Patents

Literature

46results about How to "Increase agitation range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

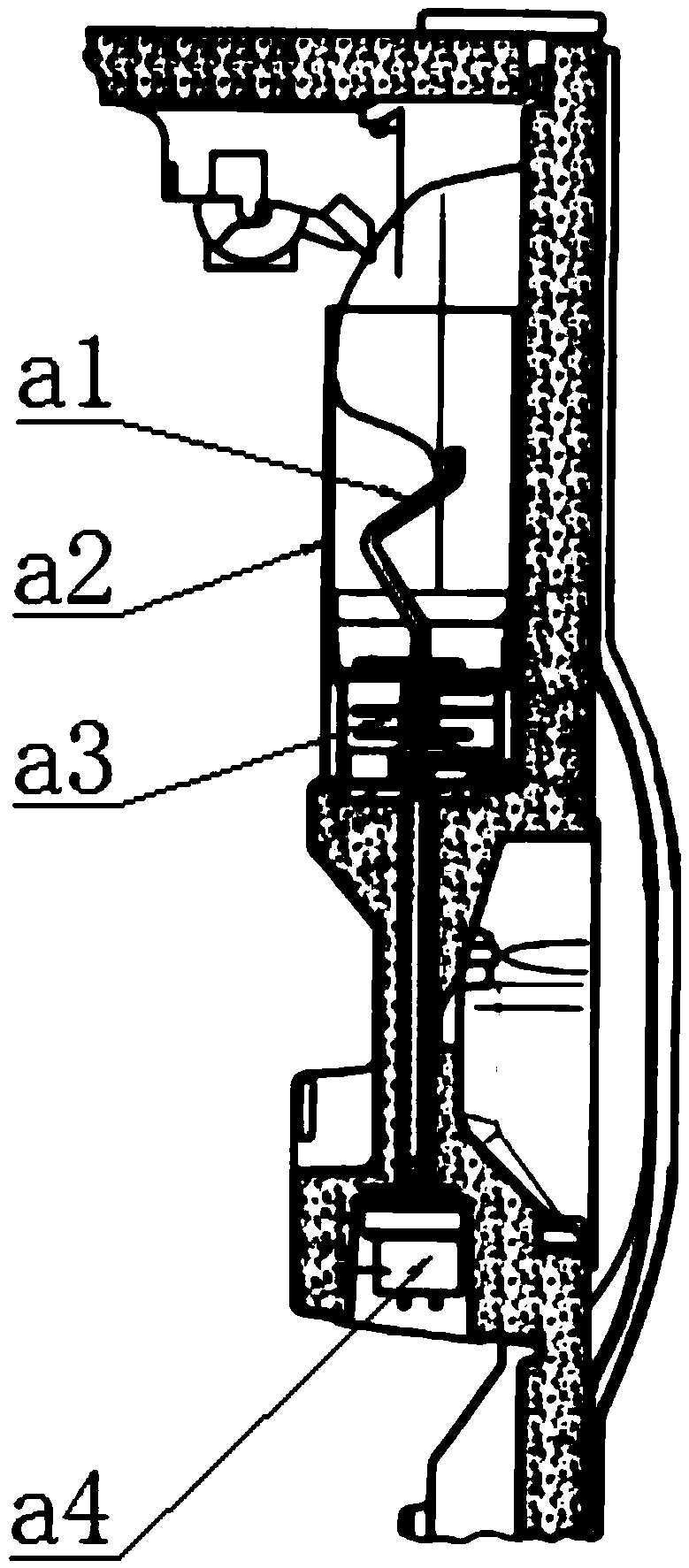

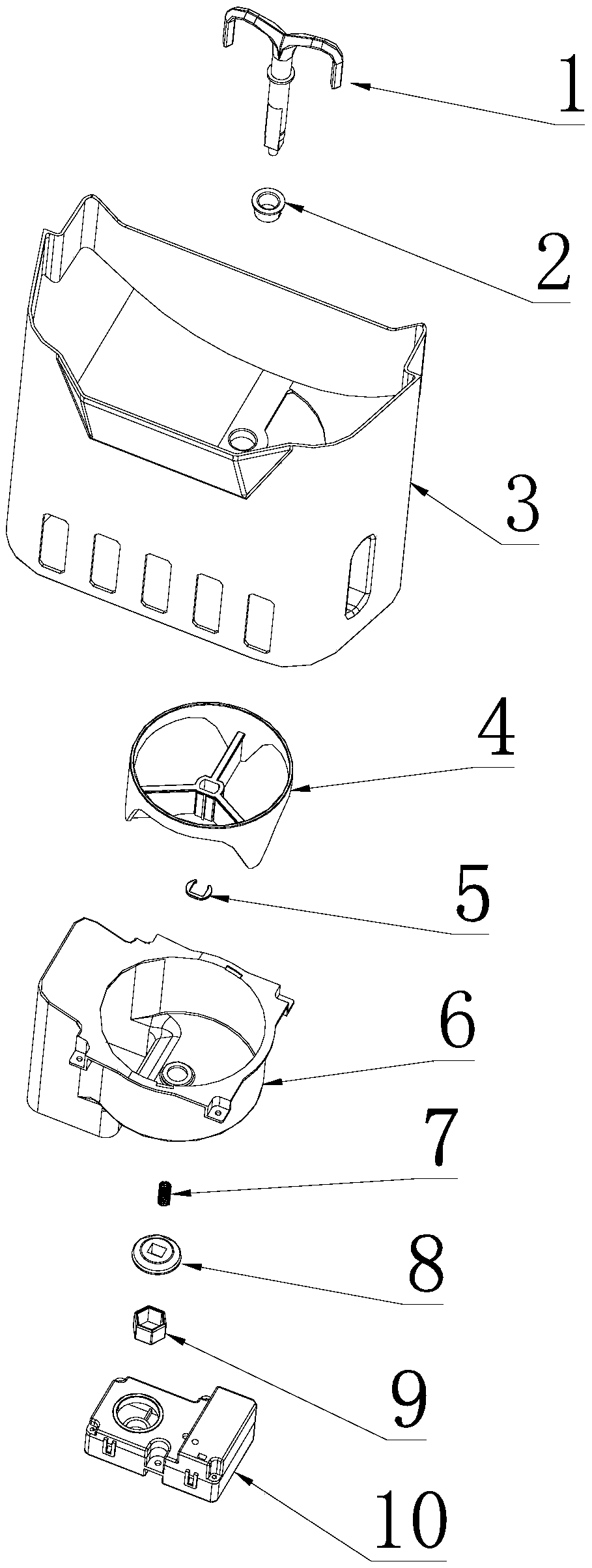

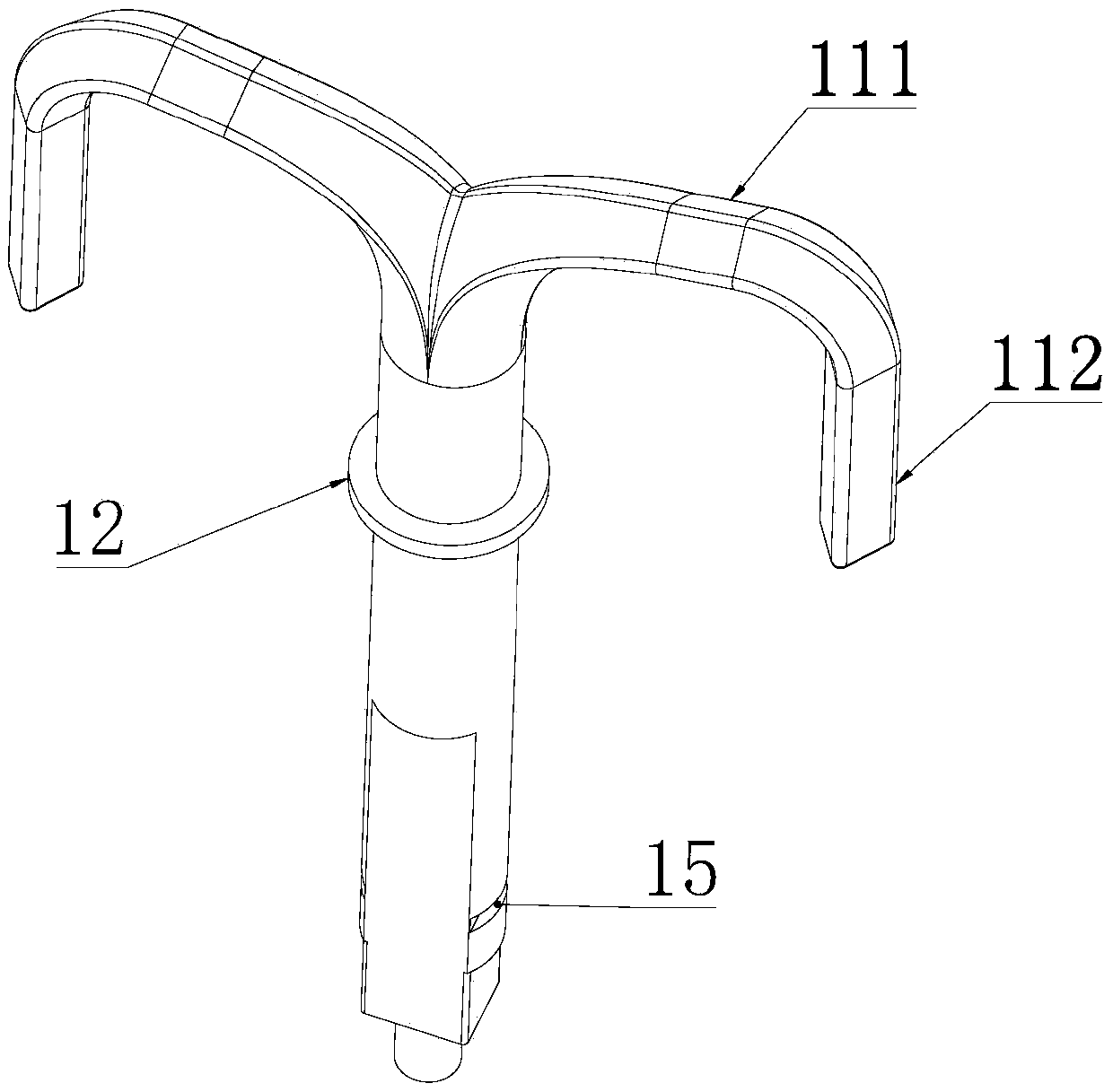

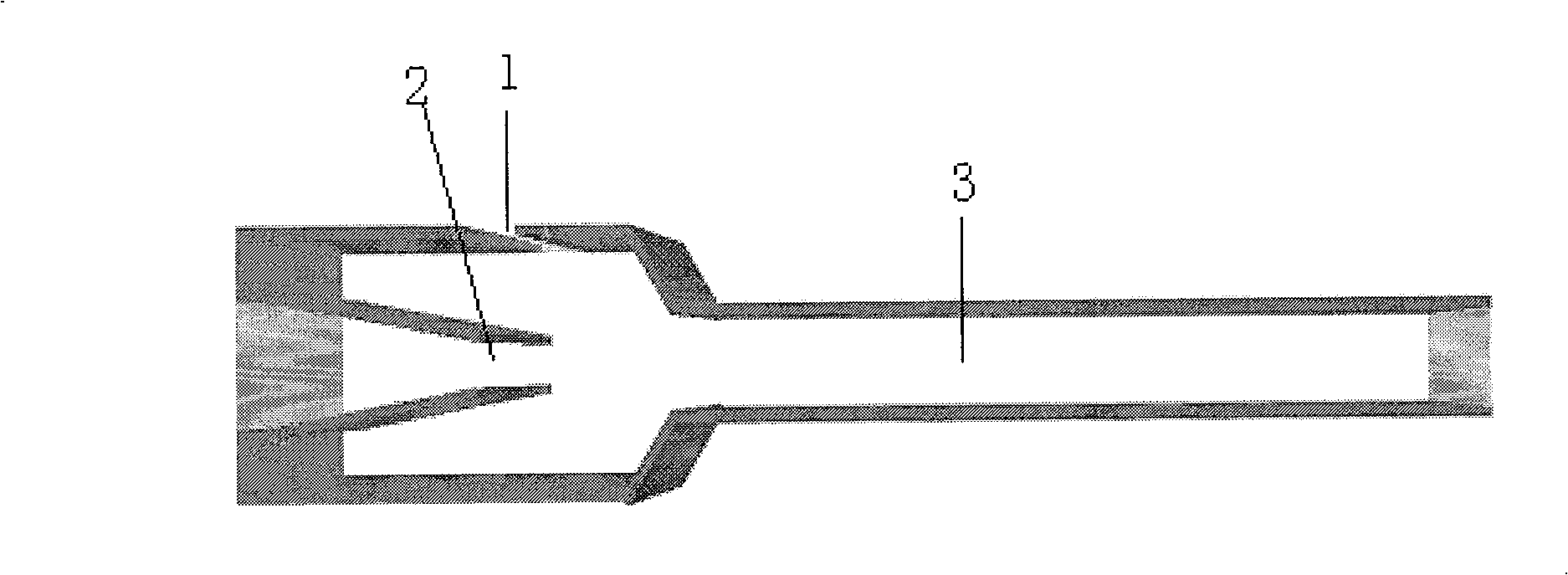

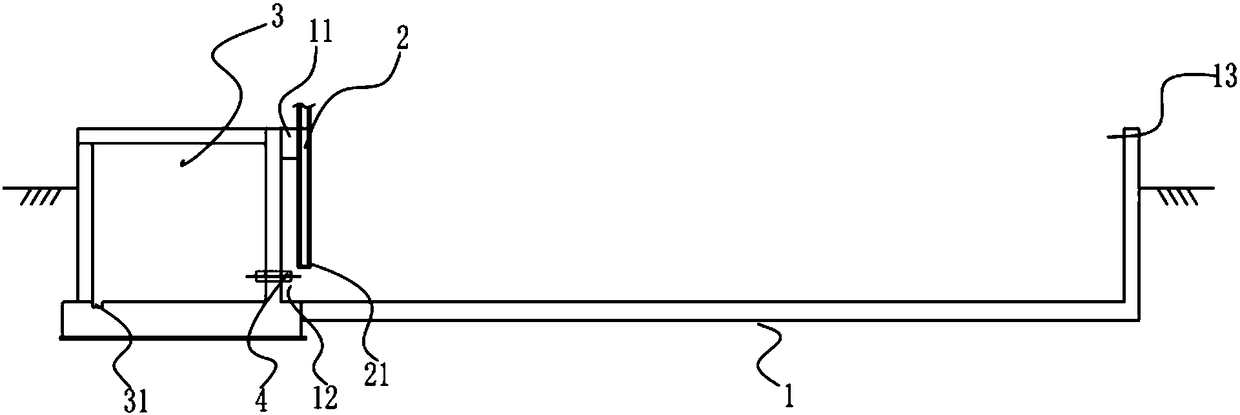

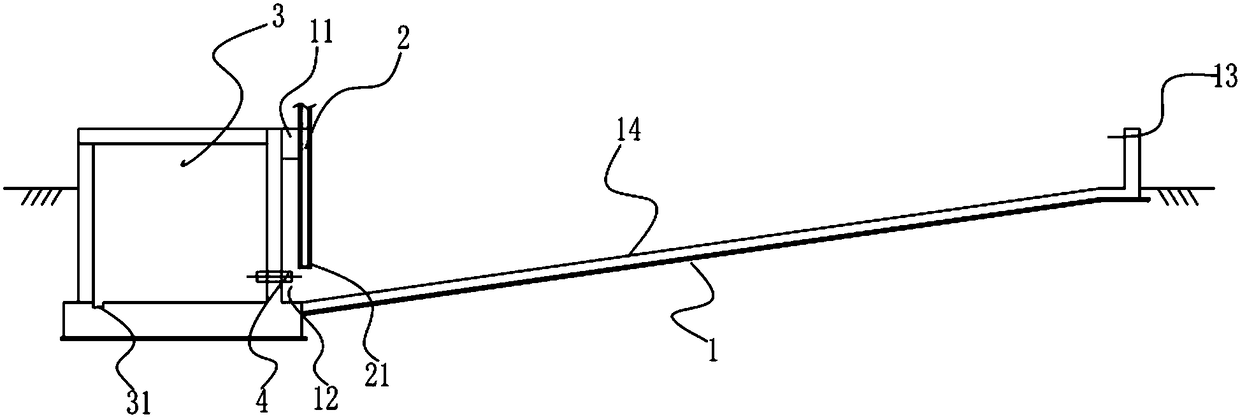

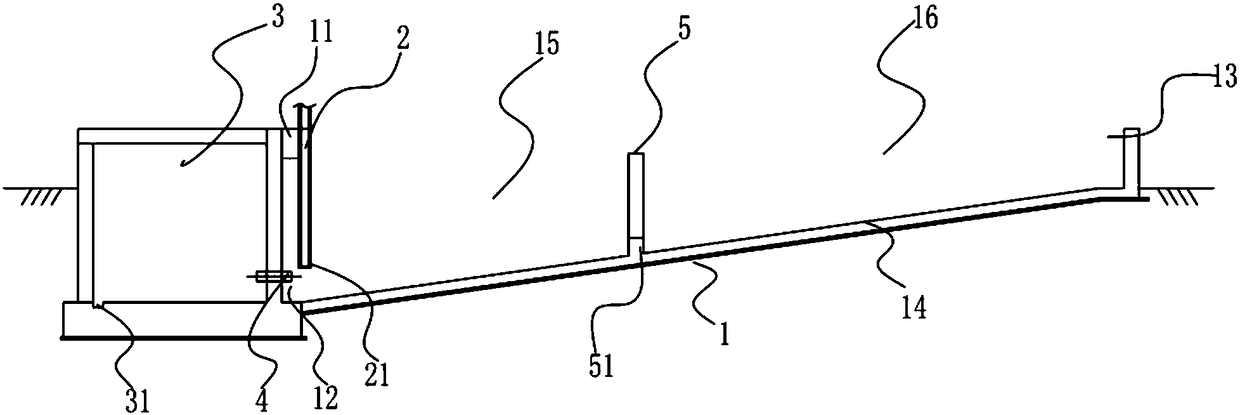

Ice conveying system for refrigerator

ActiveCN105509391AIncrease agitation rangeEnhanced ice churn effectLighting and heating apparatusIce storing/distributionPush outIce storage

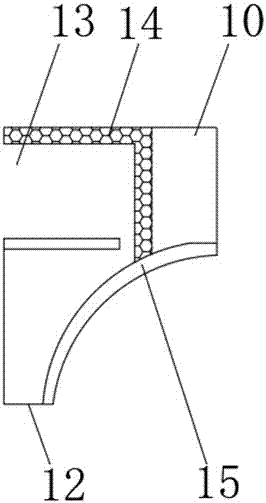

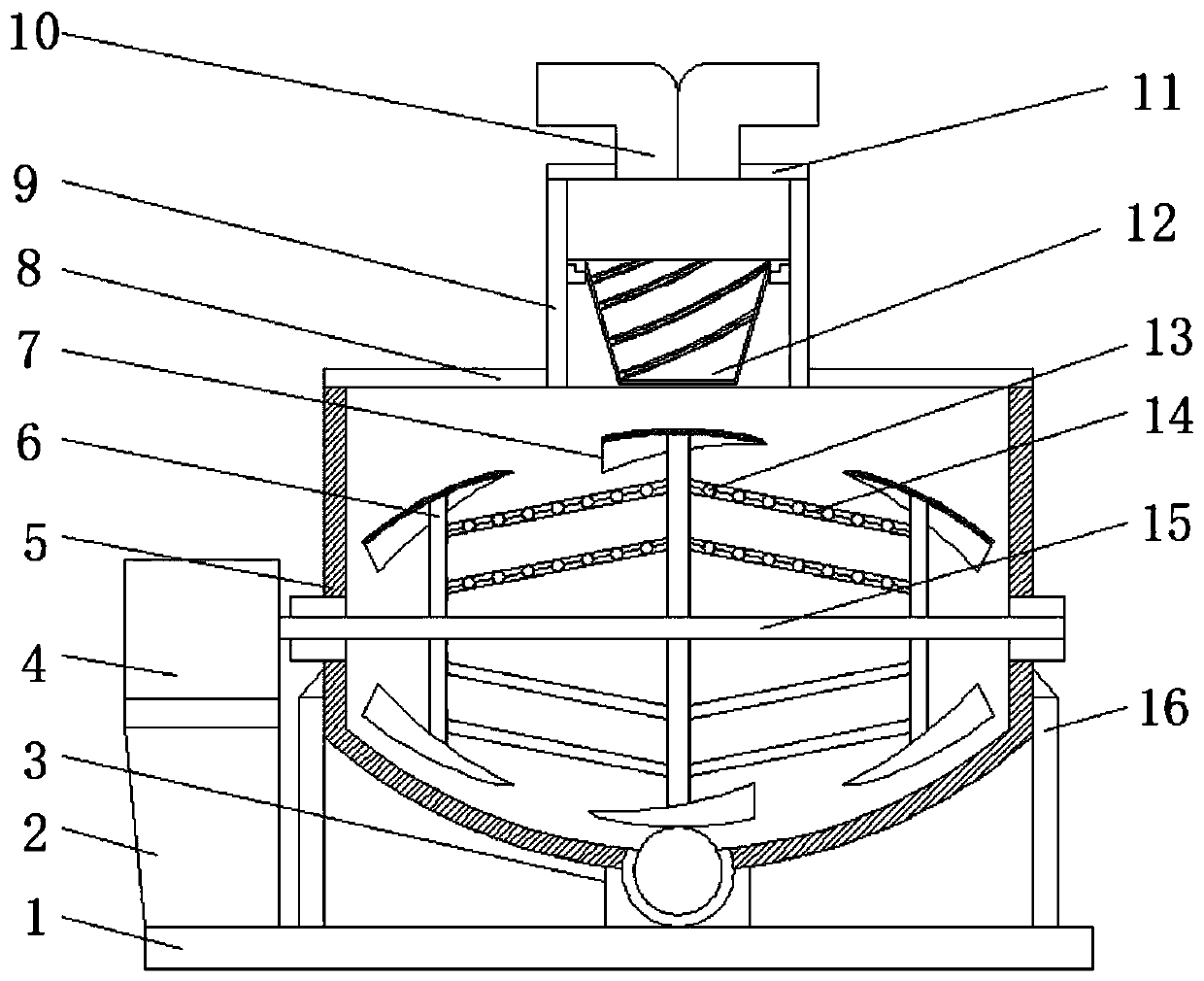

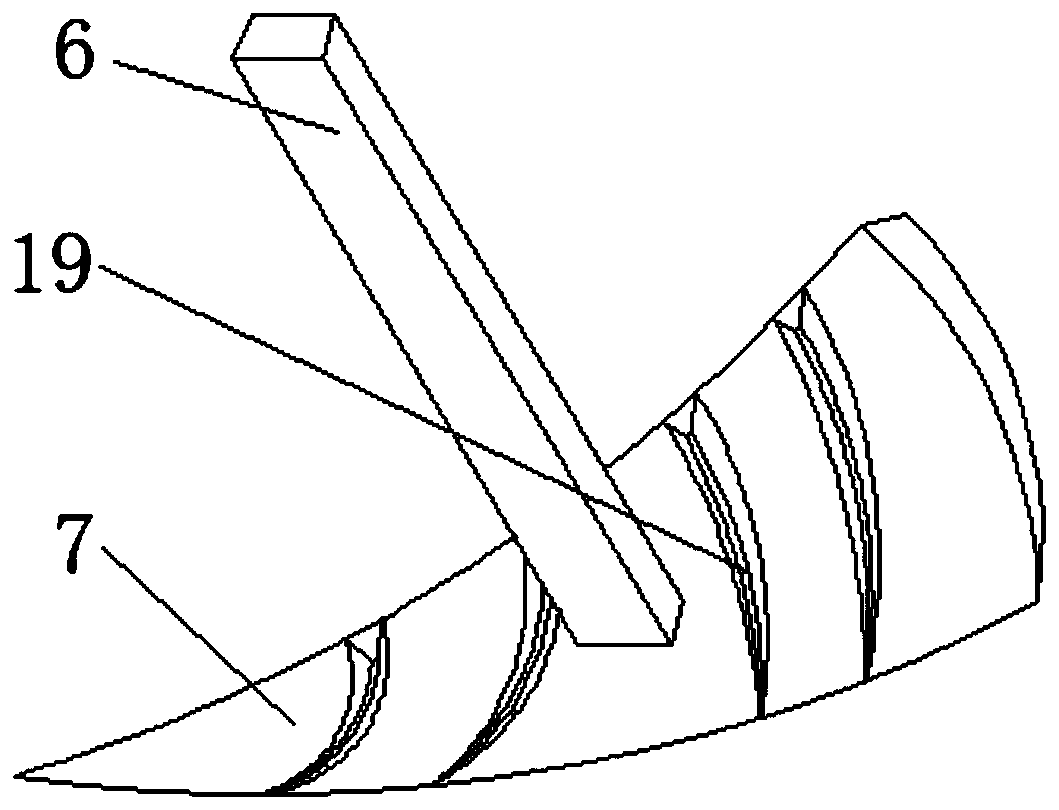

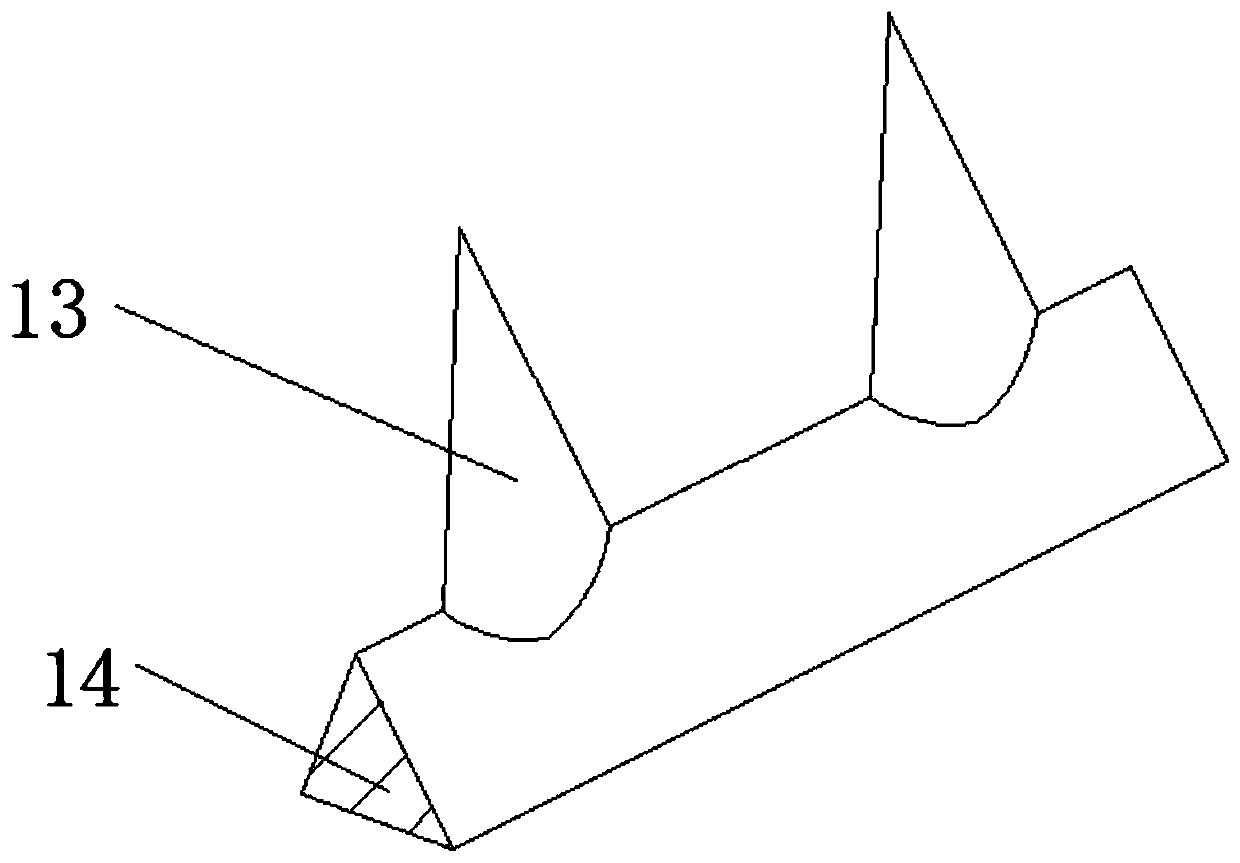

The invention belongs to the technical field of ice distribution and conveying, and discloses an ice conveying system for a refrigerator. The ice conveying system comprises an ice stirring rod, an ice storage box and a motor, wherein an ice outlet is formed in the bottom wall of the ice storage box; the lower end of the ice stirring rod penetrates through the bottom wall of the ice storage box, and is connected with the motor; the ice stirring rod comprises a rod body, and a plurality of branches arranged at the top end of the rod body and uniformly distributed by winding the rod body; the cutting side of each branch adopts a blade structure. Through the adoption of the ice stirring rod of which the cutting surface of each branch adopts the blade structure, the resistance of the ice stirring rod and ice blocks is relatively small, and the ice blocks can be successfully pushed out of the ice storage box without the ice crushing operation; the purposes of separating the ice blocks and pushing the ice blocks to move are realized at the same time in the ice stirring process, the ice blocks bonded together can be discharged from the ice outlet after being separated, the ice crushing operation is avoided, the structure of ice stirring equipment is greatly simplified, the ice storage amount of the ice storage box is increased, requirements on power of the motor for driving the ice stirring rod are relatively low, and the manufacturing cost is reduced.

