Patents

Literature

96results about How to "Smooth handover" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

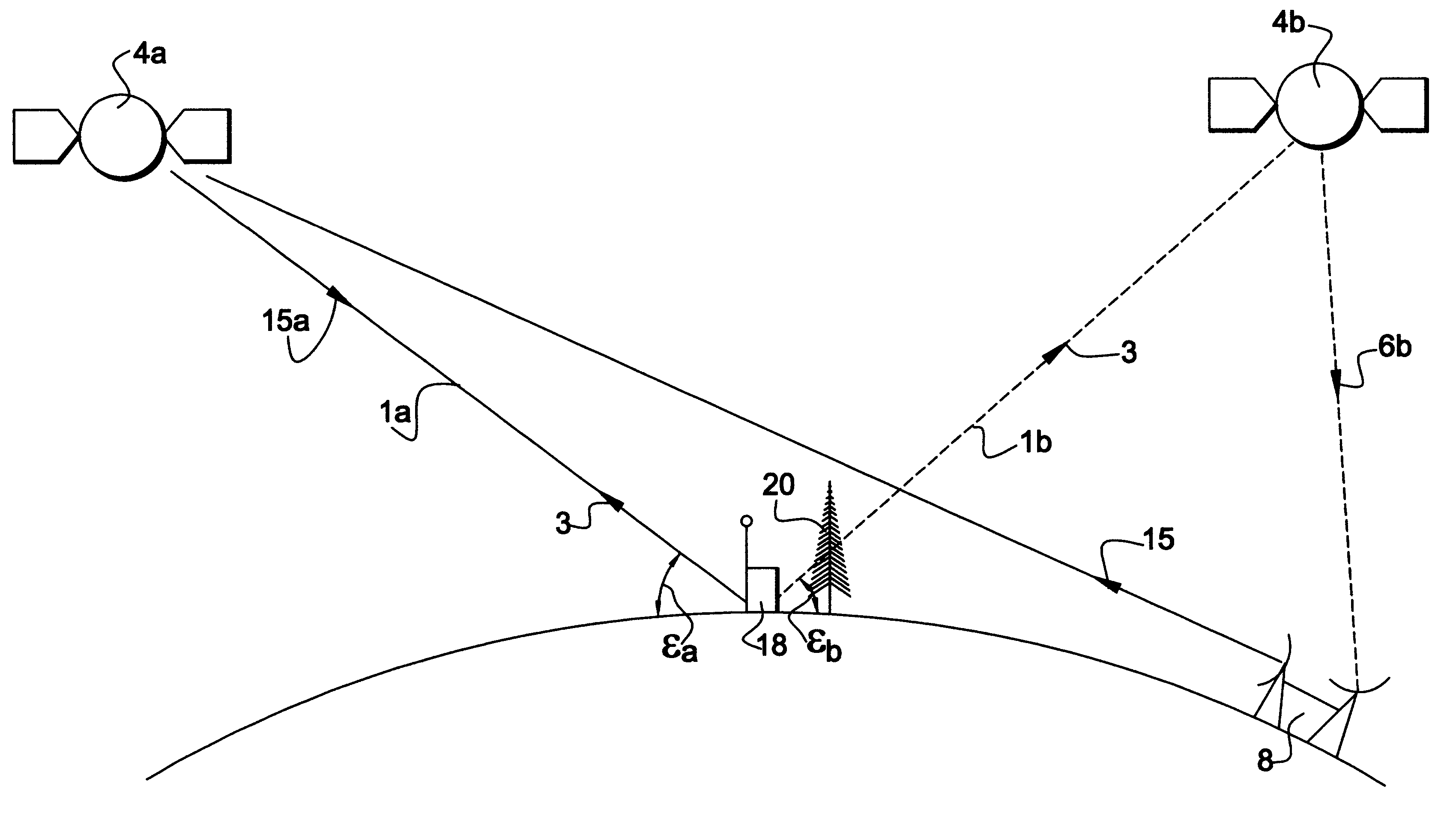

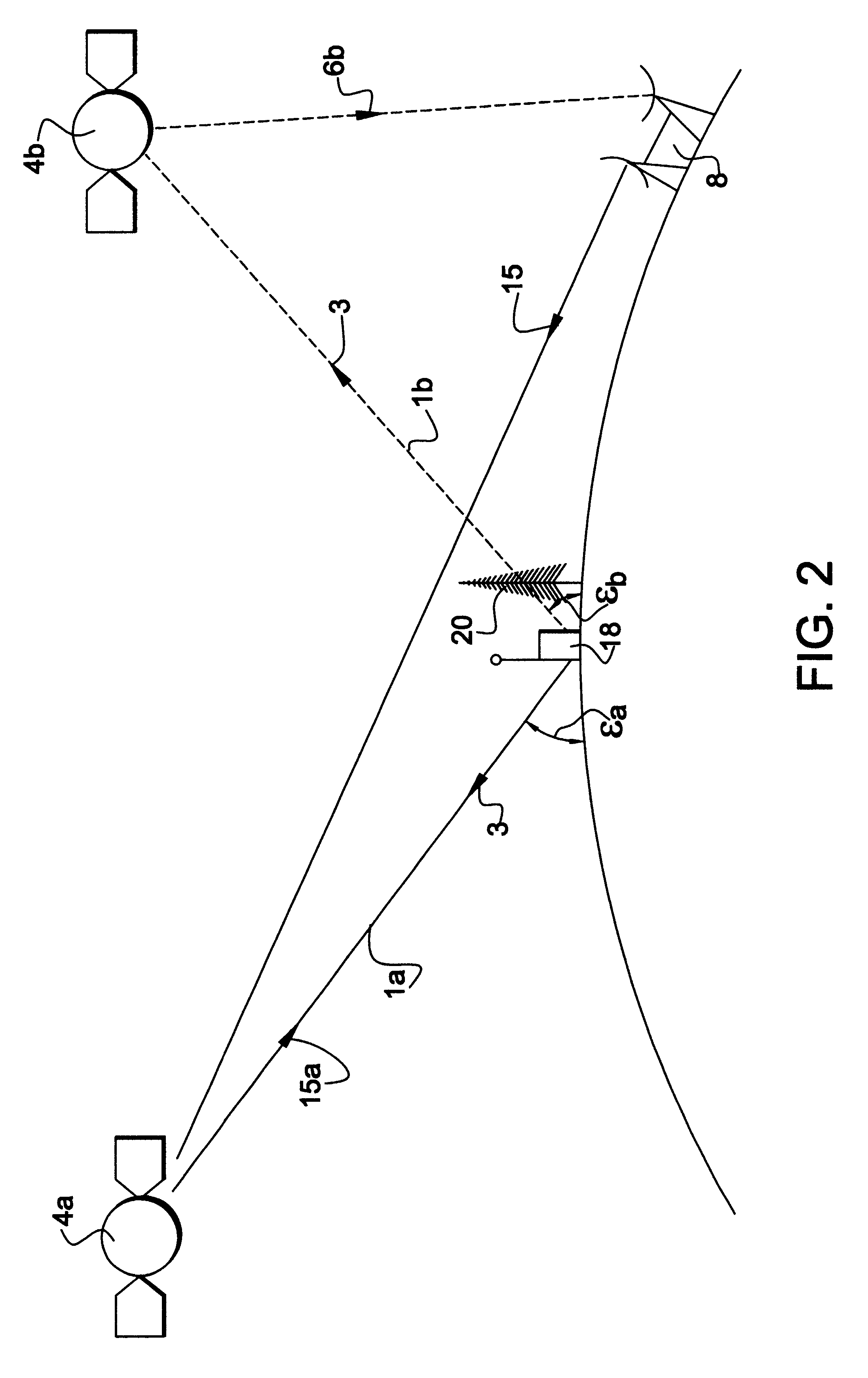

Multi-beam TDMA satellite mobile communications system

InactiveUS6314269B1Reduce congestionReduce errorsRadio transmissionWireless commuication servicesNadirSignal quality

An earth station receives a return signal via more than one satellite link from a mobile terminal using TDMA. The earth station selects one or more of the satellite links for transmitting a forward signal on the basis of the quality of signal received via each link. The earth section allocates frequency channels to the mobile terminals according to their location on the surface of the earth, so that the propagation time to and from those mobile terminals which share the same frequency channel is approximately the same. The satellite includes an antenna which generates an array of beams which are individually pointed to fixed regions of the earth, until the elevation of the satellite relative to a fixed region falls below a minimum value, in which case the corresponding beam is redirected to a new area, while the other beams remain pointed at the corresponding fixed areas. In this way, beam-to-beam handover is reduced, while maintaining the boresight of the antenna pointing at the nadir.

