stream sprayed from the nozzle is uniform, and the mass flow rate and the momentum are large, thereby effectively blowing off molten metal and other slag. Furthermore, the cut is narrow and tidy, without adhering slag staying on the edge of cutting seam, and the cutting quality and efficiency are obviously improved.

Owner:SHANGHAI JIAO TONG UNIV

Driving device for fan-shaped pouring ladle

The invention discloses a driving device for a fan-shaped pouring ladle. The key improvement is that the driving device comprises a bracket and a hydraulic cylinder, wherein the bracket is fixedly arranged at the bottom of the fan-shaped pouring ladle; the hydraulic cylinder is symmetrically arranged on two sides of the fan-shaped pouring ladle; one end of the hydraulic cylinder is hinged at the bottom of the bracket; the bracket is attached with the rear external wall and bottom of the fan-shaped pouring ladle; a positioning hook arranged on the rear wall of the fan-shaped pouring ladle is matched with a positioning hole on the bracket; and the other end of the hydraulic cylinder is hinged at the bottom of a pouring framework. The driving device has the advantages that: an angular displacement sensor and an angular speed sensor are arranged on the rotating shaft of the fan-shaped pouring ladle; two sensors transmit acquired signals to a control circuit of a hydraulic station; the control circuit regulates the moving speed of the hydraulic cylinder according to the signals, so that the constant-speed flowing of liquid iron is ensured by the fan-shaped pouring ladle at different angles, the quality of castings is ensured and the economic loss of production enterprises caused by unqualified castings is avoided.

Owner:XINXING DUCTILE IRON PIPES CO LTD

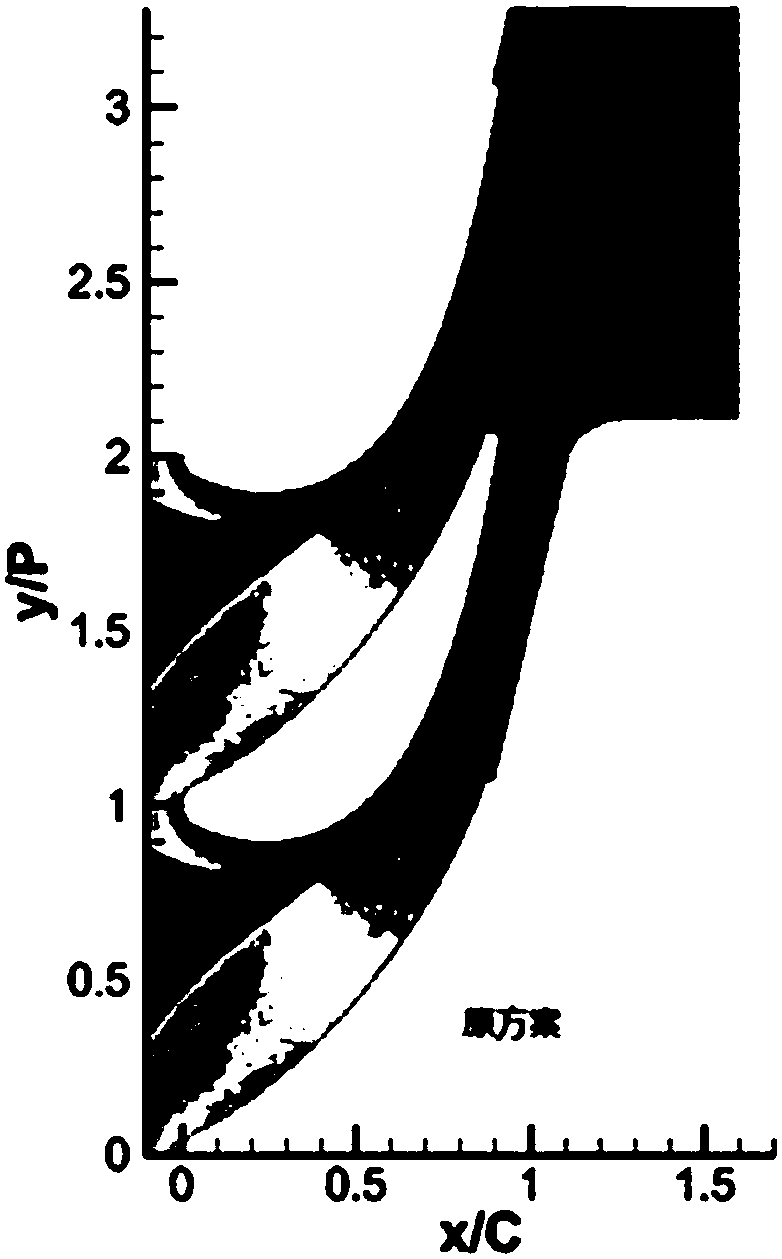

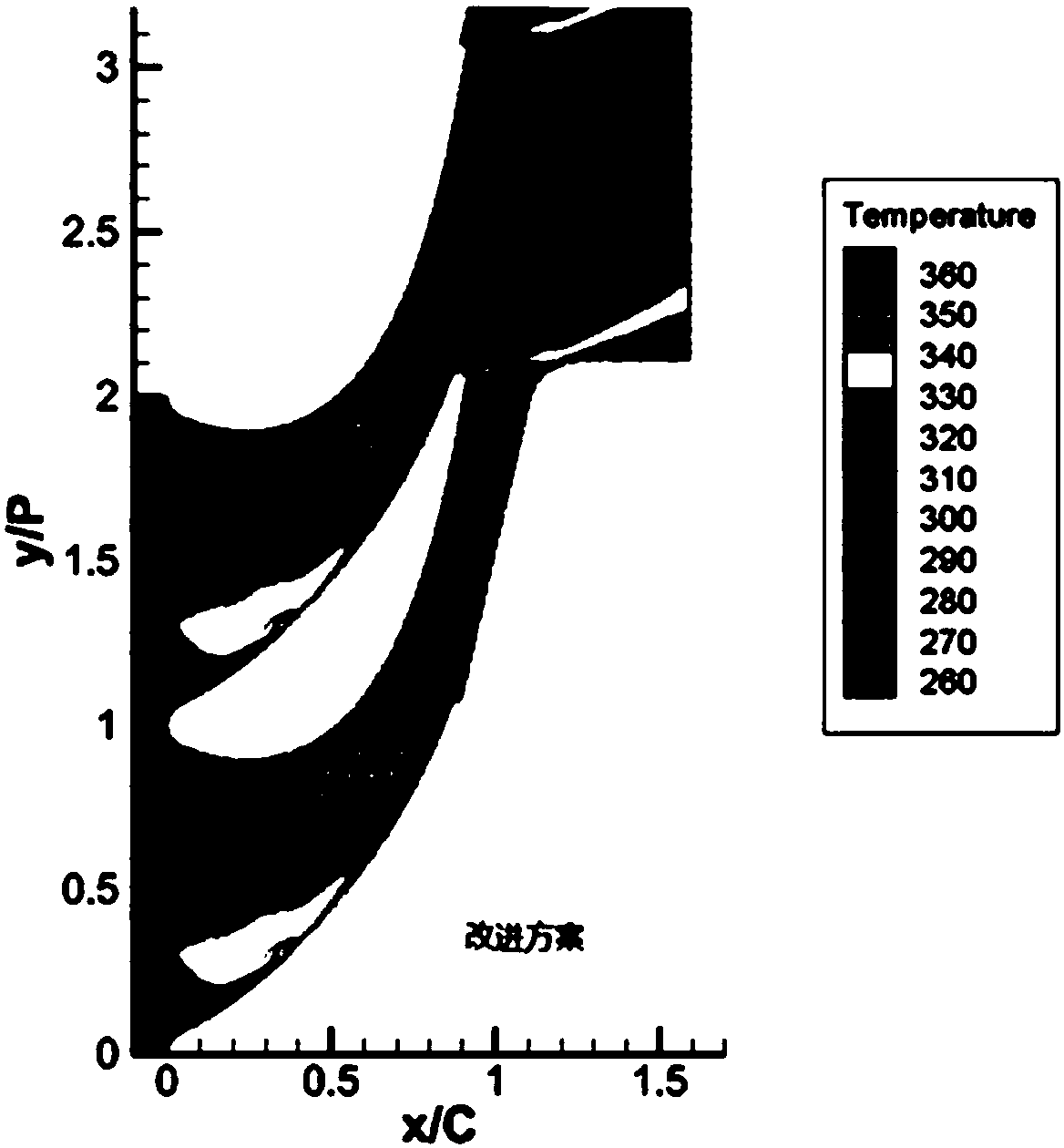

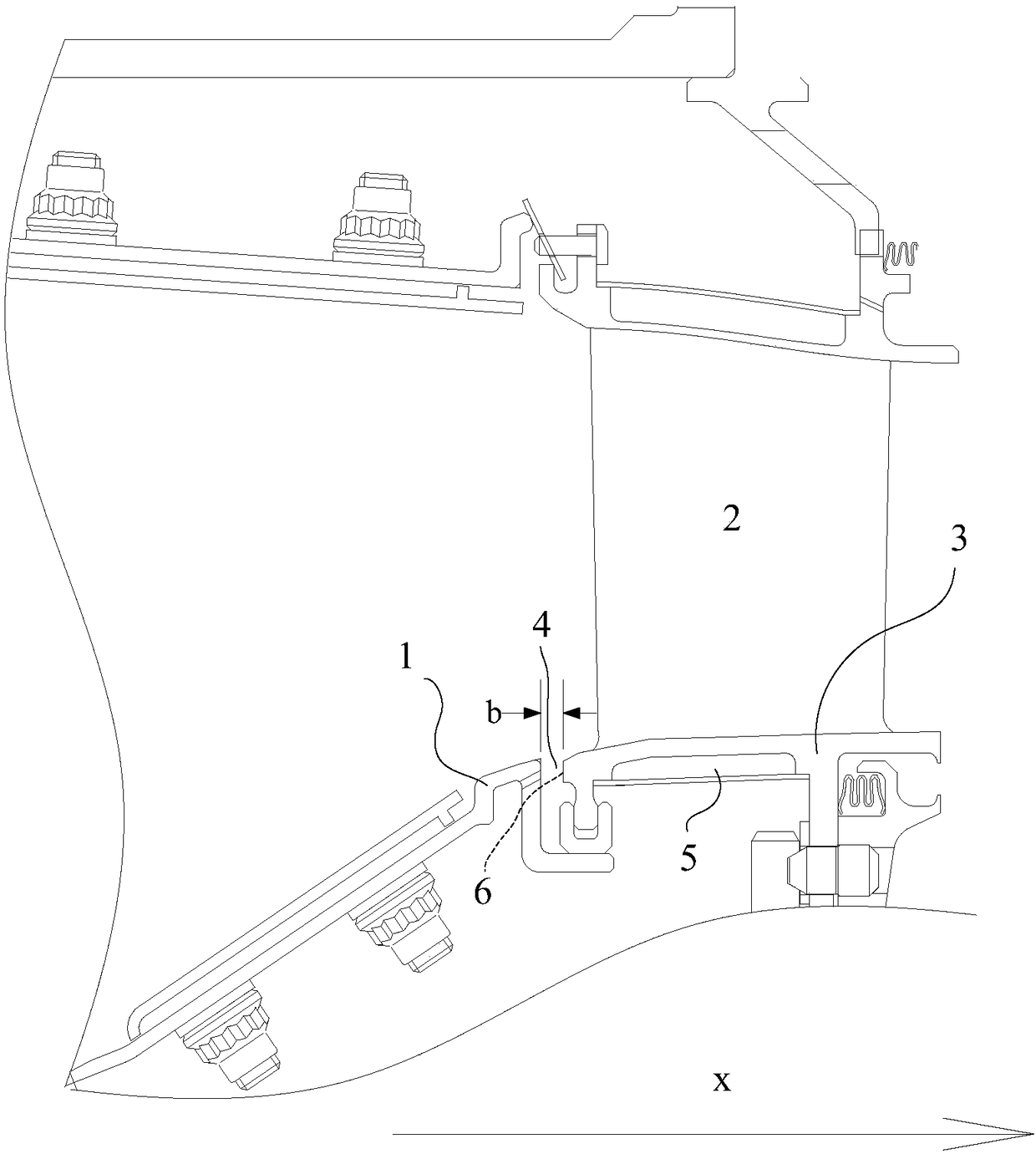

Cooling structure suitable for high-pressure turbine of gas turbine

ActiveCN109424367AIncreased outflowUniform outflowBlade accessoriesMachines/enginesTurbine bladeHigh pressure

The invention discloses a cooling structure suitable for a high-pressure turbine of a gas turbine. Through the cooling structure, outflow of cold gas along a groove slit can be more uniform, backward-flowing invasion of gas is prevented, and additionally, cooling heat-exchange of the positions, close to the pressure face sides, of the front edges of the end walls is also enhanced. The cooling structure comprises barrier ribs arranged on the positions, close to the force suction face sides of turbine blades, of the front end faces of the blade end walls, and a plurality of gas film holes formedin the positions, close to the pressure face sides of the turbine blades, of the front end faces of the blade end walls, wherein the gas film holes are connected with cooling cavities in the back faces of the blade end walls in a through hole form, P is the pitch of the turbine blades, 0%P serves as the front edge side position of the pressure face of the axially corresponding turbine blade on the front end face, 100%P serves as the front edge side positions of the force suction faces of the opposite adjacent turbine blades, the barrier ribs are circumferentially distributed within the 50-100%P range on the front end face, and the gas film holes are circumferentially distributed within the 0-50%P range on the front end face.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

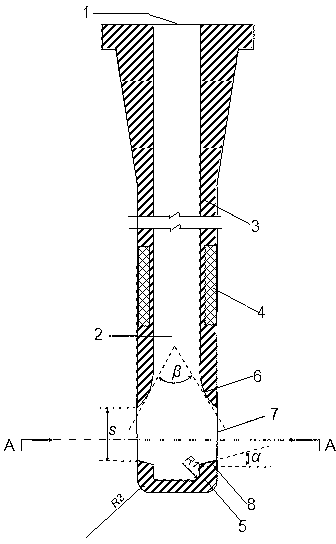

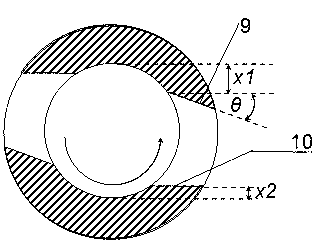

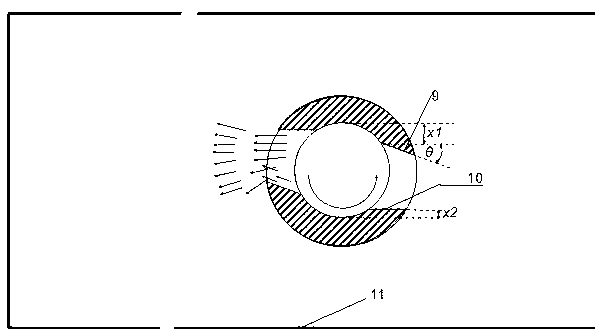

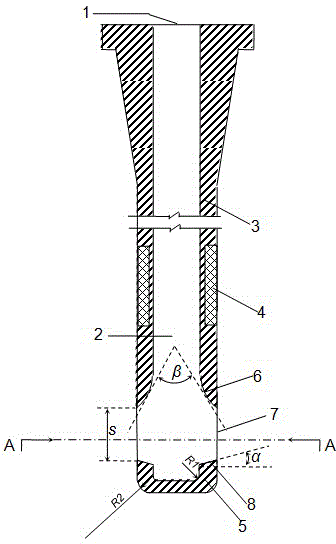

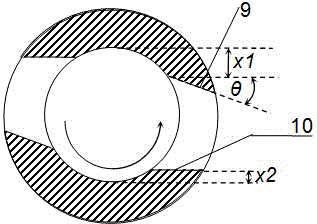

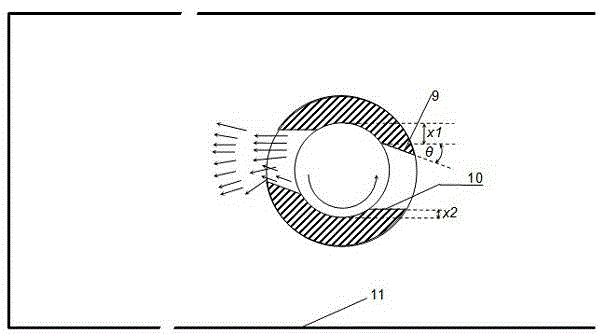

Submersed nozzle for plate blank electromagnetic rotational flow continuous casting

The invention belongs to the technical field of continuous casting and particularly relates to a submersed nozzle for plate blank electromagnetic rotational flow continuous casting. The submersed nozzle for the plate blank electromagnetic rotational flow continuous casting is composed of a molten steel inflowing end, a side wall, a hollow inner cavity, a nozzle bottom and molten steel discharging holes. The pair of molten steel discharging holes same in size and shape are laterally symmetrically formed in the side wall close to the nozzle bottom. The upper edge of each molten steel discharging hole is of an arc-shaped curved face. The included angle beta of inner surface tangents of each arc-shaped curved face is 30 degrees-120 degrees. The lower edge of each molten steel discharging hole is of a slope. The dip angle of each slope is -30 degrees to +30 degrees. One side face of each molten steel discharging hole is inclined inwards and the other side face is parallel to the wide face of a crystallizer. The included angle theta of the two side faces is 0 degree-20 degrees. According to the submersed nozzle for the plate blank electromagnetic rotational flow continuous casting, outflow of the two molten steel discharging holes can be evened, liquid level fluctuation on the meniscus portion of the crystallizer is reduced, the effect of rotational flow continuous casting is thoroughly achieved, and meanwhile impact effect on the wide face of the crystallizer by the outflow of the nozzle caused by the rotational flow can be reduced.