Owner:HEFEI HUALING CO LTD +1

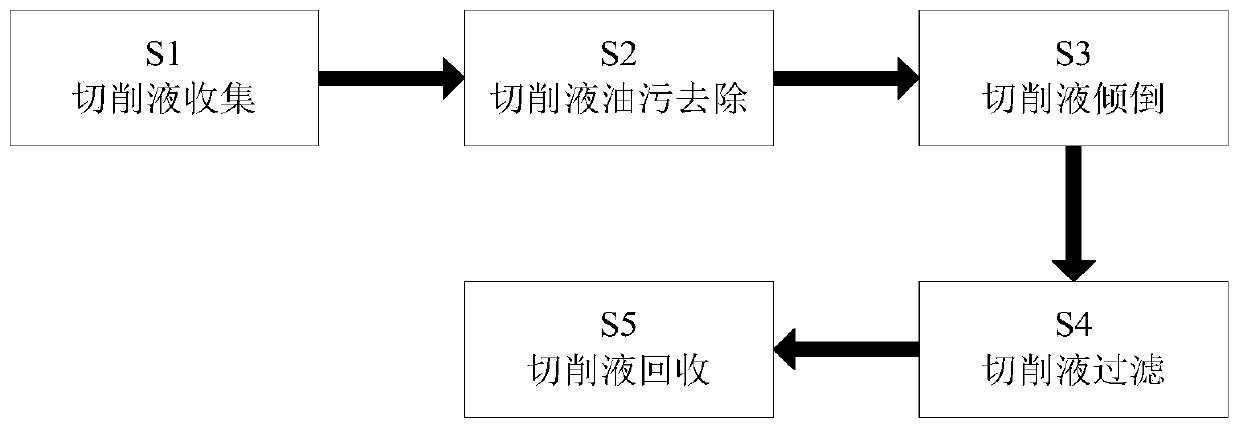

Water-soluble cutting fluid recovery treatment method

InactiveCN110683705AAvoid cloggingPrevent clogging and scratchingFatty/oily/floating substances removal devicesTreatment involving filtrationProcess engineeringFilter paper

The invention relates to a water-soluble cutting fluid recovery treatment method which comprises the following steps: S1, collecting a cutting fluid; S2, removing oil stain of the cutting fluid, namely pouring off and removing sundries such as oil stain floating on the liquid level of the cutting fluid in the step S1; S3, pouring the cutting fluid; S4, filtering the cutting fluid; and S5, recovering the cutting fluid. Corresponding treatment operation of operation procedures of steps S1-S5 of the water-soluble cutting fluid recovery treatment method is completed through cooperation of a stirring bucket, a stirring motor, a stirring rod, blades, an adsorption mechanism, a sealing plate, a filtering net and a recovery bucket. By adopting the method, problems that in conventional operation that a cutting fluid is filtered, the cutting fluid is filtered in a multistage filtration mode generally, the cutting fluid is fed through filter paper of different models to achieve the purpose of removing sundries, but the filter paper can be blocked or scratched by the sundries in the cutting fluid, the cutting fluid is poor in filtration effect, and the filter paper needs to be artificially shaken frequently, can be solved.

