Patents

Literature

109results about How to "Easy threshing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

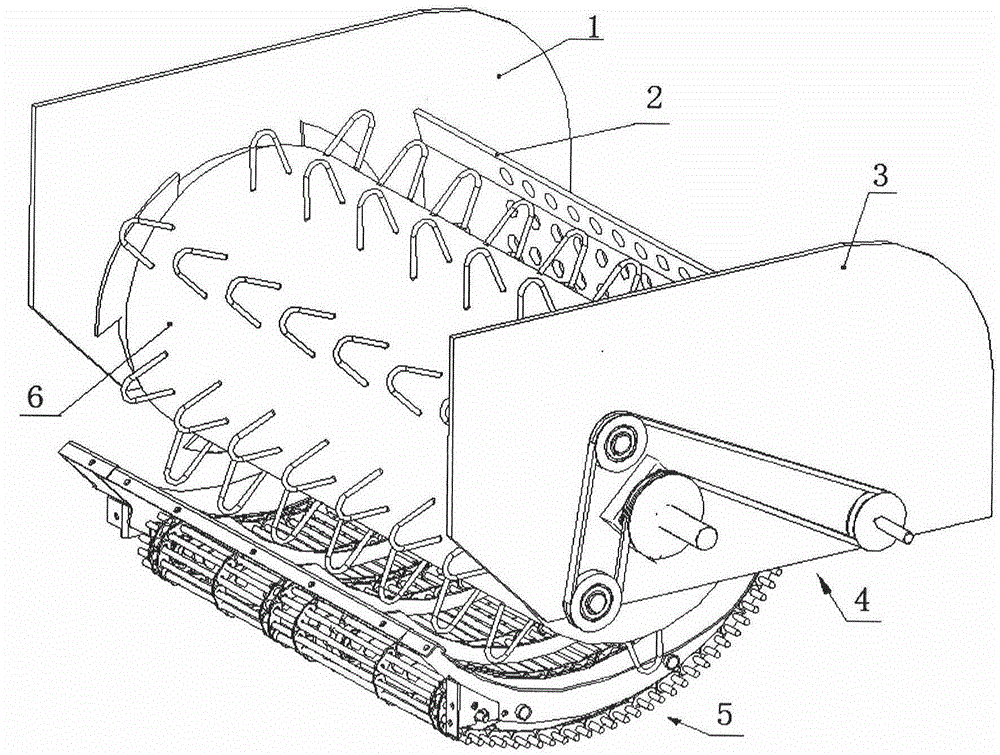

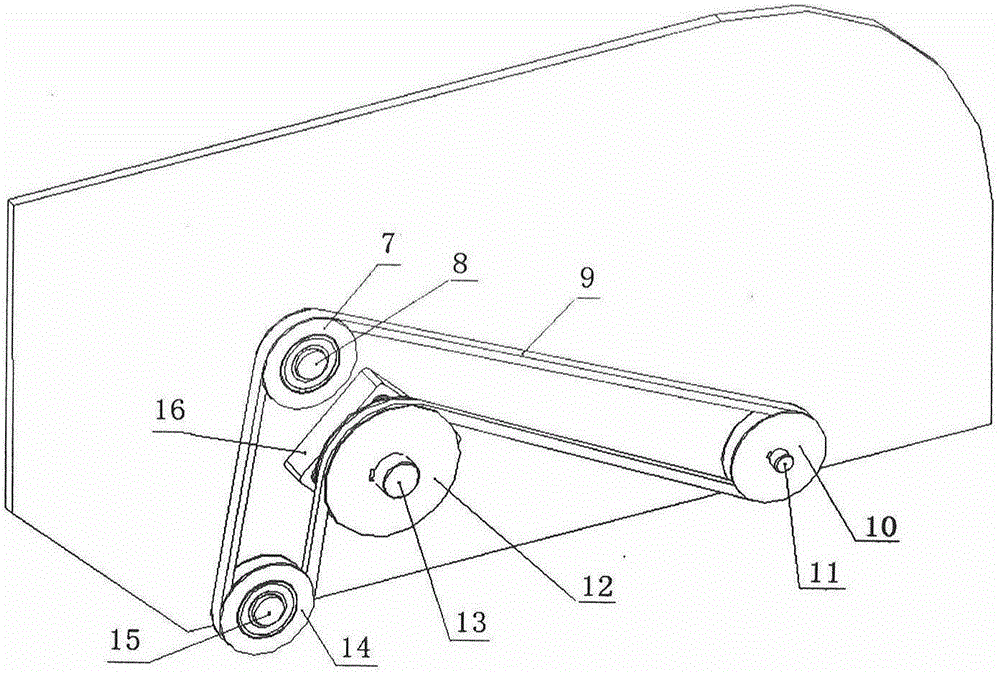

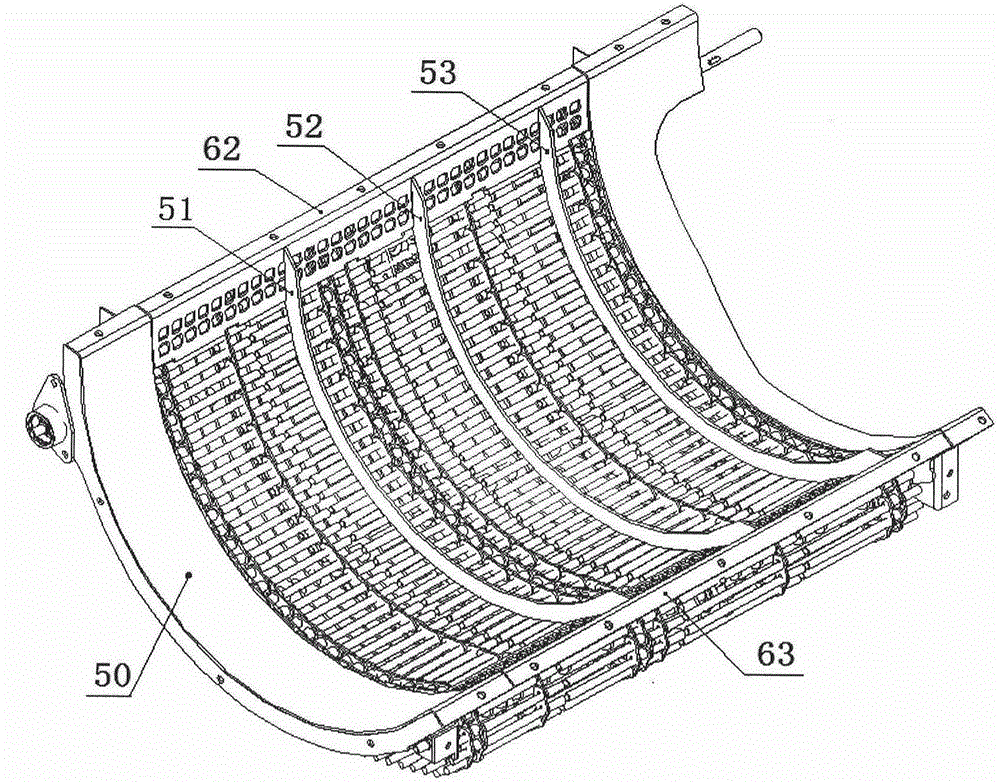

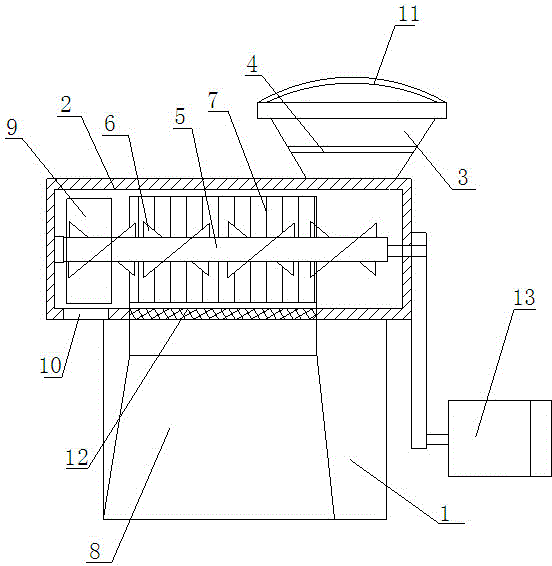

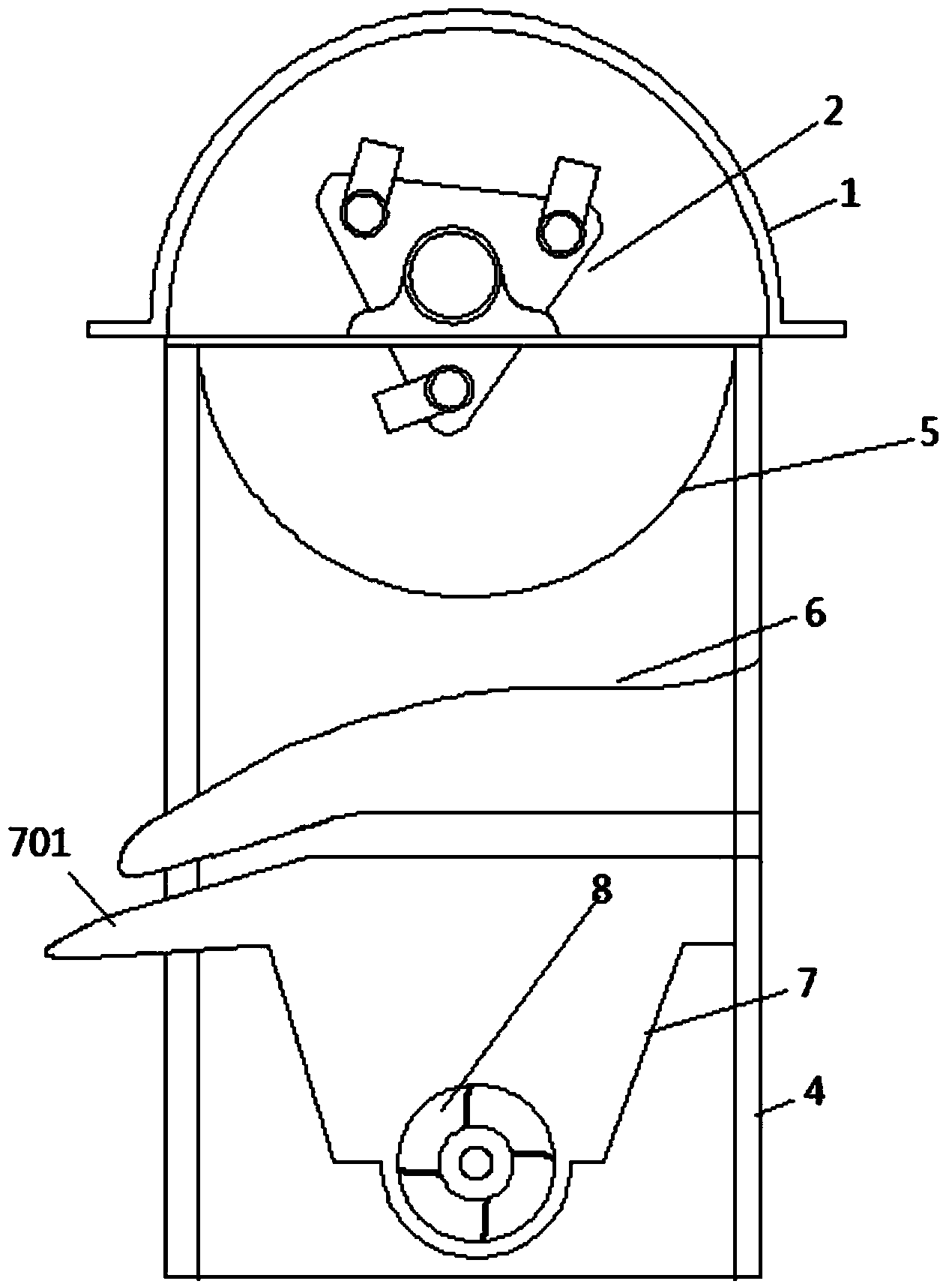

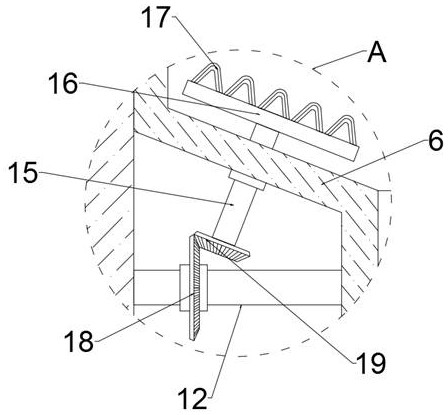

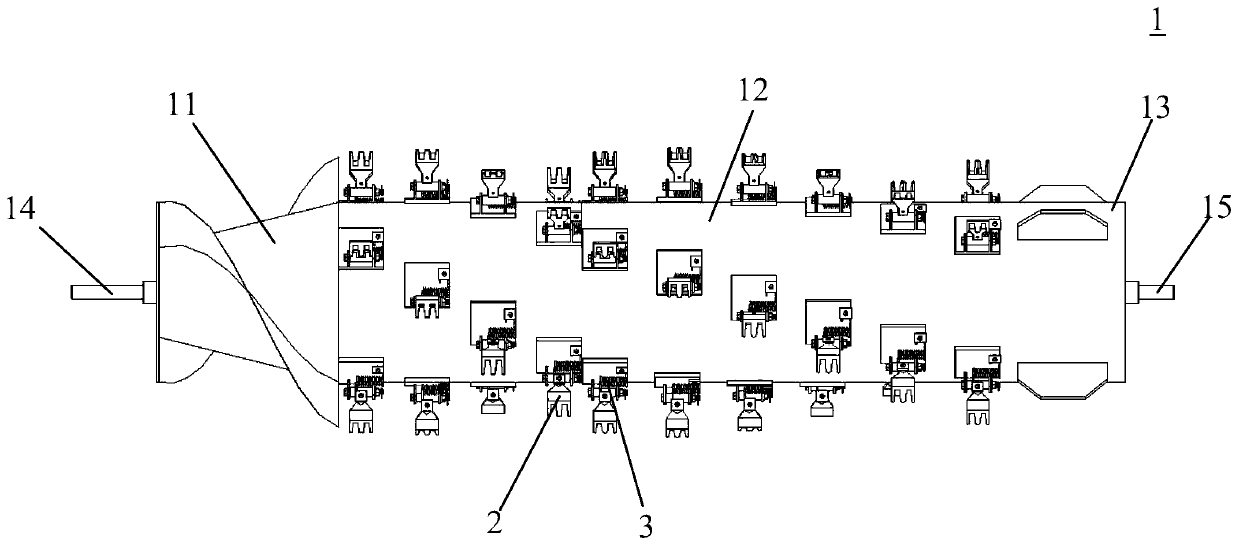

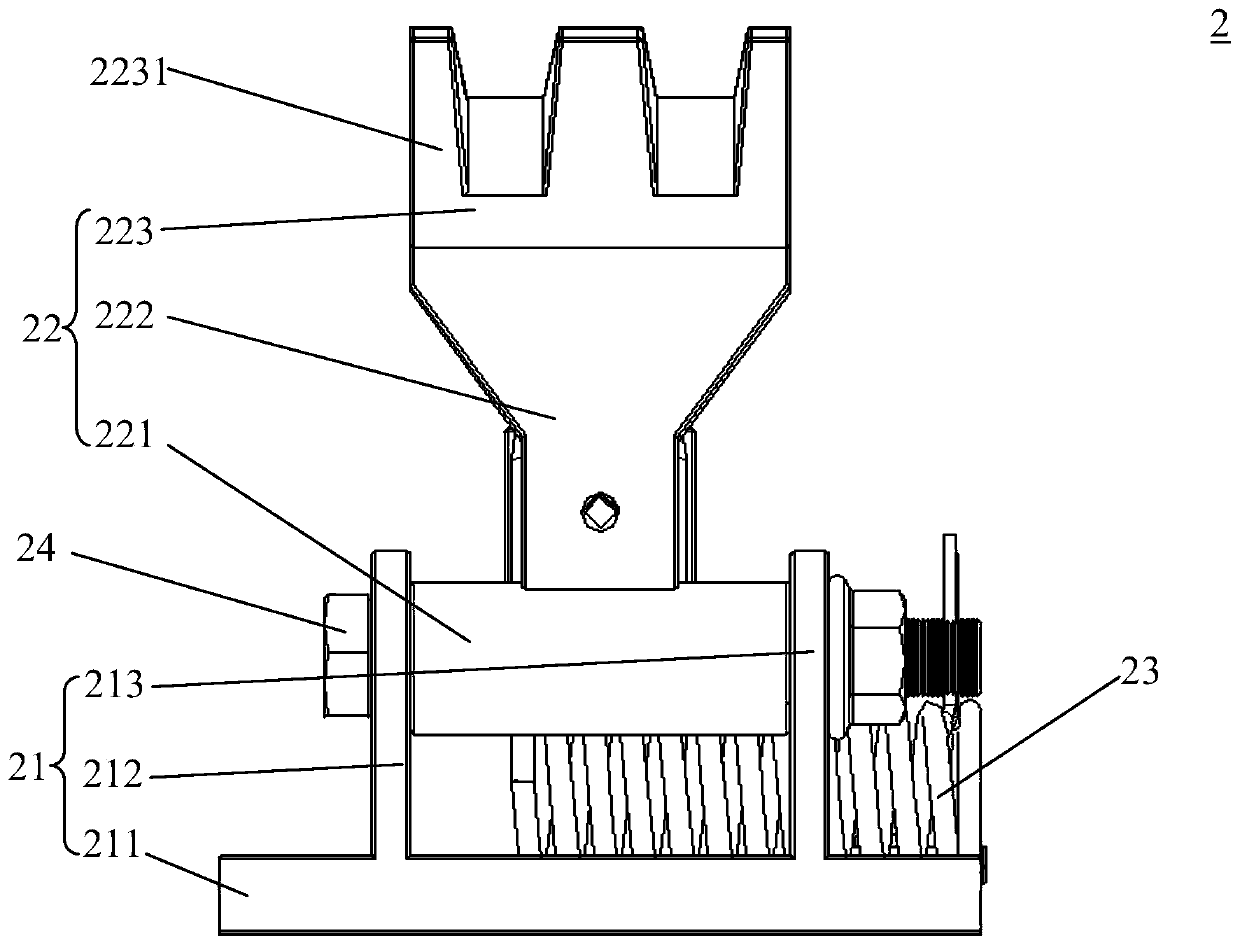

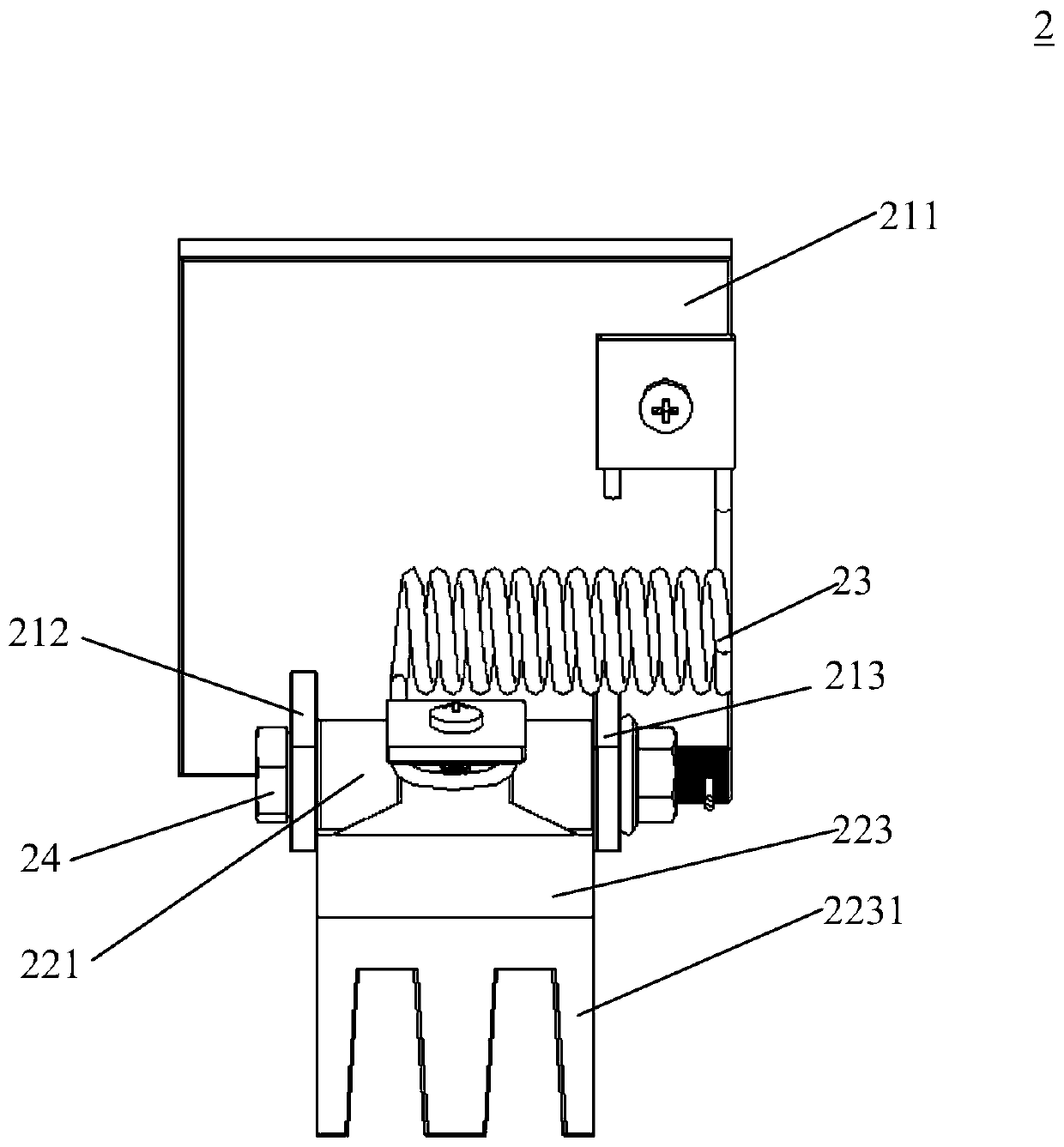

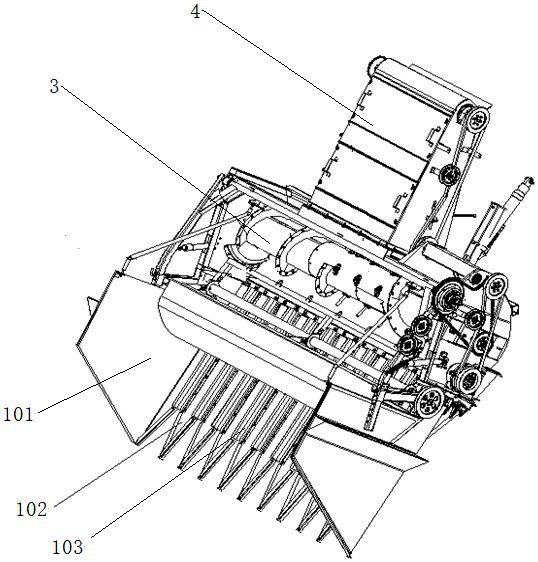

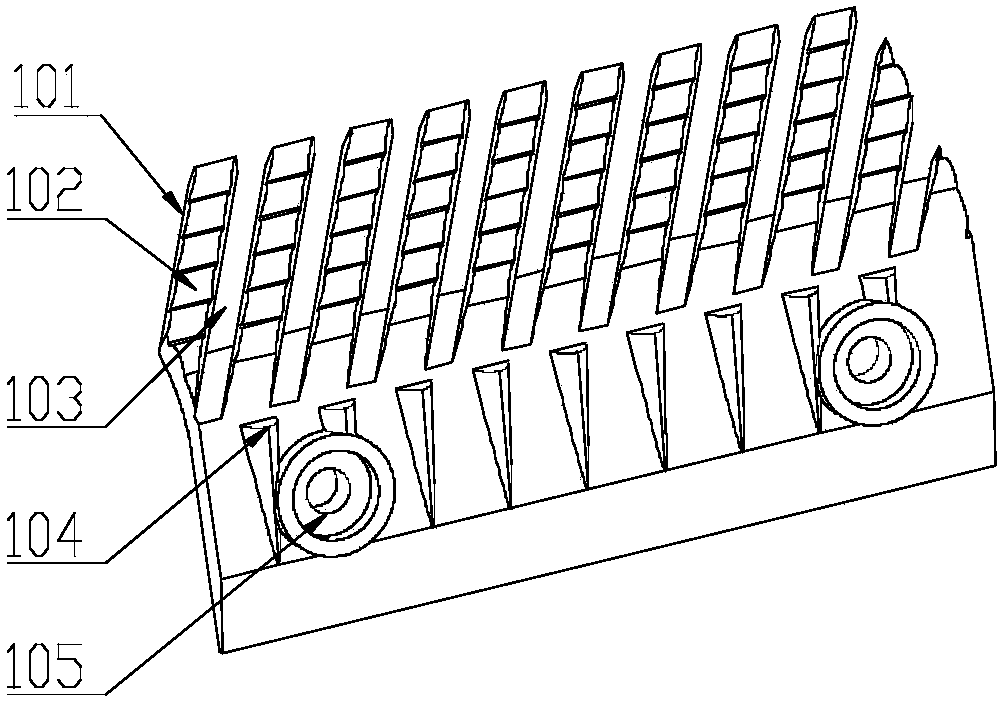

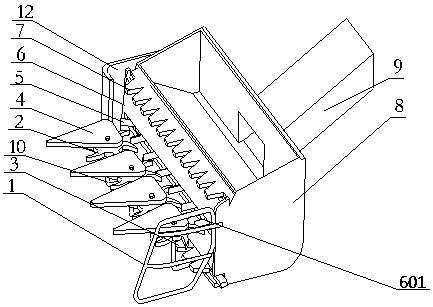

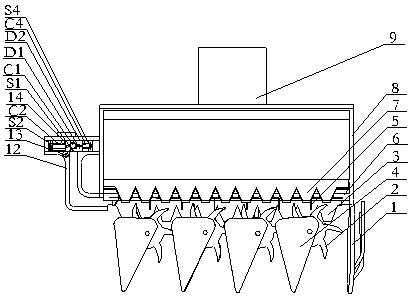

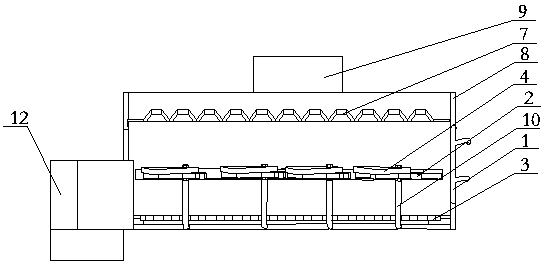

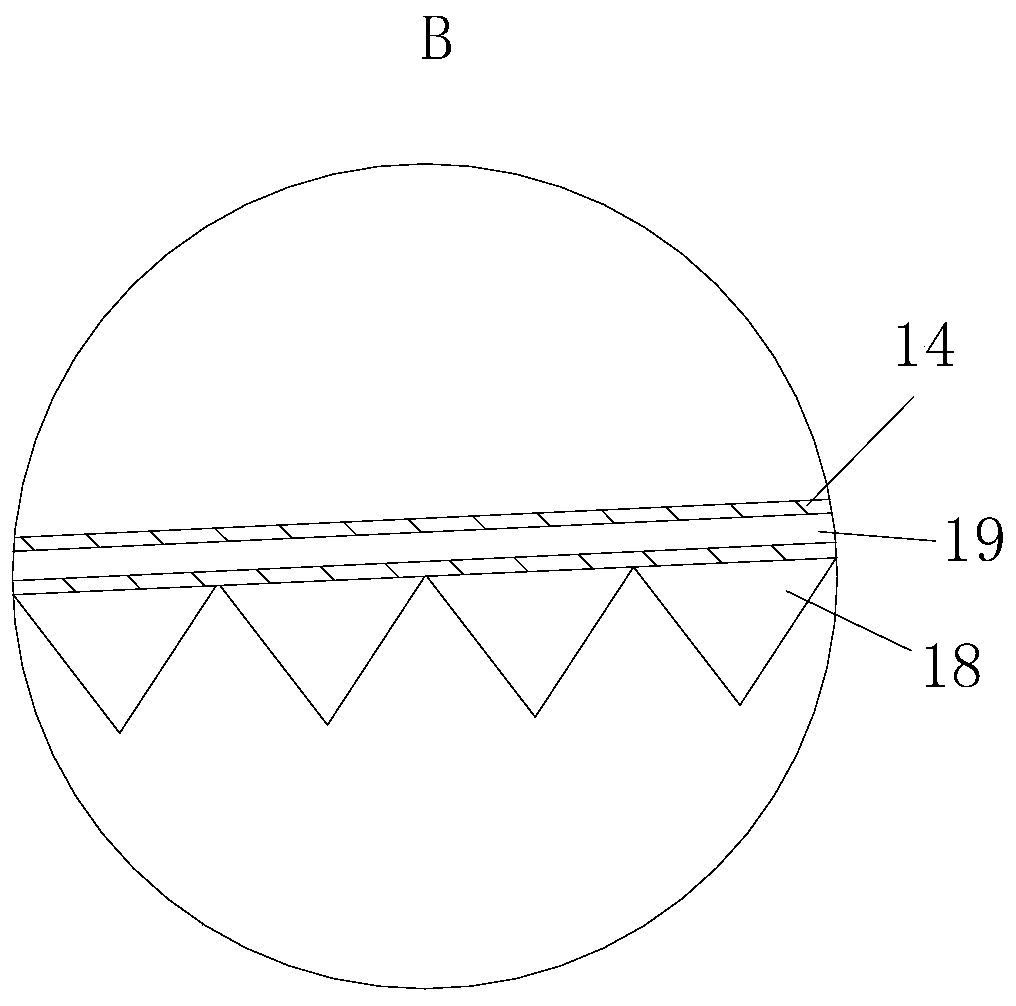

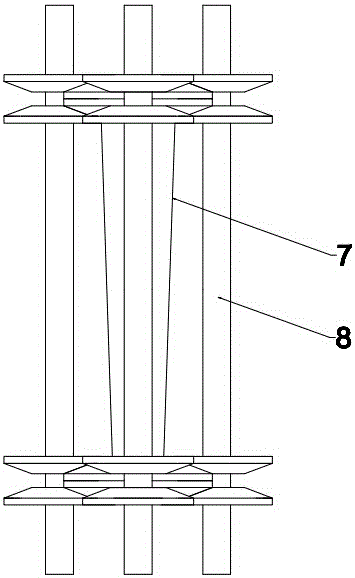

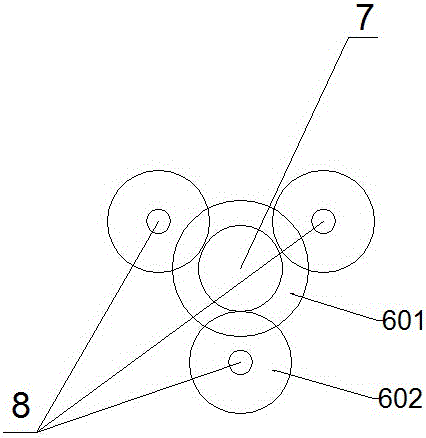

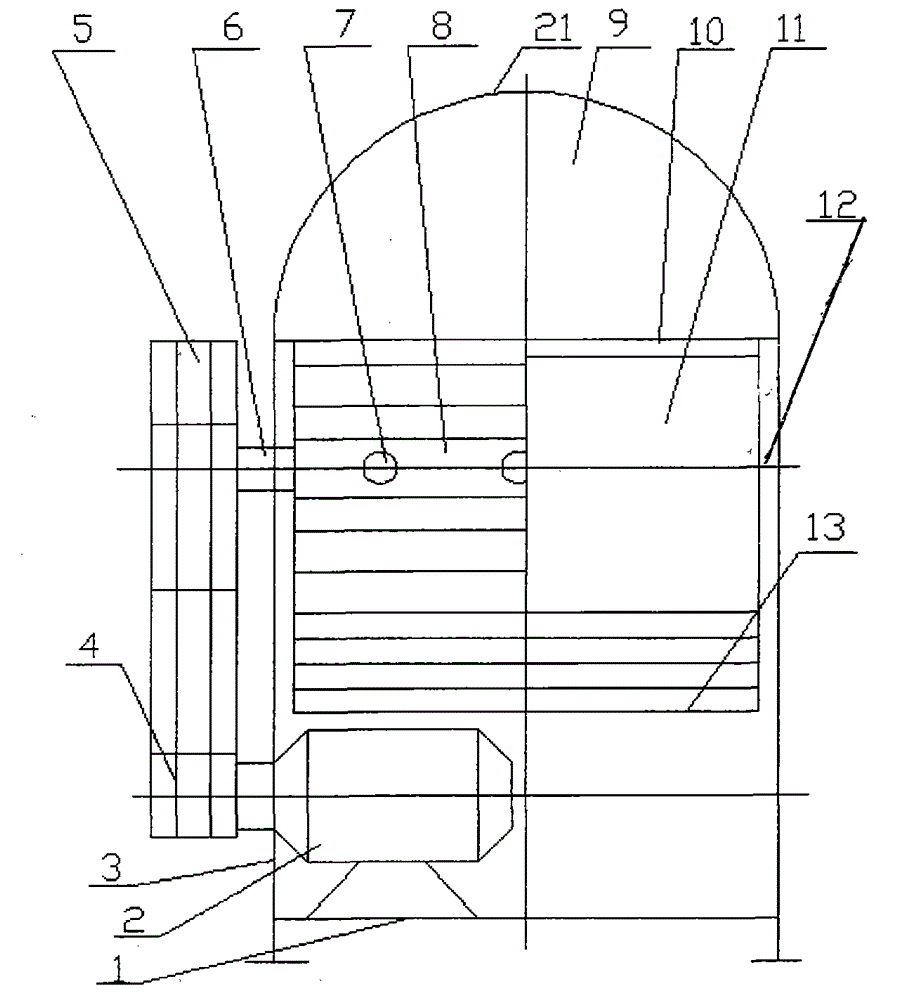

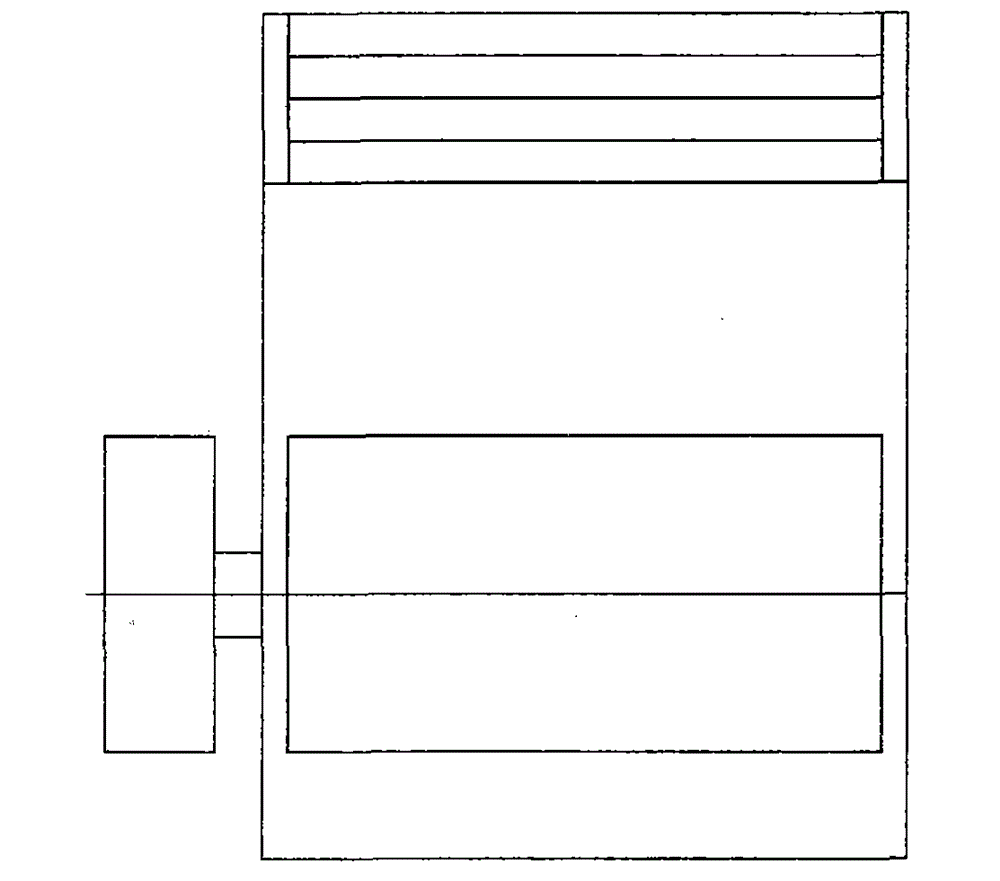

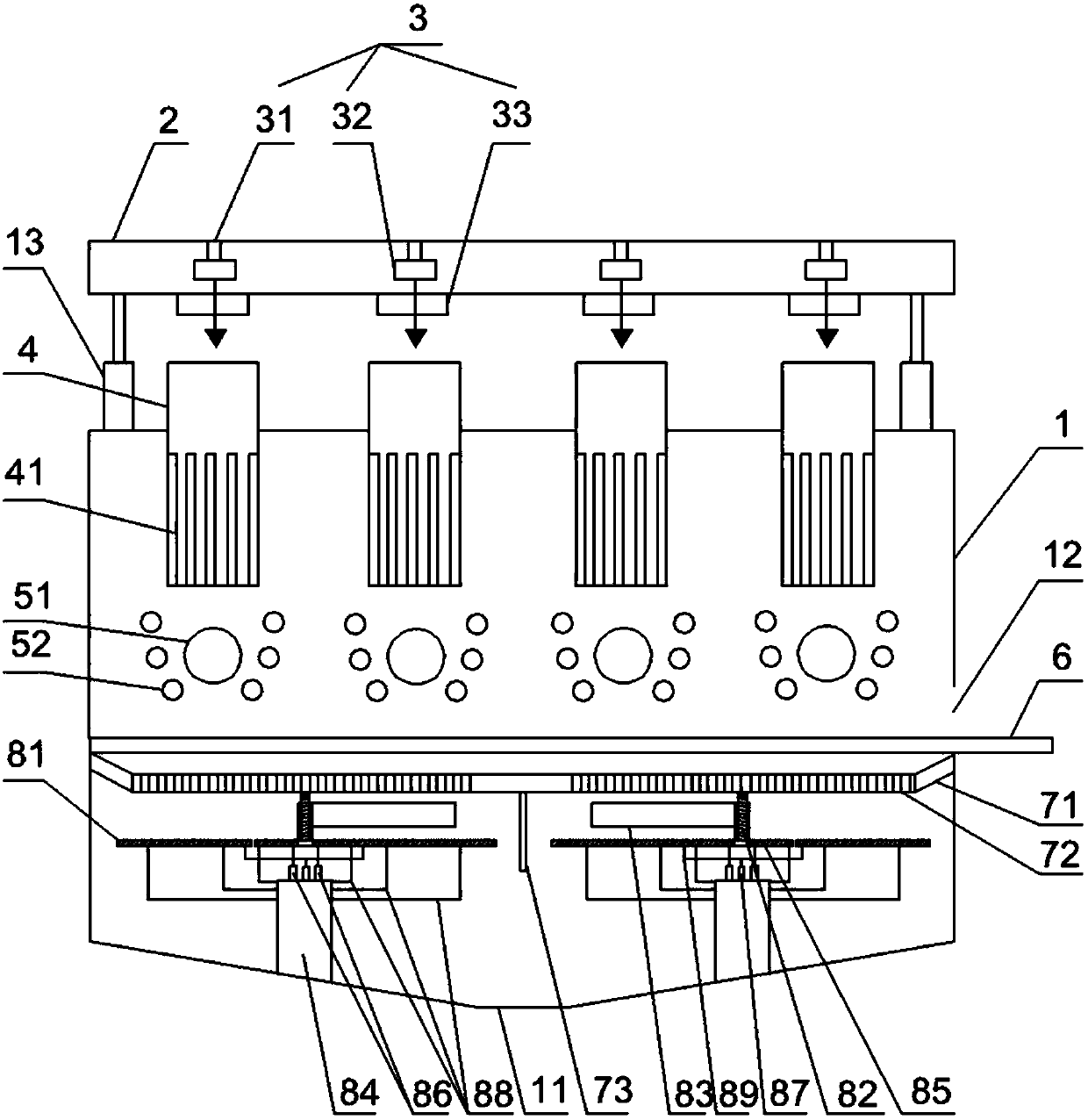

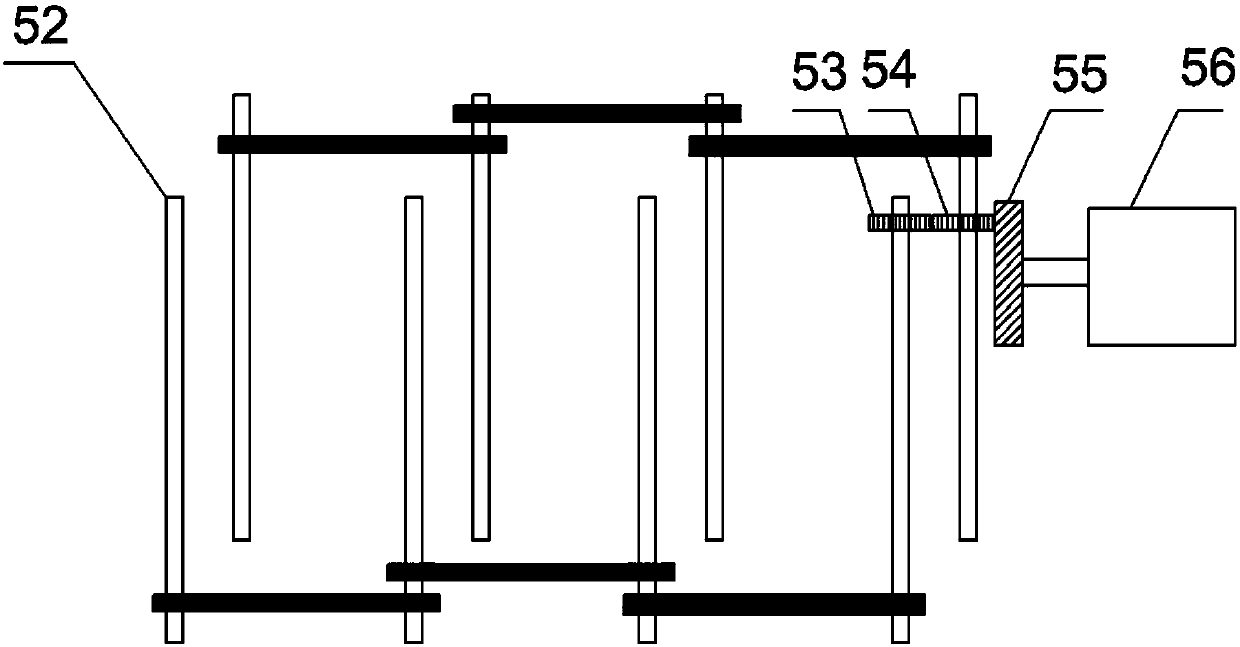

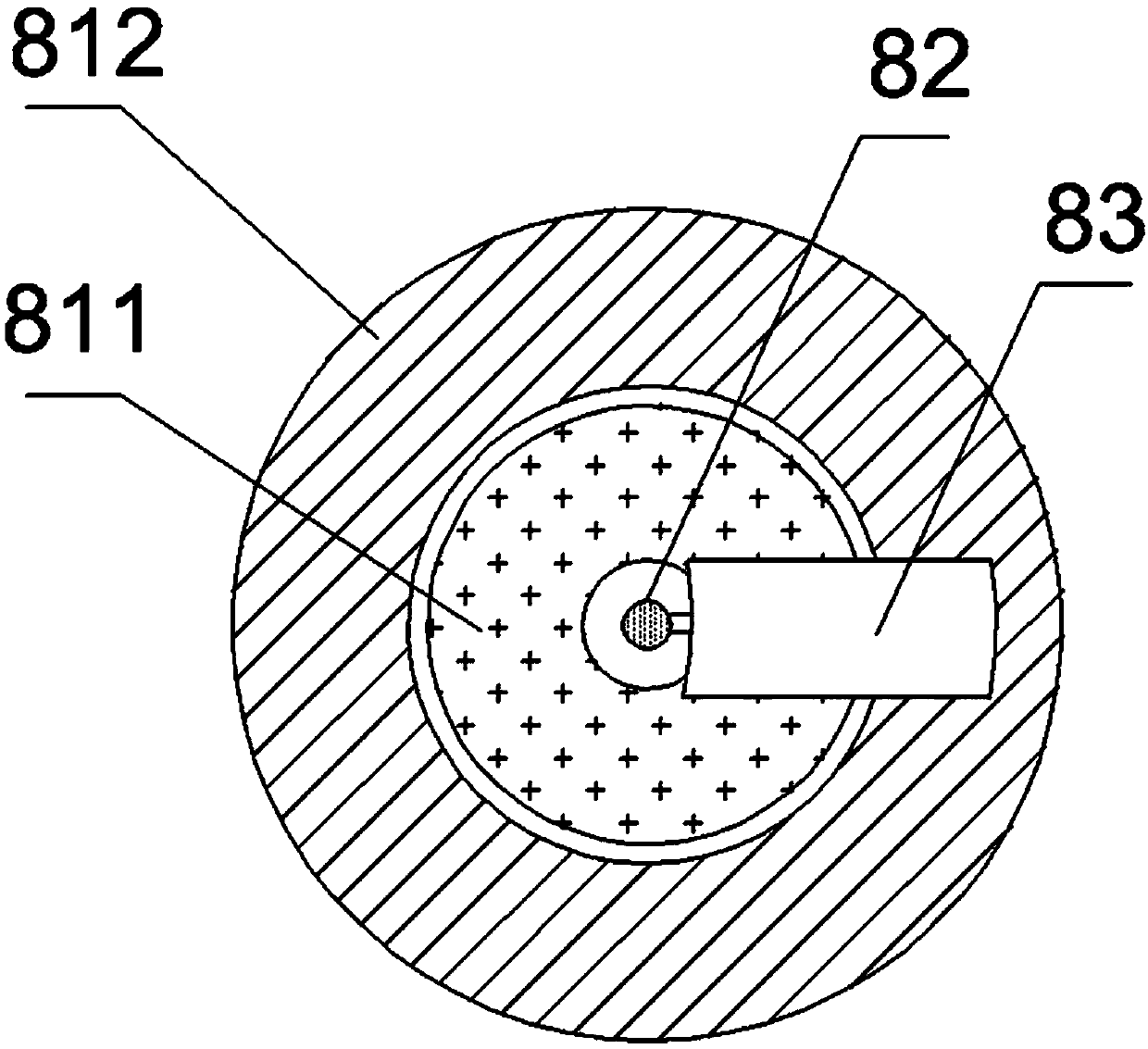

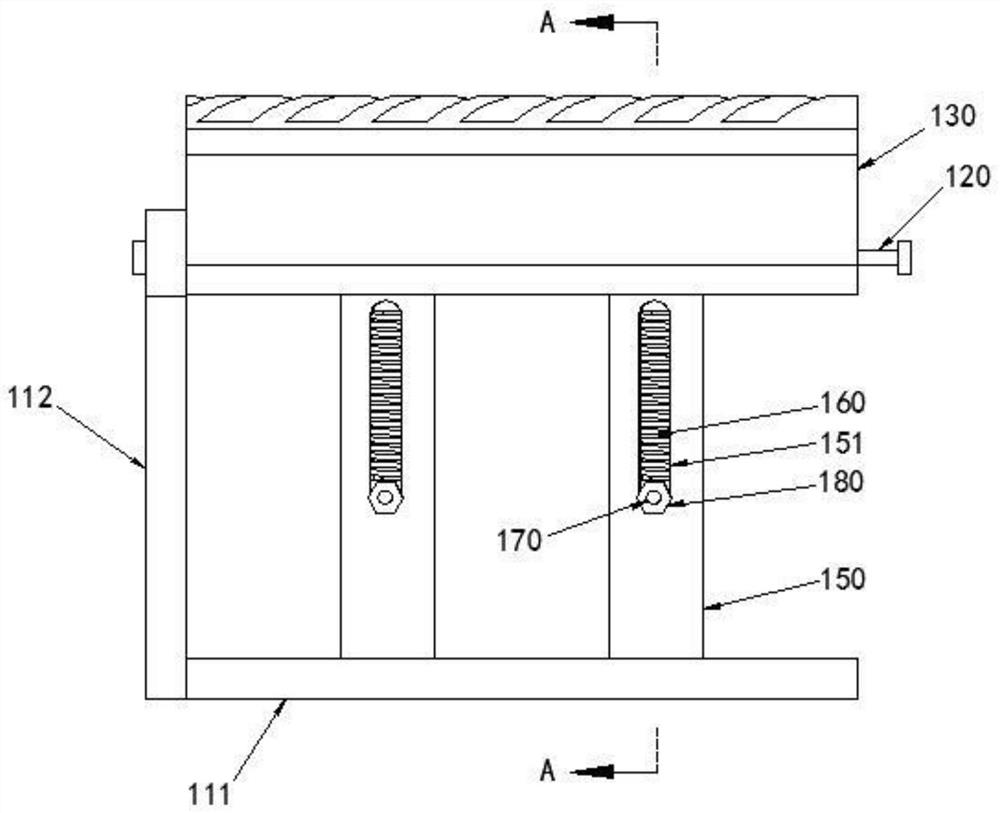

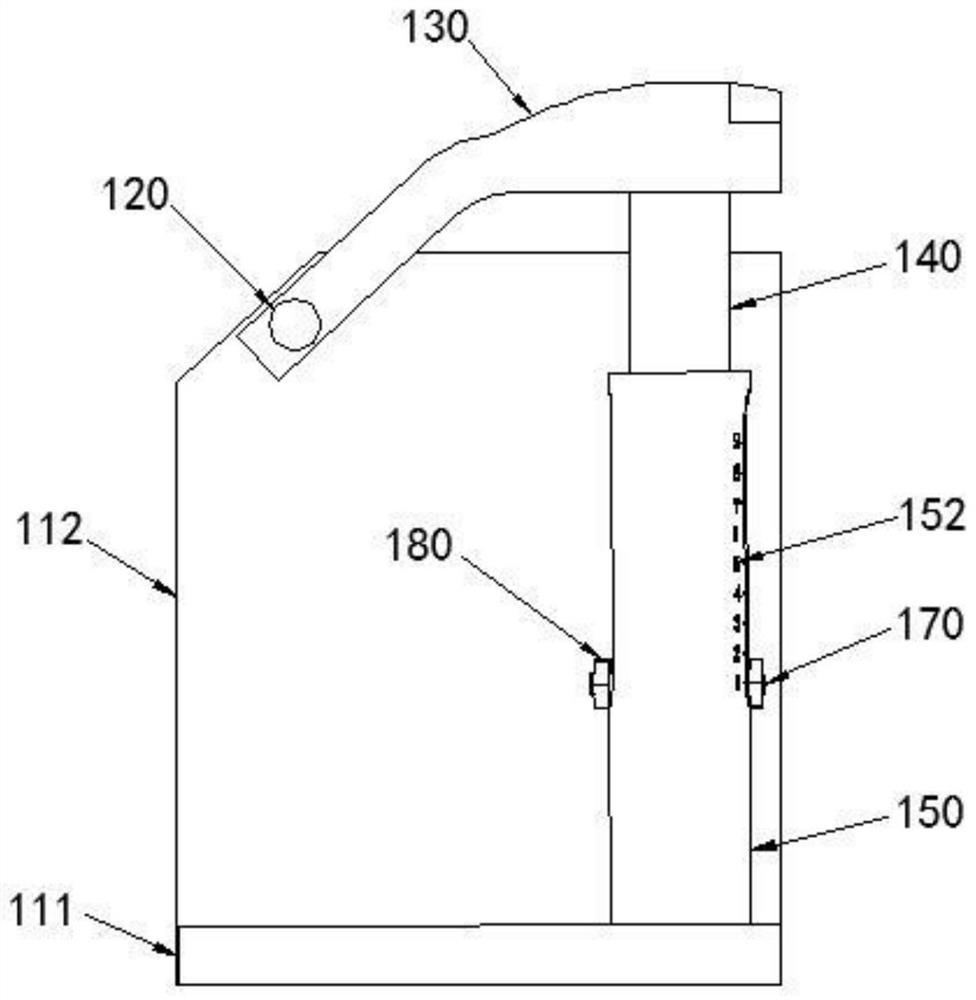

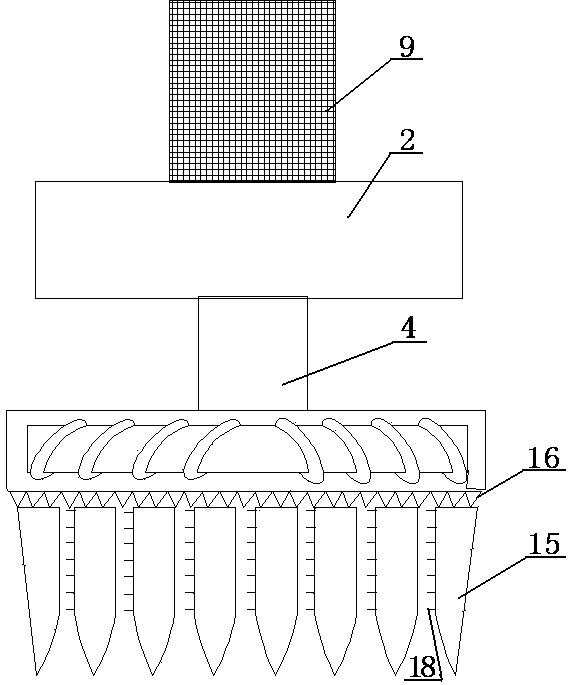

Half-feeding combine harvester threshing and separating device with revolving concave grid

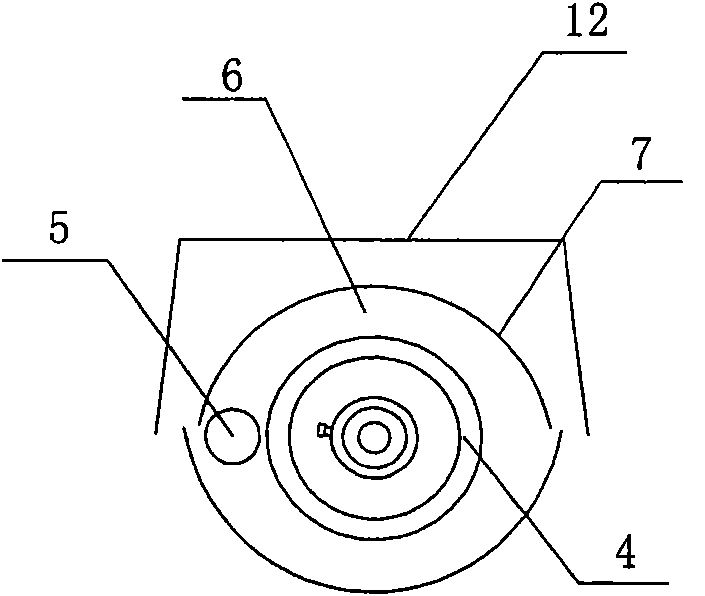

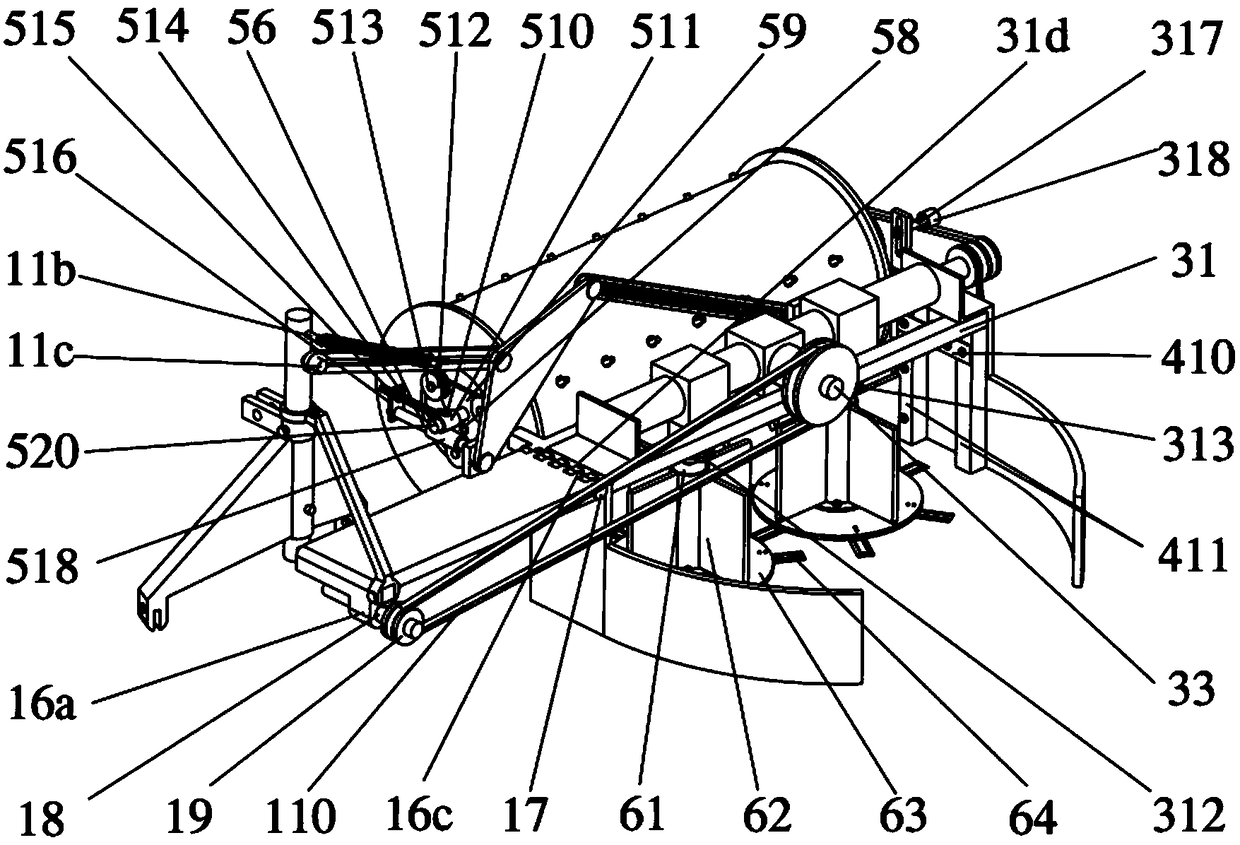

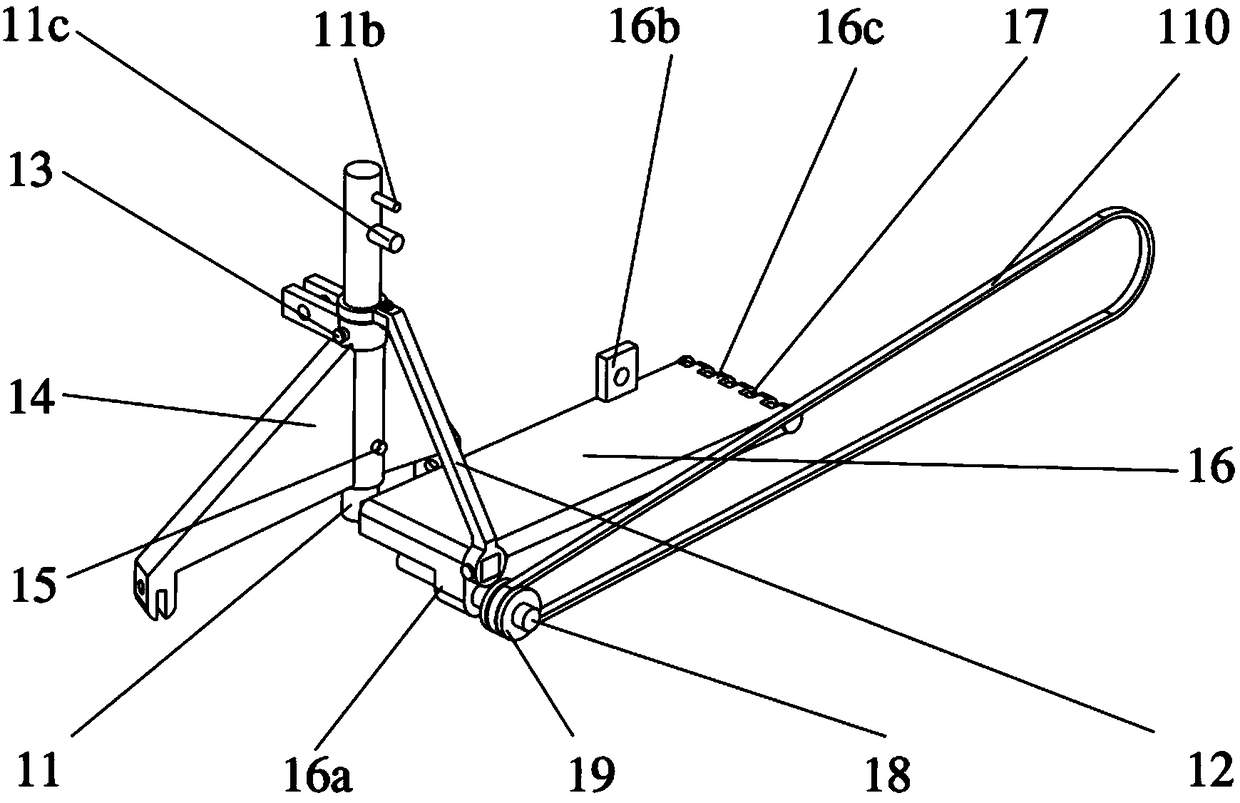

The invention relates to the field of agricultural machinery, in particular to a half-feeding combine harvester threshing and separating device with a revolving concave grid, which is mainly applied to a half-feeding paddy rice combine harvester and is used for enhancing the threshing and separating capabilities, increasing the granule threshing rate, greatly lowering the blockage probability of a threshing device and increasing the production efficiency during operation of the half-feeding paddy rice combine harvester. The half-feeding combine harvester threshing and separating device mainly comprises a left wall plate, a porous plate, a right wall plate, a V-shaped belt transmission assembly, a revolving concave grid assembly and a threshing drum. The half-feeding combine harvester threshing and separating device is reasonable in structure; crops are prevented from being accumulated in the threshing device and causing blockage due to revolving motion of a concave grid surface during operation, the threshing and separating capabilities are enhanced, and adaptation to harvesting of high-yield crops in a wet environment is realized; the upper layer surface of the concave grid moves at a certain linear speed, so that combing and threshing are realized on the upper and lower layers of the crops, overhead and bent grains are combed and threshed, and the loss caused by incomplete threshing is reduced.

