High-automation-degree corn thresher

A corn peeler and degree technology, which is used in threshing equipment, agricultural machinery and implements, agriculture, etc., can solve the problems of insufficient continuous processing of corn cobs, insufficient semi-automation, and deviation of corn cobs, and achieve semi-automation. High degree, convenient threshing, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

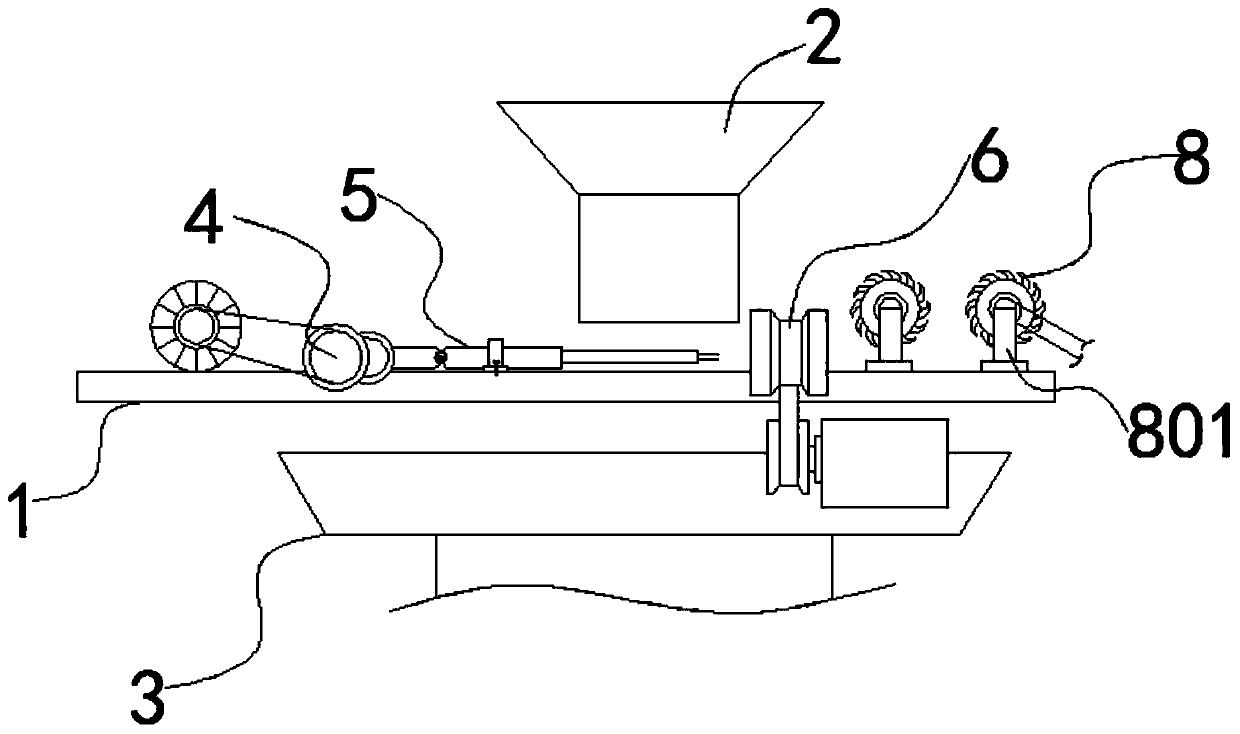

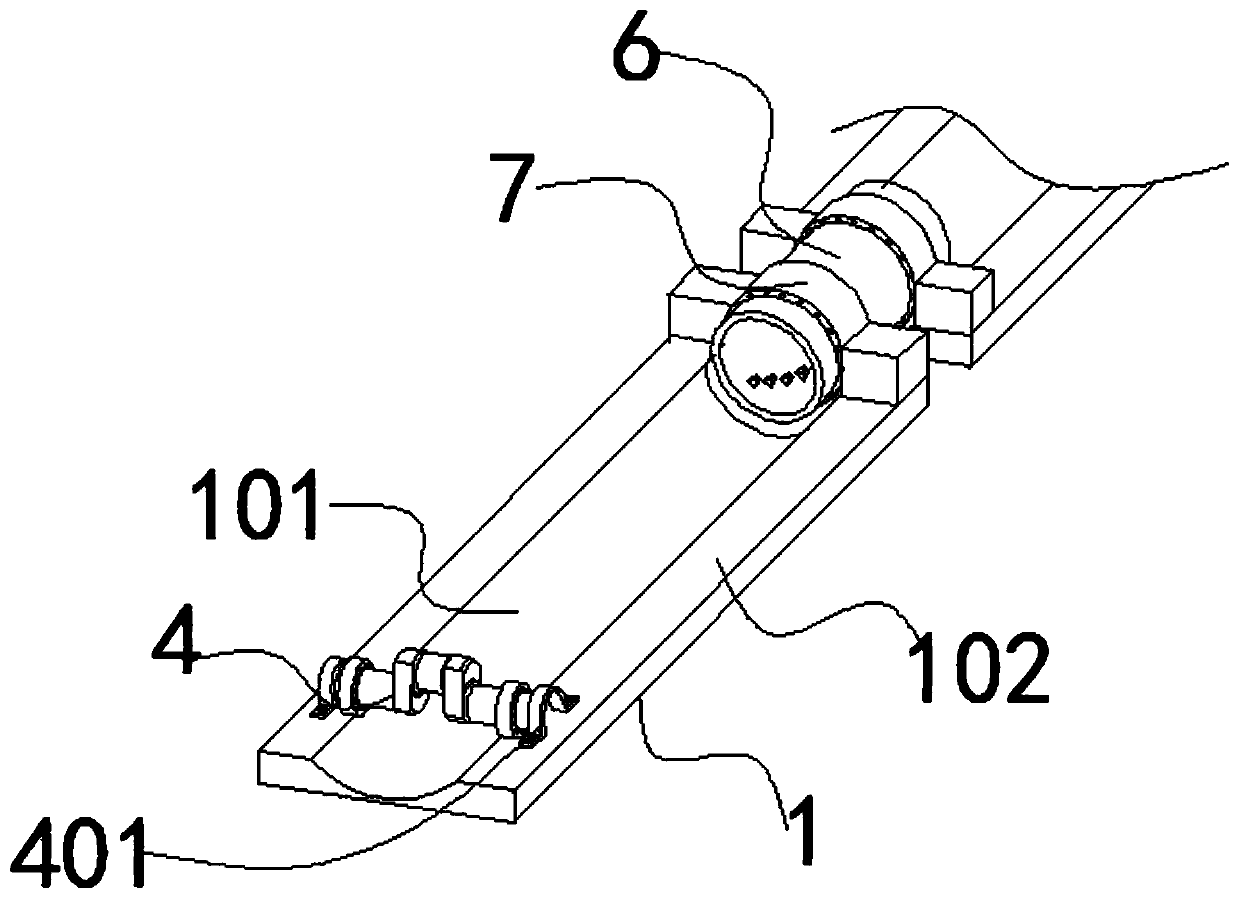

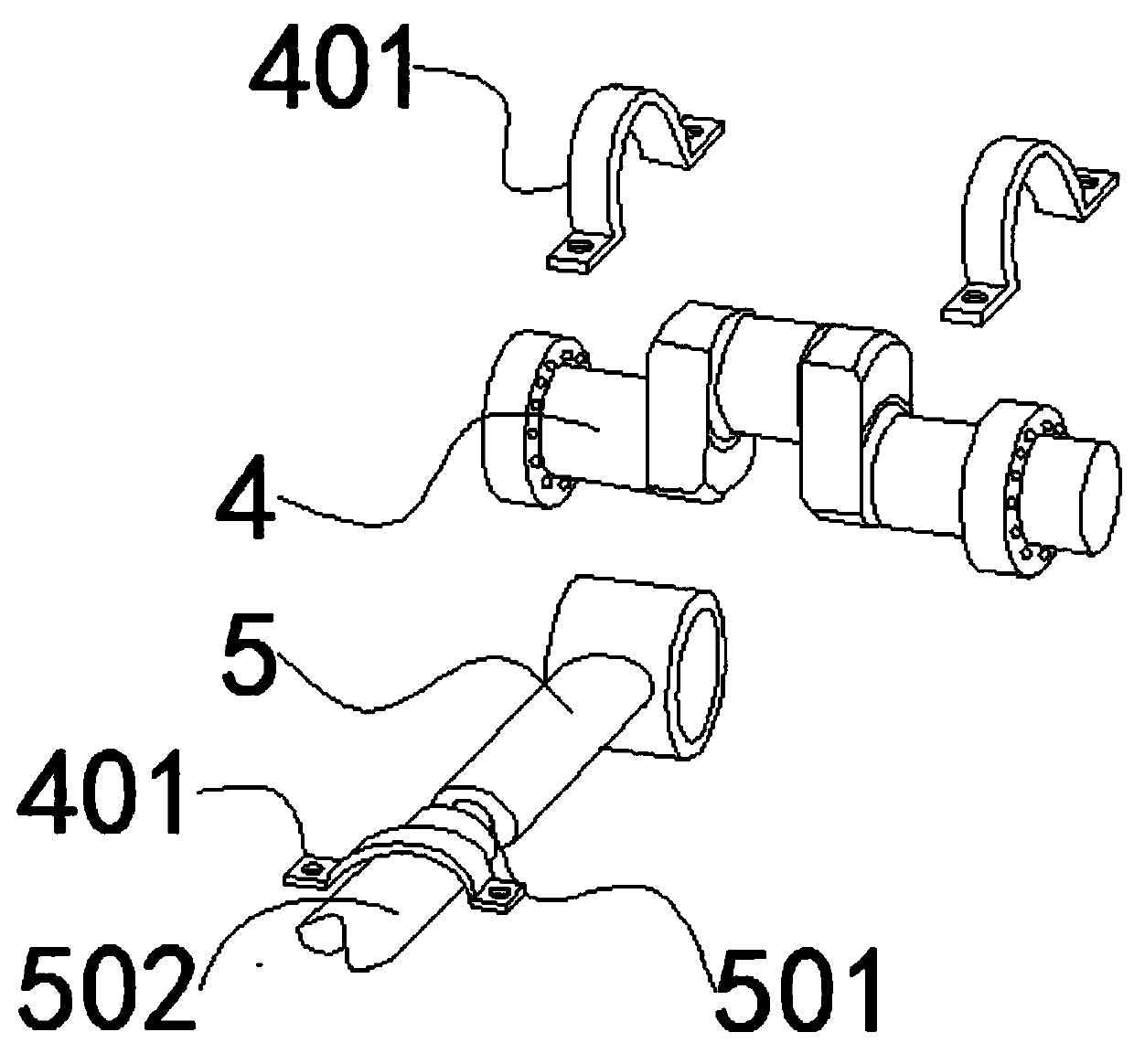

[0029] as attached figure 1 to attach Figure 6 Shown:

[0030] The present invention provides a corn peeler with a high degree of automation. The corn peeler with a high degree of automation includes a support plate 1, a feed chute 2, a discharge chute 3, a crankshaft 4, a connecting rod 5, an annular plate 6, a sleeve Plate 7, pressure bearing wheel 8, slide groove 101, carrier plate 102, buckle ring 401, hinge shaft 501, push rod 502, peeling teeth 601, passive groove 602, pulley 603, convex plate 701 and truss plate 801; support The upper and lower parts of the plate 1 are respectively fixedly connected with the feed trough 2 and the discharge trough 3, and the middle part and the left and right sides of the support plate 1 are respectively provided with a sliding groove 101 and a carrier plate 102, and the carrier plate 102 is connected from one side to the other. The crankshaft 4, the cover plate 7, and the truss plate 801 are arranged in turn on the side, and the join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com