Owner:郭寒生

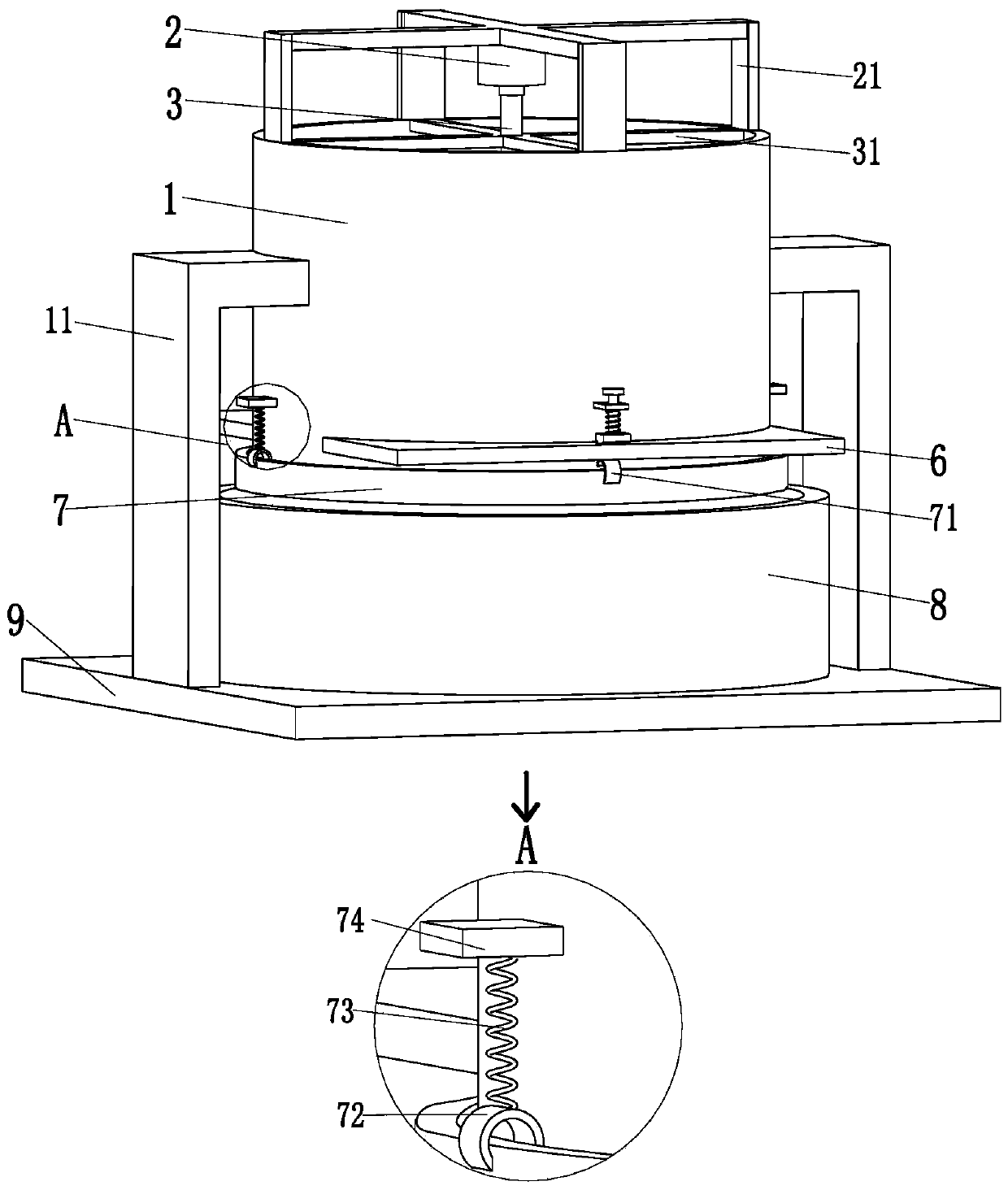

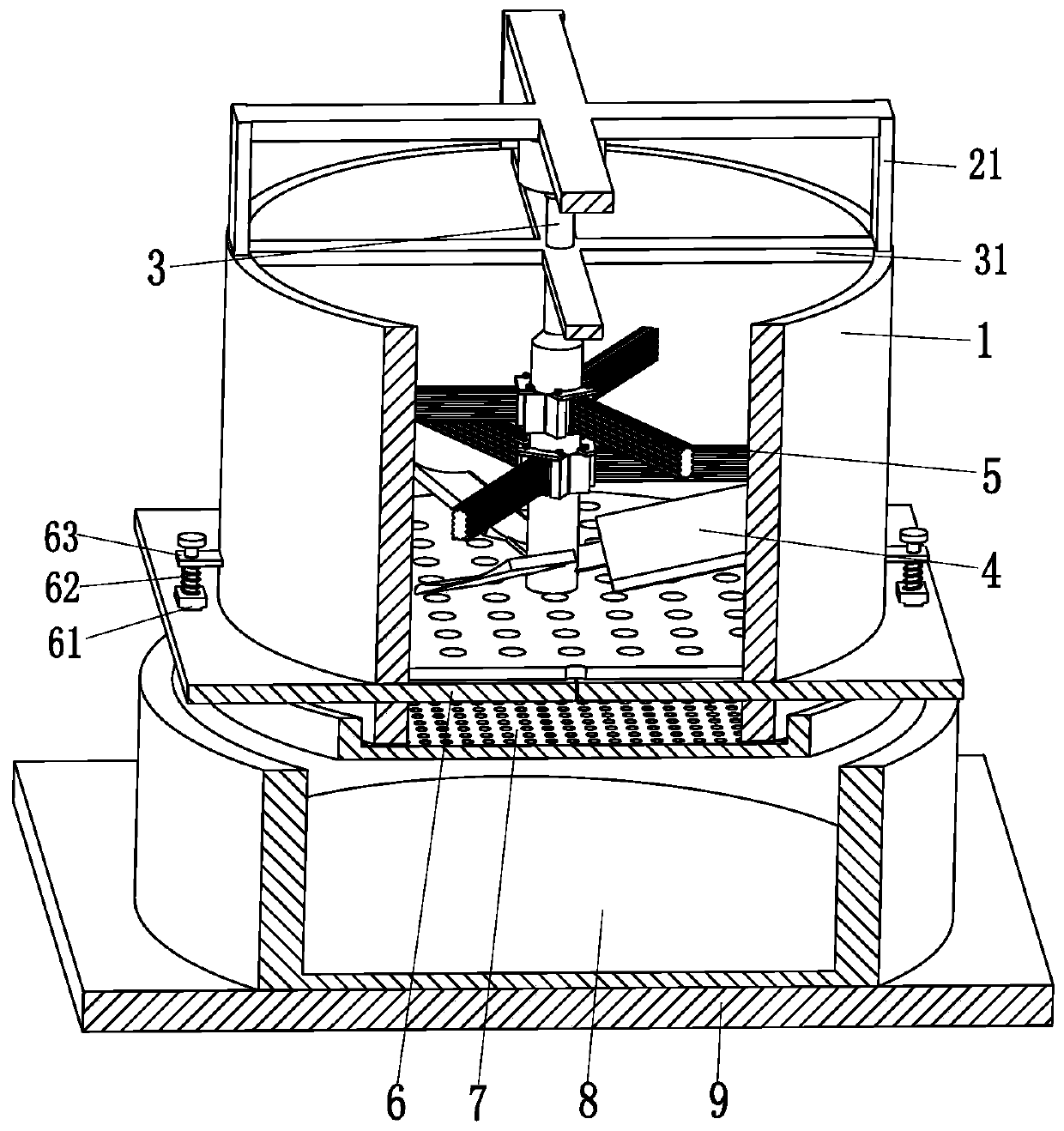

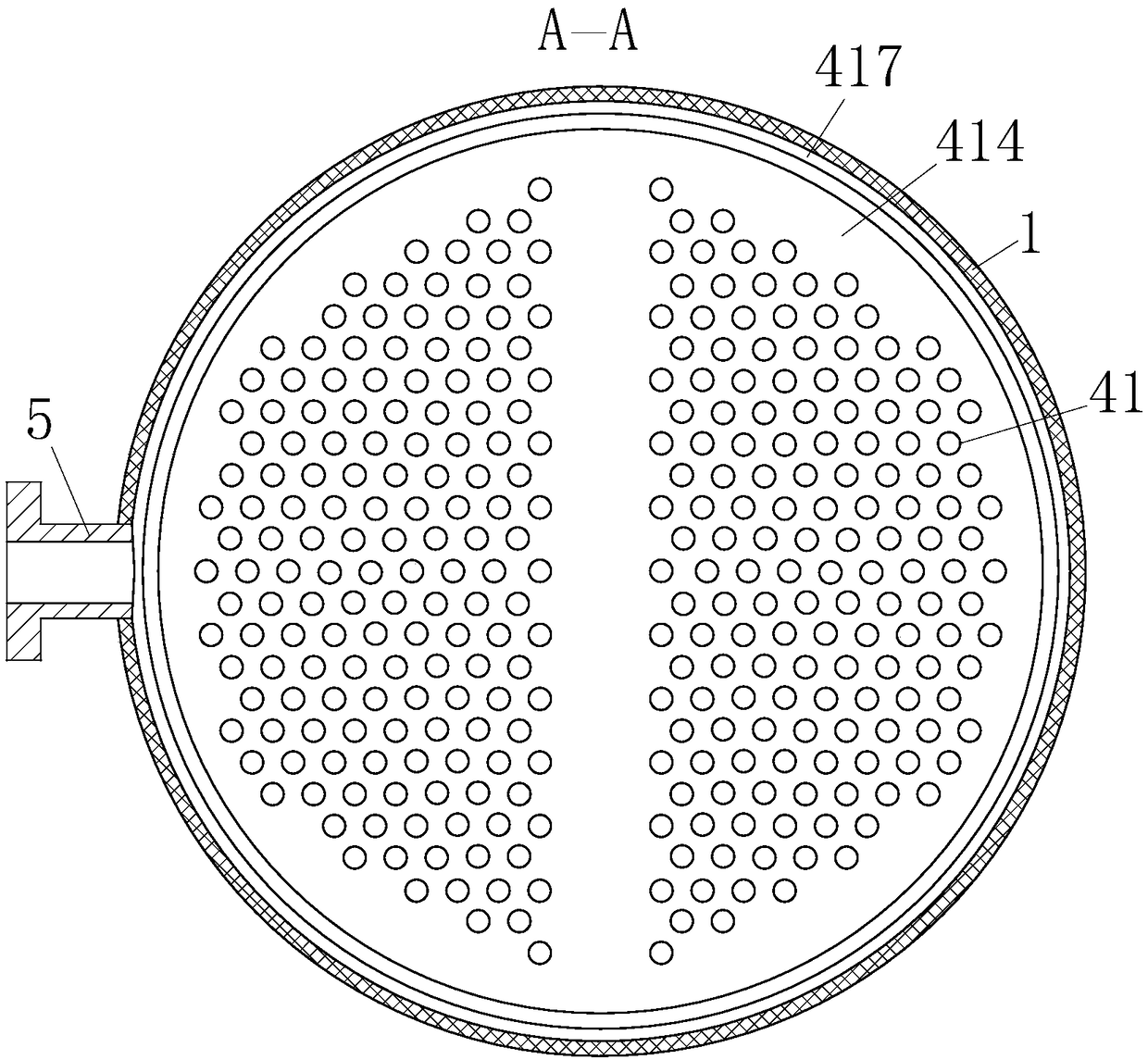

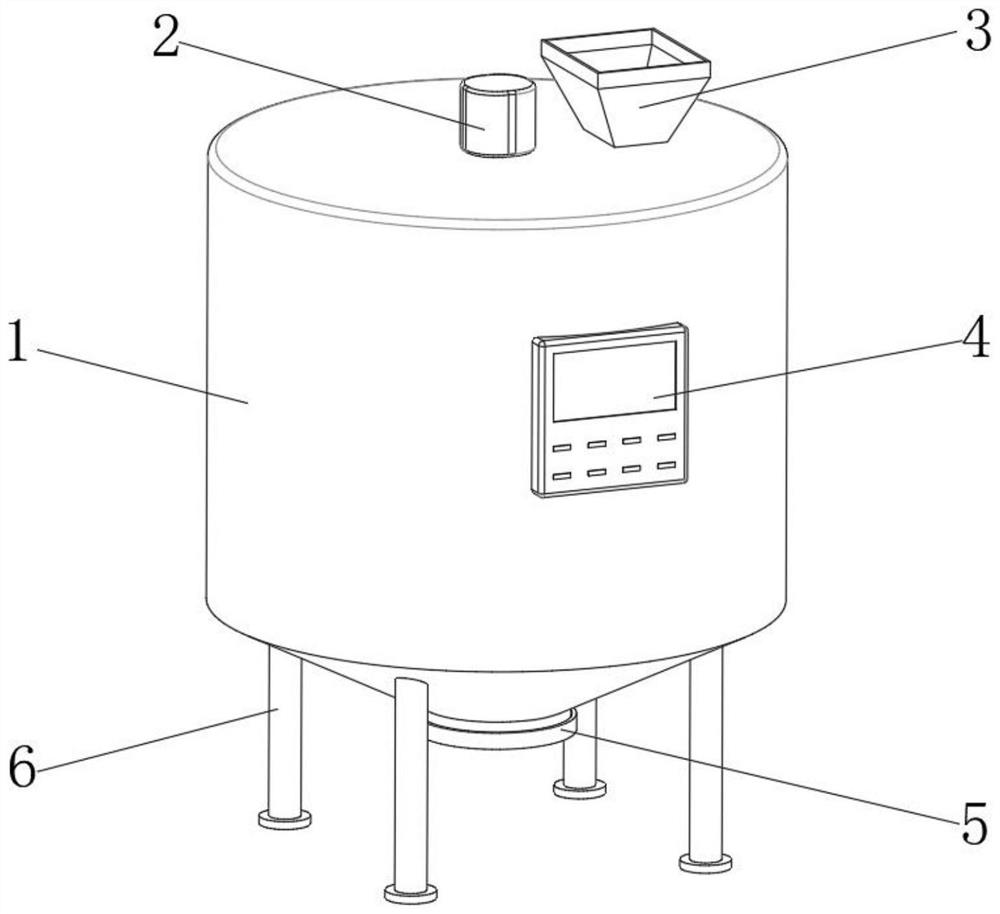

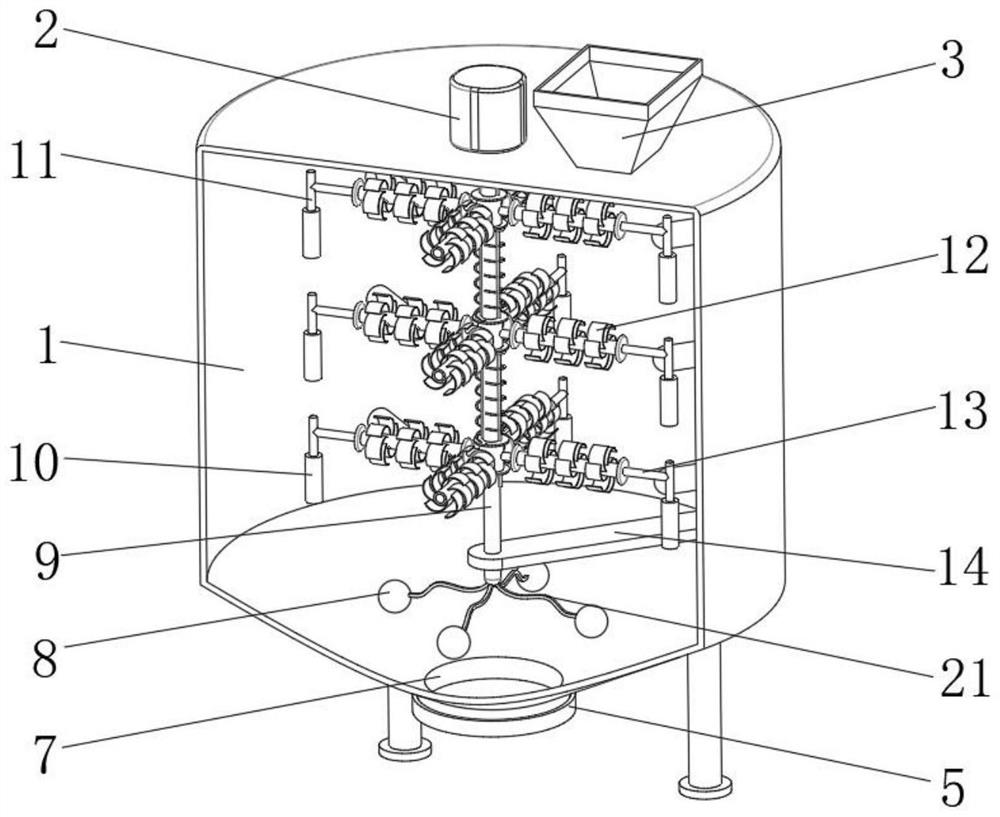

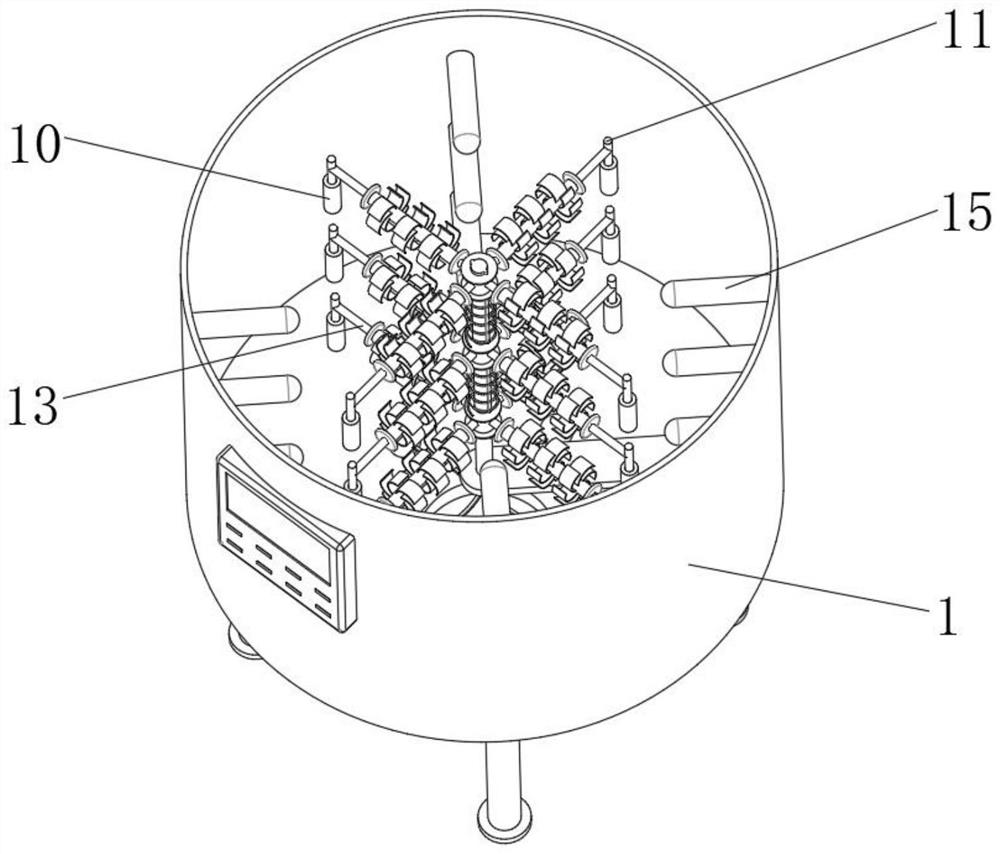

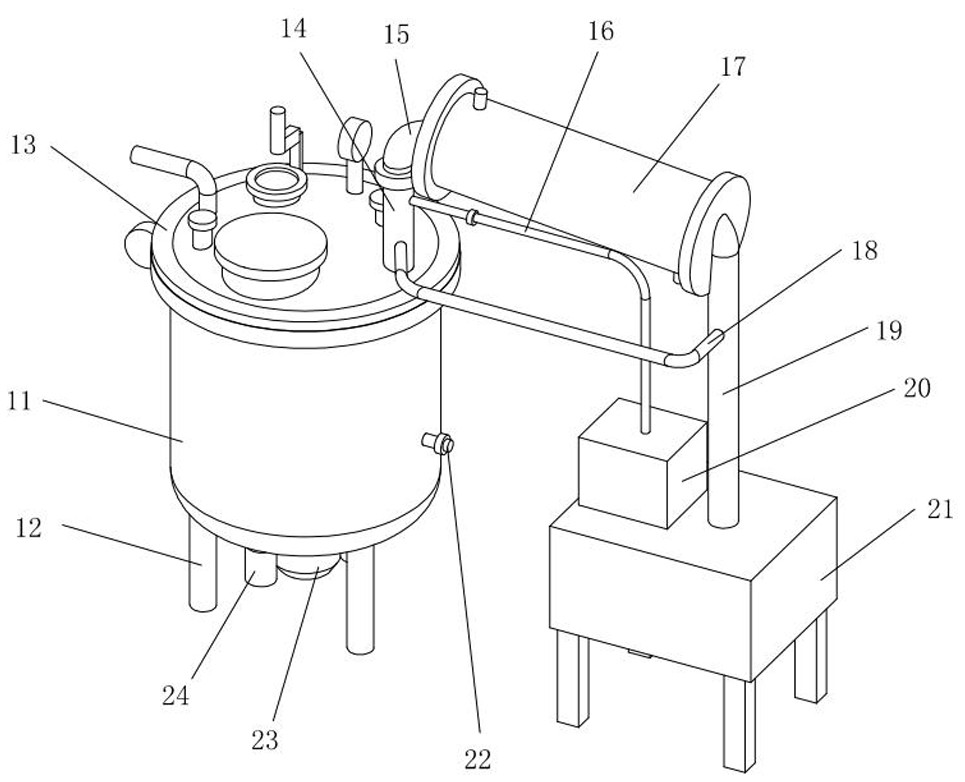

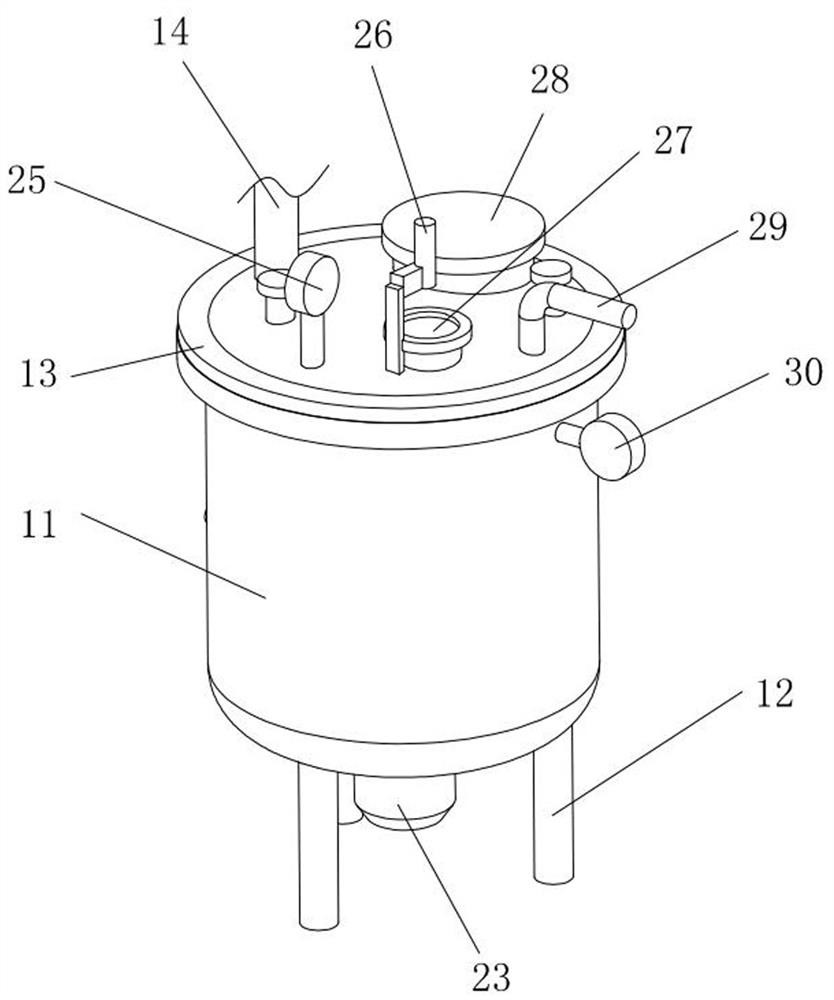

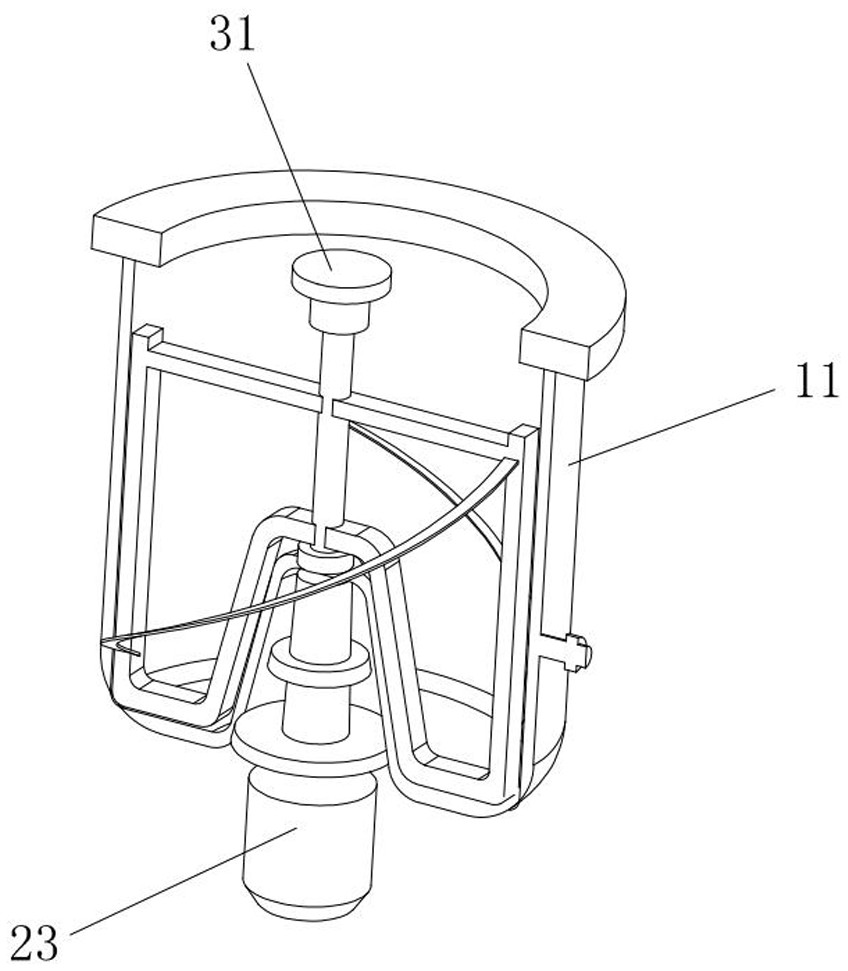

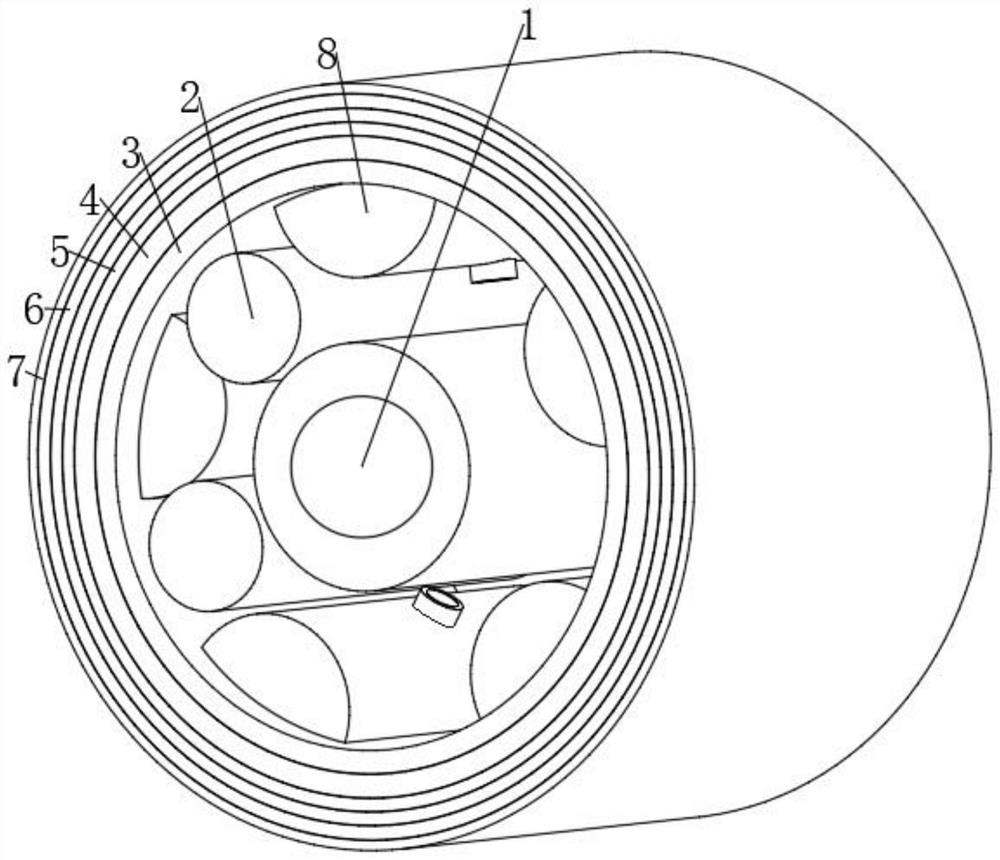

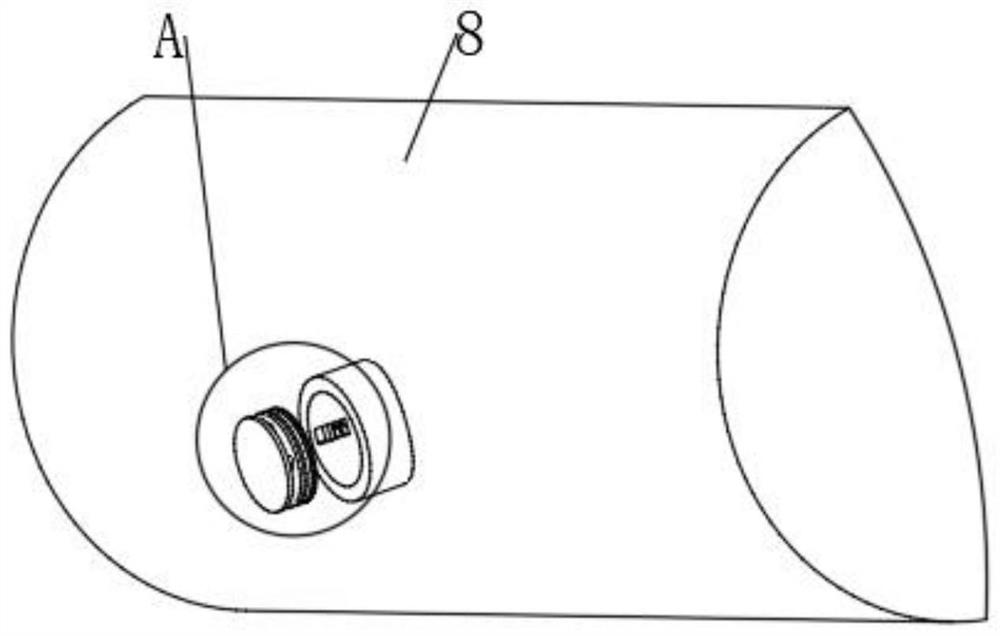

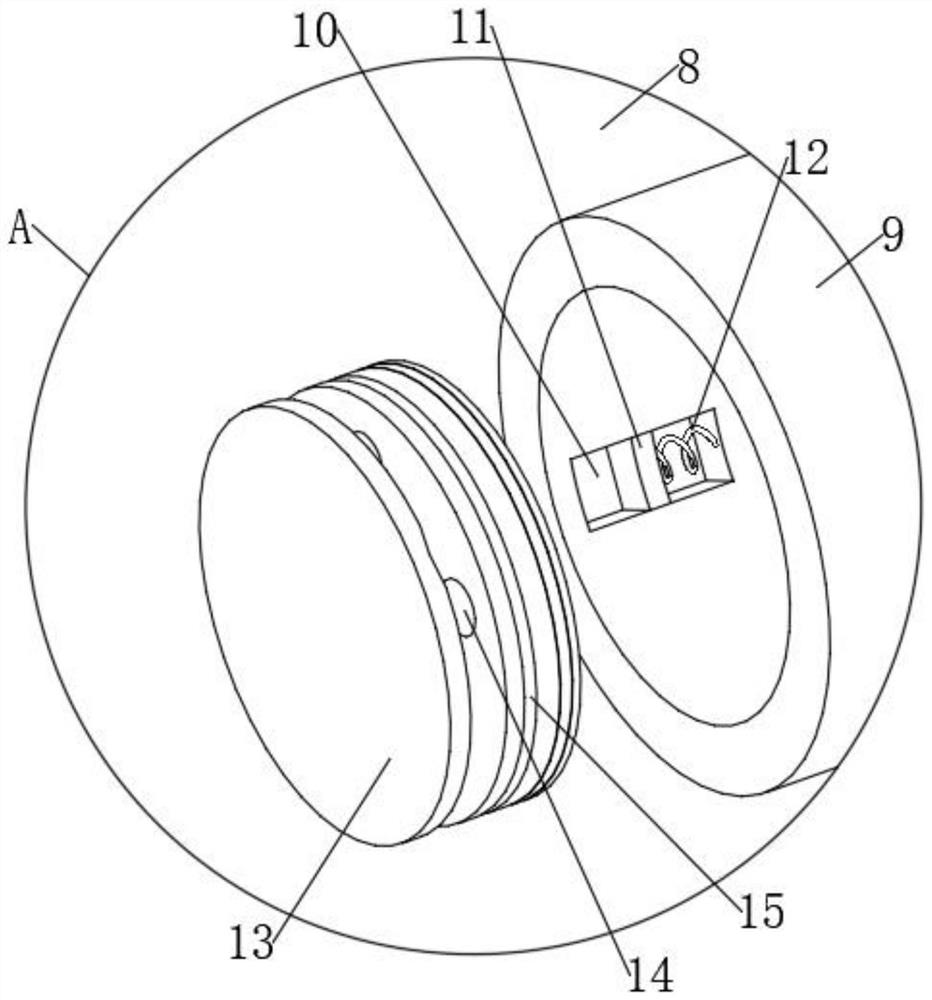

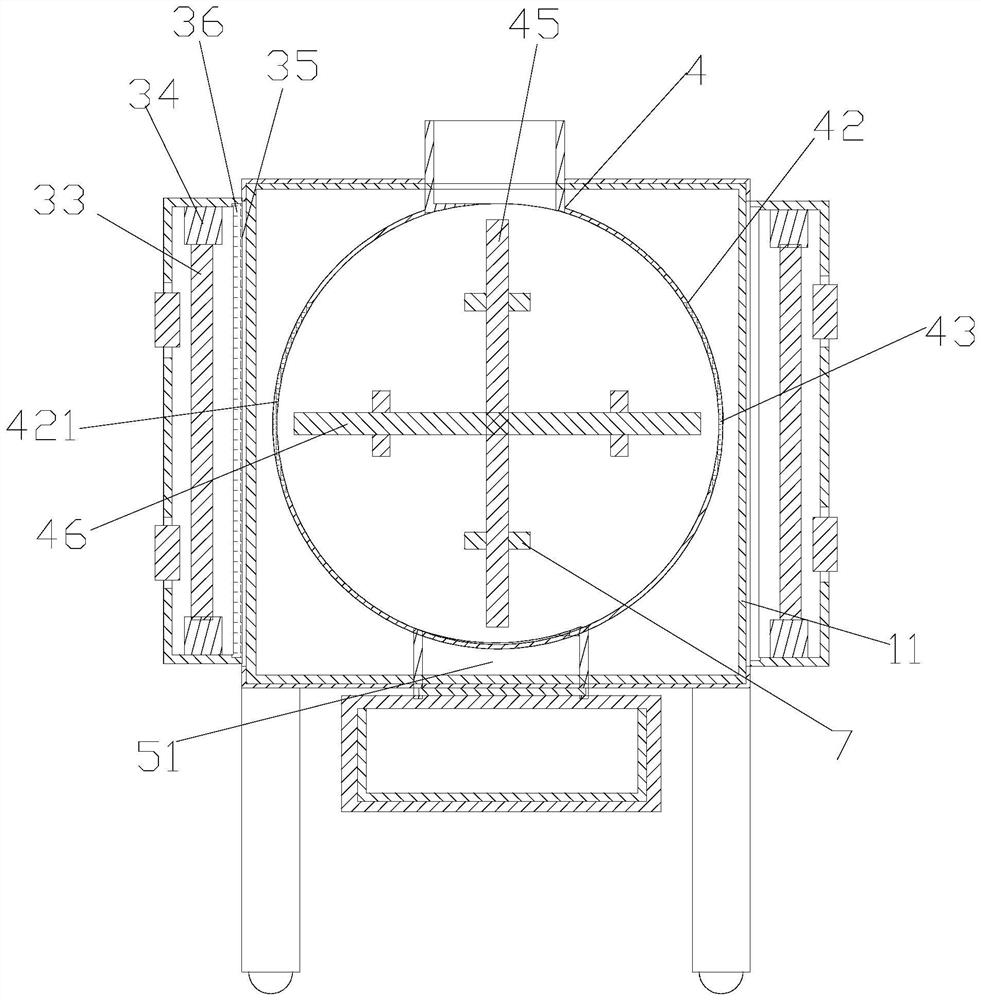

Reaction device for processing motor silicon steel sheet coating liquid

InactiveCN111482152AStir fully and comprehensivelyImprove reaction processing efficiencyShaking/oscillating/vibrating mixersRotary stirring mixersElectric machineReaction rate

The invention discloses a reaction device for processing motor silicon steel sheet coating liquid, and relates to the technical field of motor processing. The reaction device comprises a reaction cylinder, a liquid storage tank is communicated with the interior of the reaction cylinder through a transmission mechanism, a vertical reciprocating mechanism is connected to the transmission mechanism,a lifting plate is connected to the vertical reciprocating mechanism, and a circulating lifting mechanism is arranged in the reaction cylinder; a sleeve is driven by the transmission mechanism to drive stirring blades to rotate and stir coating liquid, the reaction processing efficiency of the coating liquid is improved, the arranged vertical reciprocating mechanism can drive the lifting plate tovertically ascend and descend in a reciprocating mode, the stirring range of the coating liquid in the reaction cylinder is widened, and the reaction rate is further improved; the arranged circulatinglifting mechanism can achieve circulating up-and-down stirring of the coating liquid in the reaction cylinder, the coating liquid can be repeatedly stirred by cutting blades in the stirring process,stirring of the coating liquid is more sufficient and comprehensive, and the production reaction efficiency is effectively improved.

Owner:黄国普

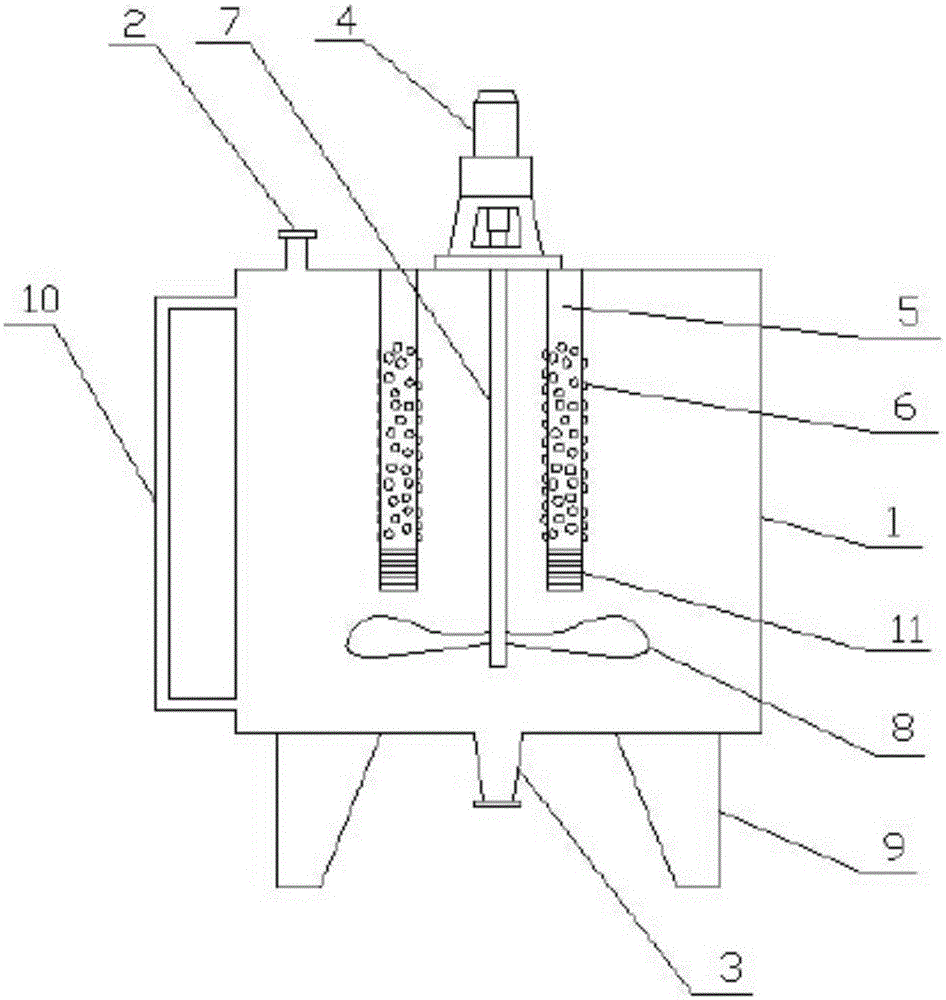

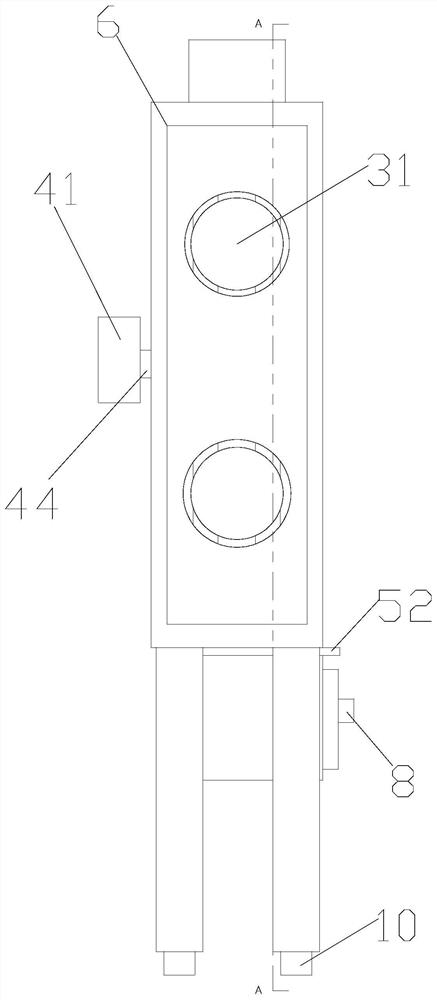

Mechanical dehydration multifunctional slurry conditioner for River and lake contaminated sediment treatment

ActiveCN106167344AGuaranteed capacityOvercoming technical problems with prolonged buildup on the bottom of the poolSludge treatment by de-watering/drying/thickeningSlurryEngineering

The invention provides a mechanical dehydration multifunctional slurry conditioner for River and lake contaminated sediment treatment. The slurry conditioner comprises a conditioner body which is provided with a slurry inlet, a slurry outlet and a water outlet. An air inlet pipe is arranged close to the slurry outlet inside the conditioner body. The air inlet pipe is equipped with multiple vents which are arranged in different directions in the air inlet pipe. According to the mechanical dehydration multifunctional slurry conditioner for River and lake contaminated sediment treatment, slurry inside the conditioner is stirred by introducing air into the conditioner body. Thus, sedimentation and hardening of slurry can be prevented, long-time accumulation of slurry at the conditioner bottom is avoided, and storage capacity of the conditioner body is effectively guaranteed. Meanwhile, the effect of noise reduction is achieved, and concentration of slurry inside the conditioner body can be adjusted.

Owner:POWERCHINA WATER ENVIRONMENT GOVERANCE

Chemical raw material mixing device

InactiveCN106693772AImprove the mixing effectWell mixedRotary stirring mixersEngineeringRaw material

The invention provides a chemical raw material mixing device which comprises a tank body and a stirring system; the top of the tank body is provided with a feed inlet, and the bottom of the tank body is provided with a discharge port; the stirring system comprises a stirring motor arranged at the top of the tank body, a stirring shaft arranged inside the tank body, and a stirring blade fixedly connected at the bottom the stirring shaft; the stirring shaft is connected with the stirring motor; the top face in the tank body is irregularly provided with a plurality of columnar bulges extending downwards and extending into a liquid. The chemical raw material mixing device has the beneficial effects that the top face in the tank body is irregularly provided with the plurality of columnar bulges extending downwards and extending into the liquid, so the stirring effect of the liquid is improved, the rotation of the liquid is not just utilized for stirring, the liquid is more easily stirred and mixed evenly, and the range of stirring is increased.