Owner:INMARSAT GLOBAL

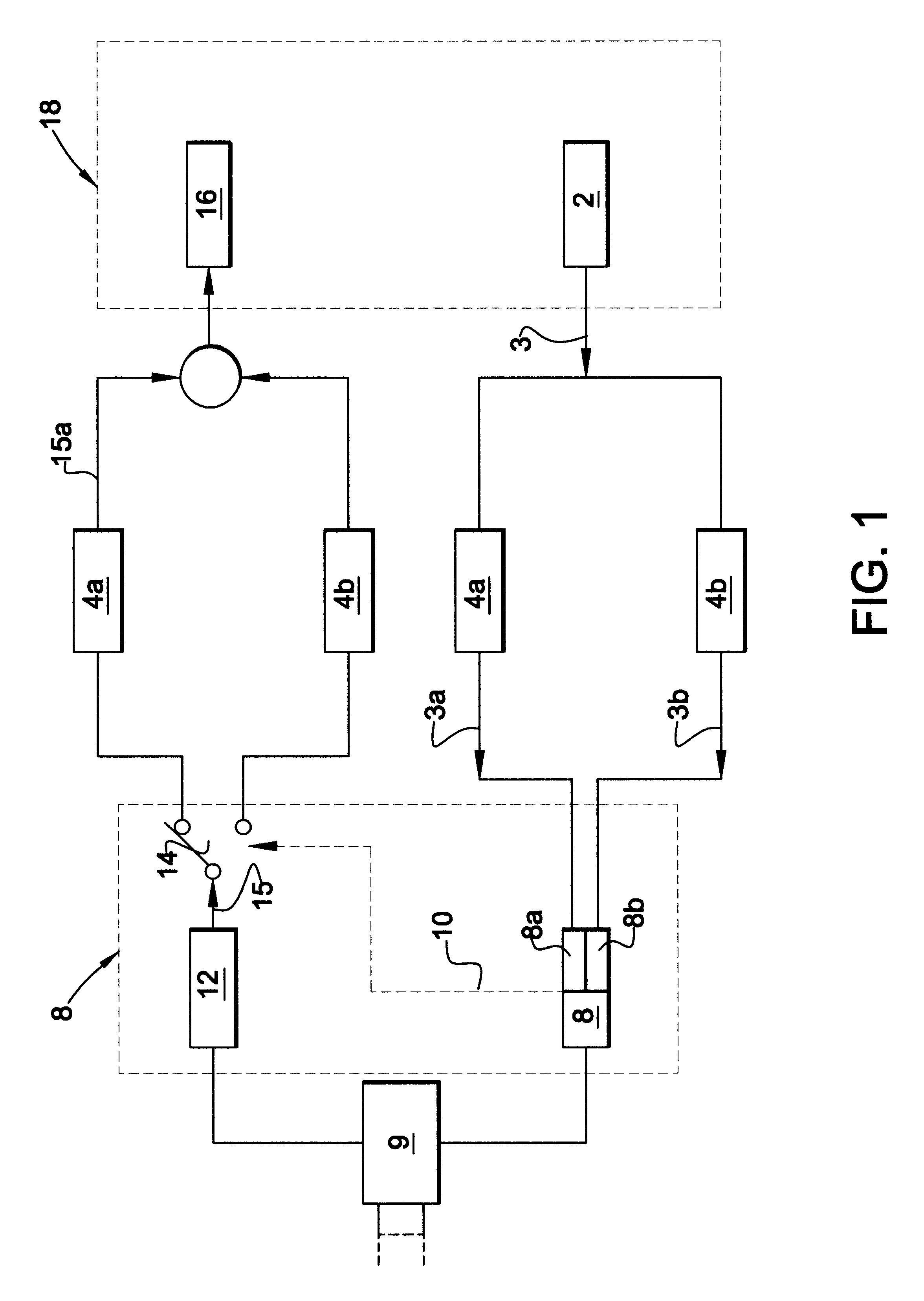

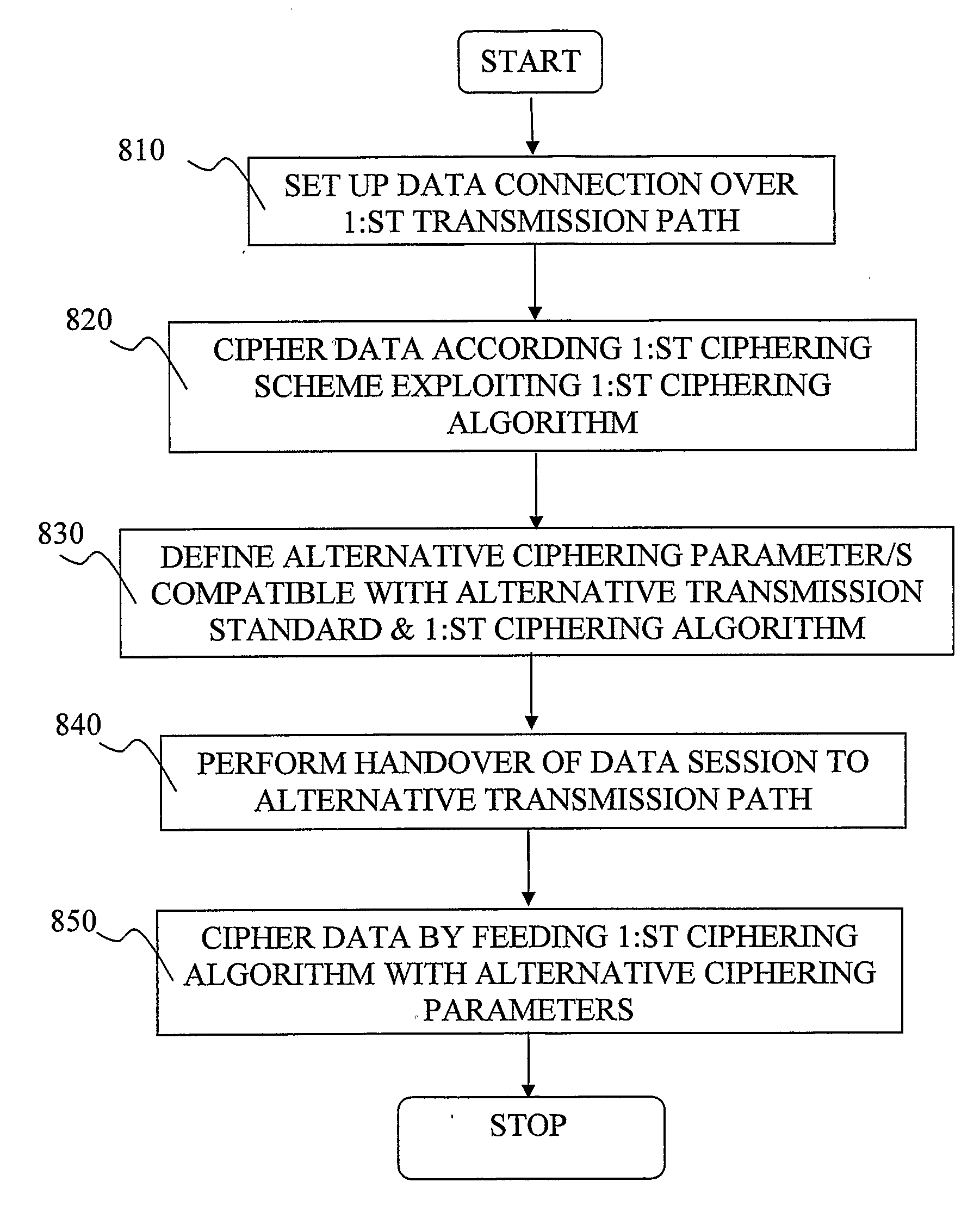

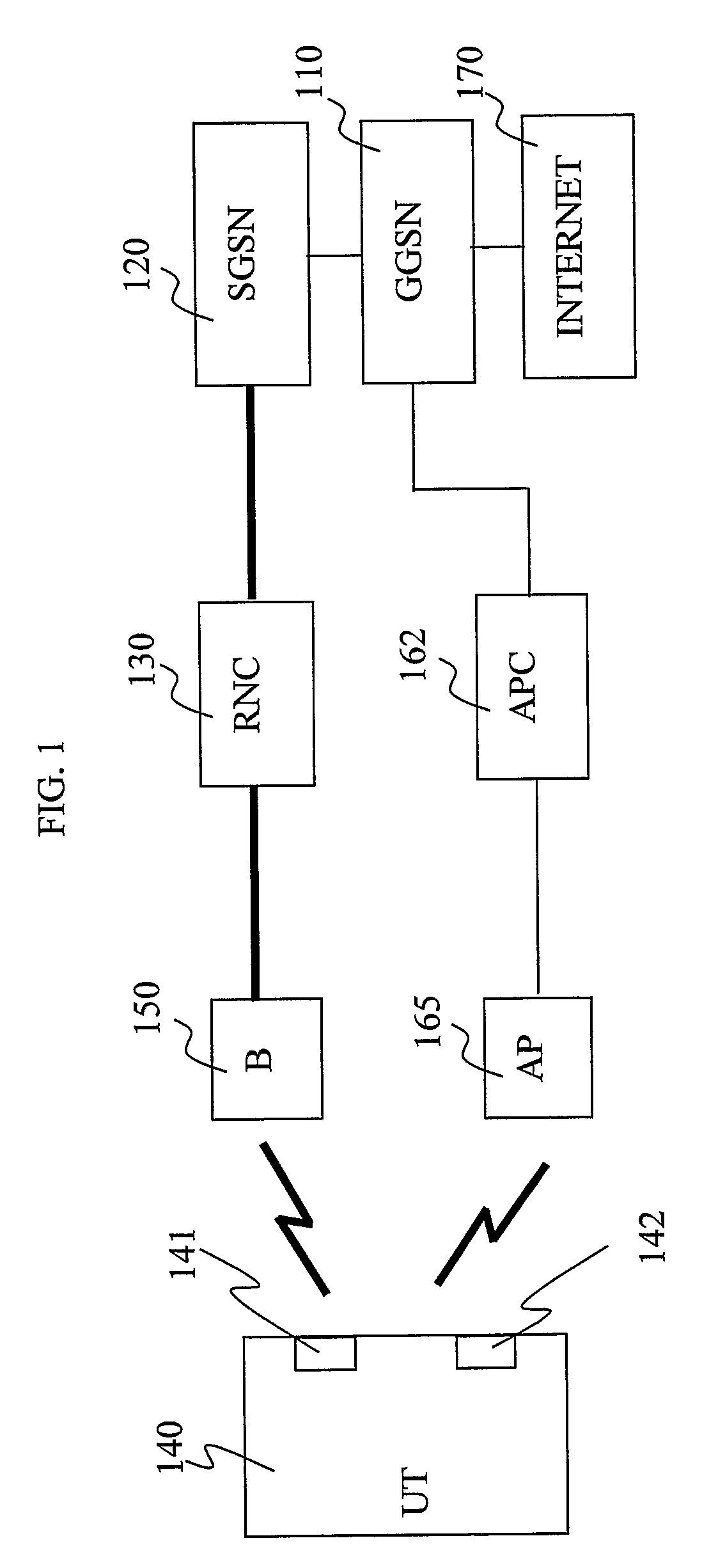

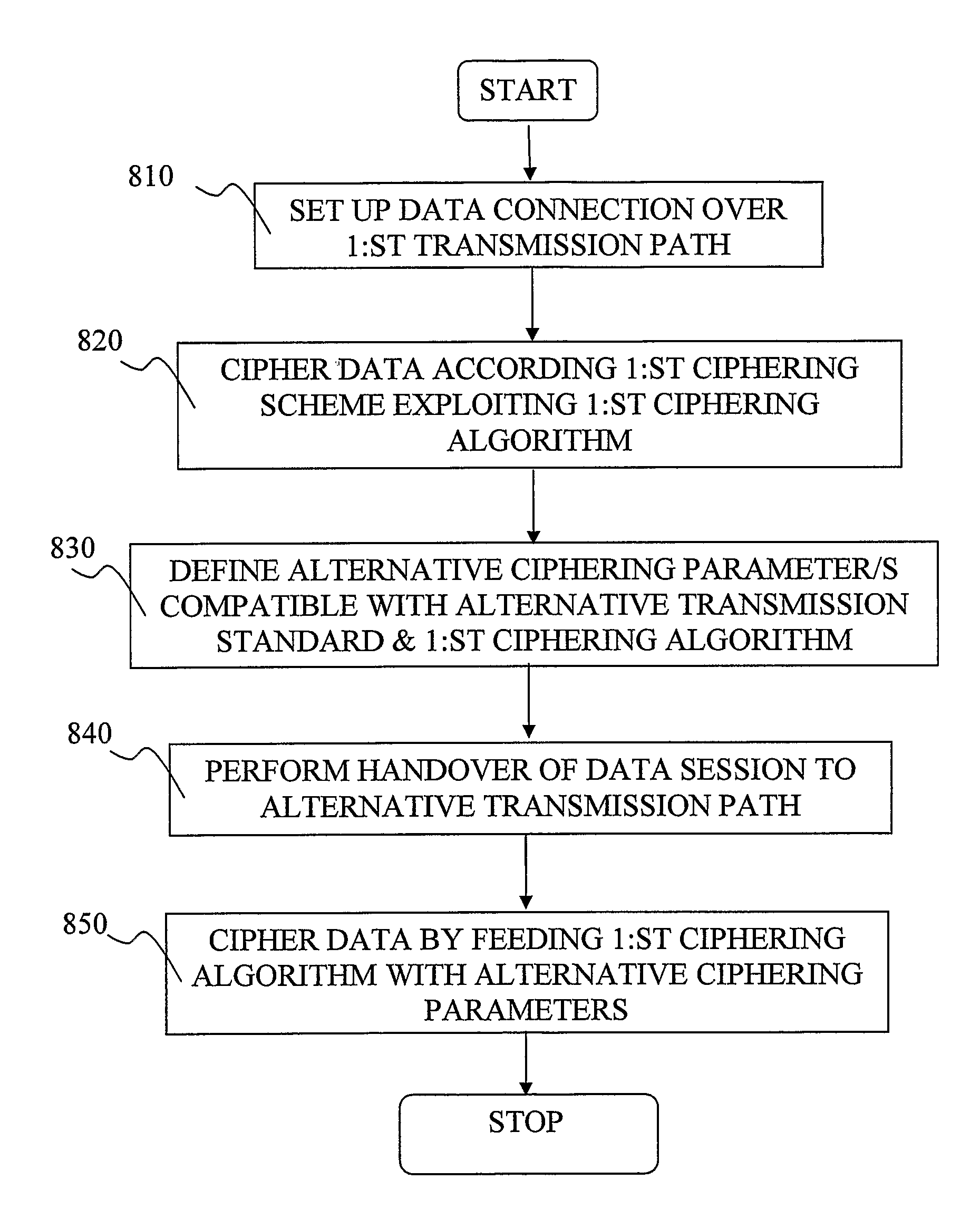

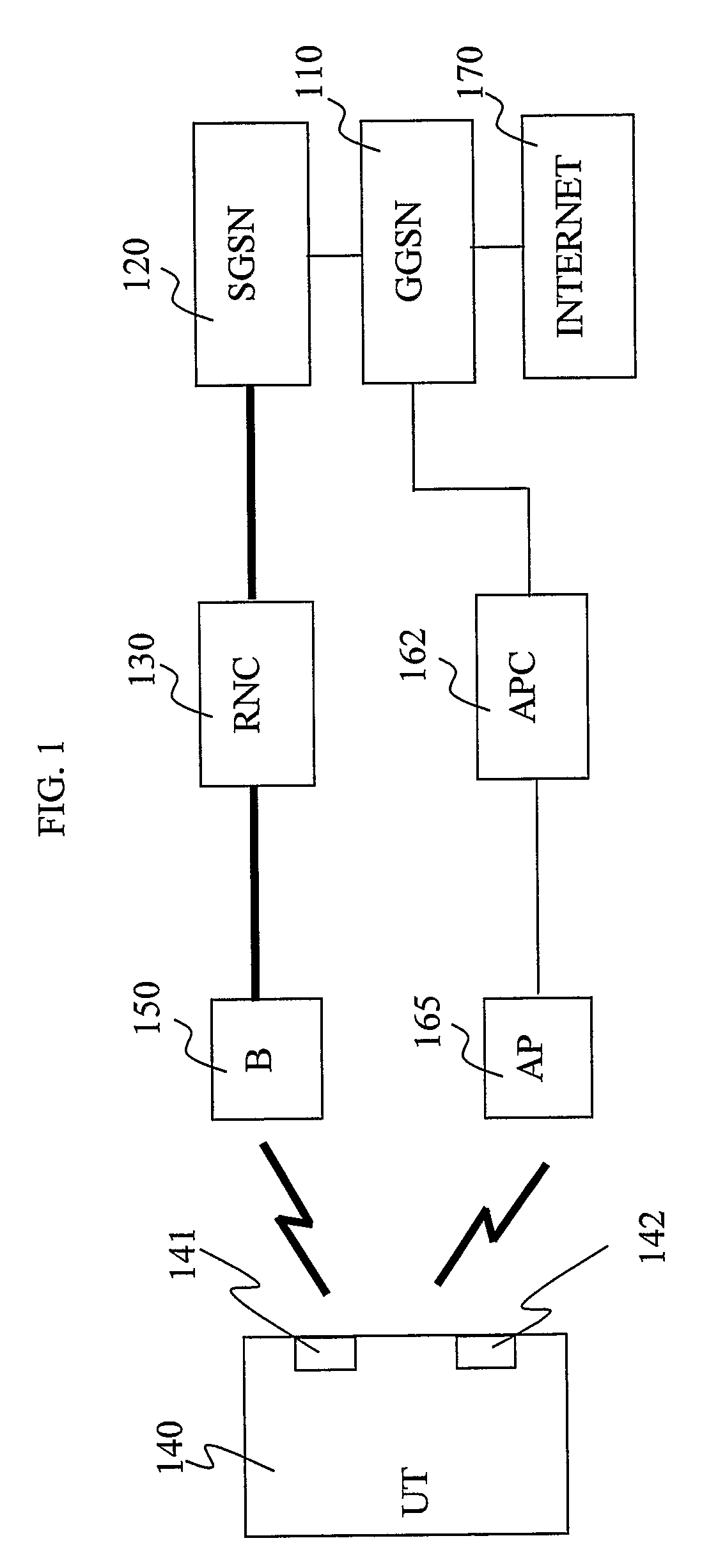

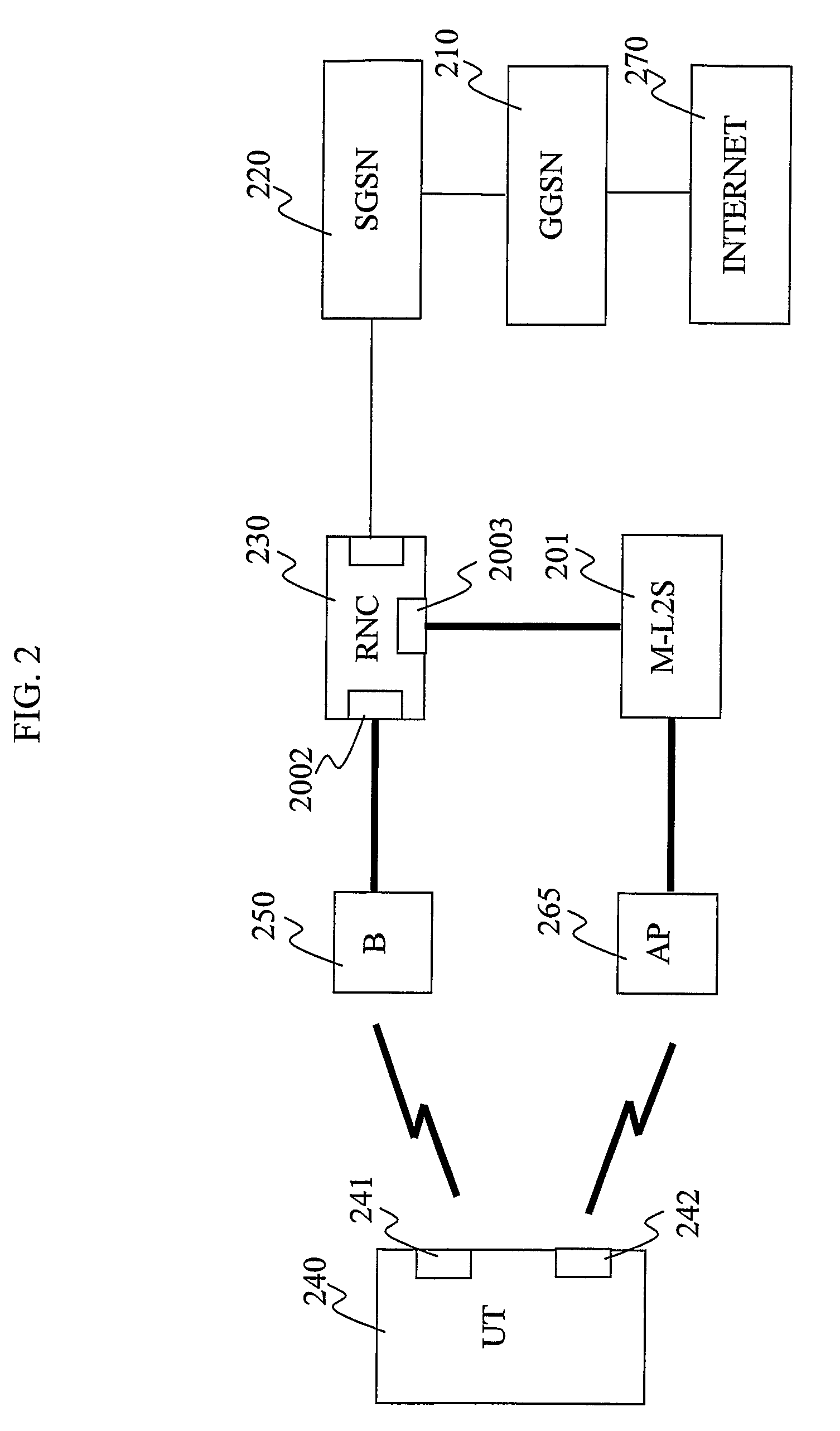

Means and Method for Ciphering and Transmitting Data in Integrated Networks

InactiveUS20080192925A1Improve safetyImprove securityKey distribution for secure communicationEncryption apparatus with shift registers/memoriesBit-lengthData processing

The invention provides a method for ciphering and transmitting data, to be used by a communication device being arranged to transmit data through a first data port (241, 2002) according to a first transmission protocol, and to form ciphered exploiting a ciphering algorithm being fed with a first set of ciphering parameters, comprising a ciphering parameter CP5; said device being further arranged to transmit data through a second data port (242, 2003) according to an alternative transmission protocol, said method comprising the steps of: defining an alternative ciphering parameter, ACP, having a bit length equal to the bit length of CP5, forming a second set of ciphering parameters by substituting said CP5 with said ACP in said first set of ciphering parameters, forming ciphered data by subjecting the data to said ciphering algorithm being fed with said second set of ciphering parameters, transmitting said ciphered data through said second data port (242, 2003). The invention also provides a software program and communication devices realising said method.

