High-water-content corn bionic flexible threshing device

A high moisture content, threshing device technology, applied in threshing equipment, applications, agricultural machinery and tools, etc., can solve the problems of high corn grain breakage rate, unclean removal, etc., to reduce mutual support effect, increase friction, slow down impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

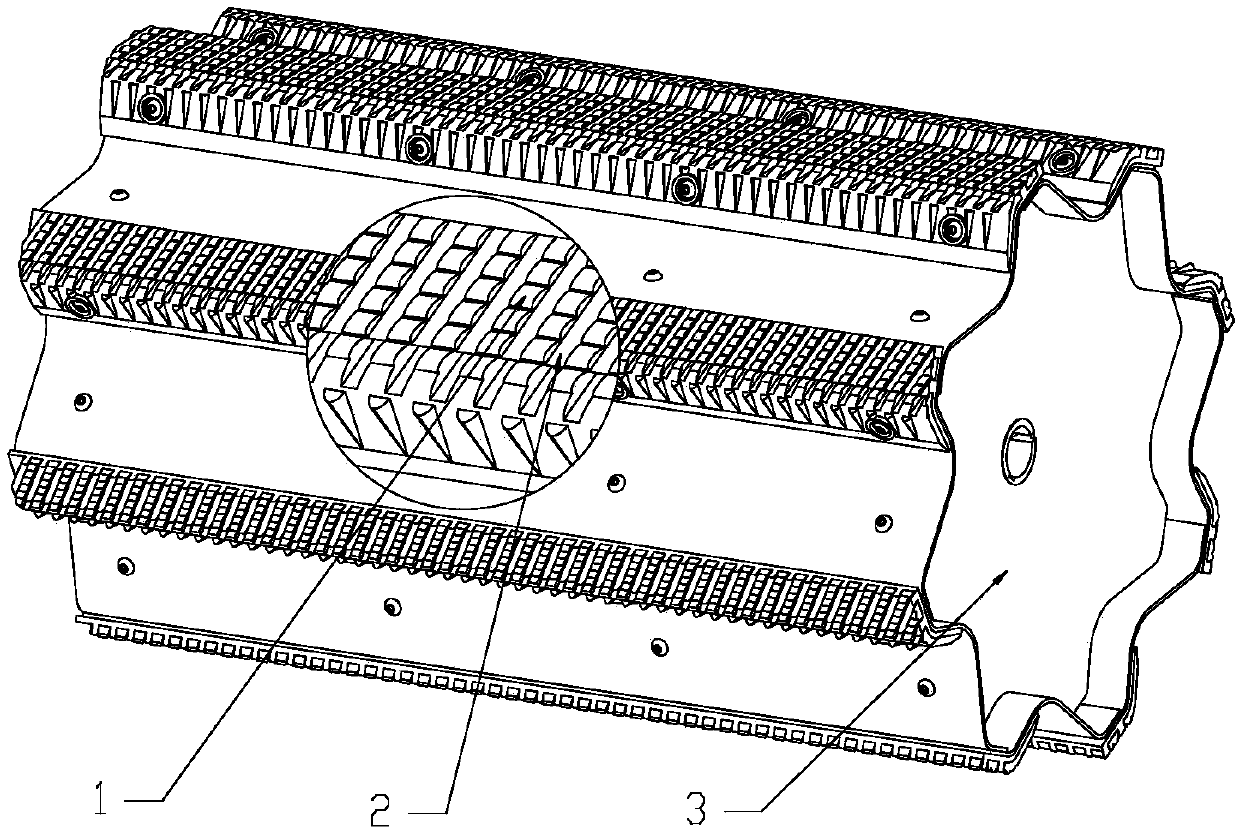

[0030] figure 1 Shown is an embodiment of the bionic flexible threshing device for high moisture content corn of the present invention. The bionic flexible threshing device for high moisture content corn includes a plurality of bionic flexible threshing parts 1 and a plurality of threshing reinforcement bases 2 and drum body 3.