Owner:苑轶

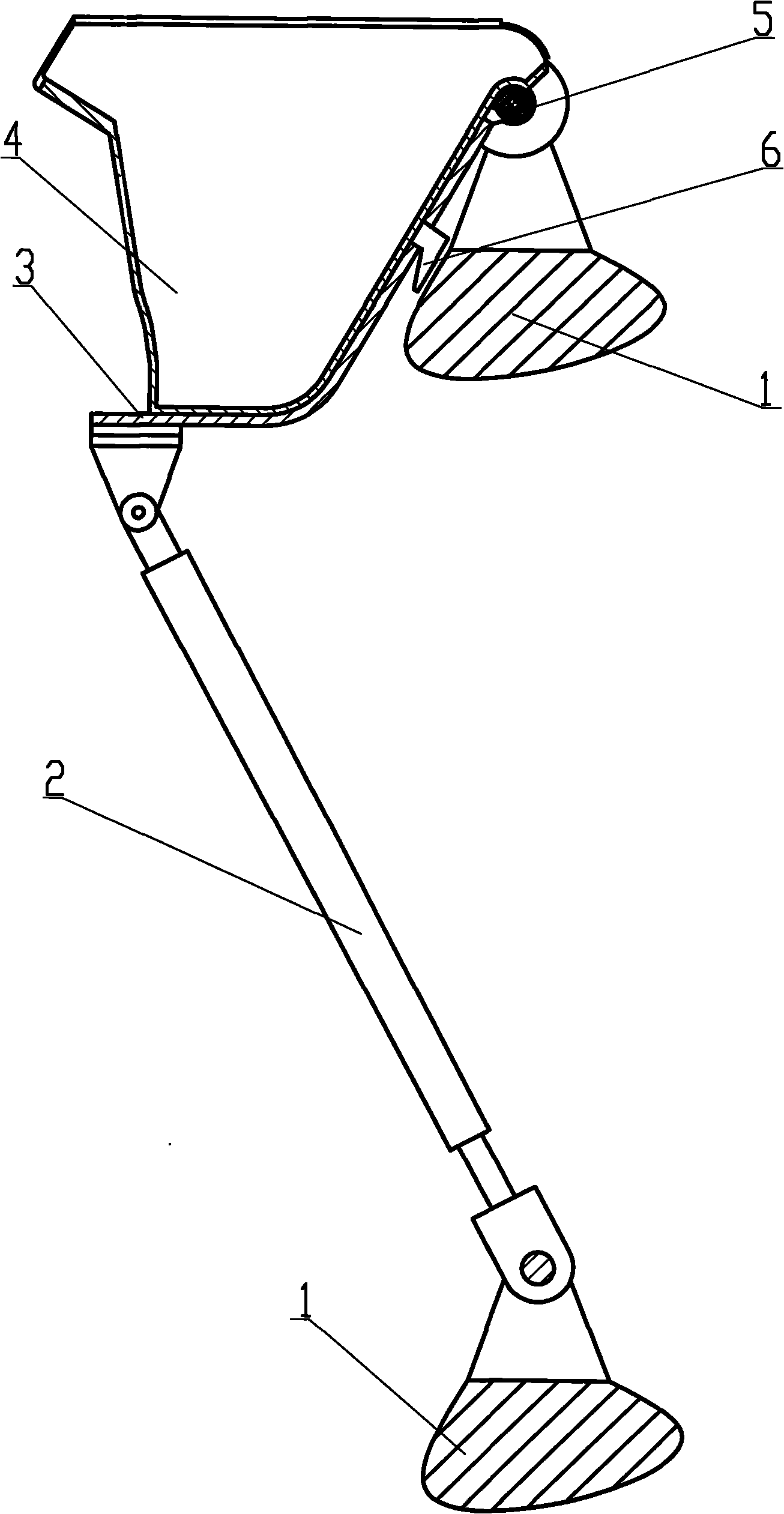

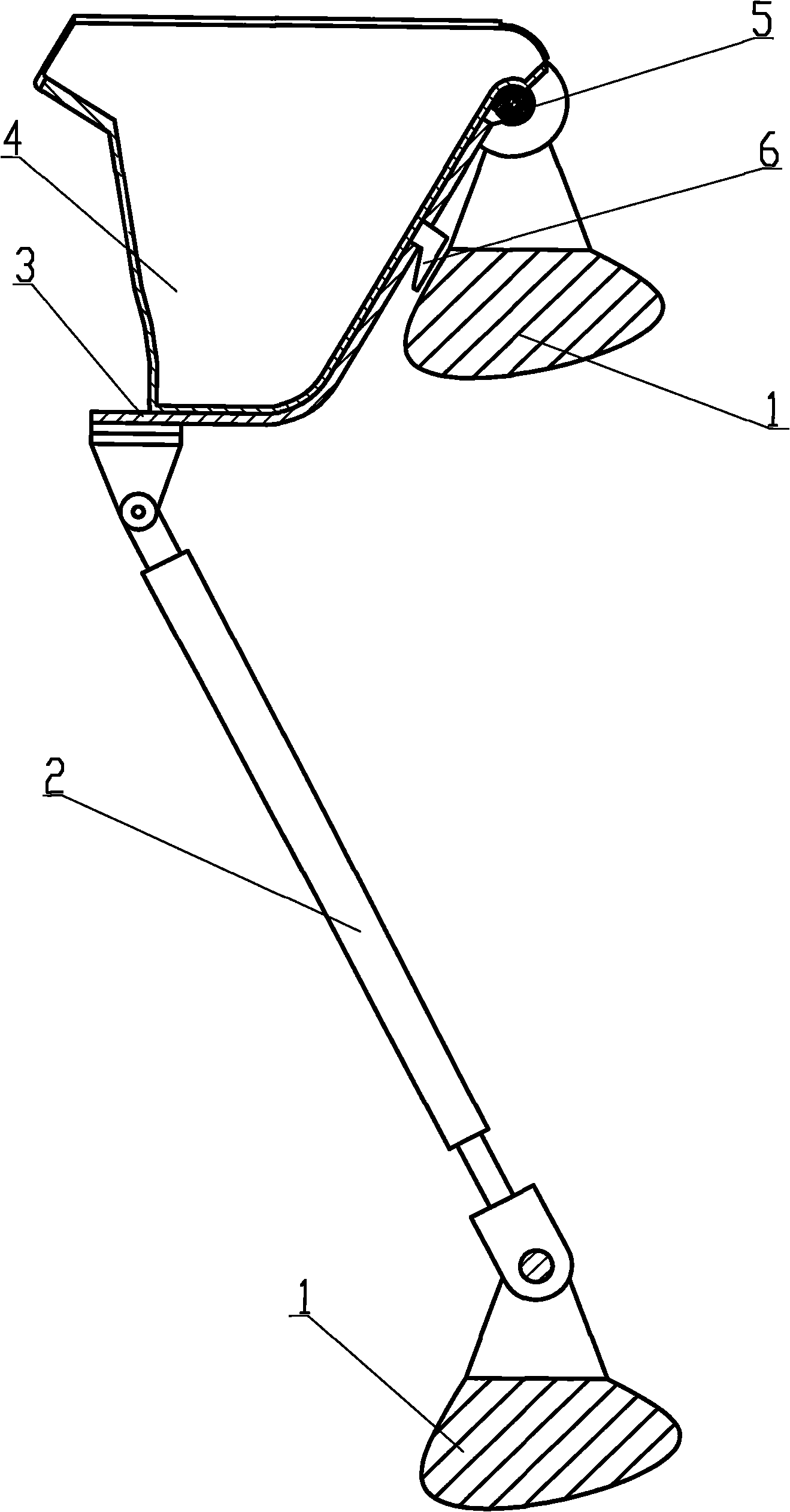

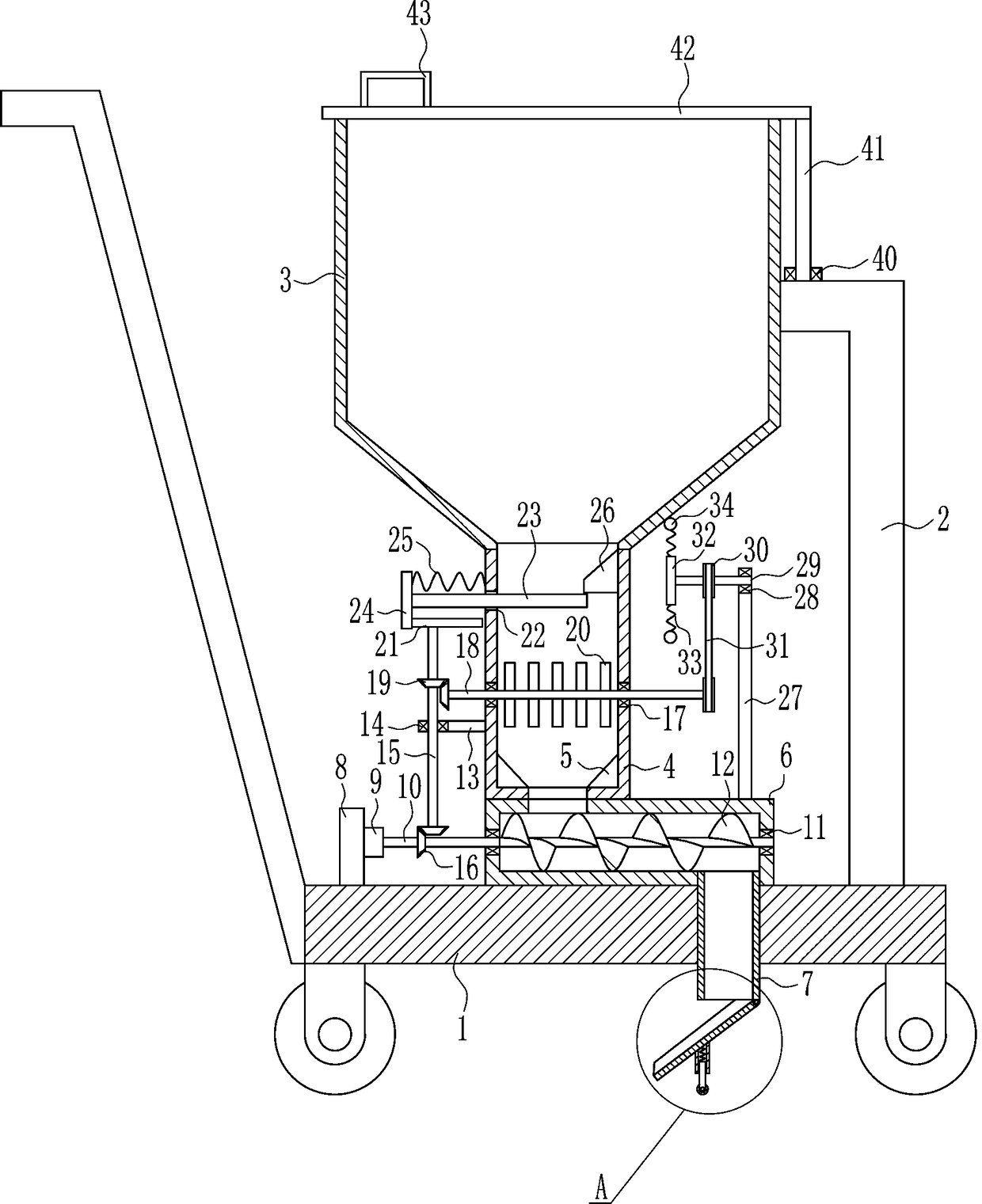

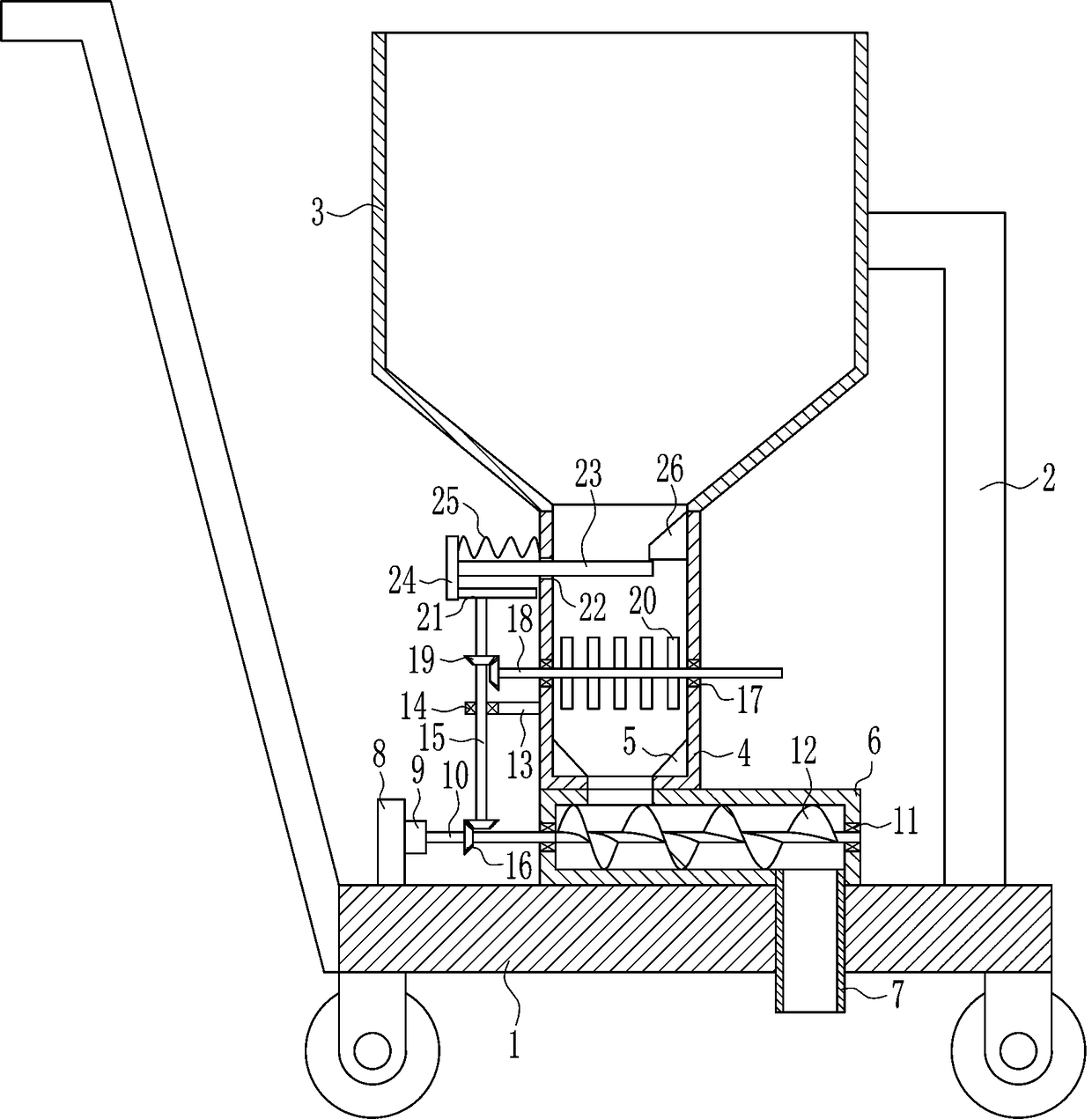

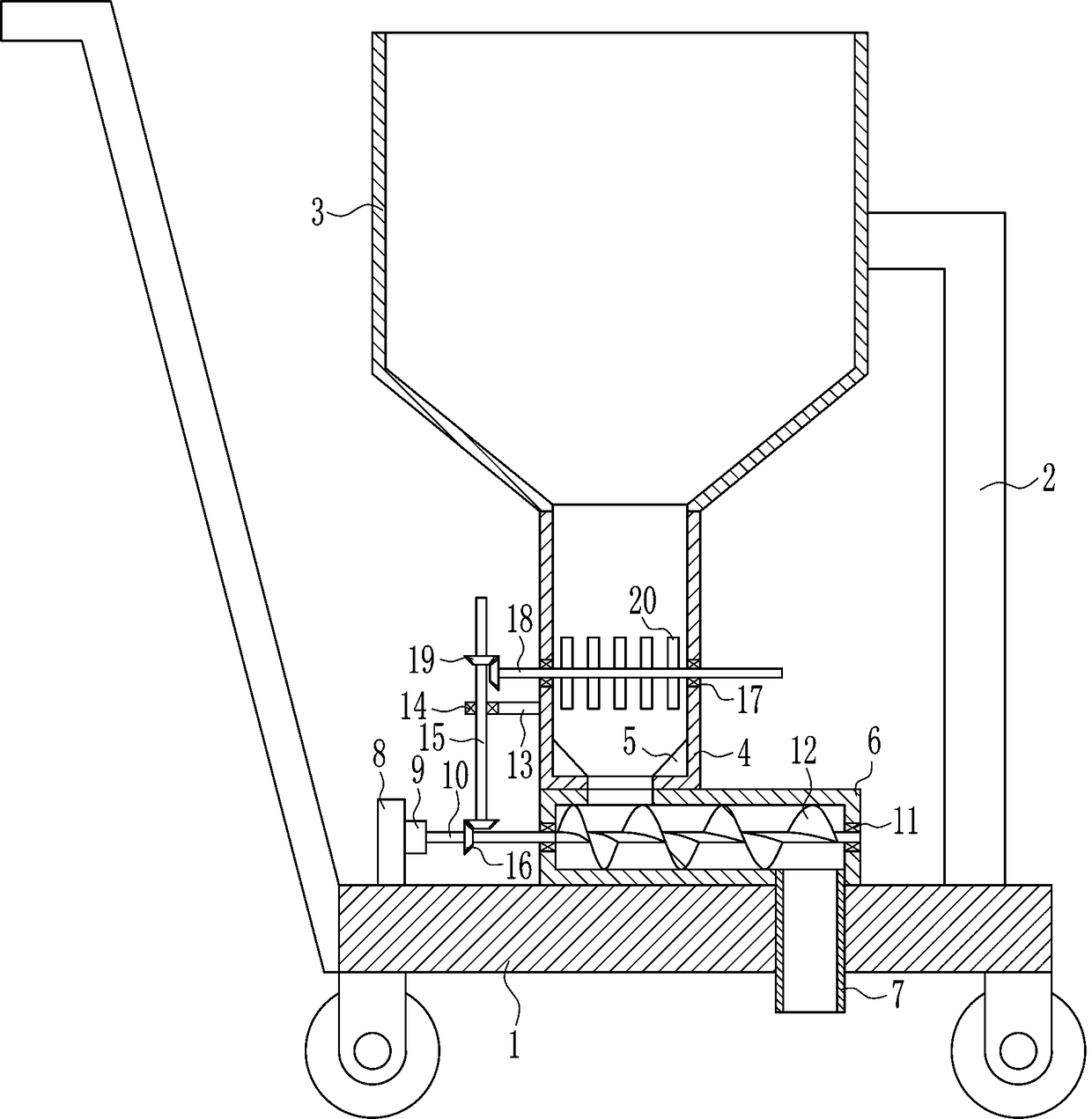

Lime setting-out device for road construction

The invention relates to a setting-out device, in particular to a lime setting-out device for road construction. The lime setting-out device for the road construction has relatively high flexibility,is relatively uniform in line drawing, and is not prone to causing waste in the operation process. The lime setting-out device for the road construction comprises a cart, a bracket, a discharging hopper, a feeding cylinder, sloping plates, a cylindrical frame body, a discharging cylinder, a mounting plate, a motor, a first rotating shaft, a first bearing seat, helical blades and the like. The bracket is arranged on the right portion of the upper side surface of the cart, and the discharging hopper is installed at the tail end of the bracket. The discharging hopper is located directly above thecart, and the feeding cylinder is arranged at the lower end of the discharging hopper. The lime setting-out device achieves the effects that flexibility is relatively high, line drawing is relativelyuniform, and waste is not prone to being caused in the operation process. By arranging the cart, the lime setting-out device can be flexibly moved, and the effect of enhancing the flexibility is achieved. By arranging a receiving hopper, lime powder can flow out more uniformly, and the relatively uniform effect of line drawing is achieved.

Owner:南昌华学科技有限公司

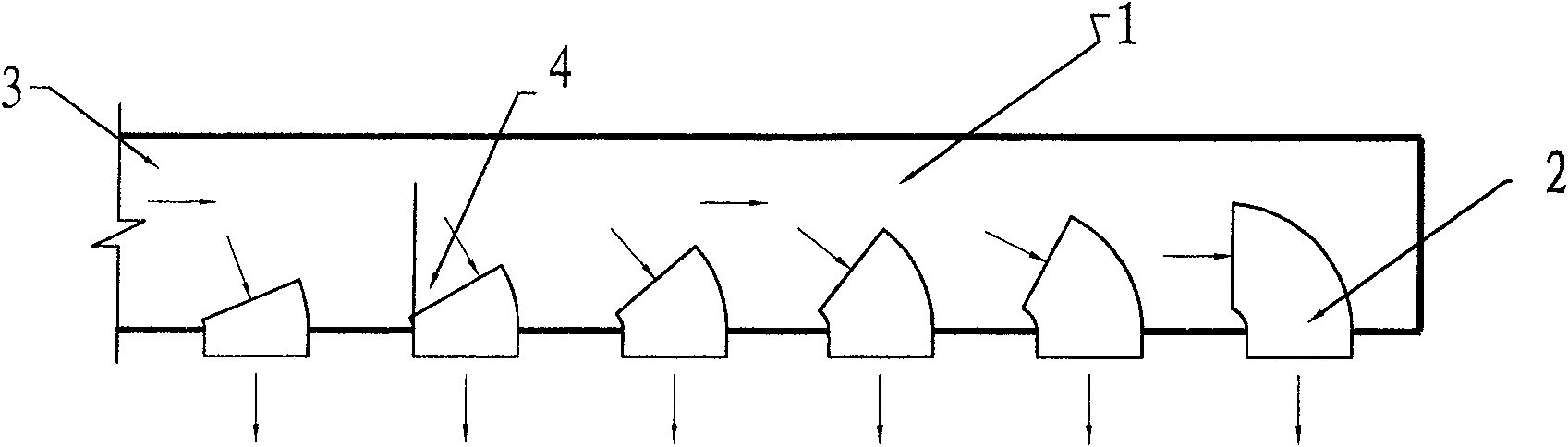

Ventilating current equalizer

ActiveCN100582594CSimple structureLow costLighting and heating apparatusSpace heating and ventilation detailsEngineeringStreamflow

This invention discloses a air supplying and discharging pipeline, especially an evenly absorbing and discharging pipeline that is adequate for long distance air supplying and discharging pipeline. It includes a simple and convenient ventilation flow equalizer, which is composed of several air ports arranged on the ventilation pipeline. The projecting area of the air port windward sections on air supplying pipeline section are increased or decreased successively. The flow rate and pressure of air port can be adjusted according to the position of air port, in order to realize evenly discharging or absorbing of the air supplying pipeline. This invention is easy to assemble too.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

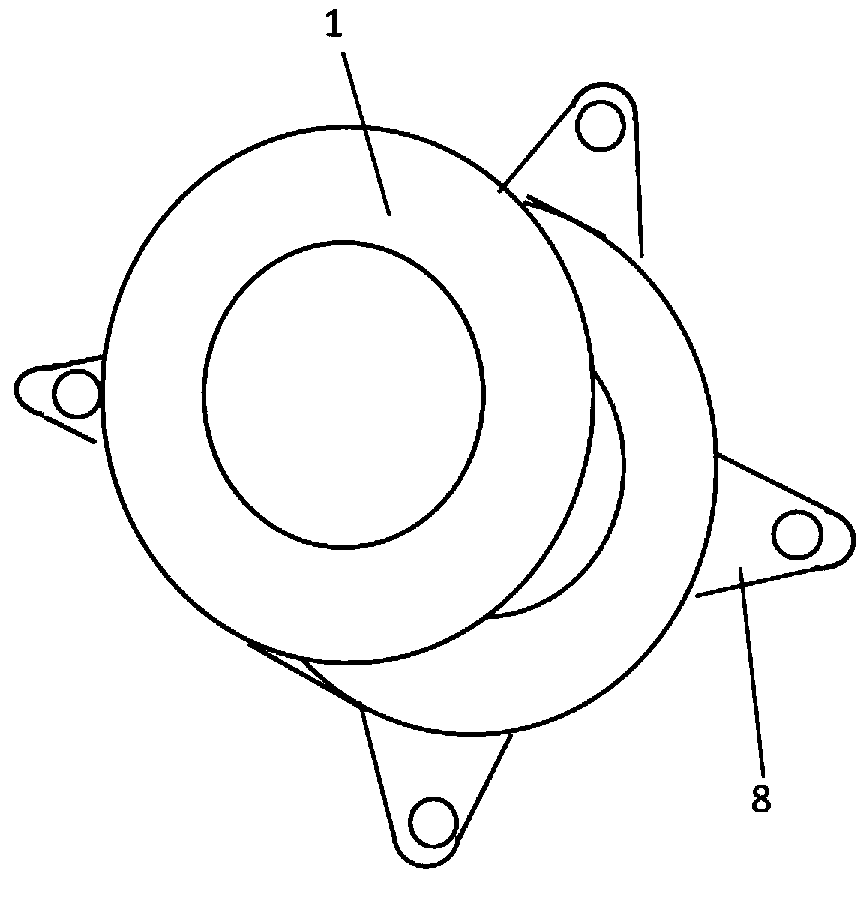

Electromagnetic type tundish restraining submersed entry nozzle from being blocked

ActiveCN108705075AEffective protectionPrevent water leakageMelt-holding vesselsSlab casterWater channel

The invention belongs to the technical field of continuous casting, in particular to an electromagnetic type tundish restraining a submersed entry nozzle from being blocked. The electromagnetic type tundish restraining the submersed entry nozzle from being blocked comprises a tundish bottom cavity, a rotating magnetic field generation device, a water channel, a circuit and a waterproof supportingplate. The rotating magnetic field generation device is installed in the tundish bottom cavity. The water channel and the circuit are provided with respective cavities. The waterproof supporting plateis arranged at the lower end. The electromagnetic type tundish restraining the submersed entry nozzle from being blocked can be universally applied to existing square blank, round blank and plate blank continuous casting machines and can be used for single-strand continuous casting or multi-strand continuous casting; steel liquid can generate clockwise or anticlockwise rotation at the positions of the submerged entry nozzle and a stopper rod, the submerged entry nozzle can be restrained from being blocked, the outflow uniformity and stability of the submerged entry nozzle can also be improved, a flow field and a temperature field in a crystallizer are made uniform, and then the quality of a cast blank is improved.

