Conveying device for producing dry-mixed mortar powder

A conveying device and dry-mixed mortar technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of powder accumulation and agglomeration, blockage of feeding pipeline, inability to mix and pulverize, etc. blocks, improve uniform crushing, and improve the effect of agitation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

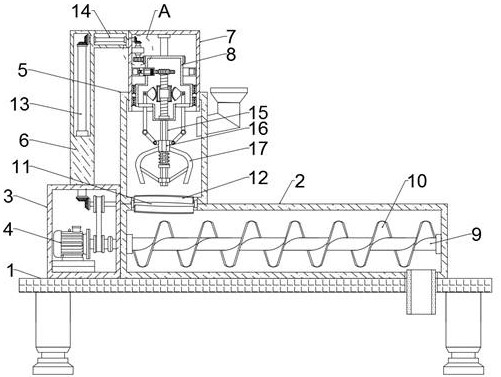

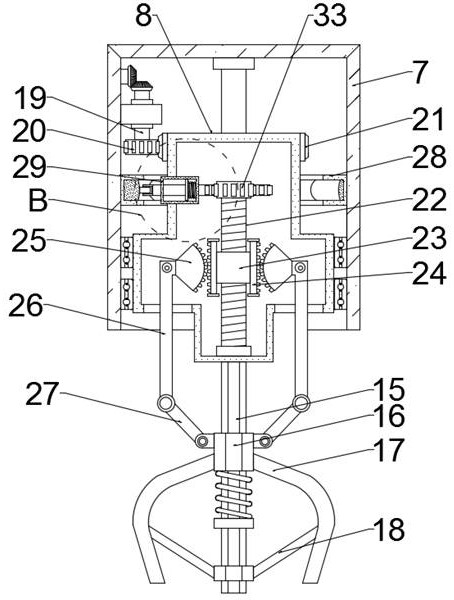

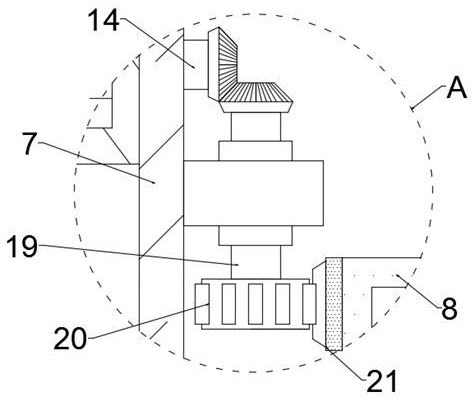

[0022] Embodiment 1: see Figure 1-5 , a conveying device for producing dry-mixed mortar powder, including a base 1, a transmission assembly, a material shifting assembly, a stirring mechanism, an adjustment mechanism and a reciprocating mechanism, the four corners of the bottom surface of the base 1 are vertically fixed with support legs; the base 1 A delivery box 2 is arranged horizontally on the top surface. The interior of the delivery box 2 is a cylindrical cavity. The bottom side of the delivery box 2 is vertically fixed with a discharge pipe, and the bottom end of the discharge pipe runs through the bottom surface of the base 1. Outside; the top surface of the base 1 on one side of the delivery box 2 is provided with a drive box 3, and the drive box 3 is provided with a motor 4, and one side of the top surface of the delivery box 2 is vertically provided with a blanking box 5, and the top of the blanking box 5 An installation opening is provided, and a fixed cylinder 7 ...

Embodiment 2

[0029] Embodiment 2: In this embodiment, the present invention also proposes a method for using a conveying device for producing dry-mixed mortar powder, comprising the following steps:

[0030] Step 1: Firstly, the motor 4 is electrically connected to the external power supply through wires; then the powder is put into the lower material box 5 through the feeding hopper, and then the driving pulley is driven by the control motor 4 to rotate, and the rotation of the driving pulley is convenient Drive the driven pulley at the other end of the belt to rotate, the rotation of the driven pulley is convenient to drive the rotating shaft 11 to grasp and rotate, and the rotation of the rotating shaft 11 is convenient to drive the shifting plate 12 to quantitatively transfer the powder in the feeding box 5 into the delivery box 2;

[0031] Step 2, by driving the conveying shaft 9 to rotate, the rotation of the conveying shaft 9 facilitates the conveying operation of the powder falling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com