Owner:JINHUA VOCATIONAL TECH COLLEGE

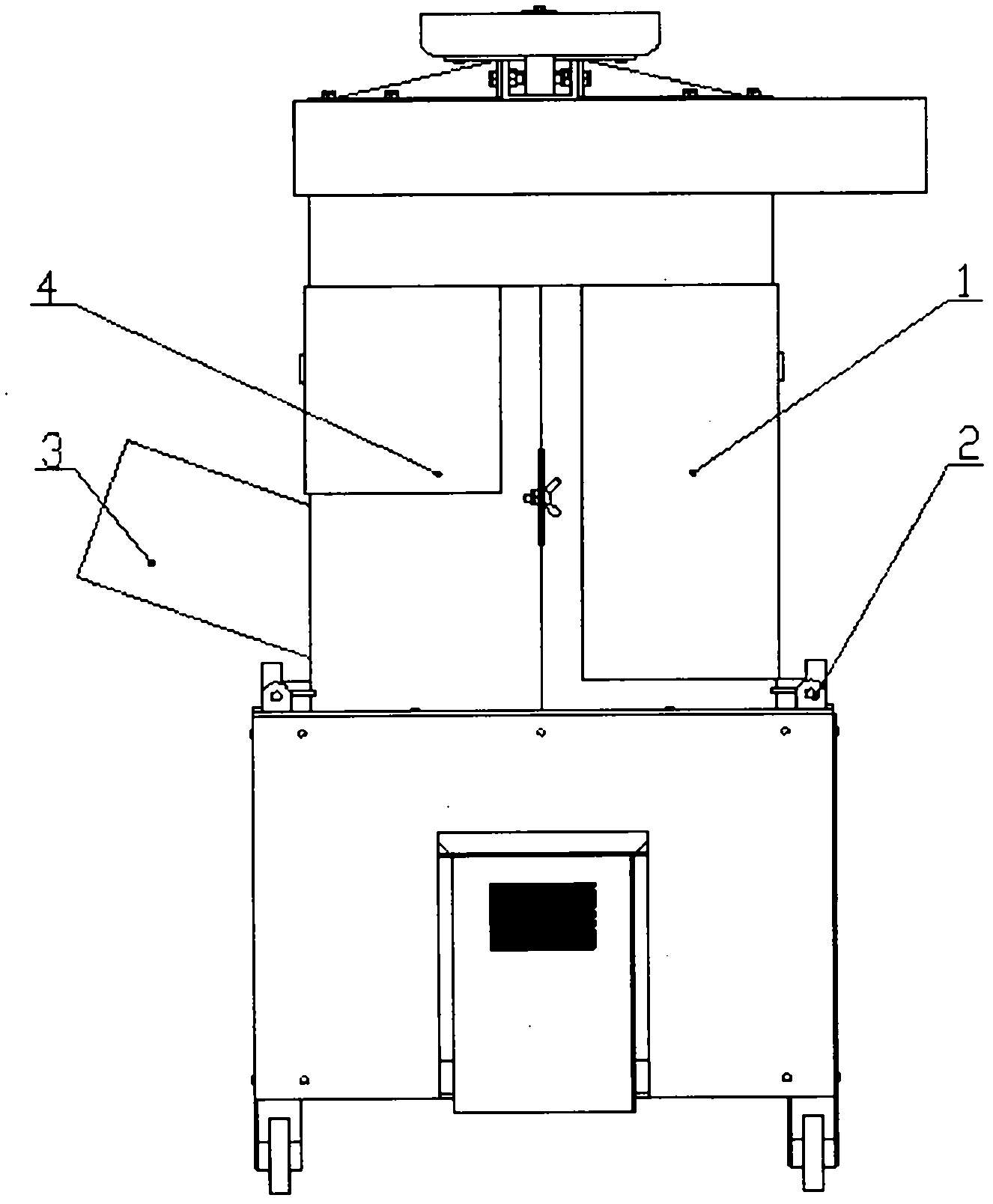

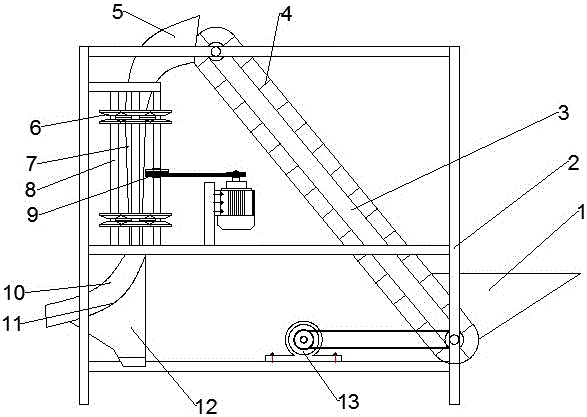

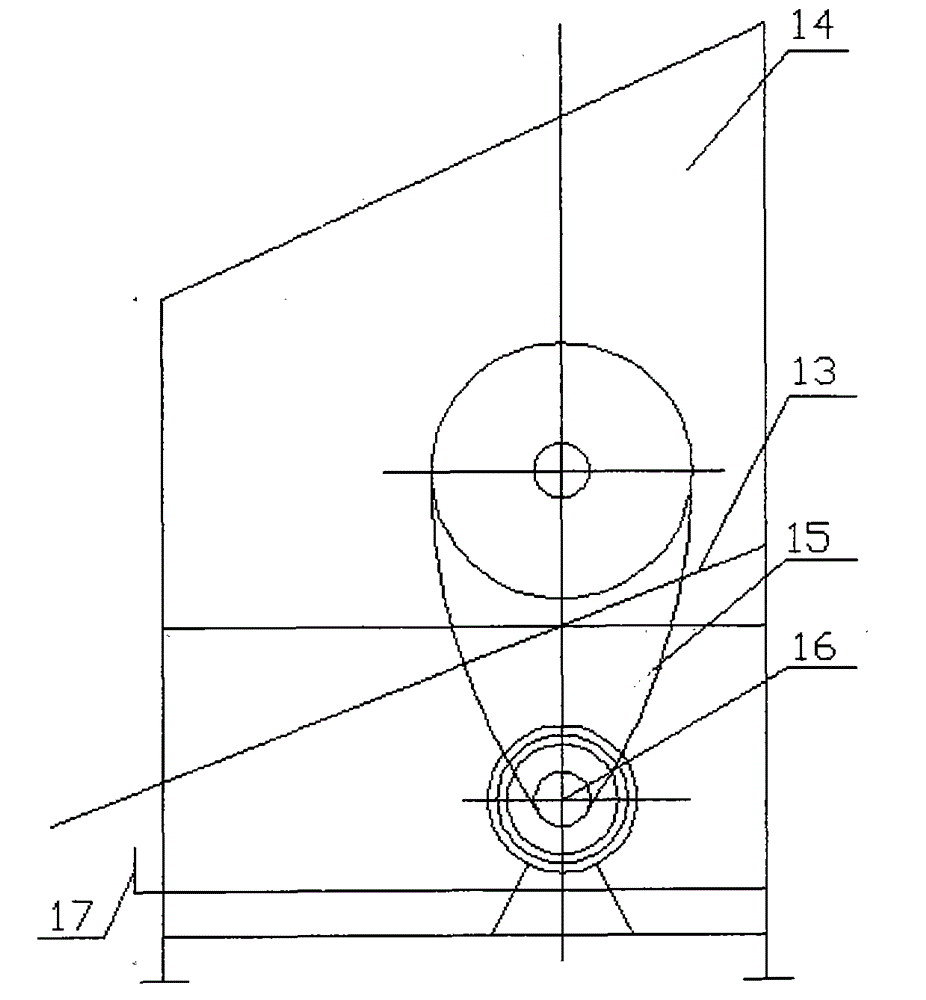

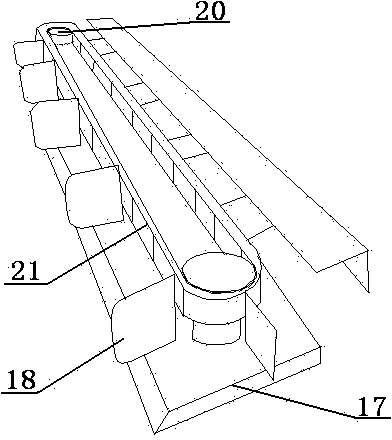

Vertical type axial flow threshing machine specially designed for breeding soybeans

The invention provides a vertical type axial flow threshing machine specially designed for breeding soybeans, and belongs to the field of farm machinery. The threshing machine consists of a machine frame, a cantilever beam, a visual combined cover, a threshing cylinder, a blade type cleaning cylinder, a stalk-discharging fan, a centrifugal fan, a feed inlet, a material collecting port and a seed outlet, wherein the visual combined cover is hinged on both ends of the machine frame and can be freely opened and closed, and organic glass is fixedly arranged on the surface of the cover; and the threshing cylinder, the blade type cleaning cylinder and the stalk-discharging fan are fixedly connected in sequence, and a cleaning air channel is arranged in the middle of the threshing cylinder. The machine can complete the operation of threshing, separating and cleaning at the same time, has the characteristics of small volume, light weight, reasonable structure, convenient and quick cleaning, high maneuverability and the like, and can meet the requirements of the accurate yield measurement in scientific research and production.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

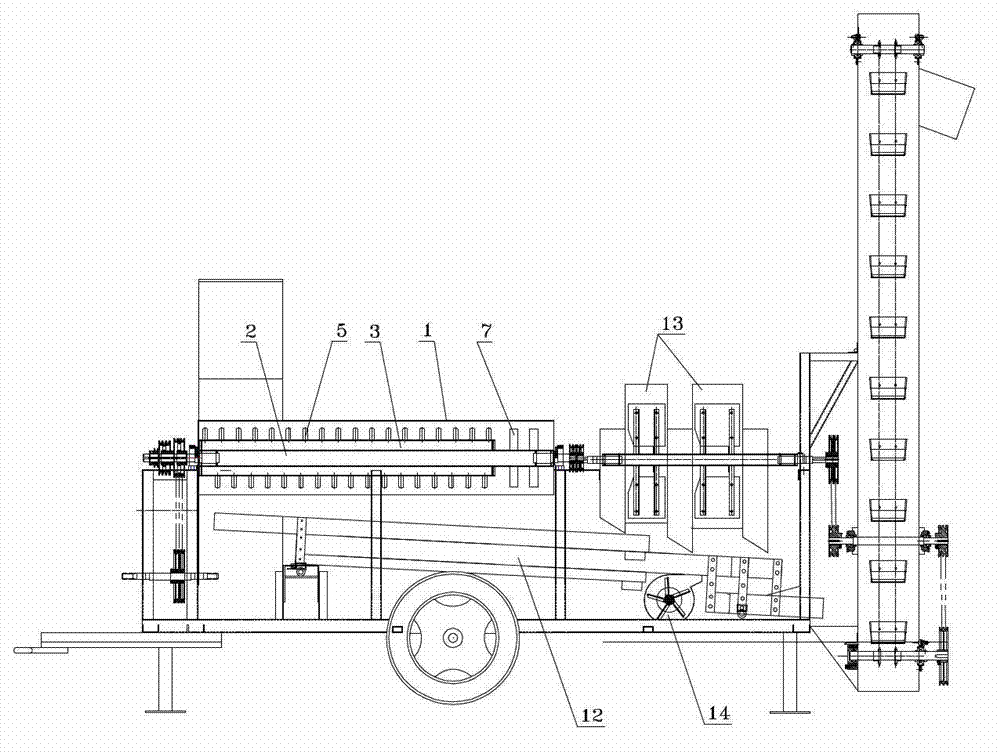

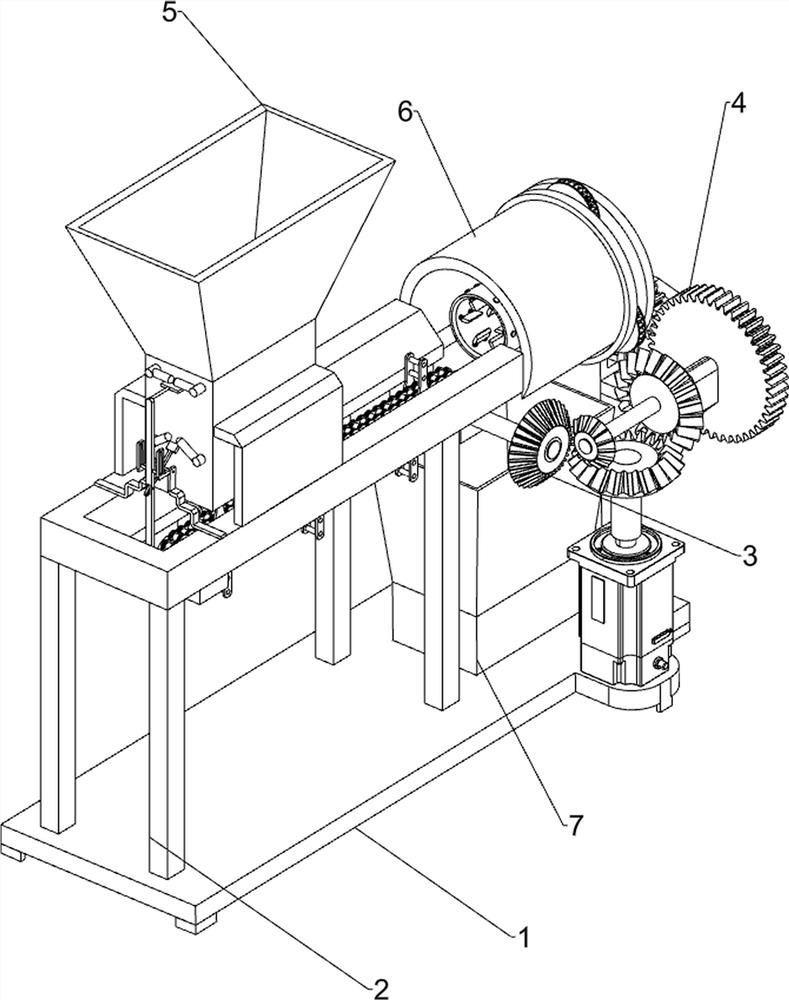

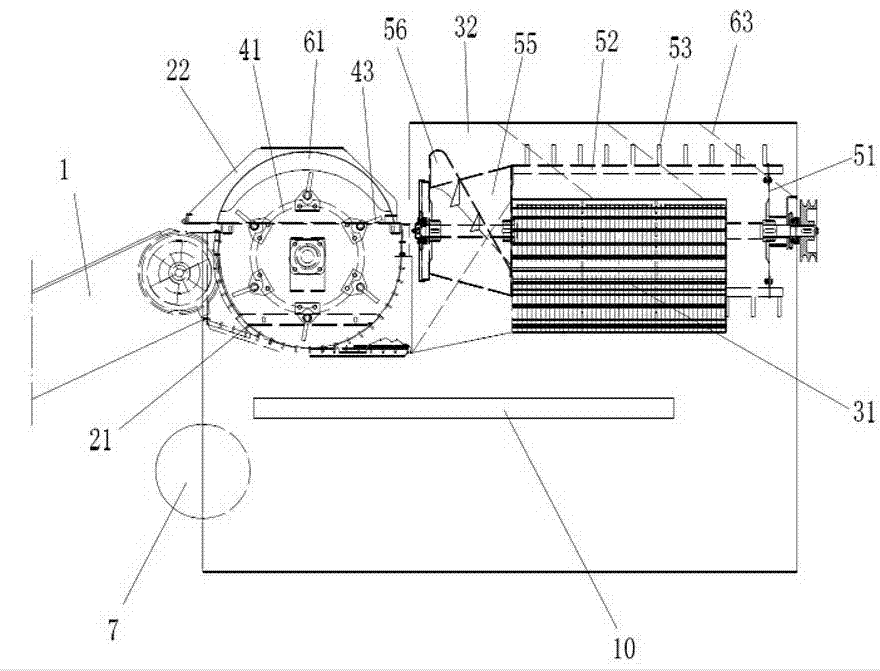

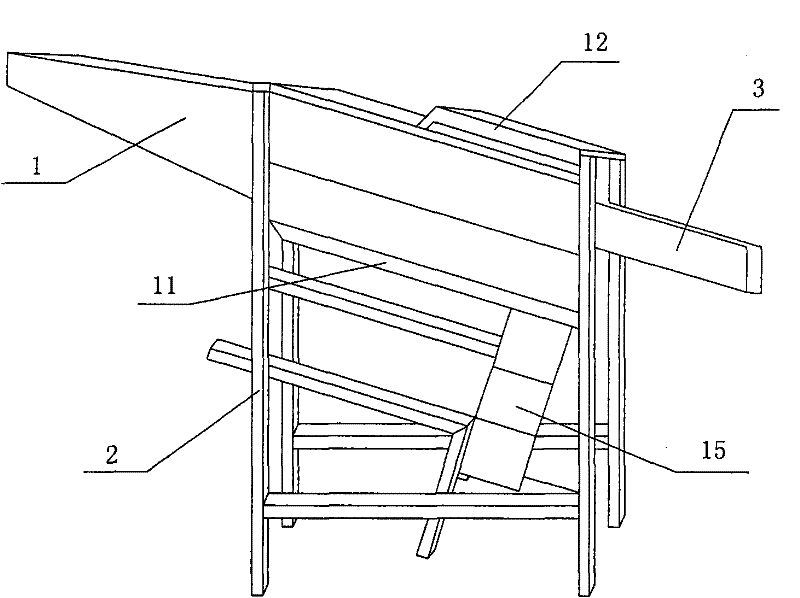

Efficient corn-threshing method

An efficient corn-threshing method mainly solves the problems that existing corn-threshing methods are low in threshing efficiency and poor in threshing and separating effect. The efficient corn-threshing method is characterized by comprising conveying corn cobs or corn cobs with skins to a main threshing barrel (1) through a feeding device; performing primary threshing on the corn cobs, and performed primary screening; performing secondary threshing on the corn cobs through an auxiliary threshing roller (4), and performing primary screening; performing secondary screening out of corns by swinging an upper sieve plate (9), a middle screen (10) and a lower sieve plate (11); performing third screening out of the corns above the upper sieve plate (9), the middle screen (10) and the lower sieve plate (11) through a suction fan (13) of a careful selection device; performing fourth screening out of the corns through a blower (14) of a cleaning device; and finally bagging the corns or loading the corns to a vehicle through an output loading device. The efficient corn-threshing method has the advantages of being high in efficiency and guaranteeing quality.

Owner:QIQIHAR BEIKUN AGRI MACHINERY MFG

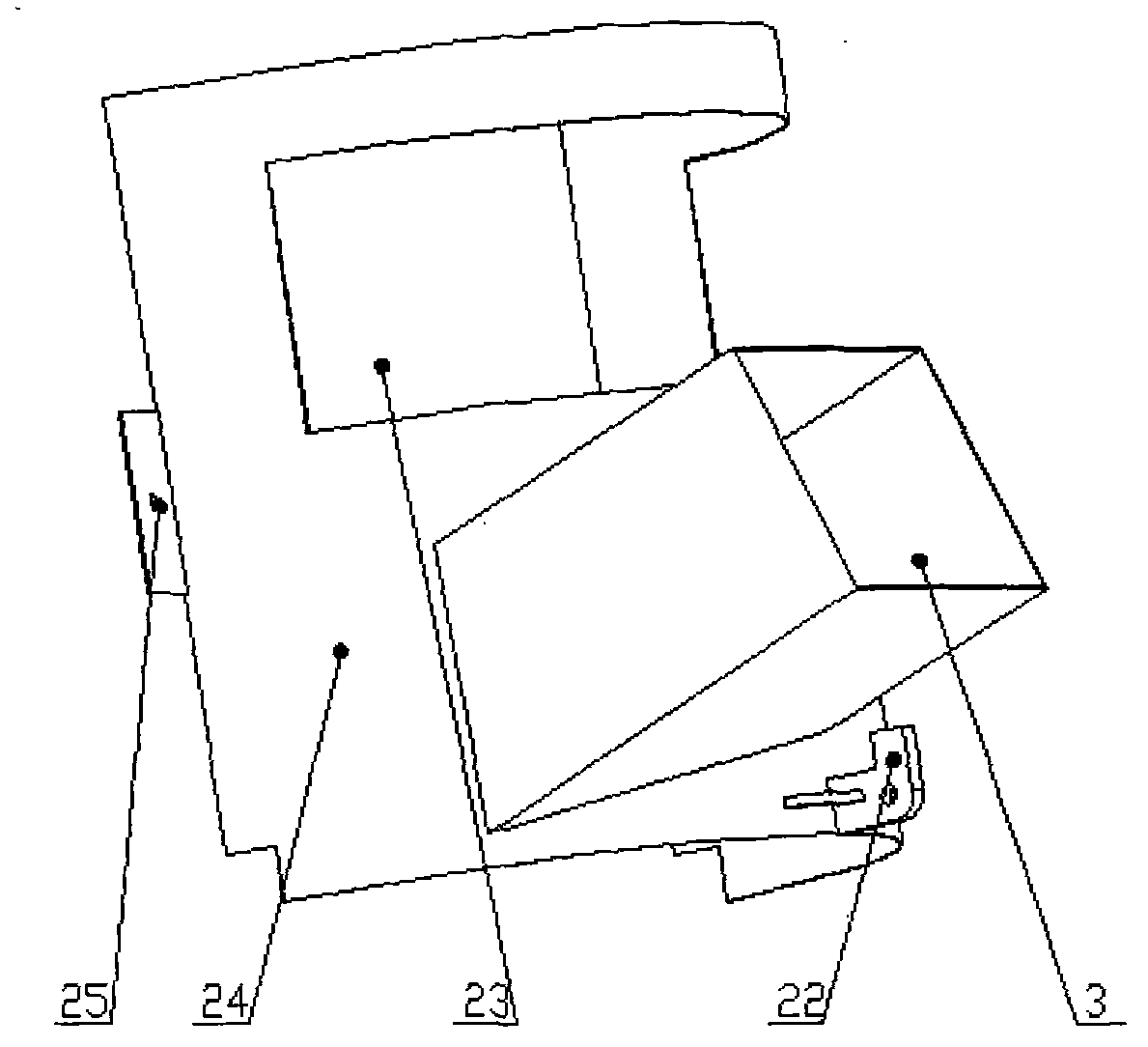

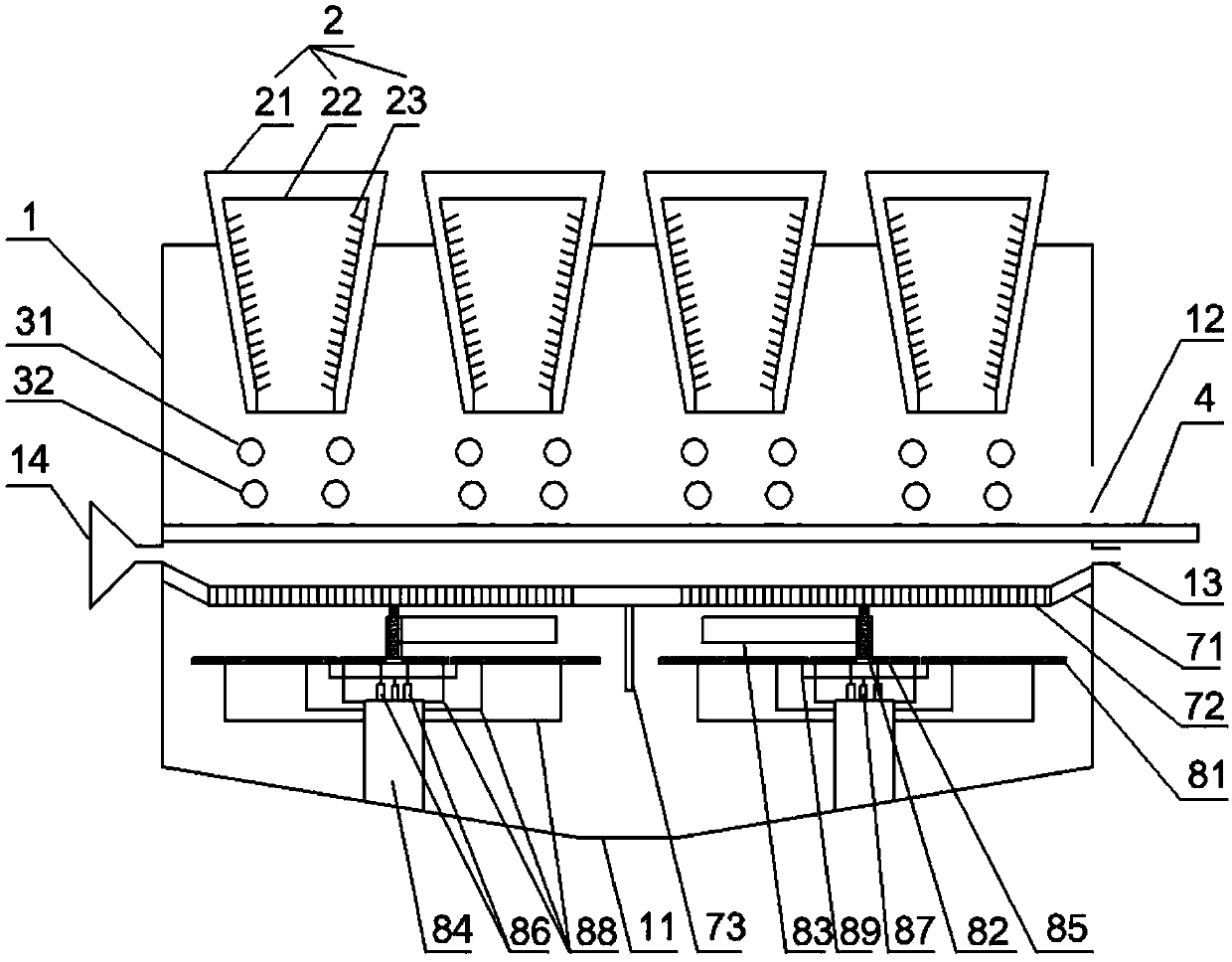

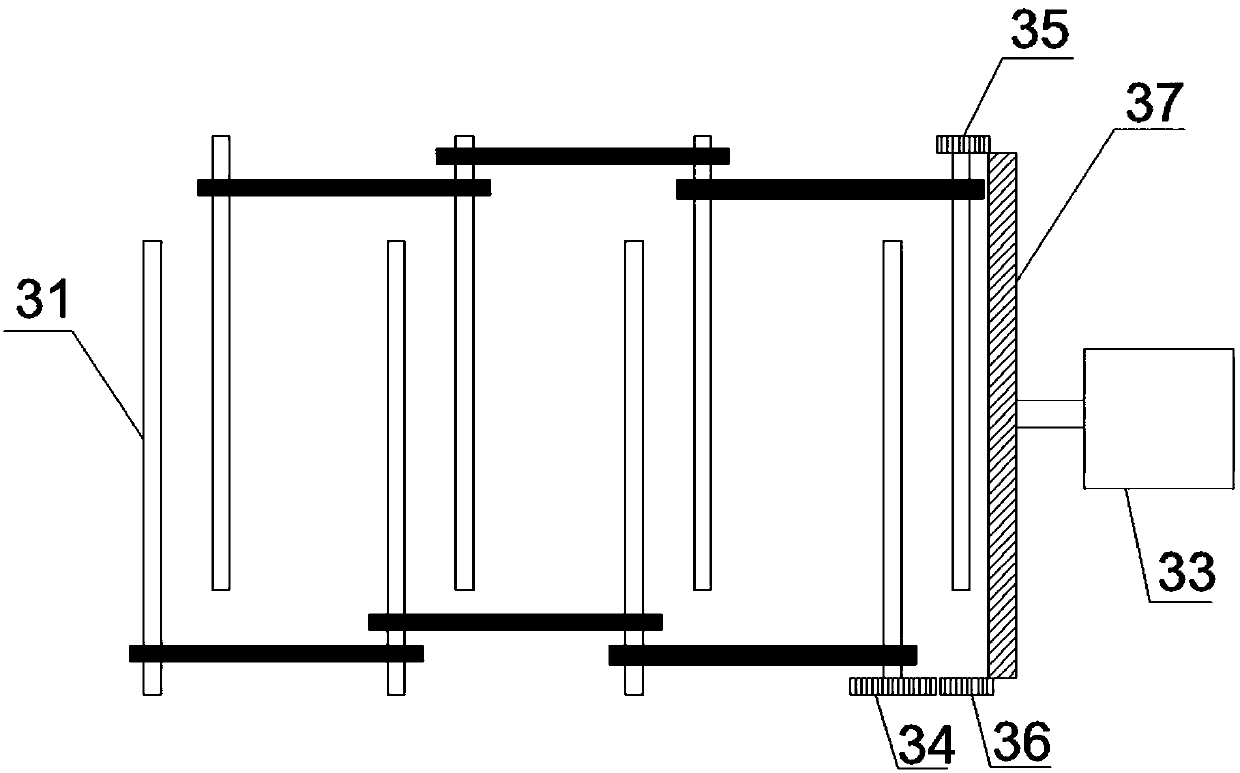

Corn threshing device with classified screening function

The invention discloses a corn threshing device with a classified screening function. The corn threshing device with the classified screening function comprises a bottom plate, a lifting mechanism, athreshing mechanism and a screening mechanism, wherein the lifting mechanism is arranged above the bottom plate; the threshing mechanism is arranged on the left of the lifting mechanism and composed of a feeding hopper, a threshing cavity, a first rotating shaft, a second rotating shaft, a ratch, helical blades, a driven gear A, a driving gear, a driven gear B, a third rotating shaft, dischargingholes and a moving door; the screening mechanism is arranged under the threshing mechanism and composed of a connecting rod, a screening plate, a support rod, a guide plate, a first collecting tank, asecond collecting tank, a third collecting tank, a fourth collecting tank and a screening cavity. The corn threshing device with the classified screening function is good and thorough in threshing effects and capable of sorting corn kernels with different diameters and facilitating classified application.