Owner:NORTHEASTERN UNIV

Closed lateral-symmetry horn mouth water inlet method for river model test

ActiveCN108330899ASimulated smoothThe test effect is accurateHydraulic modelsWater storageWater flow

The invention discloses a closed lateral-symmetry horn mouth water inlet method for a river model test. The method comprises the steps that firstly, a closed water inlet tank is manufactured; secondly, curing and pouring are carried out; thirdly, water storage is carried out; fourthly, water is fed to the water inlet tank; and fifthly, colliding energy dissipation is carried out, and water flow issimulated. According to the method, the water flow which is more stable and relatively free of acceleration can be simulated, and the test result is more accurate.

Owner:HOHAI UNIV

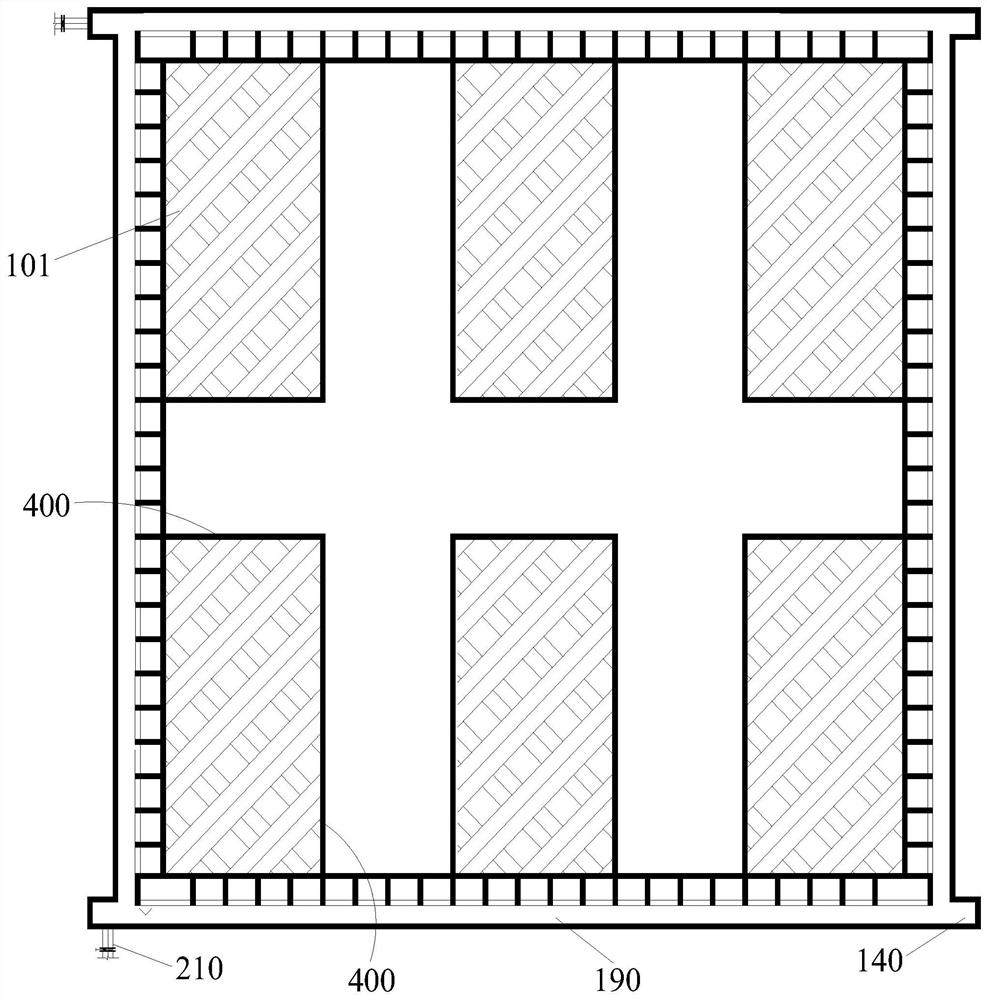

Rectification device and method for improving water distribution of diffusion type water inlet box culvert of urban water delivery pump station

InactiveCN109680754AUniform outflowHomogenized Velocity DistributionWater supply installationPumping plantsEngineeringDiffusion type

The invention discloses a rectification device and method for improving water distribution of a diffusion type water inlet box culvert of an urban water delivery pump station. The rectification devicecomprises a first bottom sill, a combined beam and a second bottom sill which are arranged in the diffusion type water inlet box culvert in a water flow direction, wherein the first bottom sill and the second bottom sill are both in a zigzag form, are both arranged on the bottom surface of the diffusion type water inlet box culvert and are symmetrically arranged along the center line of the diffusion type water inlet box culvert; the combined beam comprises multiple beams which are vertically arranged up and down; each beam is in the zigzag form and is symmetrically arranged along the centerline of the diffusion type water inlet box culvert; and an interval is formed between the beam at the lowermost part and the bottom surface of the diffusion type water inlet box culvert. According tothe rectification device and method disclosed by the invention, by adopting the first bottom sill to perform rectification on forward inflow of the diffusion type water inlet box culvert to fully diffuse a water flow, the combined beam homogenizes flow rate distribution on a vertical face of the combined beam, and then the flow rate distribution condition of the water flow on a plane is improved through the rectification effect of the second bottom sill, so that uniform outflow of the diffusion type water inlet box culvert is realized, and good inflow condition is provided for the urban waterdelivery pump station.

Owner:HOHAI UNIV

Bleed hole stemming and method for producing the same

ActiveCN100575308CGood sintered strengthEasy to openBlast furnace componentsBlast furnace detailsPyrophylliteGraphite

The invention relates to a stemming at a taphole; the weight percentages of the components are the following: 20 to 40 of corundum, 10 to 20 of silicon carbide, 3 to 10 of silicon nitride, 10 to 23 of coke powders, 1 to 5 of graphite powders, 3 to 10 of sericite, 1 to 5 of active alumina micropowders, 5 to 15 of clay, 5 to 10 of pyrophyllite, 1 to 3 of metal powders, and +15 to 25 of water-free binder. The stemming adds a plurality of materials with plasticity and good cohesiveness to cause the stemming to easily block the hole and fill interspaces, with good binding performance of new stemming and old stemming; materials with medium and high temperature expansion are added to reduce the size of the stemming contraction at high temperature, and cracks can be avoided; materials with sintering function within different temperature areas are added, so the stemming has good sintering strength in different temperature scopes; materials with high-temperature resistance and good erosion resistance are added, and thus the stemming has high strength at high temperature, washing resistance and erosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

Novel environment-friendly anhydrous stemming for blast furnace iron notch and preparation method of stemming

InactiveCN109776069AReduce pollutionPromote environmental protectionCeramicwareClaywaresPorosityEnvironmental resistance

The invention relates to a novel environment-friendly anhydrous stemming for a blast furnace iron notch. The novel environment-friendly anhydrous stemming for the blast furnace iron notch is characterized by being prepared, by mass, 10-20 parts of coke, 10-20 parts of calcined pyrophyllite particles, 10-20 parts of brown fused alumina particles, 10-20 parts of bauxite powder, 5-10 parts of ferro silicon nitride, 5-10 parts of silicon carbide powder, 10-20 parts of clay, 5 parts of a carbon-based composite material and 5-10 parts of a composite binding agent. The novel environment-friendly anhydrous stemming for the blast furnace iron notch and a preparation method of the stemming have the following advantages that the pollution is small, the environment-friendly performance is good, and the stemming is a first choice of am iron and steel enterprise; the plasticity and cohesive property are good, the stemming is easily extruded into gaps and cracks, and the gaps and cracks are easily filled with the stemming; the porosity is proper, and moisture is conveniently discharged during drying; the volume contraction is small at high temperature, so that the cracks are prevented; the stemming is good in sintering performance, high in strength and resistant to flushing and corrosion; the stemming is easily cracked, the iron notch is deep, and the iron outlet time is long.