Owner:JIANGSU JIHUA CHEMICAL CO LTD

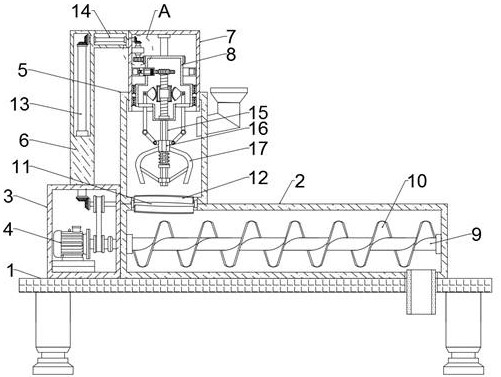

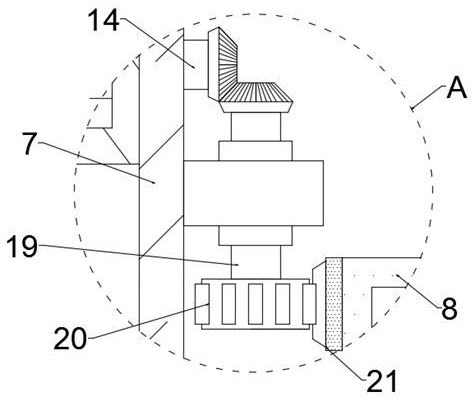

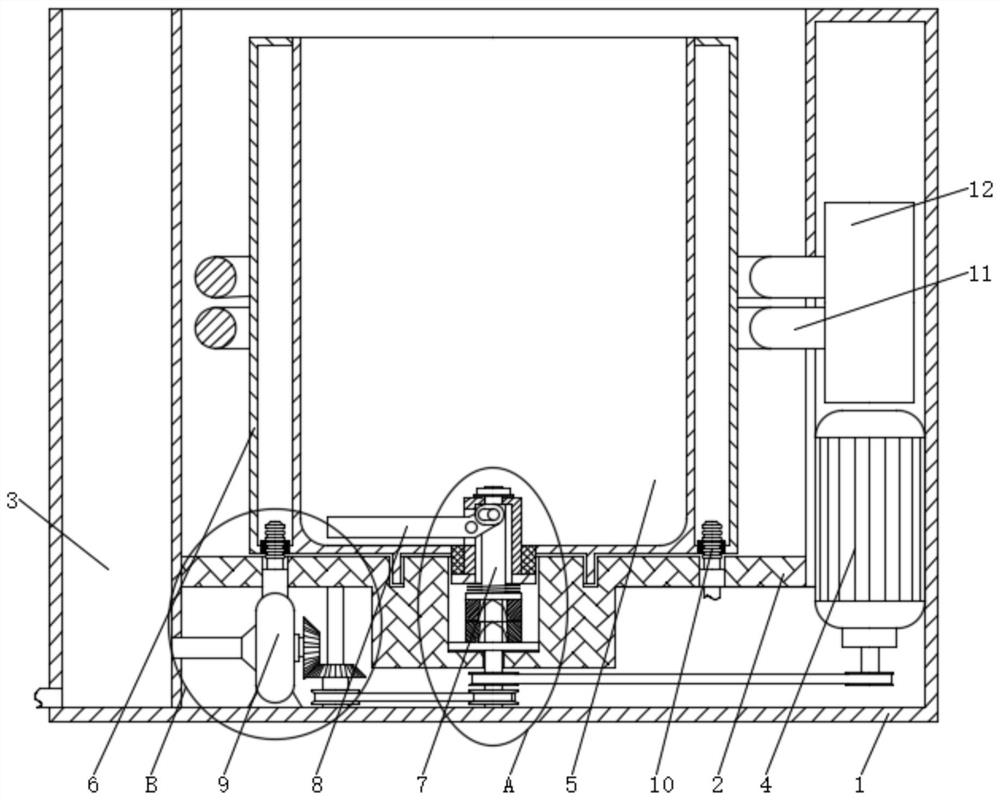

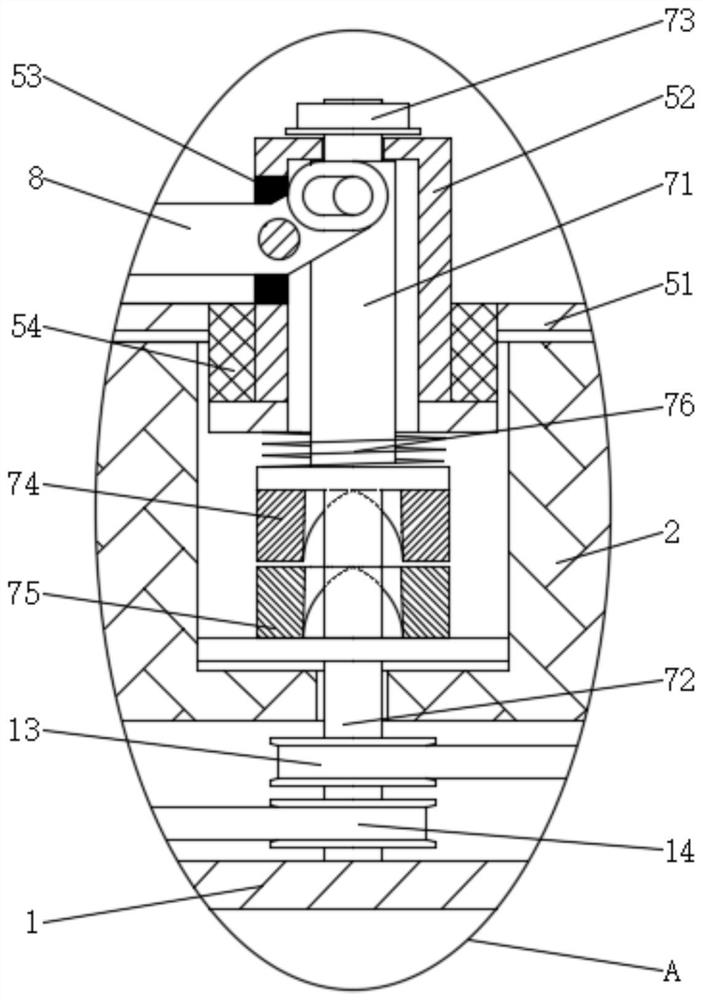

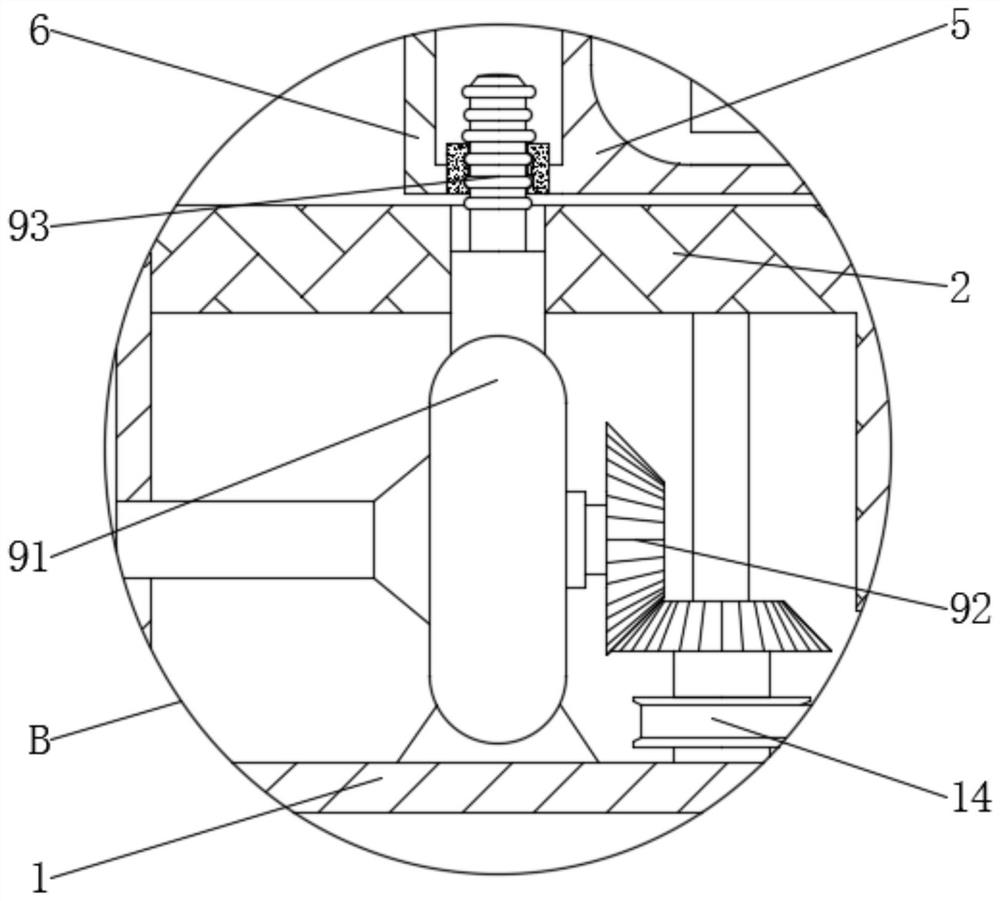

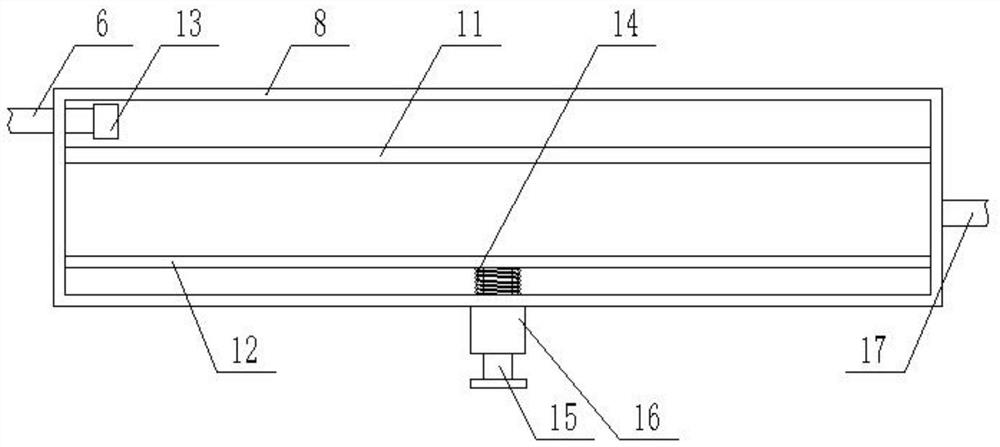

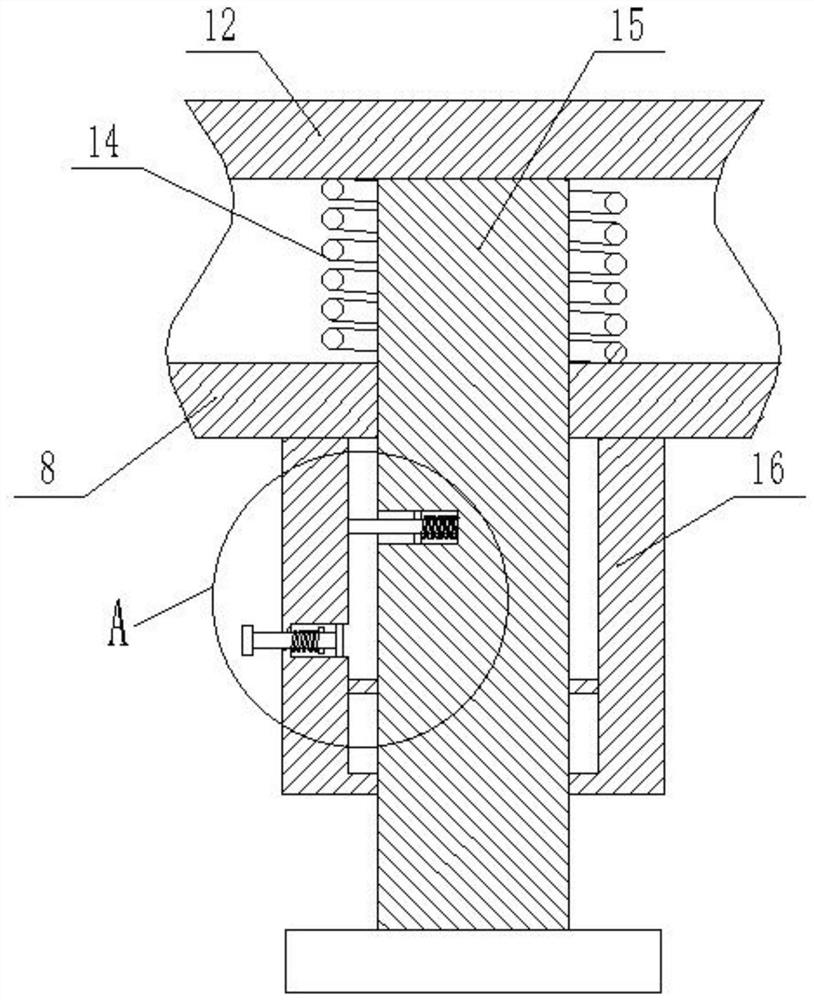

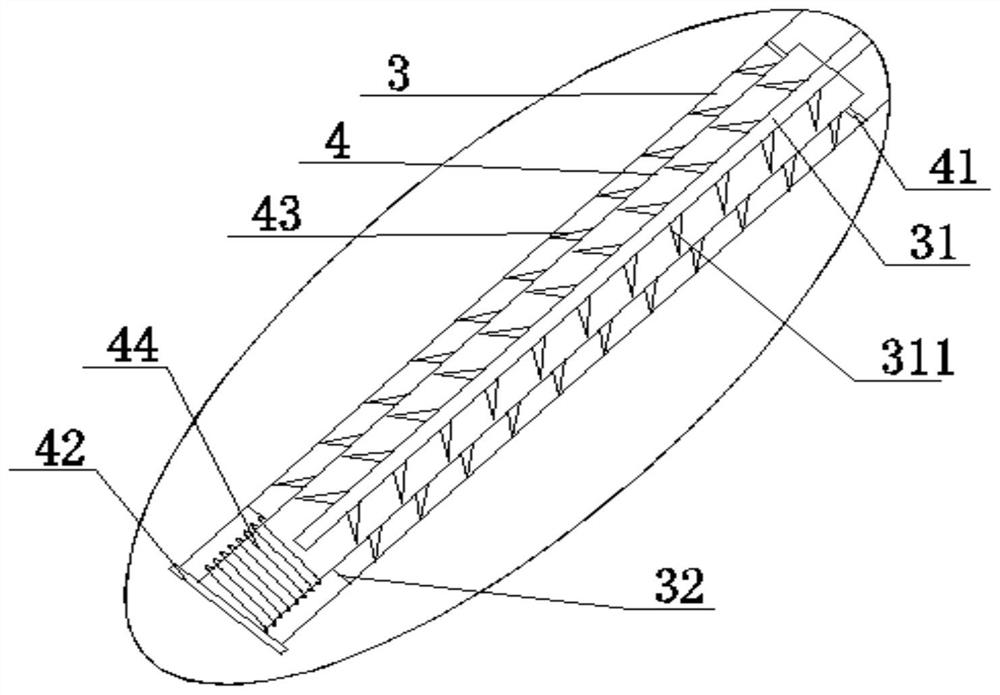

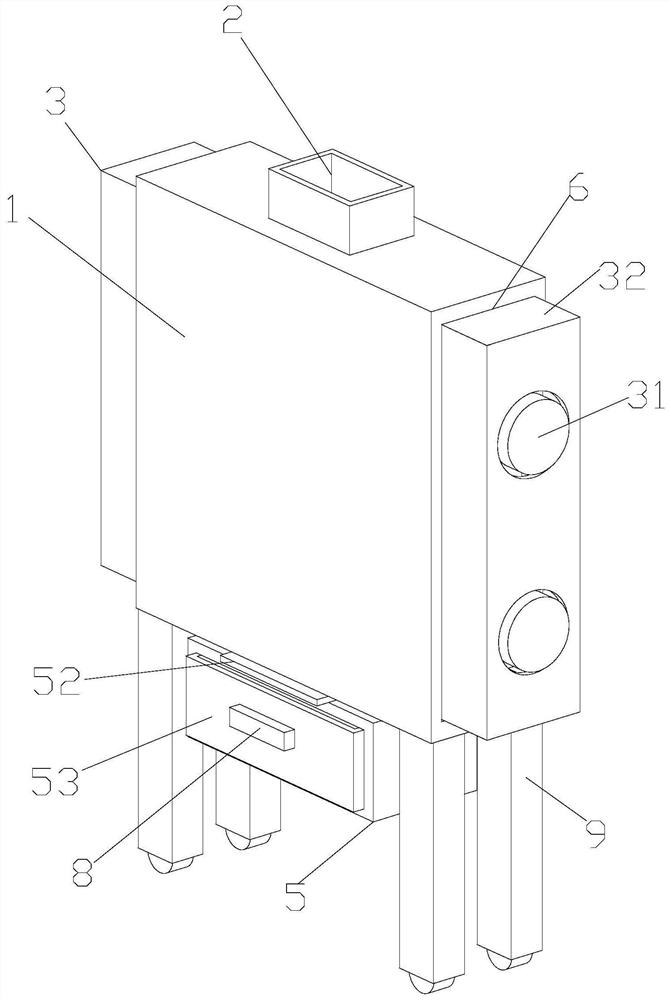

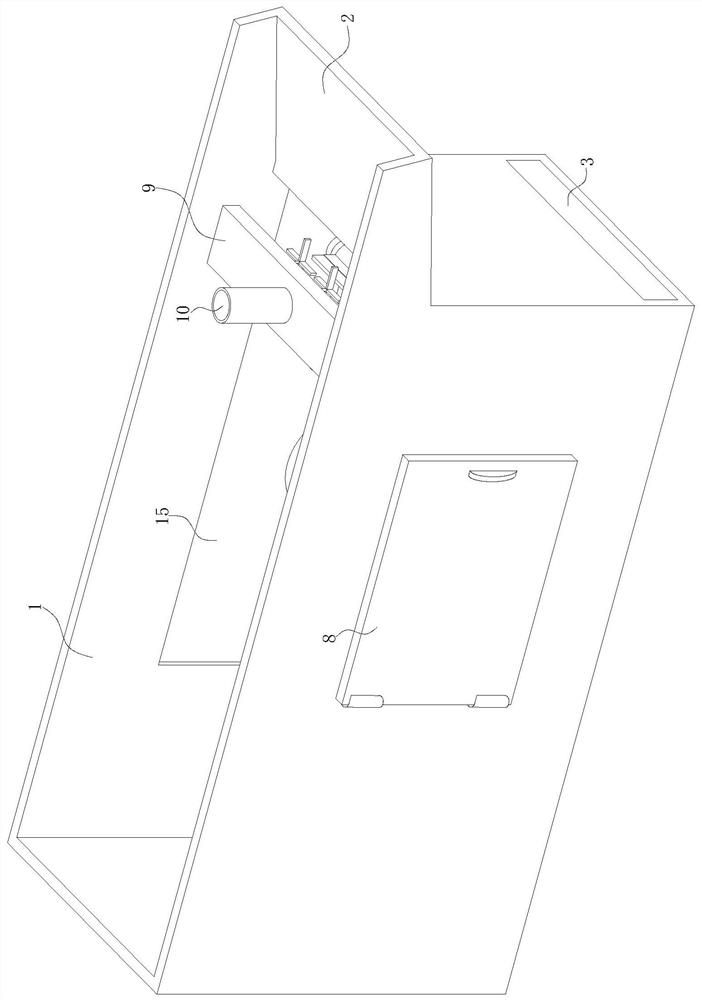

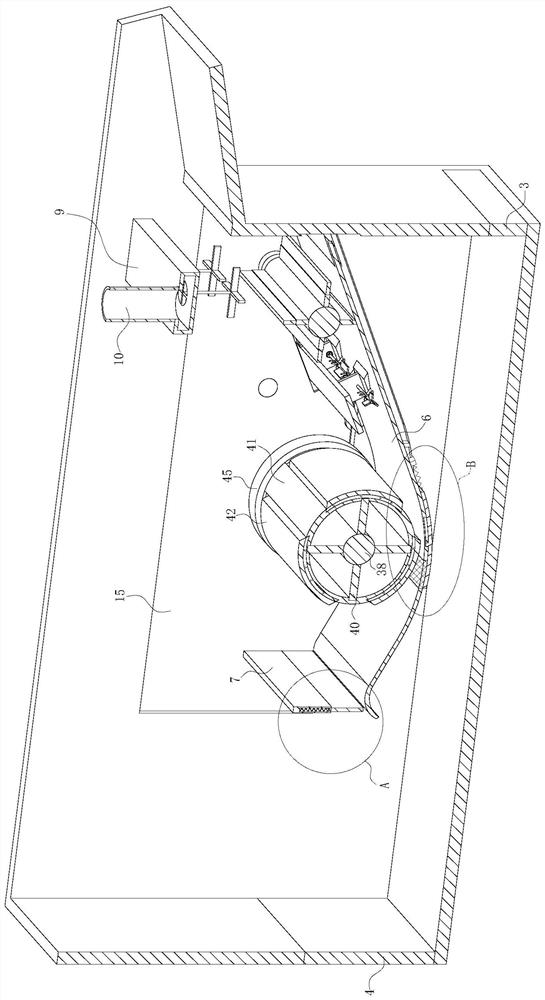

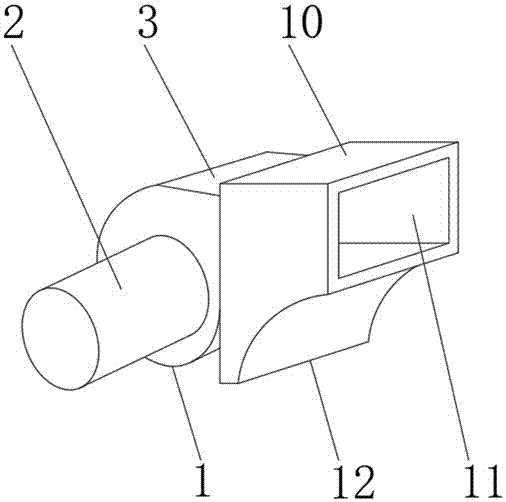

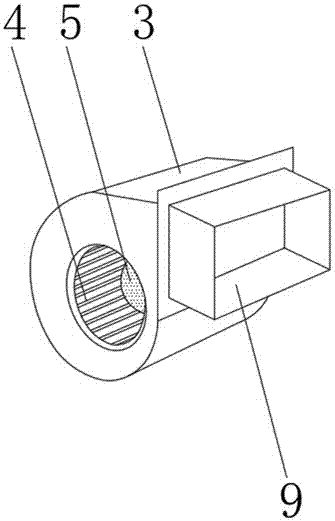

Conveying device for producing dry-mixed mortar powder

InactiveCN112407910AEasy to stir and stirStir wellConveyorsPackagingStructural engineeringMechanical engineering

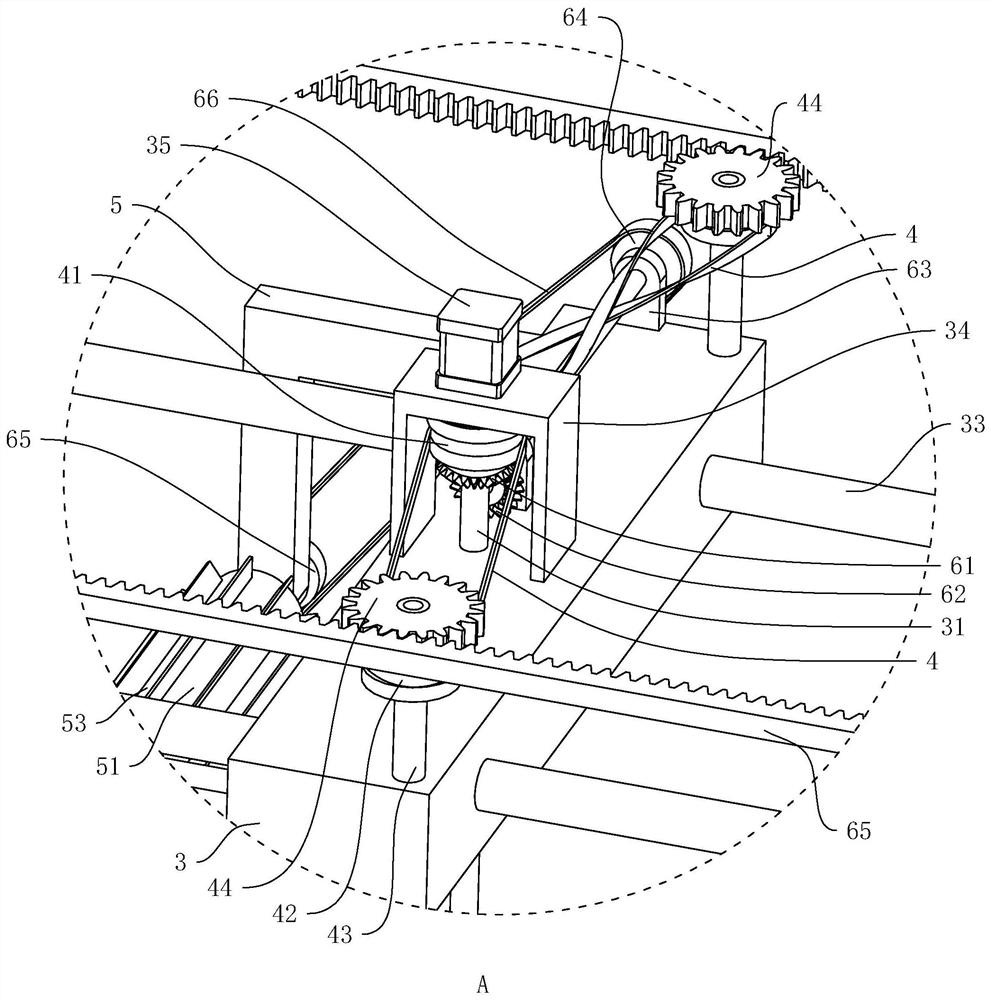

The invention discloses a conveying device for producing dry-mixed mortar powder. The device comprises a base, a transmission assembly, a poking assembly, a stirring mechanism, an adjusting mechanismand a reciprocating mechanism, and a conveying box is arranged on the top surface of the base; a driving box is arranged on the top surface of the base; a discharging box is arranged at one side of the top surface of the conveying box; a rotating cylinder is vertically and rotationally connected into a fixed cylinder through a bearing, the adjusting mechanism is arranged in the rotating cylinder,and the stirring mechanism is arranged in the discharging box; the poking assembly is arranged in a feeding opening; the device is easy to operate, and powder can be conveniently and quantitatively poked and conveyed through the poking assembly; the transmission assembly is arranged at the upper part of one side in the fixed cylinder; through cooperation of the transmission assembly and the stirring mechanism, powder in the discharging box can be stirred and turned conveniently; caked powder can be conveniently stirred and crushed; the reciprocating mechanism is matched with the adjusting mechanism; the powder in the discharging box can be conveniently stirred and turned at different depths; and the problems that in the prior art, powder is prone to accumulation and caking in the conveyingprocess, and blocking is prone to happening are solved.

Owner:潍坊凯速建筑科技有限公司

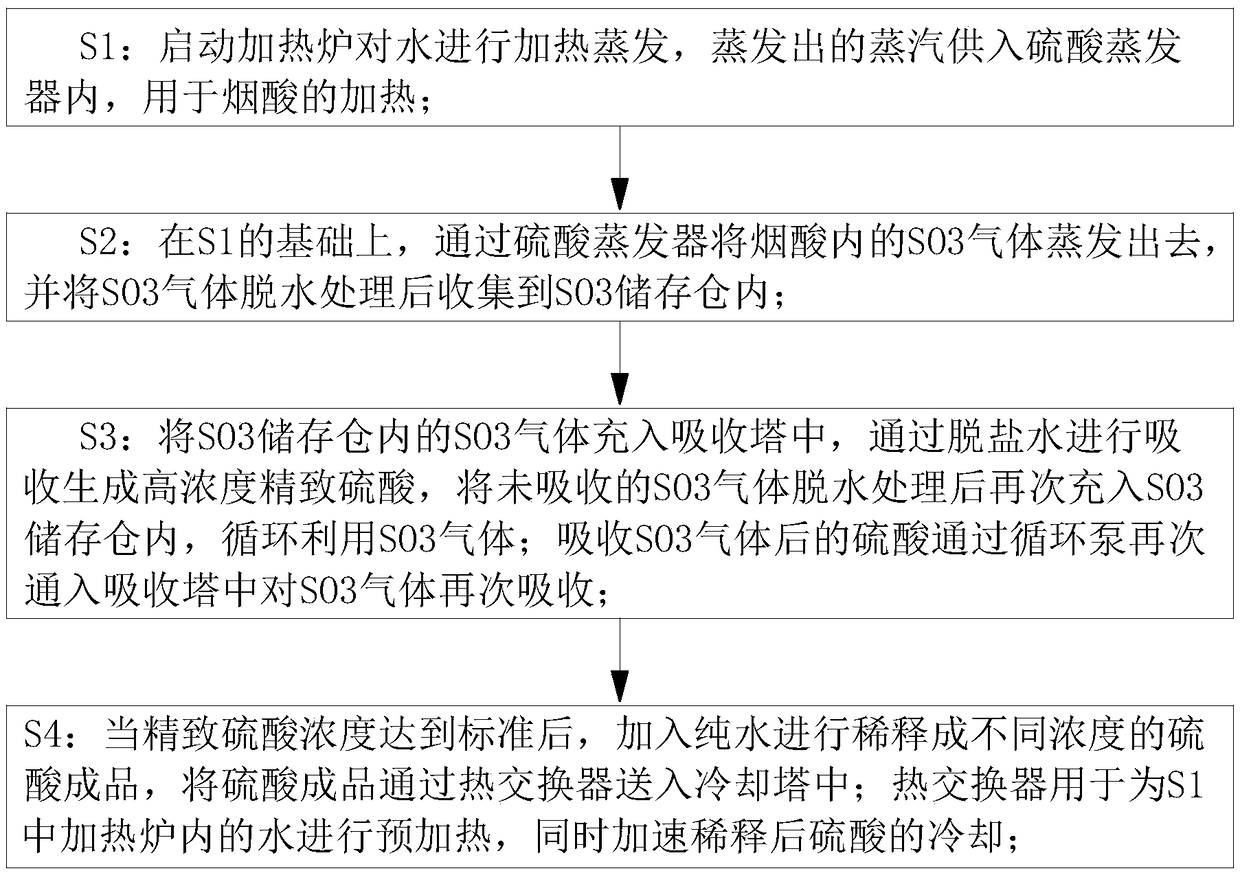

Refined acid production process

ActiveCN109437122AEvaporate evenlySpeed up evaporationSulfur-trioxide/sulfuric-acidCooling towerWater vapor

The invention belongs to the technical field of sulfuric acid production, in particular to a refined acid production process. A sulfuric acid evaporator comprises a nicotinic acid tank, a water vaportank and a bracket, wherein the water vapor tank is arranged on the lower side of the nicotinic acid tank; the nicotinic acid tank is vertically arranged on the ground through the bracket; the insideof the water vapor tank is isolated into a steam bin and a condensate bin by an isolation plate; a steam inlet is formed in the side wall of the steam bin; a condensate outlet is formed in the bottomof the side wall of the condensate bin; a U-shaped tube bundle is arranged in the nicotinic acid tank; sulfuric acid can be diluted into sulfuric acid finished products with different concentrations by adding pure water, and the sulfuric acid finished products are sent into a cooling tower through a heat exchanger; the heat exchanger is used for preheating water in a heating furnace, and accordingly, cooling of diluted sulfuric acid can be accelerated while energy consumed by the heating furnace is reduced, and production speed of refined acid is increased.

Owner:LIANSHI NEW MATERIAL CORP LTD

Environmental monitoring pretreatment digestion device for total nitrogen and total phosphorus analysis

PendingCN113720675AStir wellStir well to mixPreparing sample for investigationTotal nitrogenDigestion

The invention discloses an environmental monitoring pretreatment digestion device for total nitrogen and total phosphorus analysis. The device comprises: a box body, wherein an arc-shaped plate protruding towards the lower side is arranged in the box body, and a working cavity is limited between the arc-shaped plate and the top wall of the box body; and a rotating shaft arranged in the working cavity in the front-back direction, wherein the rear end of the rotating shaft is rotationally connected with the rear side wall in the box body, the front end of the rotating shaft rotationally penetrates through the front side wall of the box body and then is connected with a driving mechanism, the rotating shaft is fixedly sleeved with a branch bracket, the branch bracket is fixedly sleeved with an annular plate, and a plurality of stirring mechanisms are evenly arranged on the annular plate in the circumferential direction. According to the device, mixed liquid in the working cavity can be fully stirred and mixed, and the digestion efficiency of total nitrogen and total phosphorus in water can be improved.

Owner:辽宁通正检测有限公司

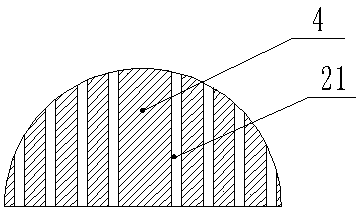

Coating dispersion machine capable of moving left and right

InactiveCN108273431AEvenly dispersedFully dispersedShaking/oscillating/vibrating mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a coating dispersion machine capable of moving left and right. The coating dispersion machine comprises a shell, a feed hopper, a motor and a base; a horizontal sliding chute is formed in the base, a horizontal sliding seat is in sliding connection with the sliding chute, and the shell is located above the sliding seat; a vertical velocity-reducing chamber is communicated in the shell corresponding to the feed hopper; slab stirring blades, a bevel stirring disc and an end cap are orderly arranged on a rotating shaft from bottom to top; the end cap is a semi-sphere, a plurality of vertically downward unloading holes are further formed in the end cap, and a vertical push plate is fixed on the tail end of a connecting rod. The falling speed of a coating in the velocity-reducing chamber can be blocked by the end cap arranged at the lower end of the velocity-reducing chamber, thus a part of the coating can fall down from the unloading holes in the end cap, the end cap is rotated to drive the coating in the unloading holes to horizontally and centrifugally move, thereby outward flying; the coating is uniformly dispersed in the shell, the upper surface of the bevelstirring disc is bevel, and the stirring range can be increased in the stirring.

Owner:盐城元之元机械有限公司

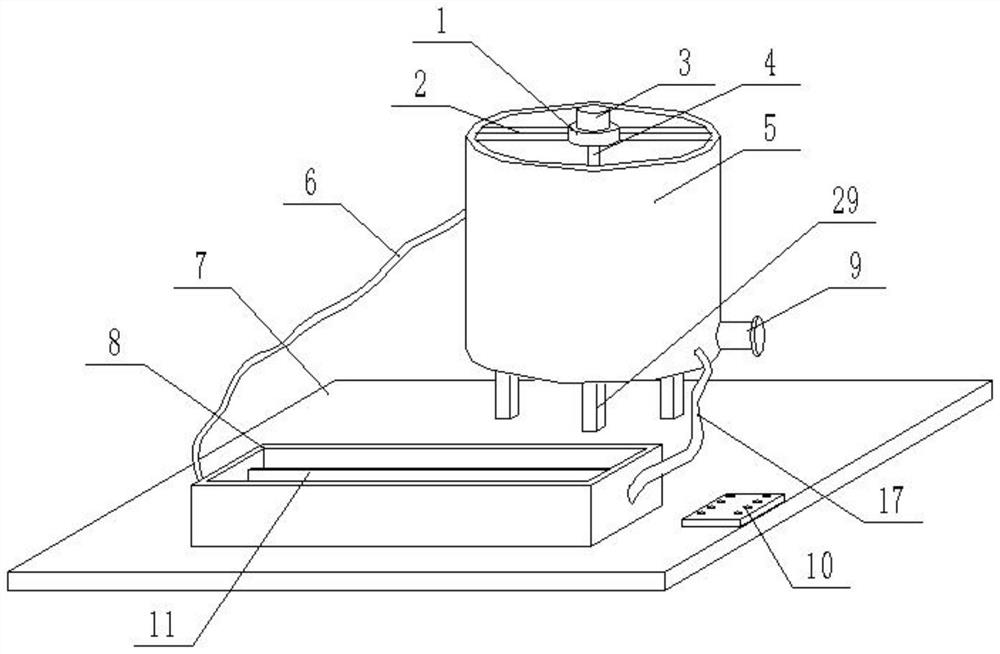

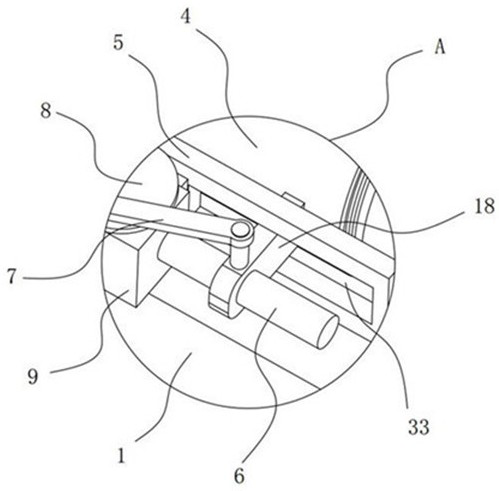

Household bread maker

The invention relates to the technical field of household equipment, and discloses a household bread maker which comprises an outer box, a dough kneading device and a control system, a motor is fixedly mounted at the lower corner of the right side of an inner cavity of the outer box, a heating ring is fixedly mounted in the middle of the inner cavity of the outer box, and the control system is fixedly mounted in the outer box. Through the arrangement of a spacer bush and a pressurizing device, water in a water tank is conveyed into the water tank to cool the inner wall of a dough kneading barrel, and the dough is cooled through the dough kneading barrel, so that the temperature of the dough is effectively prevented from exceeding the standard, the taste of the baked bread is improved, thedough can be continuously stirred, the dough forming efficiency is effectively improved, bread making time is shortened, meanwhile, when the fermented dough is baked by the heating ring, heat is intercepted by a cavity between the spacer bush and the dough kneading device, so that the dough kneading barrel is heated after the heat is uniformly distributed in the spacer bush, and uniform baking ofthe surface of the bread is ensured.