Owner:UNWIRED PLANET

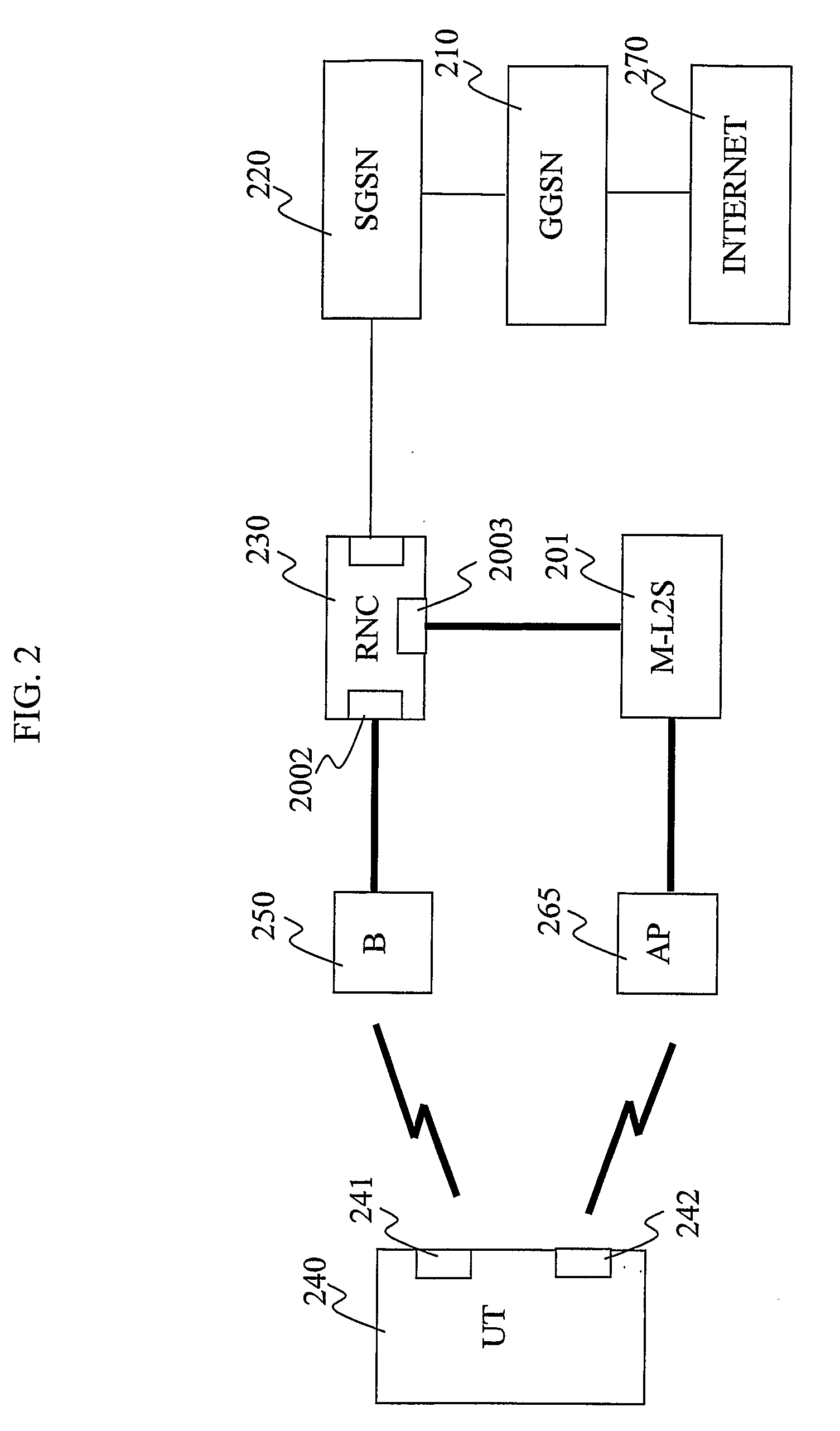

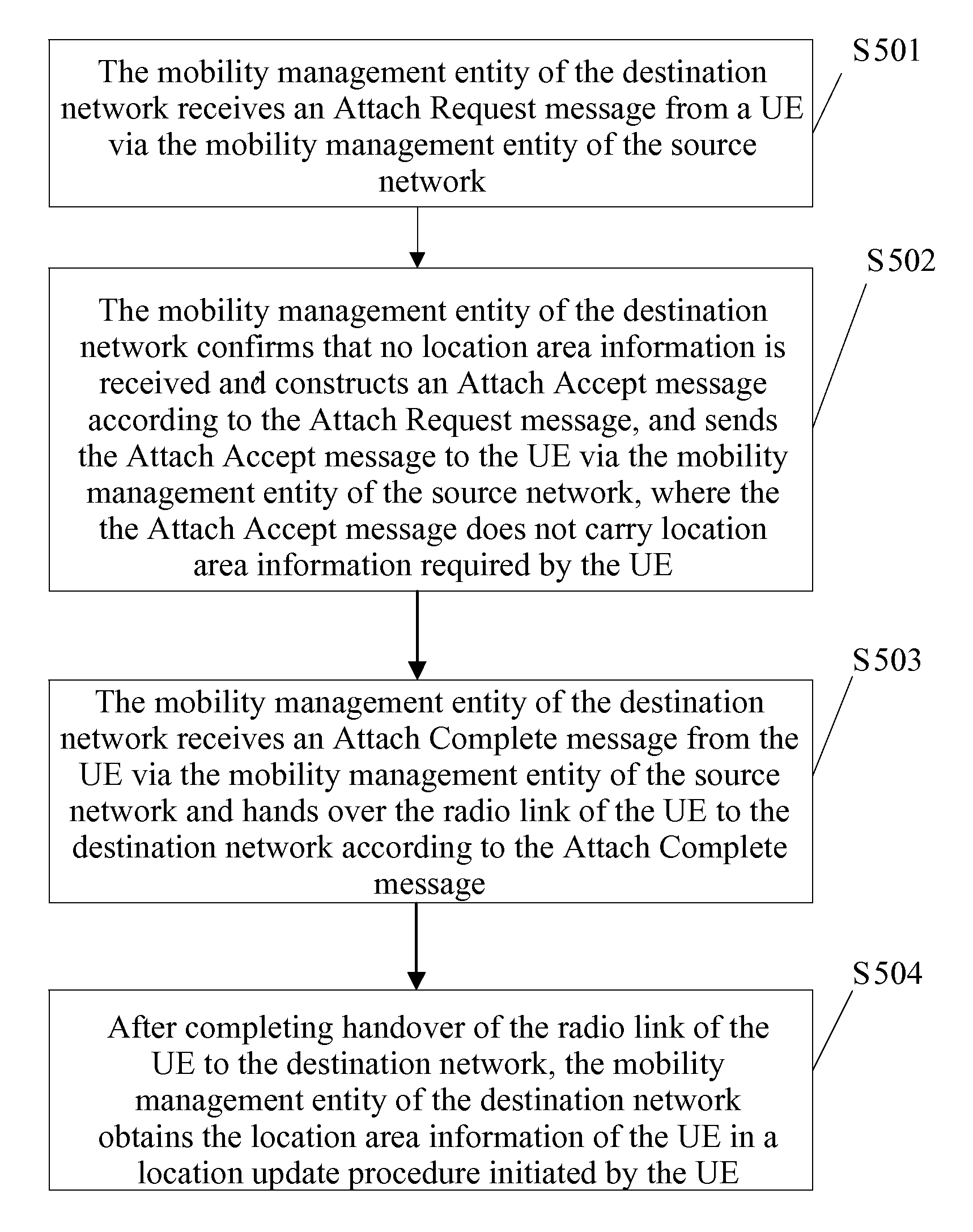

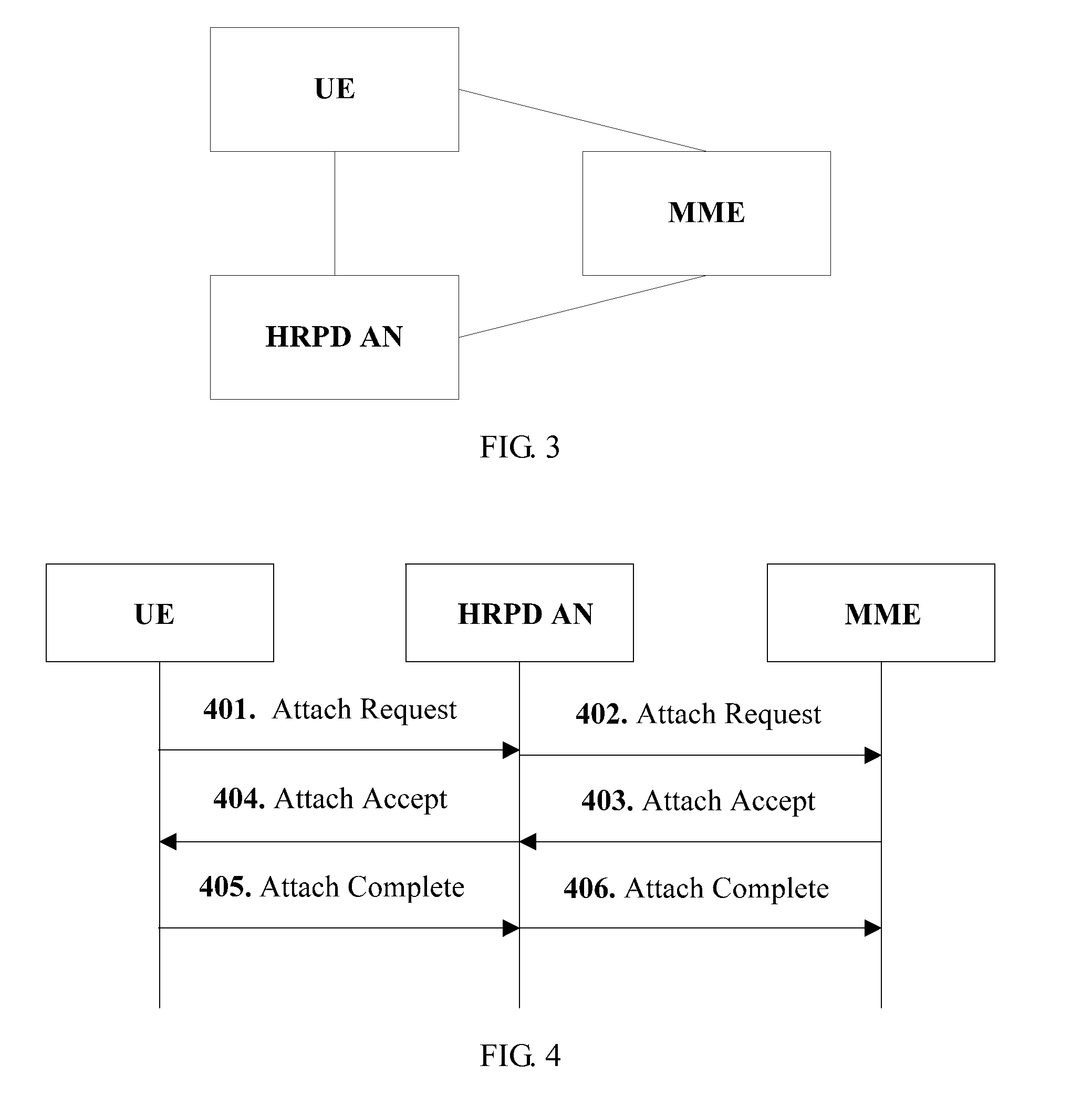

Method, Apparatus and System for Obtaining Location Area Information during Handover between Heterogeneous Networks

ActiveUS20100210269A1Easy maintenanceSmooth handoverWireless commuication servicesNetwork data managementHeterogeneous networkHandover

A method obtains area information during handover between heterogeneous networks. A mobility management entity of a destination network receives location area related information of a User Equipment (UE) from a mobility management entity of a source network. The mobility management entity obtains location area information required by the UE according to the location area related information. The mobility management entity sends the location area information required by the UE to the UE.

Owner:NOKIA TECHNOLOGLES OY

Means and method for ciphering and transmitting data in integrated networks

InactiveUS7961875B2Improve securitySmooth handoverKey distribution for secure communicationNetwork topologiesTransmission protocolData treatment

The invention provides a method for ciphering and transmitting data, to be used by a communication device being arranged to transmit data through a first data port (241, 2002) according to a first transmission protocol, and to form ciphered exploiting a ciphering algorithm being fed with a first set of ciphering parameters, comprising a ciphering parameter CP5; said device being further arranged to transmit data through a second data port (242, 2003) according to an alternative transmission protocol, said method comprising the steps of: defining an alternative ciphering parameter, ACP, having a bit length equal to the bit length of CP5, forming a second set of ciphering parameters by substituting said CP5 with said ACP in said first set of ciphering parameters, forming ciphered data by subjecting the data to said ciphering algorithm being fed with said second set of ciphering parameters, transmitting said ciphered data through said second data port (242, 2003). The invention also provides a software program and communication devices realising said method.

