Corn thresher for food processing

A corn thresher and food processing technology, which is applied in the field of threshers, can solve the problems of laborious removal of corn cobs, poor corn threshing effect, etc., and achieve the effect of saving filtration time, reducing waste, and thorough threshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

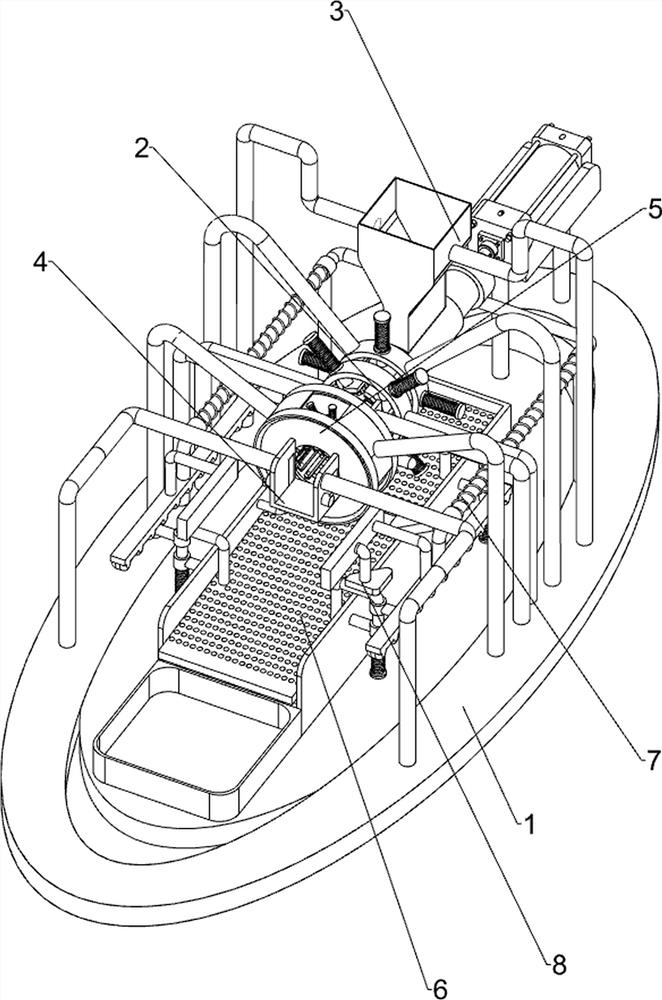

[0070] A corn thresher for food processing, such as figure 1 As shown, it includes a bottom plate 1, a pushing surface scraper mechanism 2 and a blanking pushing and scraping mechanism 3, a pushing surface scraping mechanism 2 is provided in the middle of the top of the bottom plate 1, and a blanking pushing and scraping mechanism 3 is provided on the right side of the top of the bottom plate 1.

[0071] When it is necessary to thresh the corn, the staff puts the corn into the feeding and scraping mechanism 3, then starts the feeding and scraping mechanism 3, pushes the corn to move to the left, and makes the corn enter the pushing surface scraping mechanism 2, thereby realizing Threshing, when the corn threshing is completed, the staff controls the feeding and pushing scraping mechanism 3 to reset, then closes the feeding and pushing scraping mechanism 3, takes out the corn cob in the pushing surface scraping mechanism 2, and collects the corn kernels.