Owner:季彪

Corn thresher

The invention discloses a corn thresher which comprises a case; the top of the case is connected with a threshing box; one end of the threshing box is connected with a feeding box; the inner wall of the feeding box is provided with an electric heating wire; the threshing box is internally provided with a rotary blade component; the rotary blade component comprises a rotating shaft and a screw blade arranged on the rotating shaft; a threshing bin is arranged outside the rotary blade component; the bottom of the threshing bin is connected with a corn storage box; the tail end of the rotary blade component is provided with a core discharge chamber; the bottom of the core discharge chamber is provided with a core guide hole. According to the corn thresher, the inner wall of the feeding box is provided with the electric heating wire, so that corn cobs can be rapidly dried, threshing can be better carried out, and the corn cobs are prevented from being broken in the threshing process; the rotary blade component is used for threshing in a rotating way, the threshed corns are sent into the threshing bin, and corn stalks enter the core discharge chamber; therefore, the corn thresher is high in efficiency and large in handling capacity.

Owner:彭兰娟

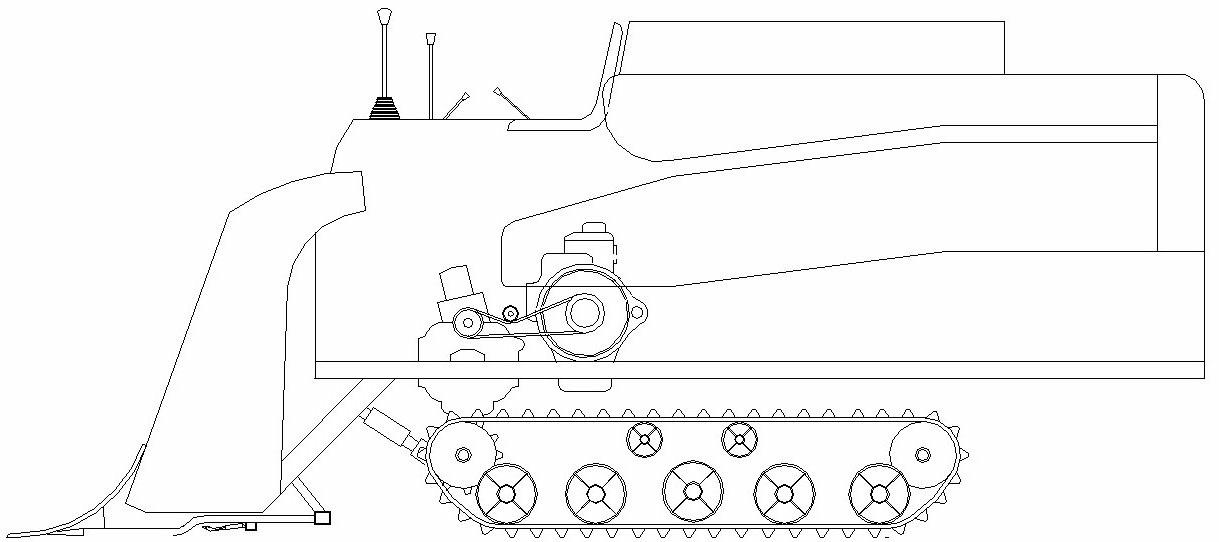

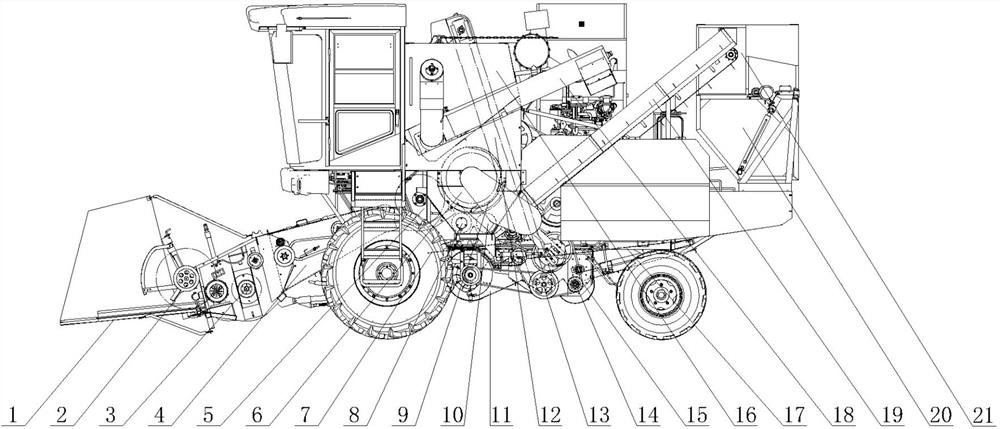

Combine harvester

InactiveCN102150503AGreat tractionShorten the lengthMowersThreshersDrive wheelAgricultural engineering

The invention relates to an agricultural machine, in particular to a combine harvester. The combine harvester comprises a harvesting table, an operating table, a threshing system, a gear box, an engine, a stalks transmitting chain, a stander, a travelling mechanism and a second cleaning system; the stander is fixedly arranged on the travelling mechanism; the travelling mechanism comprises a front guide wheel, a back driving wheel, a thrust wheel and two crawler belts; the harvesting table, the operating table, the threshing system, the gear box and the engine are fixedly arranged on the stander, the engine is arranged behind a complete machine and connected with a back driving wheel shaft in the travelling mechanism by the gear box; and the threshing system is arranged between the two crawler belts of the travelling mechanism, and the second cleaning system is arranged under the threshing system. The combine harvester changes the structure of the traditional harvester, the structure is simpler and more reasonable, and the work efficiency can be greatly improved.

Owner:夏发明

Agricultural corn threshing equipment

PendingCN111972135APrevent fallingEnsure safetyThreshersAgricultural scienceAgricultural engineering

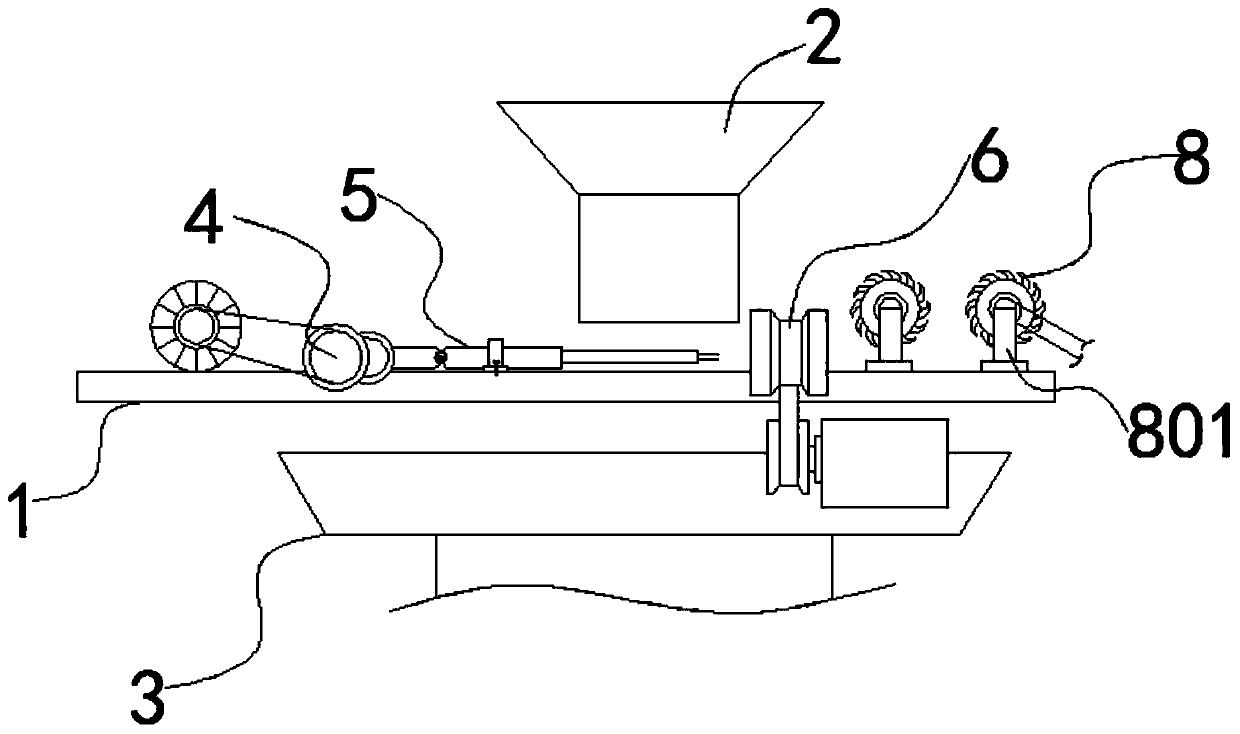

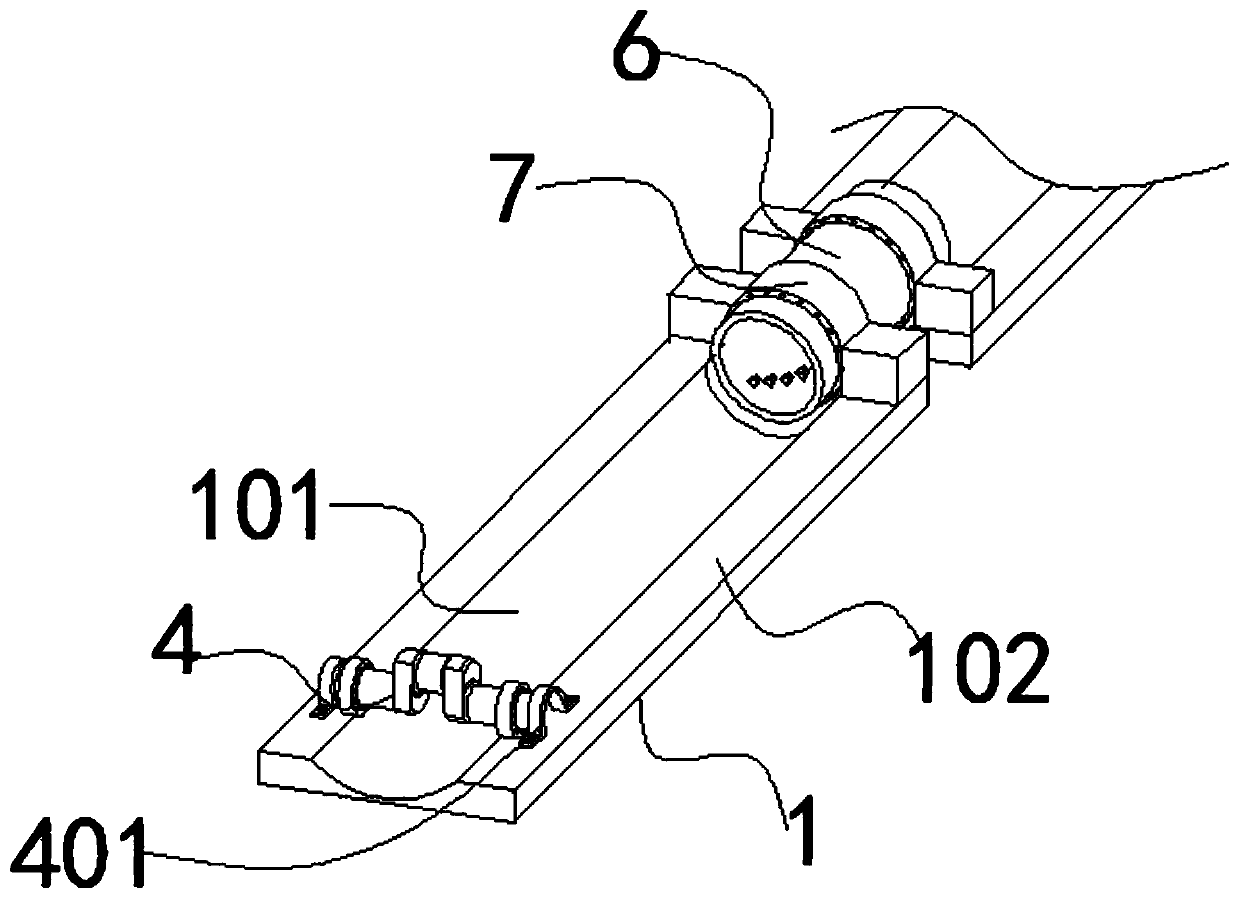

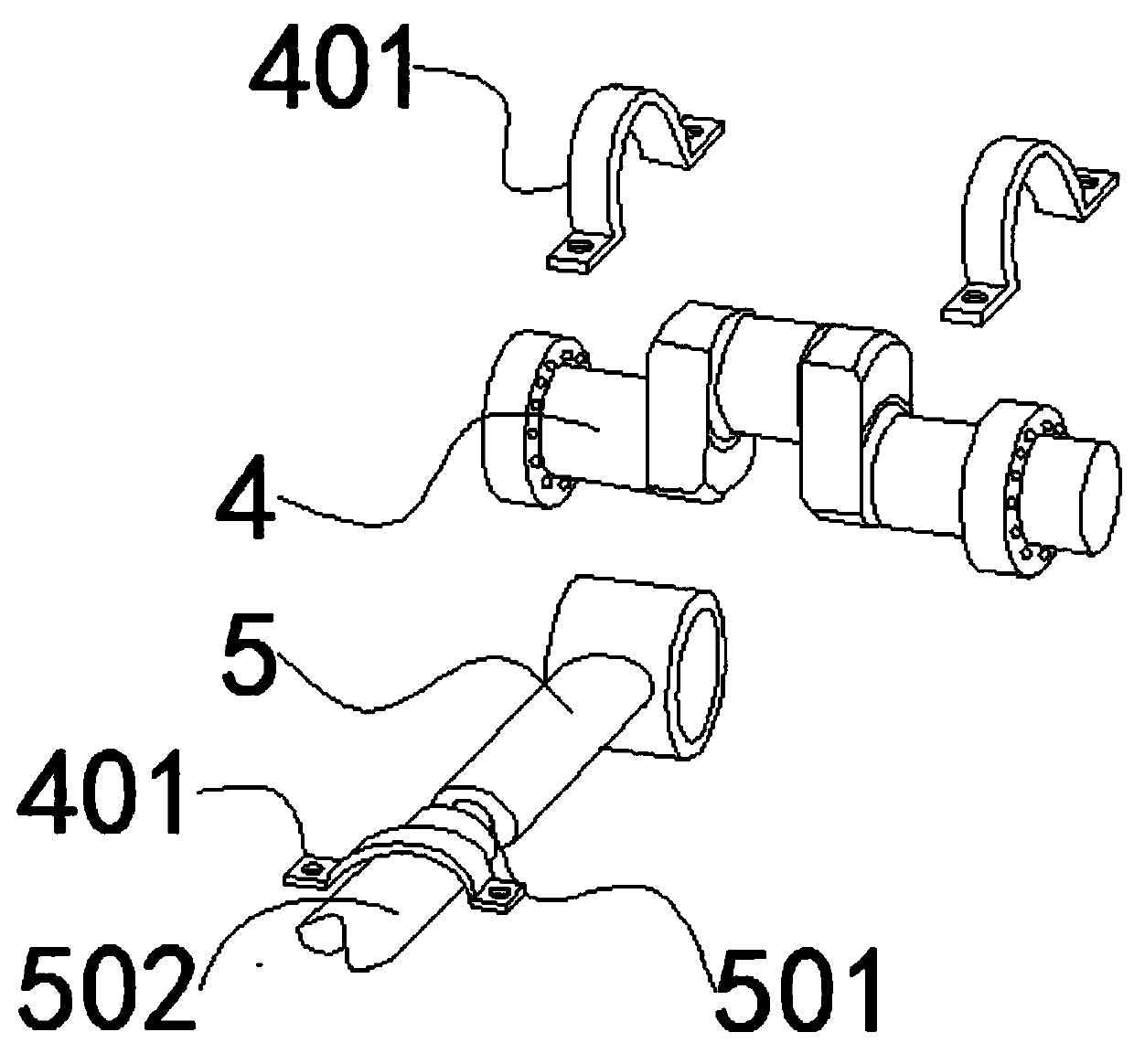

The invention relates to threshing equipment, in particular to agricultural corn threshing equipment. According to the agricultural corn threshing equipment, manual contact with the threshing processis not needed, corns are automatically conveyed through the device, and efficiency and safety are guaranteed. The agricultural corn threshing equipment comprises a first supporting frame, wherein a first supporting frame pushing mechanism is arranged on the left side of the top of a bottom plate; a pushing mechanism is arranged on the upper portion of the first supporting frame; and a threshing mechanism is connected between the front side of the pushing mechanism and the right side of the top of the bottom plate. Through the arrangement of a discharging bin and a funnel, a worker can directlyput corns in the equipment and sequentially conduct conveying and threshing; and a pushing head is arranged on a chain group, so that corns can be directly pushed into a threshing cylinder to be threshed.

Owner:李华斌

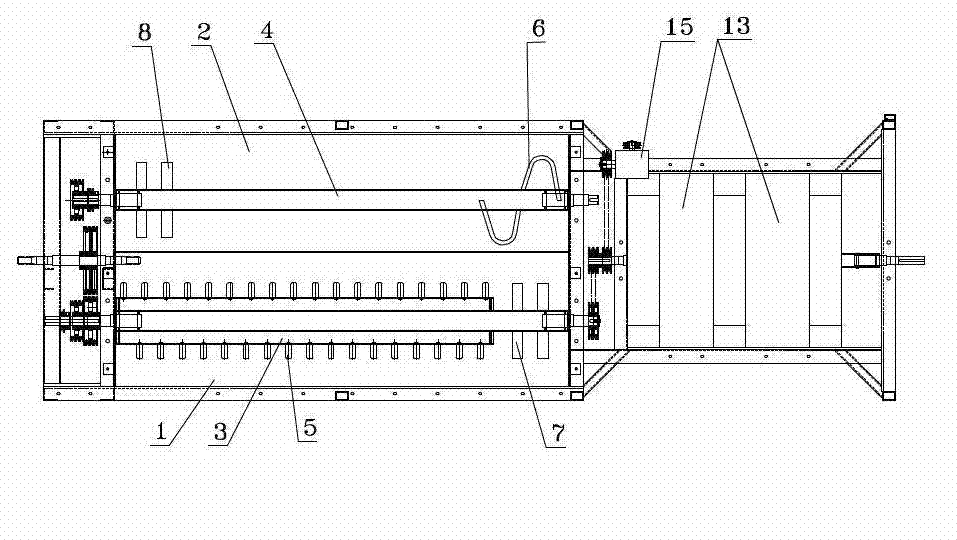

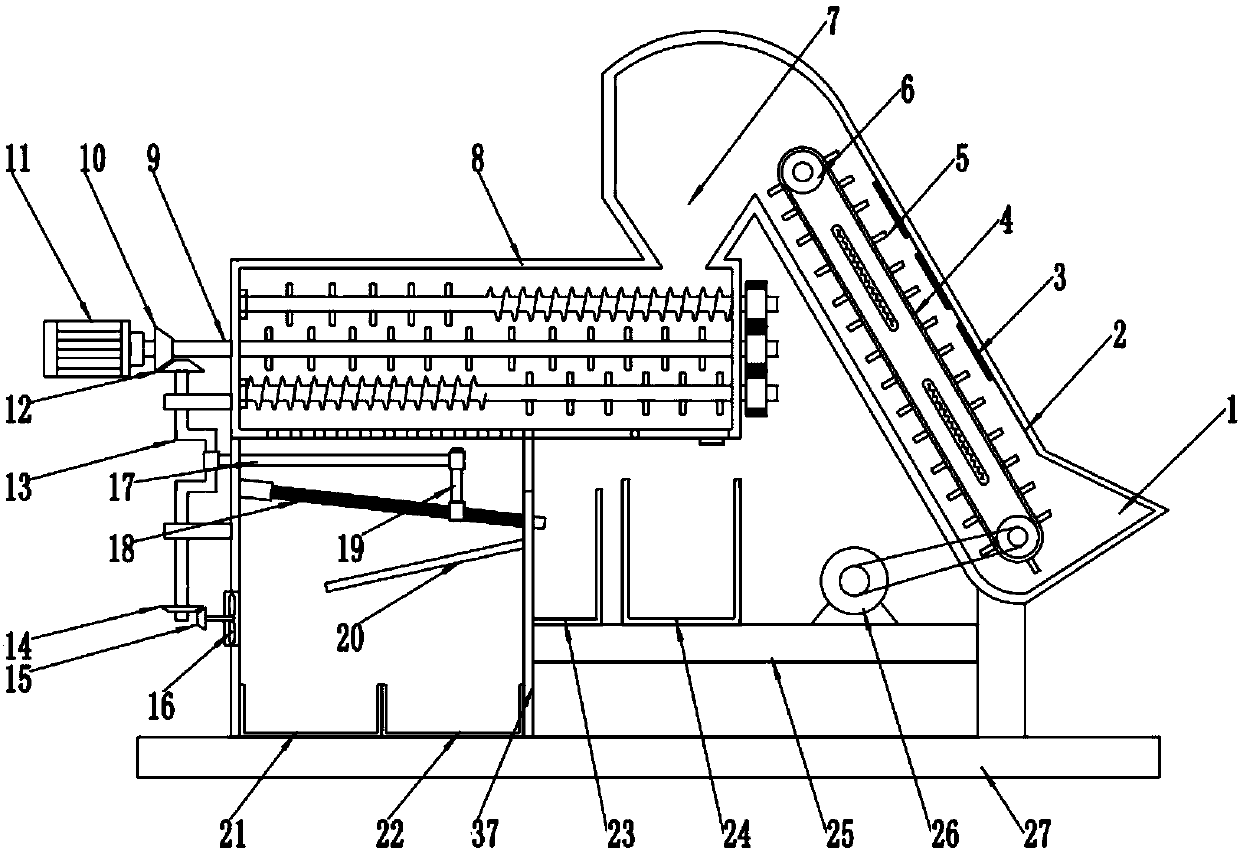

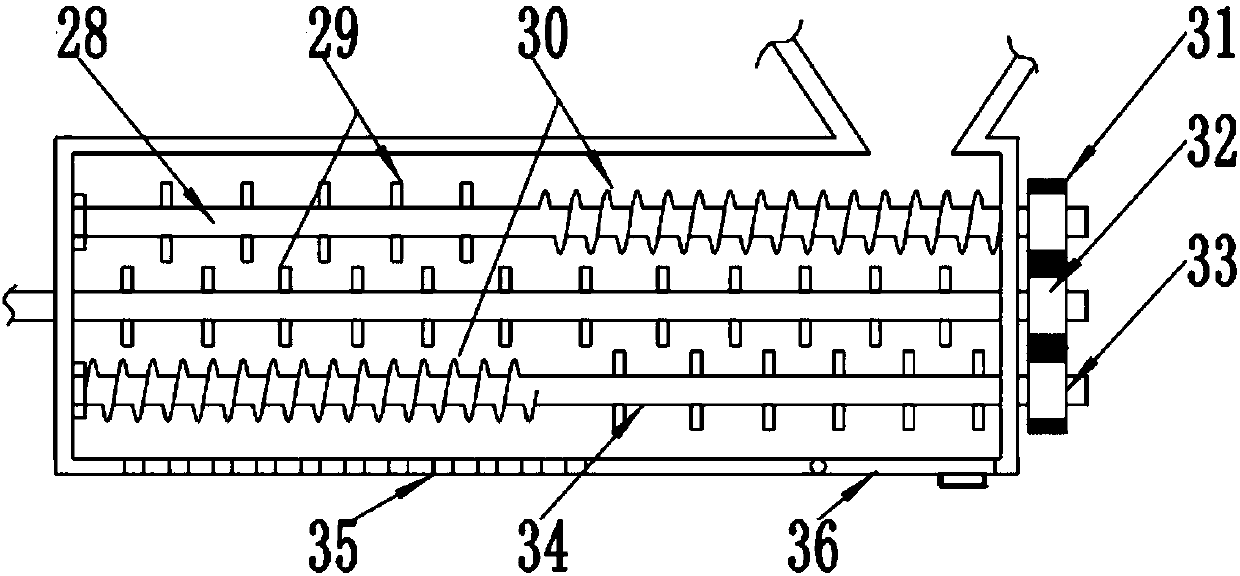

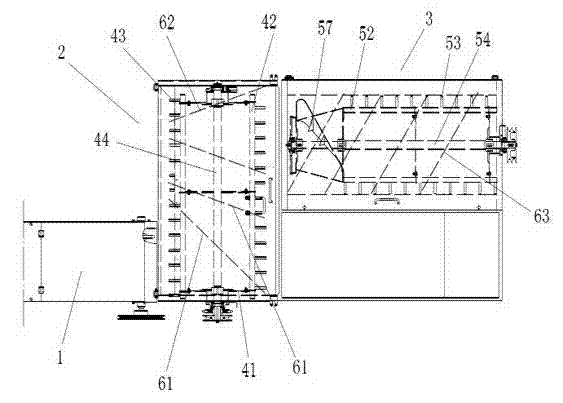

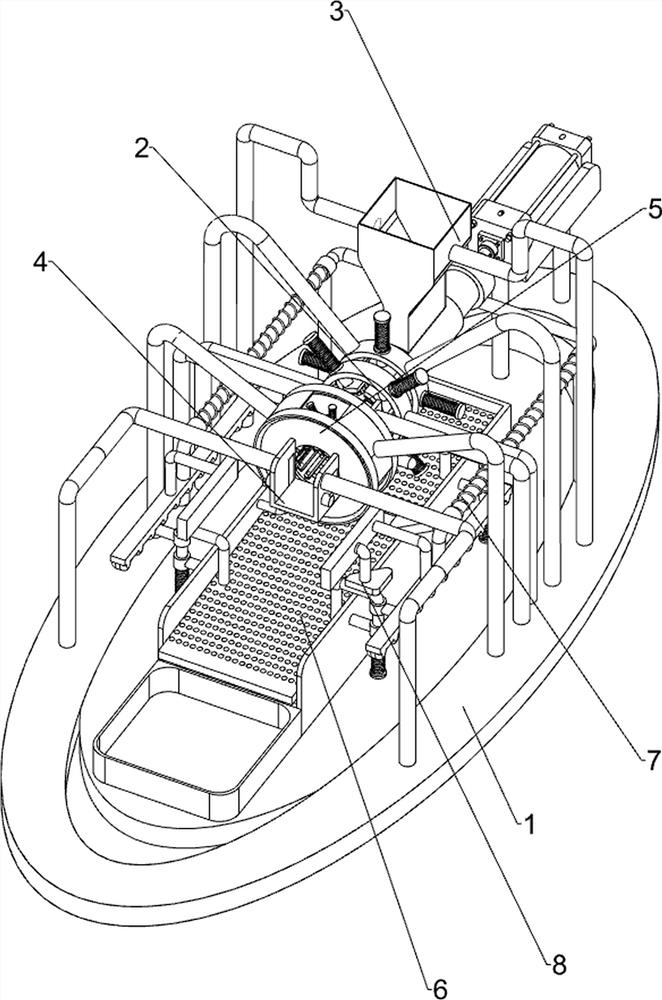

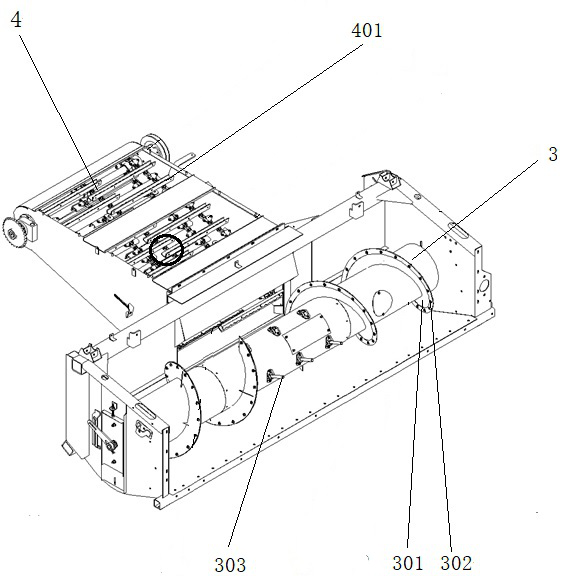

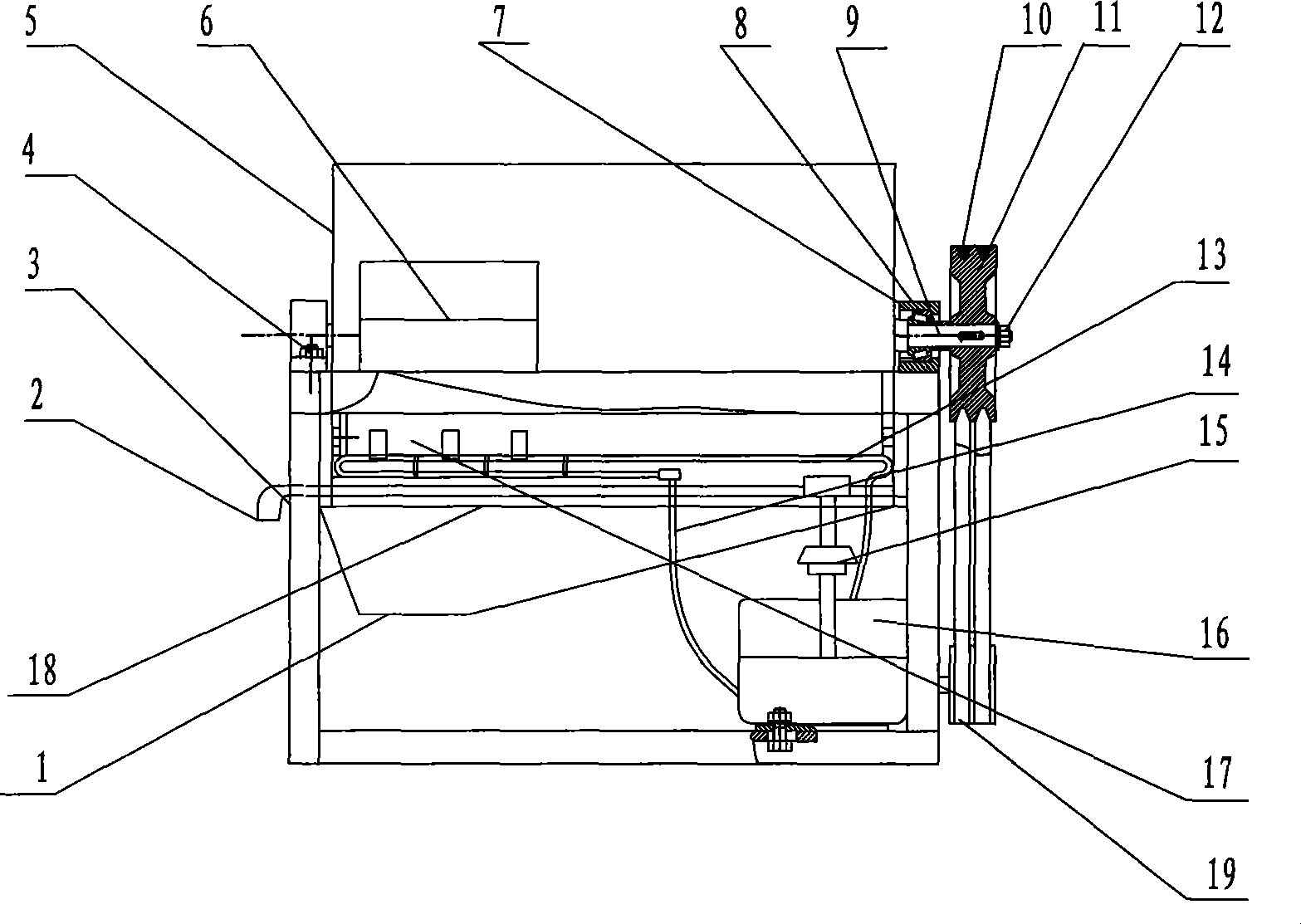

Threshing structure of L-shaped horizontal and longitudinal axial flow full-feeding combine harvester

InactiveCN103609250ALarge amount of feedImprove work efficiencyMowersThreshersTransverse axisEngineering

The invention relates to the technical field of agricultural machinery, in particular to a threshing structure of an L-shaped horizontal and longitudinal axial flow full-feeding combine harvester. The threshing structure comprises a threshing rack, a vibrating screen arranged on the threshing rack, an air blower and a middle conveyor connected on the upper portion of the front end of the threshing rack, a threshing drum communicated with the rear end of the middle conveyor is arranged on the threshing rack and comprises a horizontal axial flow drum and a longitudinal axial flow drum which are in communicated connection and perpendicular to each other to be L-shaped, two ends of the horizontal axial flow drum are connected with the middle conveyor and the longitudinal axial flow drum respectively, and the middle conveyor and the longitudinal axial flow drum are arranged on two sides of the horizontal axial flow drum respectively. The threshing structure is large in feeding quantity and high in operating efficiency during harvesting, connection of a threshing, cleaning and selecting drum and a discharging port of the middle conveyor is smooth and small in loss, crops in the horizontal axial flow drum are good in threshing, cleaning and selecting effect, and a notch board screen is large in separating area.

