Half-feeding combine harvester threshing and separating device with revolving concave grid

A combine harvester, threshing separation technology, applied in the direction of harvesters, threshing equipment, cutters, etc., can solve the problems of high-yield rice spikes, leakage, straw neck bending, etc., to improve the threshing separation ability, structure Reasonable and reduce the effect of unswept net loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

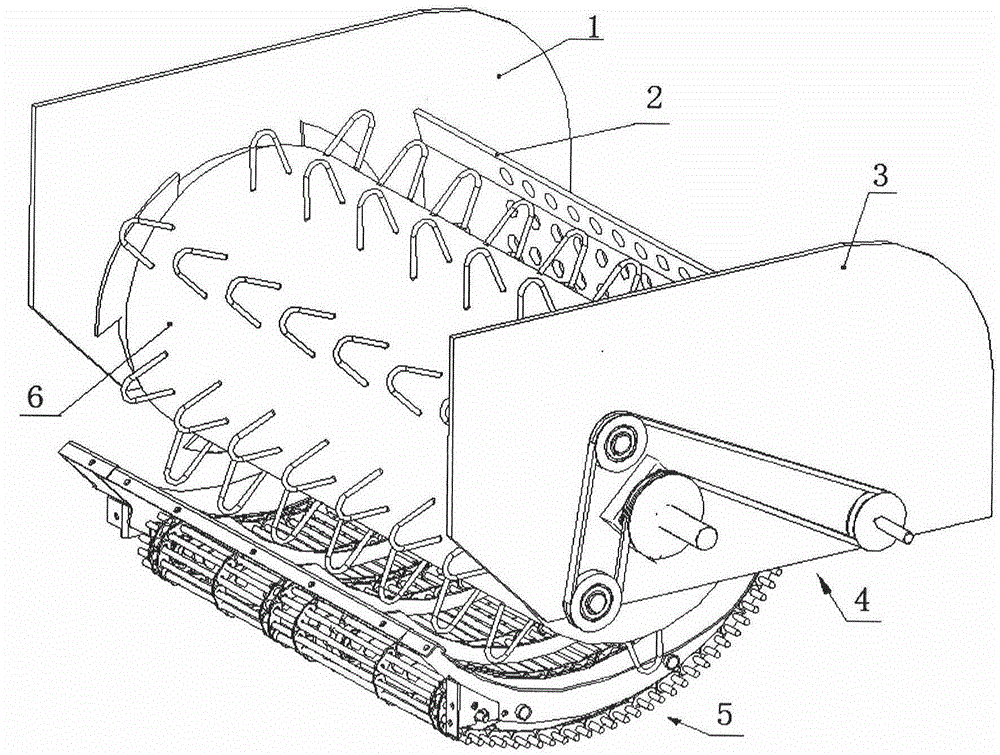

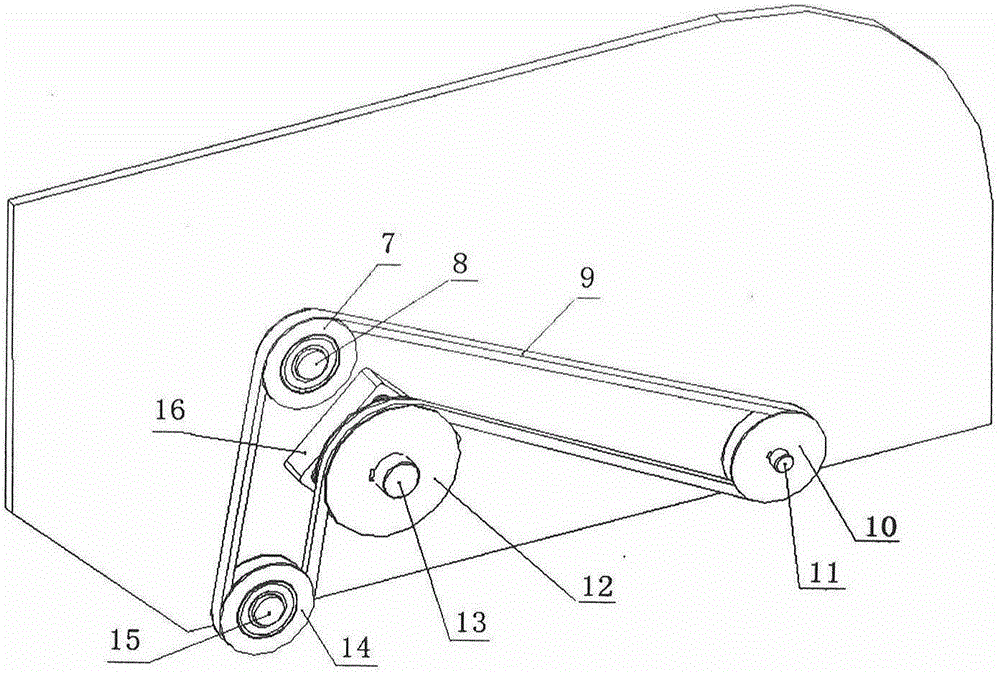

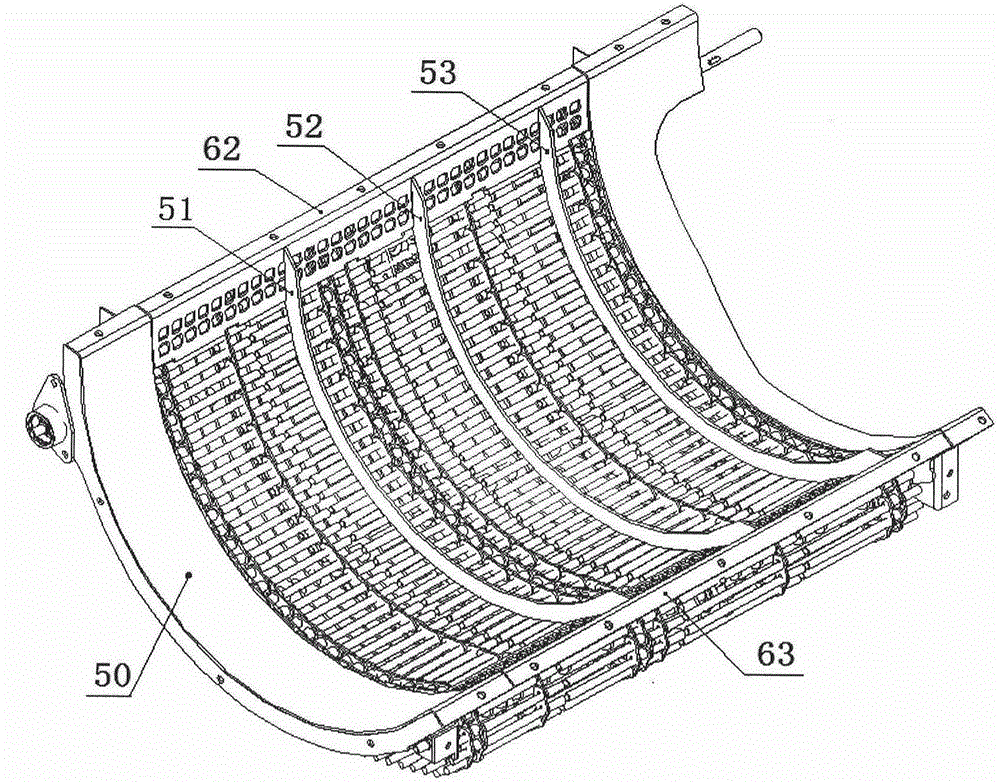

[0023]The semi-feed combine harvester threshing separation device with rotary concave screen mainly consists of the left wall panel (1), the perforated panel (2), the right wall panel (3), the V-belt The transmission assembly (4), the rotary concave screen assembly (5) and the threshing drum (6) are composed. The left side of the porous plate (2) is connected with the left wallboard (1), the right side of the porous plate (2) is connected with the right wallboard (3), and the left wallboard (1) It is fixed on the fuselage of the half-feed combine harvester, and the right wall panel (3) is fixed on the fuselage of the half-feed combine harvester. The left wallboard (1) and the right wallboard (3) are respectively equipped with one bearing block (16). Described threshing cylinder (6) has described threshing cylinder shaft (13), and the left end of described threshing cylinder shaft (13) is equipped with a rolling bearing, and the outer ring of this rolling bearing is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com