Owner:上海宝金冶金技术有限公司 +1

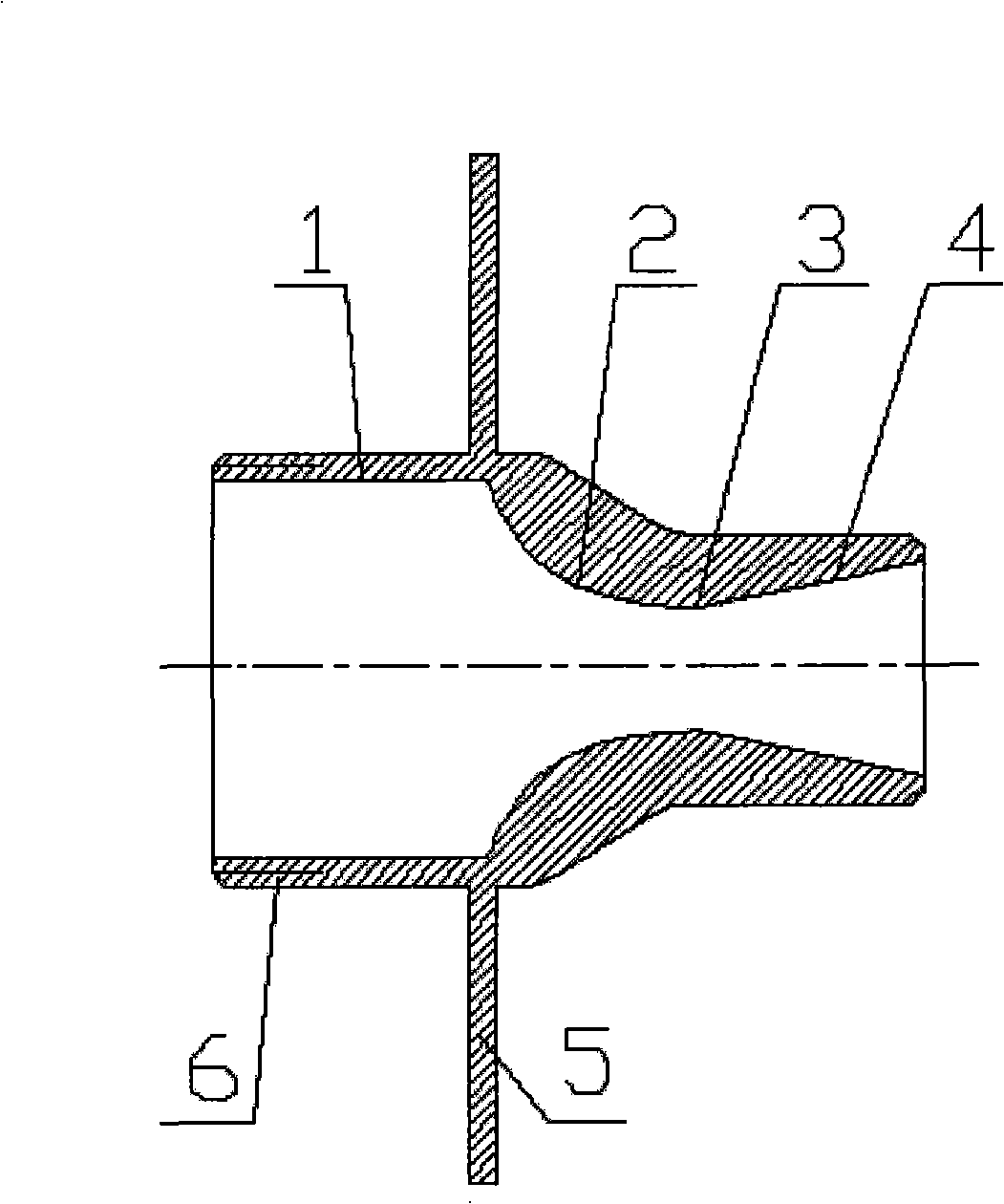

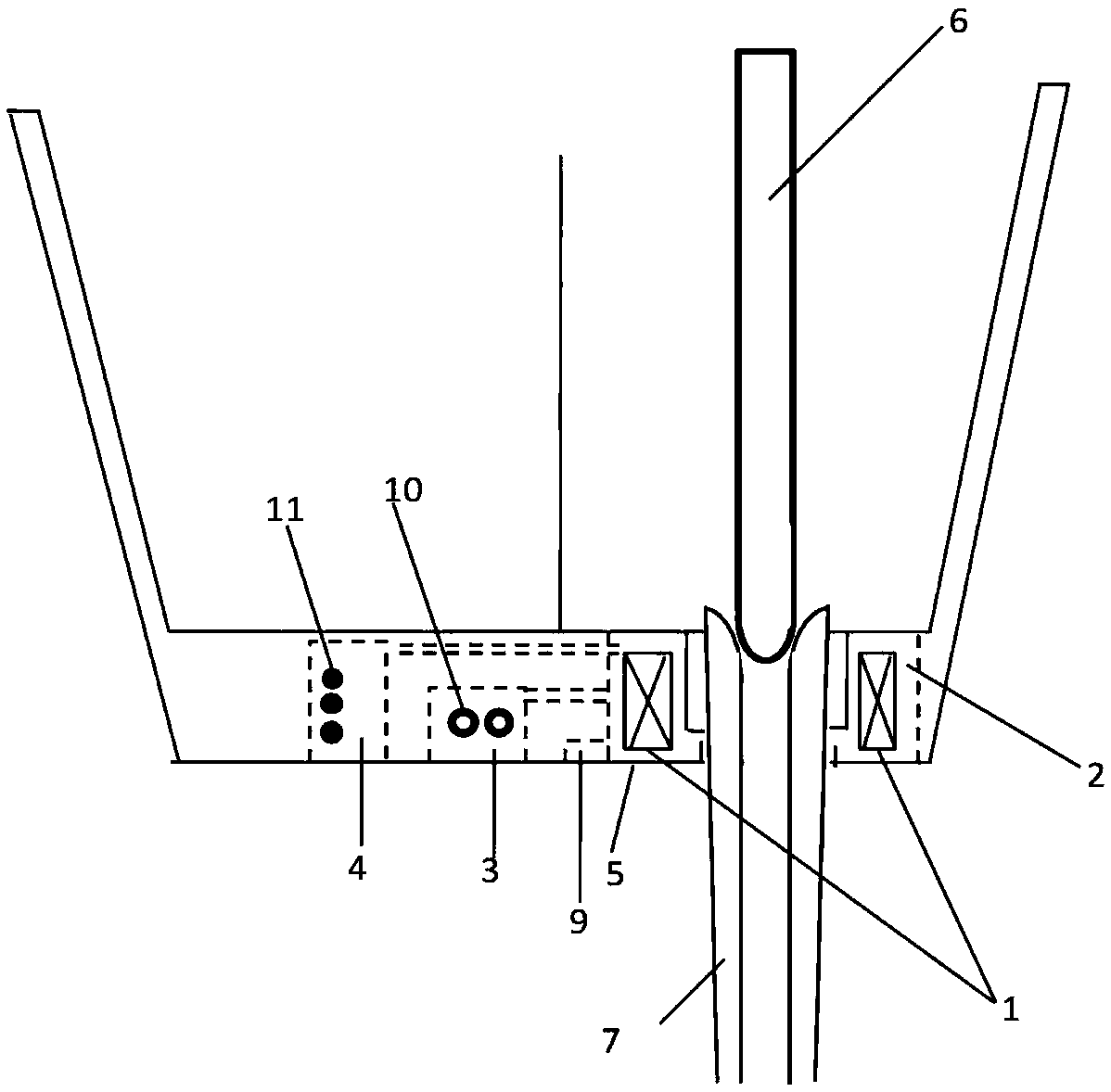

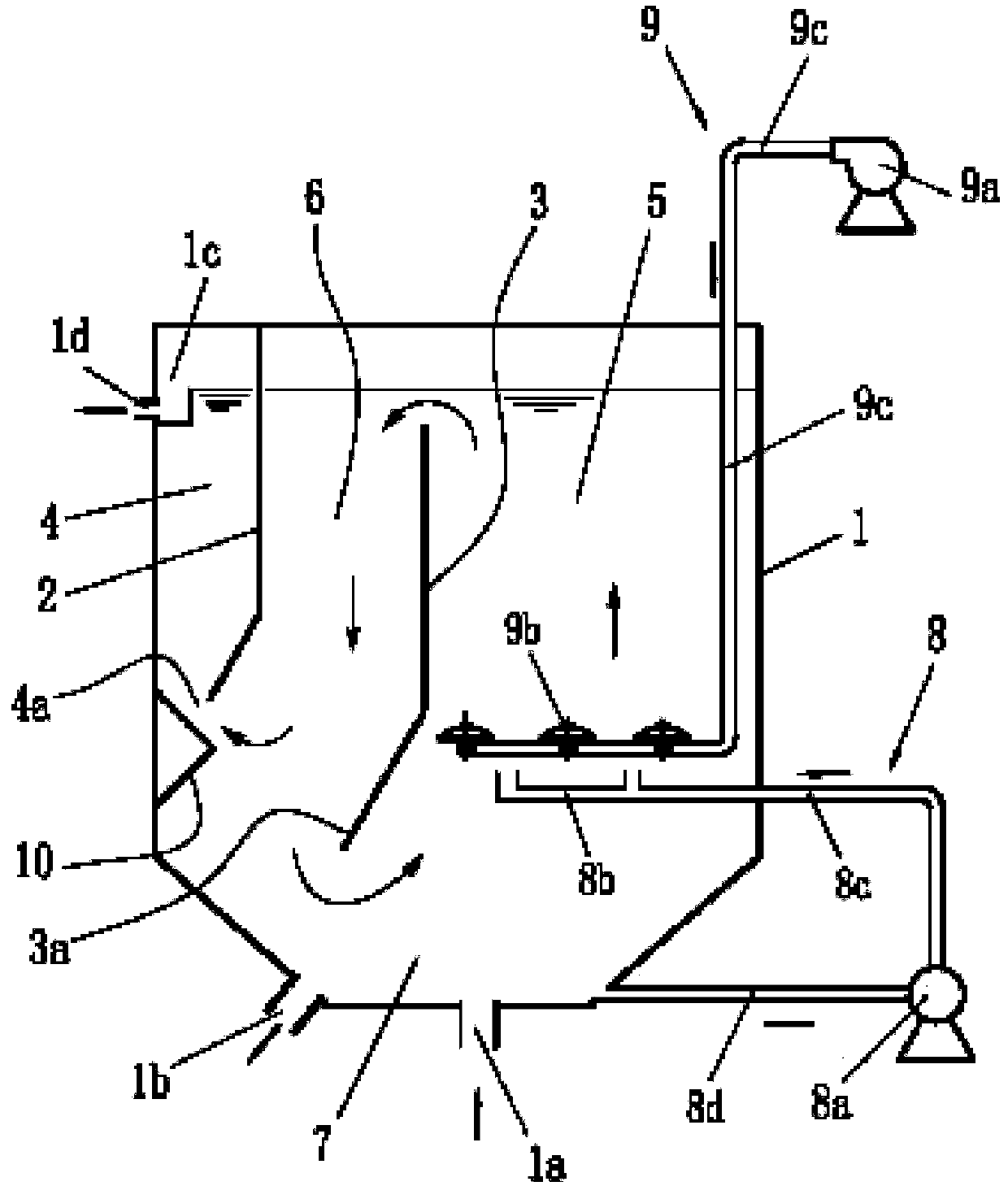

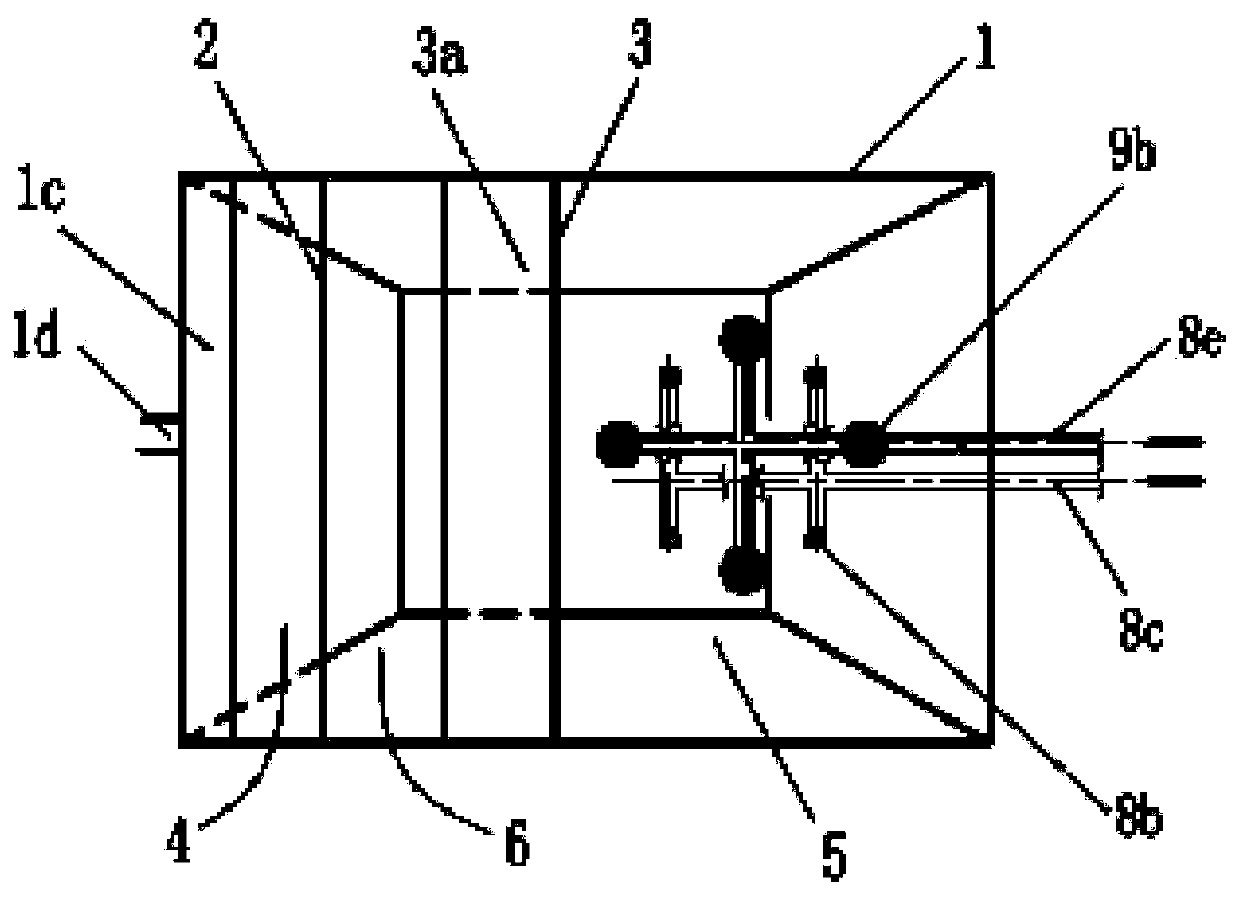

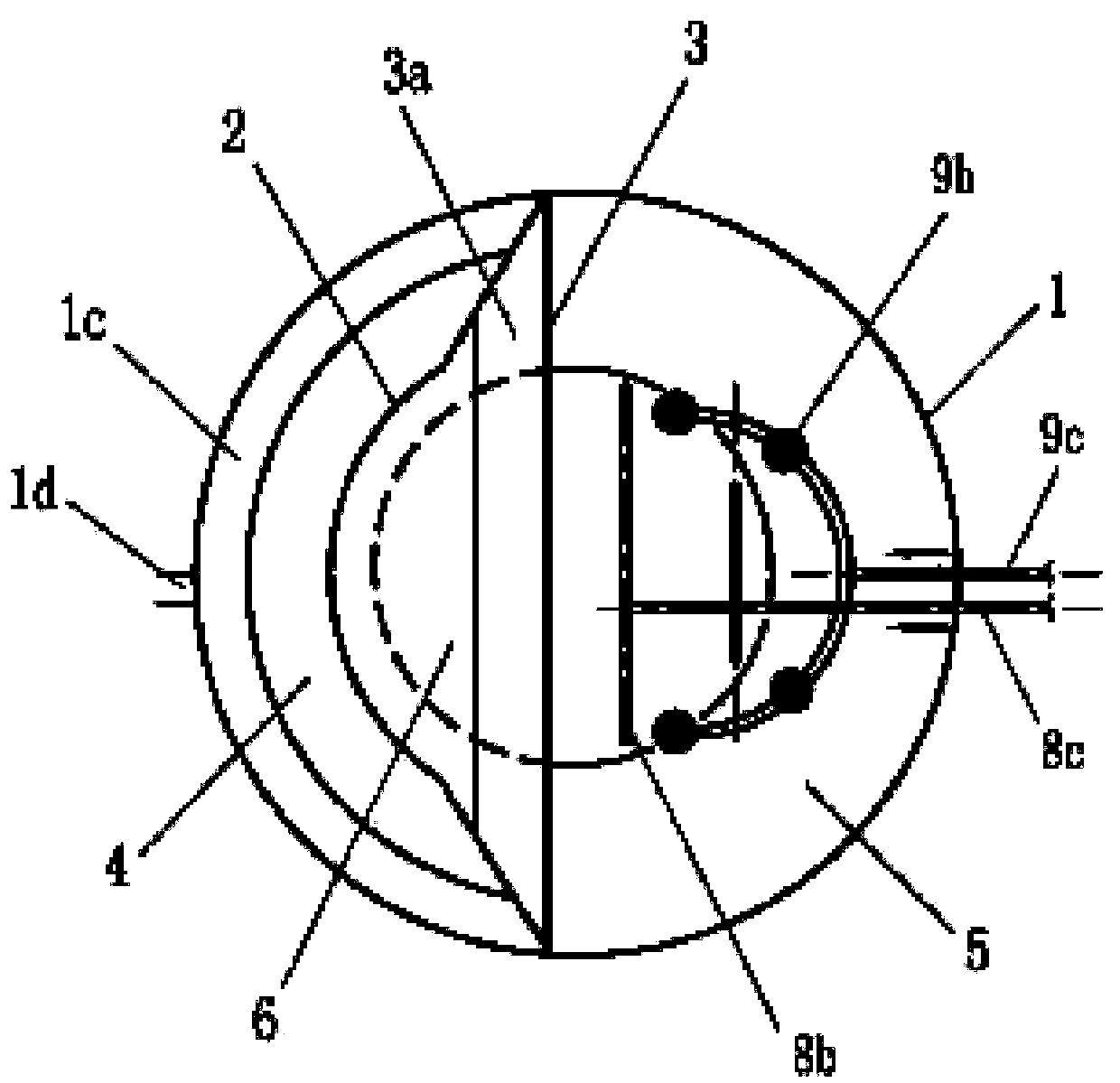

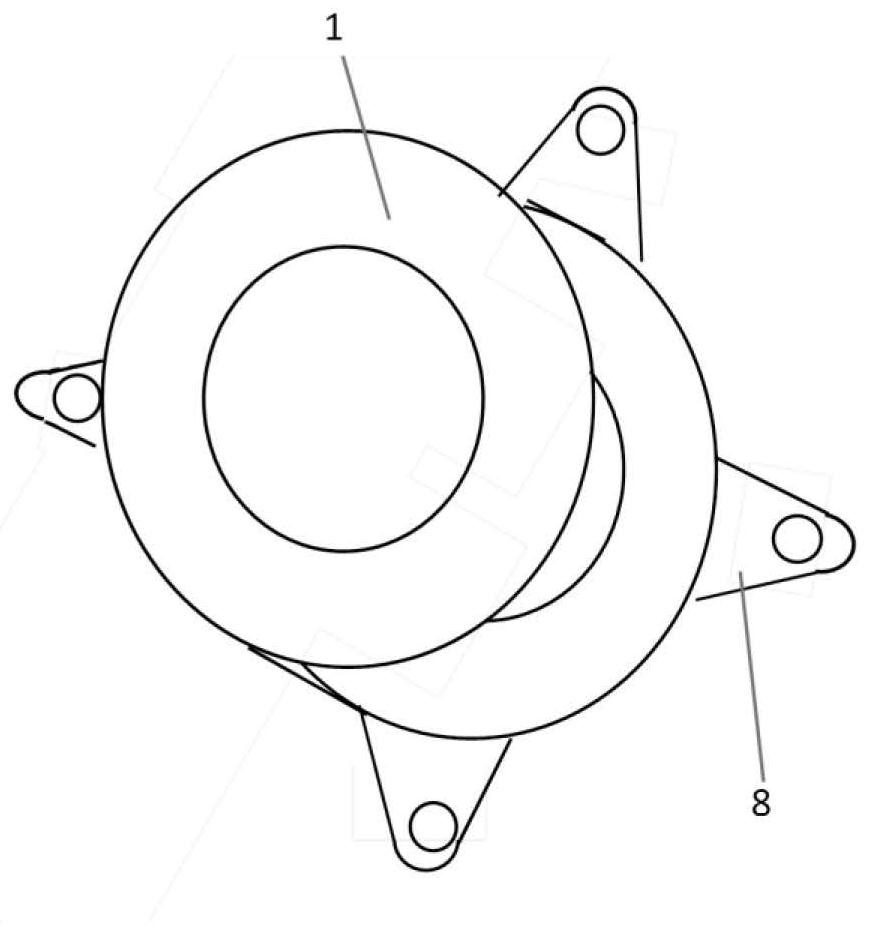

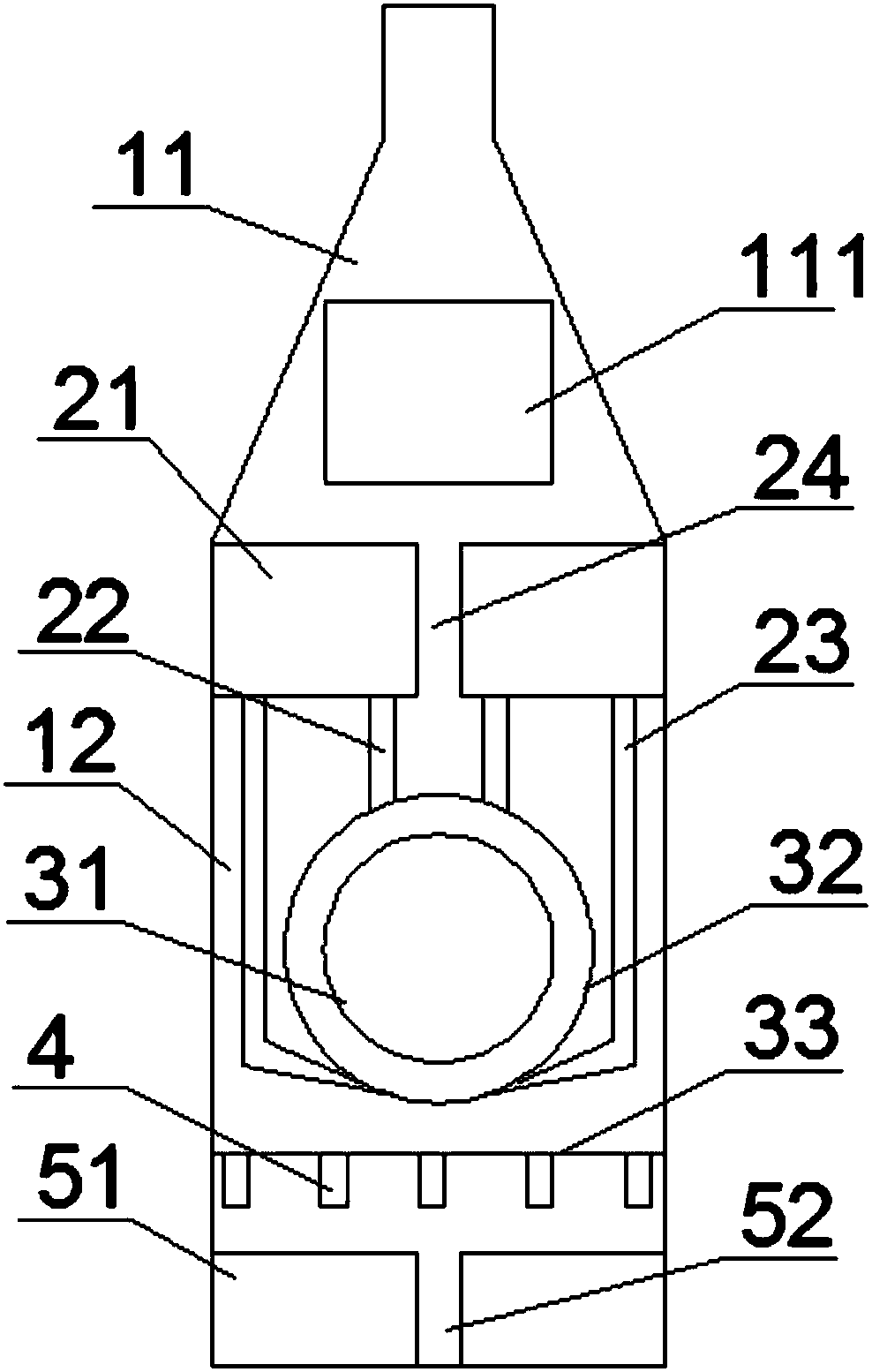

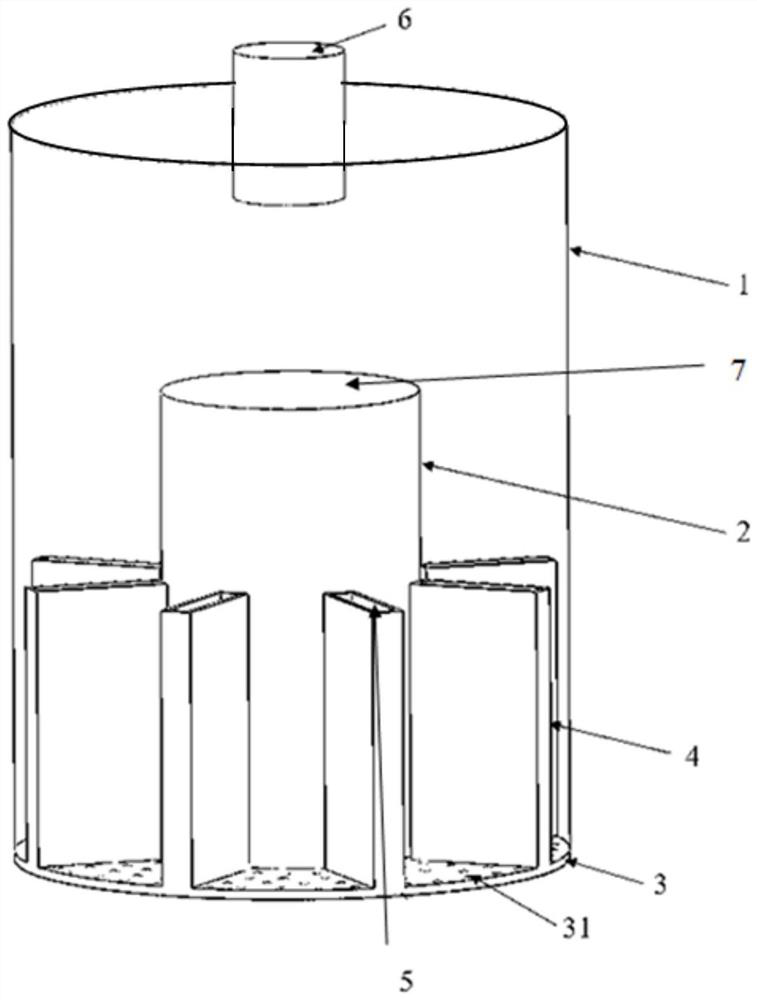

Sewage biological denitrification and dephosphorization device

PendingCN107651752AImproved resistance to shock loadsImprove processing effectWater contaminantsBiological treatment apparatusTreatment effectSewage

The invention provides a sewage biological denitrification and dephosphorization device, which comprises a casing (1) of a vertical tube body, wherein an outer vertical plate (2) is positioned insidethe casing and communicates with a water outlet opening (1d) and a sludge-water separation region (4) formed between the casing walls; an inner vertical plate (3) is positioned in the casing; the upper and lower ends of a water flow ascending passage (5) positioned at one side are respectively communicated with the upper and lower parts of a water flow descending passage (6) positioned at the other side; a water flow circulation passage is formed in the casing; an inlet of the sludge-water separation region communicates with the middle and lower part of the water flow descending passage; a sludge gathering region (7) arranged under the inner vertical plate communicates with a water inlet (1a) and a sludge discharging opening (1b) of the bottom wall of the inner cavity of the casing; a sludge water inlet of a sludge pump (8a) arranged in a sludge lifting device (8) communicates with the sludge gathering region; a spraying component (8b) is positioned at the middle lower part of the water flow ascending passage (5); an aerator (9b) arranged in an air supply device (9) is positioned at the middle lower part of the water flow ascending passage (5). The sewage biological denitrificationand dephosphorization device has the characteristics that the treatment effect is improved; the operation is stable.