Owner:曾联

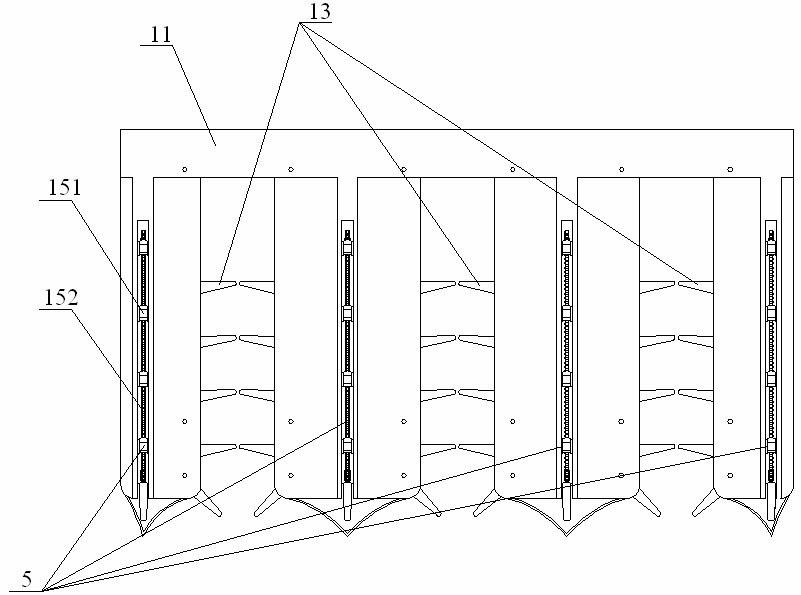

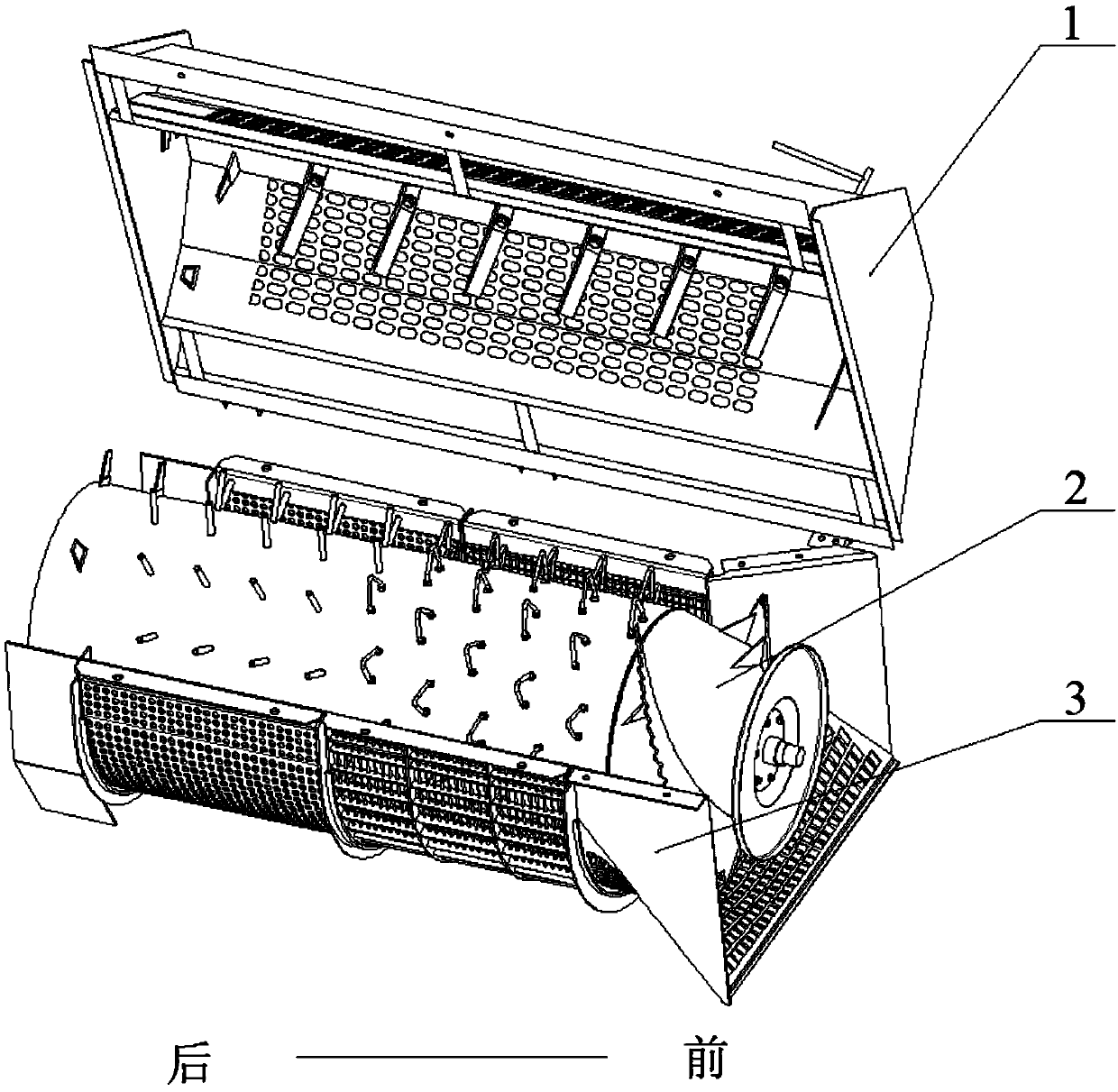

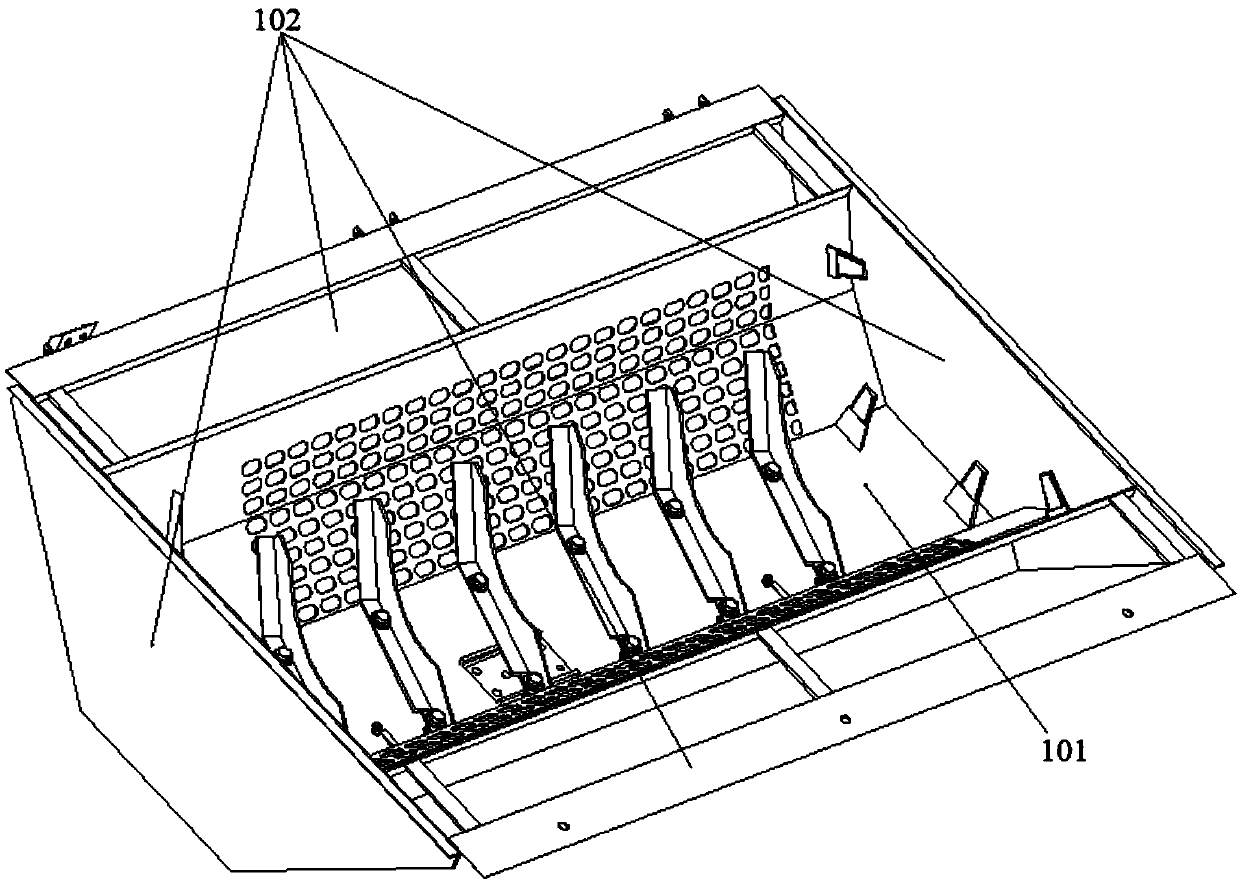

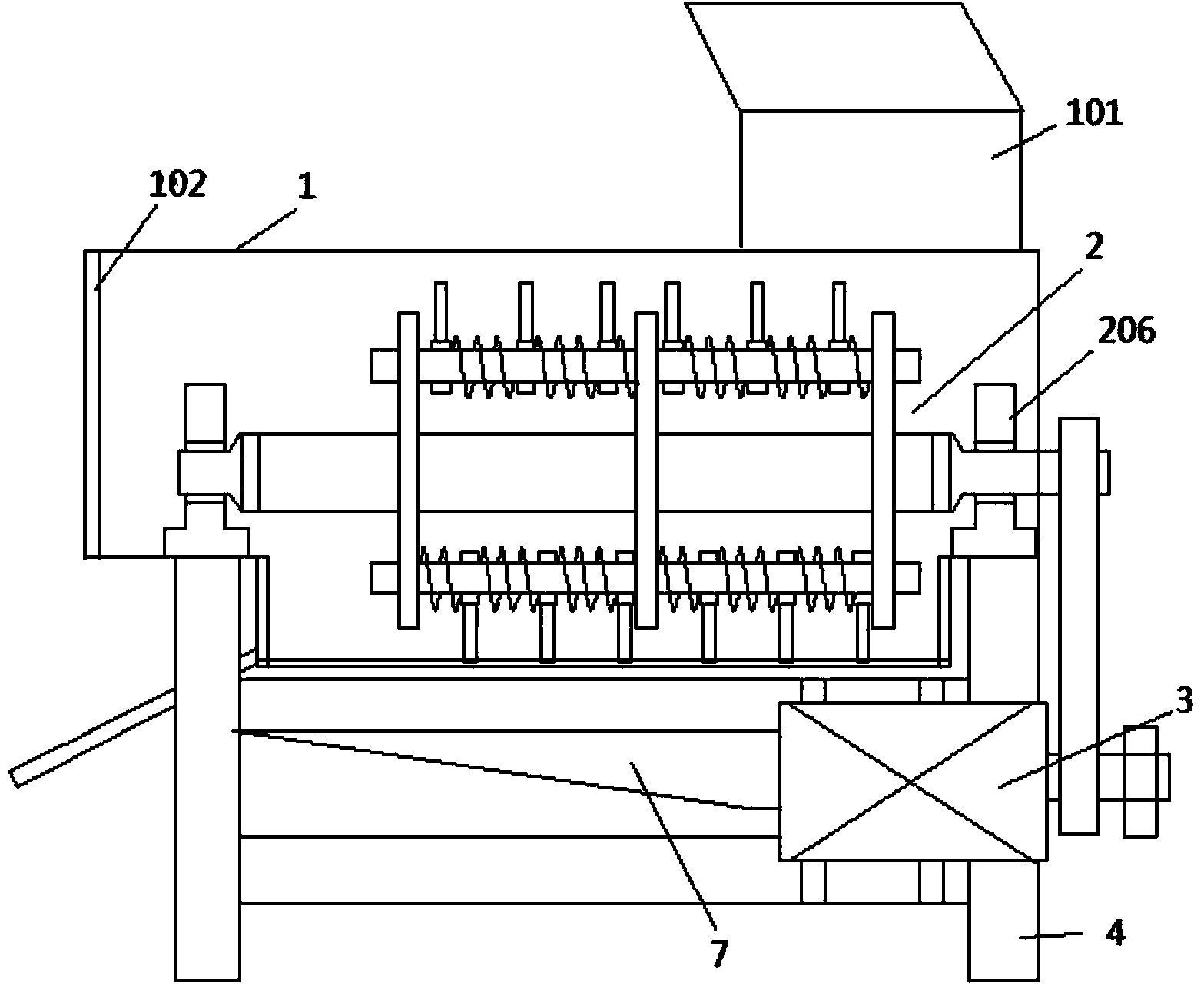

Forced feeding, threshing, separating and smashing integrated device for first-harvest rice

PendingCN109588120AClear division of laborReduce breakage rateMowersThreshersSpiral bladeEngineering

The invention provides a forced feeding, threshing, separating and smashing integrated device for first-harvest rice. The forced feeding, threshing, separating and smashing integrated device for first-harvest rice comprises a closed multifunctional threshing cylinder, a flow guide separable grass breaking top cover and a combined concave plate, wherein the threshing cylinder comprises a cylinder shaft feeding head and a cylinder body, a spiral blade is mounted on the feeding head, and an arc tooth group, a spike tooth group and a roller rotating blade group are distributed on the circumferenceof the cylinder body sequentially; the combined concave plate is located below the closed multifunctional threshing cylinder and comprises a transition concave plate, a threshing concave plate, a separating concave plate and a grass guiding concave plate sequentially; the flow guide separable grass breaking top cover is mounted above the closed multifunctional threshing cylinder and comprises a top cover inner shell and reinforcing plates, and the top cover inner shell comprises an adjusting mechanism, flow guide bars, punching plates and top cover fixed blades. The forced feeding, threshing,separating and smashing integrated device is applicable to feeding, threshing, separating and smashing of the first-harvest rice with different characteristics, has the advantages of compact structure, large separation area, light weight and the like, can effectively improve threshing performance and efficiency of the first-harvest rice and has lower power consumption.

Owner:JIANGSU UNIV

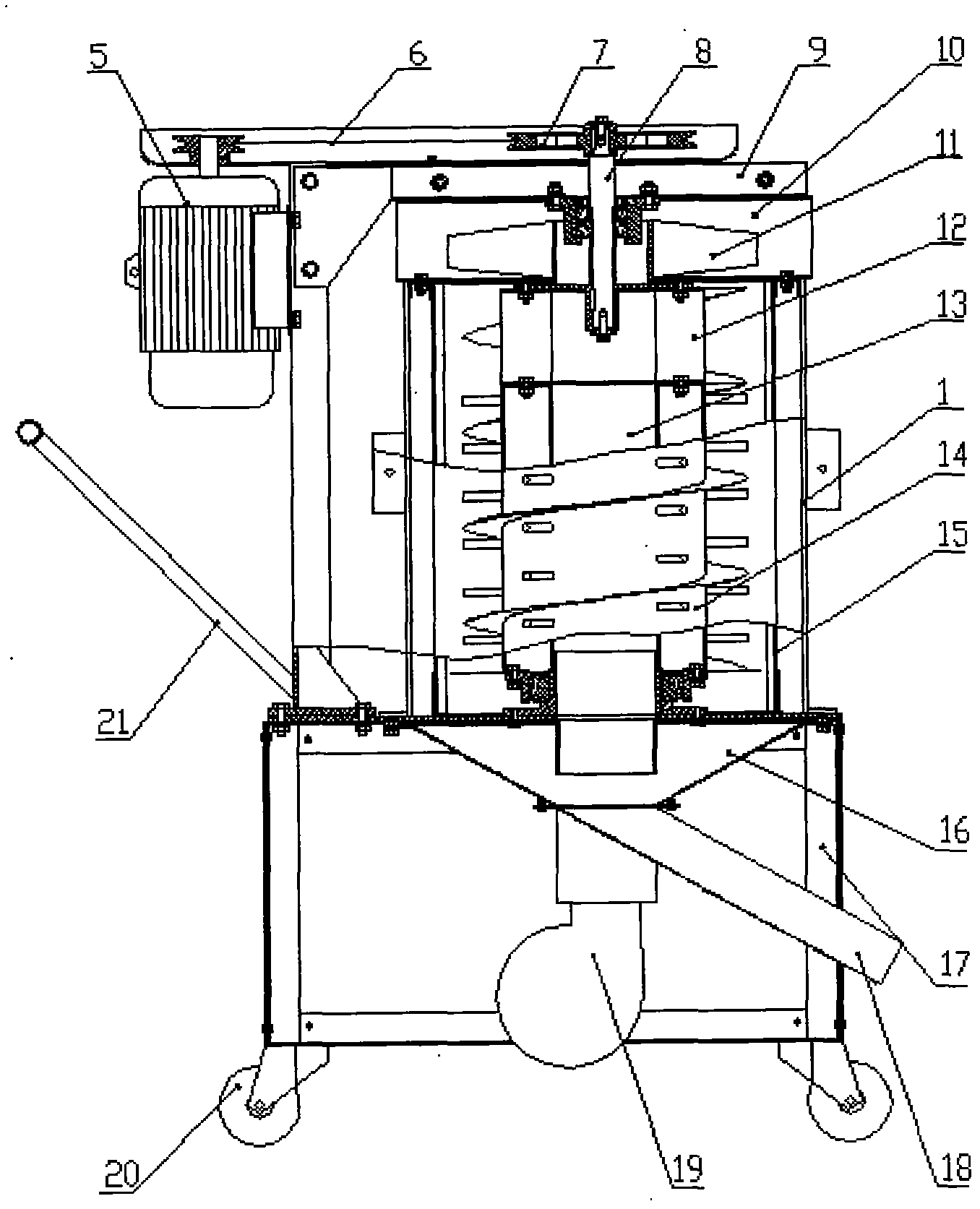

Corn threshing and silk removing device

The invention discloses a corn threshing and silk removing device which comprises a box body, a threshing rolling shaft, a driving motor and a fixed frame for supporting the box body on the ground. A filter screen plate is arranged at the lower end of the box body; the threshing rolling shaft is arranged between the box body and the filter screen plate; both ends of the threshing rolling shaft are fixedly arranged on the fixed frame by shaft sleeves; a feed hopper is arranged at the upper part of the right end of the box body; a discharge plate extends to the outside of the fixed frame; a bellows is arranged below the discharge plate; a fan is arranged at the lower end of the bellows; the bellows is provided with a receiving plate extending outwards; both a rotating shaft of the fan and a rotating shaft of the threshing rolling shaft are connected and driven by an output shaft of the driving motor through a belt. The corn threshing and silk removing device overcomes the defects in the prior art, is reasonably designed and has a compact structure; threshing throwing hammers adopts a movable structure and springs are arranged between the adjacent threshing throwing hammers, so that the motion trail of each throwing hammer is of a spiral shape, which is more beneficial to corn threshing; when material are stacked, buffering can be carried out, stress impact is reduced and the service life of equipment is prolonged; meanwhile, the fan is arranged at the lower end of the box body, so that the corn threshing and silk removing device is convenient to timely carrying out sorting on corn kernels and corn silk and production efficiency is improved.

Owner:ANHUI JIULI MACHINERY EQUIP

Centrifugal type threshing and grinding machine

InactiveCN107736138AImprove threshing effectAvoid wastingThreshersGrain treatmentsEngineeringPower unit

The invention discloses a centrifugal threshing grinder, comprising: a shell, the bottom surface of which forms a powder outlet, one side is provided with a core body outlet and an air inlet, and the other side is provided with an air outlet; A threshing cylinder, which includes a guide cylinder, a tooth cylinder, and a first motor; a first pair of roller layers and a second pair of roller layers; a conveyor belt assembly that guides the corncobs out of the housing; a blower and an exhaust fan; a vibration assembly , which includes a fixed plate and a pair of vibrating screens; a pair of grinding components, which include a grinding plate, a screw and a grinding stone, a support table, and a power unit. The invention can be fast, efficient, line-type threshing and grinding, effectively separate corn kernels, corn cobs and dust, reduce procedures, improve work efficiency, and facilitate maintenance and maintenance.

