Threshing structure of L-shaped horizontal and longitudinal axial flow full-feeding combine harvester

A combine harvester and longitudinal axial flow technology, which is applied in the direction of harvesters, threshing equipment, cutters, etc., can solve the problems of long machine length, large turning radius in the field, difficulty in controlling the loss of intermediate conveying and threshing feeding inlet, etc., and achieve improvement Performance, the effect of preventing stuck equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

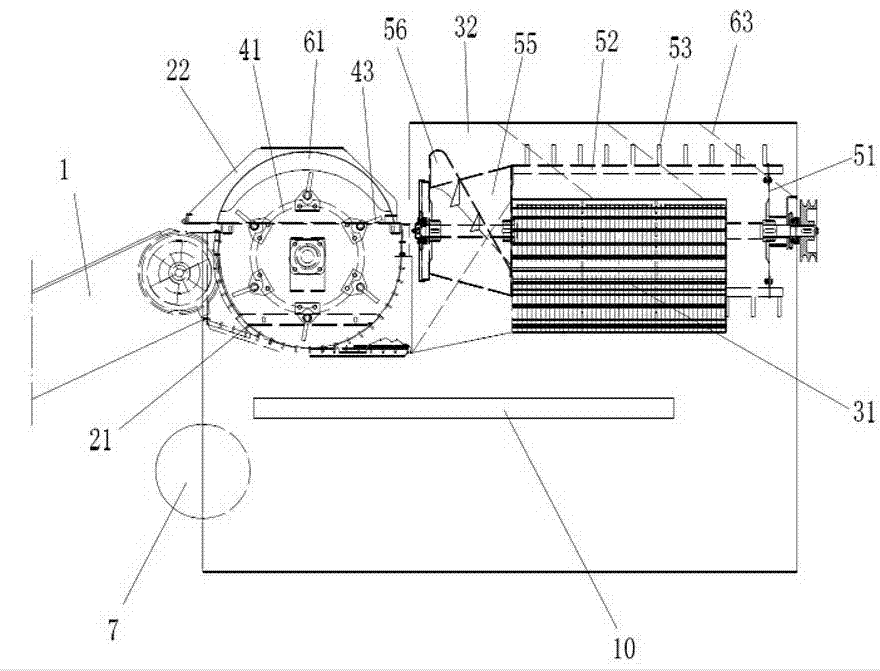

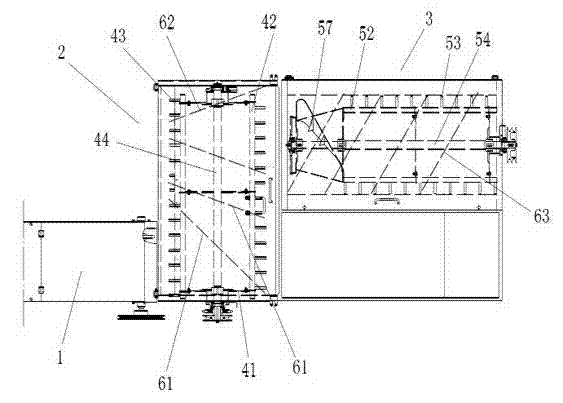

[0040] A threshing structure of an L-shaped horizontal and vertical axial flow full-feed combine harvester, comprising a threshing frame, a vibrating screen 10 arranged on the threshing frame, a blower 7 and an intermediate conveying 1 connected to the upper front end of the threshing frame, The threshing frame is also provided with a threshing drum connected with the rear end of the intermediate conveying 1, and the threshing drum includes a horizontal axial flow drum 2 and a vertical axial flow drum 3 connected in communication, and the horizontal axial flow drum 2 and the vertical axial flow drum 2 are connected to each other. The cylinders 3 are vertically L-shaped. The blower 7 is arranged obliquely below the front side of the vibrating screen, and the blower 7 blows air to the vibrating screen from bottom to top and from front to back.

[0041]Both ends of the horizontal axial flow drum 2 are respectively connected to the intermediate conveying 1 and the longitudinal axi...

Embodiment 2

[0048] The difference from the above embodiment is that the two ends of the vertical axial flow drum 3 are respectively connected to the intermediate conveying 1 and the horizontal axial flow drum 2 . The length of the horizontal axial flow drum (2) is 1500 mm, and the length of the vertical axial flow drum (3) is 1800 mm.

Embodiment 3

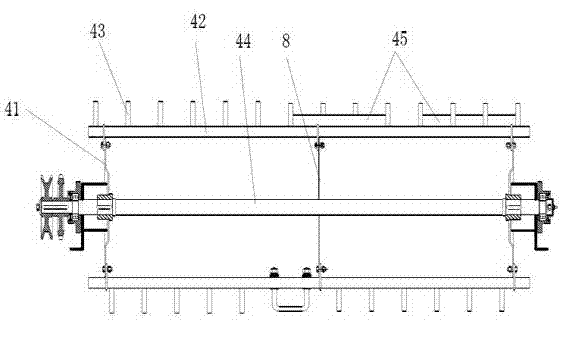

[0050] The difference from the above embodiment is that the angle between the projection of the first baffle to the horizontal plane where the shaft-44 axis line is located and the shaft-44 axis line is 25 degrees, and the middle baffle is Two arranged in parallel, the included angles between the projection of the middle deflector and the turning deflector 62 to the horizontal plane where the axis line of the rotating shaft-44 is located and the axis line of the rotating shaft-44 are respectively 45 degrees and 135 degrees , the length of the horizontal axial flow drum 2 is 1300mm, and the length of the vertical axial flow drum 3 is 1500mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com