Owner:UNWIRED PLANET

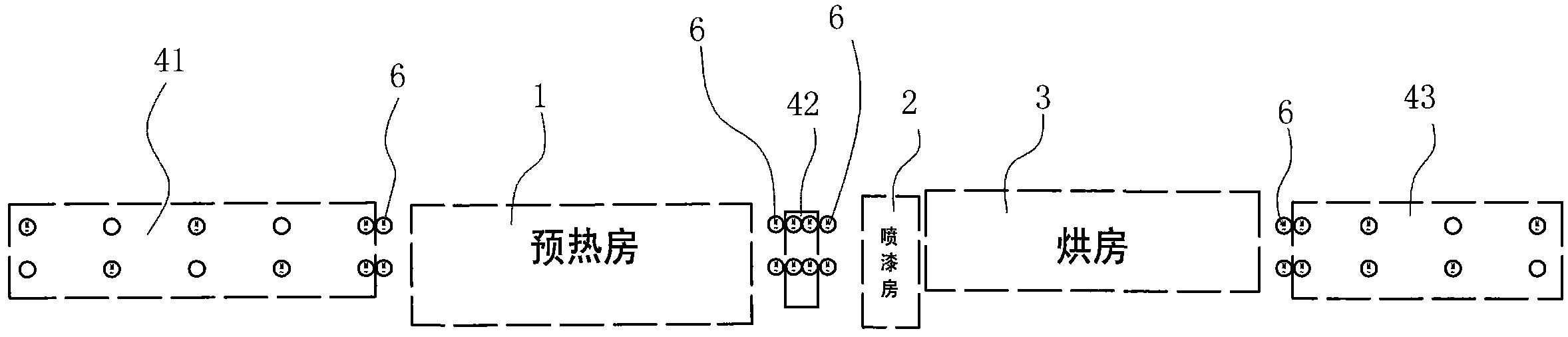

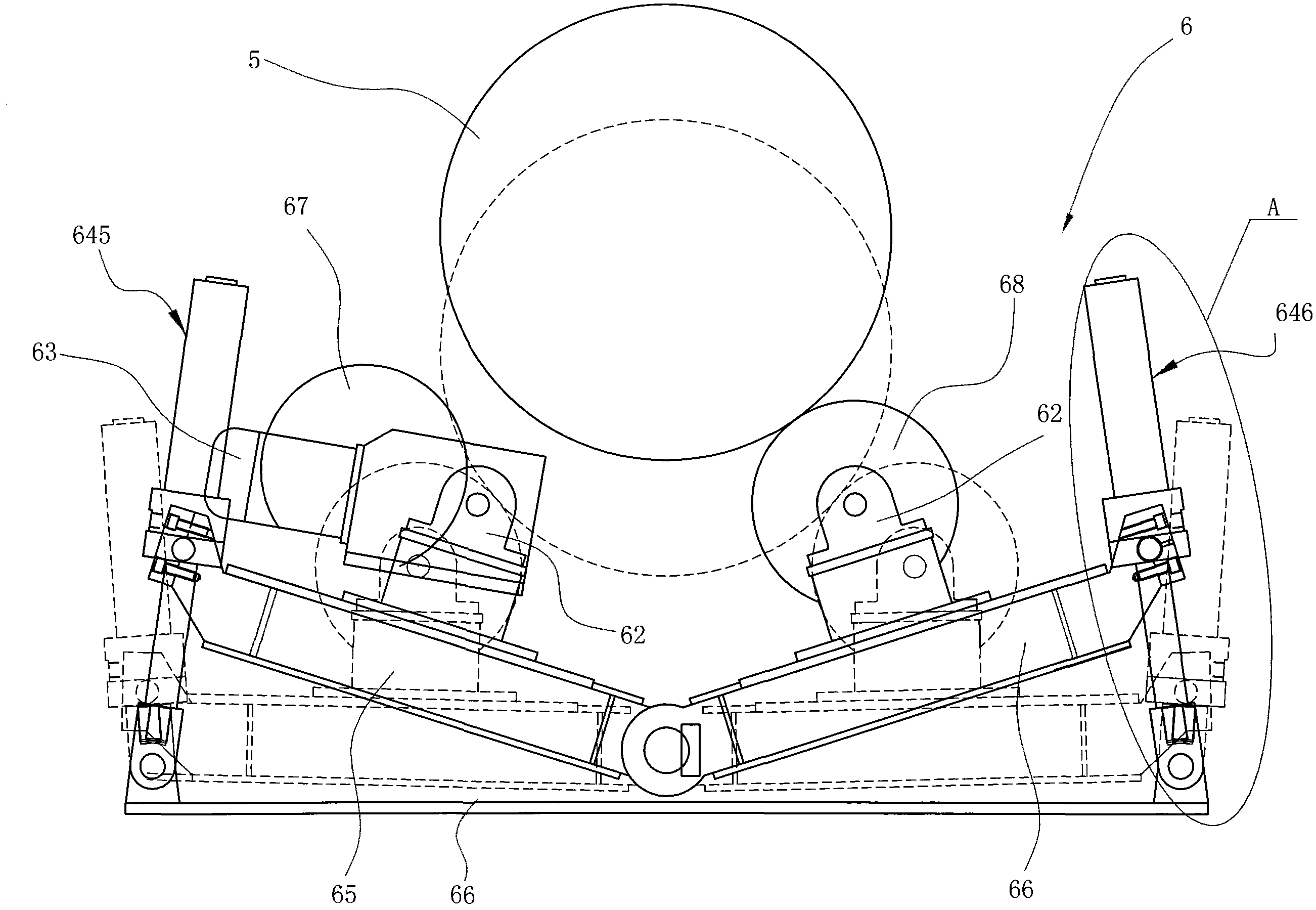

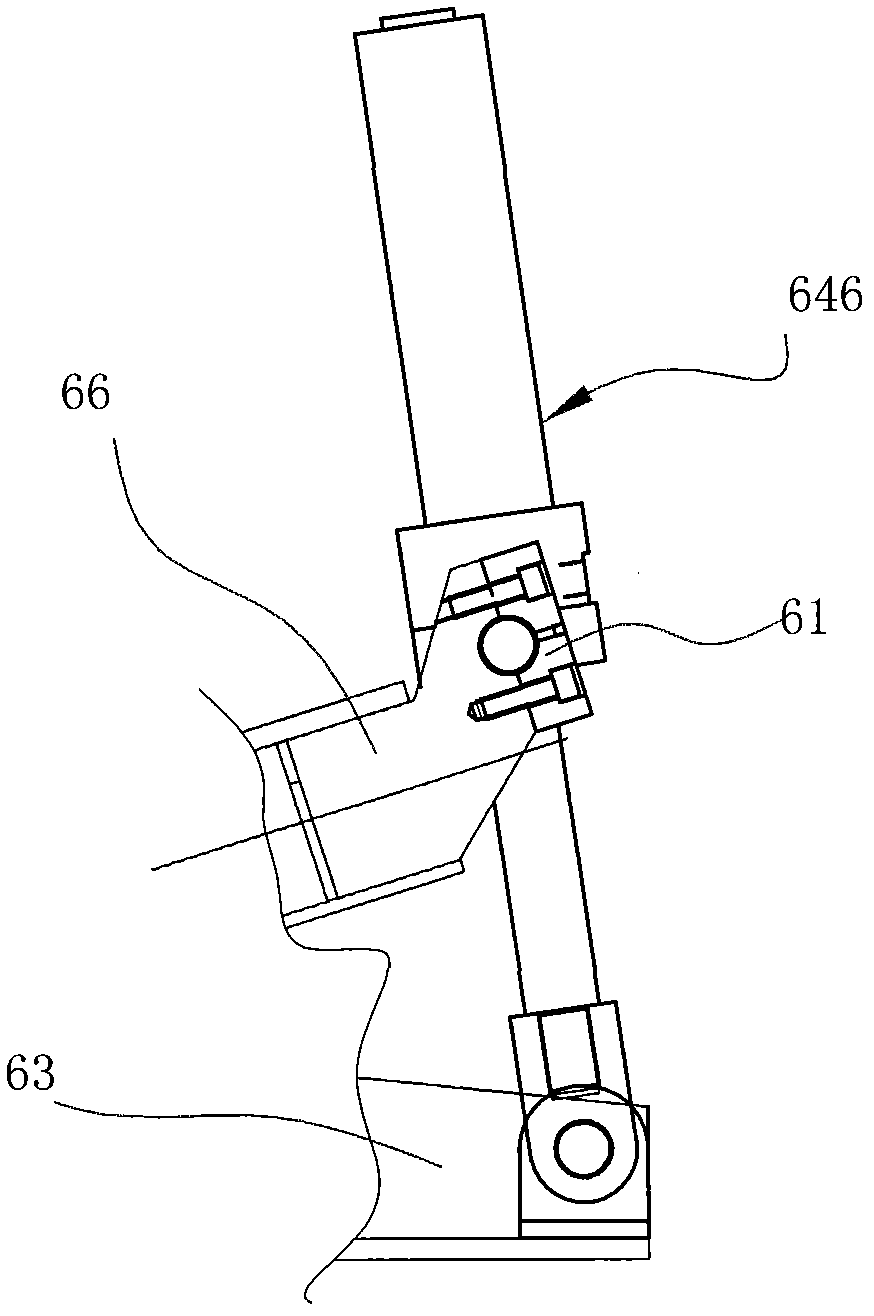

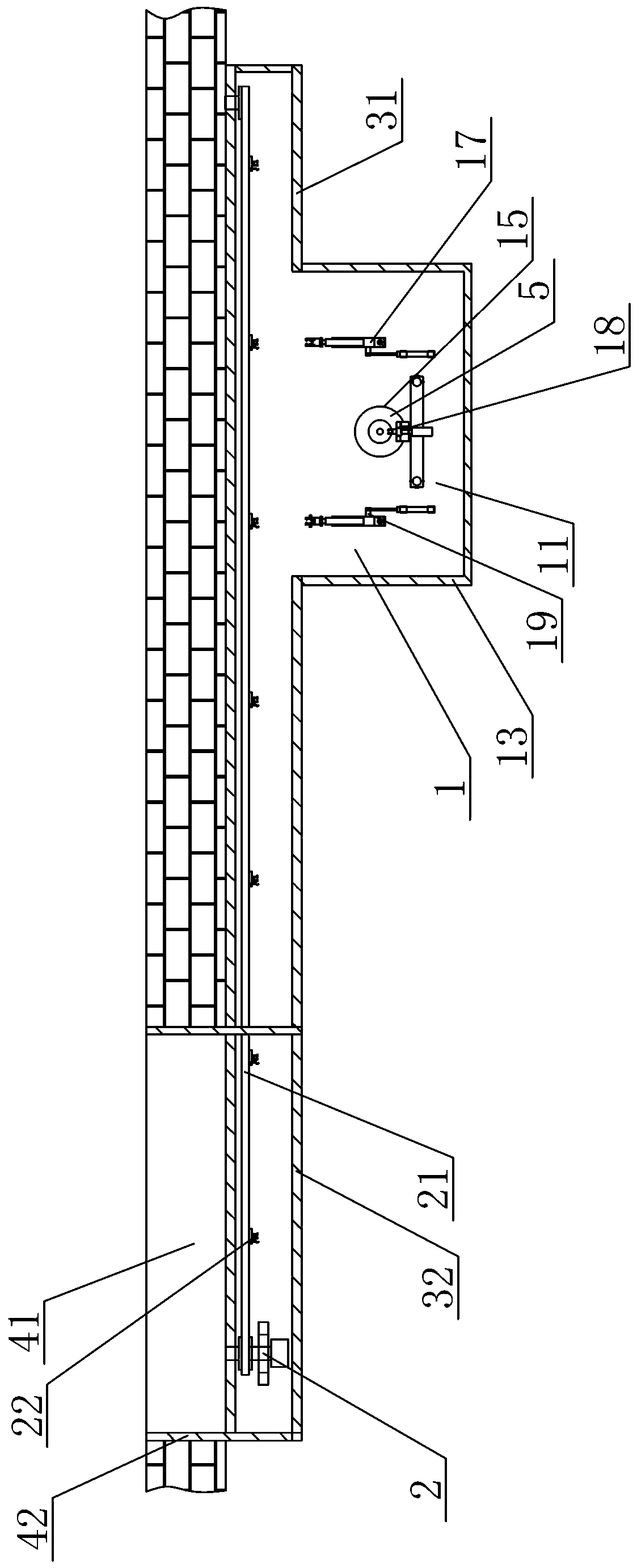

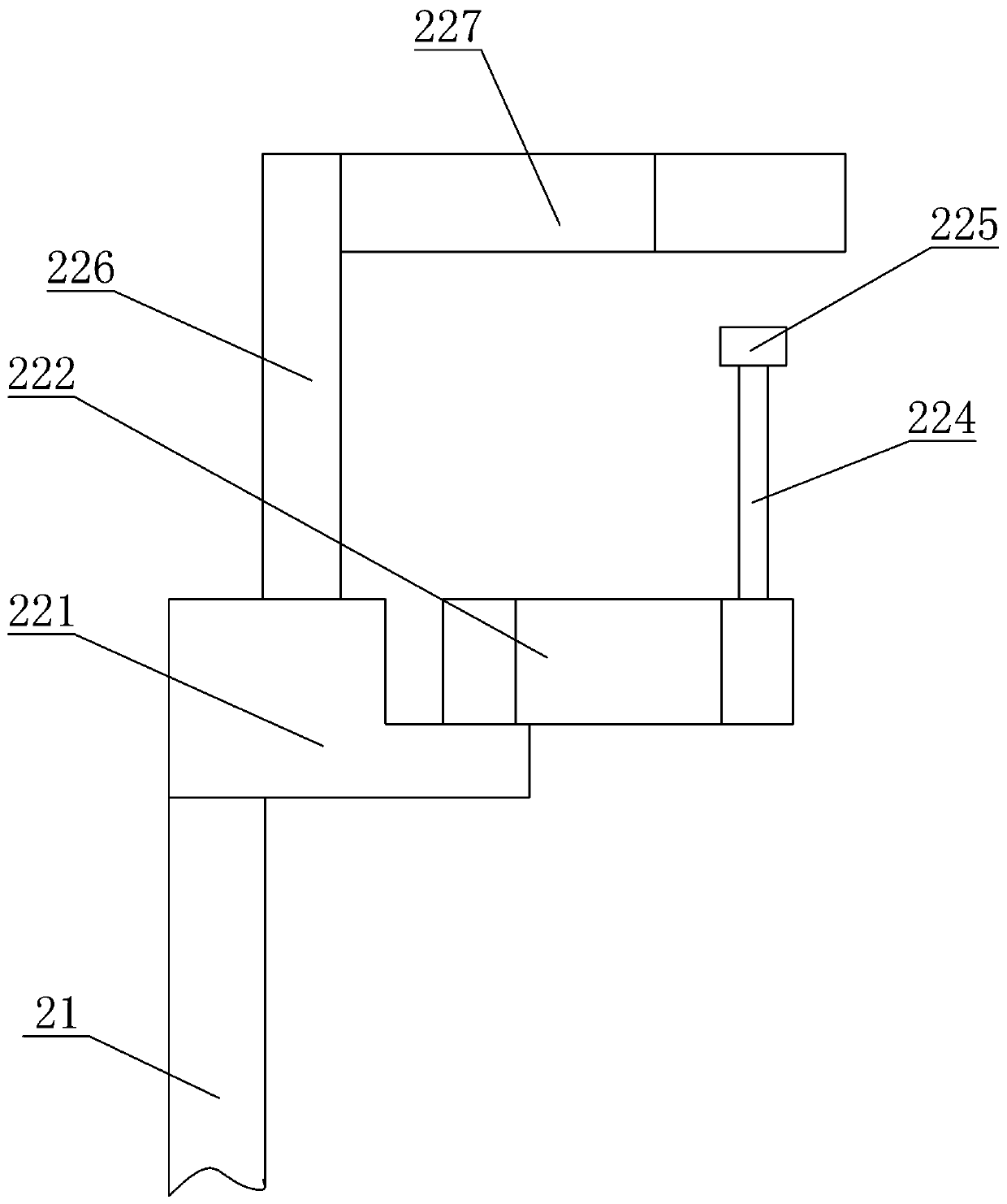

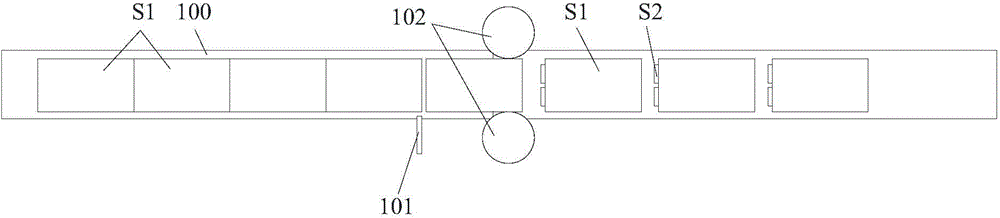

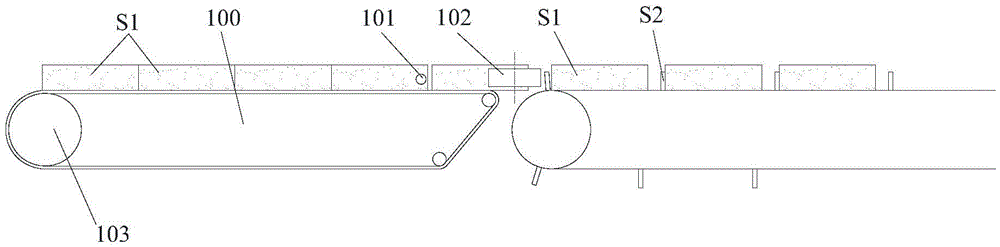

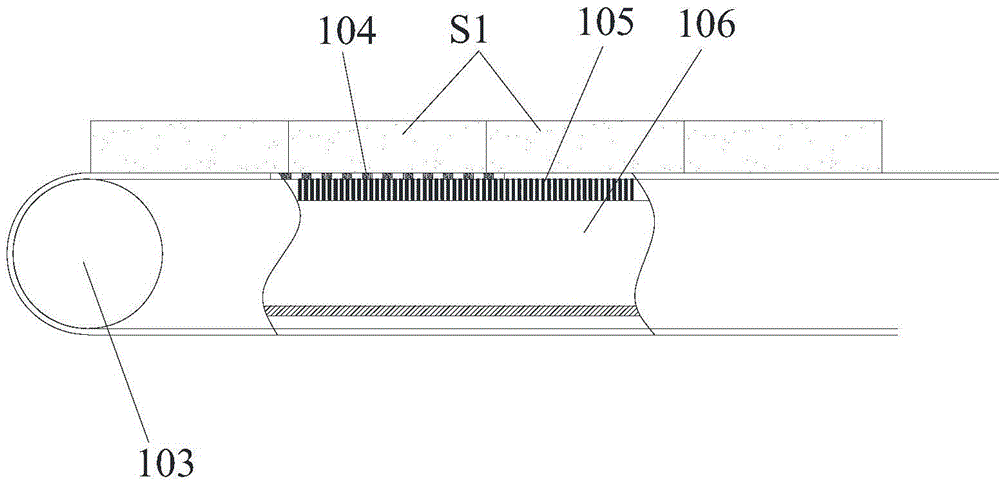

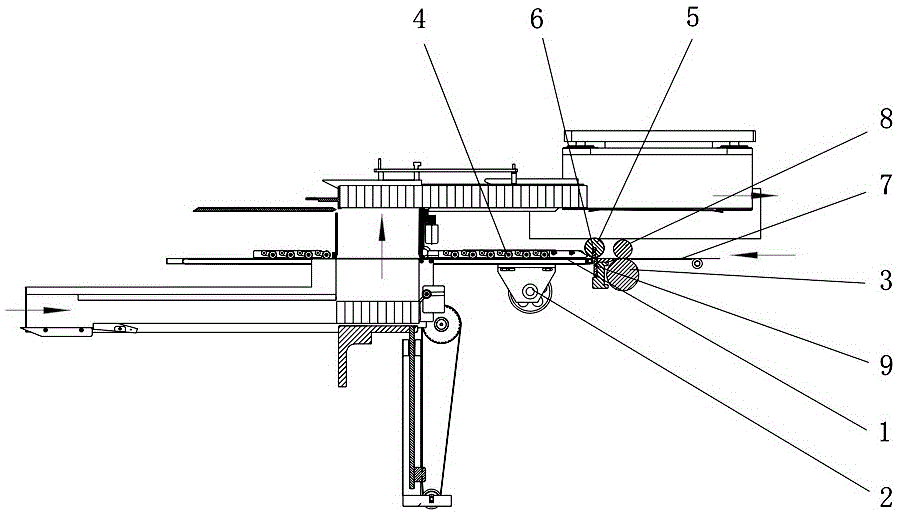

Steel pipe lifting carrier roller device

InactiveCN101966910ASecurity supportStable supportLifting framesRoller-waysProduction lineThrough transmission

The invention relates to a steel pipe lifting carrier roller device arranged on a production line for conveying steel pipes. The steel pipe lifting carrier roller device comprises a first carrier roller and a second carrier roller which support the steel pipes, wherein the first carrier roller and the second carrier roller are respectively rotationally arranged on a first lifting body and a second lifting body; and the first lifting body and the second lifting body are connected with a first motor through transmission mechanisms. Compared with the prior art, the invention can effectively solve the problem that the steel pipes can not normally advance because a suspension segment declines in the advancing process of the steel pipes; particularly, the steel pipe lifting carrier roller device supports the steel pipes and then automatically supports the steel pipes to a needed height by adopting a first oscillating arm and a second oscillating arm as the lifting bodies and a first oil cylinder and a second oil cylinder as driving parts and a matched hydraulic transmission system and realizes the automatic lifting of the carrier rollers by utilizing a sensor and a limit switch, thereby greatly reducing the operation of operators and enhancing the work efficiency; and in addition, the invention prevents the defects of spraying quality, safety accidents, and the like which are caused by the suspension of the steel pipes, and enhances the production efficiency of production lines, i.e. an automatic spraying production line and the like.