Owner:李斌施

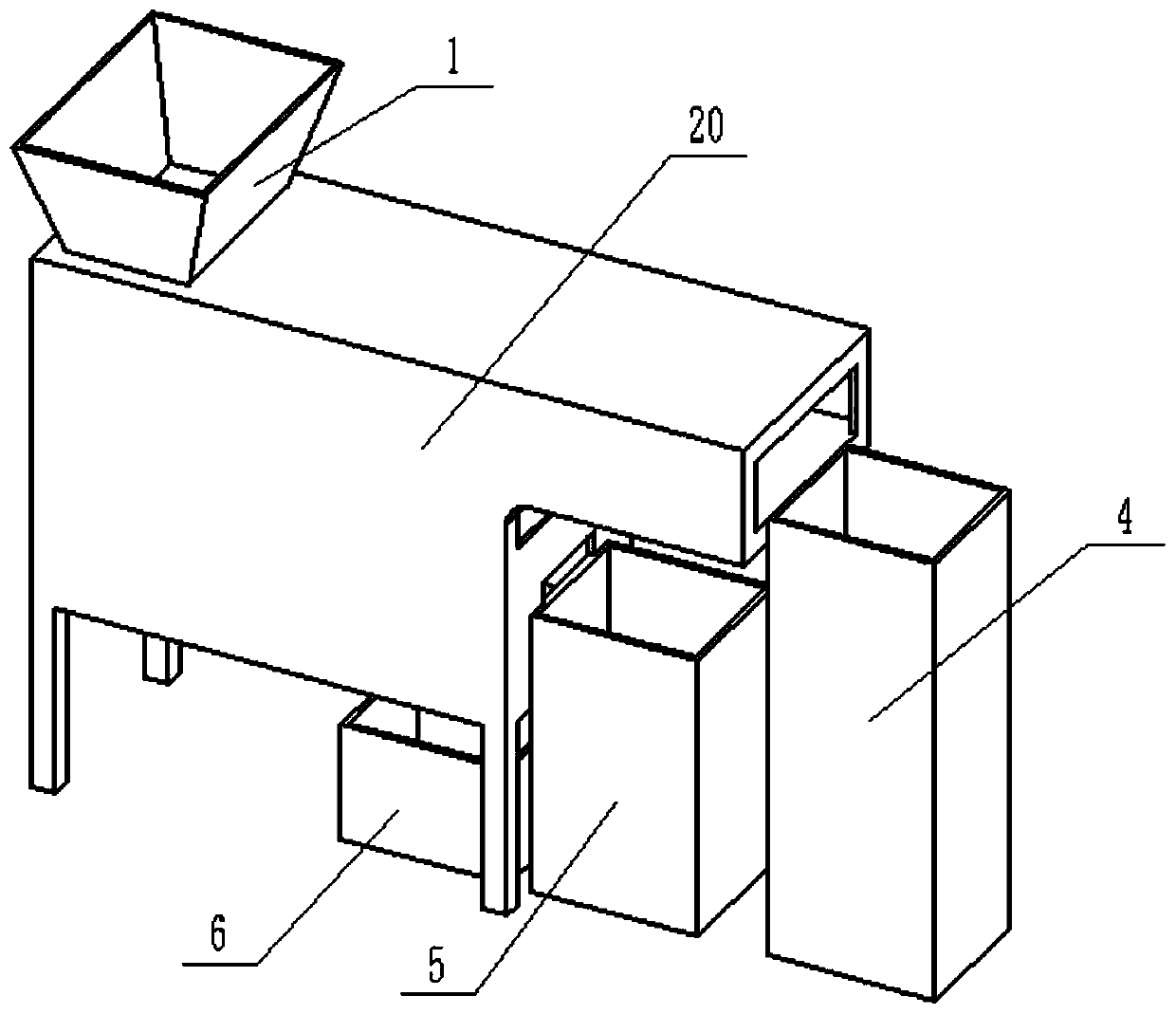

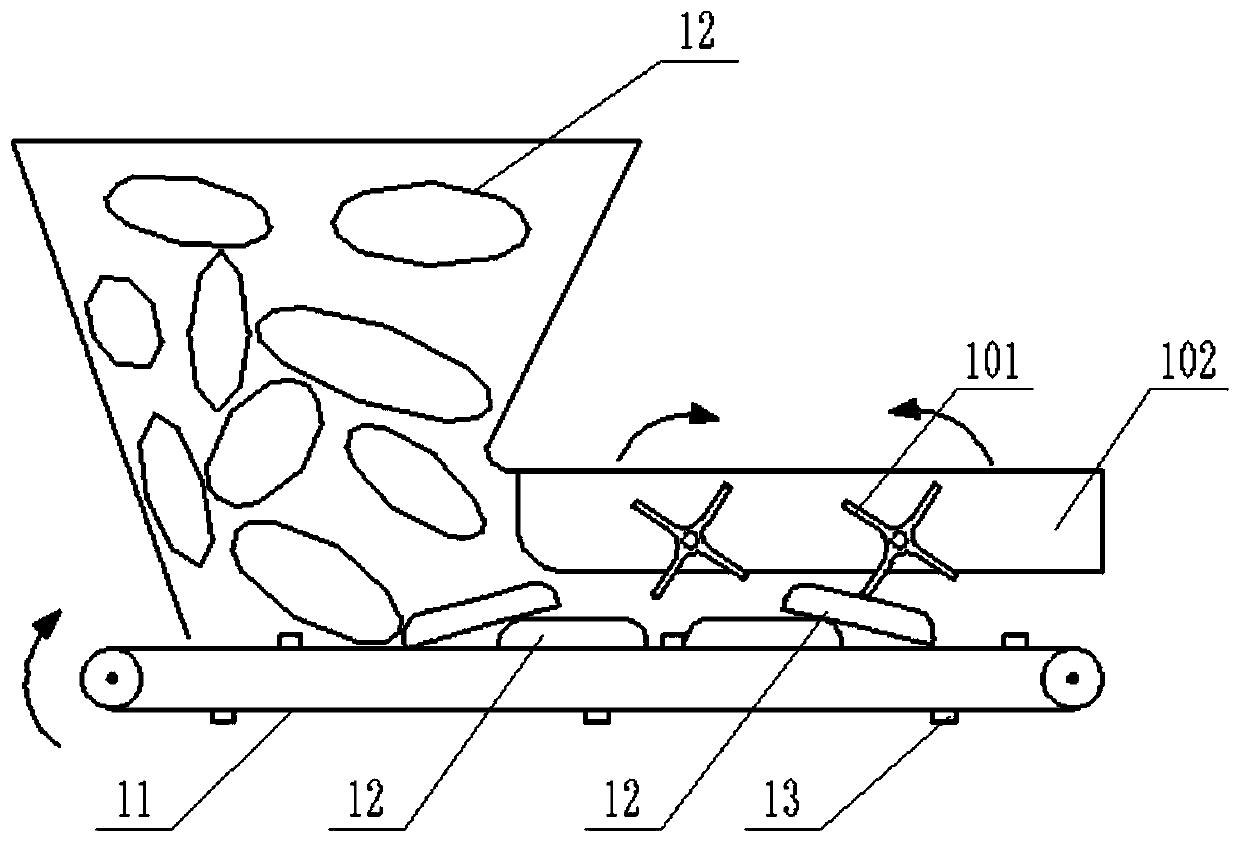

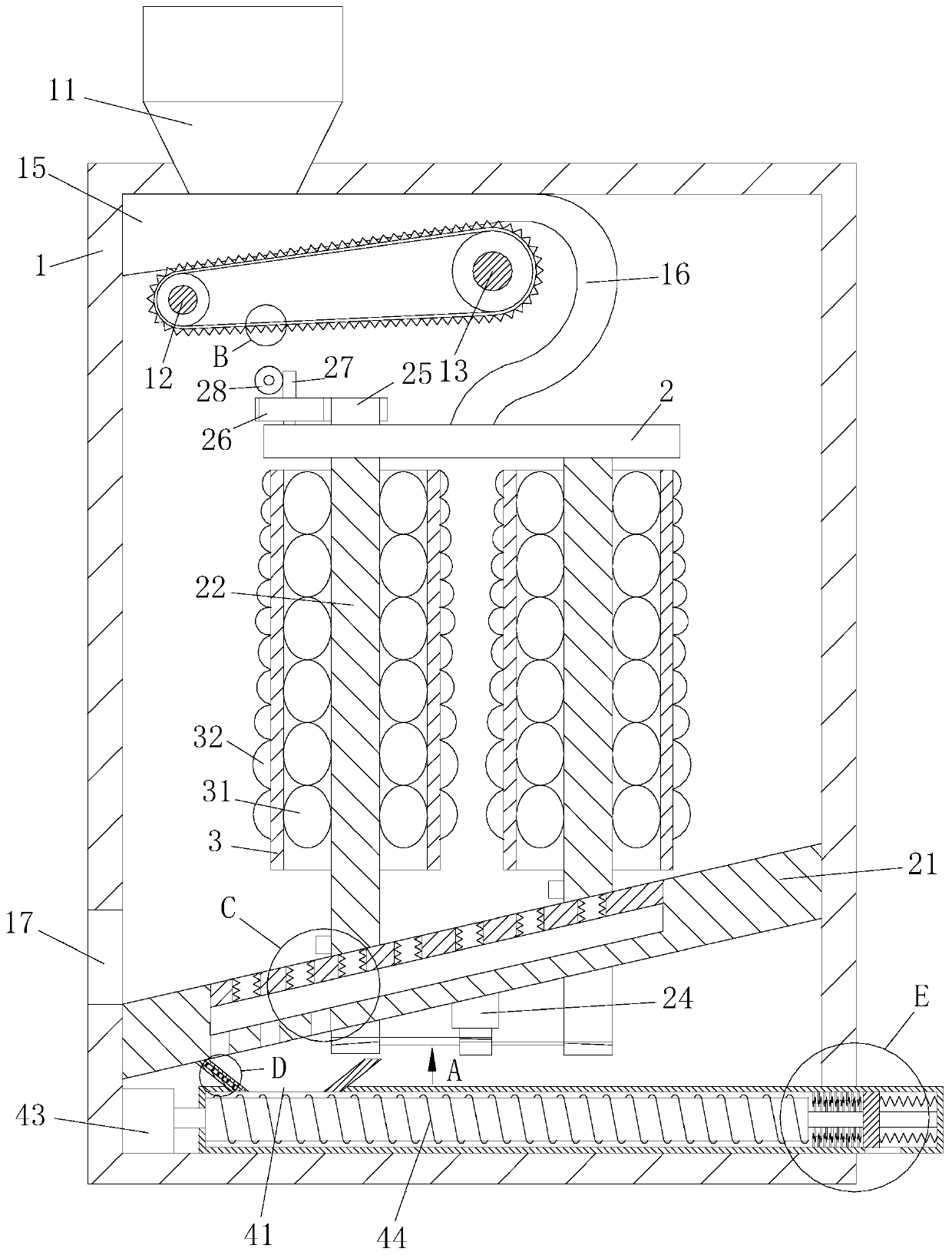

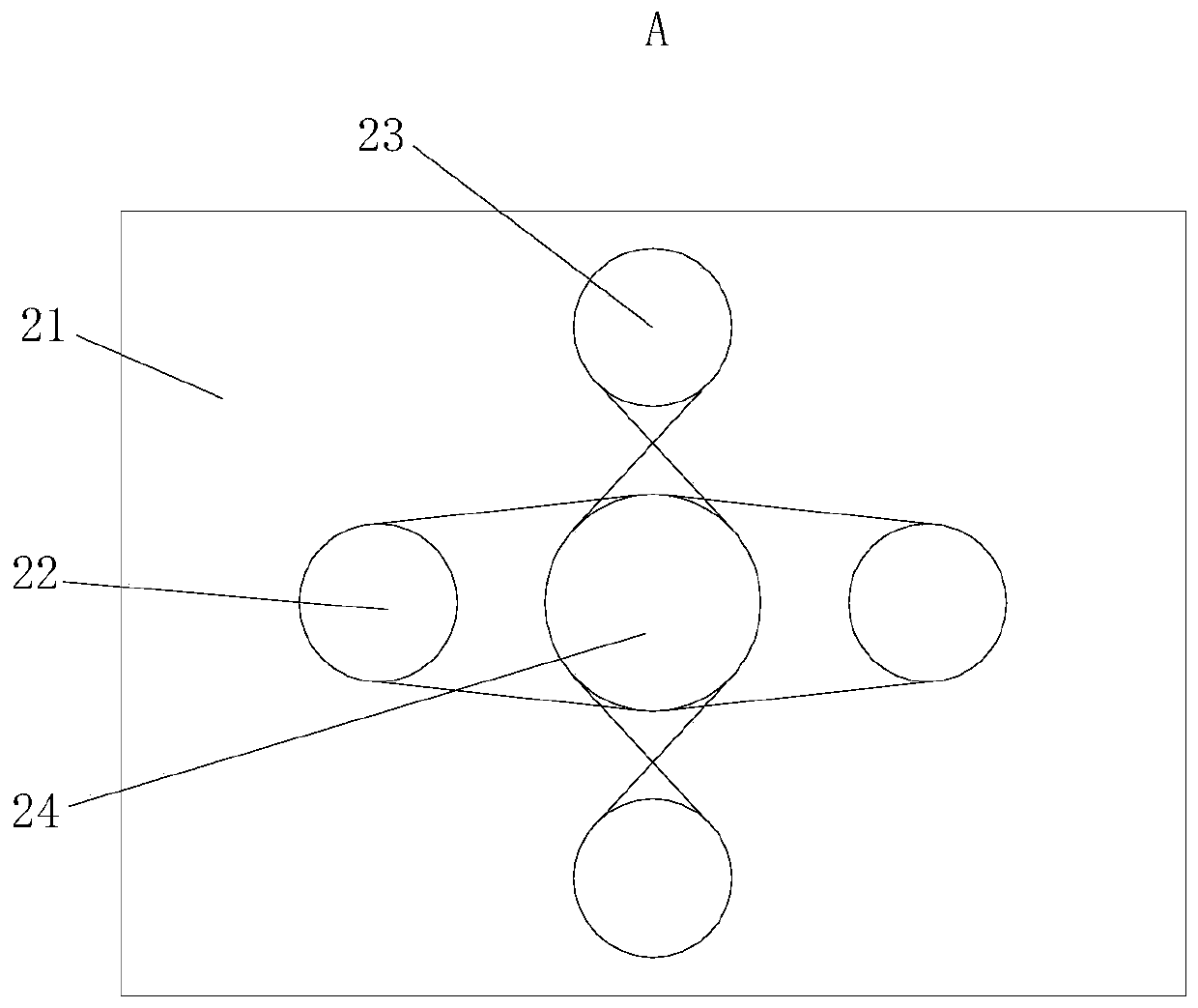

Deseeding machine for sunflower discs

InactiveCN109757223AReduce breakage rateEasy to storeThreshersAgricultural engineeringProduct processing

The invention relates to a deseeding machine for sunflower discs and belongs to the field of agricultural product processing machinery. The deseeding machine comprises a feeding device, a threshing device, a screening device, a sunflower disc receiving device and an outer box, wherein the feeding device, the threshing device, the screening device and the sunflower disc receiving device are mountedin the outer box of the deseeding machine, the threshing device is fixedly mounted at the tail of the feeding device, the screening device is arranged at the lower part of the threshing device, and the sunflower disc receiving device is arranged behind the threshing device. The device can rapidly obtain removed sunflower seeds and sunflower discs, the damage rate of obtained sunflower seeds is low, the sunflower discs can be better retained and cannot be damaged greatly, and few sunflower disc scraps exist in the sunflower seeds removed by the device.

Owner:严高超

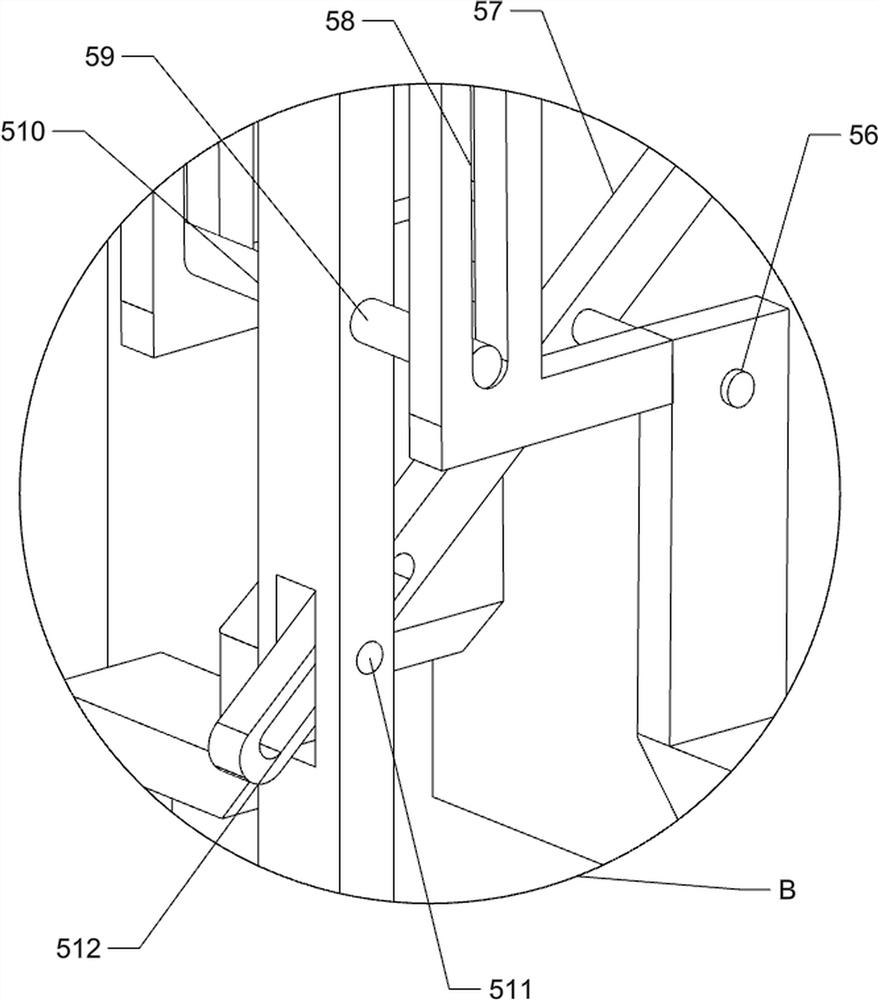

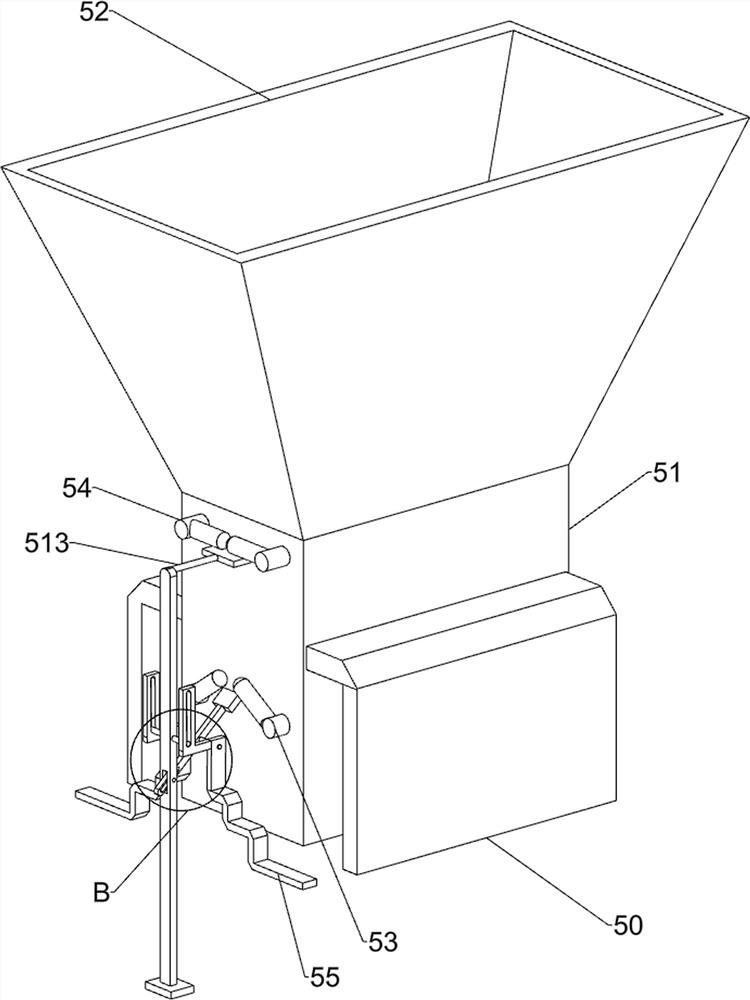

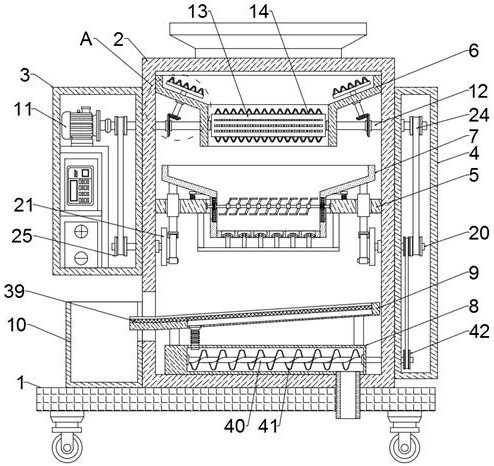

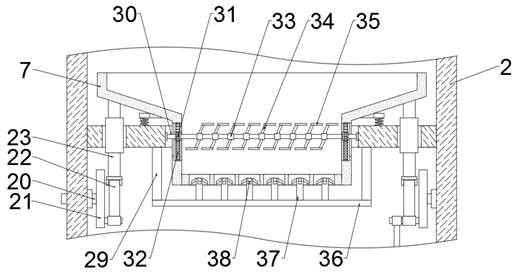

Threshing machine for cereal food processing

InactiveCN112385403AEasy threshingEasy threshing operationGrain huskingGrain polishingAgricultural scienceAgricultural engineering

The invention discloses a threshing machine for cereal food processing. The threshing machine comprises a base, a threshing mechanism, transmission mechanisms, a stirring mechanism and a dredging assembly; a threshing box is fixedly connected to the top face of the base, a driving box is arranged on the upper portion of one side of the threshing box, and a transmission box is arranged on the otherside of the threshing box; a lifting hopper is arranged in a partition plate; the stirring mechanism is arranged in the lifting hopper; the dredging assembly is arranged below the bottom surface of the partition plate; the threshing mechanism is arranged in a collecting hopper; and the transmission mechanisms are arranged at the positions, located at the two sides of the lower portion of the partition plate, on the inner walls of the threshing box. The threshing machine is easy to operate; the working efficiency of grain threshing is effectively improved through the threshing mechanism and ascraping assembly; through cooperative use of the transmission mechanisms and the stirring mechanism, cereals in the lifting hopper can be stirred and stirred conveniently, husks on the cereals can beseparated from kernels conveniently, and the dredging quickness of a discharging hole is effectively improved; the workload of cleaning broken slag by workers is reduced; and the problems that the cereals are prone to blocking a discharging hole and dredging is inconvenient in an existing threshing device are solved.

Owner:潍坊惠米农业科技发展有限公司

Flexible threshing cylinder and thresher provided with same

The invention discloses a flexible threshing cylinder and a thresher. The flexible threshing cylinder is arranged in the corn thresher and used for threshing corn cobs and comprises a leading-in conical barrel, a threshing cylinder and an impurity discharging cylinder, wherein the threshing cylinder is arranged between the leading-in conical barrel and the impurity discharging cylinder, and two ends of the threshing cylinder are respectively and integrally connected with the leading-in conical barrel and the impurity discharging cylinder; a plurality of flat-head flexible threshing tooth assemblies are arranged on the outer surface of the front section of the threshing cylinder, and a plurality of round-head flexible threshing tooth assemblies are arranged on the outer surface of the rearsection of the threshing cylinder. The contact between corn ears and the flat-head flexible threshing tooth assemblies and the round-head flexible threshing tooth assemblies is flexible contact ratherthan rigid contact, so that the damage rate of corn grains is reduced, and the corn production quality is improved; meanwhile, the flat-head flexible threshing tooth assemblies can damage the 'circulating force ring' of corns to the maximum extent, subsequent threshing is facilitated, and the round-head flexible threshing tooth assemblies can reduce the breakage rate of grains to the maximum extent and improve the quality of the grains.

Owner:SHANDONG UNIV OF TECH

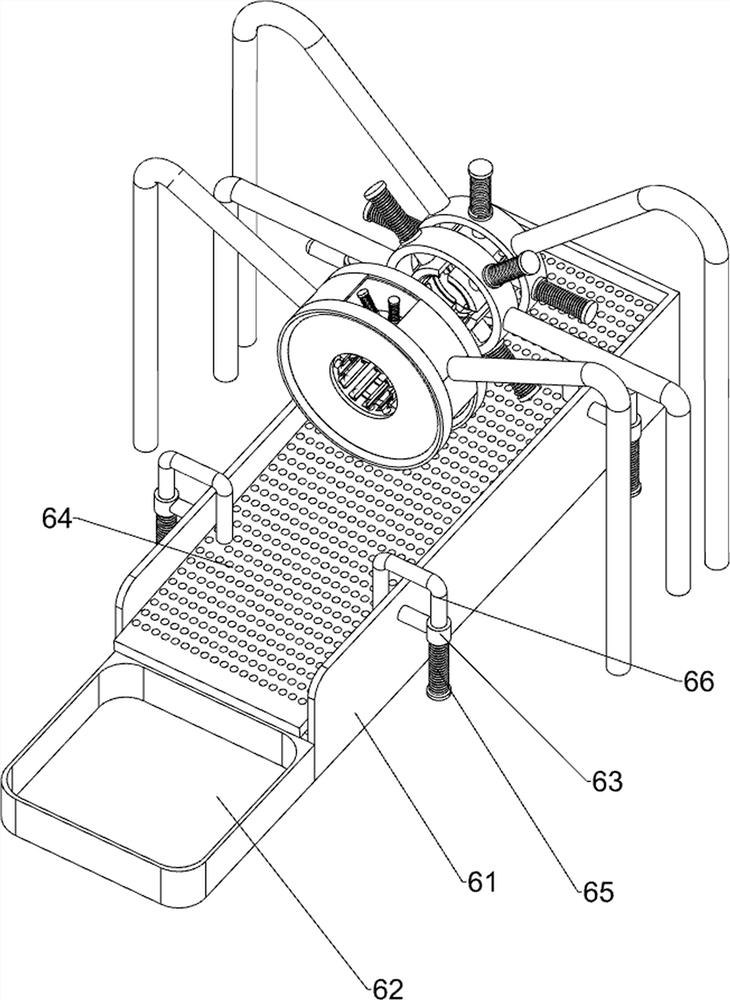

Corn thresher for food processing

PendingCN112314185AEasy threshingConvenient for secondary threshingThreshersAgricultural scienceAgricultural engineering

The invention relates to a threshing device, in particular to a corn thresher for food processing. The corn thresher for food processing is good in threshing effect, and corn cobs are easy to take out. The corn thresher for food processing comprises a bottom plate, a pushing surface scraper mechanism and a discharging pushing scraping mechanism. The pushing surface scraper mechanism is arranged inthe middle of the top of the bottom plate. The discharging pushing scraping mechanism is arranged at the top of the bottom plate. A worker starts an air cylinder to extend to drive corns to move leftwards, so that the corns are threshed by a sliding scraper conveniently and quickly; impurities on corn kernels can be filtered by a mesh screen plate, so that the filtering time of workers is saved;when the air cylinder contracts, the mesh screen plate continuously shakes up and down, the filtering efficiency is improved, and meanwhile, a slope pushing plate is driven to move rightwards, so thata clamping plat clamps the corn cobs; and when the air cylinder contracts, a one-way straight gear is driven to rotate clockwise to thresh the corns, so that the corns are threshed more thoroughly, and waste is reduced.