Owner:吴廷琴

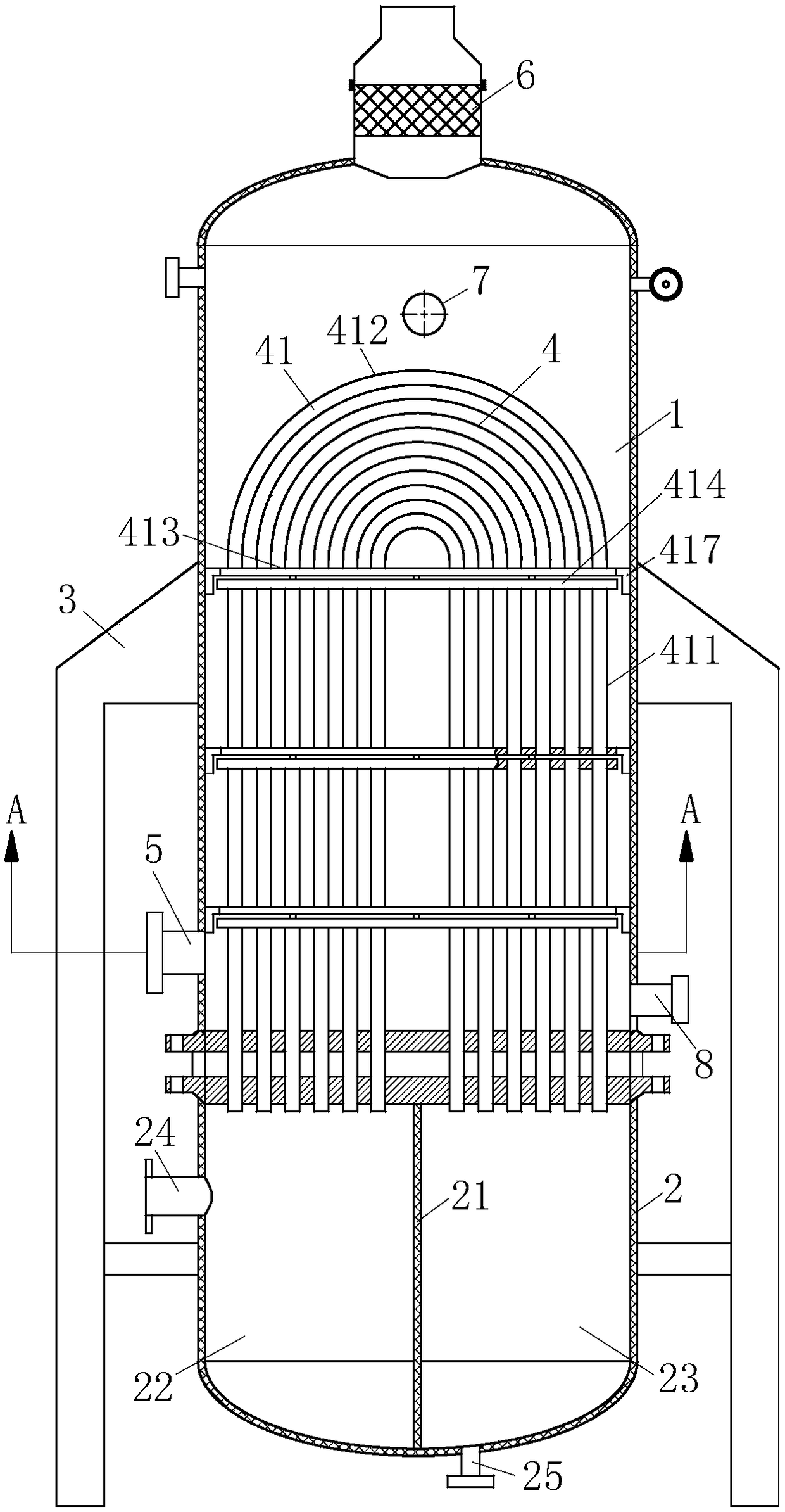

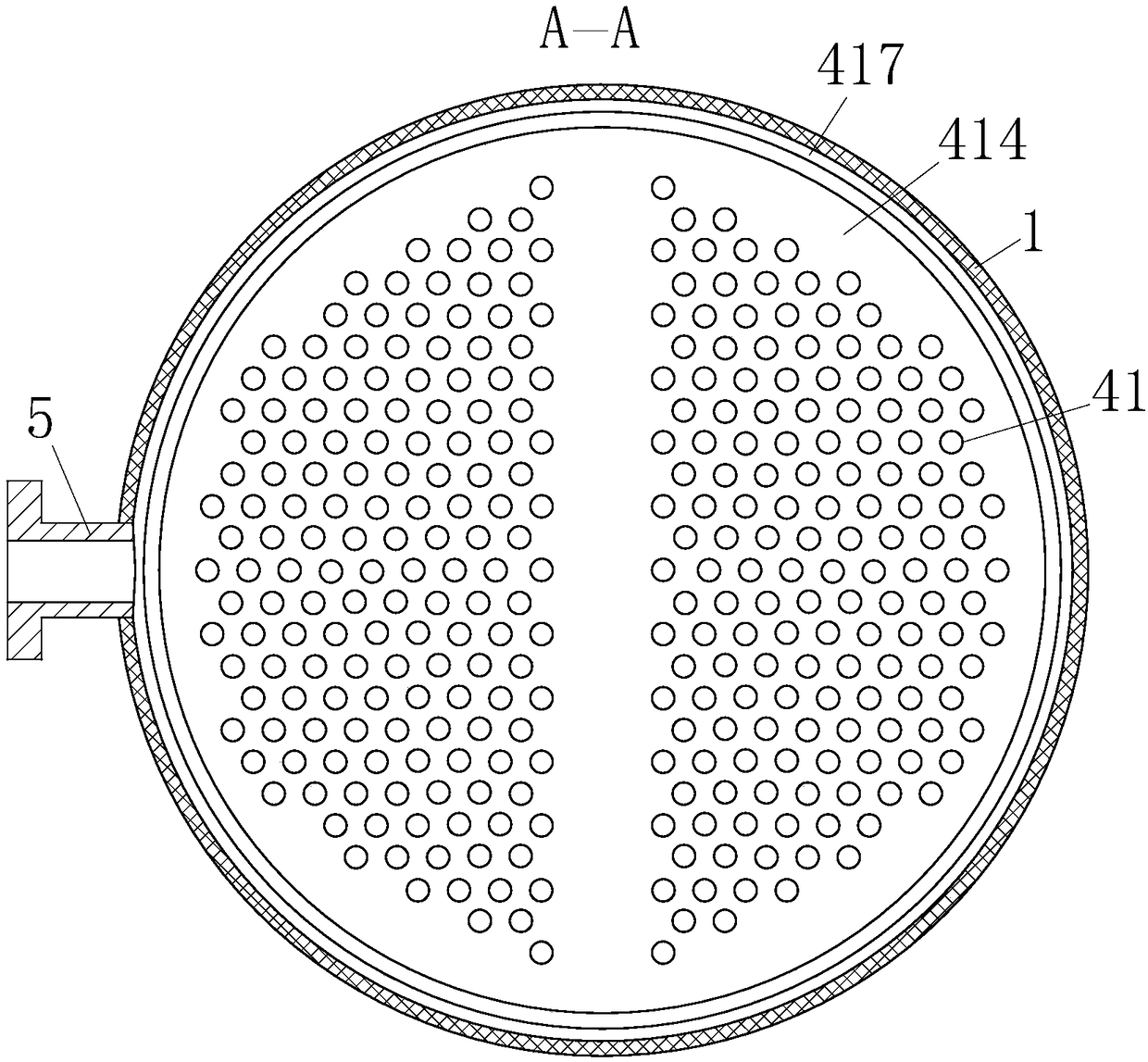

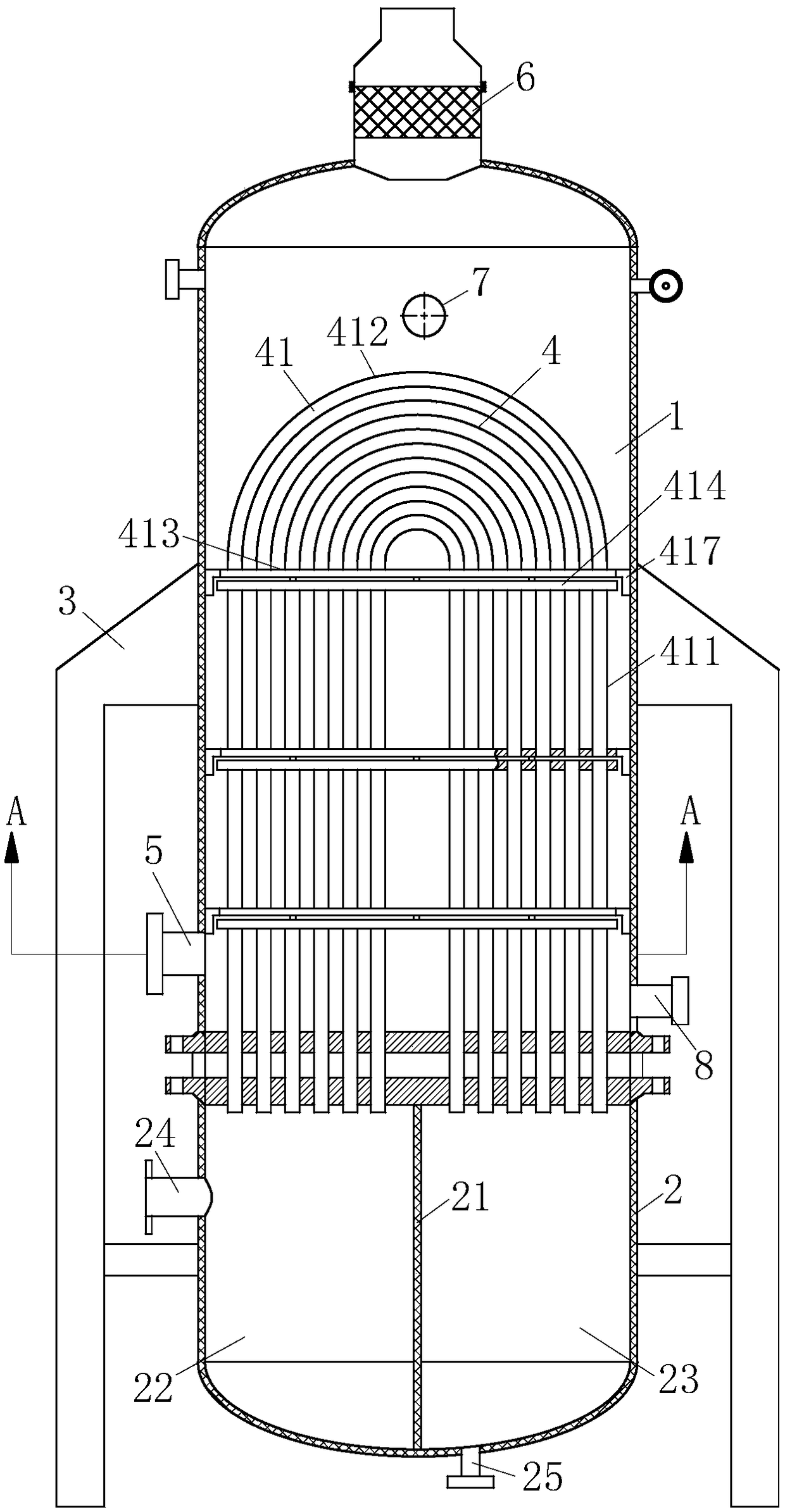

Sulfuric acid evaporator

InactiveCN109364503AEvaporate evenlySpeed up evaporationEvaporator accessoriesSulfur compoundsNicotinic AcidsChemistry

The invention belongs to the technical field of sulfuric acid production equipment, and particularly relates to a sulfuric acid evaporator. The sulfuric acid evaporator comprises a nicotinic acid tank, a water vapour tank and a support; the water vapour tank is arranged on the lower side of the nicotinic acid tank; the nicotinic acid tank is vertically arranged on the ground through the support; the interior of the water vapour tank is divided into a steam bin and a condensation bin by a partition board; a steam inlet is formed in the side wall of the steam bin; a condensate water outlet is formed in the bottom of the side wall of the condensation bin; through cooperation of each straight pipe, each curved pipe, a first round disk and a second round disk, a corresponding U-shaped pipelineprovided with multiple gaps is formed, so that the problem of exorbitant cost caused by using an overlong U-shaped pipeline is avoided; by forming the 0.01-mm gaps in the U-shaped pipelines, by meansof vomited steam, on one hand, nicotinic acid can be prevented from flowing into the U-shaped pipelines, so that a sealing effect is achieved, and on the other hand, the nicotinic acid can be stirredto make the nicotinic acid evenly evaporated.

Owner:广德县桃州镇明莲蔬果种植家庭农场

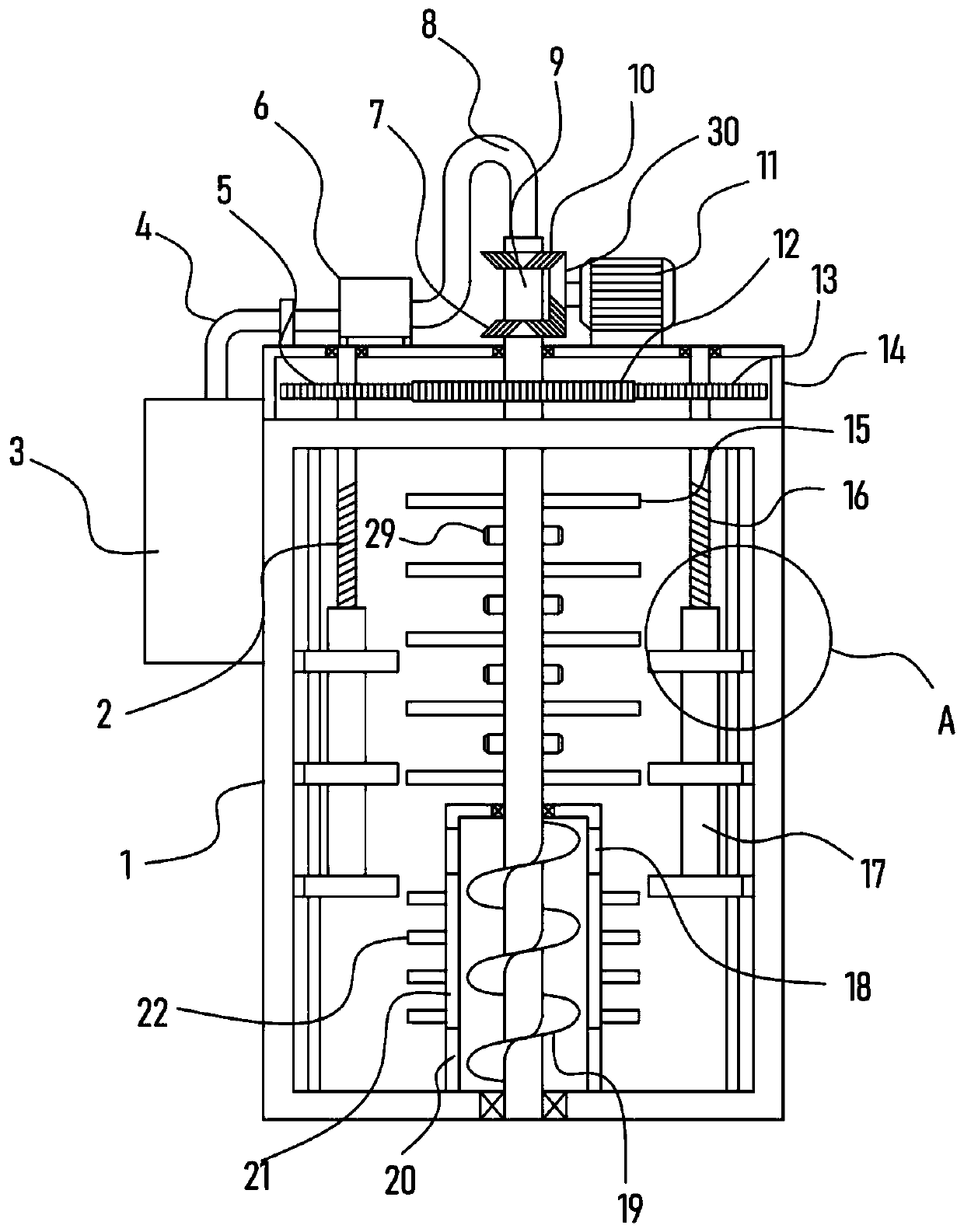

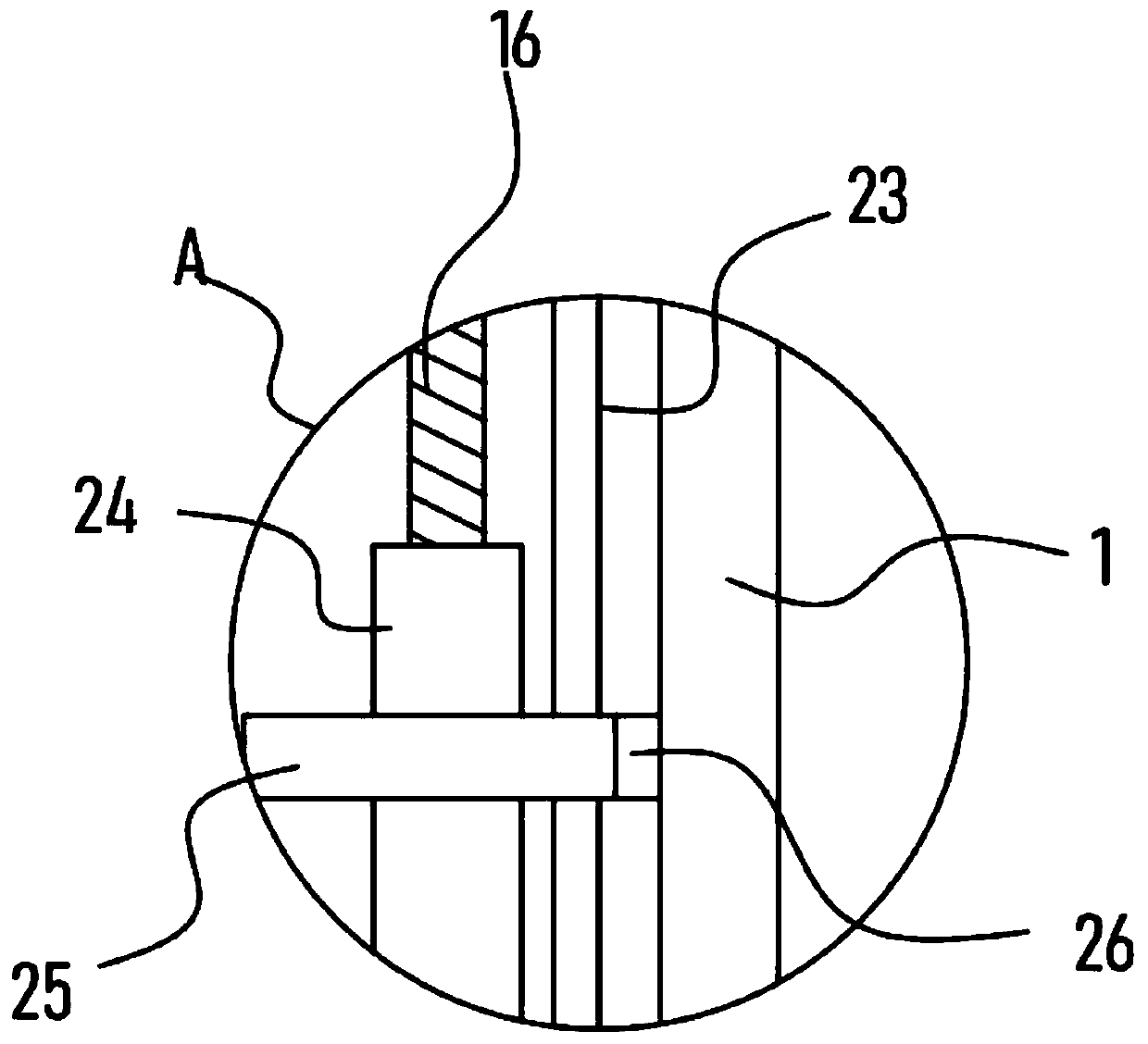

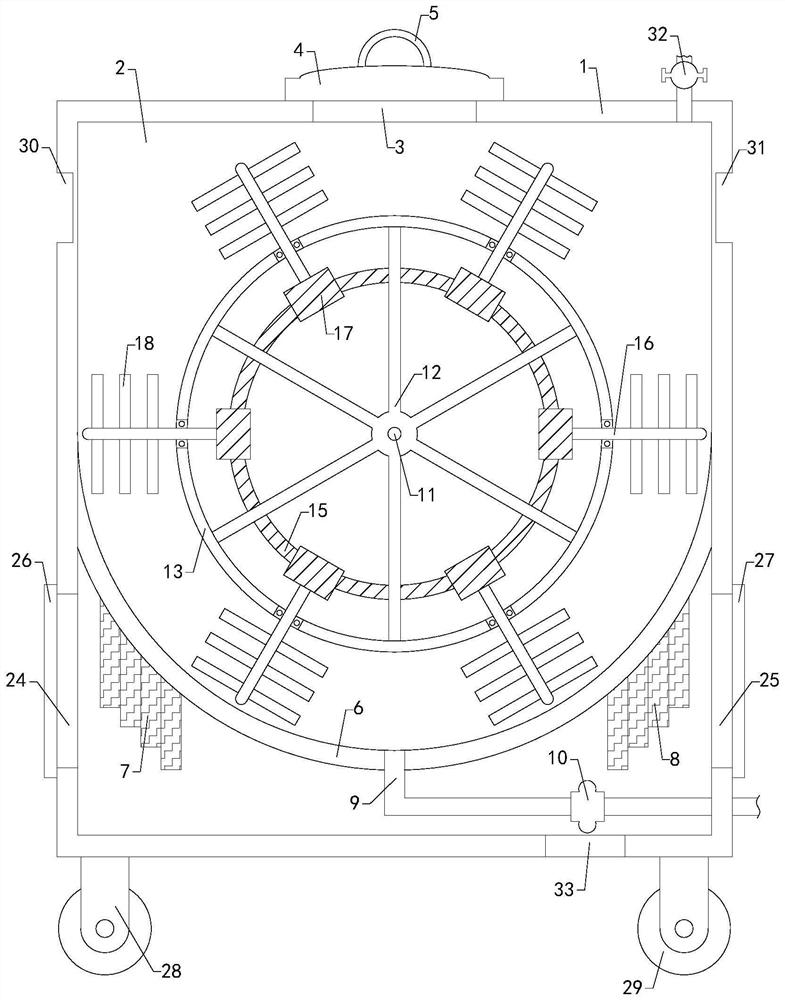

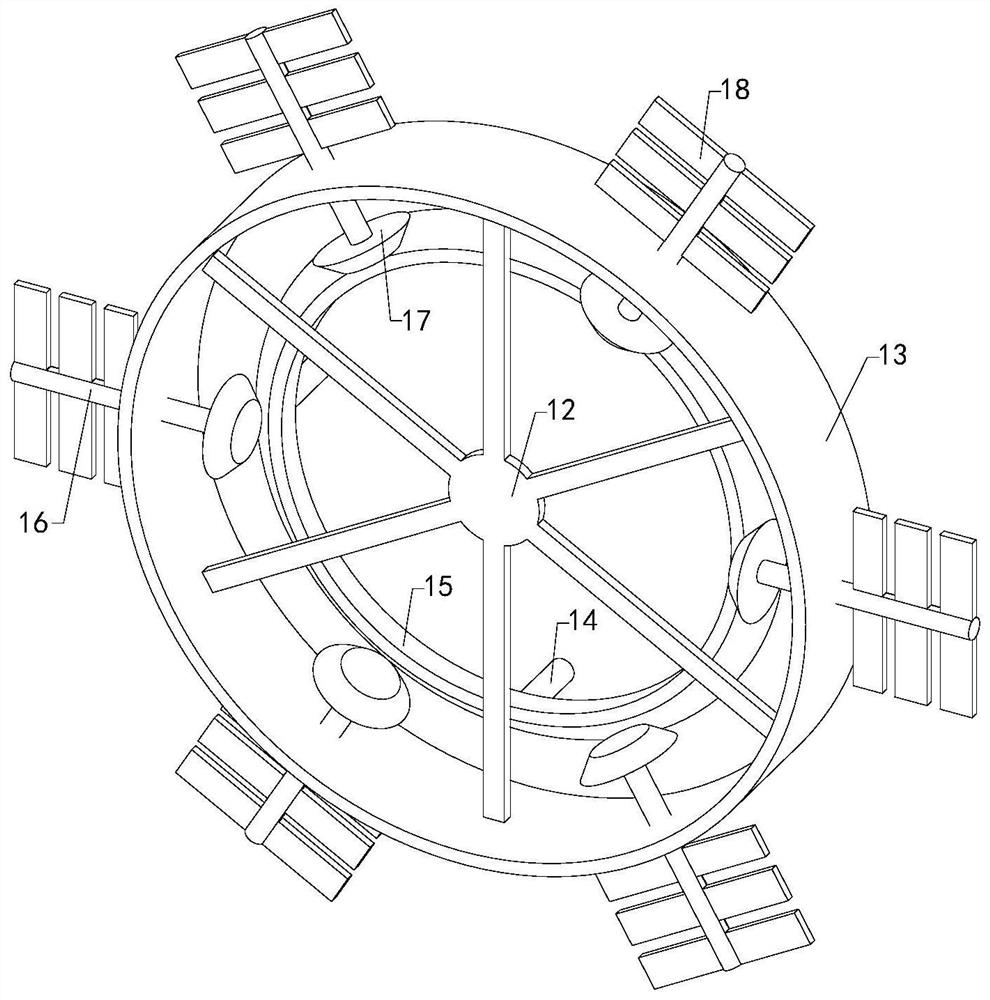

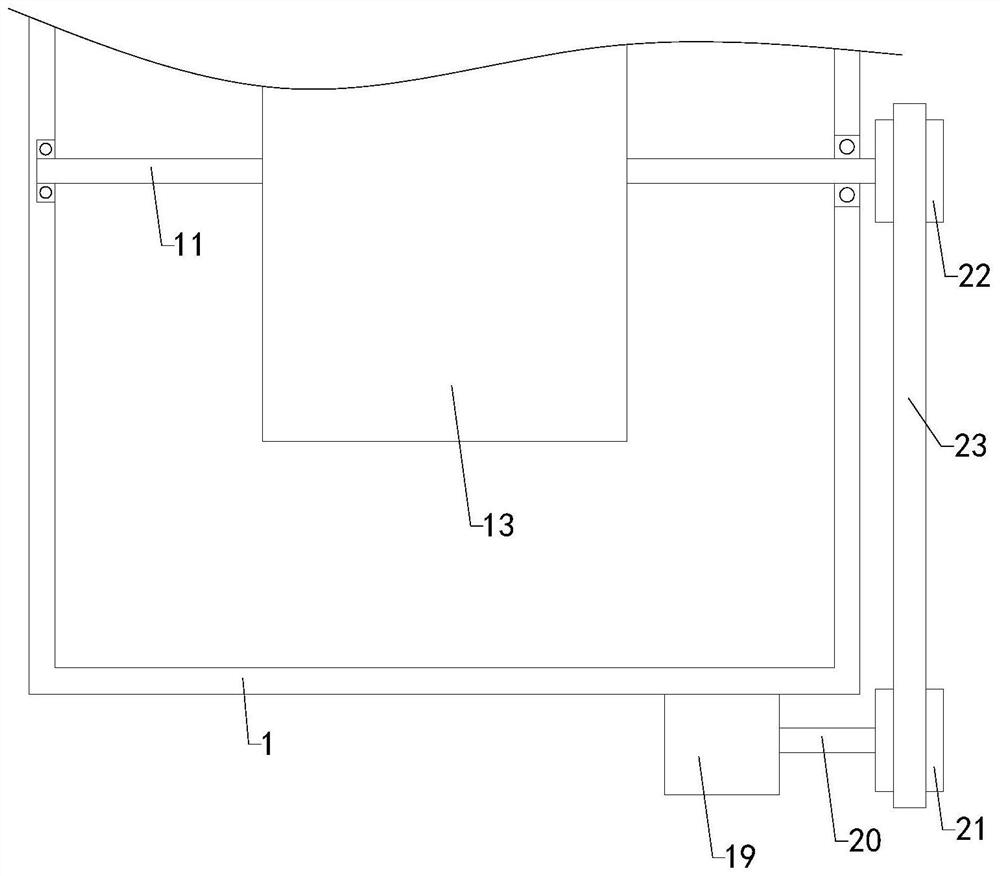

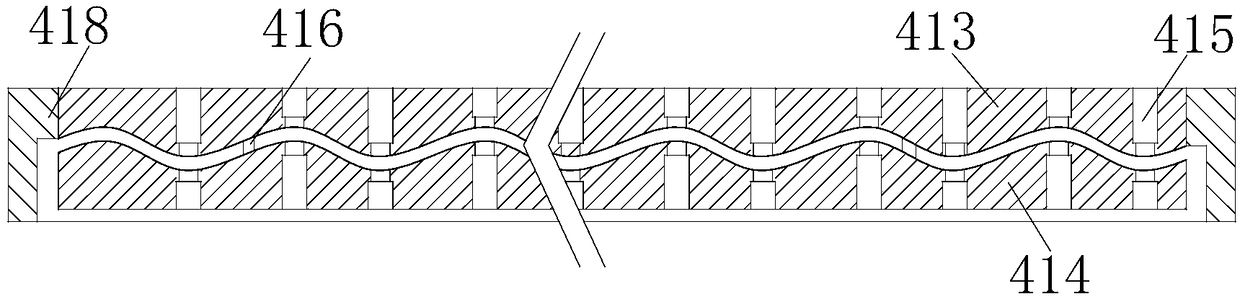

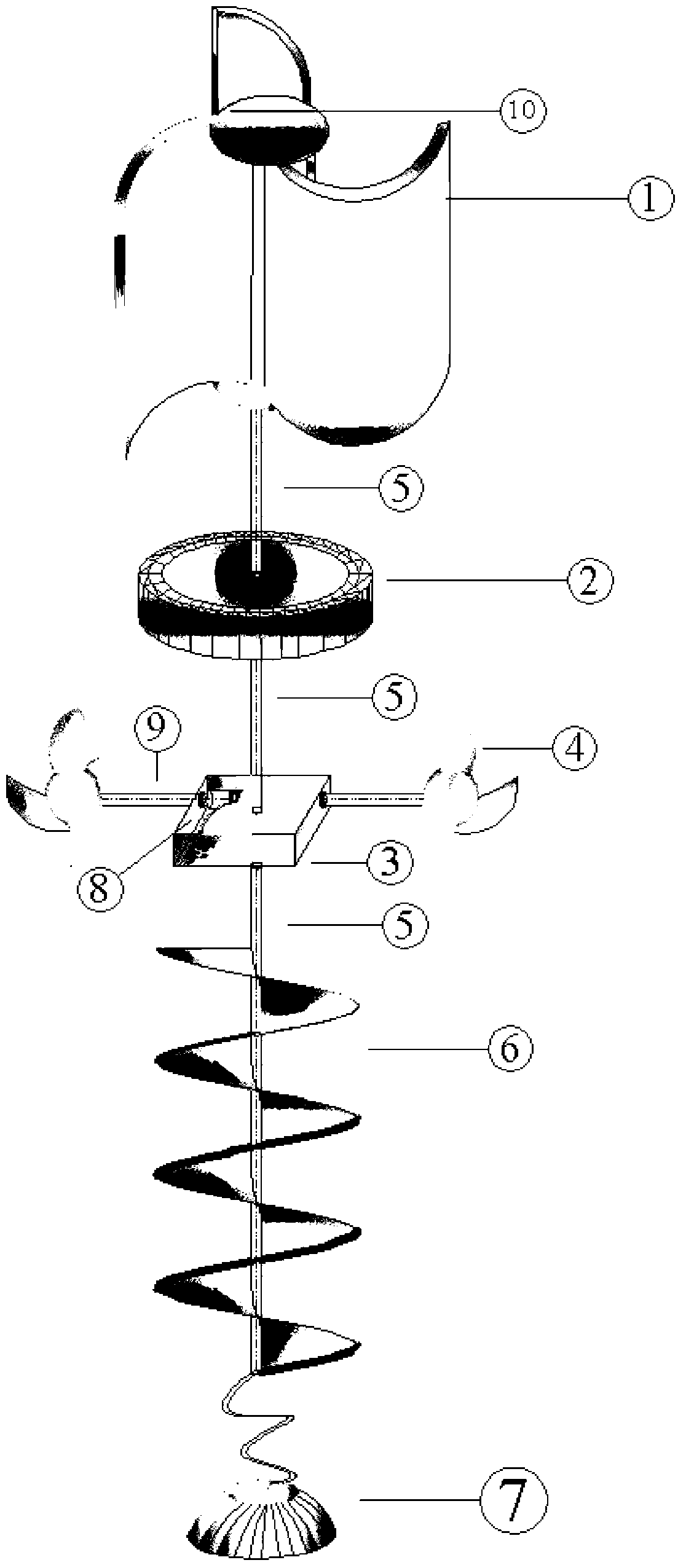

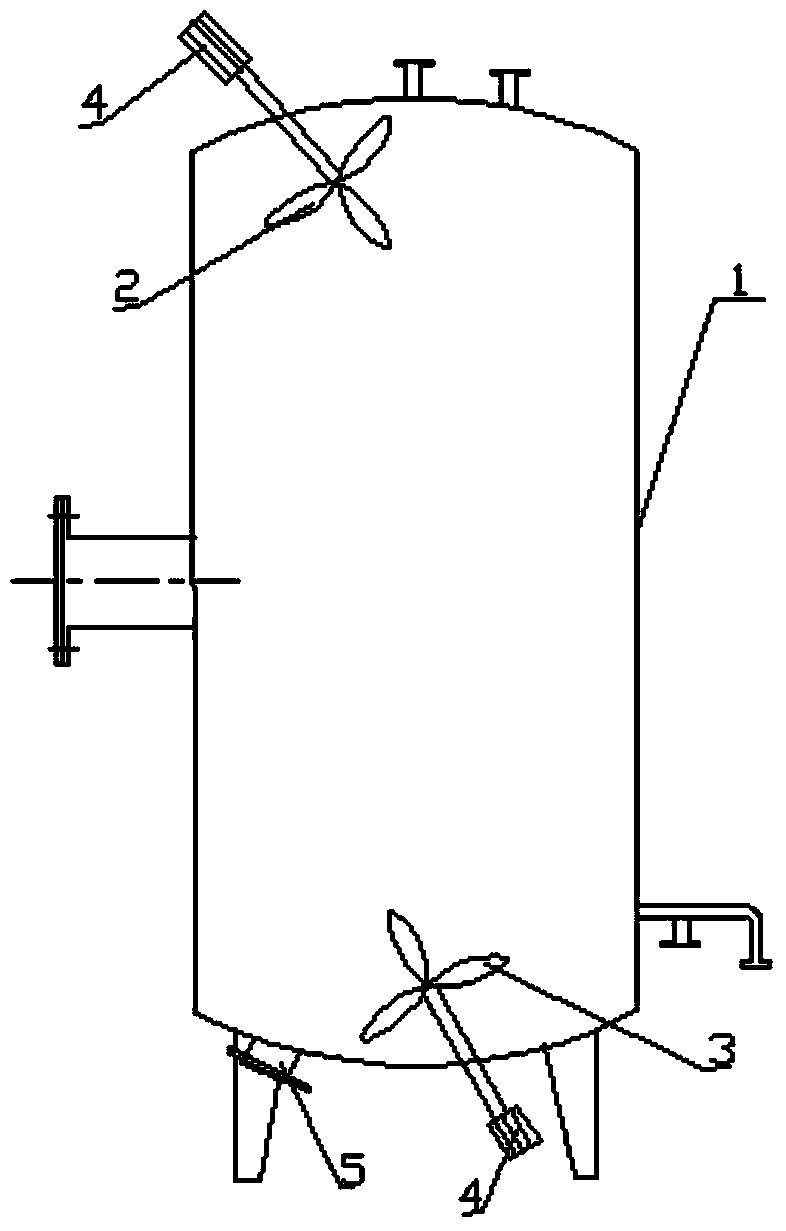

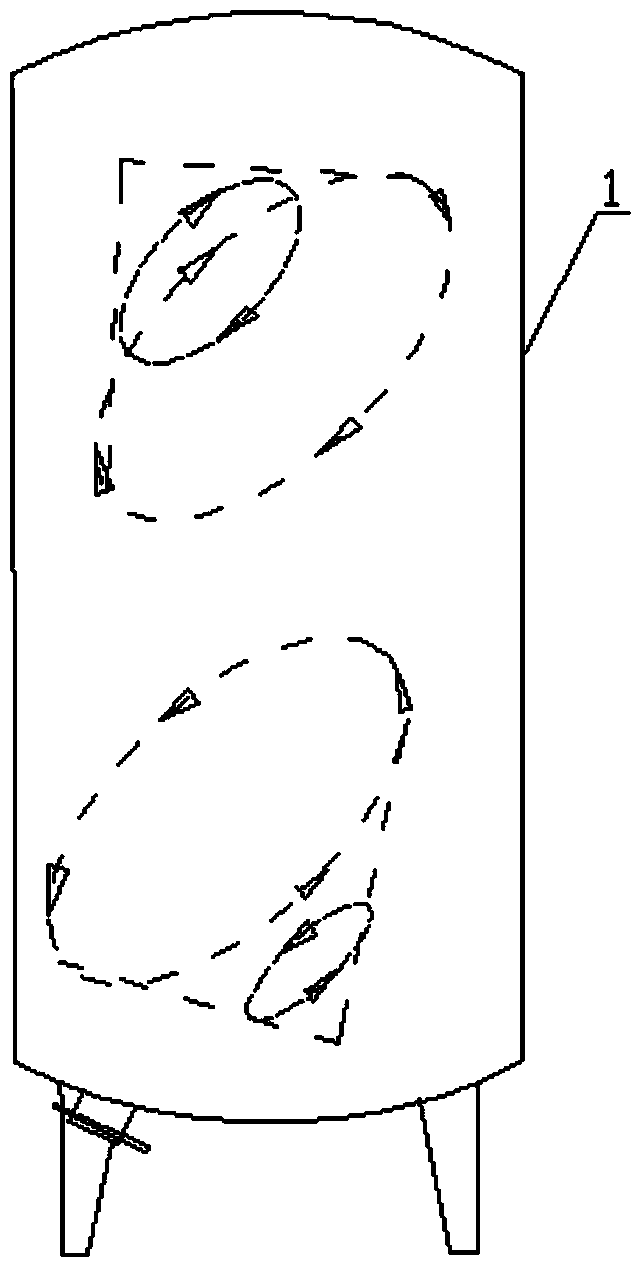

Wind power directly-driven circulated oxygen inflating equipment

ActiveCN102765823BIncrease the stirring areaIncrease agitation rangeWater aerationSustainable biological treatmentWater qualityEngineering