Owner:CHINA MACHINERY INT ENG DESIGN & RES INST

A Tundish for Electromagnetically Suppressing Submerged Nozzle Clogging

ActiveCN108705075BEffective protectionPrevent water leakageMelt-holding vesselsSlab casterStructural engineering

Owner:NORTHEASTERN UNIV LIAONING

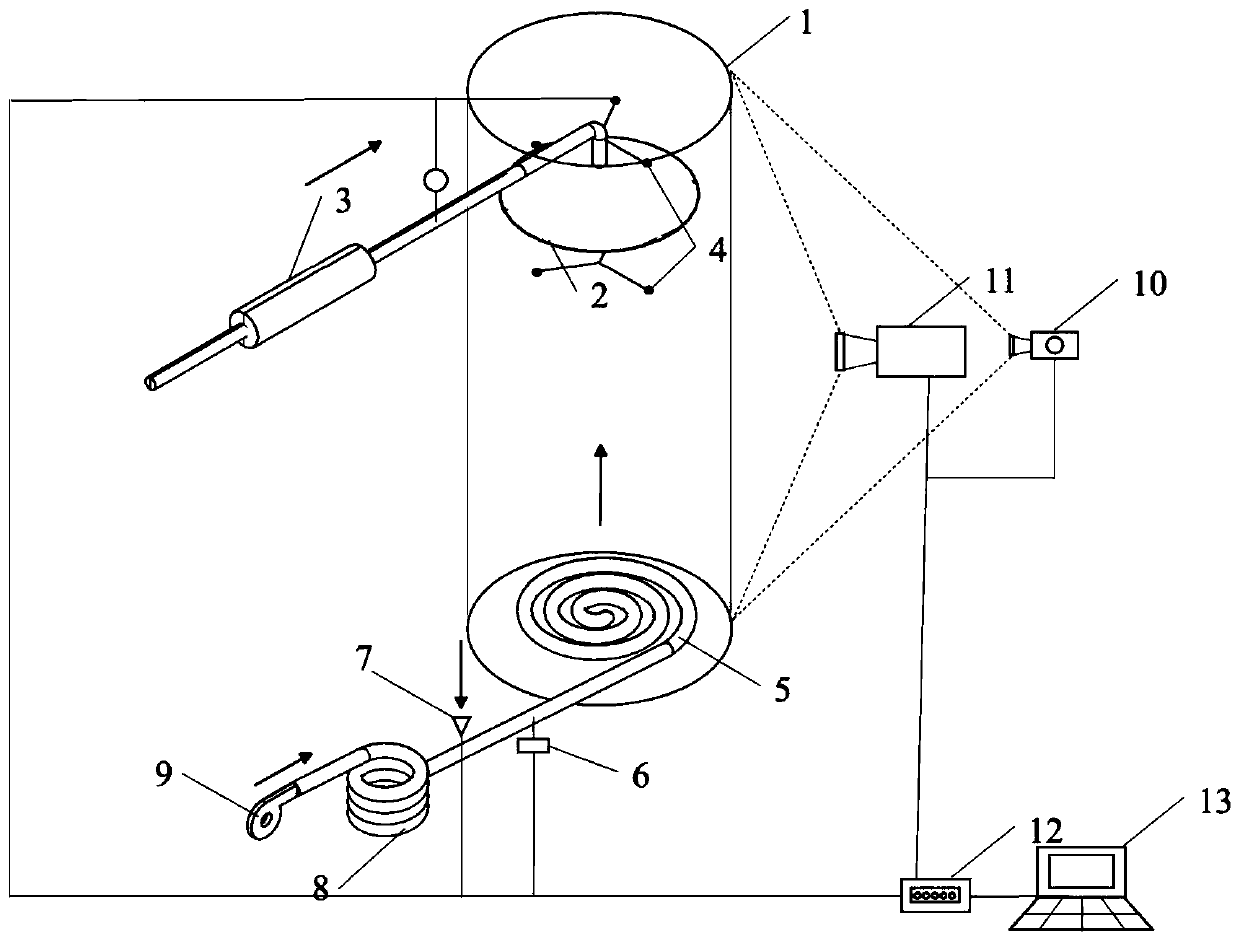

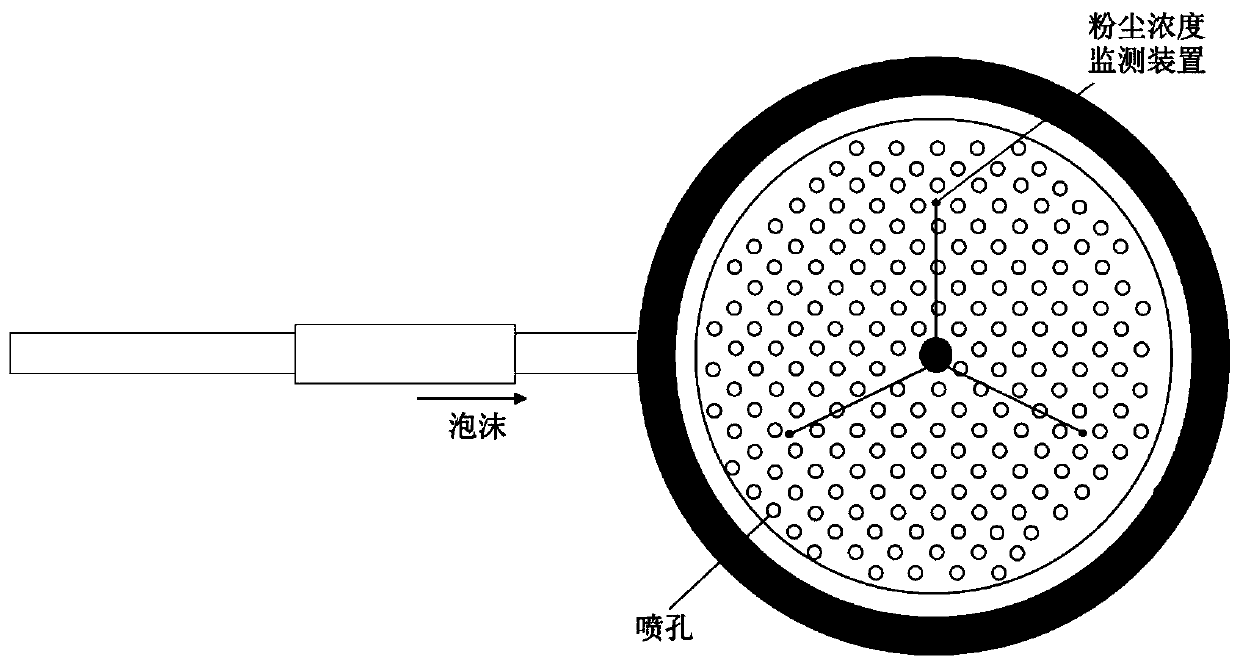

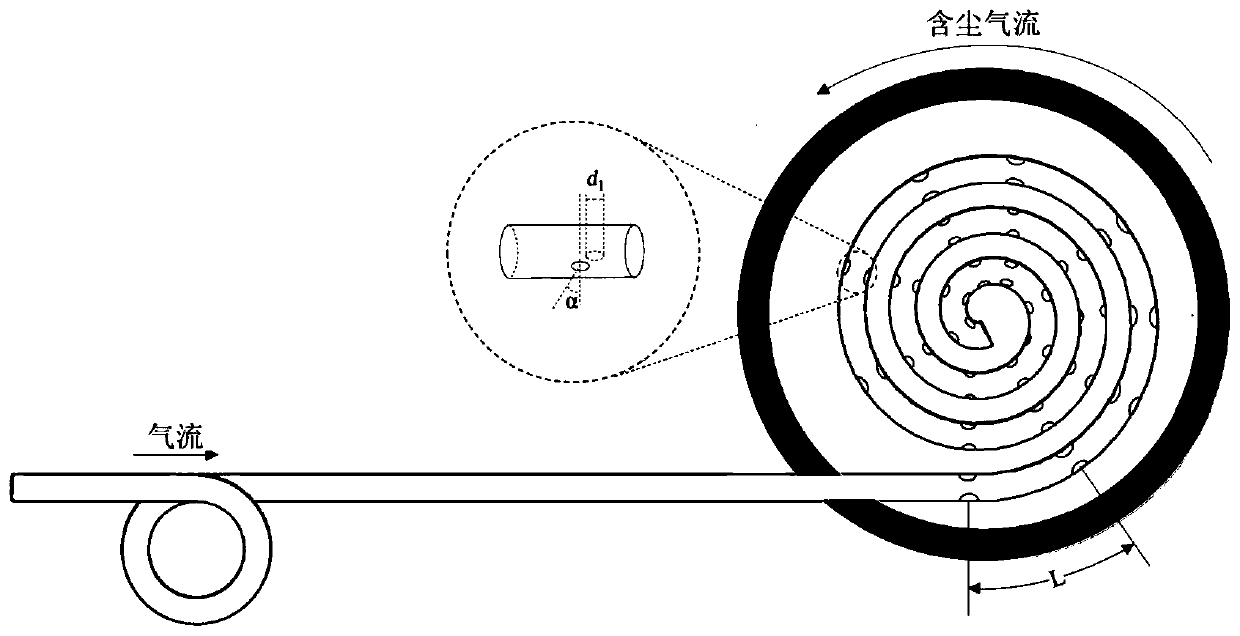

Foam prevention and control industrial dust method and evaluation device

ActiveCN111337395AUniform outflowHeating rapid quantificationTelevision system detailsUsing liquid separation agentThermodynamicsDust control

The invention discloses a foam prevention and control industrial dust method and an evaluation device, relates to the technical field of industrial dust prevention and control, and can realize comprehensive evaluation of dust removal performance of different foams at different temperatures. The device mainly comprises a transparent shell, a foam spraying device, an air supply device, a spiral outflow device, a digital display temperature sensor, a dust control device, a heating device, a high-speed camera, a thermal imager and a dust concentration monitoring device, wherein the foam spraying device is positioned in the transparent shell and is connected with the external foam generating device through a horizontal pipeline; dust concentration monitoring devices which are annularly and uniformly arranged are arranged above and below the foam spraying device; the spiral outflow device is located at the bottom of the transparent shell and outwards connected with a digital display temperature sensor, a dust control device, a heating device and an air supply device in sequence through a horizontal pipeline; the high-speed camera and the thermal imager device are arranged outside the transparent shell. The whole set of testing device is simple to operate, low in cost, good in controllability and comprehensive in testing parameters, and is particularly suitable for evaluating and researching the dust removal performance of different foams at different temperatures.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

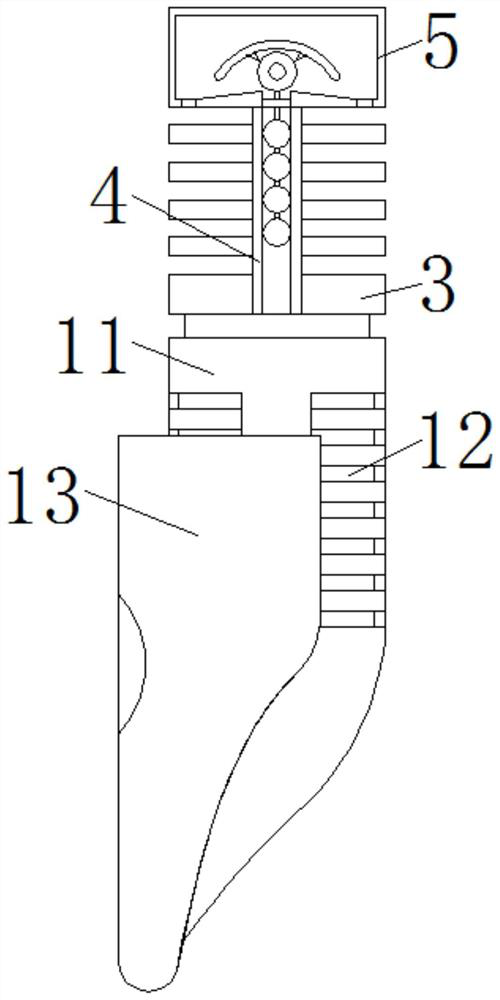

Safe and reliable electronic cigarette

InactiveCN107668776AOvercome the dripping problemIncrease the heating areaTobacco devicesElectricityEngineering

The invention discloses a safe and reliable electronic cigarette, which comprises: a casing with a cigarette holder on the upper end and a filter in the cigarette holder; a liquid storage mechanism including two horizontally opposite liquid storage boxes, two storage boxes The first channel is reserved between the liquid boxes, and the bottom of the liquid storage box is provided with the first catheter and the second catheter; the heating mechanism includes a hollow heating ball, a tennis ball sleeved outside the heating ball and The heating plate is horizontally arranged under the heating ball, and the space between the heating ball and the tennis ball is filled with heat-conducting medium; the upper end of any air guiding tube passes through the heating plate; the battery is electrically connected to the heating ball and the heating plate. The invention has the advantages of safety and reliability, can generate appropriate amount of smoke with excellent taste, and improves the mouthfeel of smokers.

Owner:BEIHAI HUAYUAN ELECTRON CO LTD

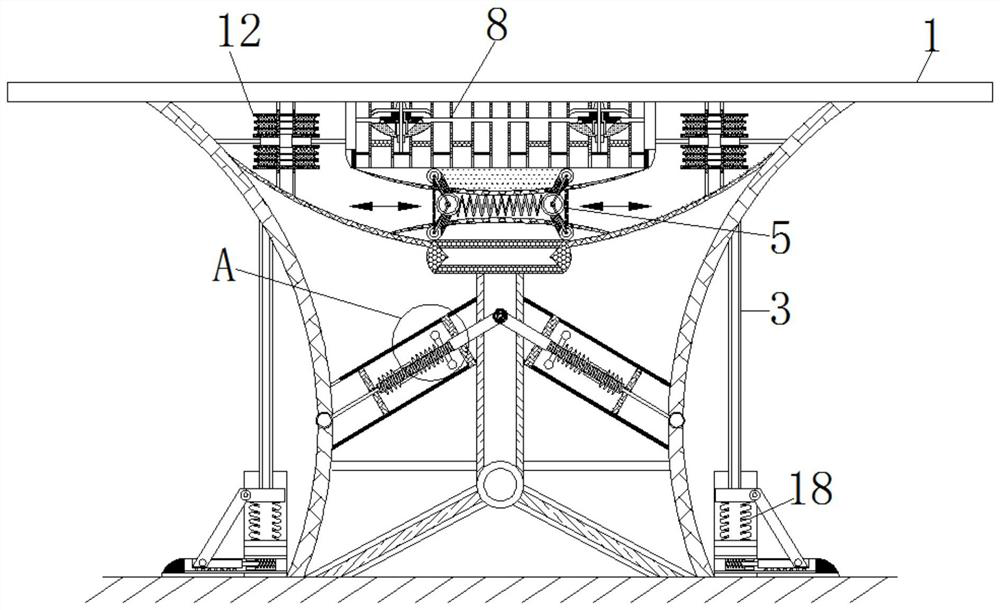

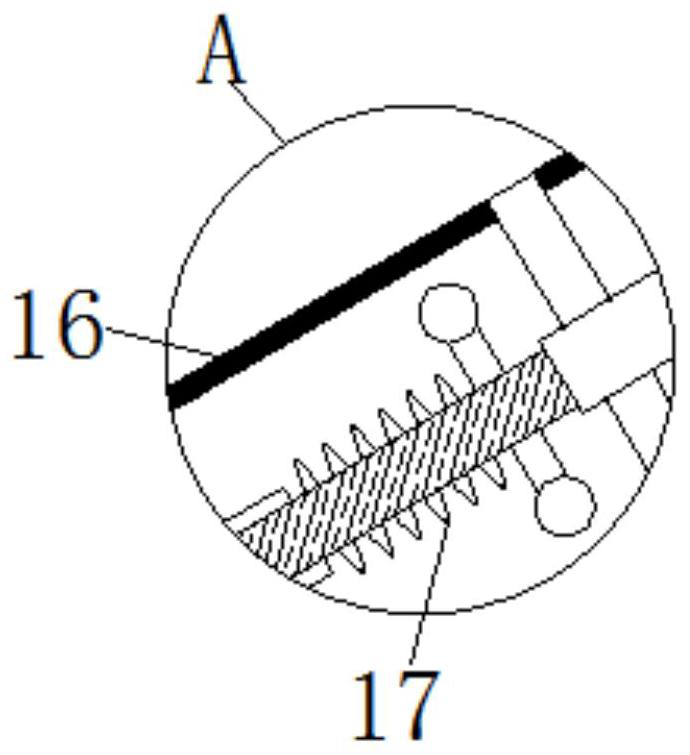

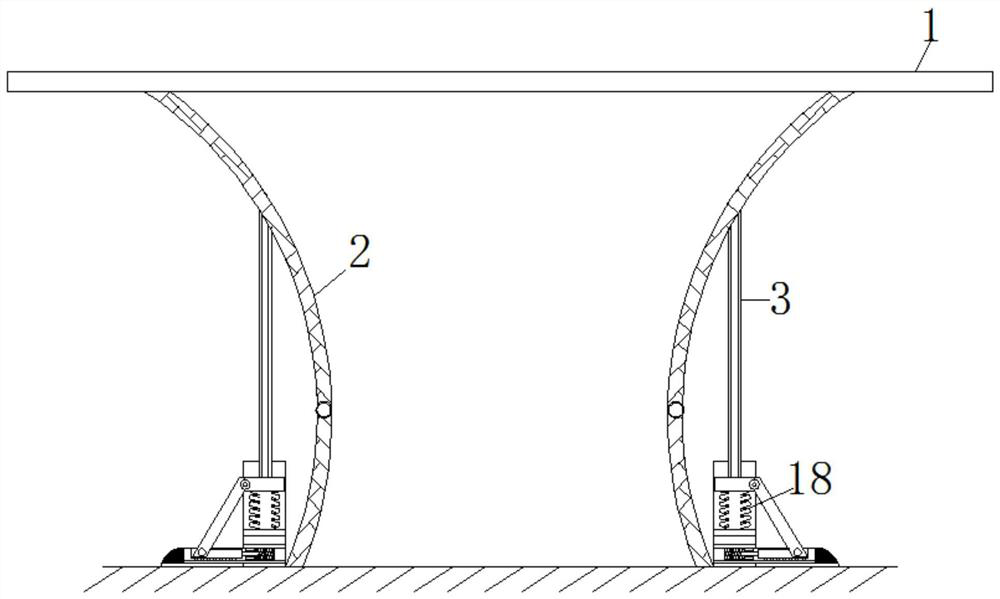

Wafer coating detection equipment for electronic commerce control chip

InactiveCN112275515AImprove cooling effectLittle elasticityPretreated surfacesSemiconductor/solid-state device manufacturingEpoxyWafer

The invention relates to the technical field of electronic commerce wafer coating, and discloses wafer coating detection equipment for an electronic commerce control chip. The wafer coating detectionequipment comprises a conveyor belt, wherein an elastic plate is movably connected to the bottom of the conveyor belt, a support rod is movably connected to one side of the elastic plate, an arc-shaped cover is movably connected to the interior of the elastic plate and located at the bottom of the conveyor belt, an expansion frame is movably arranged in the arc-shaped cover, an air storage bag ismovably connected to the surface of the expansion frame, rollers are movably connected to the left and right ends of the expansion frame, a homogenizing layer is fixedly connected to the bottom of theconveying belt and located on the surface of the expansion frame, and liquid storage pipes are fixedly connected to the left and right sides of an airflow groove. Part of air flowing out of the air storage bag flows out of an air flow groove, the other part of the air flows to the surface of a sliding plate,so that the sliding plate can be blown to extrude epoxy resin in the liquid storage pipe to be sprayed out of a guide nozzle, the driving force of the sliding plate extruding the epoxy resin is the weight of a wafer, and therefore, the effect that the coating amount is matched with the weight of the wafer is achieved.