Owner:陈美凤

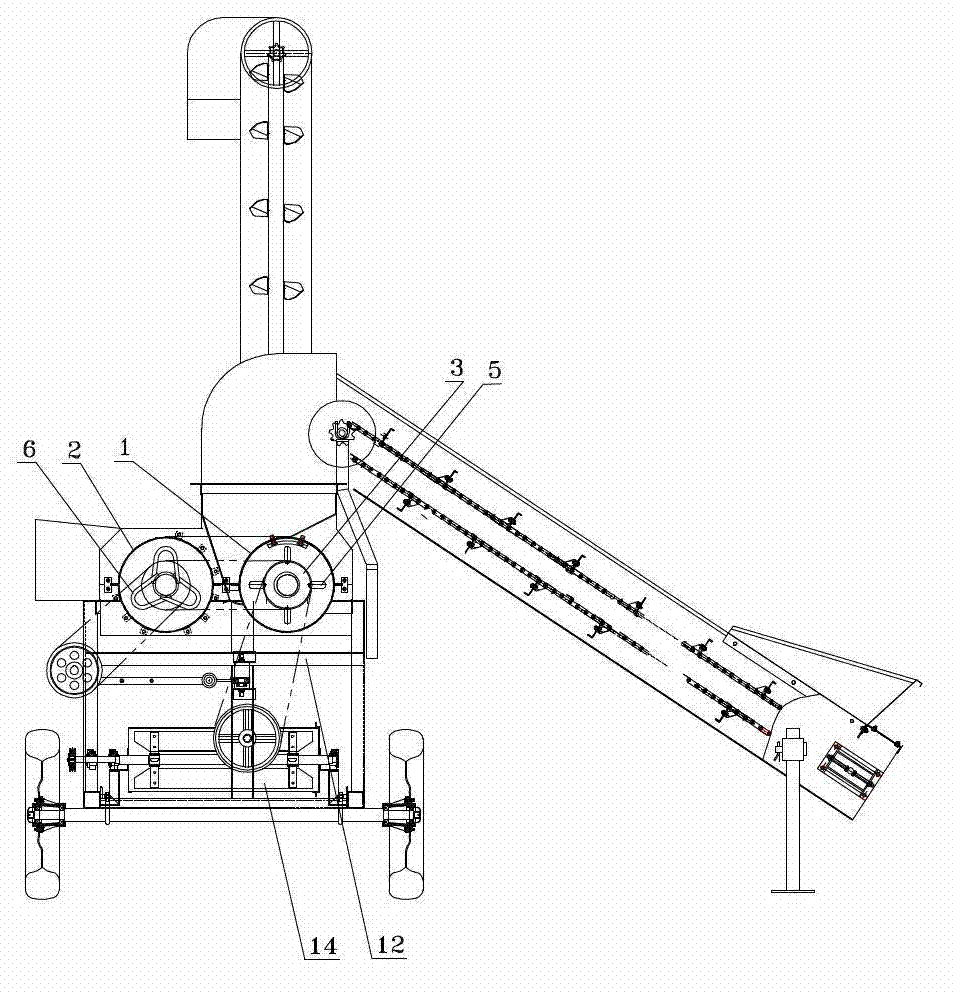

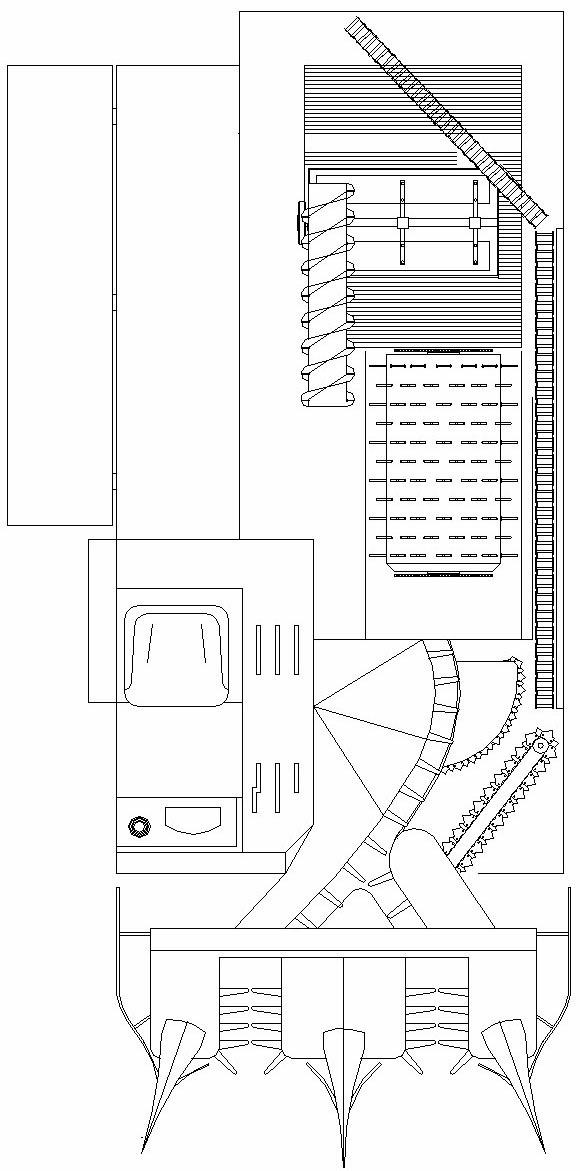

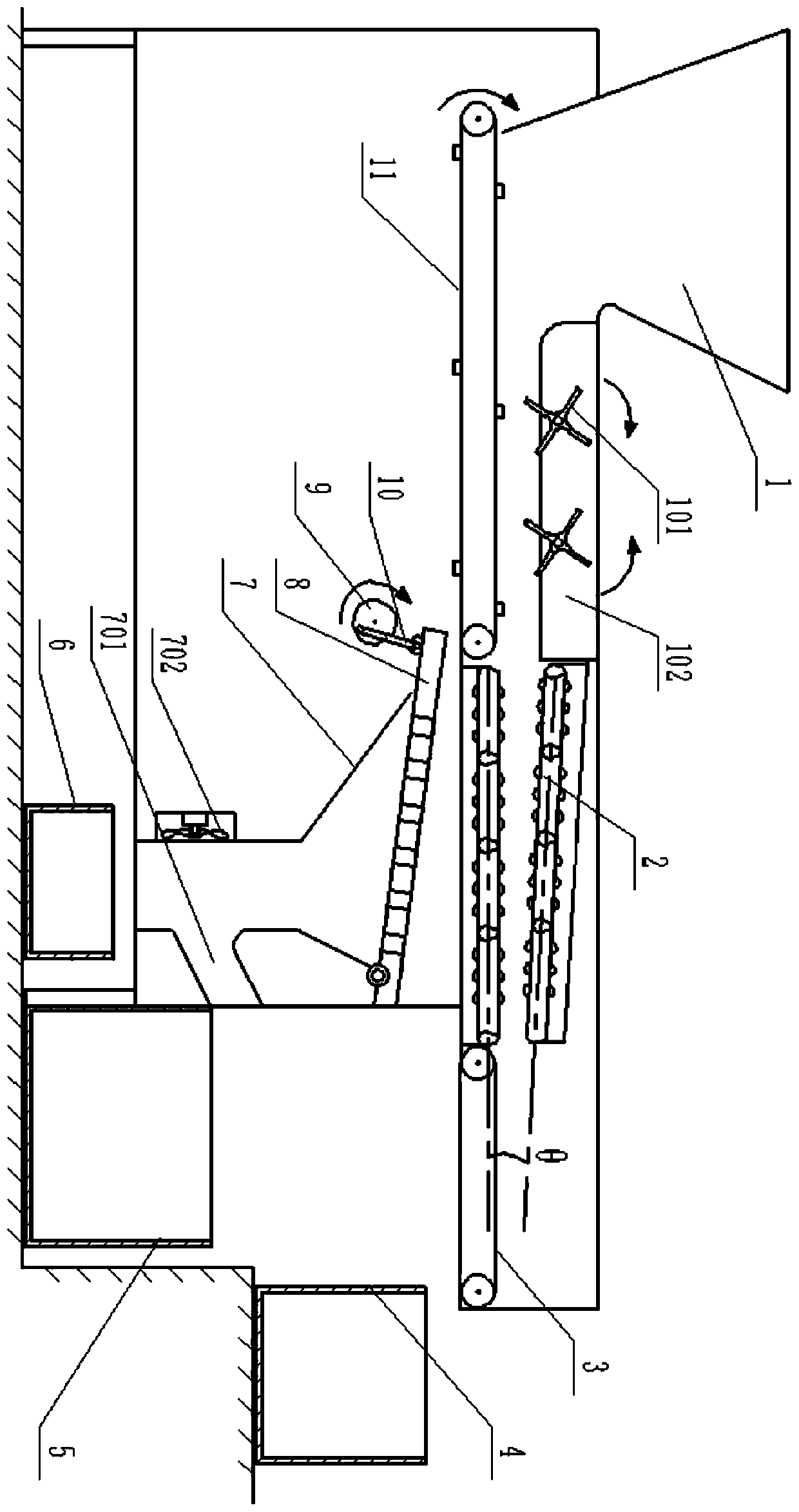

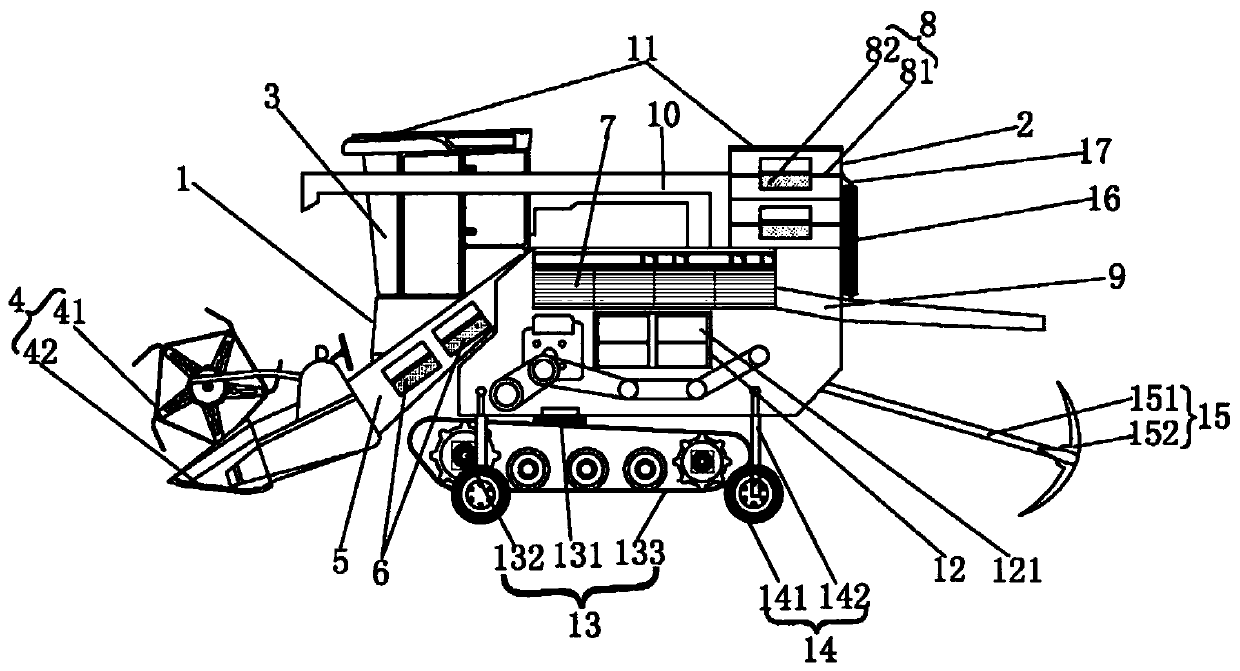

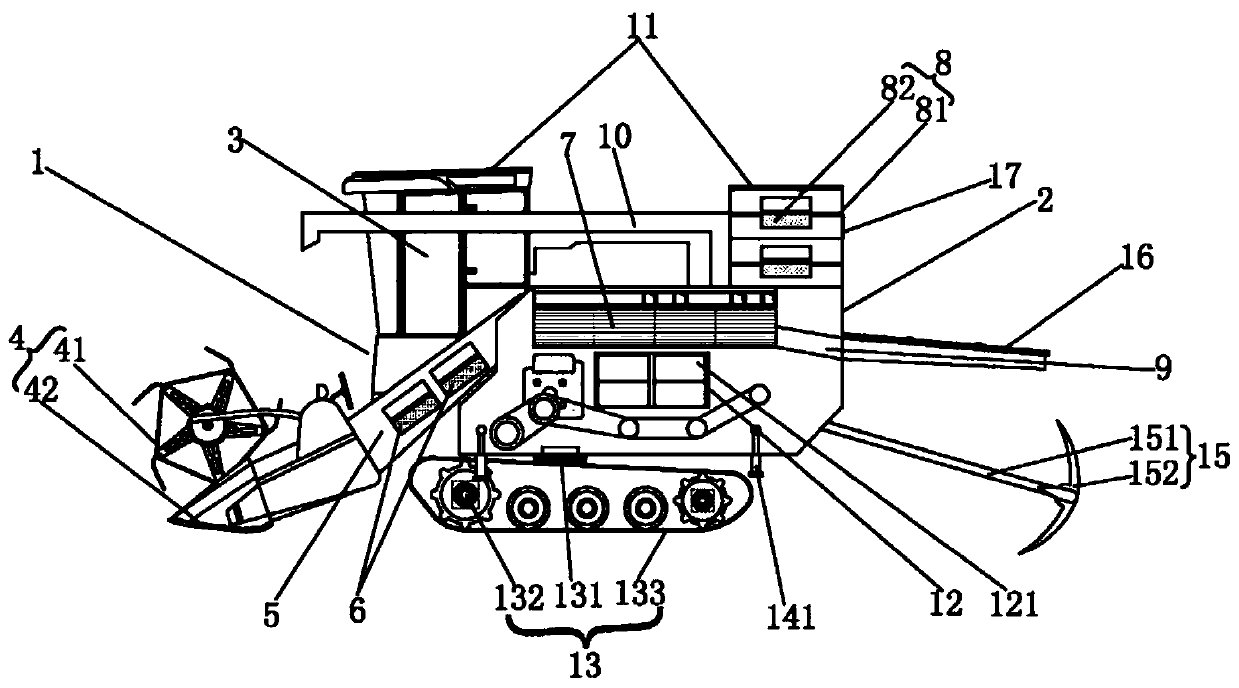

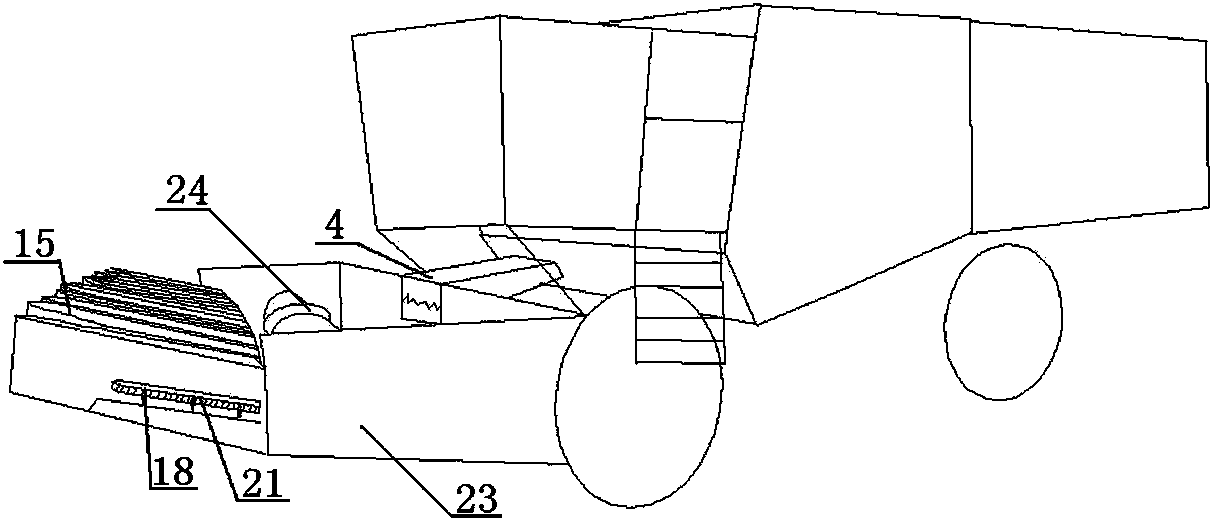

Sunflower seed harvester

The invention provides a sunflower seed harvester. The sunflower seed harvester comprises a vehicle body, a header mechanism, a feeding mechanism, a threshing mechanism, a cleaning mechanism, a sunflower plate collecting mechanism and a material storage device, wherein the vehicle body provides walking support and a power source for the header mechanism, the feeding mechanism, the threshing mechanism, the cleaning mechanism, a seed lifting mechanism, the seed collecting mechanism, a sunflower plate lifting mechanism, the sunflower plate collecting mechanism and the material storage device; theheader mechanism is arranged at the front end of the vehicle body; the feeding mechanism is arranged on the rear side of the header mechanism; the cleaning mechanism and a pushing device of the threshing mechanism are correspondingly arranged on the lower side of the vehicle body; the sunflower plate collecting mechanism is arranged on one side of the vehicle body; and the material storage deviceand the cleaning mechanism are correspondingly arranged on the other side of the vehicle body. The sunflower seed harvester is compact in structure, good in threshing and cleaning effects, high in harvesting efficiency and good in mechanical harvesting effect, the production cost is reduced, and the income of farmers is increased.

Owner:LUOYANG ZHONGSHOU MACHINERY & EQUIP

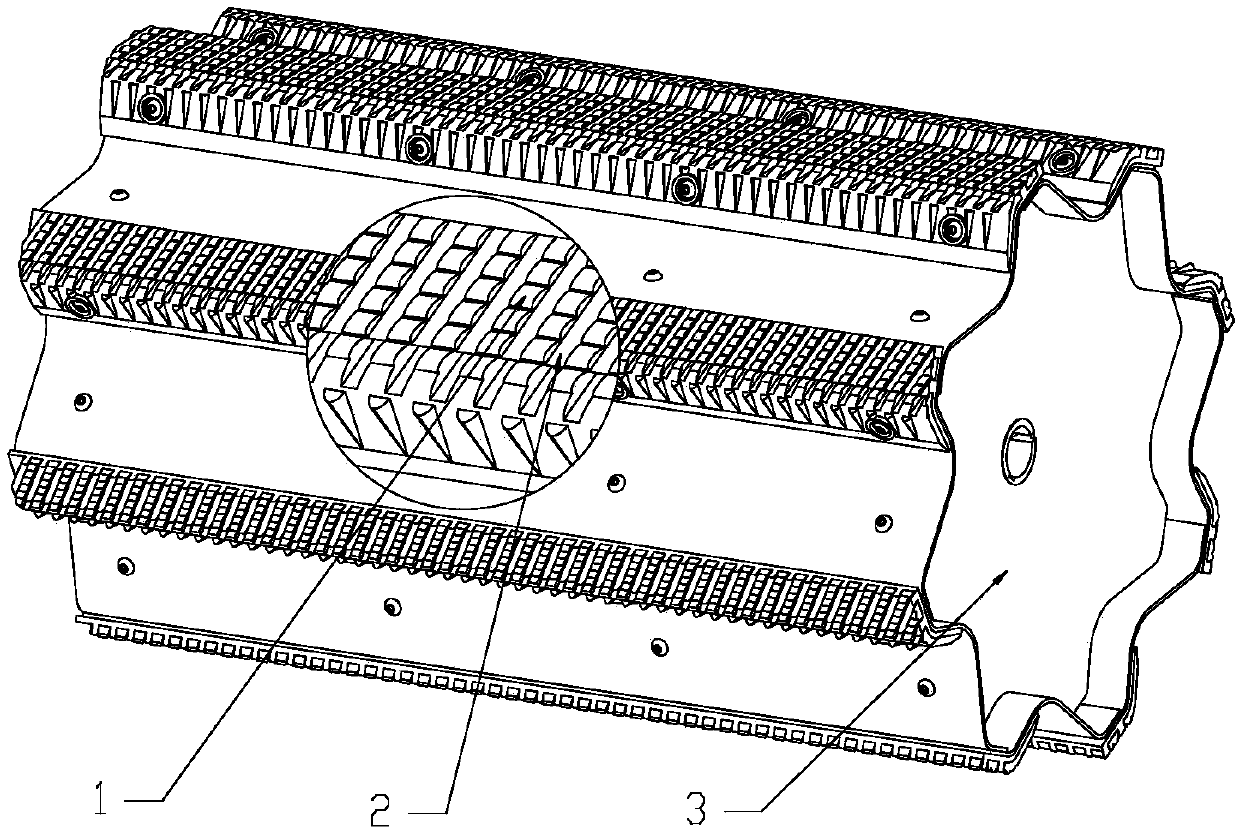

High-water-content corn bionic flexible threshing device

The invention relates to a high-water-content corn bionic flexible threshing device. The device comprises a bionic flexible threshing part, a threshing reinforcing base and a roller body. The bionic flexible threshing part is installed on the surface of the threshing reinforcing base, and the bionic flexible threshing part and the threshing reinforcing base are arranged on the roller body. A plurality of rows of threshing lines are distributed on the top surface of the bionic flexible threshing part, a plurality of wedge-shaped protrusions are distributed on the front inclined surface, the topsurface of the threshing reinforcing base is provided with a plurality of rows of supporting lines distributed in the longitudinal direction, and the threshing lines and the supporting lines are mutually embedded. By means of the bionic manual corn threshing principle, the wedge-shaped protrusions of the bionic flexible threshing part thresh part of corn kernels, and then remaining corn kernels are further threshed through the bionic flexible threshing part and top protrusions of the threshing reinforcing base. When the corn kernels high in water content are harvested, a low corn kernel breaking rate can be guaranteed, the non-removing rate of the corn kernels can be reduced, and the corn threshing effect is improved.

Owner:JIANGSU UNIV

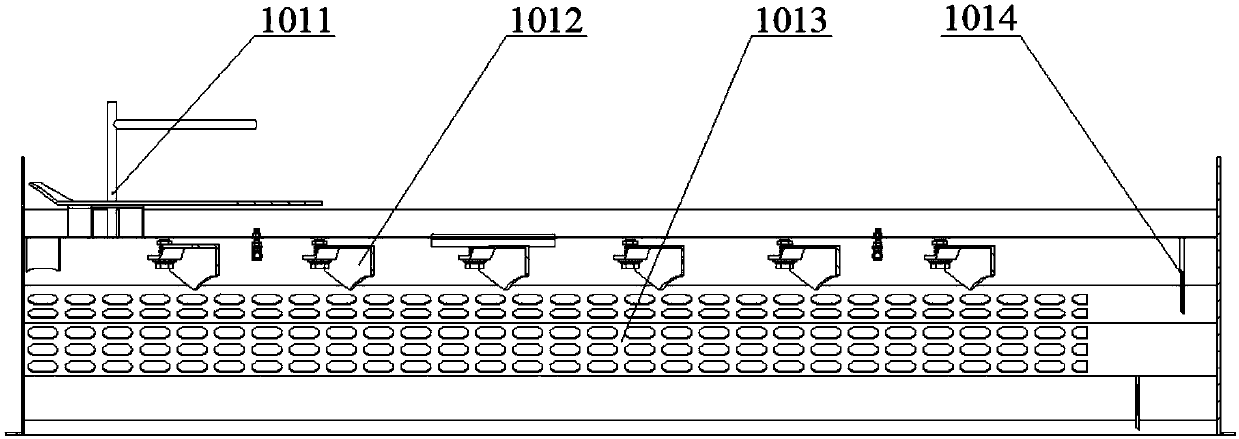

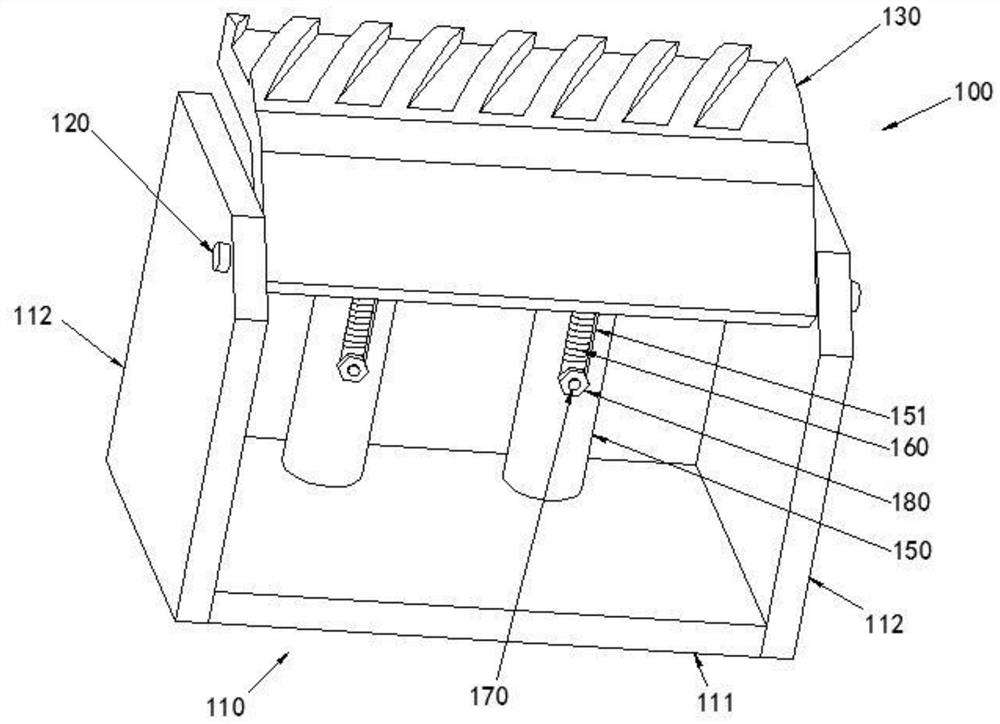

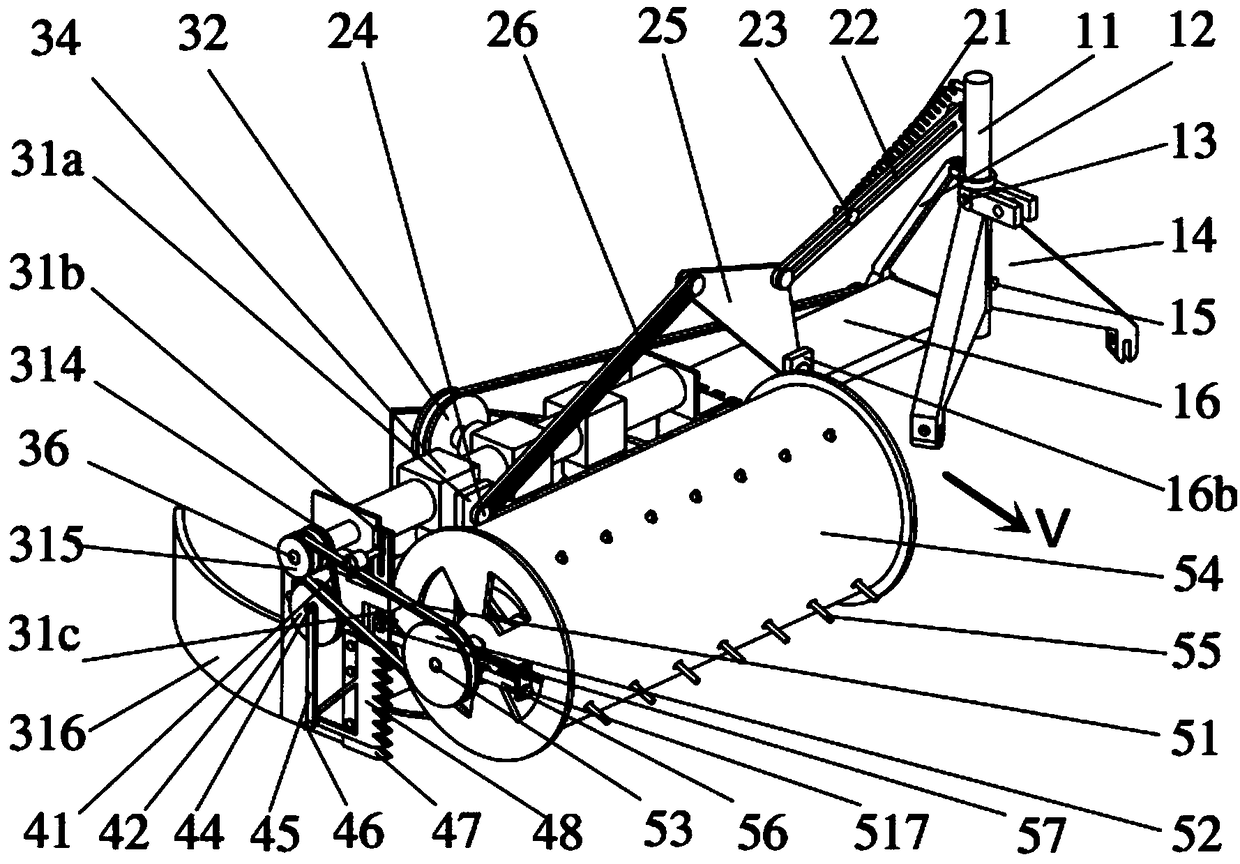

Combined harvester header for partitioned harvest of millet stalks and ears and application method thereof

The invention provides a combined harvester header for partitioned harvest of millet stalks and ears and an application thereof with the aim of resolving the problem that a conventional millet combined harvester causes waste by harvesting ear heads and stalks together. The combined harvester header comprises a header rack, a lower-layer cutting knife, an upper-layer cutting knife, a grain liftingboard, a conveyor and an adjusting device. The lower-layer cutting knife is arranged on the header rack and close to the one side of the ground. The upper-layer cutting knife is arranged by being close to the position above the header rack. The grain lifting board is arranged between the lower-layer cutting knife and the upper-layer cutting knife and used for pressing against to-be-harvested millets. The conveyor is used for collecting millet ears which are cut off by the upper-layer cutting knife. The adjusting device is arranged between the lower-layer cutting knife and the upper-layer cutting knife and used for adjusting the distance between the lower-layer cutting knife and the upper-layer cutting knife so as to be suitable for different kinds of millet heights. With the combined harvester header for partitioned harvest of millet stalks and ears, power consumption of machinery is reduced, which facilitates threshing and cleaning subsequently. Therefore, waste of millets is reduced.Segments of cut stalks are uniform in lengths, which is good for subsequent processing and feeding of stalk segments. Therefore, feeding value of stalks is increased.

Owner:HENAN UNIV OF SCI & TECH

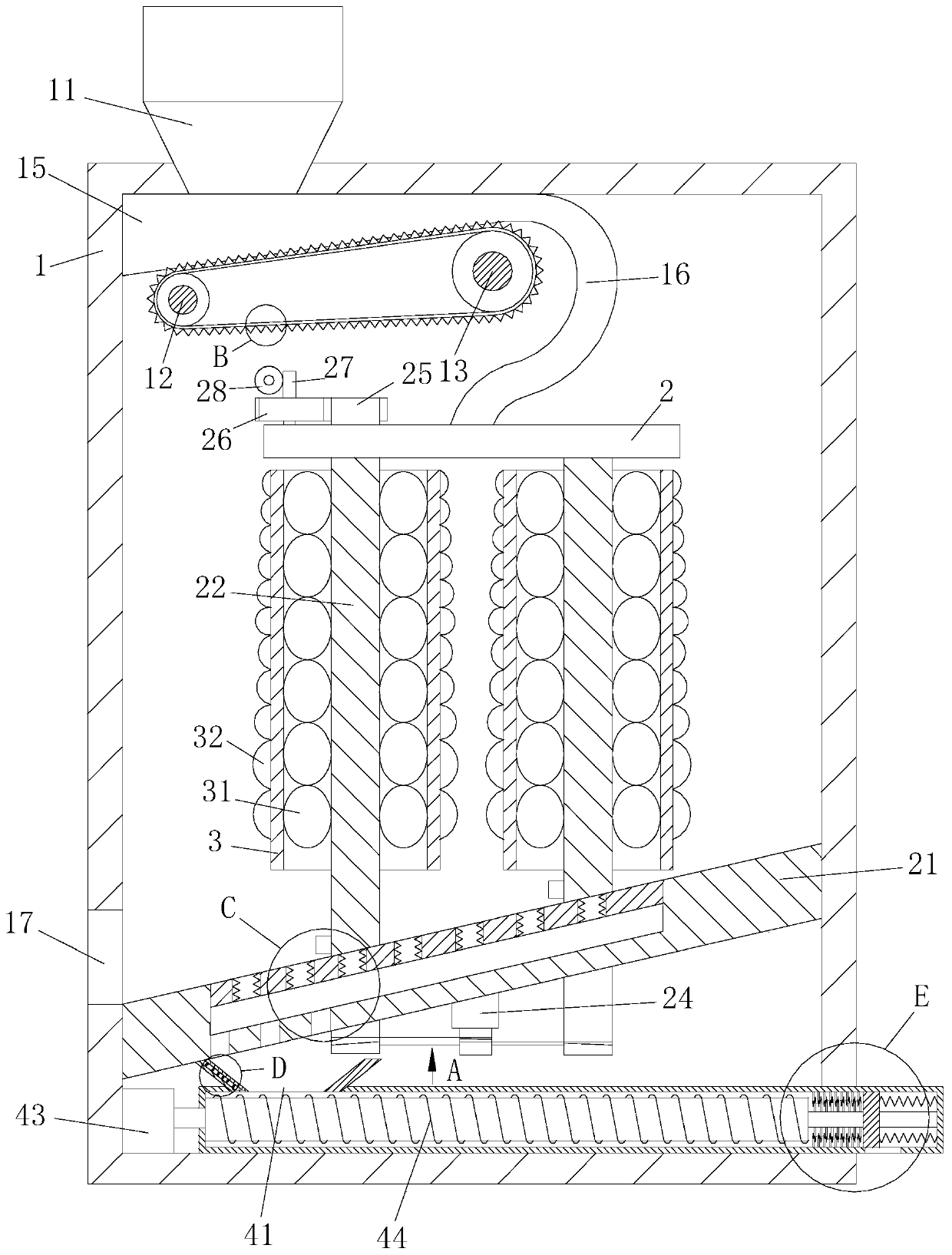

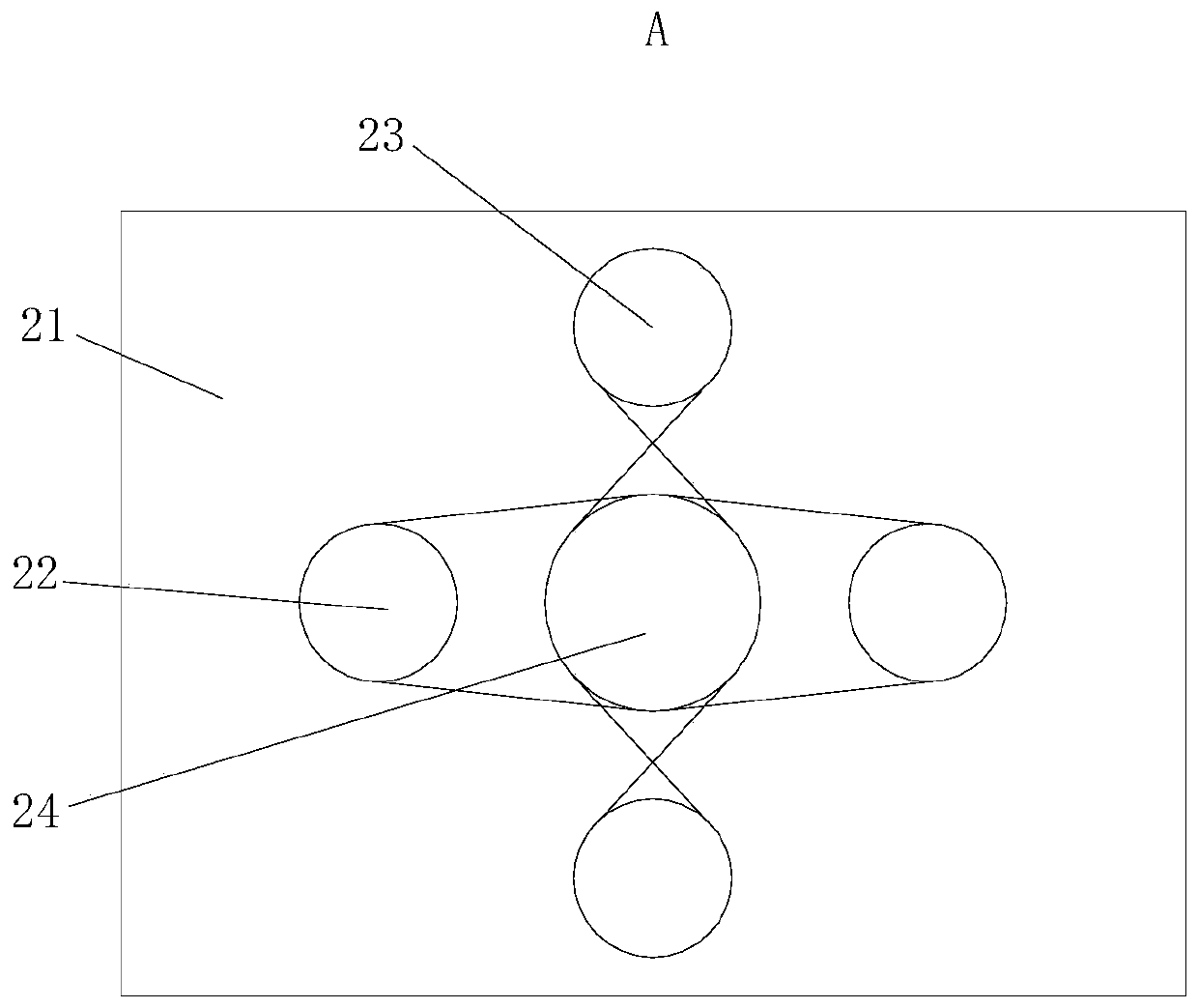

Corn flour food processing production device

InactiveCN109805261AEasy threshingImprove threshing efficiencyThreshersGrain treatmentsCorn flourEngineering

The invention belongs to the technical field of food processing machinery and specifically relates to a corn flour food processing production device which comprises a frame body and a controller, wherein a first rotating shaft and a second rotating shaft are in rotary connection in the frame body, the diameter of the first rotating shaft is smaller than that of the second rotating shaft, a conveying belt is jointly in sleeve connection to the surfaces of the first rotating shaft and the second rotating shaft, a second fixed plate is fixedly connected to an inner wall of the frame body, the second fixed plate is obliquely designed, parts penetrating through the second fixed plate of a third rotating shaft and a fourth rotating shaft are respectively in transmission through hemp ropes, the hemp ropes are wound to the surface of a first motor rotating shaft, the winding directions of the hemp ropes are opposite, a smashing barrel is arranged under the second fixed plate, semicircular second air bags are evenly distributed on the surface of a kneading roller, and the radiuses of the second air bags increase successively from top to bottom. The v corn flour food processing production device disclosed by the invention can effectively thresh the corn cobs under the situation that the corn cobs are not damaged and simultaneously can completely smash corn kernels; furthermore, the purity of smashed corn flour is high.

Owner:陈同翔

Corrugated tapered corn thresher

The invention discloses a corrugated tapered corn thresher. The corrugated tapered corn thresher comprises a conveying mechanism, a threshing mechanism, a separation mechanism, a transmission mechanism and a rack, wherein the threshing mechanism comprises a tapered roller and a driving device for driving the tapered roller to rotate; the tapered roller is vertically arranged; a large-opening end of the tapered roller corresponds to a discharging end of a material distribution cabin and a small-opening end of the tapered roller corresponds to a core discharging cabin; a plurality of rows of corrugated threshing belts and dispersion teeth are distributed on the inner surface of the tapered roller in a staggered manner; the setting direction of each row of corrugated threshing belts and the setting direction of each row of dispersion teeth are parallel to the middle axis of the tapered roller; each corrugated threshing belt is of a solid structure formed by extending a sealed plane formed by surrounding a lower bottom edge, two side edges and circular arcs connected with the upper ends of the two side edges according to an S-shaped track; and each dispersion tooth is of a conical solid structure formed by surrounding a bottom end surface, a side curved surface and a spherical surface connected with the upper end of the side curved surface. With the adoption of the corrugated tapered corn thresher, mechanical loss in a corn threshing process can be reduced, the threshing rate is improved, and corncobs are not crushed.

Owner:HENAN UNIV OF SCI & TECH

Multifunctional rice harvester

PendingCN109769460AEasy to harvestEasy threshingMowersSaving energy measuresHydraulic motorAgricultural engineering

The invention discloses a multifunctional rice harvester, which comprises a harvester body, wherein the harvester body comprises a harvester frame, a cab, a harvesting device, a rice conveying pipeline, a threshing device, a circulating drying box and a straw shaker, a stirring cage and a second heating plate are arranged in the circulating drying box, the circulating drying box is connected witha high-level grain unloading cylinder; the top end of the harvester frame is provided with a solar panel, the bottom end of the harvester is provided with a field walking mechanism and a road surfacewalking mechanism, the field walking mechanism comprises a rotating hydraulic motor, a walking hydraulic motor and a crawler wheel, the crawler wheel is rotatably connected with the harvester frame through the rotating hydraulic motor, the front end and rear end of the crawler wheel are both connected with the output shaft of the walking hydraulic motor; the road surface walking mechanism comprises a hydraulic telescopic rod and a rubber wheel; the rear end of the harvester body is provided with an anti-sinking device. The harvester is energy-saving and environment-friendly, adopts a four-drive structure with sufficient power, can achieve 360-degree rotation in the field, can walk on a road surface, and has a plurality of functions of harvesting, threshing, drying, anti-sinking and the like.