Owner:浙江龙驰防腐技术有限公司

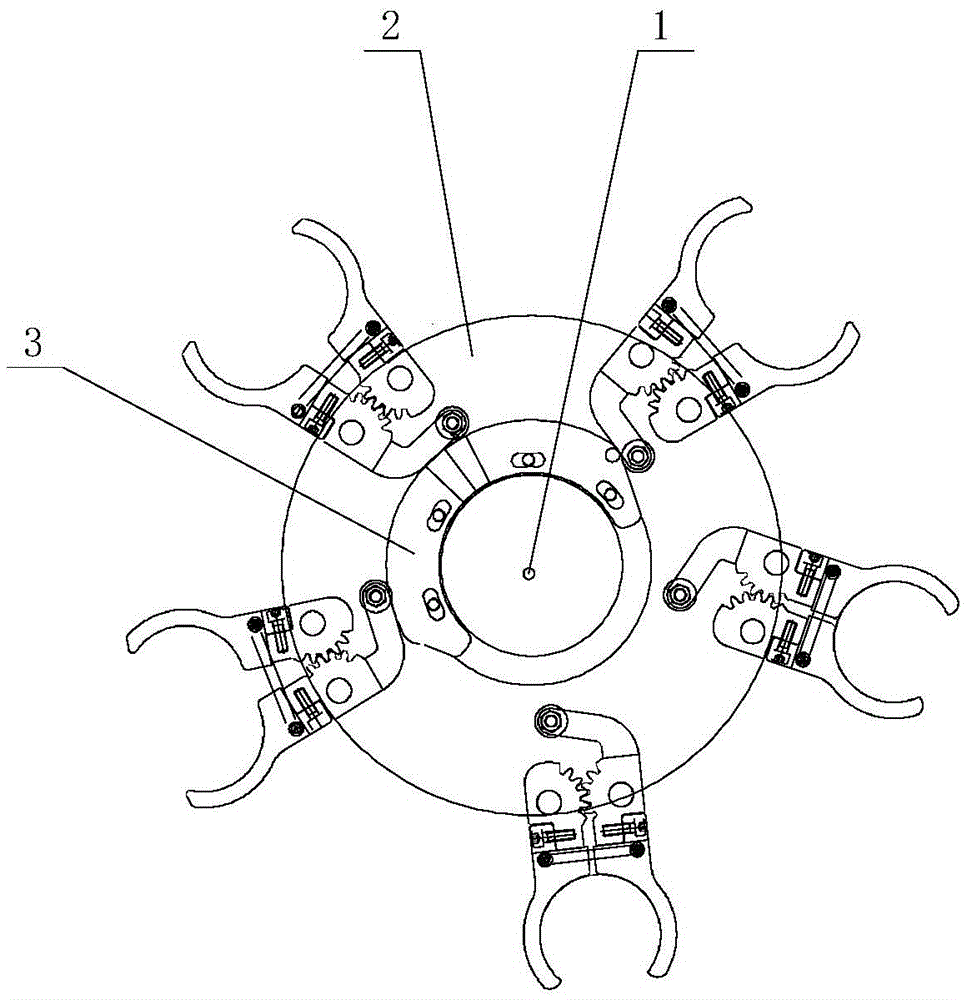

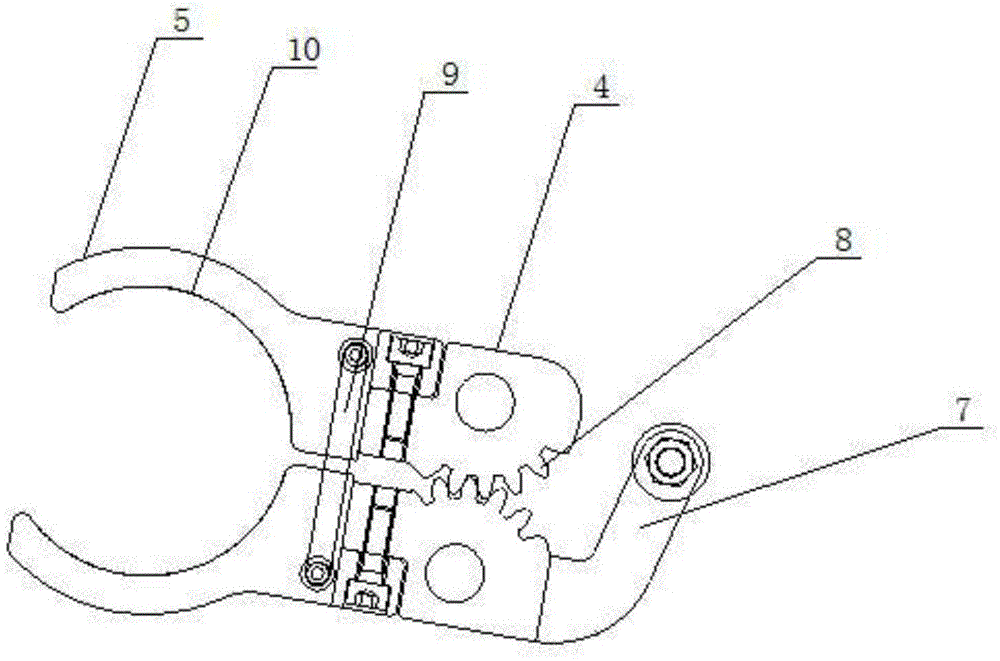

Bottle holding type transfer star wheel and achievement method thereof

InactiveCN105540170APrevent damageSimple structureConveyor partsRotary conveyorsTransfer procedureEngineering

The invention discloses a bottle holding type transfer star wheel and an achievement method thereof. The problems that an conveying belt or a clamping device adopted in the prior art transports bottles containing liquid products, a bottle overturning phenomenon and mutual extrusion easily occur during direct conveying of the conveying belt, the bottles are easily scratched in the conveying process, and the surfaces of the bottles are easily damaged in conveying of the clamping device are mainly solved. The bottle holding type transfer star wheel comprises a turntable, a motor driving the turntable, at least one cam and a supporting column for fixing the cam. The edge of the turntable is connected with multiple clamping claws. The cam is located in the turntable. The clamping claw located at the highest position of the cam is in an opened state, and the clamping claw located at the lowest position of the cam is in a closed state. By the adoption of the scheme, the bottle holding type transfer star wheel achieves the purpose that the bottles are not overturned, are not mutually extruded and are not damaged in appearance and has very high practical value and promotional value.

Owner:CHENGDU HONGRUI TECH

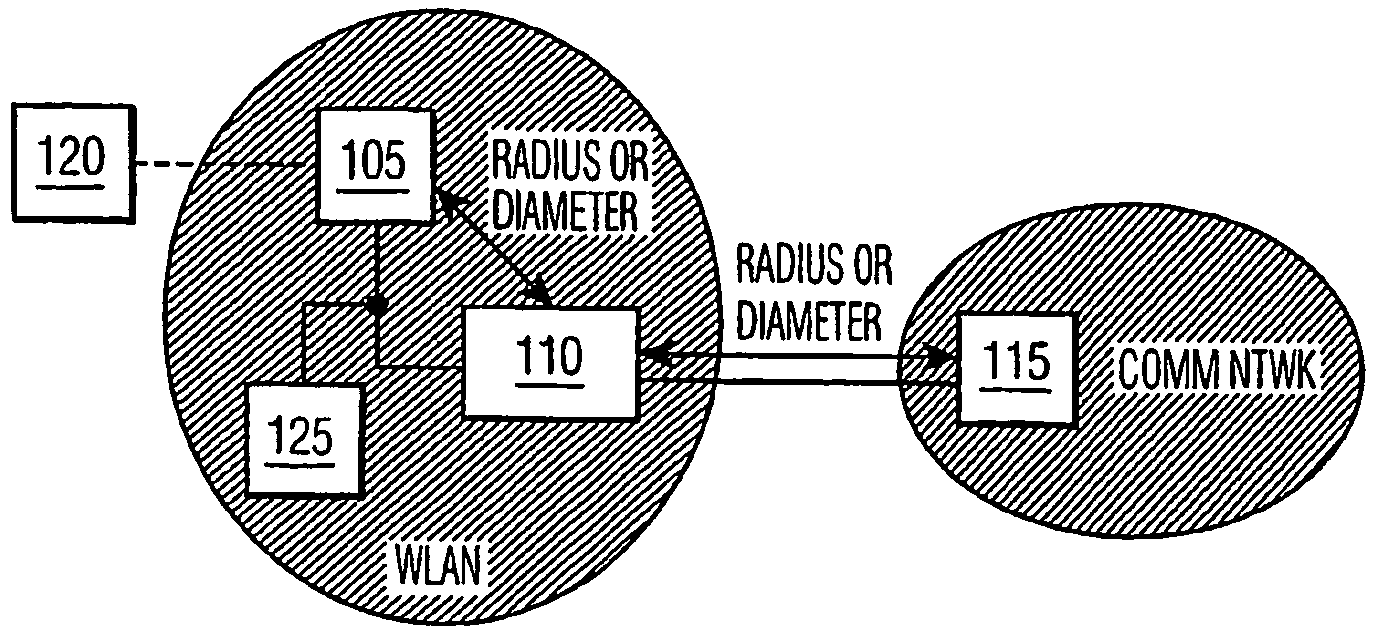

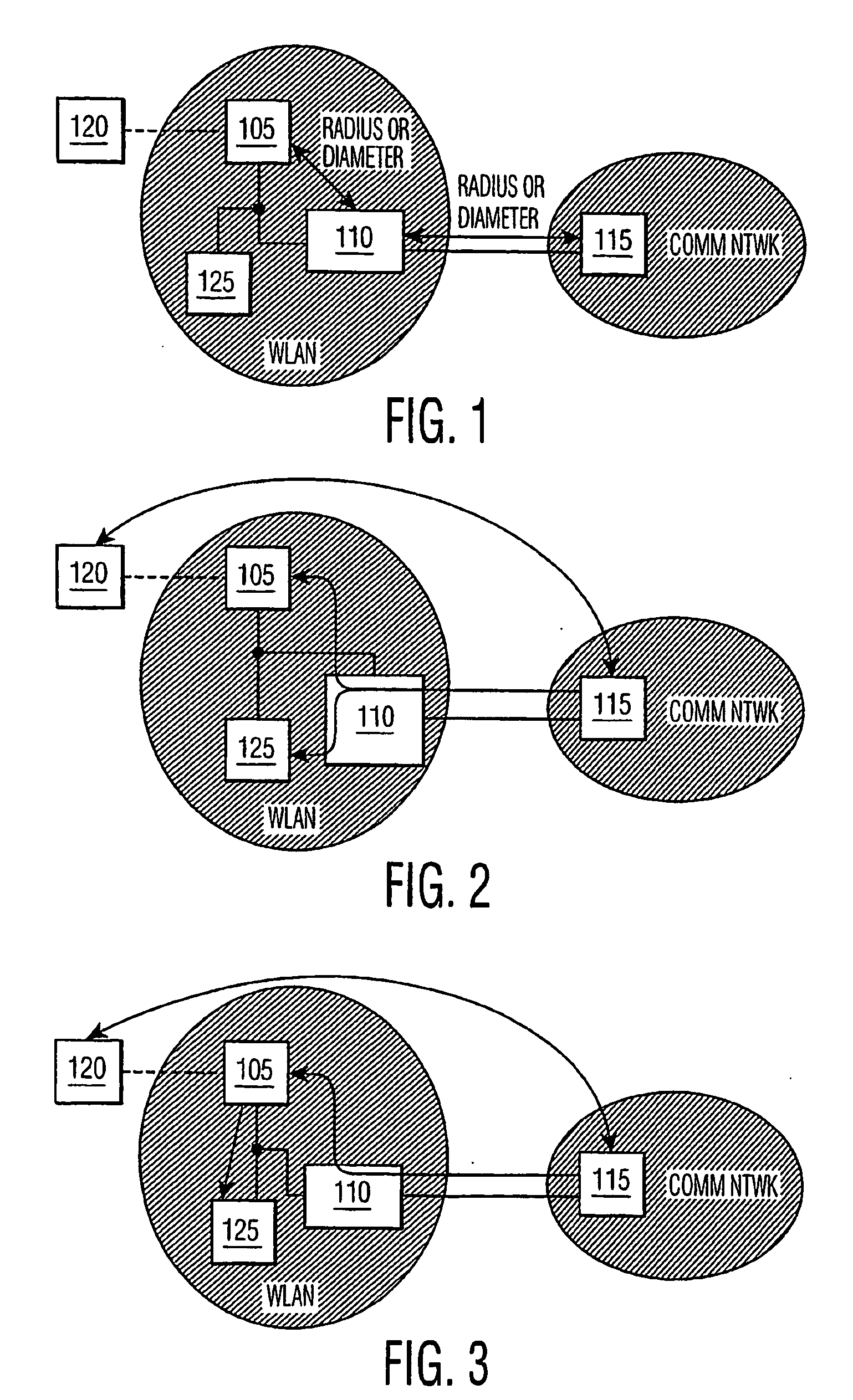

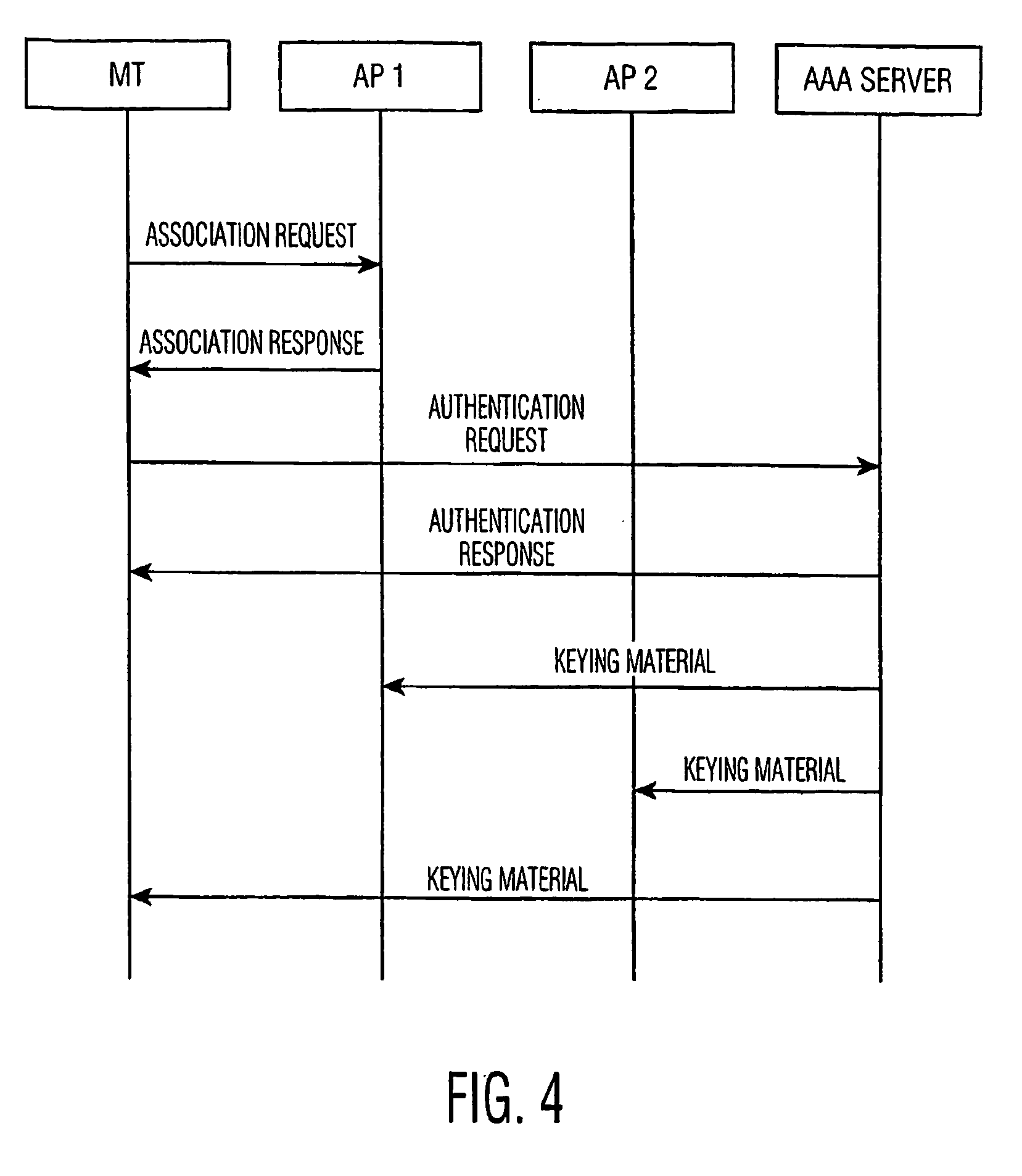

Secure handoff in a wireless local area network

InactiveUS20090282238A1Smooth handoverFast smooth handoff mechanism without compromising securityKey distribution for secure communicationNetwork topologiesSecurity domainMobile device

A system and method including computing keying information by a server for authentication of devices accessing a wireless local area network and forwarding the keying information by the server to access points included in a security domain of the wireless local area network, wherein one of the access points is associated with a mobile device are described.