Owner:义乌春绘贸易有限责任公司

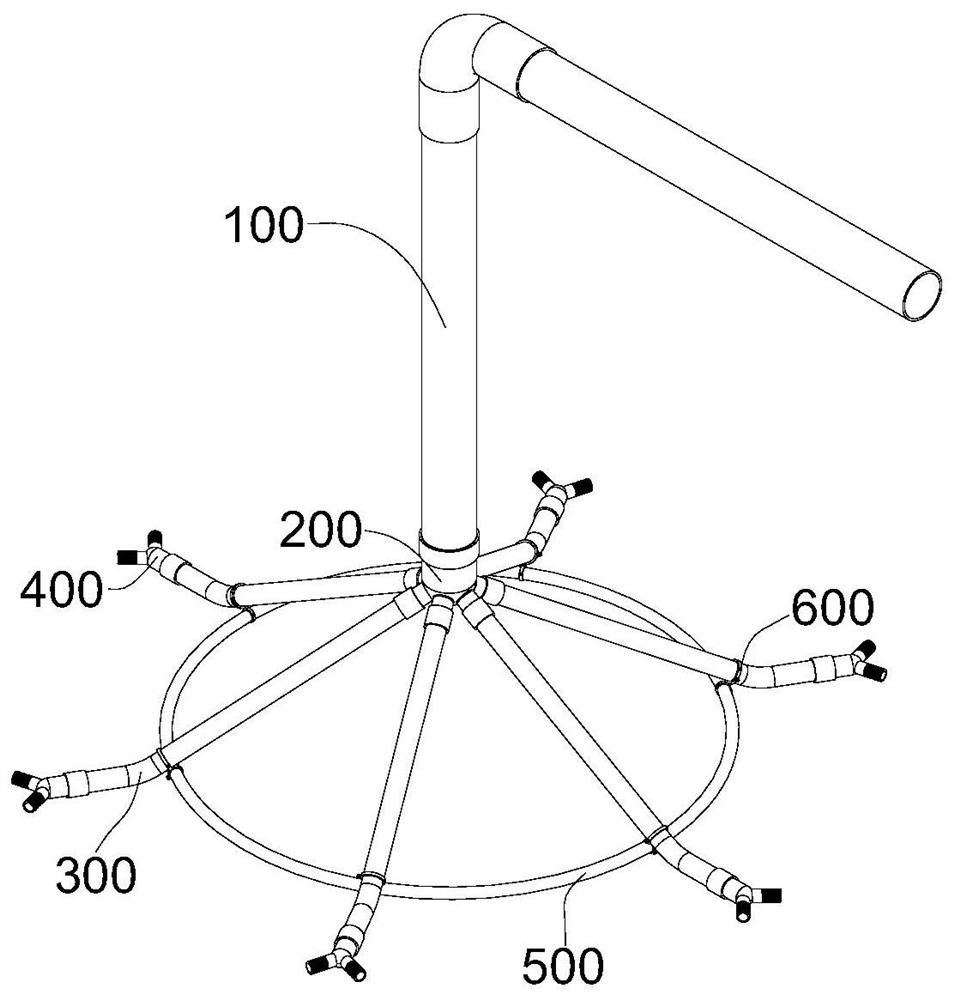

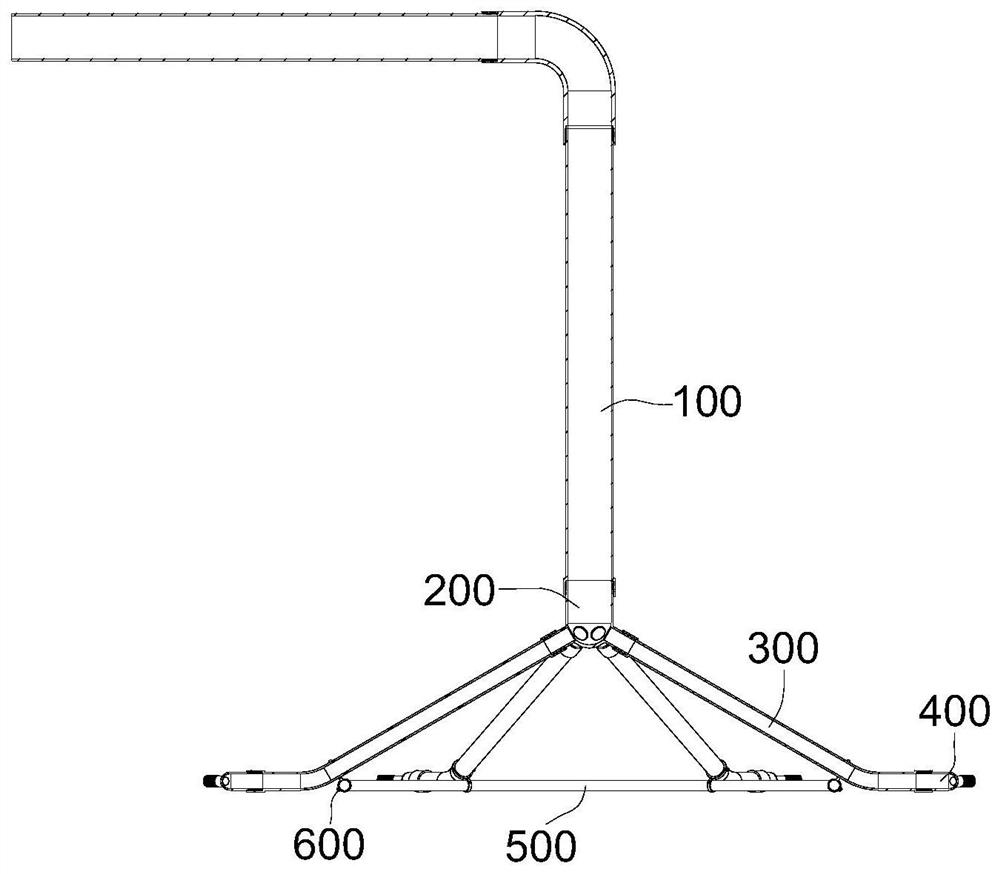

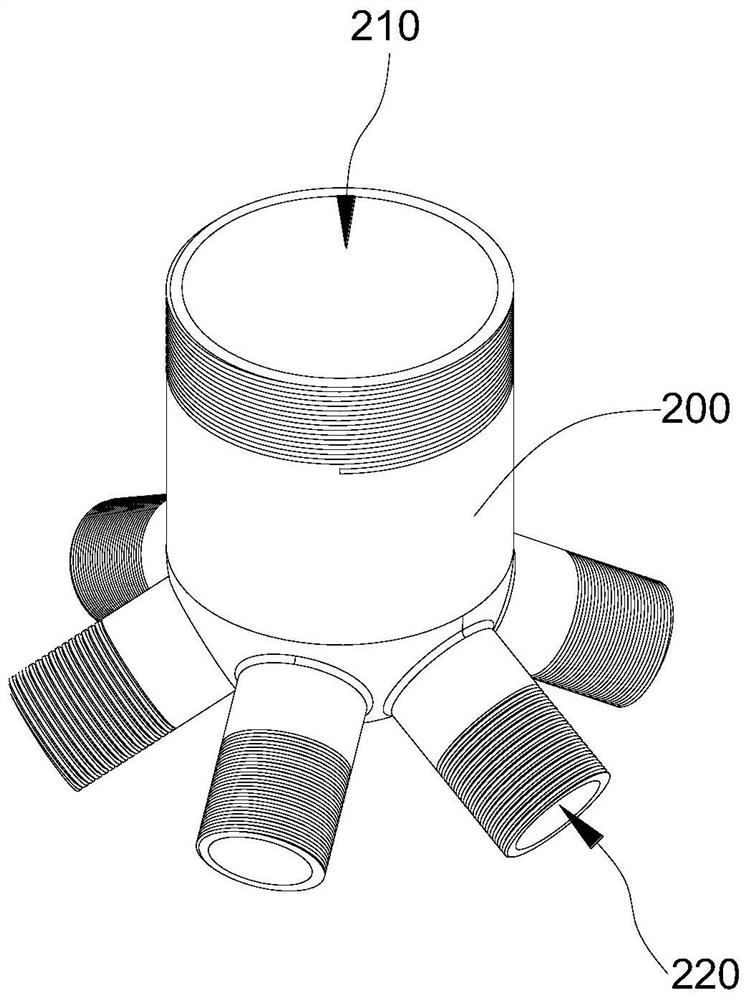

Novel fire extinguishing pipeline system

PendingCN111991739ASmall pressure lossReduce energy lossFire rescueEngineeringStructural engineering

The invention discloses a novel fire extinguishing pipeline system. The novel fire extinguishing pipeline system comprises a main pipeline and at least two auxiliary pipelines, wherein the main pipeline comprises a main flow pipe and a spherical flow dividing body; the spherical flow dividing body comprises a cavity, a first runner and at least two second runners; the main flow pipe communicates with the first runner; the first runner and the at least two second runners communicate with the cavity; the at least two second runners are evenly distributed in the circumferential direction of the spherical flow dividing body, and the second runners and the first runner are obliquely arranged; and each auxiliary pipeline comprises a connecting pipe and a connector, wherein one end of the connecting pipe is connected with the spherical flow dividing body, the at least two connecting pipes and the at least two second runners are arranged in a one-to-one correspondence manner, and the connectoris arranged at the end, deviating from the spherical flow dividing body, of the connecting pipe. According to the novel fire extinguishing pipeline system disclosed in the embodiment, the spherical flow dividing body is adopted for flow dividing, the second runners on the spherical flow dividing body are distributed in a completely symmetric manner, the pressure drop is consistent, and the purpose of uniform outflow is achieved.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

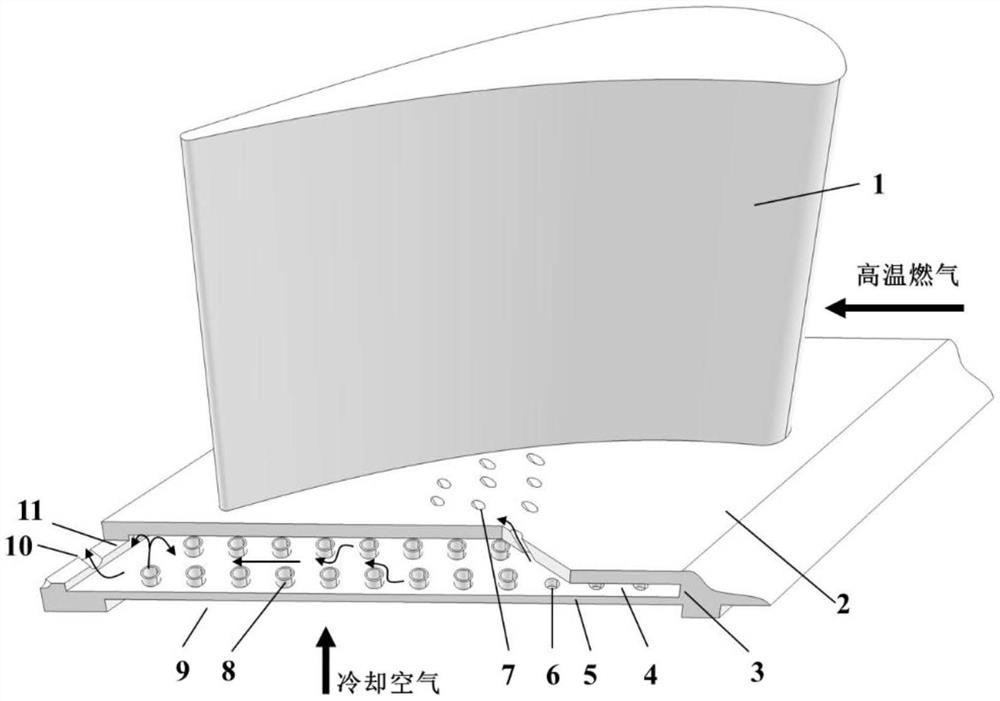

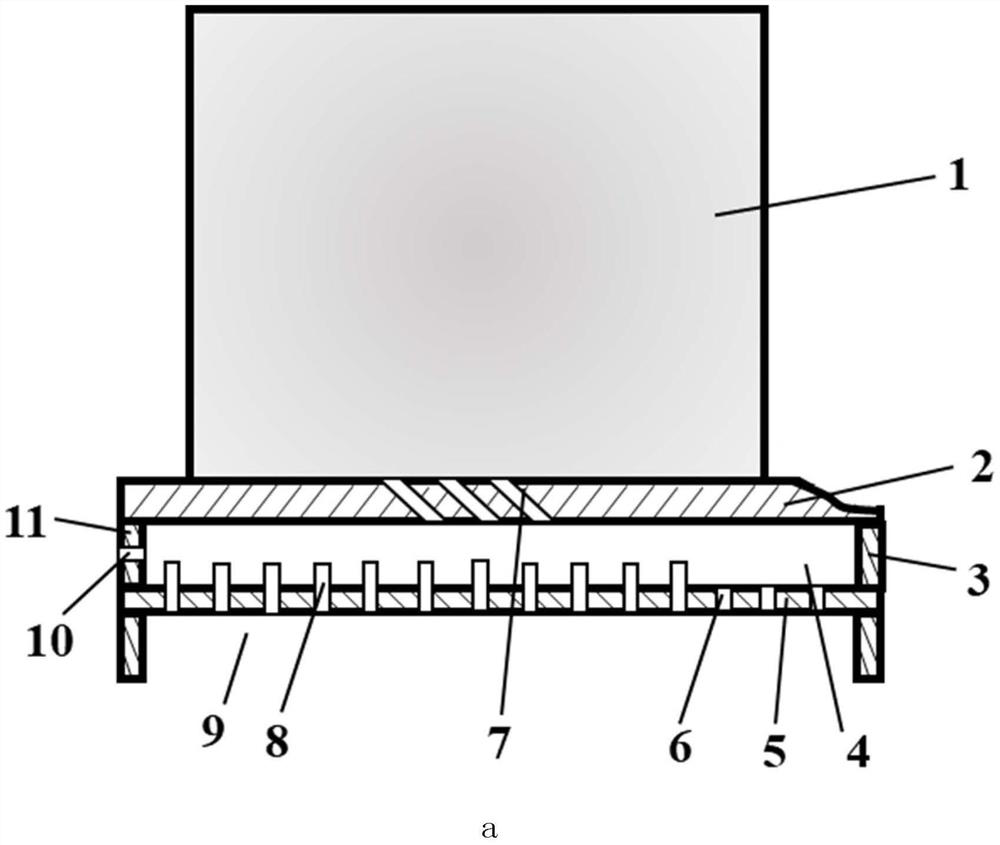

Turbine guide vane end wall composite cooling structure

ActiveCN113266429AImprove gas thermal performanceReduce usageEngine fuctionsStatorsCold airLeading edge

The invention discloses a turbine guide vane end wall composite cooling structure. Multiple rows of first air film holes are included, the first air film holes are formed in a guide vane end wall at intervals, the guide vane end wall is connected with an impact plate through an impact cavity leading edge side plate and an impact cavity trailing edge side wall, multiple rows of impact holes are formed in the impact plate, and the impact holes and the first air film holes are arranged in a staggered manner. Second air film holes are formed in the impact cavity trailing edge side wall, cooling air impacts the inner side of the guide vane end wall through the impact holes to form impact transverse flow, and the impact transverse flow achieves end wall external air film cooling and secondary cooling of the downstream end wall through the first air film holes and the second air film holes. Performance improvement of internal impact cooling and external air film cooling of the end wall is taken into consideration, the synergistic effect of internal impact cooling and external air film cooling is brought into full play, the comprehensive cooling performance of the end wall is effectively improved, meanwhile, the secondary cooling effect of cold air to the downstream moving vane end wall is utilized, the cold air use amount of the end wall is reduced, and the overall performance of an aero-engine is improved easily.

Owner:XI AN JIAOTONG UNIV

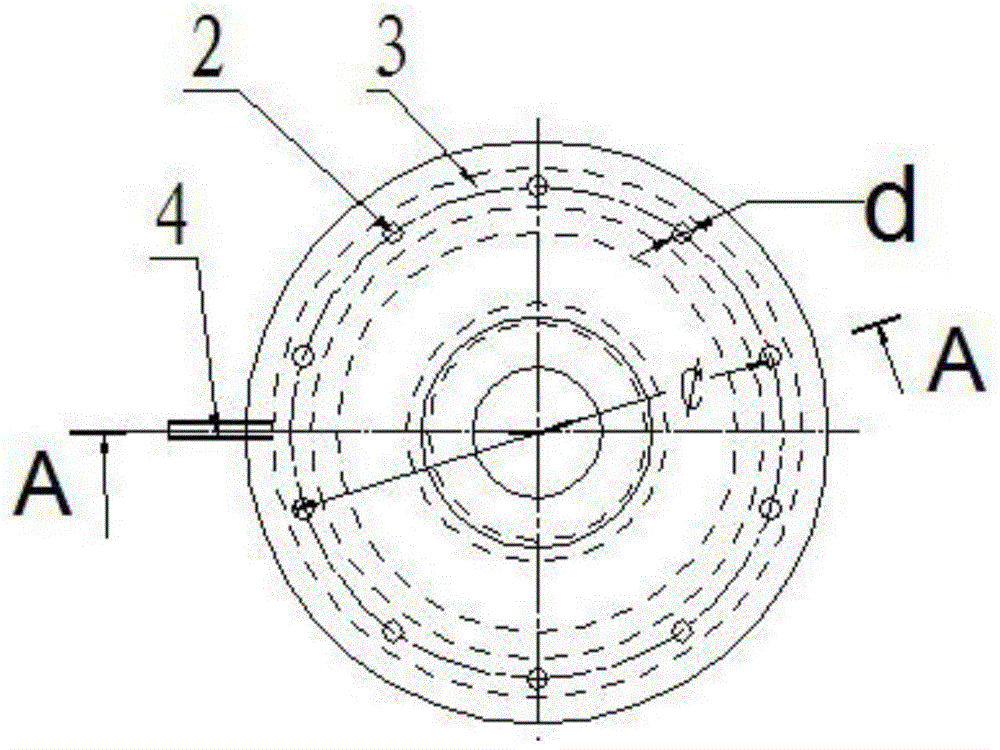

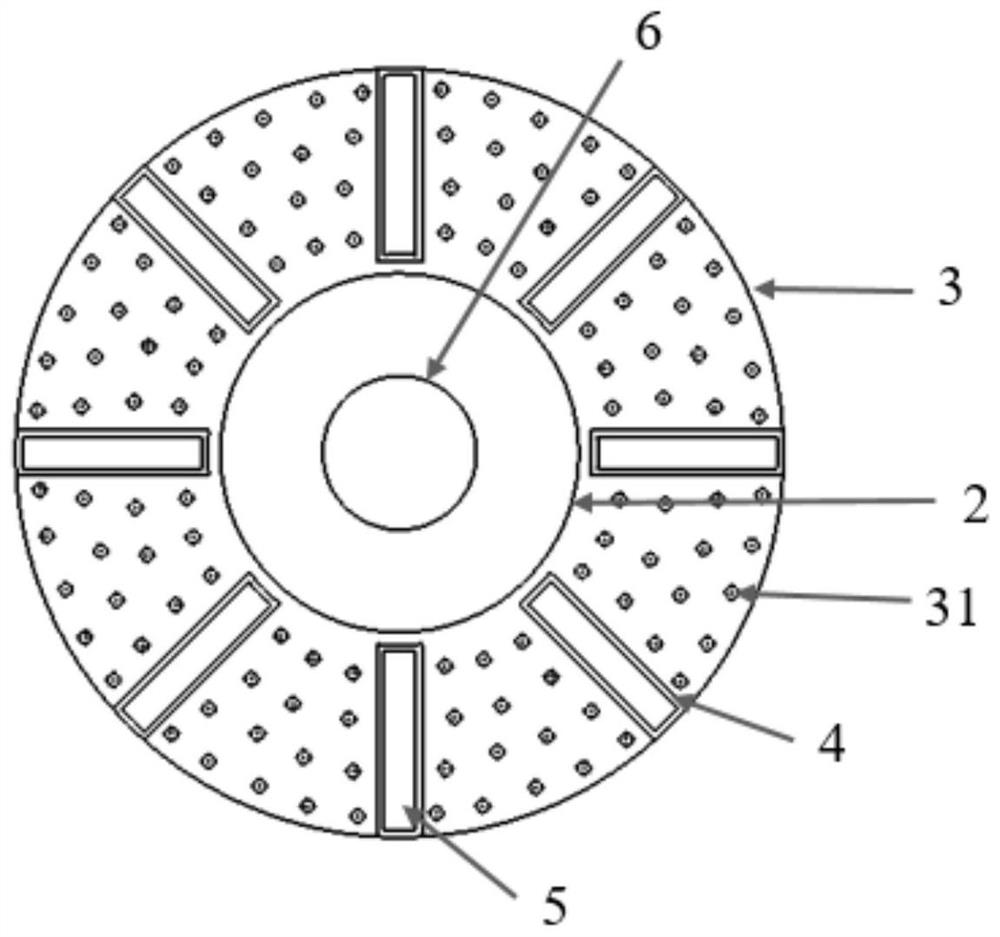

Disc type gas-liquid two-phase fluid uniform distribution device

The invention provides a disc type gas-liquid two-phase fluid uniform distribution device. The disc type gas-liquid two-phase fluid uniform distribution device comprises a vertically arranged shell barrel, a central barrel is arranged in the shell barrel, an upper end of the central barrel is sealed by a baffle, an external wall of a lower part of the central barrel is provided with a ring plate fastened and connected with an inner wall of the shell barrel, and a plurality of flow equalizing holes are uniformly formed on the ring plate; several stop dogs are uniformly arranged between the shell barrel and the central barrel, inside of each stop dog is hollow and two ends of each stop block are opening to form a gas phase channel, bottom ends of the several stop dogs are all fixedly connected with the ring plate, external side walls are all fixedly connected with the inner wall of the shell barrel, and a gap is arranged between internal side walls and the external wall of the central barrel. With the disc type gas-liquid two-phase fluid uniform distribution device, after outside gas-liquid phase fluid flows into the shell barrel, a gas-phase fluid flows into the gas phase channel and flows downwards through diffusion, a liquid-phase fluid falls freely and flows onto the ring plate and flows out through the flow equalizing holes, thus, a fluid gas-liquid phase uniform distribution channel is relatively independent, and the disc type gas-liquid two-phase fluid uniform distribution device has relatively better uniform distribution effect for the fluid having low air rate.