Embodiment 2

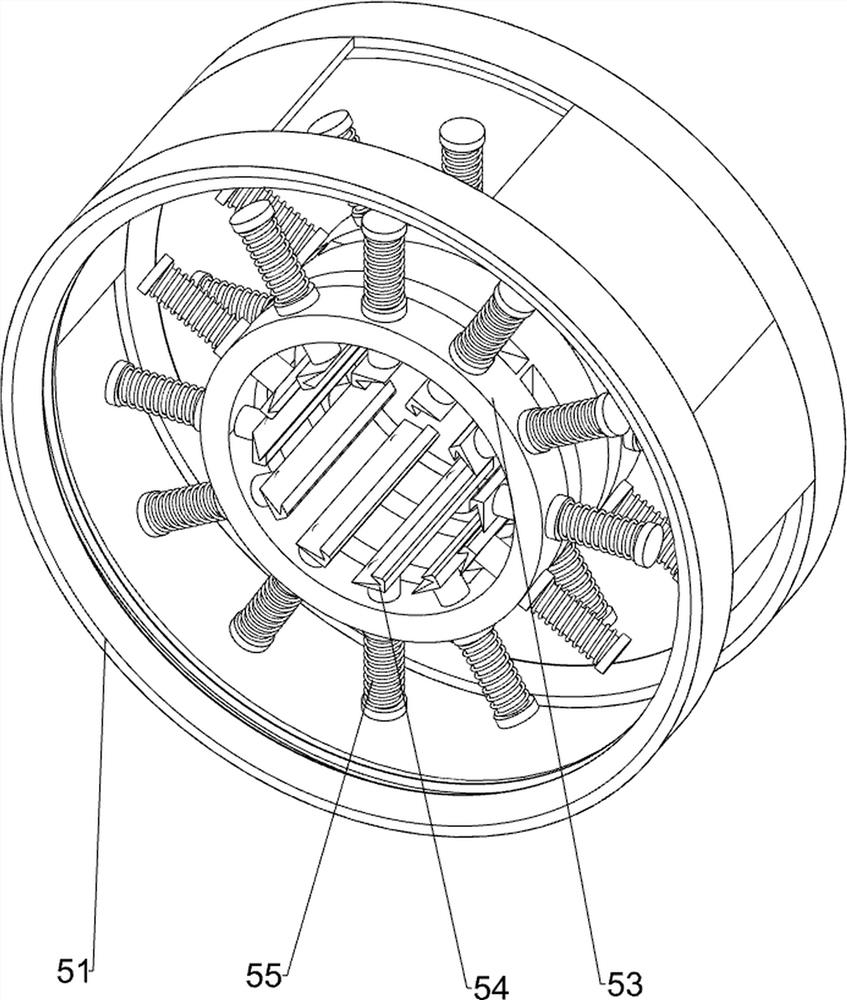

[0073] On the basis of Example 1, such as Figure 2-4 As shown, the pushing surface scraper mechanism 2 includes a fixed connecting ring 21, a sliding scraper 22 and a first spring 23, the middle part of the top of the bottom plate 1 is provided with a fixed connecting ring 21, and a sliding scraper 22 is arranged in a uniform sliding manner in the fixed connecting ring 21, A first spring 23 is provided between the sliding scraper 22 and the outer wall of the fixed connection ring 21 , and the two ends of the first spring 23 are respectively connected with the sliding scraper 22 and the outer wall of the fixed connection ring 21 .

[0074] When it is necessary to thresh the corn, the staff puts the corn between the sliding scrapers 22, and pushes the corn to the left, and utilizes the sliding scraper 22 to thresh the corn, and the staff catches the corn kernels under the sliding scraper 22. A spring 23 is compressed, and after the threshing is completed, the staff takes out th...

Embodiment 3

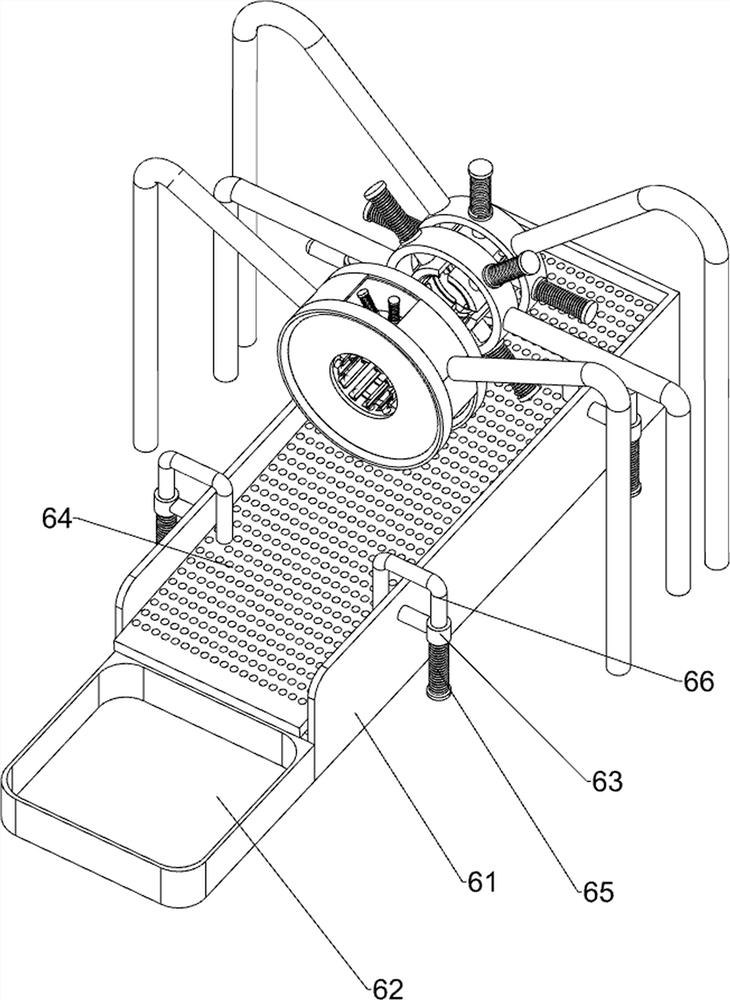

[0078] On the basis of Example 2, such as Figure 5-10 As shown, a clamping mechanism 4 is also included. The clamping mechanism 4 includes a discharge track 41, a fixed sliding sleeve plate 42, a clamping plate 43 and a second spring 44. The left side of the bottom plate 1 is provided with a discharge track 41. (The number of discharge rails 41 is two), and the front and rear sides of the middle part of the discharge rail 41 are symmetrically provided with fixed sliding sleeve plates 42, and a clamping plate 43 is slidingly provided on the fixed sliding sleeve plate 42, and the clamping plate 43 is connected with the discharge The middle part of the track 41 is slidingly connected, the clamping plate 43 is covered with a second spring 44, and the two ends of the second spring 44 are respectively connected with the clamping plate 43 and the fixed sliding sleeve plate 42.

[0079] After threshing through the sliding scraper 22, there may still be a small amount of corn residue....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com