Threshing machine for cereal food processing

A food processing and thresher technology, applied in threshing equipment, grain hulling, application and other directions, can solve the problems of blockage of blanking holes, reduce the labor intensity of farmers' threshing production, poor separation effect, etc. Work efficiency, the effect of reducing the workload of cleaning debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

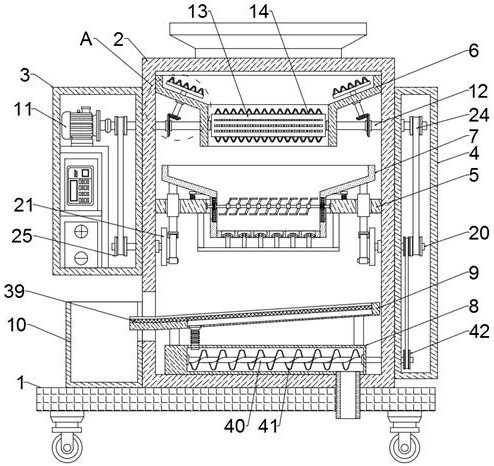

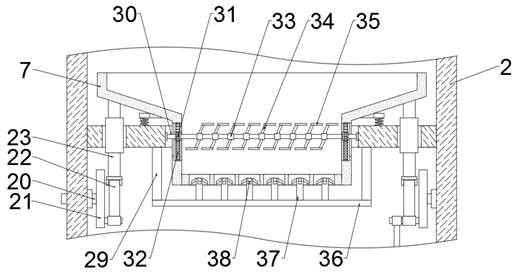

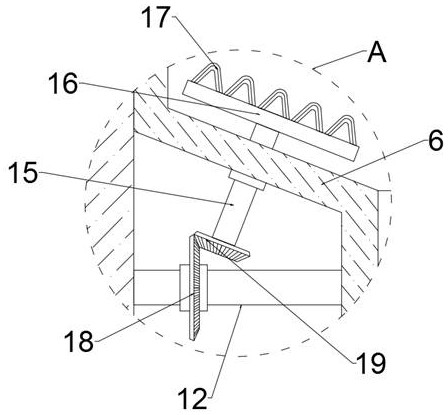

[0023] Embodiment 1: see Figure 1-6 , a threshing machine for cereal food processing, comprising a base 1, a threshing mechanism, a transmission mechanism, an agitating mechanism and a dredging assembly, the top surface of the base 1 is fixedly connected with a threshing box 2 with a feeding hopper on the top, and one side of the threshing box 2 The upper part is provided with a drive box 3, one side of the drive box 3 is provided with a mounting frame, the mounting frame is provided with a controller and a storage battery, and the top of the mounting frame is provided with a motor 11; the other side of the threshing box 2 is vertically provided with a transmission Box 4; the middle part of the threshing box 2 is horizontally fixed with a partition plate 5 with a lifting port, and the lifting port of the partition plate 5 is provided with a lift bucket 7 with a closed bottom, and the inner bottom surface of the lift bucket 7 is evenly opened. There are several feeding holes; ...

Embodiment 2

[0029] Embodiment 2: In this embodiment, the present invention also proposes a method for using a thresher for cereal food processing, comprising the following steps:

[0030] Step 1: Firstly, electrically connect the motor 11 and the controller to the storage battery through wires; then put the grain to be threshed into the threshing box 2 from the feed hopper, and then control the motor 11 to drive the rotating shaft 12 to move forward. Rotation, through the normal rotation of the rotating shaft 12, it is convenient to drive the threshing roller 13, the threshing hook 14 and the scraping assembly to perform the threshing operation on the bottom and side of the grain. The feeding hole at the bottom of the bucket 7 falls on the top surface of the sieve net 39, through the sieve net 39 it is convenient to make the cereal crumbs in the grain fall into the sieving tank, and the collection bucket in the sieving tank is convenient to make the grain The debris falls into the slag di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com