Owner:THOMSON LICENSING SA

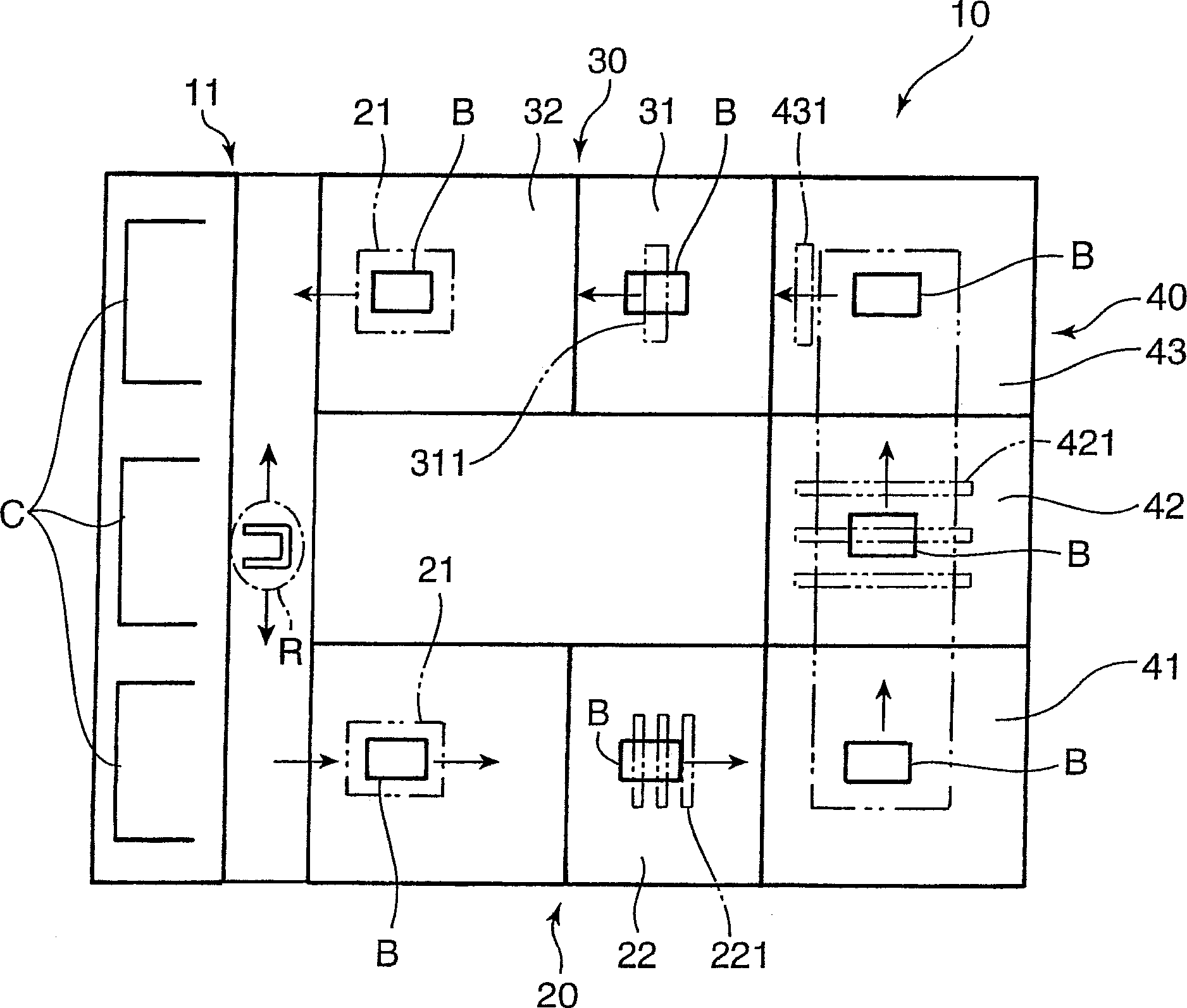

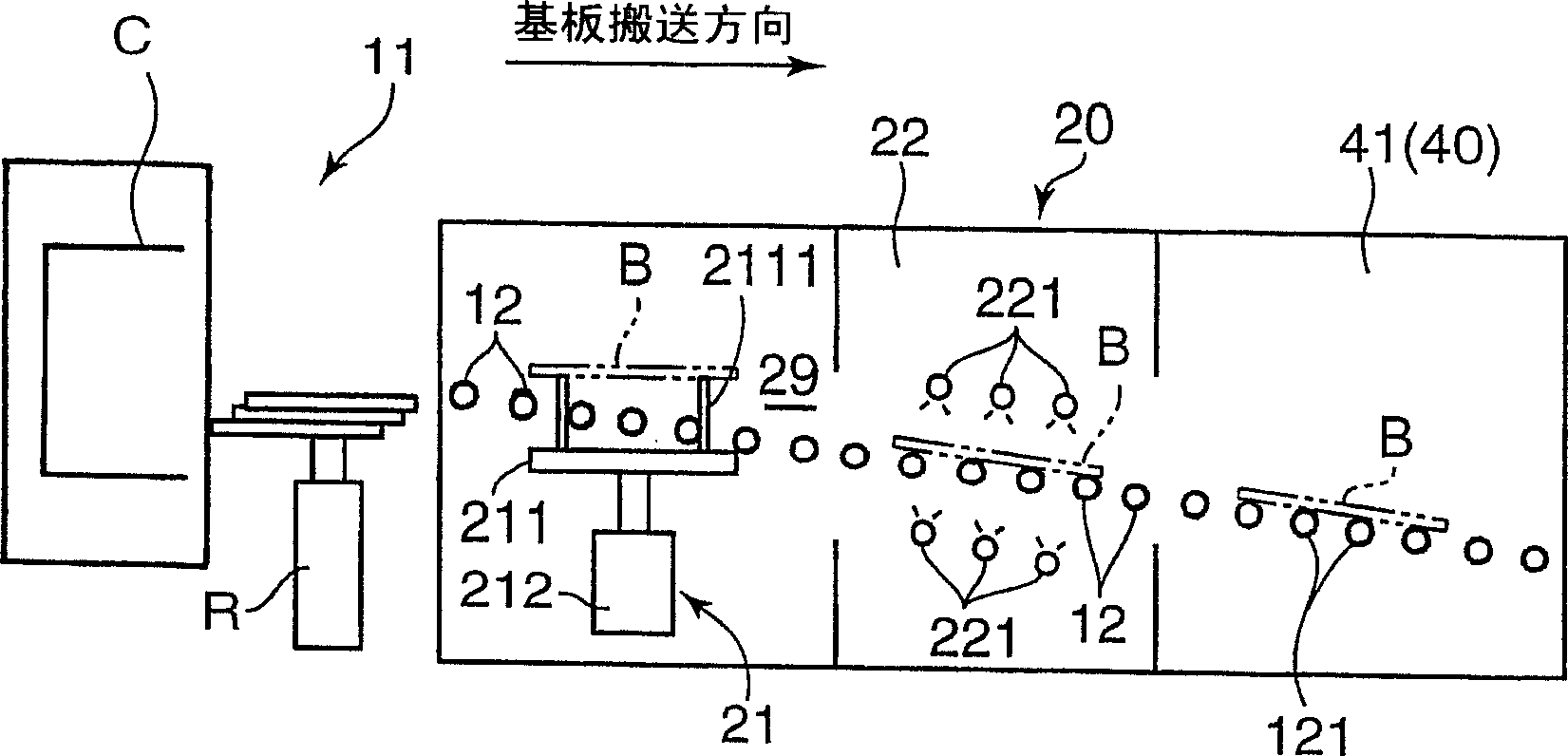

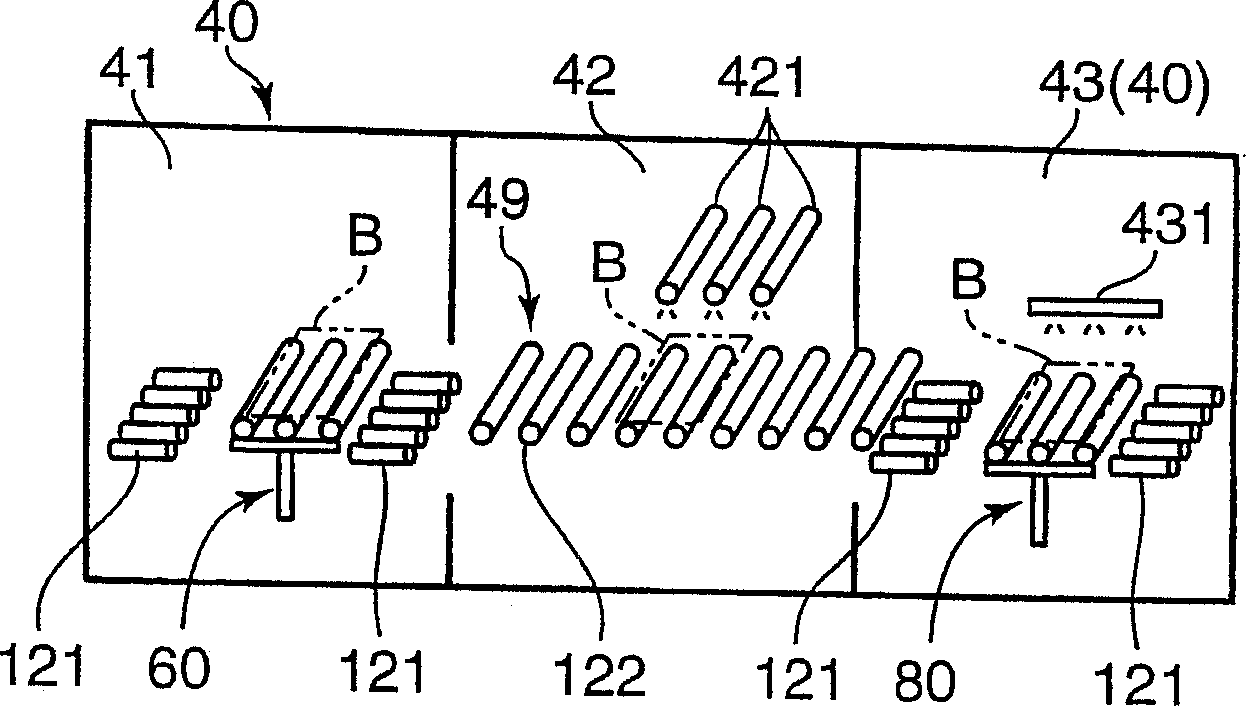

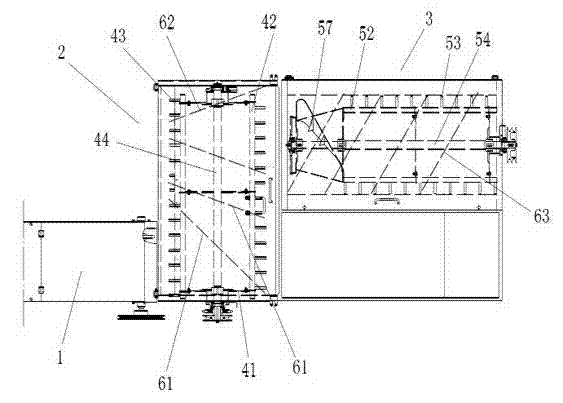

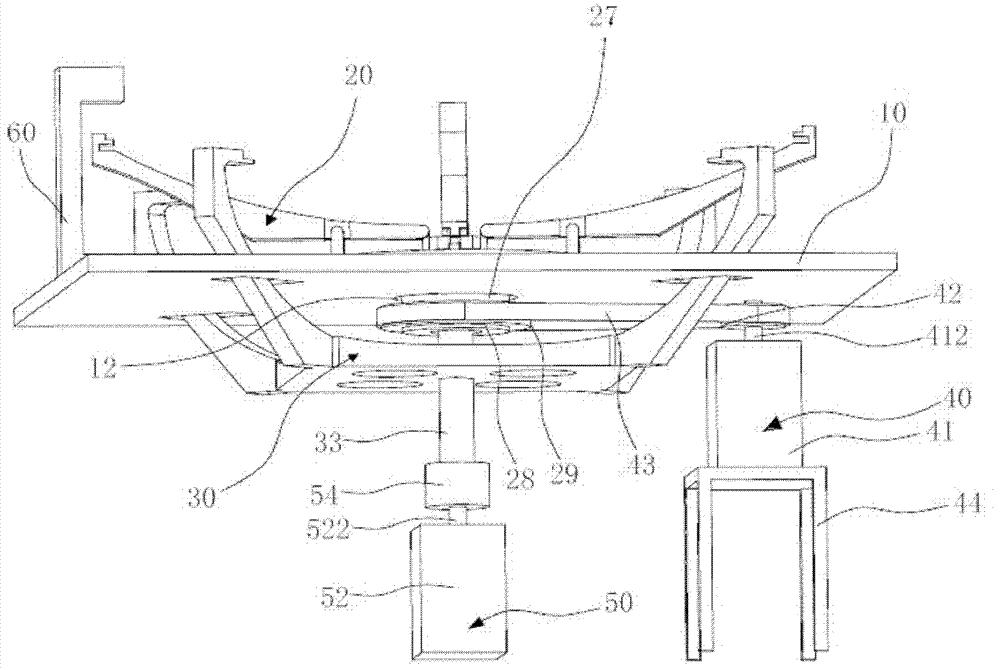

Substrates treating device

InactiveCN1812071ASmall footprintLow costSemiconductor/solid-state device manufacturingCharge manipulationMechanical engineering

This invention is to provide a substrate processing apparatus which contributes to reduction of costs for equipment by reducing a floor surface required for installation and carrying a board in an inclined posture by a simple mechanism. After the board is treated by a first treatment part 20, a carrying direction changing part 40 changes the carrying direction of the substrate, and its inclined carrying part 49 carries the substrate to a second carrying path 43 nearly keeping the inclined posture made by the inclination of the first carrying path 41. A liquid supplying part supplies a treatment liquid to the main surface of the substrate B carried by the inclined carrying part 49. The second carrying path 43 and a second treatment part 30 treats the substrate whose inclined posture is kept by the inclined carrying part 49, by carrying the substrate in a direction reverse to the first treatment part 20 without changing the posture.

Owner:DAINIPPON SCREEN MTG CO LTD

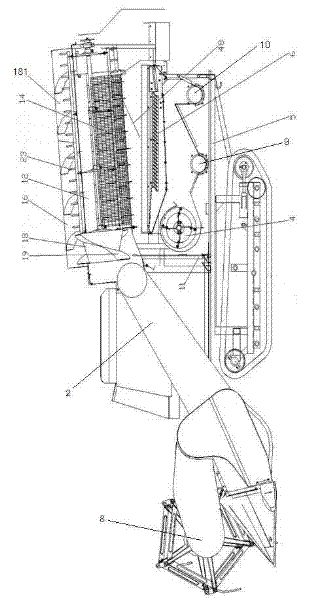

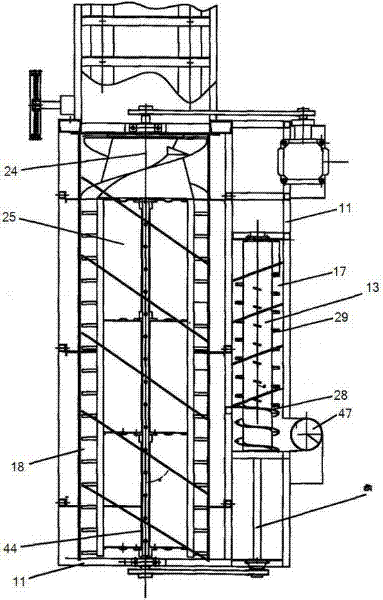

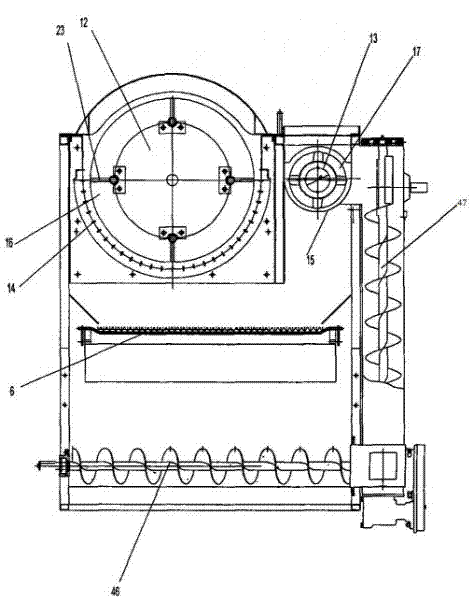

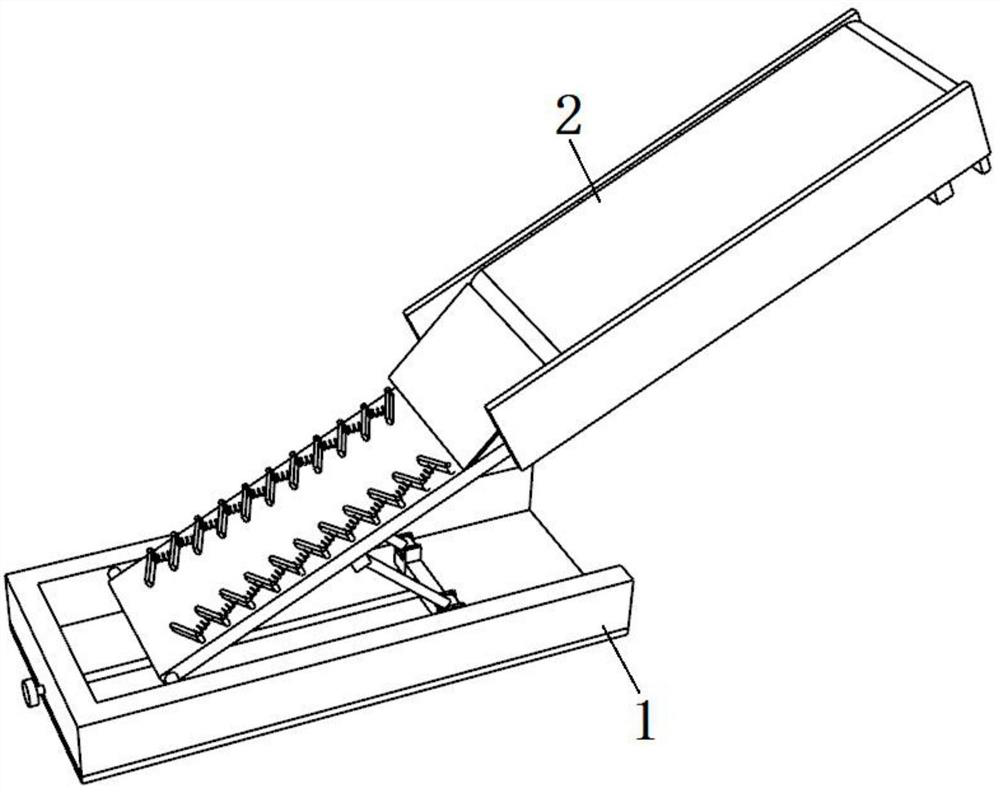

Threshing device of harvester

The invention relates to a harvester, in particular to a threshing device of a harvester. According to the technical scheme, the threshing device of the harvester comprises an underframe, a threshing frame, a main threshing mechanism, a rethreshing mechanism, a separation, cleaning and vibration screen and an impurity lifting screw, wherein the threshing frame is fixed on the underframe, both the main threshing mechanism and the rethreshing mechanism are connected to the threshing frame and disposed along the travelling direction of the harvester, the separation, cleaning and vibration screen is fixedly connected to the threshing frame and positioned between the underframe and the main threshing and rethreshing mechanisms, and the impurity lifting screw is disposed between the position below the rear end of the separation, cleaning and vibration screen and the rethreshing mechanism. The main threshing mechanism comprises a main threshing roller, a large concave screen and a main roller cover, wherein the main threshing roller is hinged to the threshing frame, the large concave screen is fixed to the threshing frame and encloses the main threshing roller, and the main roller cover covers an opening of the large concave screen. The main threshing roller is slantingly disposed along the advancing direction of the harvester. A corner between the main threshing roller and a conveying chute of the threshing device compared with the prior art is reduced, so that conveying of crops is smooth, and the shortages of the prior art are made up.