Owner:福建省氿鑫隆电器有限公司

Miniature peanut picking machine

The invention discloses a miniature peanut picking machine. Two ends of a threshing roller are installed on the left side and the right side of a cover plate. A large belt pulley is installed at the external shaft end of the threshing roller. The large belt pulley is connected with a small belt pulley through a belt. The small belt pulley is installed at the external end of a motor. Wheel baskets are arranged at the two ends of the threshing roller. Iron angles are arranged between the wheel baskets. Rubber pads are installed at the tops of the iron angles. Mud guards are installed below the iron angles. A sieve plate is arranged at the bottom of the mud guards. The edge diameter of the top surface plate of each iron angle is same as and / or similar to the edge diameter of each rubber pad. The top plates of the mud guards are fixedly installed on the bottom surfaces of the iron angles. The rubber pads, the iron angles and the mud guards are tightly fixed by using bolts. The number of the rubber pads is more than one. The number of the mud guards is more than one. The sieve plate is obliquely installed below the threshing roller. The motor is installed on a bottom plate and is an electric motor and / or a fuel engine. Cover plate installation holes are arranged in the cover plate. Rack installation holes are arranged in a rack. The cover plate and the rack are fixedly connected through bolts and nuts. Spaces exist between the rubber pads and the iron angles. The mud baffles are arranged below the spaces. The sieve plate is arranged blow the mud guards. The rubber pads are made of rubber and plastic materials. The mud guards are made of iron plates and / or rubber and plastic plates.

Owner:陈景华

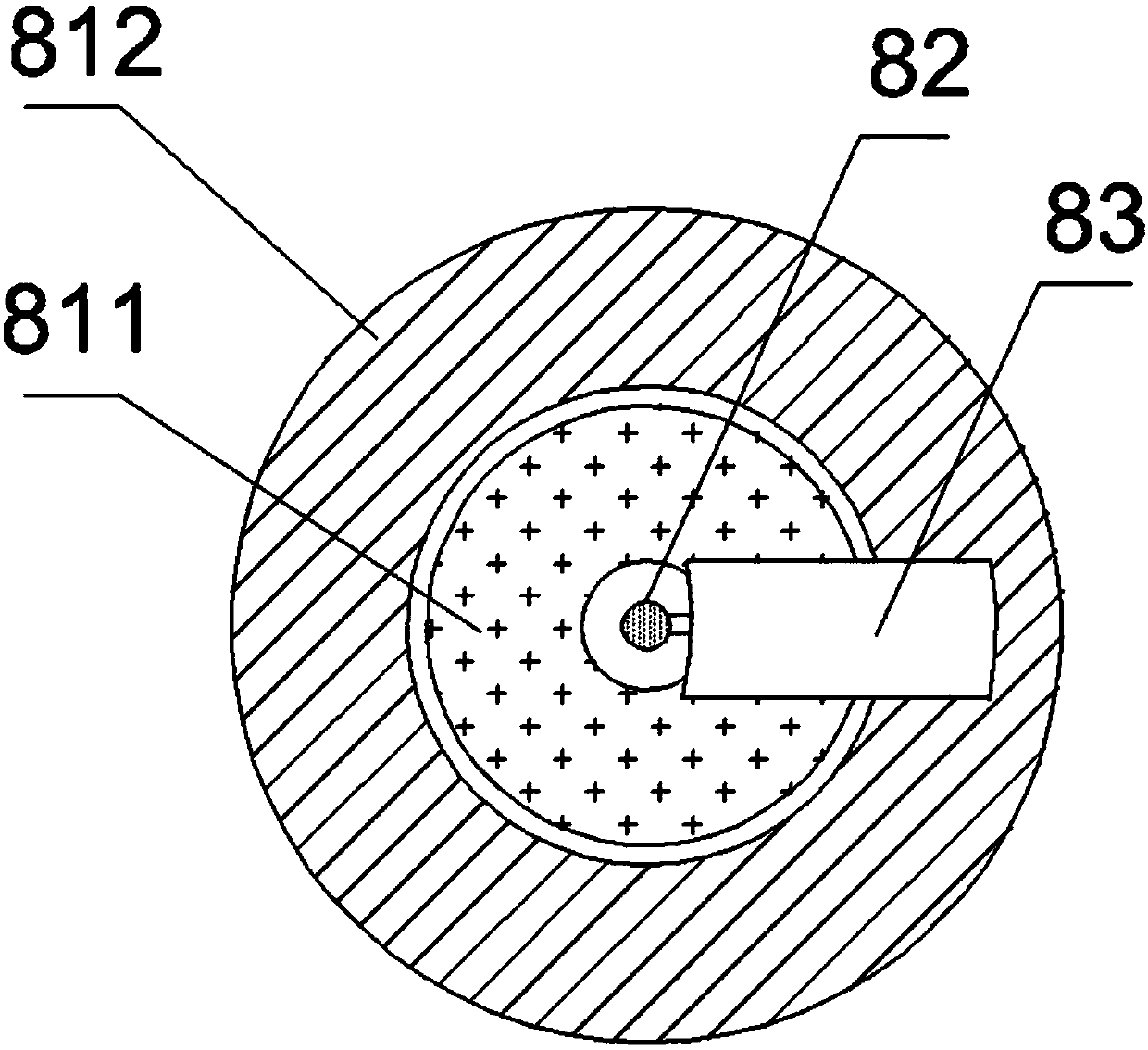

Integrated device for corn aftertreatment

The invention discloses an integrated device for corn aftertreatment. The integrated device comprises a shell body, a cover body, a plurality of needle pricking assemblies, a plurality of threshing drums, a plurality of roller shaft assemblies, a conveying belt assembly, a vibration assembly and a pair of grinding assemblies, wherein a powder discharging opening and a first air cylinder are formedon the bottom face of the shell body, and a cob discharging opening is formed in one side of the shell body; each needle pricking assembly comprises a first motor, a second air cylinder and a push cylinder; multiple columns of [-shaped rasps are uniformly distributed on the internal wall of each threshing drum; each roller shaft assembly comprises a first roller shaft and multiple pairs of secondroller shafts; the conveying belt assembly is used for leading out corncobs from the shell body; the vibration assembly comprises a fixing plate and a pair of vibration screens; and the grinding assemblies comprise grinding plates, screws, grinding stones, supporting tables and power units. According to the integrated device for corn aftertreatment, threshing and grinding can be carried out in arapid, efficient and assembly-line manner, corn kernels, corncobs and fugitive dust are effectively separated, procedures are reduced, the working efficiency is increased, and the maintenance and servicing are convenient.

Owner:李斌施

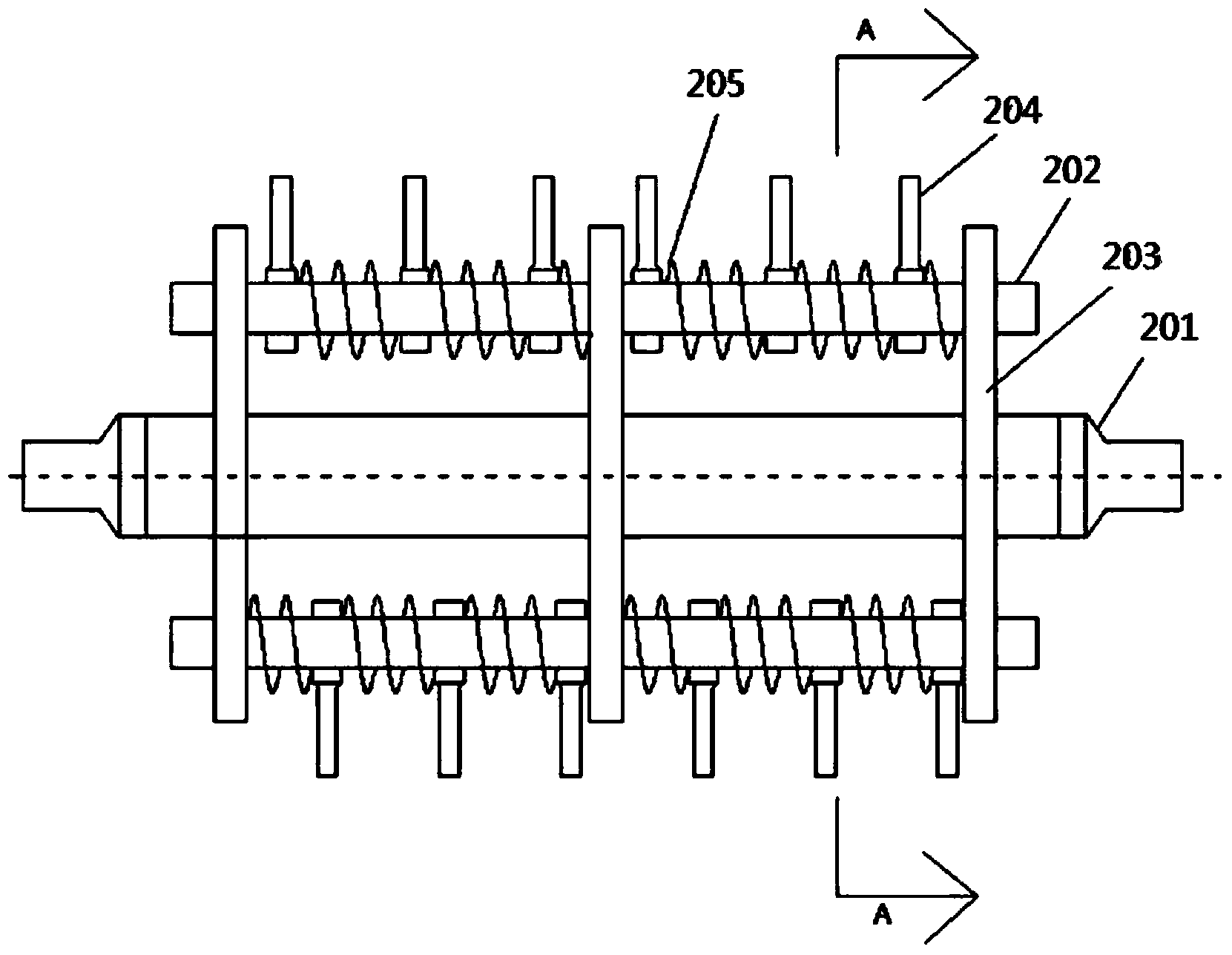

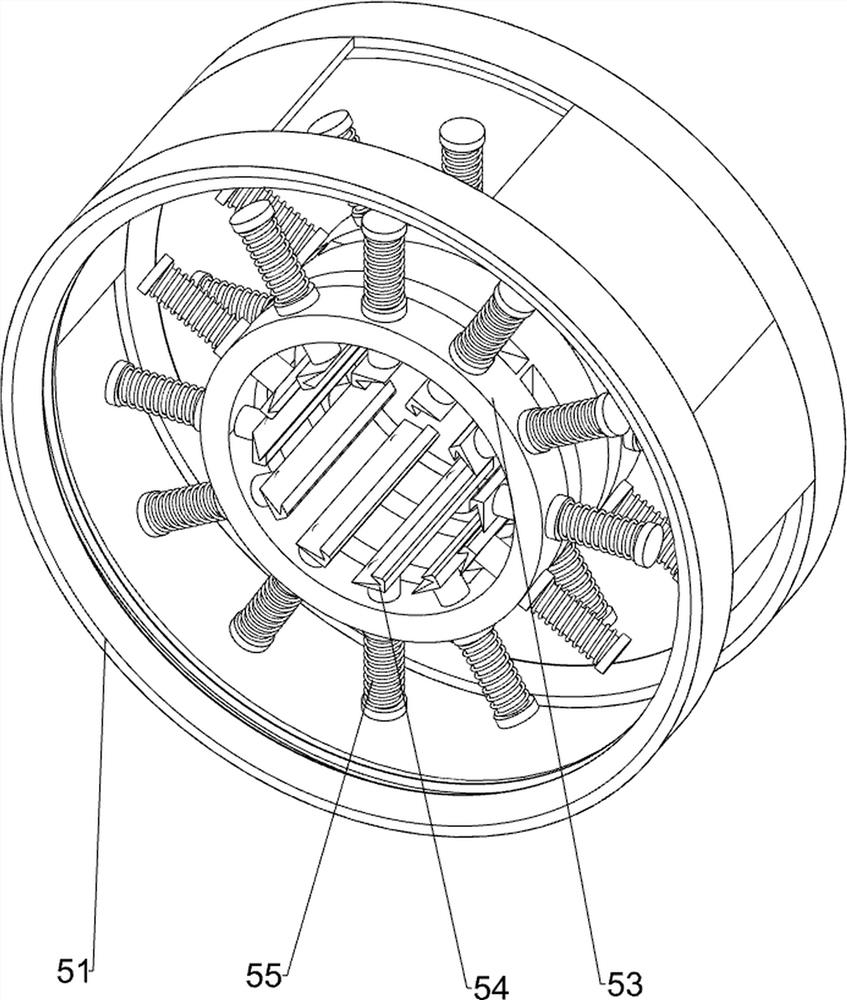

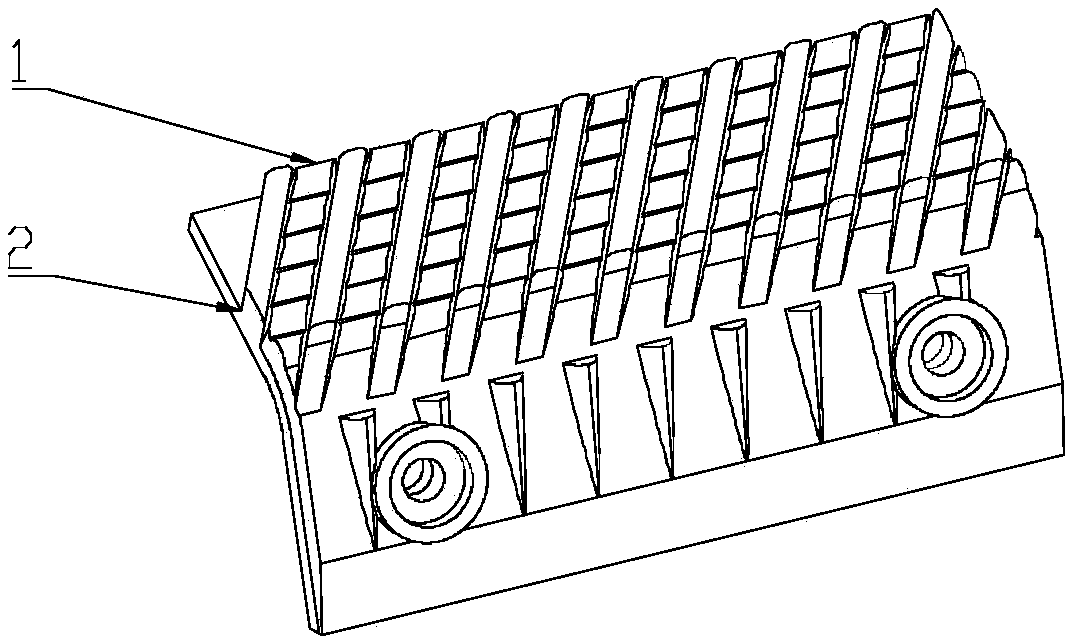

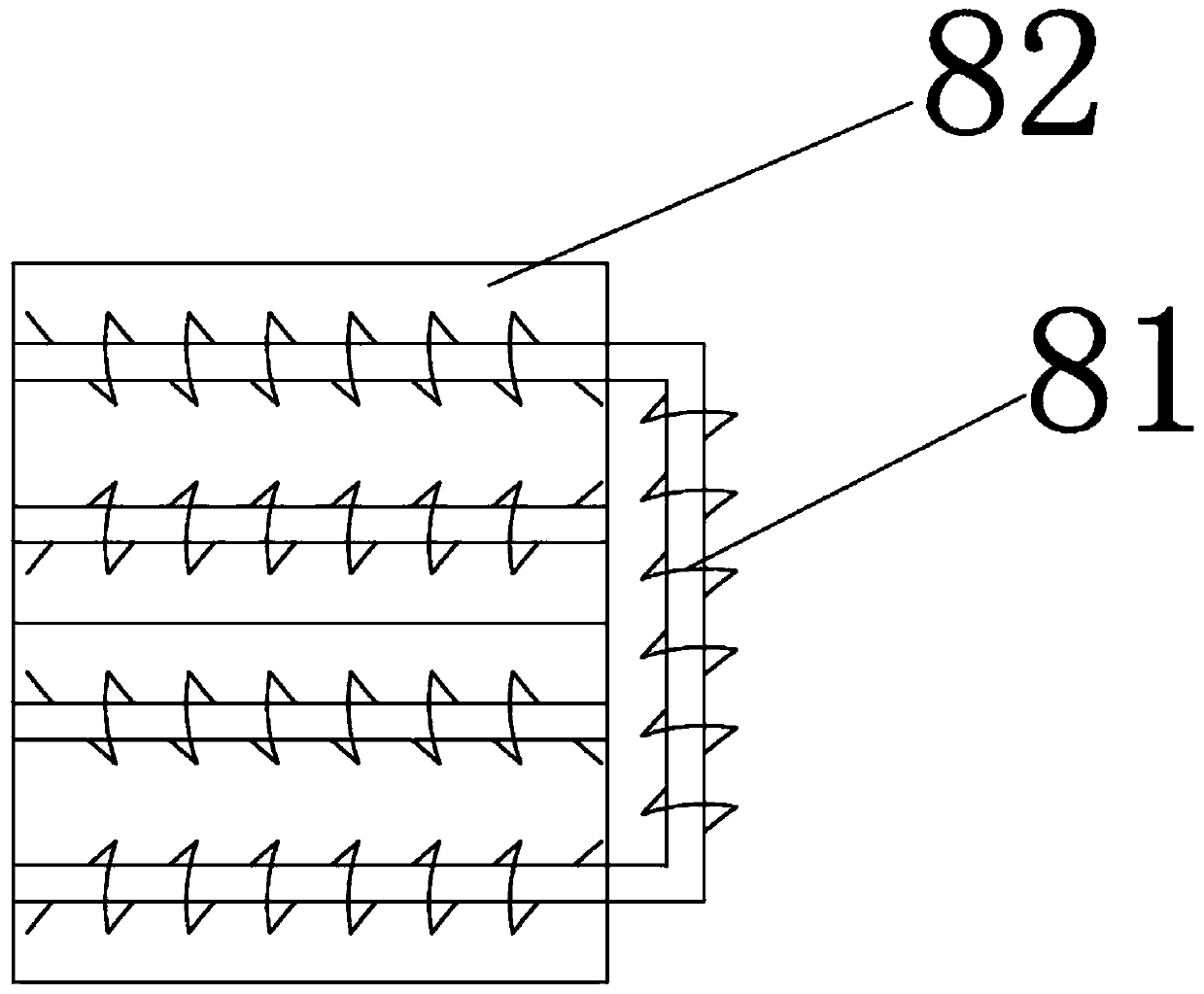

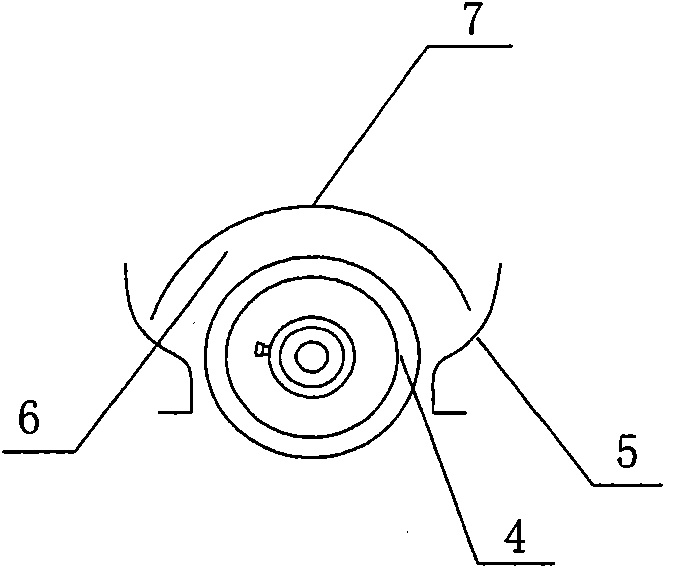

Rasp bar mechanism and edible bean threshing cylinder applying rasp bar mechanism

The invention discloses a rasp bar mechanism. The rasp bar mechanism comprises a base, a first rotating shaft, a rasp bar block, an upper adjusting column, a sleeve and an elastic body. The surface ofthe rasp bar block is provided with inclined grooves. The rasp bar block is installed on the base through the first rotating shaft. The rasp bar block can rotate around the first rotating shaft. Thesleeve is installed on the base. The elastic body is located in the sleeve. The upper adjusting column is connected with the rasp bar block. The upper adjusting column is inserted into the sleeve andlocated above the elastic body. According to the rasp bar mechanism, the rasp bar block is used to configure the first rotating shaft and the elastic body, so that the gap between the rasp bar block and a sieve cylinder can adaptively change with the change of the size of bean pods when the rasp bar mechanism is used. The rasp bar block is always in contact with the bean pods and applies basicallythe same pressure on the bean pods, thereby ensuring that both large and small bean pods can be threshed normally without damaging seeds.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Threshing method based on waste heat utilization and thresher based on waste heat utilization

The invention discloses a threshing method based on waste heat utilization and a thresher based on the waste heat utilization. The thresher comprises a threshing cylinder, a concave sieve plate arranged below the threshing cylinder and an engine for driving the threshing cylinder; and is characterized in that the concave sieve plate is internally provided with a circulating cooling water pipe which is used for performing heat exchange with the inside of the concave sieve plate and cooling the engine; and the concave sieve plate is internally provided with an exhaust pipe which is used for performing heat exchange with the inside of the concave sieve plate and exhausting waste heat of the engine. The threshing method and the thresher make full use of waste heat of the engine, and are applicable to threshing of different crops by preheating and predrying materials in the threshing cylinder.

Owner:HUNAN AGRICULTURAL UNIV

Sunflower harvester

The invention provides a sunflower harvester which comprises a sunflower-row cutting part, a transferring part, a threshing part and a screening storage part, wherein sunflower stalks are cut off by a serrated knife to obtain sunflower heads; the sunflower heads are transferred to the threshing part from the transferring part for threshing; the sunflower heads are rubbed and pressed by rotating an inner cylinder; the threshed grains are screened by a dual-layer vibrating screen and are centralized and elevated to a grain storage bin in a spiral conveying manner. The sunflower harvester has the benefits that only the sunflower heads are cut; the stalks on the sunflower heads are extremely short and convenience is brought to subsequent threshing and screening; the grains and the heads are thoroughly separated; the sunflower heads are great in broken piece; the grains and the heads are easily separated; sunflower seeds are prevented from being broken; when the sunflower harvester and the sunflower reaper are combined, the sunflower seeds with fewer impurities can be directly obtained from the field; the threshing, screening and storing for a stock bin can be realized; the stock bin is great in size and high in capacity, so non-stop harvesting for a longer time can be realized.

Owner:许开军

corn thresher

The invention discloses a corn thresher, comprising a feed hopper, a threshing device and a support, the feed hopper is installed on the upper part of the threshing device, the threshing device is fixed on the support, the lower end of the threshing device is provided with a discharge port, the threshing device consists of a threshing cylinder, a pressing plate Composed of baffles, the pressing plate is located above the threshing cylinder in an arc shape, the baffle is located on the side of the threshing cylinder and the pressing plate, and an arc-shaped threshing chamber is formed between the threshing cylinder, pressing plate and the baffle, and the diameter of the inlet port of the threshing chamber is larger than the diameter of the outlet port; The threshing cylinder is provided with threshing tendons or threshing teeth, and the bottom of the threshing cylinder is provided with a protective shell; the pressure plate is composed of a pressure plate, a pressure tube, a pressure strip and a pressure spring, and an elastic device is arranged on the top of the pressure plate; The problem of feeding and threshing corn cobs with different diameters, and can be fed and threshed in batches, the threshing effect is very good, the threshing speed is very fast, the cleaning rate can almost reach 100%, the structure is simple, the production cost and the use cost are relatively low Low.

Owner:李禄海

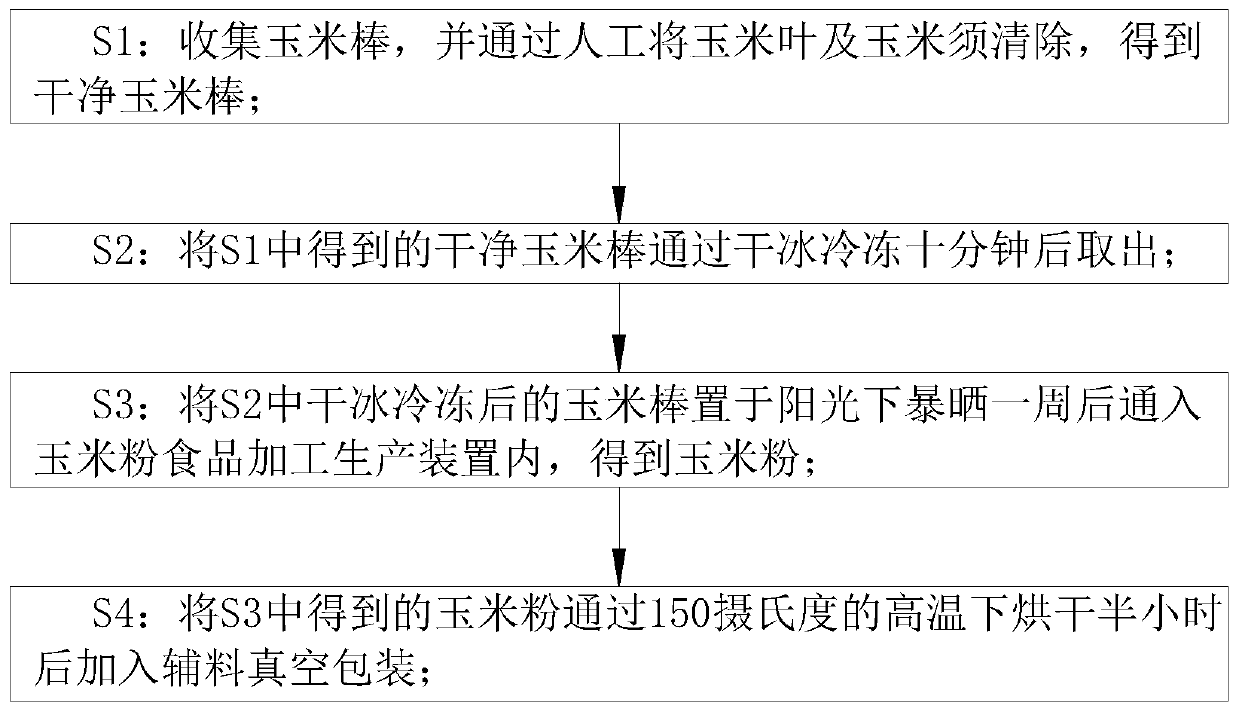

Corn flour food processing technology

PendingCN109805260AEffective antivirusRich tasteSeed preservation by dryingThreshersAdditive ingredientCorn flour

The invention belongs to the technical field of food processing technologies and specifically relates to a corn flour food processing technology. By means of dry ice refrigeration, cells in corn kernels can be broken, so that effective ingredients in corns can be completely released; meanwhile, convenience is brought to smashing the corn kernels later and primarily sterilizing the corns; by meansof exposure under the sunshine and high-temperature drying, moisture in the corn kernels can be evaporated, and the corn kernels are simultaneously and effectively sterilized; by means of adding different tastes of auxiliary materials, the corn flour has more tastes and is more suitable for the popular need. A corn flour food processing production device used in the processing technology comprisesa frame body and a controller, and parts penetrating through a second fixed plate of a third rotating shaft and a fourth rotating shaft are respectively in transmission through hemp ropes. The processing technology disclosed by the invention has the advantages of simple work procedures, convenience in operation and ability in effectively threshing corn cobs and smashing the corn kernels; the prepared different tastes of high-purity corn flour is more suitable for the popular taste.

Owner:陈同翔

High-automation-degree corn thresher

ActiveCN109997524AHigh degree of semi-automationPromote convenient and smoothSaving energy measuresThreshersPush and pullEngineering

The invention provides a high-automation-degree corn thresher, which comprises a supporting plate, a feeding hopper, a discharging tank, a crankshaft, connecting rods, an annular plate, sleeve plates,pressure bearing wheels, a slide groove, carrier plates, retaining rings, hinge shafts, push rods, threshing teeth, driven grooves, a belt pulley, convex plates and truss plates. The feeding hopper and the discharging tank are fixedly connected above and below the exterior of the supporting plate respectively, and the middle of the supporting plate is penetratingly provided with the slide groovewhile left and right sides of the supporting plate are provided with the carrier plates. By rotational connection between the connecting rods and crank necks of the crankshaft, the connecting rods above the middle of the slide groove move under the linkage action of the crankshaft, the push rods circularly push and pull under the action of the retaining rings to continuously push corn cobs into the annular plate, and the corn cobs are threshed by the threshing teeth in the annular plate, so that the semi-automation level of the corn thresher is raised.

Owner:江西创嘉智能技术有限公司

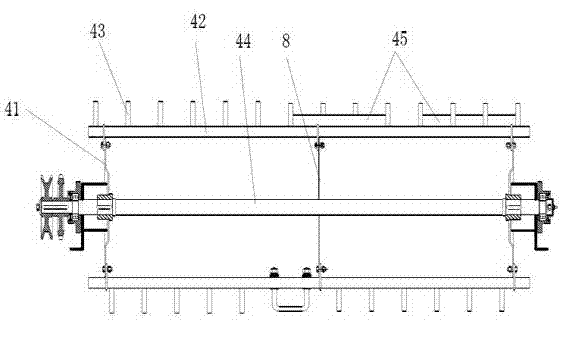

Side-mounted disc type pea windrower

The invention belongs to the technical field of agricultural machinery, in particular to a side-mounted disc type pea windrower. The side-mounted disc type pea windrower includes a rack unit, a side tool unit, a reeling unit and a cutting unit. The side tool unit comprises a side tool-driven belt (41), a side tool driven pulley (42), a side tool driven pulley shaft (43), an offset shaft (44), a connecting rod (45), a connecting rod connecting shaft (46), a stationary blade (47), a moving blade (48), a plummer block (49), a bearing seat plate (410) and a side tool fixed longitudinal bar (411).The side-mounted disc type pea windrower is provided with the side tool unit to prevent pea seedlings from being wound on one side of the windrower during a moving process of the windrower. The side-mounted disc type pea windrower uses a cutter disk to cut, anti-interference ability is good, and the cutter disk is not easy to wear and has longer service life. The side-mounted disc type pea windrower can gather the cut pea seedlings into a row to facilitate subsequent threshing of peas.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com