Sunflower harvester

A harvester and sunflower technology, applied in the field of agricultural machinery, can solve the problems of grain loss, dirty threshing, broken sunflower seeds, etc., and achieve the effects of easy processing and production, simple and clear structure, and high harvesting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

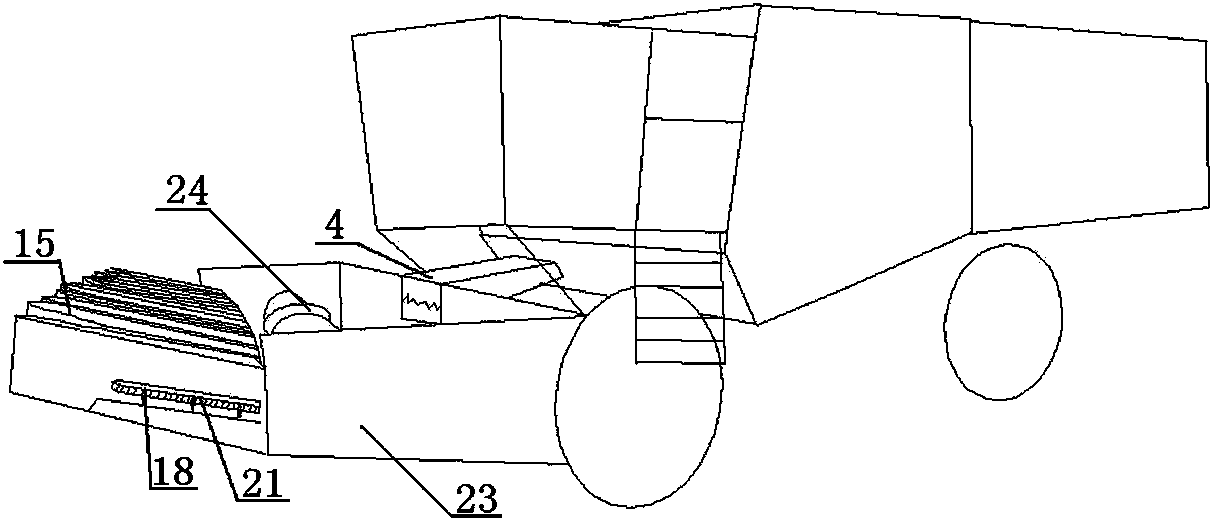

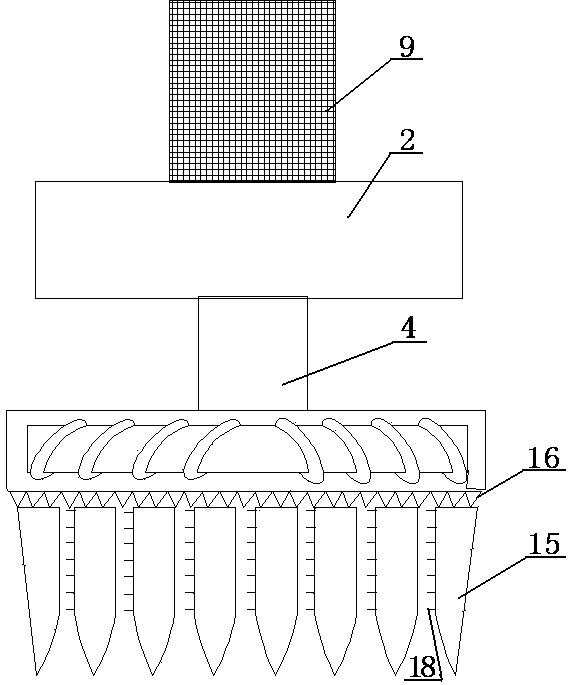

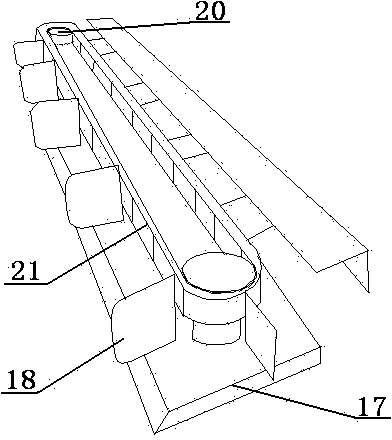

[0020] As shown in the figure, a sunflower harvester includes a row divider 15, a cutting tooth knife 16, and the cutting tooth knife 16 is adjacent to the rear end of the spreader 15, and the cutting tooth knife 16 reciprocates to cut off the stalk, making it a reciprocating part The cutter structure on the wheat harvester or electric razor can be used. The branching device 15 is supported by the bracket 17. The front end of the branching device 15 is an arc-shaped streamlined structure similar to the front end of a ship, which is convenient for the stalks to enter the row. 15 stretches out the sunflower stalk dividing plate 18, and the sunflower stalk dividing plate 18 is fixed on the rotating device inside the row divider 15, and forms the grid that gap can accommodate vertical sunflower stalk between the adjacent sunflower stalk dividing plate 18 , along with the advancement of the sunflower harvester, the sunflower stalks are constantly gathered in the grid, and the sunflo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com