The invention relates to wind power directly-driven circulated oxygen inflating equipment comprising a vertical force transmission shaft, wherein a wind wheel, a floating system, a gear switching device, a water lifting worm wheel and a fixing block are sequentially arranged on the vertical force transmission shaft from top to bottom, wherein the gear switching device comprises a gear box and the gear box is internally provided with a main gear and a secondary gear; the main gear is connected with the vertical force transmission shaft; the secondary gear is connected with a transverse force transmission shaft; and two ends of the transverse force transmission shaft are provided with a pair of flow pushing impellers with blades in opposite directions. According to the equipment disclosed by the invention, the wind wheel rotates under the effect of wind power to convert wind energy into power; a bottom water body is upwards circulated through transmitting force by an axial agitating worm wheel and the water lifting worm wheel of the vertical force transmission shaft; and shallow-layer water is transversely dispersed under the effect of the agitating worm wheel to be exchanged with a surface layer water body, so that large-area water body disturbance is realized. The wind power directly-driven circulated oxygen inflating equipment has the advantages of simple structure, compact arrangement, convenience for operation and energy source saving, and is suitable for improving the water quality of a river and a water pond.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

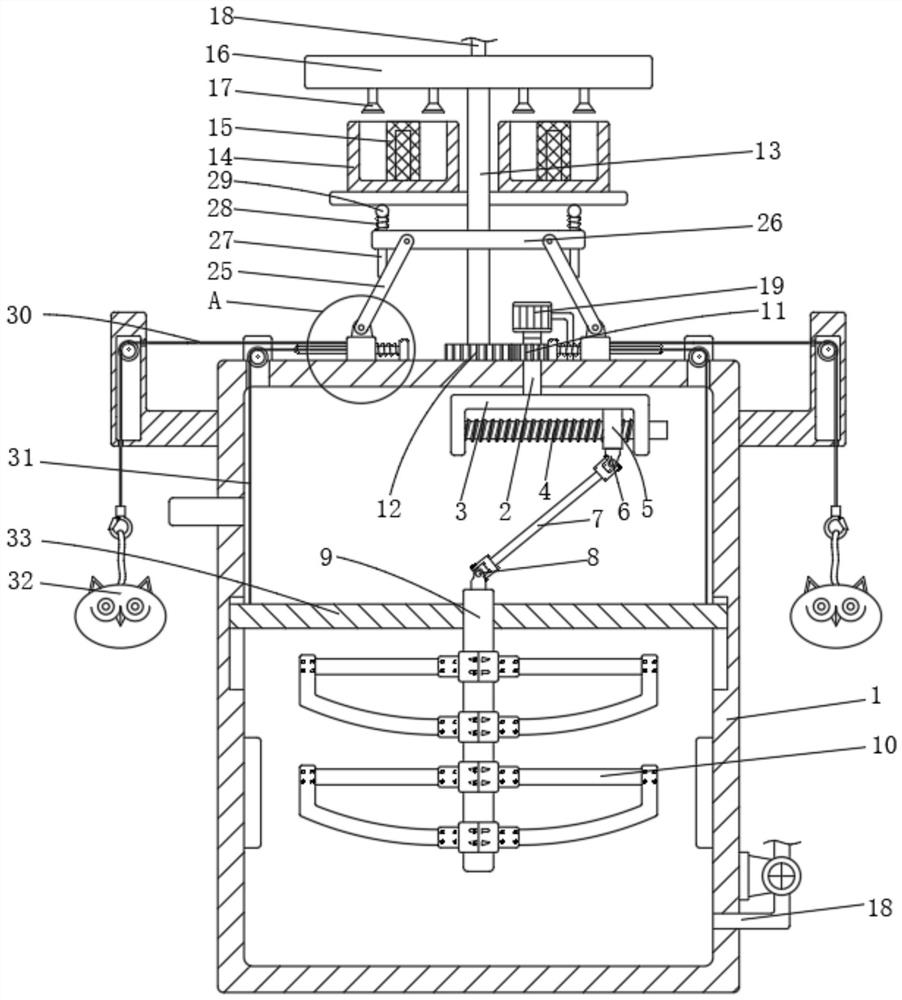

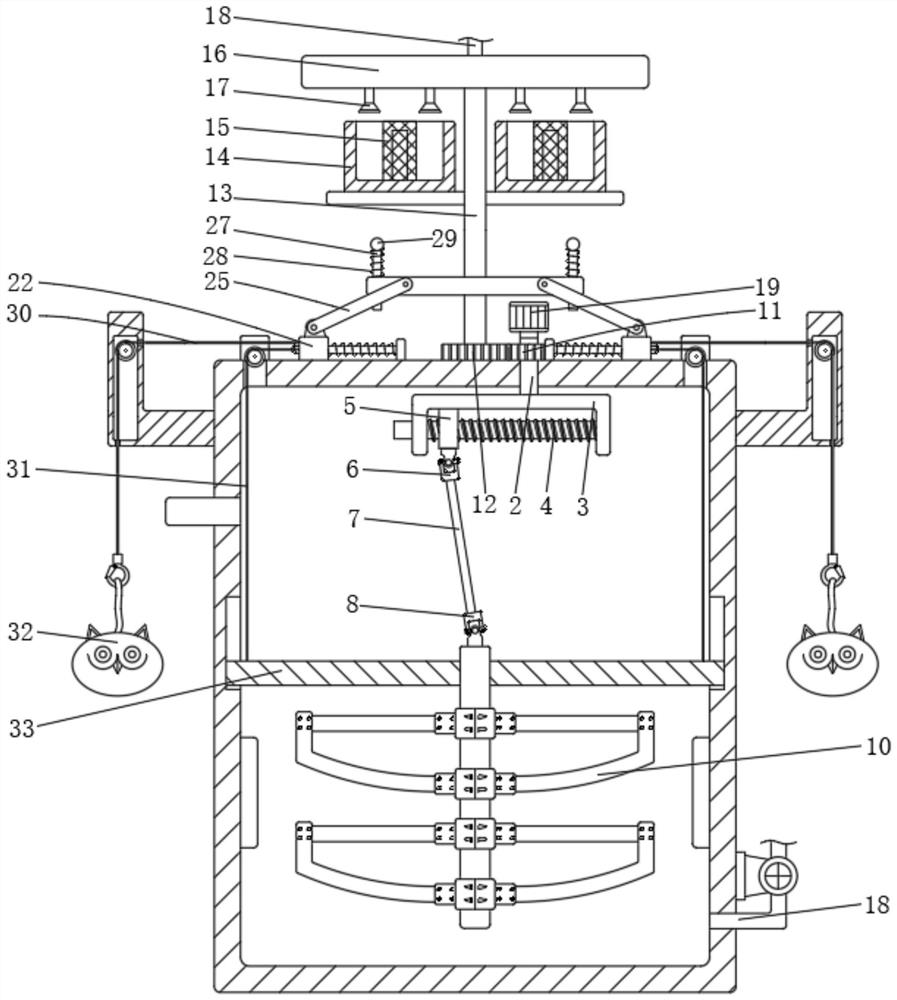

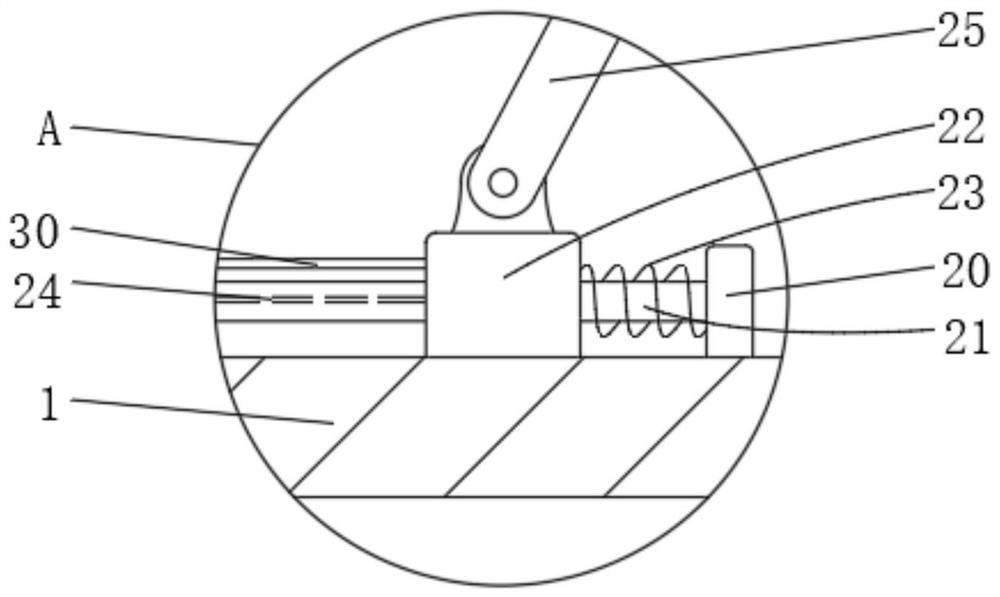

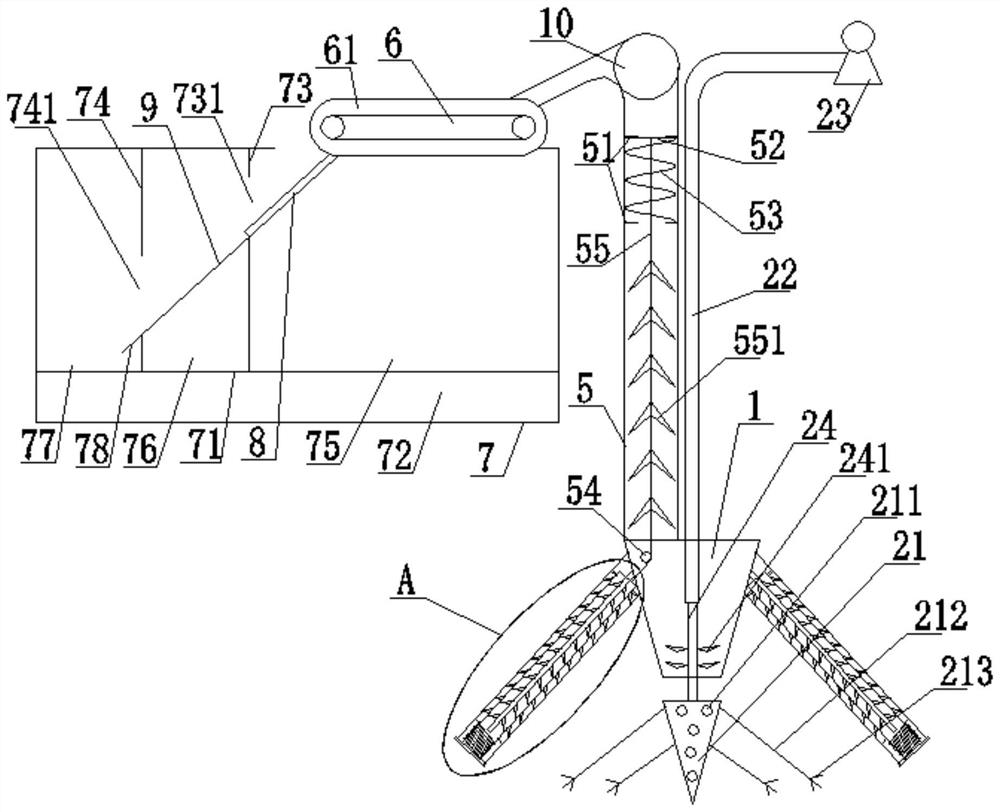

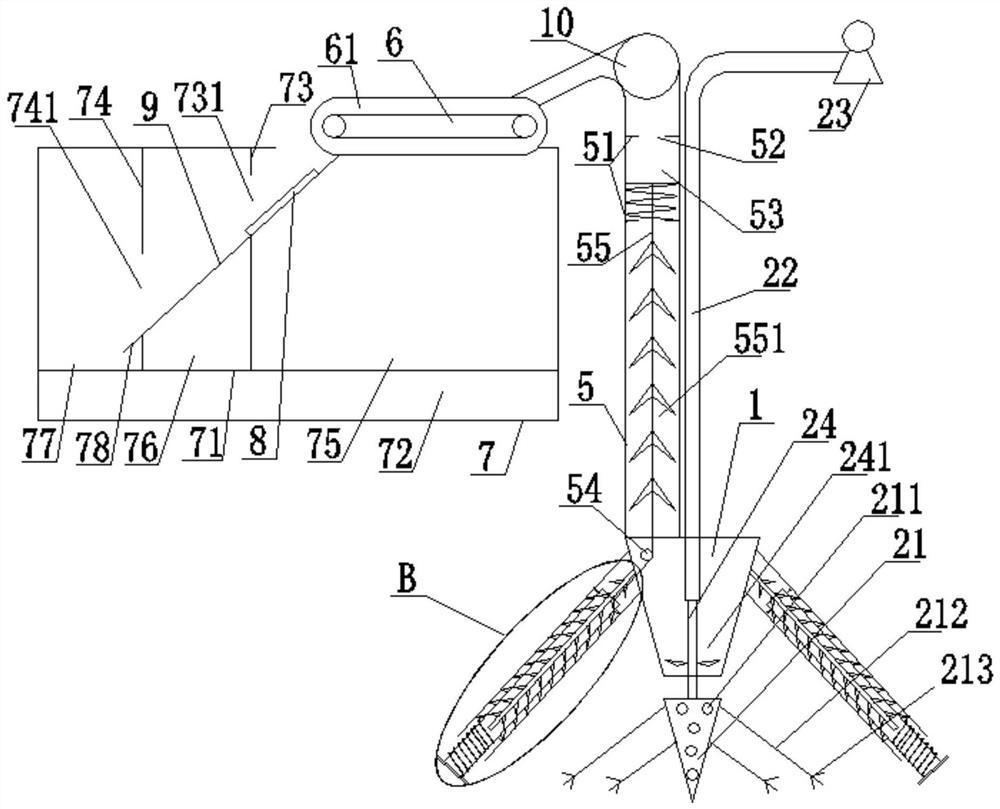

Environment-friendly agricultural deinsectization device

ActiveCN113875714AGuarantee the quality of workPrevents reduction in pest control efficiencyAnimal repellantsCleaning processes and apparatusAgricultural scienceAgricultural engineering

The invention discloses an environment-friendly agricultural deinsectization device, and relates to the technical field of deinsectization devices. The environment-friendly agricultural deinsectization device comprises a box body and a first rotating shaft, the box body is provided with a driving part for driving the first rotating shaft to rotate, a second rotating shaft is fixedly and rotatably connected with the upper surface of the box body, and a deinsectization box is fixedly mounted on the surface of the second rotating shaft; a baffle is fixedly connected to the upper surface of the box body, a guide rod is fixedly connected to the side face of the baffle, a moving block sleeves the surface of the guide rod, a rotating plate is hinged to the surface of the moving block, and a beating part used for making the deinsectization box vibrate is arranged on the rotating plate; and a transmission part used for driving a sliding plate to reciprocate up and down is arranged on the first rotating shaft. The environment-friendly agricultural deinsectization device has the effects that the rotating plate rotates to drive a sleeve block to perform up-and-down reciprocating translation movement, so that a knocking block is driven to perform up-and-down reciprocating translation movement to knock the deinsectization box, the deinsectization box vibrates, insect corpses on the surface of the deinsectization box are vibrated off, the situation that the subsequent deinsectization efficiency is reduced due to excessive accumulation of the insect corpses is prevented, and the deinsectization quality is guaranteed.

Owner:新疆傲阳科技有限公司

Gypsum proportioning equipment

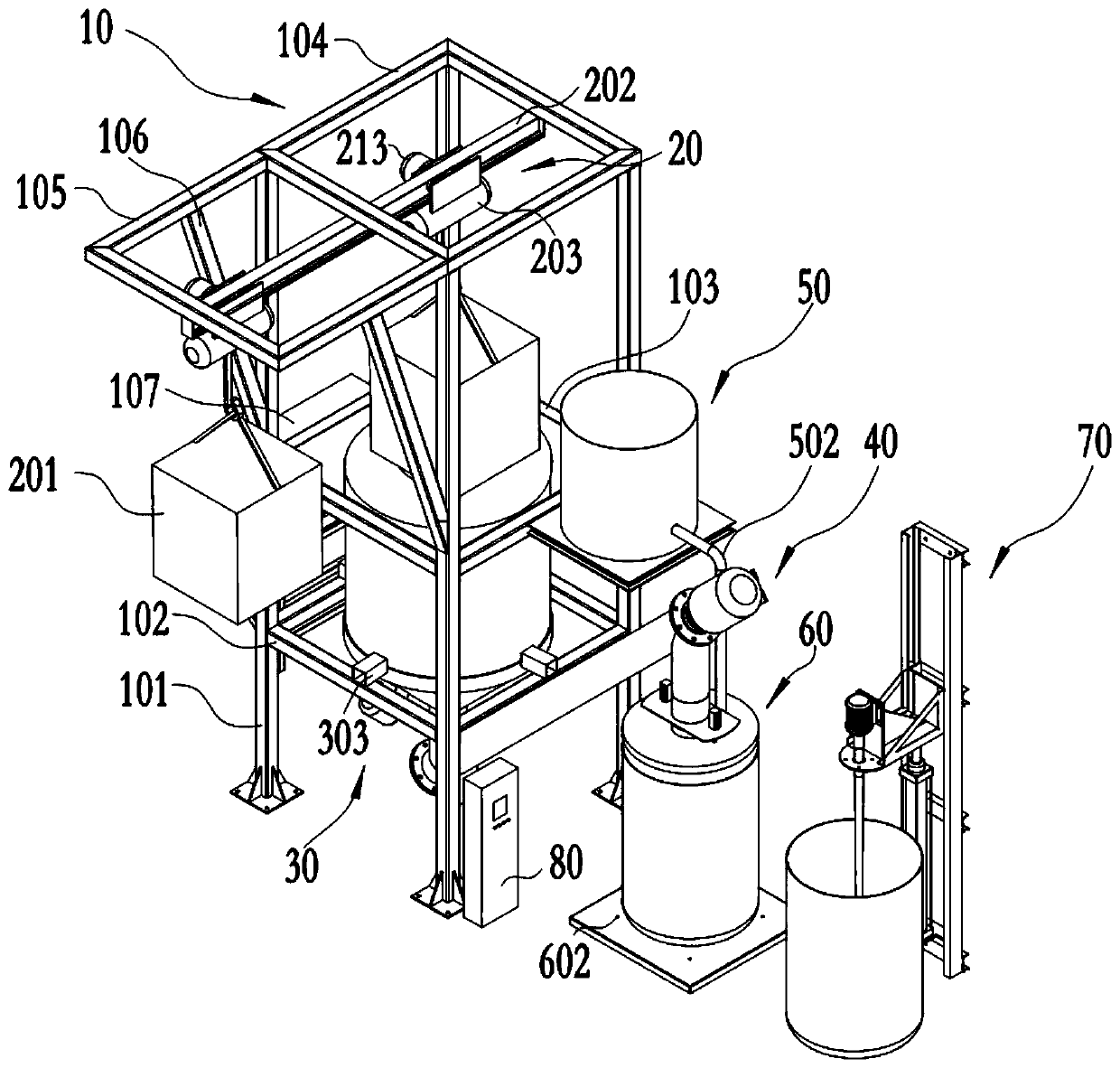

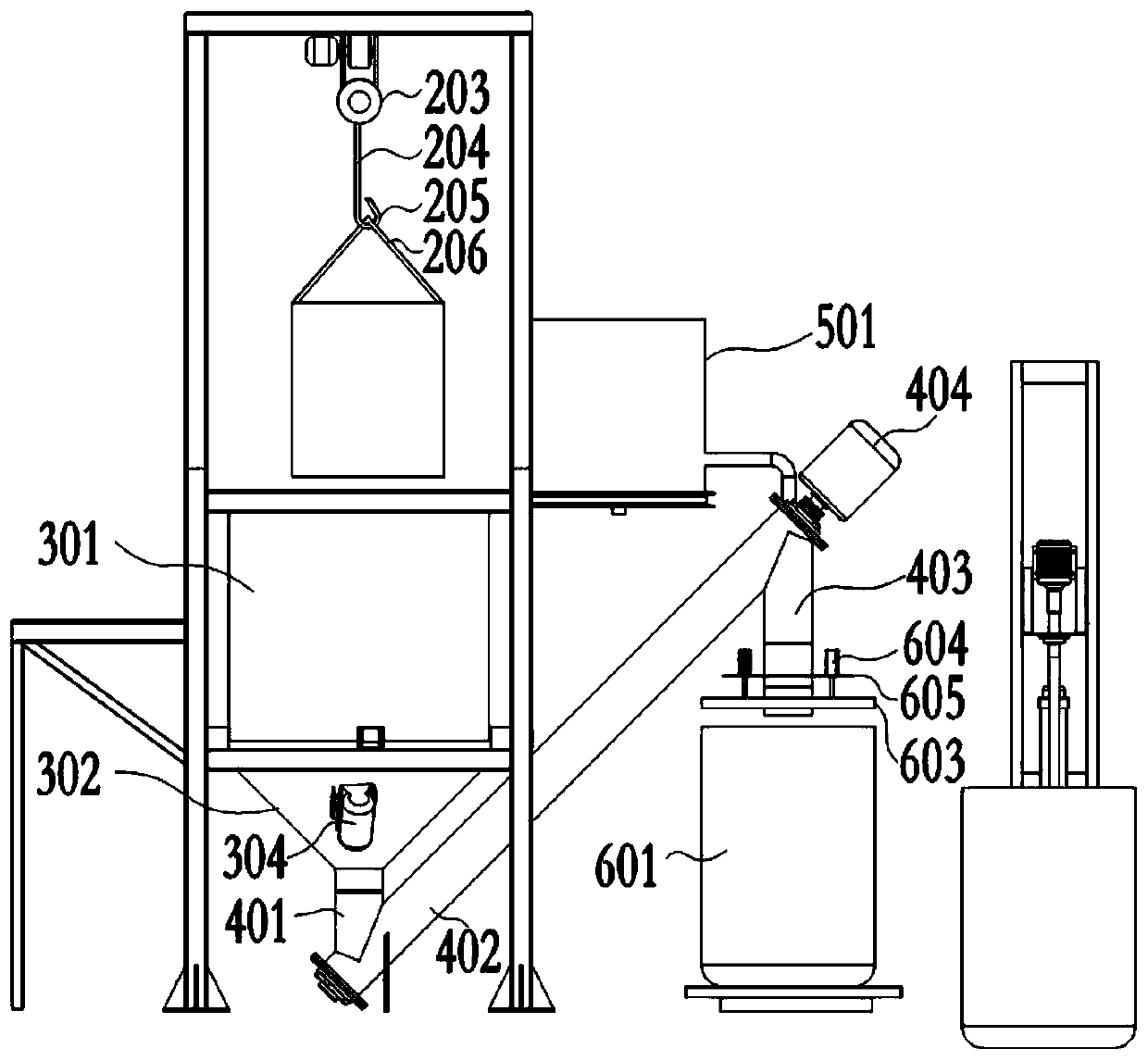

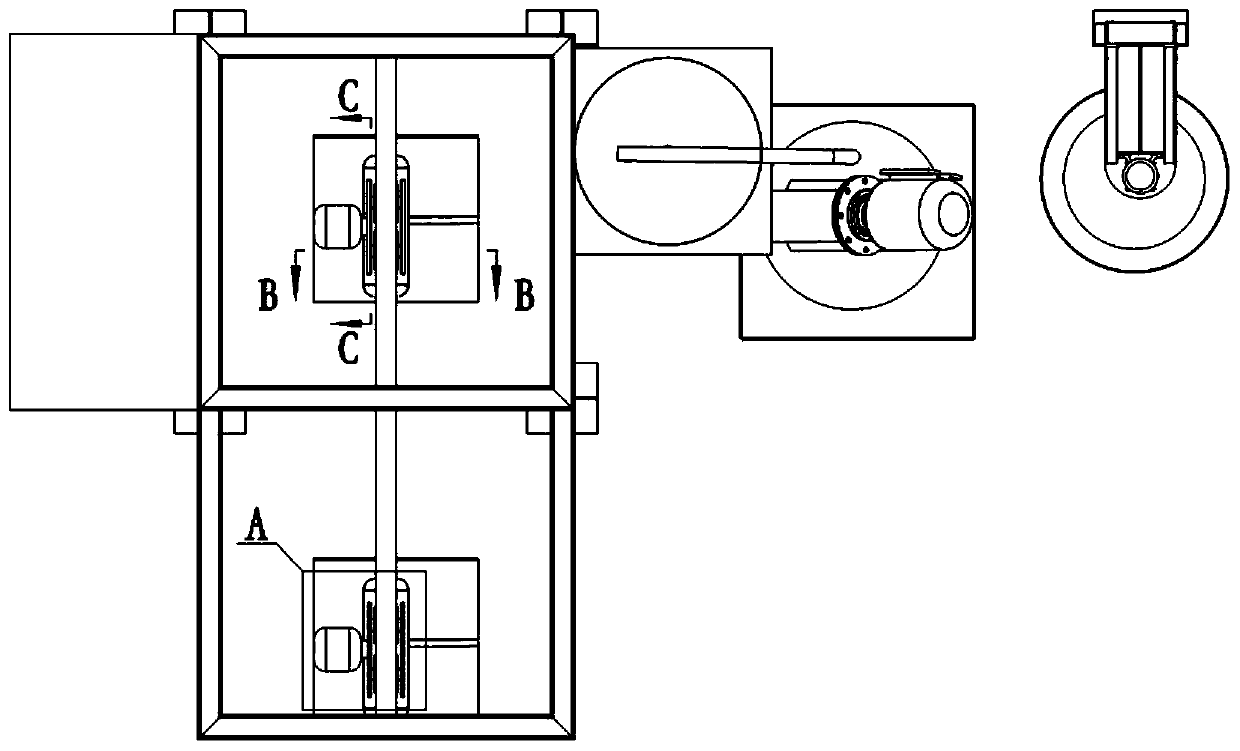

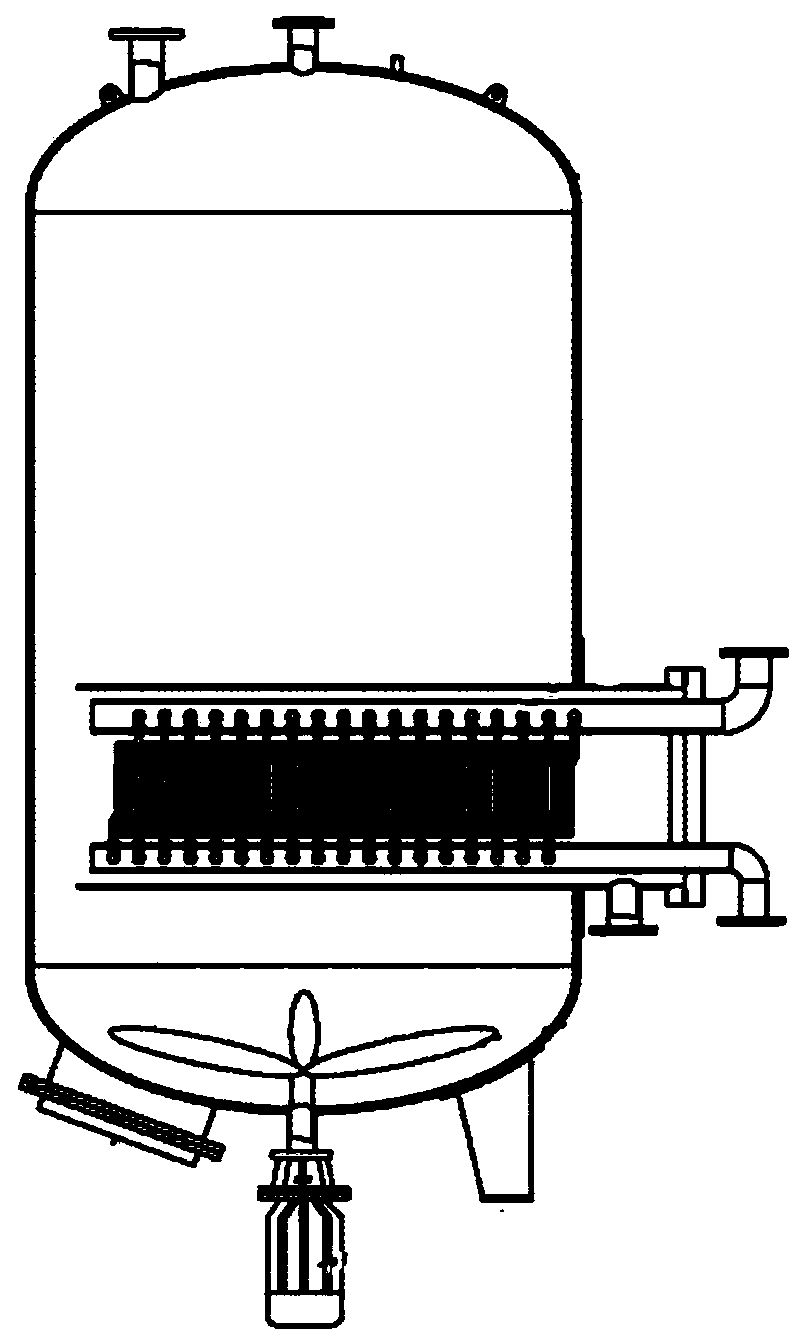

InactiveCN111151176APrecise ratioSolve the time-consuming and labor-intensive problem of manual matchingShaking/oscillating/vibrating mixersTransportation and packagingPhysical chemistryMechanical engineering

The invention relates to the technical field of gypsum production equipment, in particular to gypsum proportioning equipment. In the gypsum proportioning equipment, a powder proportioning bin is fixedly connected with a support frame; a discharge hole is formed in the bottom of the powder proportioning bin; gypsum powder in a ton bag is fed into the powder proportioning bin through a feeding mechanism; a powder feeding mechanism is used for conveying gypsum powder in the powder mixing cavity into a mixing barrel; a water feeding mechanism is communicated with a batching barrel and is used forconveying water to be proportioned into the batching barrel; a weighing mechanism comprises a weighing sensor and a weighing plate, the weighing plate is connected with the batching barrel in a combined / separated mode, the weighing sensor is used for detecting and feeding back the weight of materials in the batching barrel; and a control device receives a signal of the weighing sensor to control the operation or stop of the powder feeding mechanism and the water feeding mechanism. In the embodiment of the invention, the weighing sensor and the control device are used for controlling the amountof gypsum powder conveyed by the powder feeding mechanism and the amount of water conveyed by the water feeding mechanism to carry out proportioning, so that the problem of time and labor waste of manual proportioning is solved, and the processing efficiency is improved.