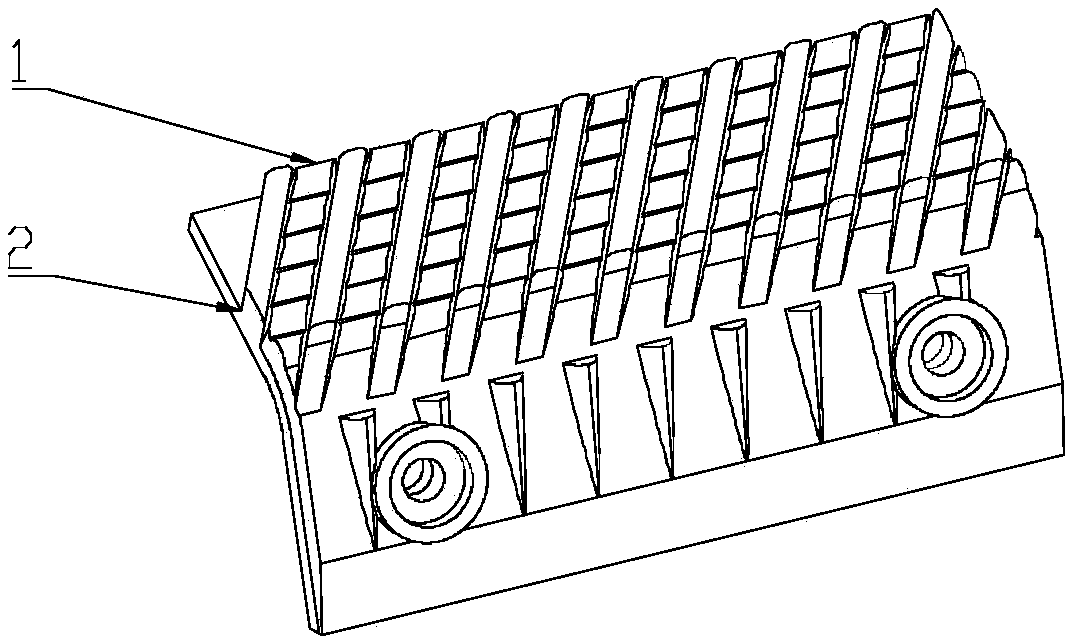

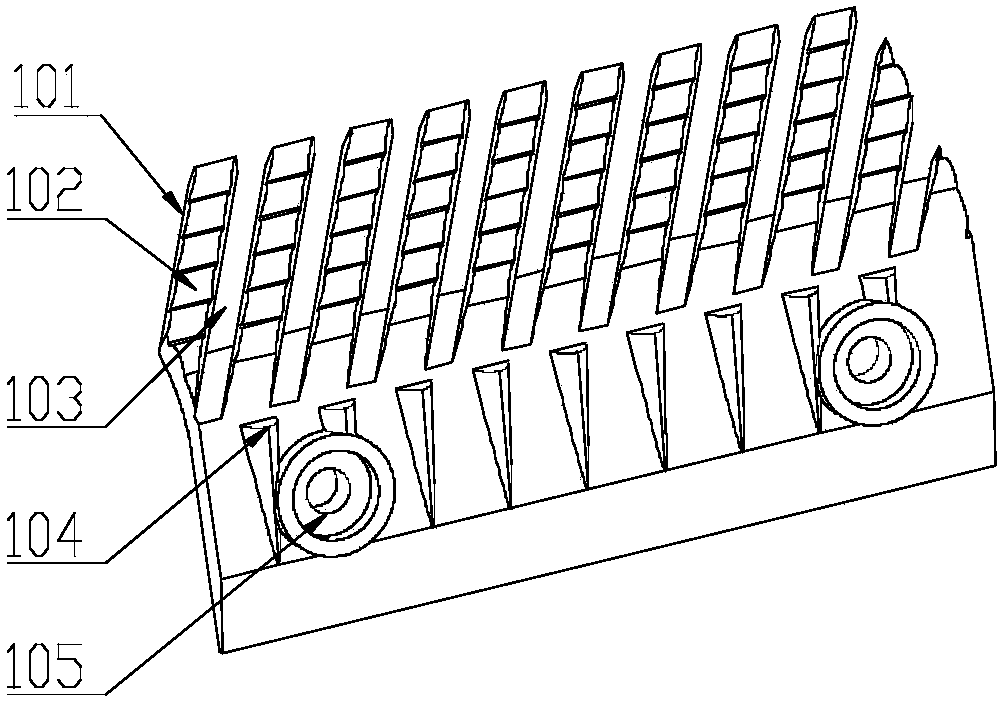

[0031] Such as figure 2 , 3 As shown in and 4, the top surface of the bionic flexible threshing component 1 is provided with multiple rows of threshing lines 101 distributed longitudinally, and the threshing lines 101 have an included angle with the horizontal direction, and grooves 103 are arranged between adjacent threshing lines 101 The threshing lines 101 are provided with a plurality of arc-shaped protrusions 102; the front slope of the bionic flexible threshing component 1 is distributed with a plurality of wedge-shaped protrusions 104 and a first installation hole 105, and the wedge-shaped protrusions 104 have an included angle with the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com