Owner:ZHONGJI SOUTHERN MACHINERY

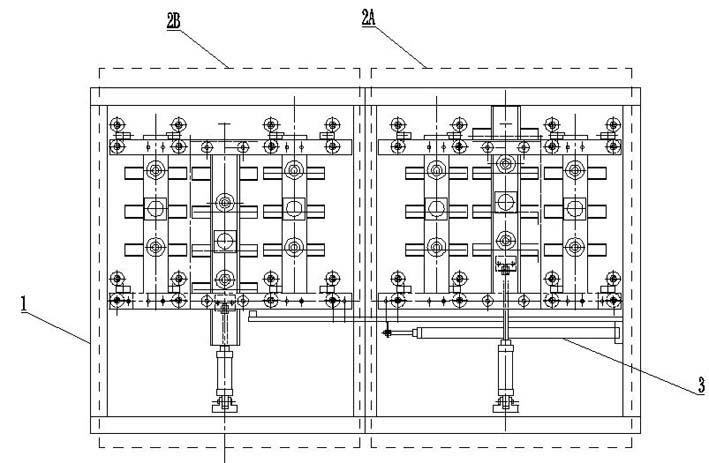

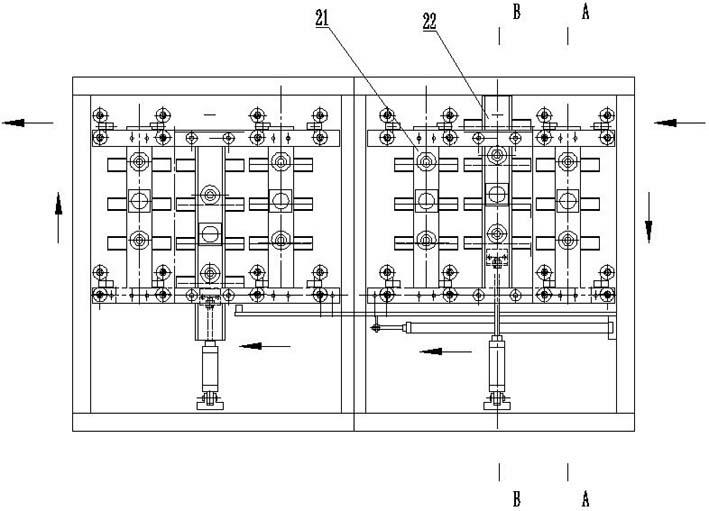

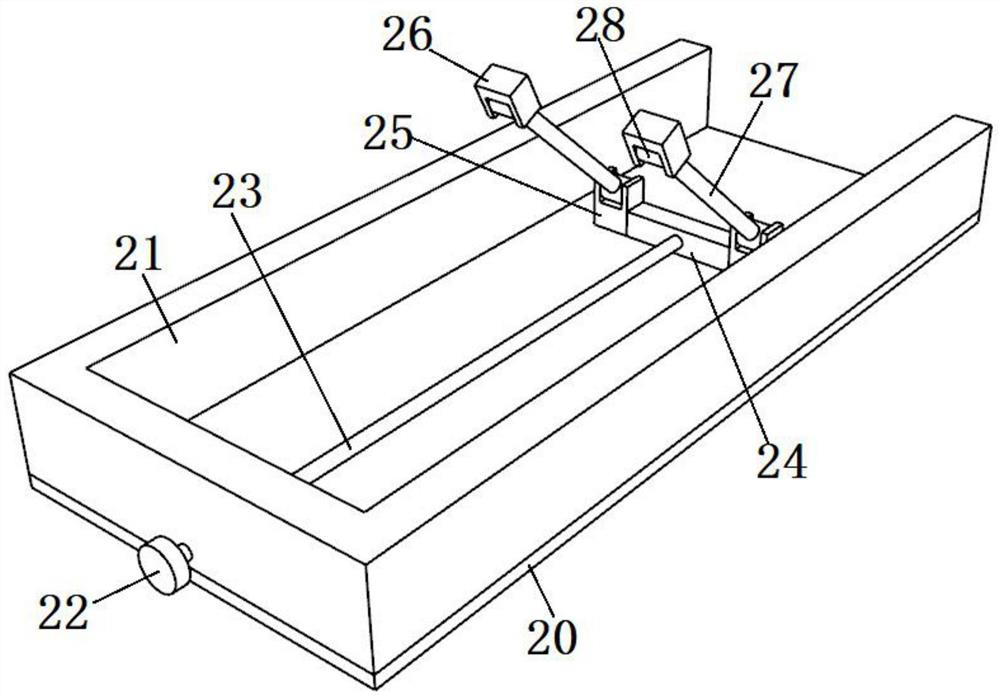

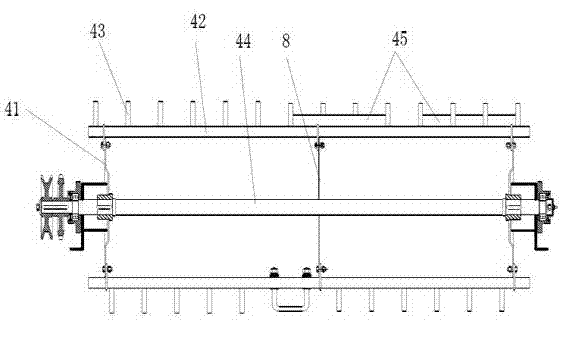

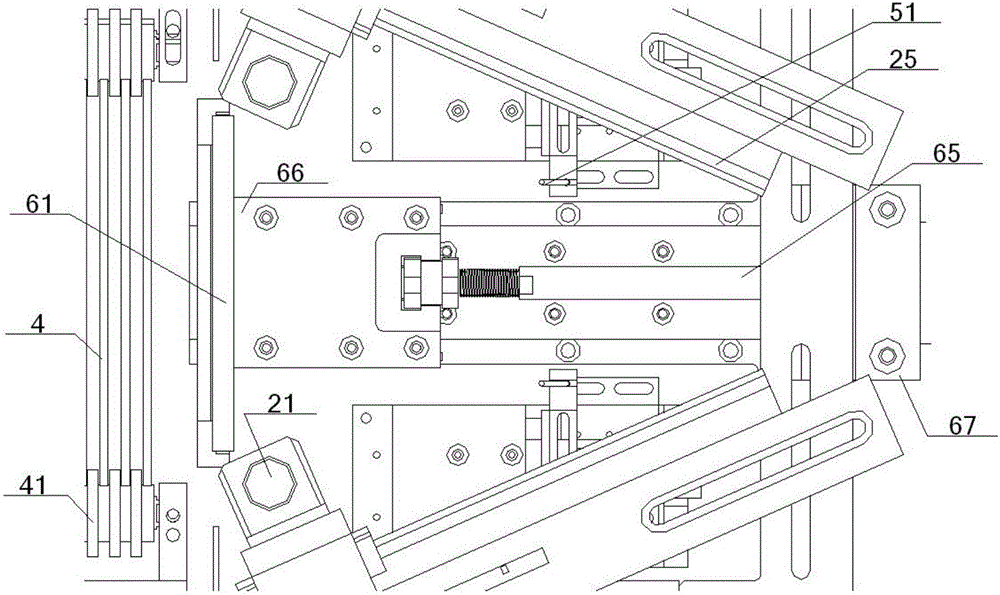

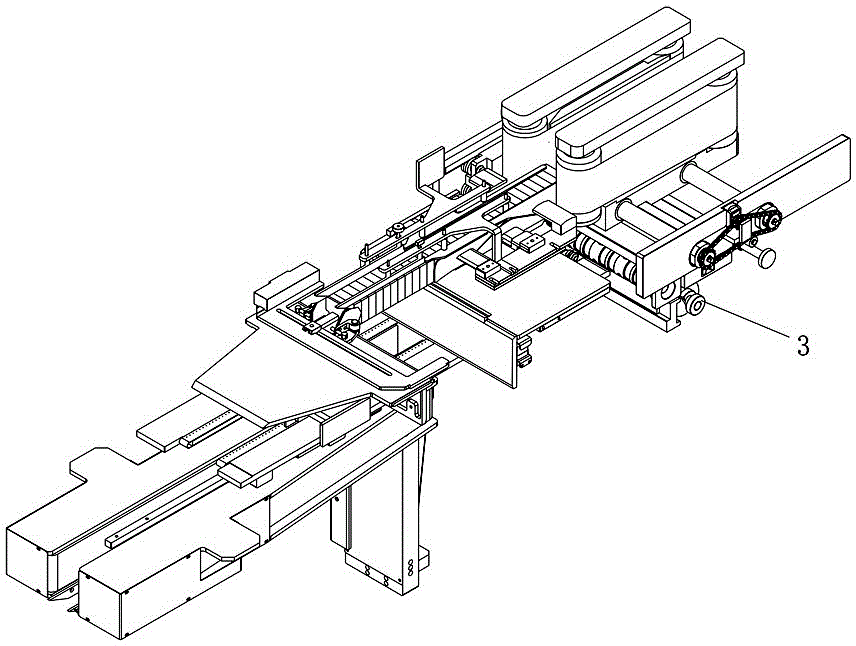

Platen moving pair for full-automatic printing machine

ActiveCN102582225AIncrease the number ofImprove printing efficiencyScreen printersEngineeringRelease - action

The invention relates to a platen moving pair for a full-automatic printing machine. The platen moving pair comprises a rack, and a feeding side lifting conveying mechanism, a discharge side lifting conveying mechanism, and a horizontal conveying mechanism, which are installed on the rack. The platen moving pair is characterized in that each of the feeding side lifting conveying mechanism and thedischarge side lifting conveying mechanism comprises a lifting support bracket and a lifting handover bracket, platen supports are distributed on the lifting support brackets and the lifting handoverbrackets, clamping driving mechanisms are arranged on the lifting support brackets and the lifting handover brackets and handover driving mechanisms are arranged on the lifting handover brackets. Through arrangement of the lifting conveying mechanisms in such a structure form, the quantity of printing platens is increased in unit space on the basis that the floor space of the printing machine is not increased and the printing efficiency is improved for sure. By virtue of clamping and releasing actions of the lifting support brackets and the lifting handover brackets and in cooperation with the lifting handover brackets, the printing platens can be handed over successfully and operation reliability and stability of equipment is ensured.