Owner:CNOOC GAS & POWER GRP +1

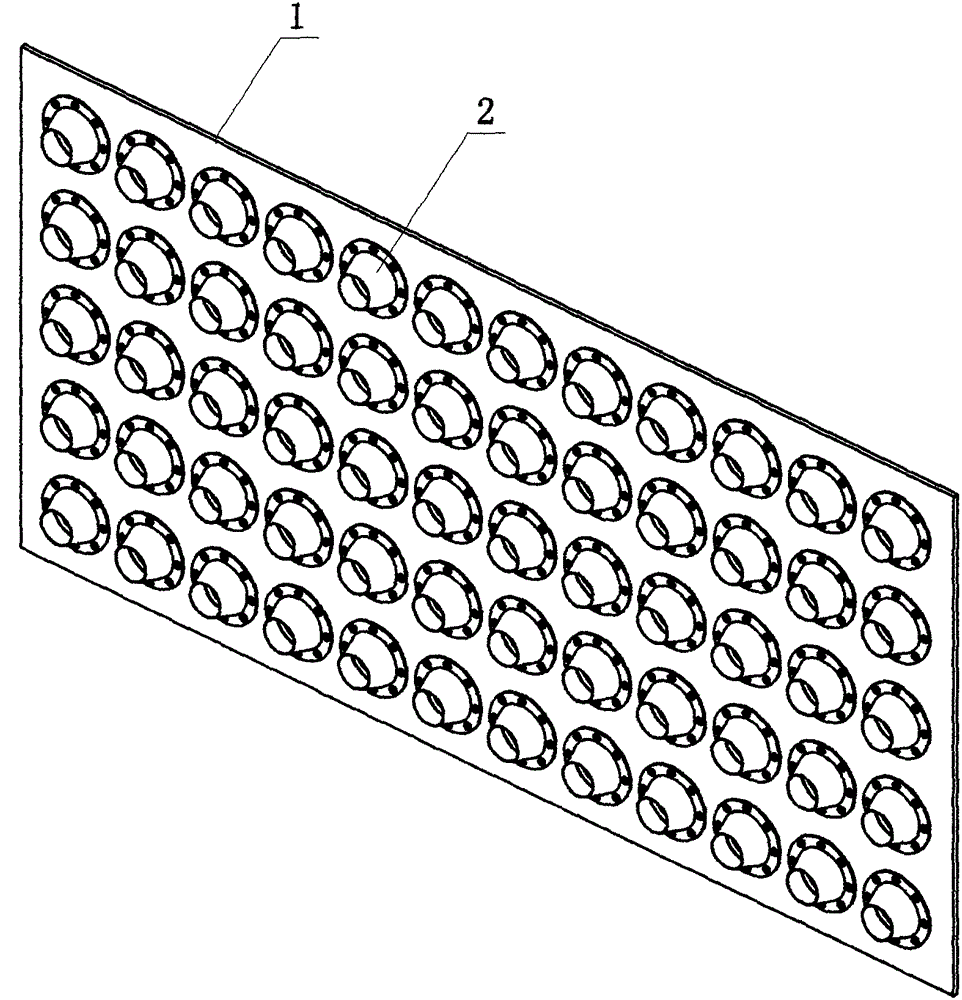

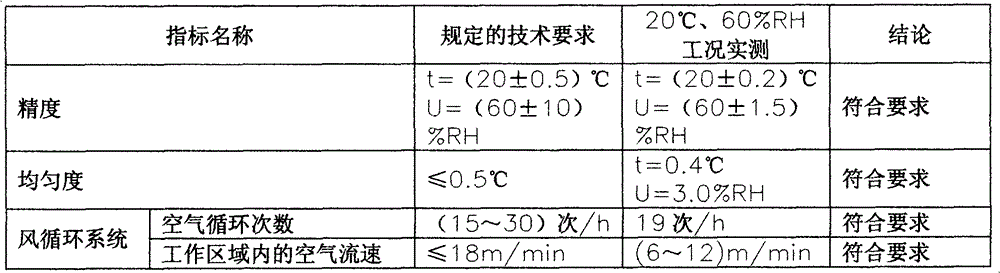

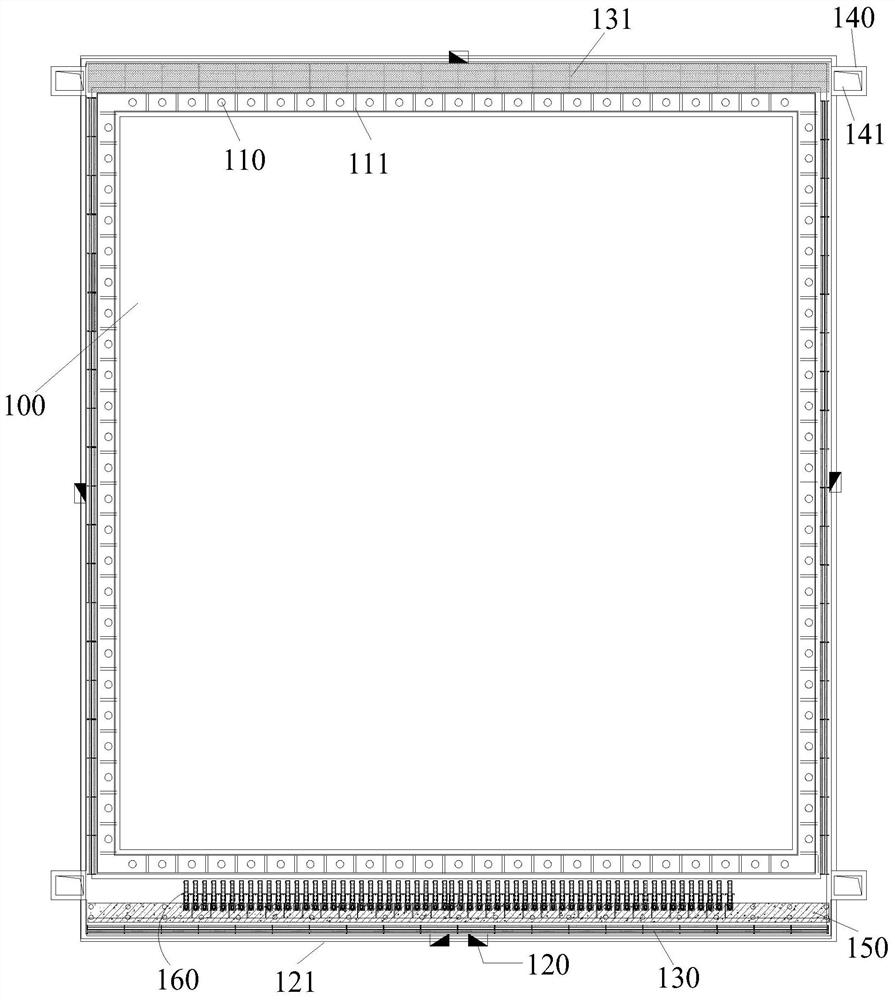

A method to solve the problem of uniformity of air supply in large-area, large-space and high-precision environments

InactiveCN102434952BGuaranteed stabilityUniform outflowDucting arrangementsLighting and heating apparatusVena contracta diameterPorosity

The invention discloses a method for solving the problem of air supply uniformity in a large-area, large-space and high-precision environment. A horizontal air supply and horizontal air return mode is adopted in the method, wherein the horizontal air supply means to supply air to the large space through a horizontal air supply sandwich wall, and the air supply side of the horizontal air supply sandwich wall is formed by an air supply lug boss orifice plate; and the air supply lug boss orifice plate comprises an orifice plate in which holes are uniformly distributed and conical lug bosses, air flues are arranged in the conical lug bosses, the air inlets of the air flues are big, the air outlets of the air flues are small, a conical lug boss is fixed in each hole of the orifice plate, the porosity k of the orifice plate is 0.2 to 5 percent, the escape velocity of the holes is less than 4 meters per second, and the ratio of the air flow velocity vertical to the escape direction of the holes before the flow escapes the holes to the flow rate of the holes is less than or equal to 0.25. According to the method, the requirements of control precision, stability and uniformity of the air in a working area can meet the international requirements, and the stability, the uniformity and the precision of the temperature and the humidity of the air in the large-area large space are effectively ensured.

Owner:广州约顿电子科技有限公司

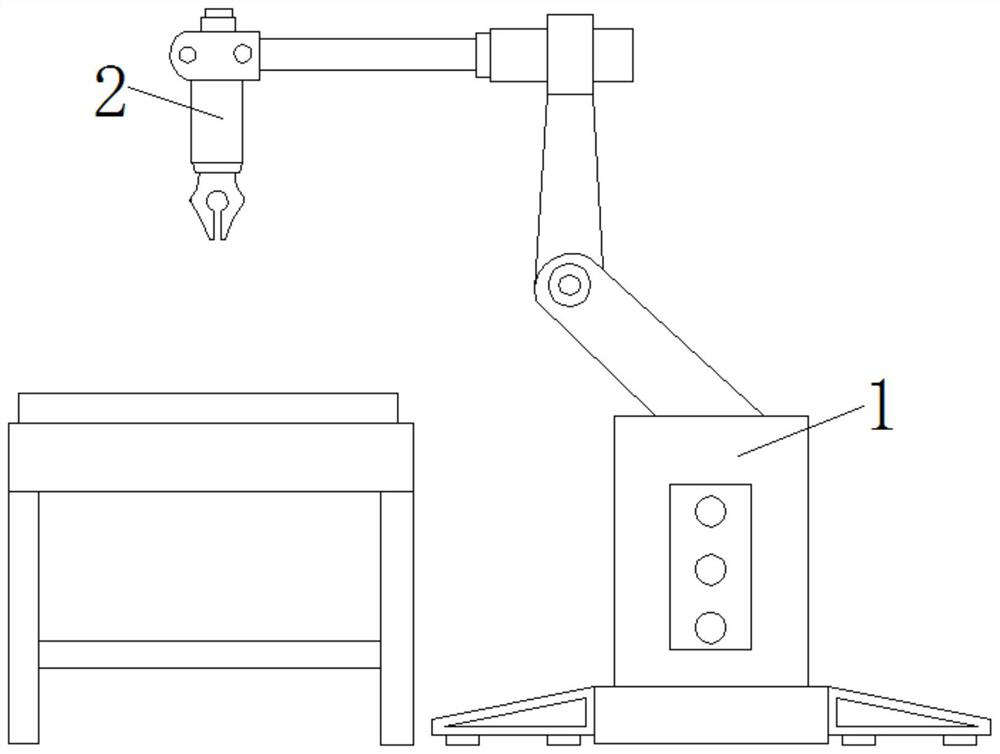

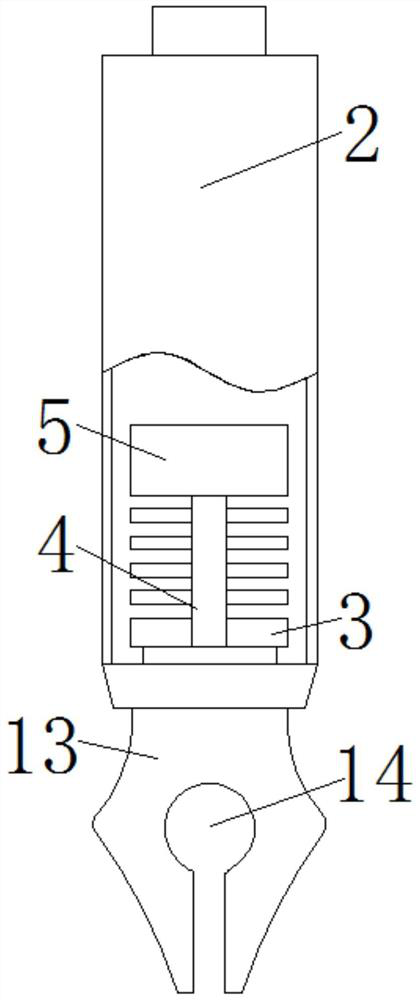

An electric vehicle gluing robot that can control the amount of gluing

ActiveCN110560329BEffectively blockedReduce outflowLiquid surface applicatorsCoatingsAdhesive glueElectric cars

The invention relates to the technical field of electric vehicles, and discloses an electric vehicle gluing robot capable of controlling the amount of glue applied, comprising: a base, a rubber storage shell is fixedly installed at the left end of the base, and a rubber storage shell is fixedly installed at the lower end of the rubber storage shell. The fixed frame, the middle part of the fixed frame is fixedly inserted with a feed pipe, the upper end of the feed pipe is fixedly installed with a fixed shell, the inside of the fixed shell is movably connected with a storage wheel, the inside of the fixed shell is fixedly installed with a fixed plate, the fixed plate There are two symmetrical scrapers fixedly installed on the lower surface. Through the combined use of the fixed frame, fixed block, material storage tank and dispensing tip, the glue can be effectively guaranteed to flow out at a uniform speed, and the glue will not flow out particularly uniformly, so that individual parts of the car body are particularly thickly coated. After affixing the label, the part where the glue is thick will form a bulge, which will affect the overall appearance of the vehicle, thus ensuring the uniform output of glue and the overall flatness of the vehicle body.

Owner:长春安特恩涂胶设备有限公司

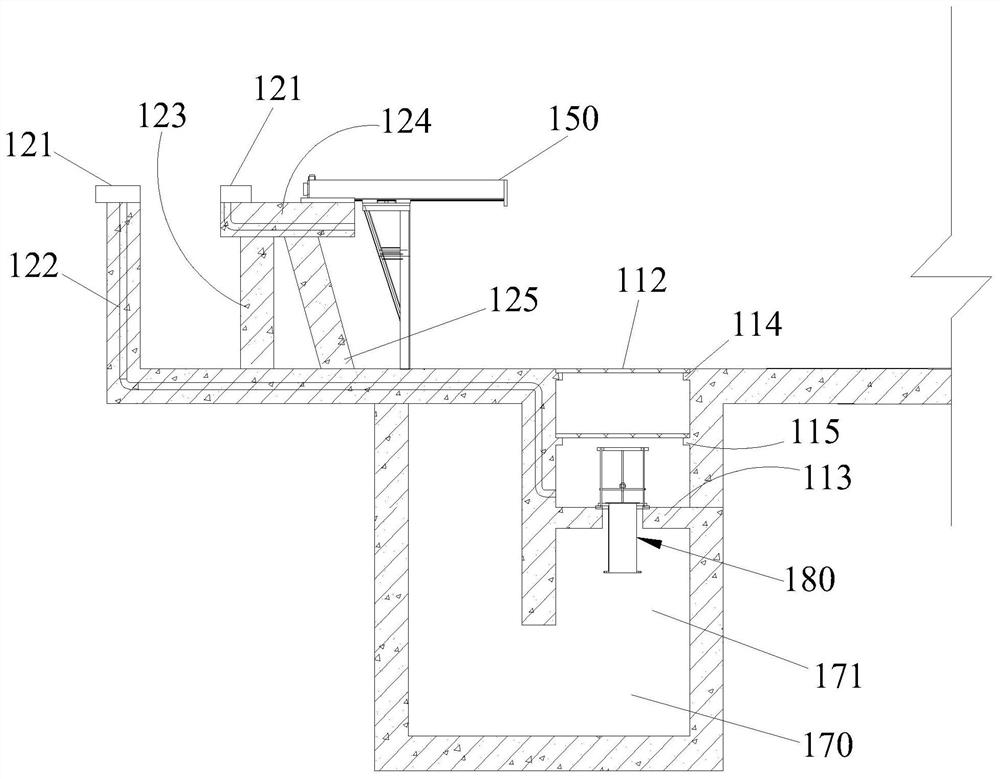

Tidal structure of wave current in harbor basin

The invention relates to the technical field of manufacturing wave flow in a harbor basin, and discloses a tidal structure of a wave flow in a harbor basin, including tidal equipment, a pump well and an underground reservoir. The bottom wall of the harbor basin is preset with a reserved through hole, and the reserved through hole Through the thickness direction of the bottom wall, the tidal generating equipment is fixedly arranged in the reserved through hole, the lower end of the tidal generating equipment leads to the pump well, the pump well leads to the underground reservoir, and the upper end of the tidal generating equipment leads to the harbor basin, when the tidal generating equipment After start-up, the tide-generating equipment drives the water in the underground reservoir to be transported into the harbor basin through the reserved through-hole; There is an underground reservoir connected to the bottom of the reserved through holes, so that during the simulation process of tidal growth, the water flows out from the bottom to the top of the reserved through holes, which can flow out more evenly and smoothly, achieving a more realistic simulation effect. It is more suitable for the tidal process and has better simulation effect.