Owner:SHANDONG HUAYU UNIV OF TECH

Displacement heat exchanger

InactiveCN104329963AExtended service lifeImprove heat transfer efficiencyStationary tubular conduit assembliesHeat transfer modificationImpellerPlate heat exchanger

The invention relates to a displacement heat exchanger for solving the problem that a heating pipe in the heat exchanger can be scaled easily. The displacement heat exchanger comprises a tank body and stirring impellors. The displacement heat exchanger is characterized in that the stirring impellors comprise a first stirring impellor and a second stirring impellor which are arranged in the tank body and are not distributed symmetrically in the tank body, and are respectively driven by a motor outside the tank body. The displacement heat exchanger enables the outer wall surface of the heating pipe not to be scaled easily, the service life of the heat exchanger is prolonged, and the heat exchanger efficiency is improved.

Owner:山东林安热能科技有限公司

Wastewater ozone oxidation advanced treatment device

ActiveCN112811570AIncrease profitReduce wasteRotary stirring mixersTransportation and packagingWastewaterWater treatment

The invention relates to a wastewater ozone oxidation advanced treatment device, and belongs to the field of water treatment. The wastewater ozone oxidation advanced treatment device comprises a device body, the interior of the device body is divided into a settling chamber and an ozone treatment chamber through a partition plate, and the partition plate is provided with a communicating opening for communicating between the settling chamber with the ozone treatment chamber; the settling chamber communicates with a water inlet pipe for introducing wastewater, a slag discharge pipe for discharging waste slag and a tail gas pipe for communicating with a tail gas treatment device, and a catalytic filler layer is arranged in the ozone treatment chamber; and the ozone treatment chamber communicates with a gas inlet pipe for introducing ozone, a water outlet pipe for discharging wastewater and an ozone recovery pipe extending below the liquid level of the wastewater in the settling chamber. The wastewater ozone oxidation advanced treatment device has the effect of reducing waste of ozone.

Owner:深圳市澳洁源环保科技有限公司

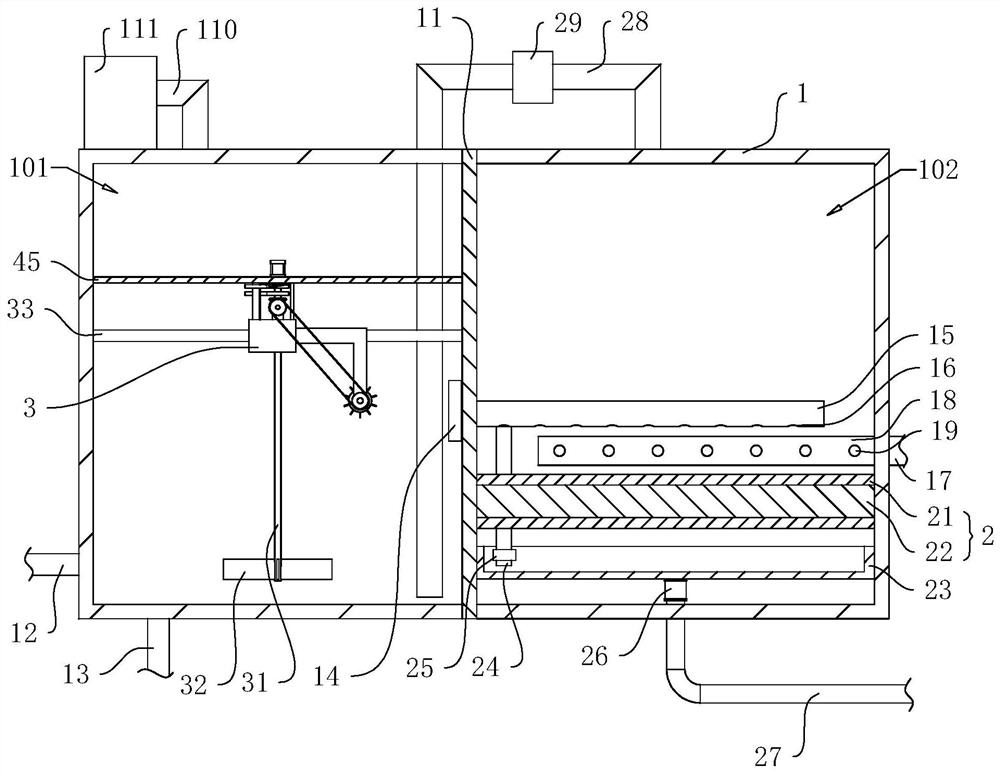

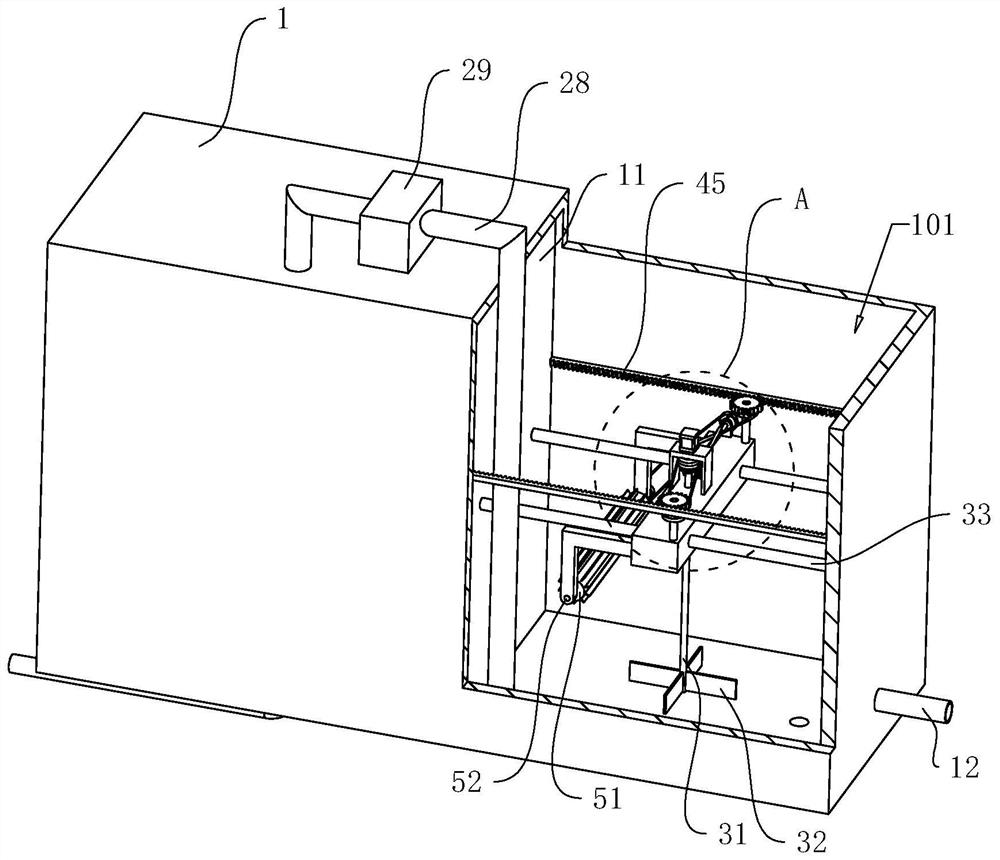

Antibacterial spraying-free plastic, production device and processing method

InactiveCN113172787AAchieve the effect of auxiliary mixingIncrease agitation rangeElectric machineryAnti bacteria

The invention discloses antibacterial spraying-free plastic, a production device and a processing method, and relates to the technical field of plastic production and processing. In order to improve the product quality, the device comprises a mixing tank body, a mixing motor is fixed to the outer wall of the top of the mixing tank body, the output end of the mixing motor is rotatably connected with a rotating main shaft, and the outer wall of the rotating main shaft is slidably connected with more than two sliding seats. The antibacterial spraying-free plastic comprises components including, by weight, 55-95 parts of ABS resin, 1-2 parts of a compatilizer and 1-2 parts of a lubricant. The method comprises the following steps that all raw materials are weighed according to the weight parts, and the raw materials are added into the mixing tank body through a feeding hopper. Elastic columns are arranged, in the moving process of vertical mixing rods, the vertical mixing rods make contact with the elastic columns and extrude the elastic columns, the elastic columns deform, when the vertical mixing rods are disengaged from the elastic columns, resilience force of the elastic columns promotes the elastic columns to reset, meanwhile, nearby materials are stirred, and the auxiliary mixing effect is achieved.

Owner:东莞市久磐塑胶有限公司

Polylactic acid polycondensation synthesis equipment and method

PendingCN113181866AReduce concentrationReduce retentionProcess control/regulationProductsPolymer scienceWater collection

The invention discloses polylactic acid polycondensation synthesis equipment and method. The equipment comprises a reaction kettle, the bottom of the reaction kettle is connected with three sets of supporting legs, the top of the reaction kettle is connected with a sealing cover, the sealing cover is provided with a detection piece and a feeding piece, and the reaction kettle is provided with a discharging piece; a steam exhaust pipe is mounted on the sealing cover, and the steam outlet end of the steam exhaust pipe is connected with a condensation assembly for collecting and condensing steam in the reaction kettle; and according to the present invention, the design is performed according to the existing requirements, the circular truncated cone can reduce the concentration of the material in the middle of the reaction kettle inner cavity, the material is well contacted and heated with the reaction kettle side wall, the shearing effect of the stirring assembly is small, the fluidity and the mixing degree of the material can be increased, and the disassembly and the assembly are easy, and the water collection assembly can prevent the condensed water on the inner wall of the steam exhaust pipe from dropping in the inner cavity of the reaction kettle. Water is prevented from dropping into the inner cavity of the reaction kettle to influence the condensation polymerization of materials, and effective condensation polymerization synthesis of polylactic acid is facilitated.

Owner:峰特(浙江)新材料有限公司

A vertical rotation cooling system for lead-acid batteries

ActiveCN111969281BGuaranteed stabilityAvoid shakingFinal product manufactureCell temperature controlElectrical batteryWater flow

The invention discloses a lead-acid battery up and down rotary cooling system. The opening is set; the upper end of the base is provided with a cooling water tank, an overflow plate is fixedly connected in the cooling water tank, the rear end of the overflow plate is connected with an outlet pipe on the cooling water tank, and the front end of the overflow plate is connected with an inlet pipe on the cooling water tank. Water pipe; the front end of the overflow plate is provided with a clamping device in the cooling water tank. A lead-acid battery up and down rotary cooling system described in the present invention cools down the lead-acid battery by means of up and down circulating water cooling, the cooling water heats up faster after absorbing heat, and the cooling efficiency of the lead-acid battery is high. In addition, By adding a clamping device in the water tank, the device can prevent the lead-acid battery from shaking under the action of water flow in the water tank.

Owner:JIESHOU HUAYU POWER SUPPLY

Silt removal device for water conservancy projects

The invention discloses a desludging device for hydraulic engineering. The desludging device for hydraulic engineering comprises a cover, a sludge stirring mechanism, a plurality of sludge inlet pipesdistributed in the circumference direction of the cover at intervals, a plurality of desludging pipes, a sludge pumping pipe, a sliding plate, a second spring, a fixed pulley and a rope, wherein thesludge stirring mechanism comprises a drill bit, a high-pressure air pipe and an air pump; and each sludge inlet pipe is coaxially sleeved with the corresponding desludging pipe. The desludging devicefor hydraulic engineering has the functions of automatically dredging the sludge inlet pipes and the sludge pumping pipe, thereby avoiding pipe blockage caused by sludge, ensuring normal running of the desludging work and improving the desludging efficiency. Meanwhile, the desludging device for hydraulic engineering has the function of separately collecting sludge based on particle sizes, and therefore sludge can be conveniently transported and reused as needed.

Owner:周秒

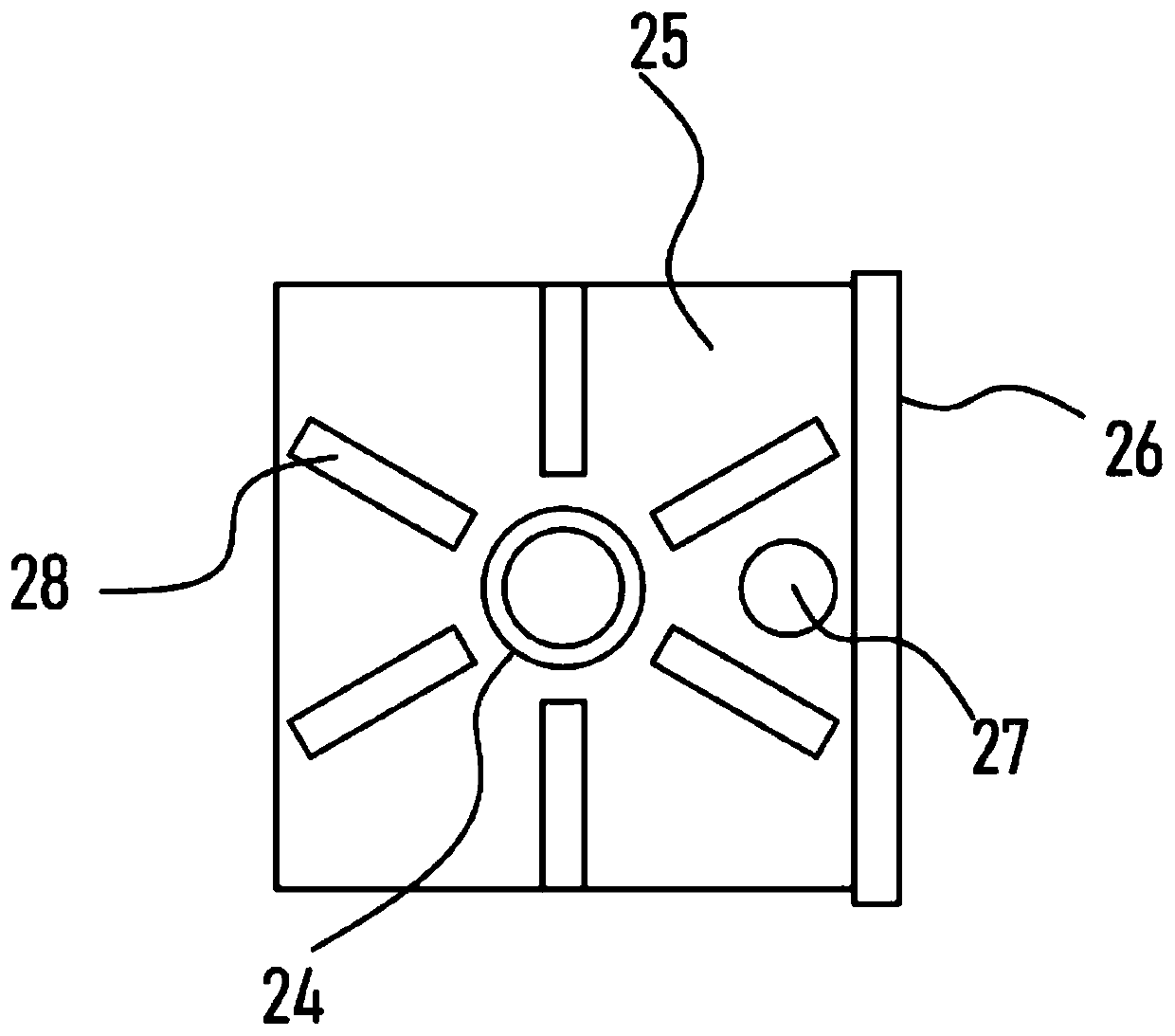

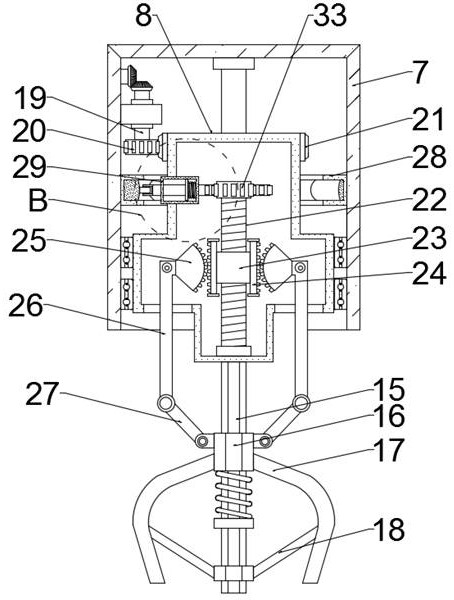

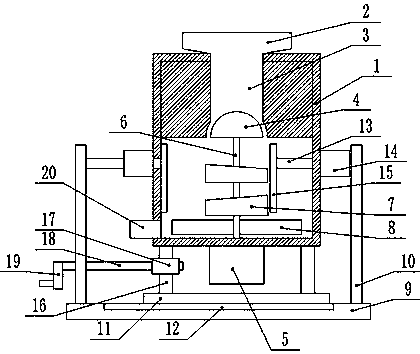

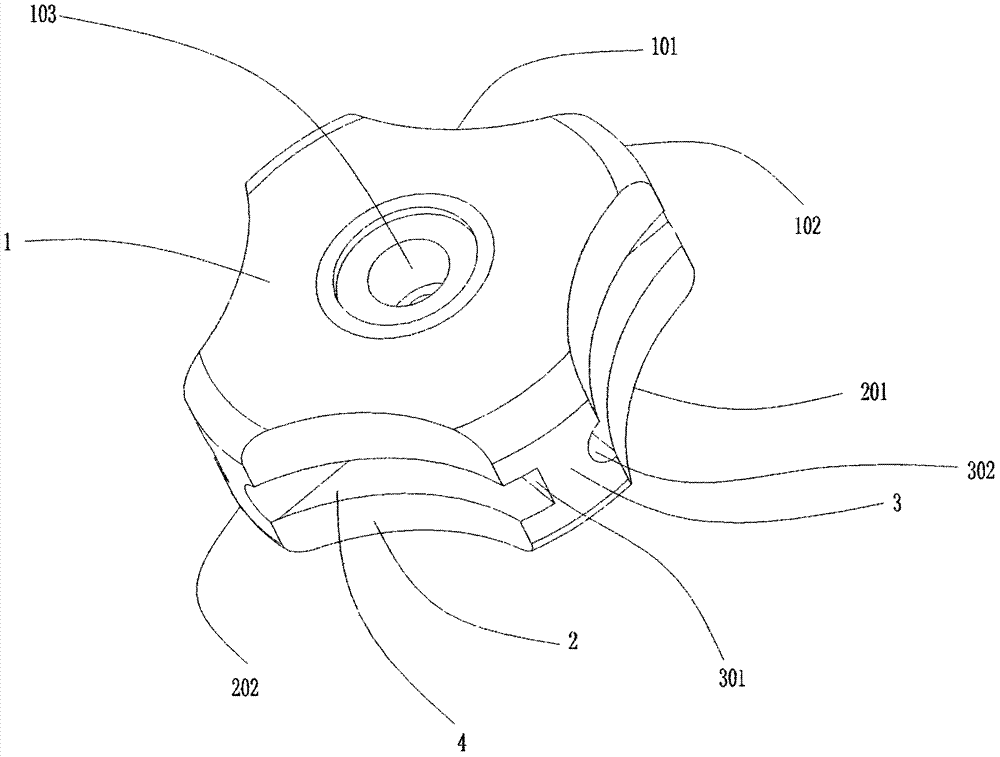

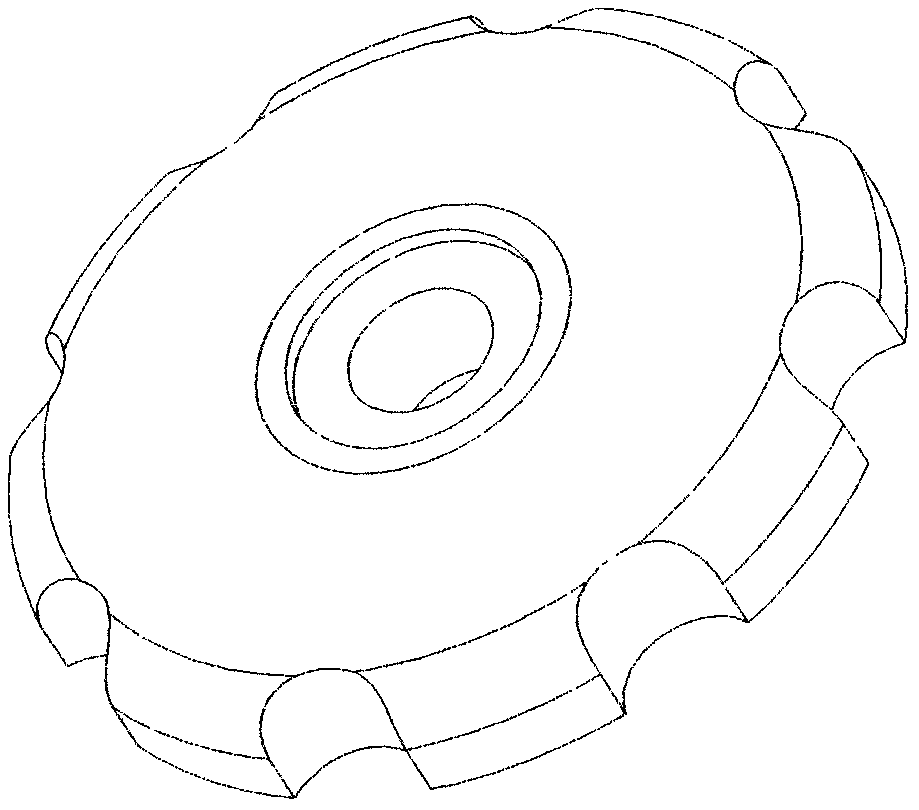

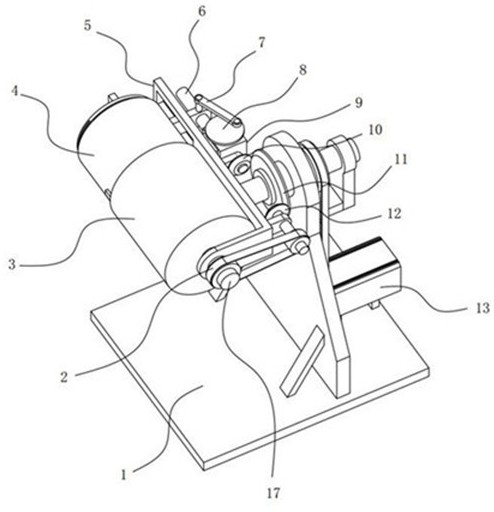

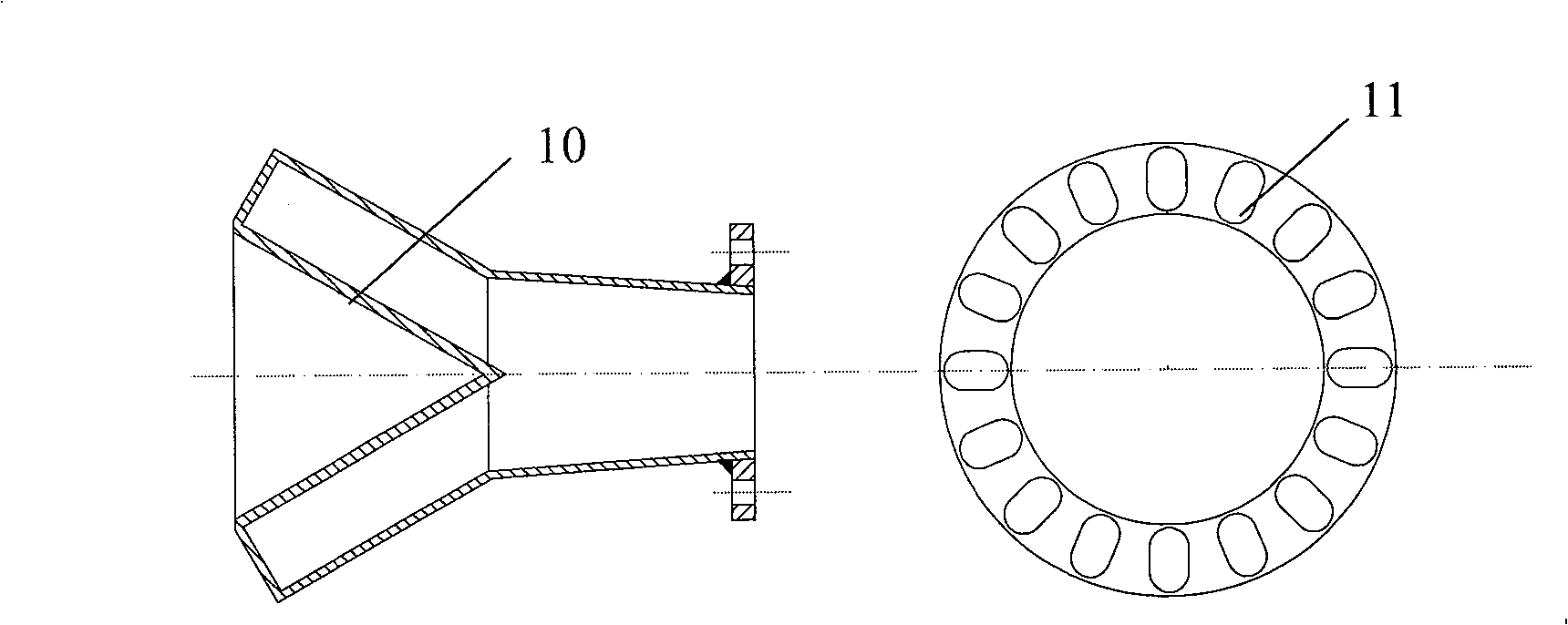

Rotary stirring apparatus for dispersing gas during melting metal

The invention provides a rotary stirring apparatus for dispersing gas during melting metal. The rotary stirring apparatus comprises a hollow rotary shaft and a rotary nozzle, wherein the bottom end of the hollow rotary shaft is connected with the rotary nozzle; the rotary nozzle comprises a top plate, a bottom plate and a partition plate; the outer contour of the cross section of the top plate is a first octagon; the first octagon comprises four upper long sides and four upper short sides; the four upper long sides and four upper short sides are arranged at intervals; an upper circular hole is formed in the center of the top plate; the outer contour of the cross section of the bottom plate is a second octagon; the second octagon comprises four lower long sides and four lower short sides; the four lower long sides and four lower short sides are arranged at intervals; a lower circular hole is formed in the center of the bottom plate; the diameter of the lower circular hole is greater than that of the upper circular hole; the partition plate is positioned between the top plate and the bottom plate; and upper and lower ends of the partition plate are connected with the top plate and the bottom plate. According to the invention, the outer contour of the cross section of each of the top plate and the bottom plate is the octagon, and compared with the circle in the prior art, the octagon has higher stirring force, larger stirring range and higher shearing action to gas to generate more disperse fine bubbles with a larger covering range; and a drainage groove is arranged to guide flow of gas so as to accelerate diffusion of gas.