Owner:PEARL RIVER HYDRAULIC RES INST OF PEARL RIVER WATER RESOURCES COMMISSION

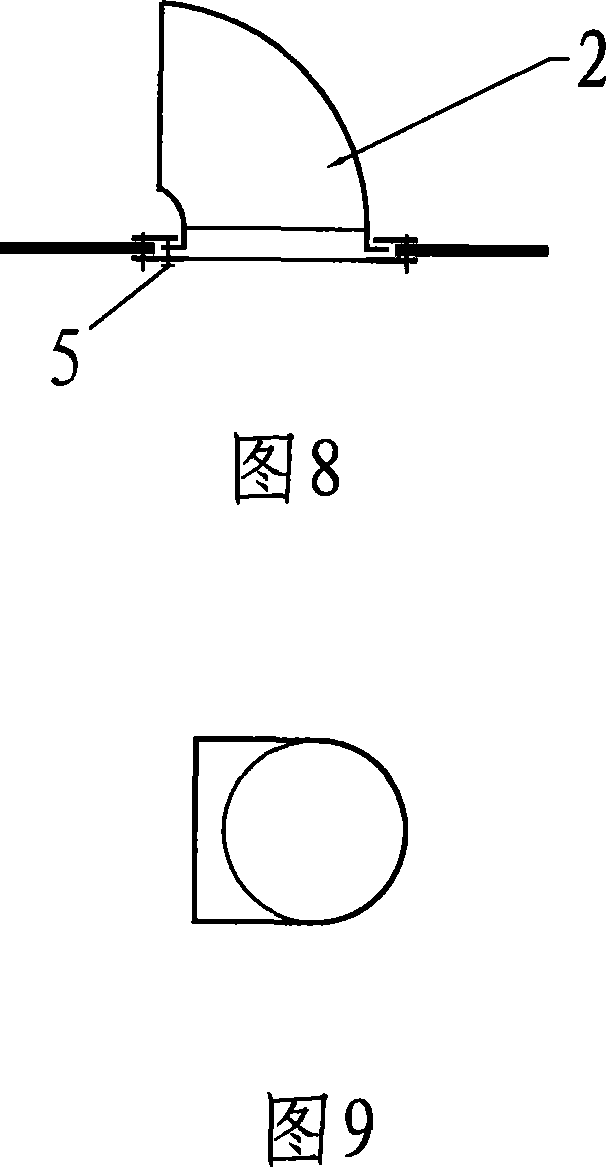

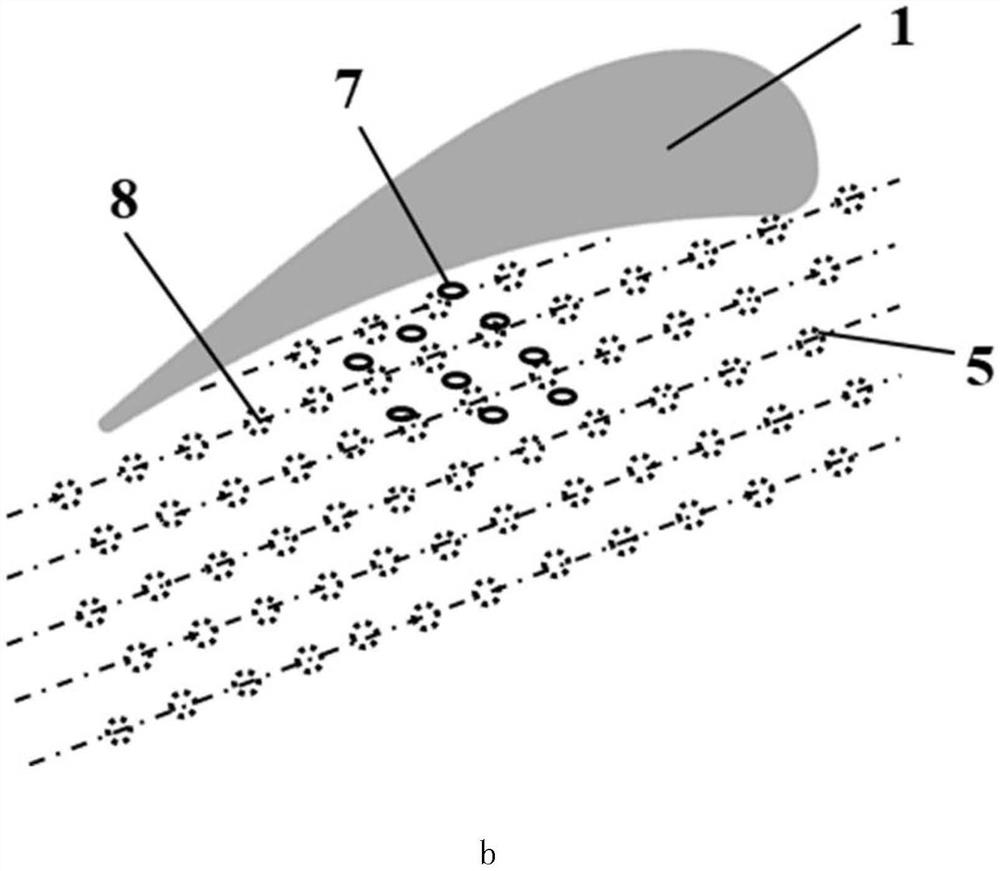

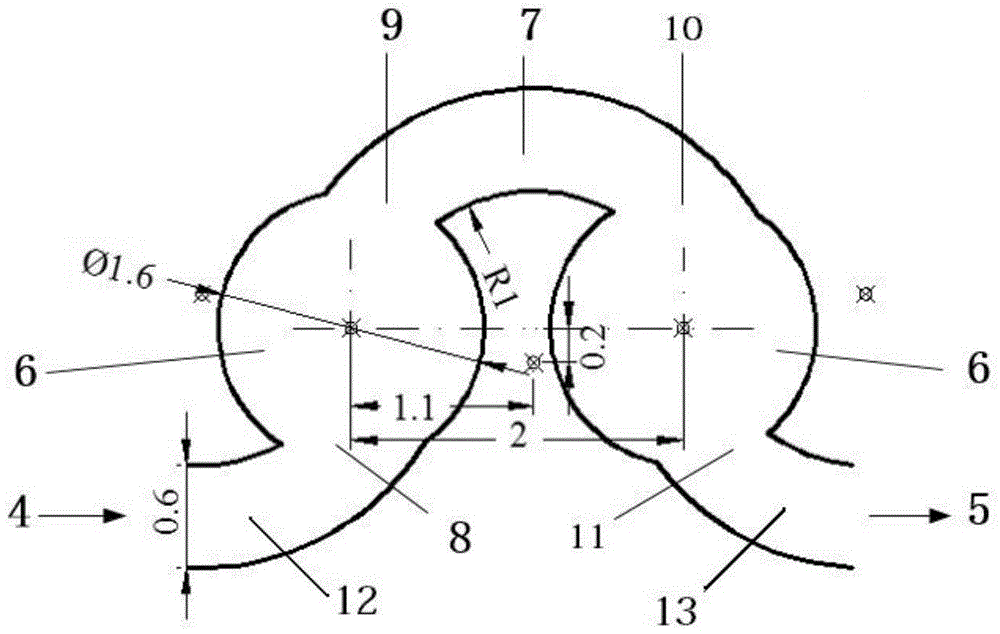

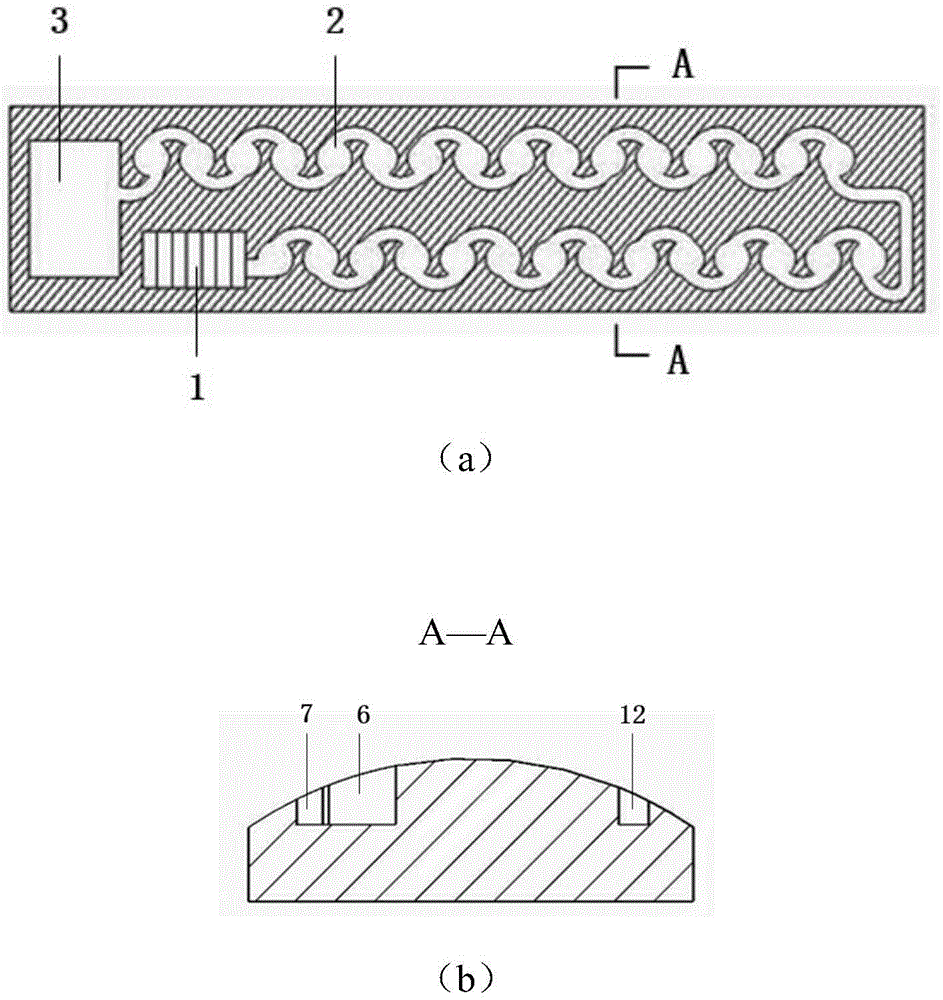

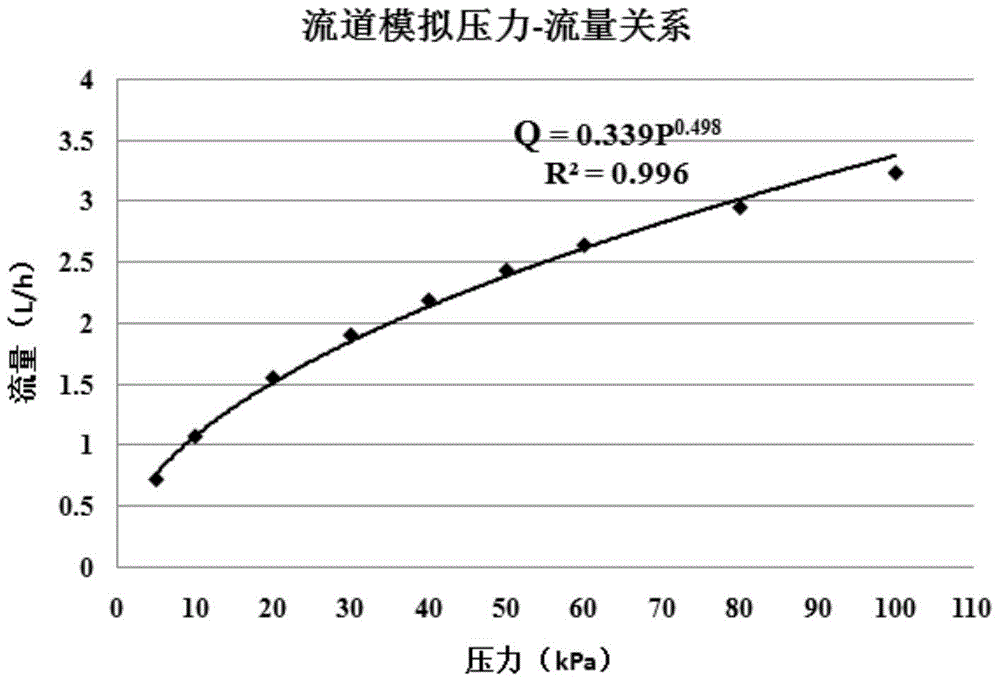

A Karman vortex-shaped flow channel and drip irrigation emitter

InactiveCN104488665BStrong turbulenceGood blocking resistanceWatering devicesCultivating equipmentsDrip irrigationEngineering

The invention discloses a karman vortex street shaped runner and a drip irrigation emitter comprising the same, and belongs to the technical field of agricultural water-saving irrigation. The karman vortex street shaped runner consists of two or more karman vortex street shaped runner units, wherein each karman vortex street shaped runner unit comprises a first upper arc-shaped columnar channel, a first lower half-arc-shaped columnar channel, a second lower half-arc-shaped columnar channel and two columnar channels; when being fed into one karman vortex street shaped runner unit from the inlets of the karman vortex street shaped runner unit, liquid passes through a sudden expansion part, a sudden shrinkage part, a sudden expansion part and a sudden shrinkage part in sequence, and enters the next karman vortex street shaped runner unit from the outlet of the karman vortex street shaped runner unit. The drip irrigation emitter comprises a runner base body and the karman vortex street shaped runner formed in the surface of the rubber base body, wherein a water inlet groove and an irrigation emitter outlet are respectively formed in two ends of the karman vortex street shaped runner. The karman vortex street shaped runner and the drip irrigation emitter comprising the same are large in passage cross section, low in vortex energy consumption, intense in turbulent fluctuation and good in flow uniformity.

Owner:XI AN JIAOTONG UNIV

Detachable jet aerator and using method thereof

ActiveCN100544829CUniform outflowIncrease agitation rangeTreatment using aerobic processesFlow mixersActivated sludgeJet flow

The invention discloses a split jet aerator, which comprises the following parts: suction inlet, water nozzle, mixing tube, dispersing pipe, tail pipe and distributor, wherein the distributor connects the tail pipe; a cone with the action of deflecting the composite liquid and reducing the local resistance is set in the pipe segment with diffusing angle of tail pipe; the CFD company adopts artificial software value to optimize the design of the structure of jet aerator, which transmits the composite liquid of effluent-living sludge into water nozzle; certain vacuum is formed in the course of jet to form three-phased composite liquid of gas, liquid and solid, which enters into the dispersing pipe to form jet distributor with certain pressure to do inclined ejection to aerate oxygen and stir. The invention improves more dynamic efficiency and more oxygen utility than traditional one, which possesses larger suction quantity, higher bubble quality, evener stirring power and more energy saving.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

Submersed nozzle for plate blank electromagnetic rotational flow continuous casting

The invention belongs to the technical field of continuous casting and particularly relates to a submersed nozzle for plate blank electromagnetic rotational flow continuous casting. The submersed nozzle for the plate blank electromagnetic rotational flow continuous casting is composed of a molten steel inflowing end, a side wall, a hollow inner cavity, a nozzle bottom and molten steel discharging holes. The pair of molten steel discharging holes same in size and shape are laterally symmetrically formed in the side wall close to the nozzle bottom. The upper edge of each molten steel discharging hole is of an arc-shaped curved face. The included angle beta of inner surface tangents of each arc-shaped curved face is 30 degrees-120 degrees. The lower edge of each molten steel discharging hole is of a slope. The dip angle of each slope is -30 degrees to +30 degrees. One side face of each molten steel discharging hole is inclined inwards and the other side face is parallel to the wide face of a crystallizer. The included angle theta of the two side faces is 0 degree-20 degrees. According to the submersed nozzle for the plate blank electromagnetic rotational flow continuous casting, outflow of the two molten steel discharging holes can be evened, liquid level fluctuation on the meniscus portion of the crystallizer is reduced, the effect of rotational flow continuous casting is thoroughly achieved, and meanwhile impact effect on the wide face of the crystallizer by the outflow of the nozzle caused by the rotational flow can be reduced.

Owner:苑轶

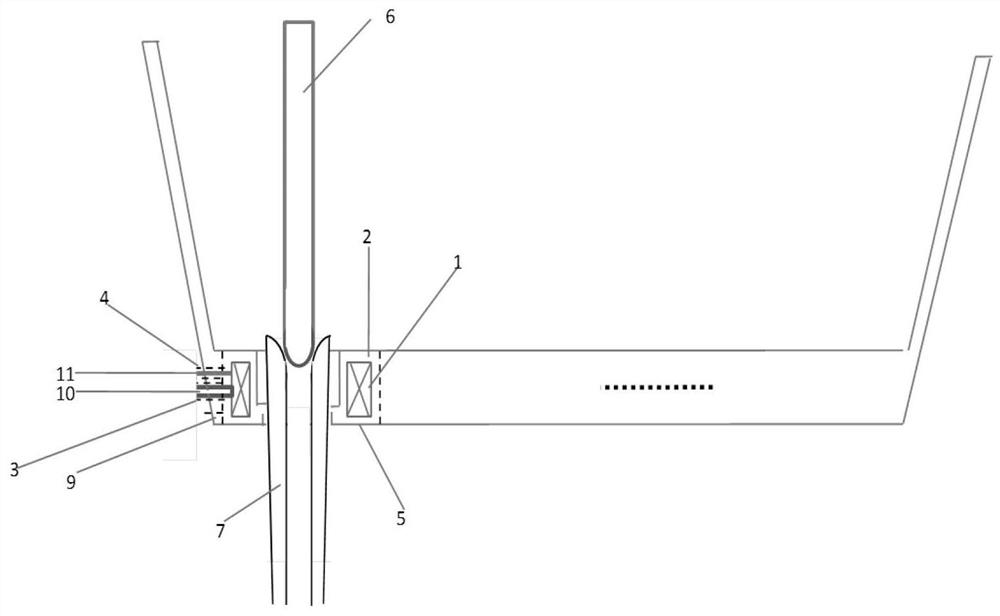

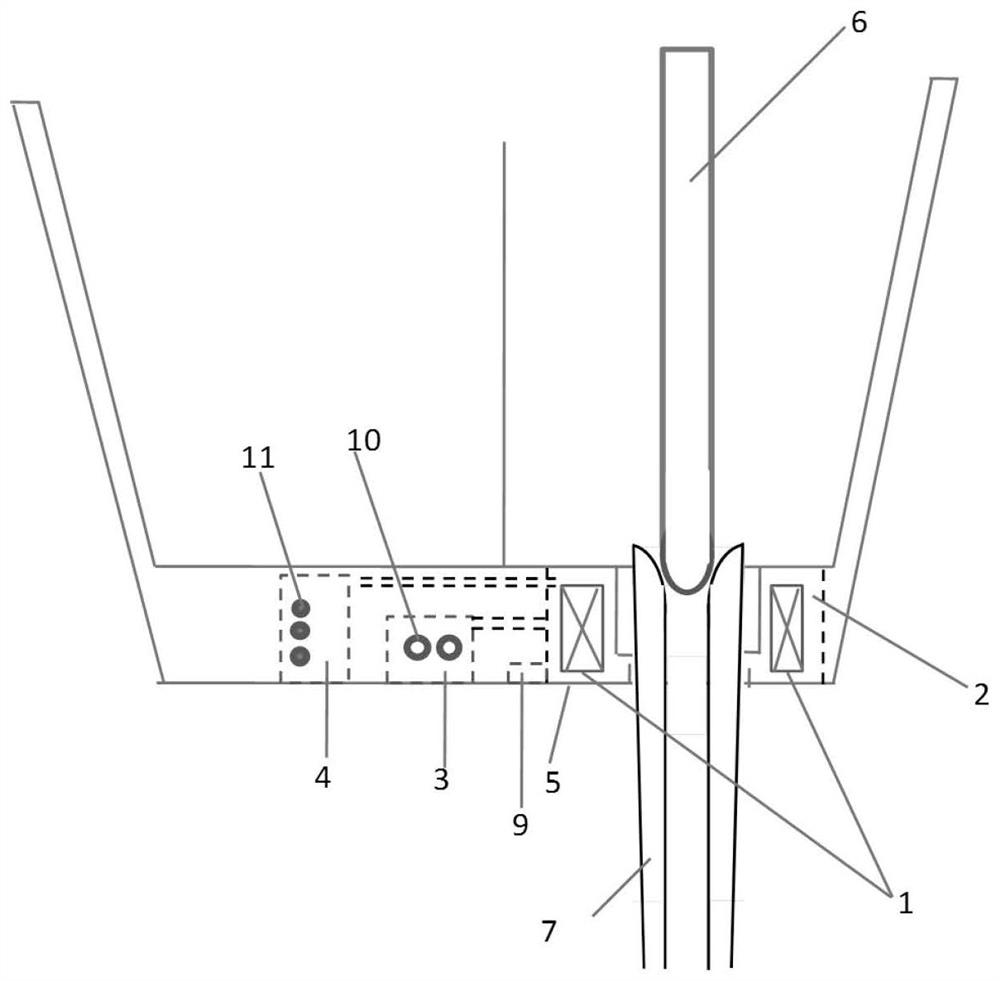

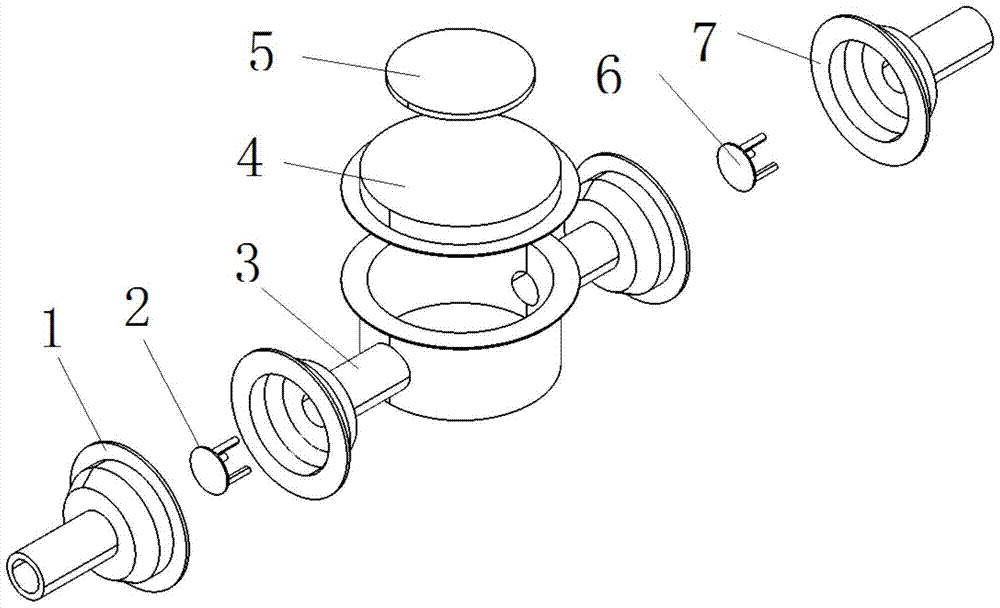

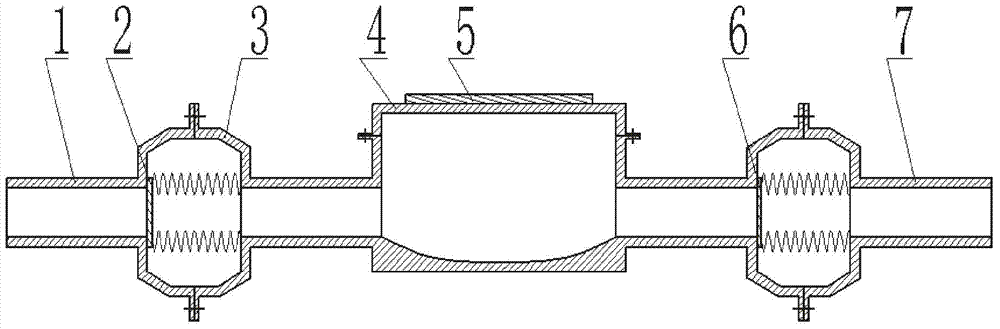

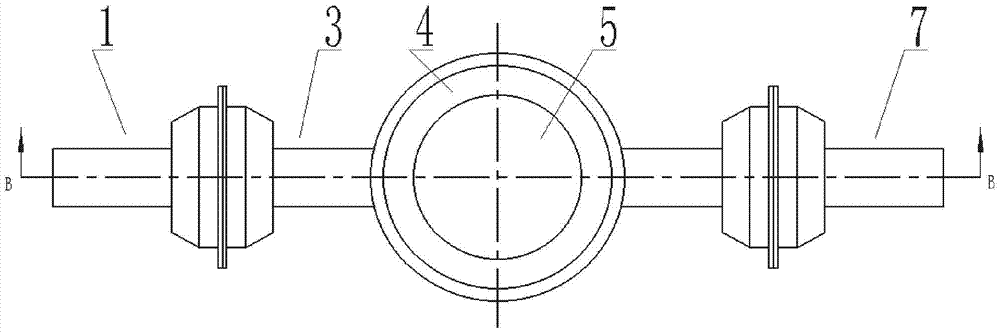

A spring type piezoelectric pump with valve

ActiveCN105201792BShort reaction timeEasy to usePositive displacement pump componentsFlexible member pumpsEngineeringCheck valve

The invention discloses a spring-type piezoelectric pump with valve. One end of a lower pump body is connected with a liquid inlet section through a flange, and an inlet check valve is arranged at the liquid inlet section of the liquid inlet section close to one end of the lower pump body. The other end is connected with the liquid outlet section through a flange, and an outlet check valve is provided at the liquid outlet of the lower pump body, the upper end of the lower pump body is connected with the upper pump body through a flange, and the top surface of the upper pump body is closely The piezoelectric vibrator is fixed together; the present invention designs a new type of spring-type passive valve structure, and proposes to use the pre-tightening force of the spring to help shorten the response time of the valve. The piezoelectric pump body and the pipeline are connected by flange, which is more concise and convenient to install. The chamfered structure is adopted on the protrusion of the installed valve, which can be closer to the streamline than the case without chamfering, reduce the vortex generated when the liquid flows, and reduce the energy loss.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com