Owner:珠海肯赛科有色金属有限公司

Fiber-reinforced resin-based composite core overhead insulated cable

InactiveCN114496379AImprove fire performanceHigh activityInsulated cablesFire rescueElectric cablesHigh heat

The invention belongs to the technical field of cables, and particularly relates to a fiber-reinforced resin-based composite core aerial insulated cable which comprises a fiber-reinforced resin-based composite core, a plurality of heat-resistant aluminum alloy single wires are arranged on the outer side of the fiber-reinforced resin-based composite core, and the same shielding layer is arranged on the outer sides of the heat-resistant aluminum alloy single wires. A plurality of armoring sleeves are bonded to the circumferential inner wall of the shielding layer, air outlet pipes are fixed to the arc outer walls of the armoring sleeves in a penetrating mode, first sliding grooves are formed in the inner walls of the two sides of each air outlet pipe, first sliding blocks are slidably connected into the first sliding grooves, and the same first spring is fixed between the first sliding blocks and the inner walls of the first sliding grooves through bolts; the same exhaust column is fixed between the two first sliding blocks through bolts, a plurality of exhaust holes are formed in the bottom of the exhaust column, and the armored sleeve is filled with dry powder. According to the invention, the air pressure in the armoring sleeve is suddenly increased through high temperature generated by fire, and then dry powder in the armoring sleeve is sprayed out to extinguish fire, so that the fireproof effect is improved.

Owner:谢成双

Adjustable multifunctional malt batch drying and processing device for beer production

InactiveCN112797765AEasy to dryEasy flipDrying gas arrangementsDrying solid materialsElectric machineryEngineering

The invention discloses an adjustable multifunctional malt batch drying and processing device for beer production. A feeding port is located above a drying box, openings are formed in the two sides of the drying box, each group of drying assemblies is located at the opening of the drying box, a stirring assembly is located in the drying box, a collecting assembly is located below the drying box, a motor is located on the side edge of the drying box, a cylindrical box is located in the drying box, hole grooves are formed in the two sides of the cylindrical box, fine hole nets are arranged at the hole grooves, one end of a rotating shaft is fixedly connected with the output end of the motor, the other end of the rotating shaft is sequentially inserted into the drying box and the cylindrical box and fixedly connected with a first rotating piece, and a second rotating piece is fixedly connected with the first rotating piece and located above the first rotating piece. Through the structural design, malt is not prone to accumulation, and the drying effect of the malt is improved.

Owner:东台市金穗麦芽有限公司

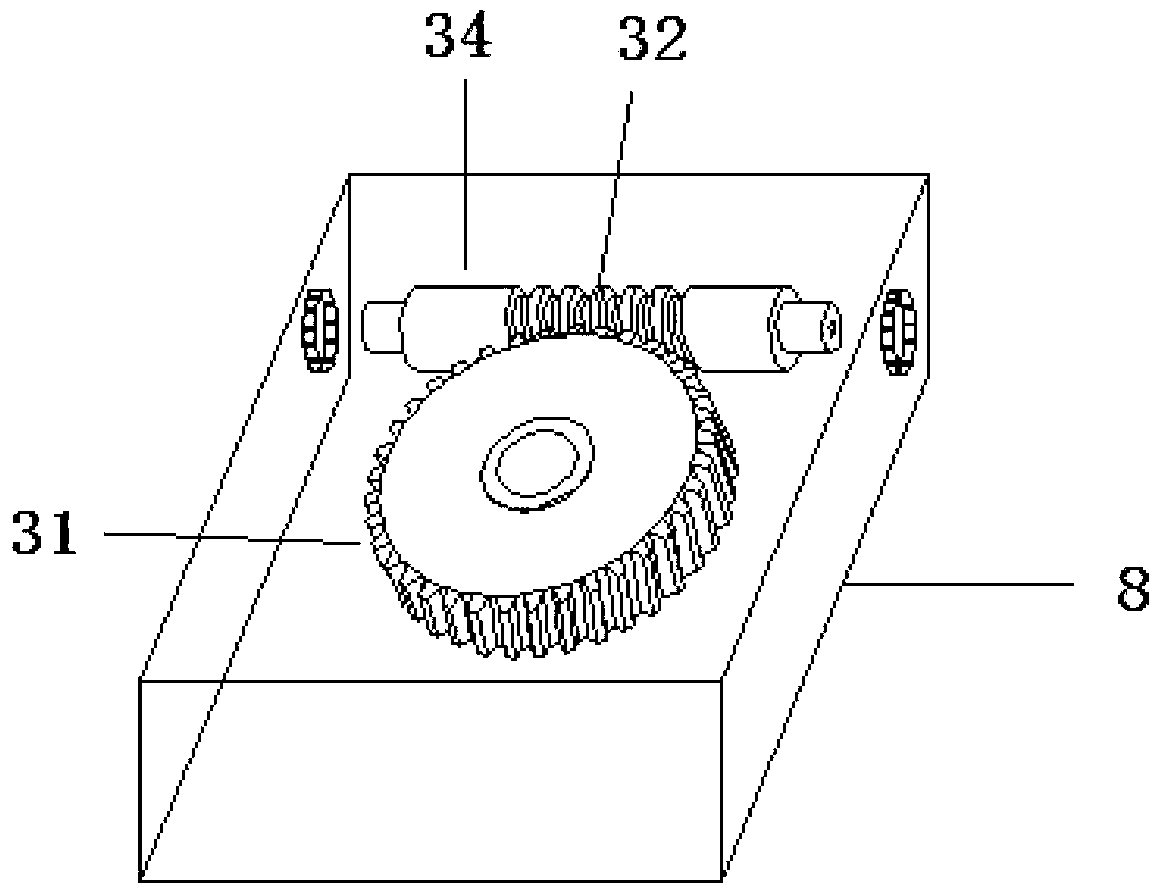

A feed mixing device for animal husbandry

ActiveCN114377583BAchieving rotational agitationSmooth rotationRotating receptacle mixersShaking/oscillating/vibrating mixersAnimal scienceGear drive

The invention discloses a feed mixing device for animal husbandry, which relates to the technical field of mixing devices, and comprises a frame on which a drive shaft is rotatably mounted, and the drive shaft is connected to a bevel gear through a transmission assembly. There is an agitating assembly in the mixing inner cylinder, a gear box is installed on the turret, and a gear transmission assembly is arranged in the gear box, and a translation assembly is connected to the gear transmission assembly, and the translation assembly is used to drive the mixer. The material inner cylinder moves axially relative to the material mixing outer cylinder; the invention can drive the turret to rotate through the rotation of the set driving shaft, so as to realize the rotation of the mixing outer cylinder and the mixing inner cylinder, and promote the rotation of the internal feed around the turret, while at the same time , through the transmission of the transmission component, the mixing component drives the mixing outer cylinder and the mixing inner cylinder to rotate and stir the internal feed, which greatly improves the dispersion of the feed and the feed is fully mixed.

Owner:诸城市中裕机电设备有限公司

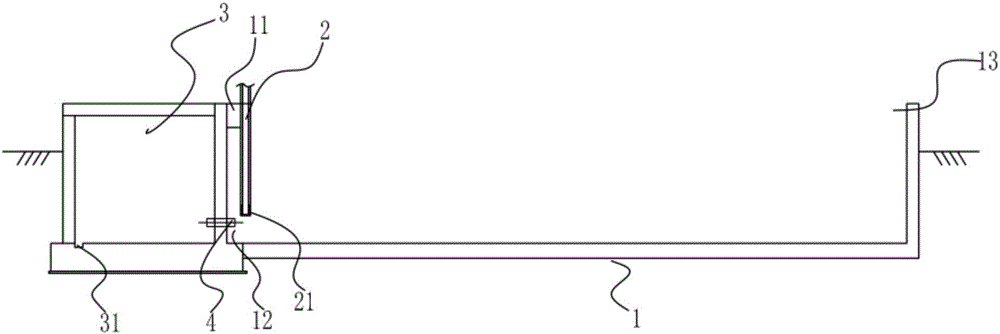

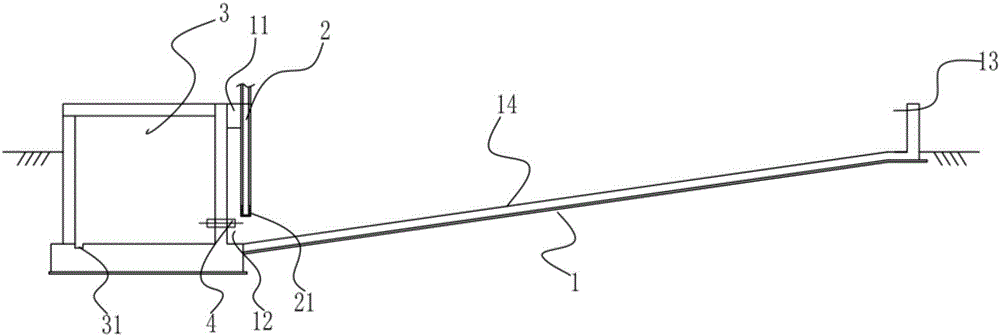

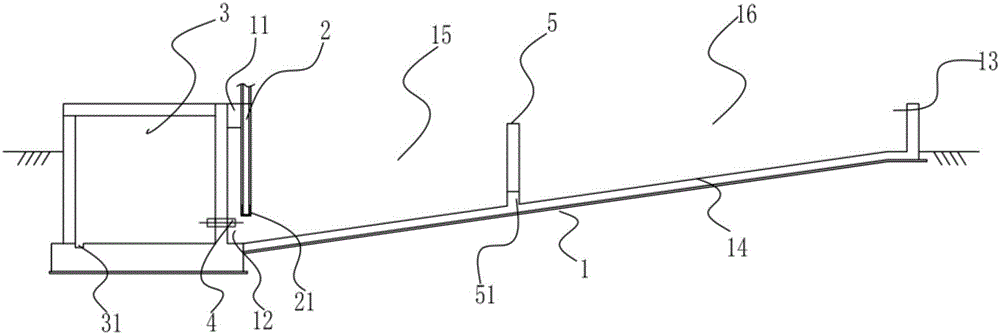

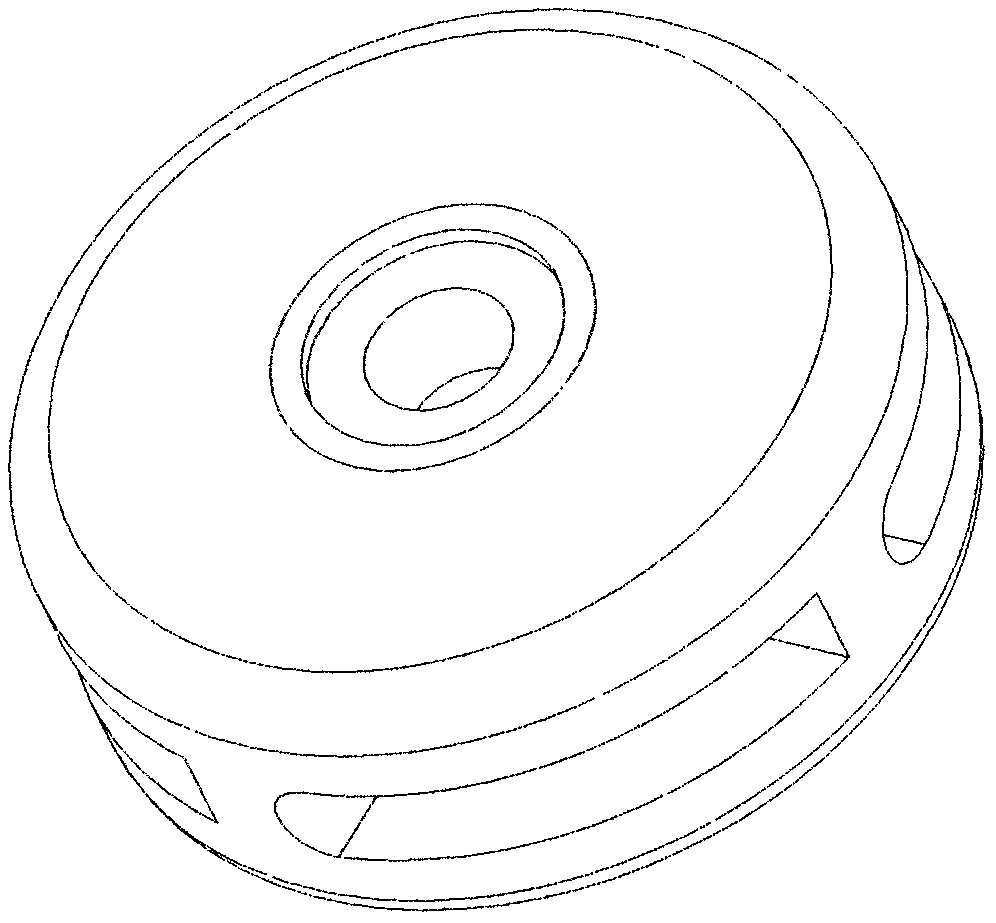

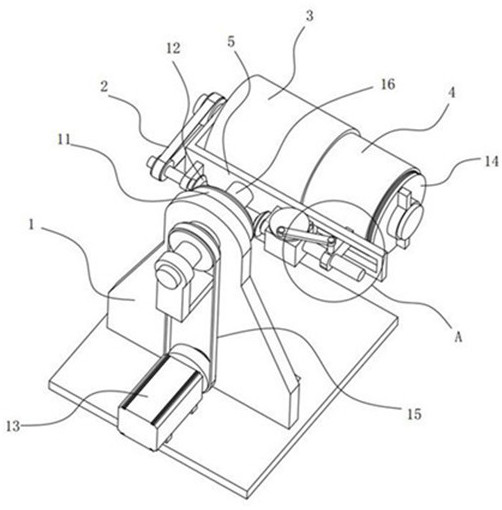

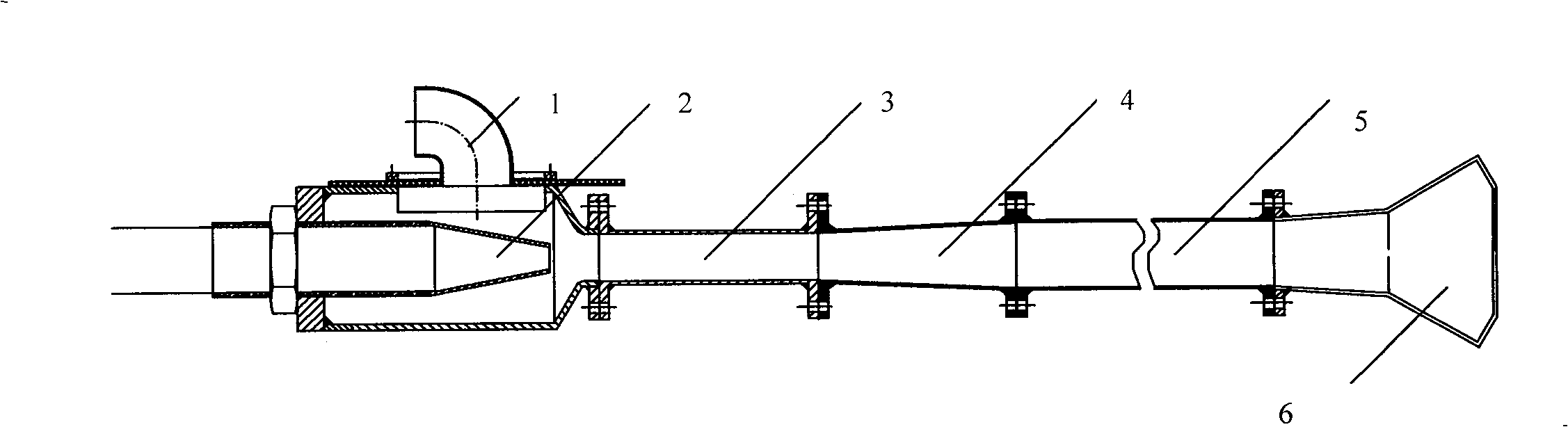

Detachable jet aerator and using method thereof

ActiveCN100544829CUniform outflowIncrease agitation rangeTreatment using aerobic processesFlow mixersActivated sludgeJet flow

The invention discloses a split jet aerator, which comprises the following parts: suction inlet, water nozzle, mixing tube, dispersing pipe, tail pipe and distributor, wherein the distributor connects the tail pipe; a cone with the action of deflecting the composite liquid and reducing the local resistance is set in the pipe segment with diffusing angle of tail pipe; the CFD company adopts artificial software value to optimize the design of the structure of jet aerator, which transmits the composite liquid of effluent-living sludge into water nozzle; certain vacuum is formed in the course of jet to form three-phased composite liquid of gas, liquid and solid, which enters into the dispersing pipe to form jet distributor with certain pressure to do inclined ejection to aerate oxygen and stir. The invention improves more dynamic efficiency and more oxygen utility than traditional one, which possesses larger suction quantity, higher bubble quality, evener stirring power and more energy saving.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

A spinning machine for polypropylene processing

ActiveCN113005530BIncrease agitation rangeReduce gapSpinnerette packsArtificial thread manufacturing machinesPolypropyleneManufacturing engineering

The invention discloses a spinning machine for polypropylene processing. Its structure includes a heating bucket, a base and a spinneret. The heating bucket is welded on the upper surface of the base. The spinneret runs through the inner position of the heating bucket and extends through the outside The inertial force generated by the rod extending outward can make the extension block slide upward along the bottom frame on the linkage rod, so that the stirring groove can increase the stirring range of the molten polypropylene inside the spinneret, so the extension The rod can agitate and mix two batches of molten polypropylene together with the cooperation of the stirring tank, which effectively avoids the gap between the two batches of molten polypropylene introduced into the spinneret at different times. When the take-out mechanism stops rotating Afterwards, the outer expansion plate can be pulled and contracted outward by the elastic sheet, so that the inner side of the outer expansion plate can be vibrated by the impact of the fixed frame, so that the vibration generated by the outer expansion plate can push the molten polypropylene attached to the outer surface of the outer expansion plate. fall.

Owner:山东东泰力特新材料科技有限公司

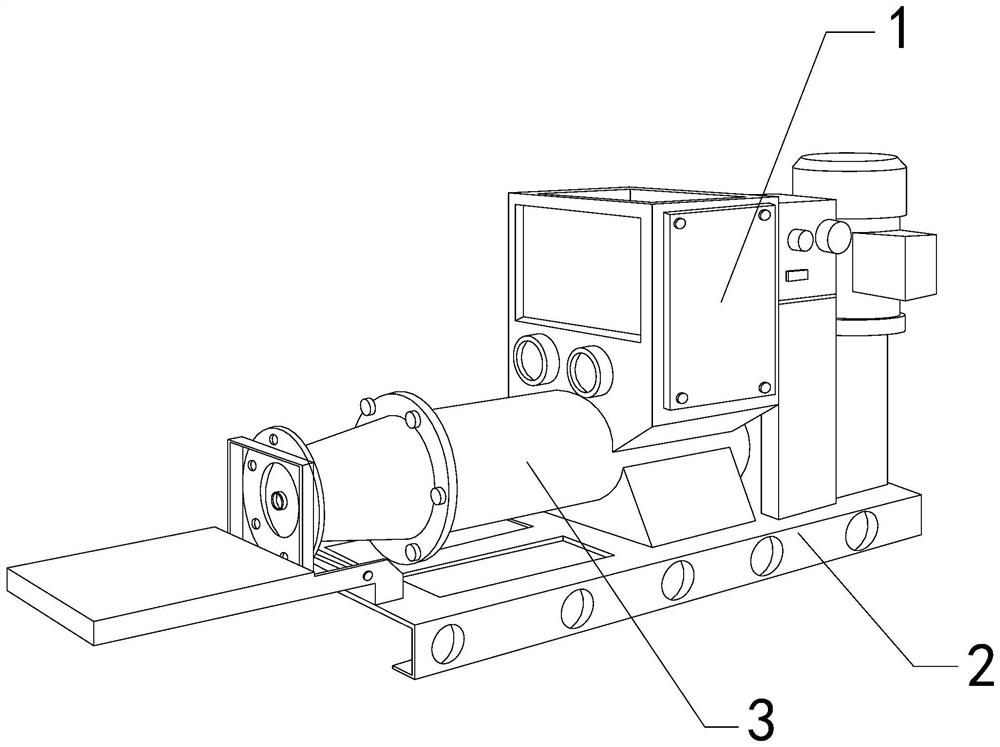

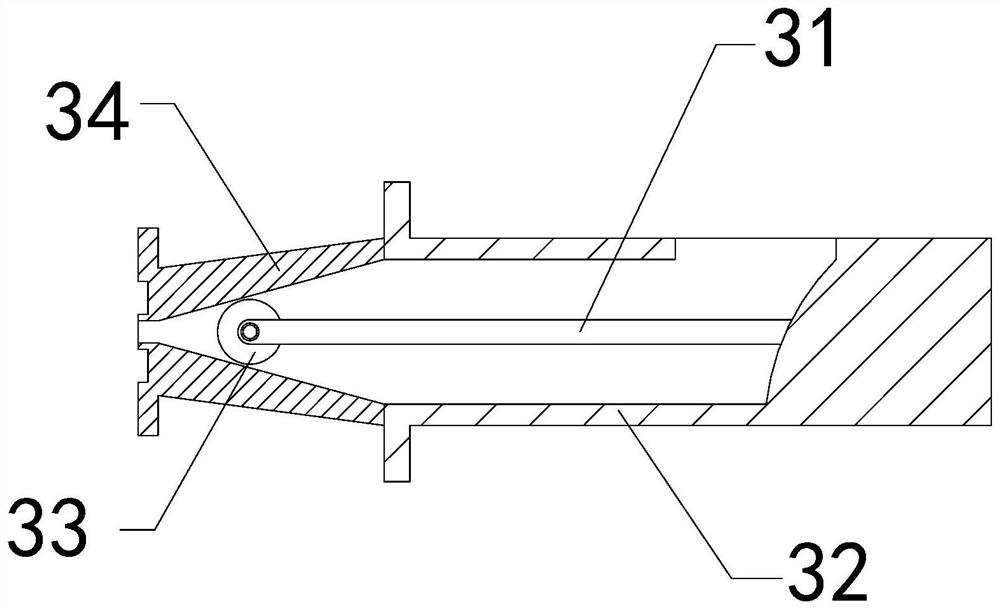

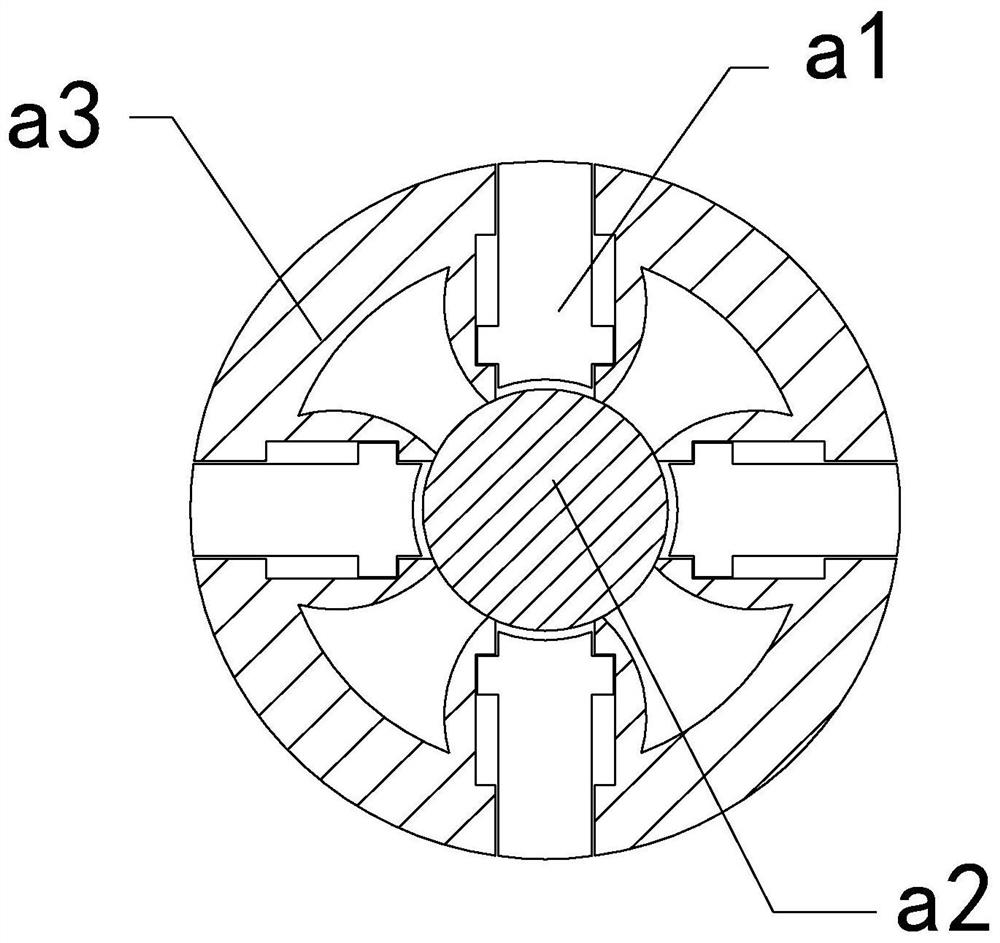

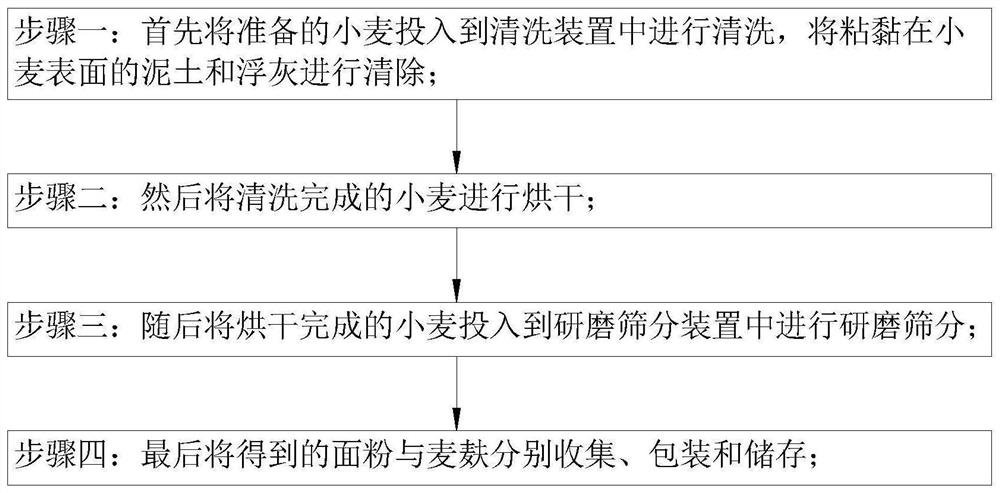

A kind of production technology of selenium-enriched nutritionally fortified flour

ActiveCN113231124BEasy to cleanClean up fullyGrain huskingGrain polishingAgricultural engineeringWater flow

Owner:青岛天祥食品集团有限公司 +2

Backward-tilting multi-wing centrifugal ventilator

InactiveCN107989802AIncrease absorptionIncrease centrifugationPump componentsPump installationsImpellerCurrent collector

The invention discloses a backward-tilting multi-wing centrifugal ventilator. The backward-tilting multi-wing centrifugal ventilator comprises a ventilator main body, wherein an explosion-proof motoris fixedly arranged on the outer surface of one side of the ventilator main body; a worm board is arranged at one side of the explosion-proof motor; a current collector is arranged inside the worm board; an impeller is fixedly arranged inside the current collector; a rotating shaft is arranged at the center inside the impeller; in addition, fan wings are fixedly arranged on the outer surface of the rotating shaft; a vertical baffle is fixedly arranged at the center of the outer surface at one side of each fan wing; a connecting port is formed in the upper end of the outer surface of one side of the worm board; an operation box is arranged on the outer surface of one side, close to the connecting port, of the worm board. The backward-tilting multi-wing centrifugal ventilator disclosed by the invention is provided with the vertical baffles, a dust outlet and a filtering plate; a suction force and a centrifugal force can be improved and an operation process is facilitated; in addition, air can be filtered and finally dust can be collected and discharged, so that a dust raising effect is effectively avoided and a better use prospect is brought.

Owner:JIANGSU HENGKANG ELECTRICAL

Cosmetic raw material stirring device

InactiveCN110917925AIncrease productivityAvoid the phenomenon that cannot be flippedRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention belongs to the technical field of cosmetic production, and especially relates to a cosmetic raw material stirring device. The raw material stirring device is provided to solve a problemthat many powder additives can form many fine powder balls after being added and are dissolved through stirring for a long time by a traditional stirring device. The device comprises a base, two supporting frames are fixedly installed at the top of the base, a tank body is fixedly installed between the top ends of the two supporting frames, a sealing cover is fixedly installed at the top end of the tank body, a liquid discharging pump is installed at the bottom of the tank body, and a driving mechanism is fixedly installed at the top end of the base. The phenomenon that raw materials at the bottom of the tank body cannot be turned over can be avoided through the arrangement of stirring blades, and a powder dough in the raw materials is sheared and crushed by the corner of a shearing rod when the shearing rod rotates along with the stirring rod, so the dough crushing effect is improved, the raw material stirring time is shortened, and the cosmetic production efficiency is improved.

Owner:周晶晶

River and lake polluted sediment treatment mechanical dehydration multifunctional mud conditioning pool

ActiveCN106167344BGuaranteed capacityOvercoming technical problems with prolonged buildup on the bottom of the poolSludge treatment by de-watering/drying/thickeningSlurryNoise reduction

The invention provides a mechanical dehydration multifunctional mud conditioning pond for processing polluted bottom mud of rivers and lakes, which includes a conditioning pond body, which is provided with a slurry inlet, a slurry outlet and a water outlet, and the conditioning pond body is close to the slurry outlet An air inlet pipe is arranged at the center, and a plurality of ventilation holes are arranged on the air inlet pipe, and the plurality of air holes are arranged on the air inlet pipe in different directions. The mechanical dehydration multi-functional mud conditioning pool for treating river and lake polluted bottom sludge of the present invention realizes stirring the mud in the conditioning pool by ventilating the body of the conditioning pool, which can prevent the mud from settling and hardening, and avoid mud from accumulating at the bottom of the pool for a long time, effectively The storage capacity of the conditioning tank body is guaranteed, and at the same time, it also plays the role of noise reduction and can adjust the mud concentration in the conditioning room body.

Owner:POWERCHINA WATER ENVIRONMENT GOVERANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com