Owner:如皋市天元服饰印业有限公司

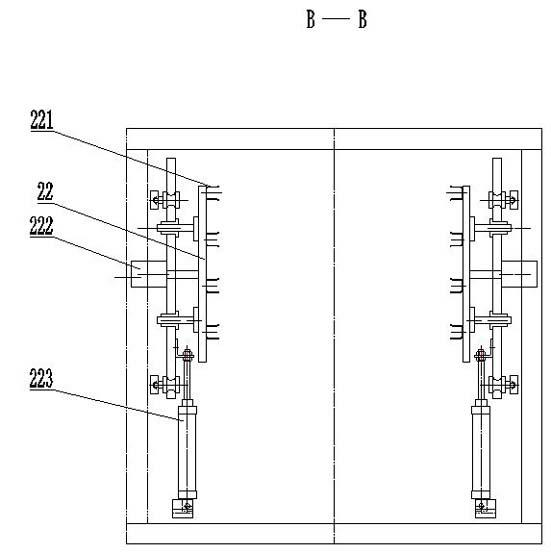

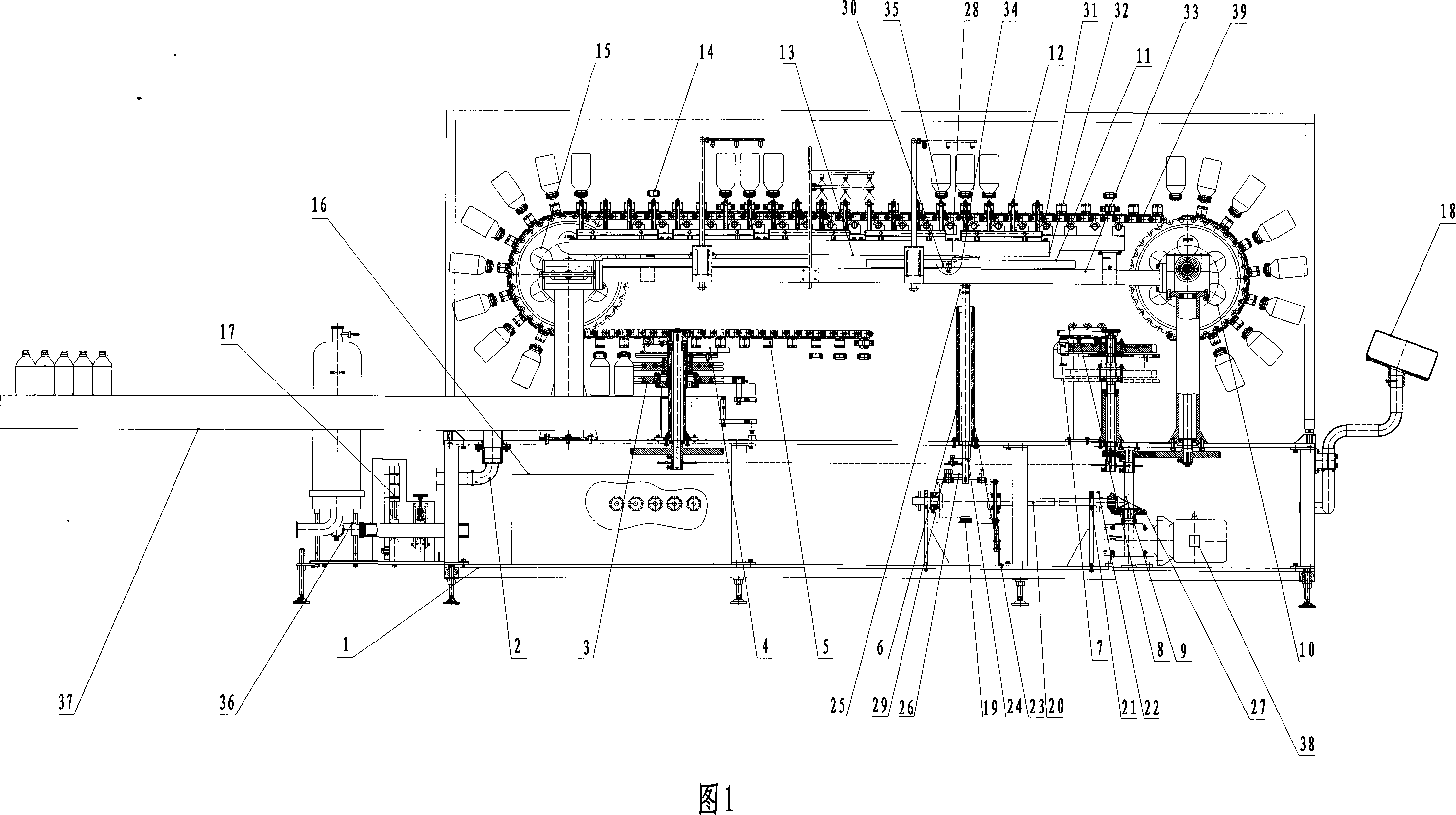

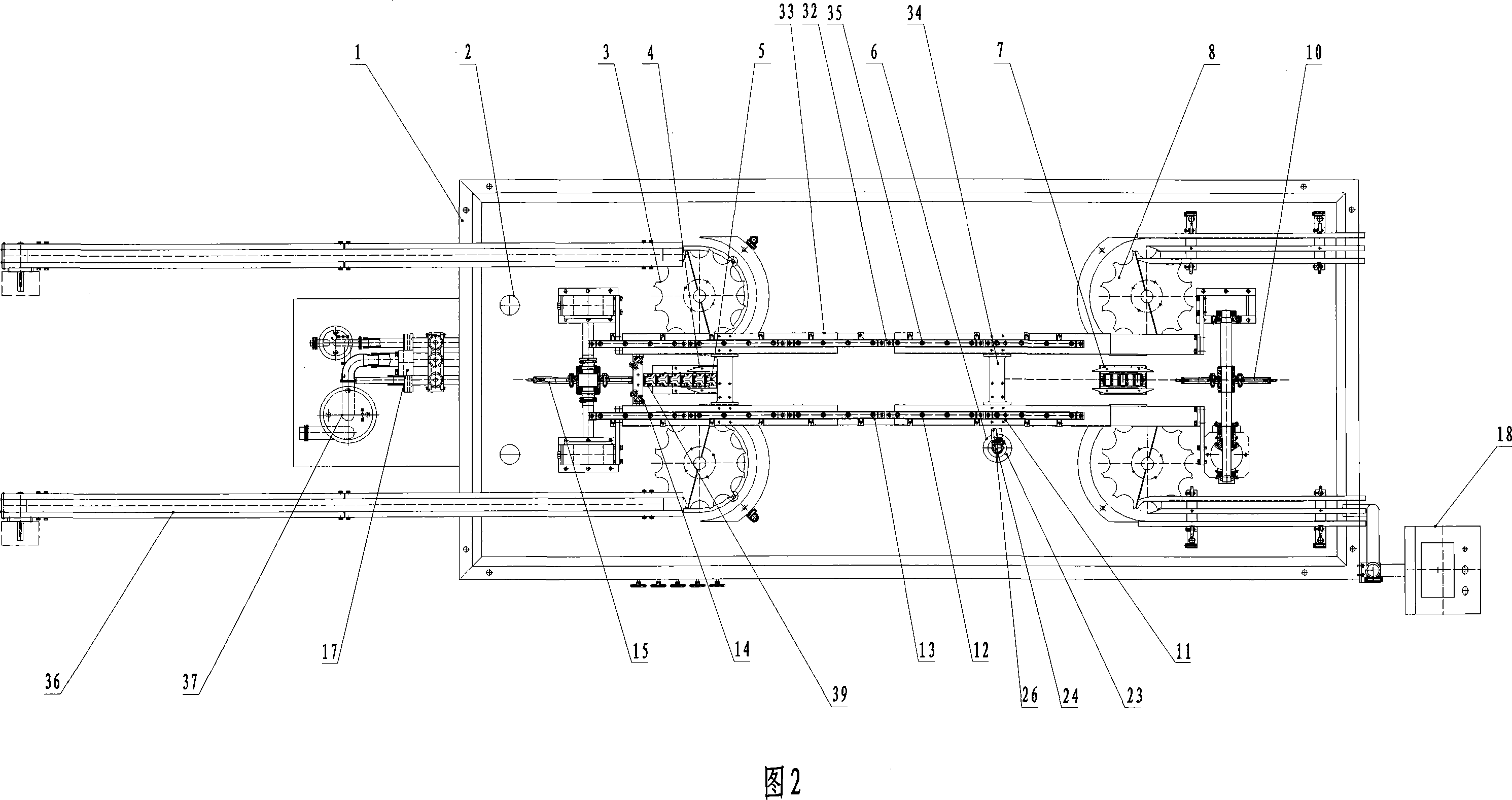

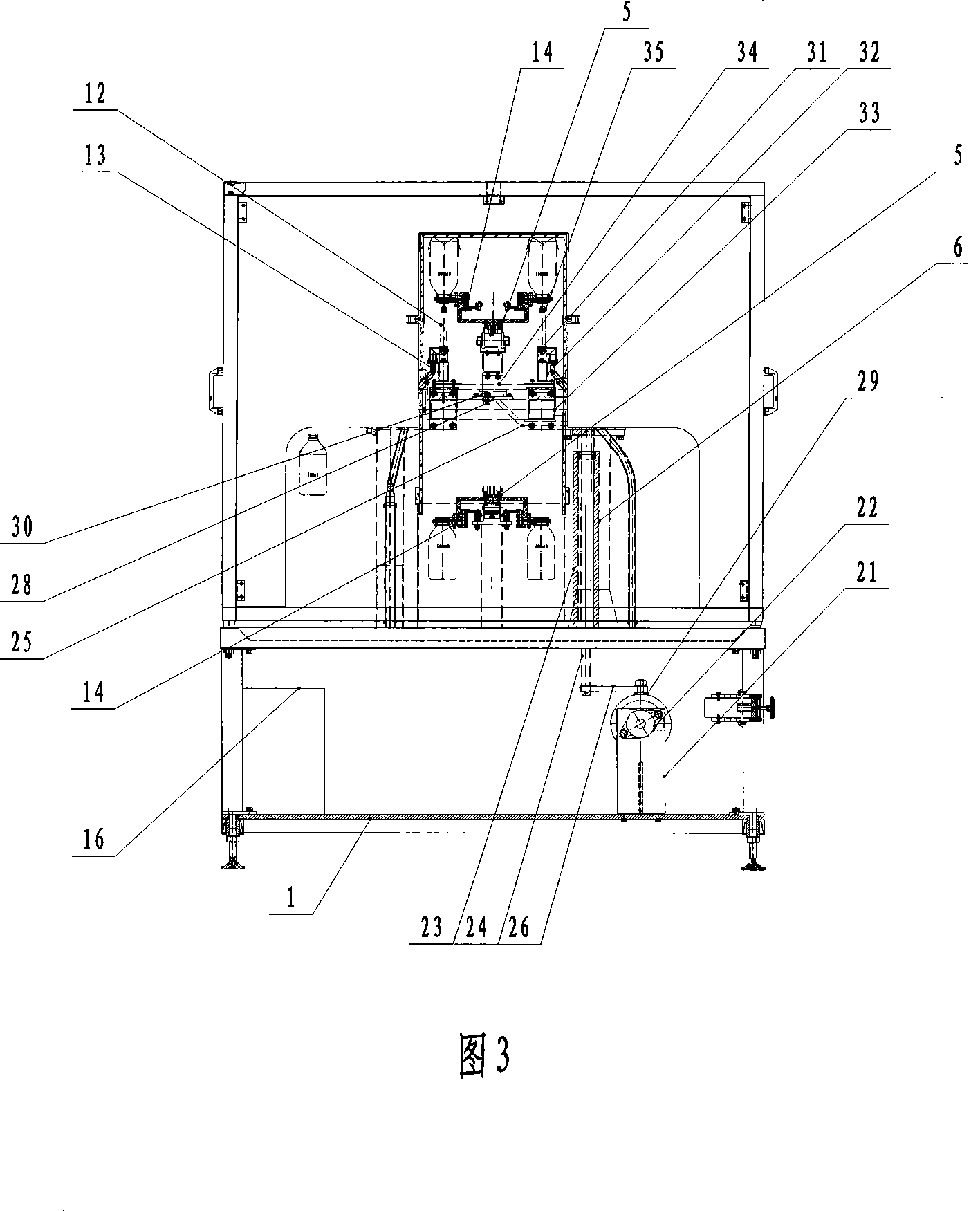

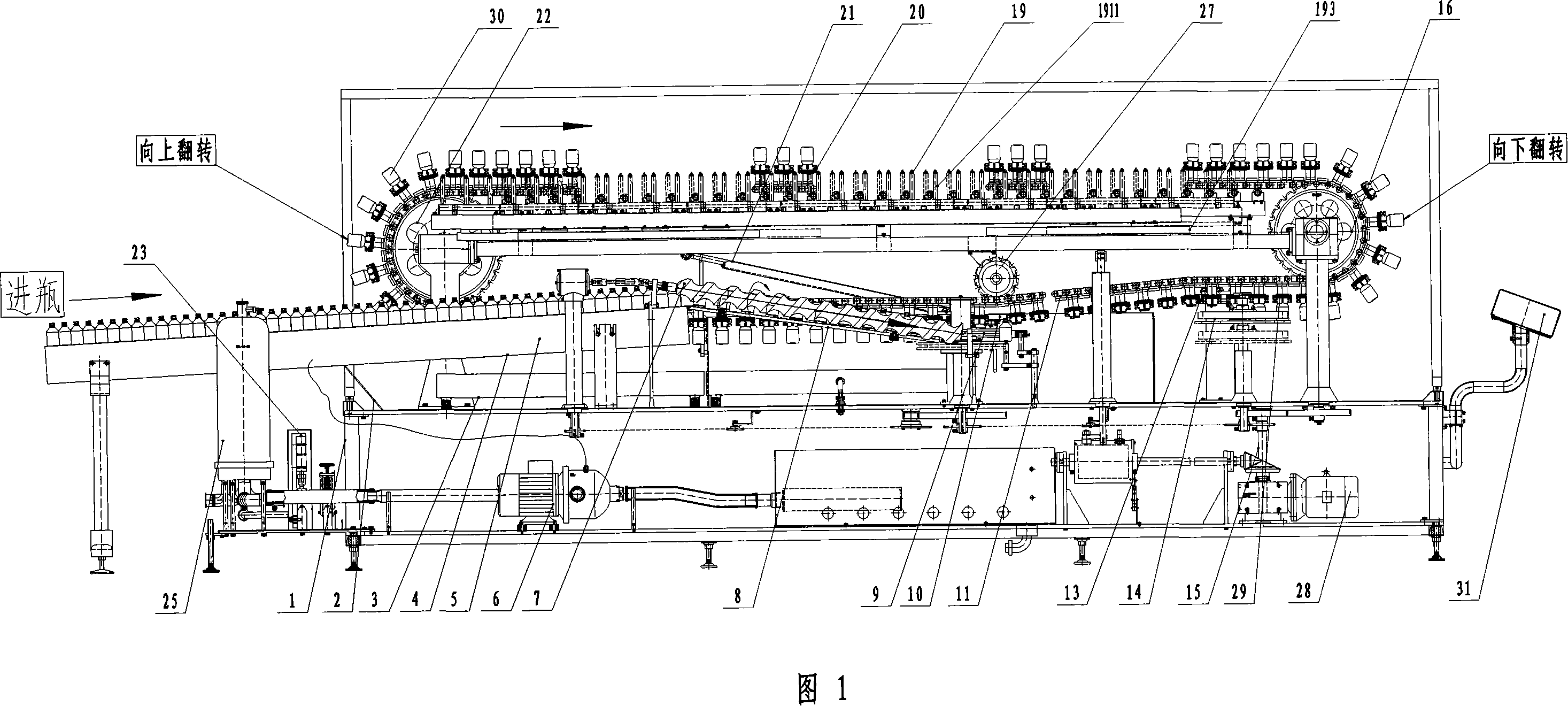

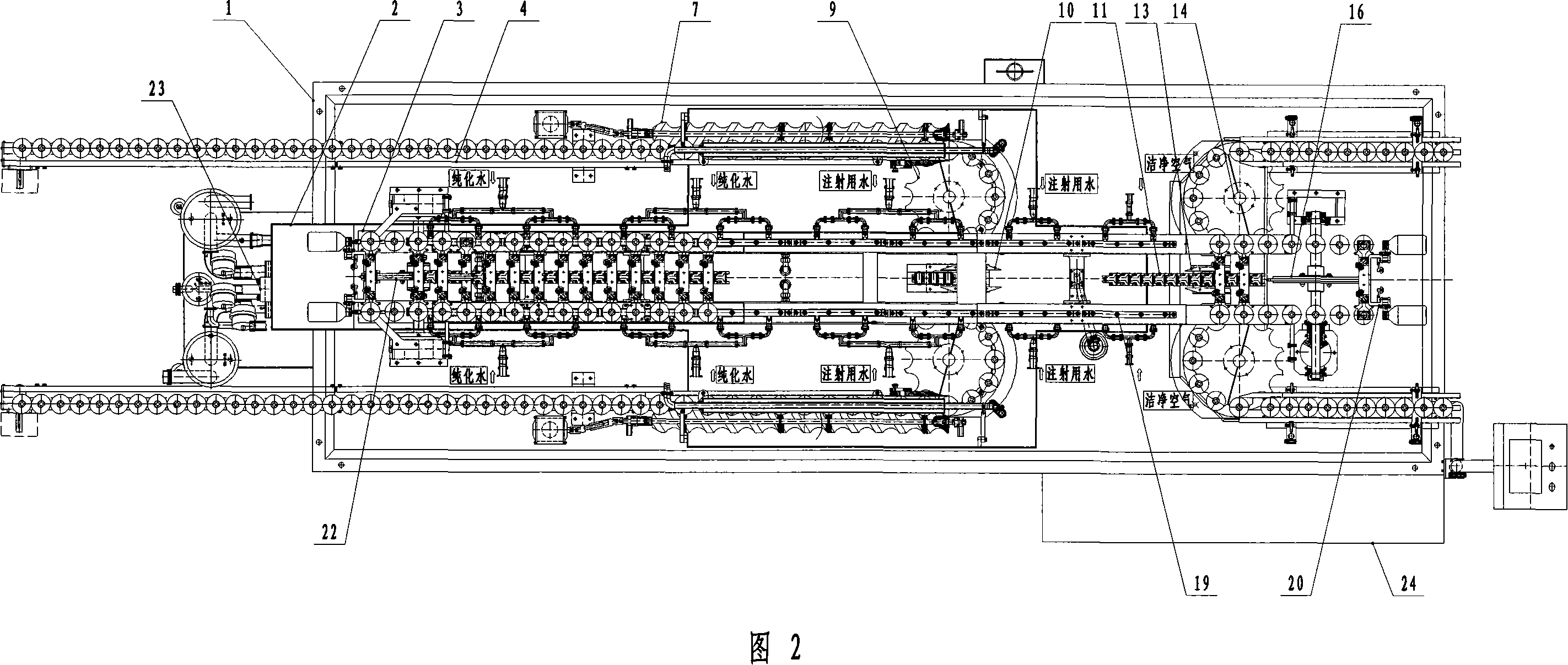

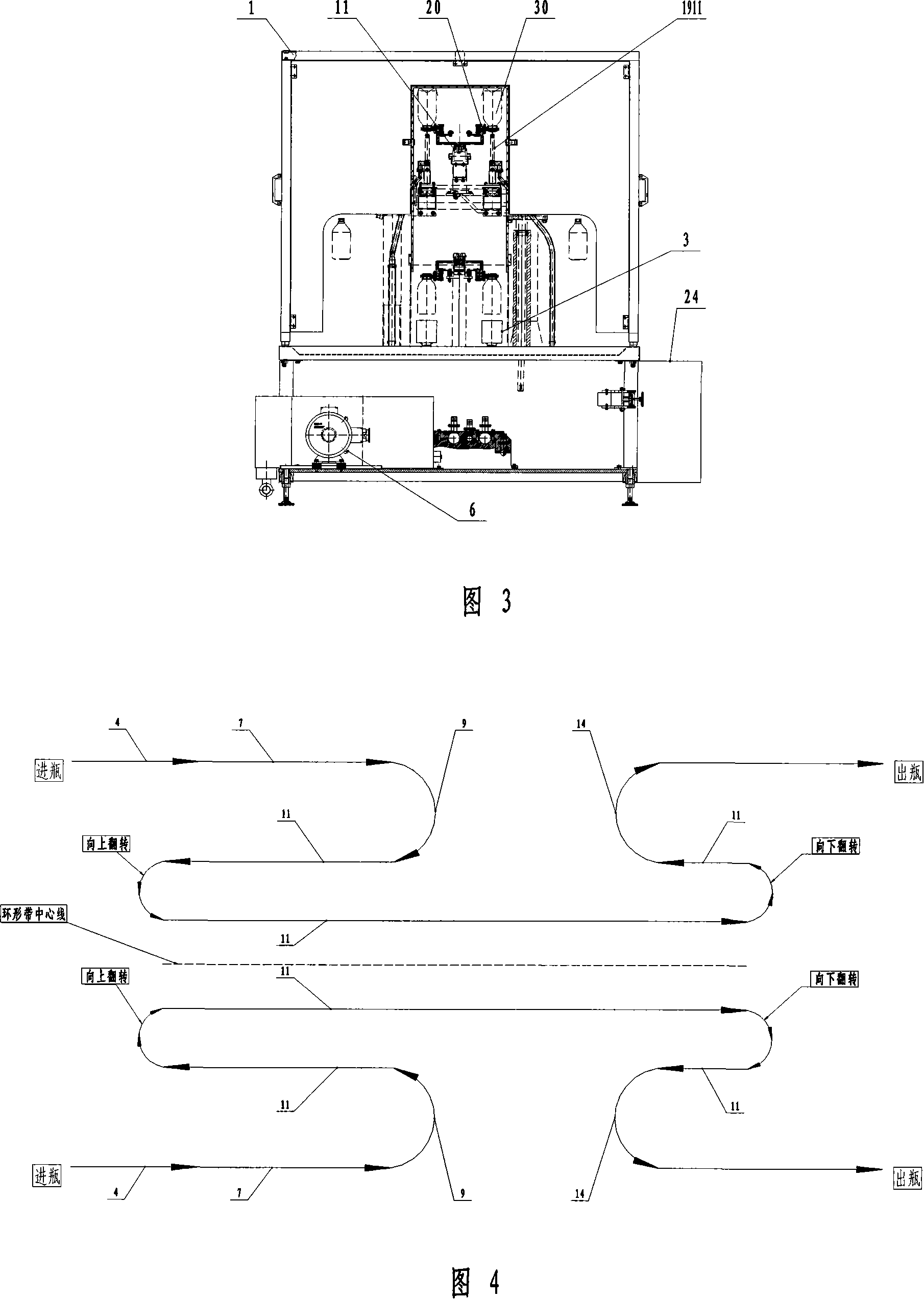

Straight line type bottle washing machine

InactiveCN101195120ACompact structureSmall footprintHollow article cleaningLow noiseElectrical control

The invention discloses a liner-type bottle cleaning machine, which comprises a frame, a water and air supplying device, a bottle input mechanism, a bottle input dial wheel mechanism, a circulating transmitting mechanism, a reciprocal tracking mechanism, a bottle output dial wheel mechanism, a tracking cleaning mechanism, an electrical control box and a power device, wherein the bottle input mechanism, the bottle input dial wheel mechanism, the circulating transmitting mechanism, the reciprocal tracking mechanism, the bottle output dial wheel mechanism, the tracking cleaning mechanism, the electrical control box and the power device are arranged on the frame, the bottle input mechanism is connected with the bottle input dial wheel mechanism, one portion of an upper bottle sending rail which is on the circulating transmitting mechanism is matched and connected with the bottle input dial wheel mechanism, the other portion of the upper bottle sending rail is matched and connected with the bottle output dial wheel mechanism, the tracking cleaning mechanism which is connected with the reciprocal tracking mechanism is located between the upper bottle sending rail and a lower bottle sending rail of the circulating transmitting mechanism, a water and air controlling device is arranged on a pipe line of the water and air supplying device which is connected with the reciprocal tracking mechanism and the bottle input dial wheel mechanism, the circulating transmitting mechanism, the reciprocal tracking mechanism, the bottle output dial wheel mechanism and the tracking cleaning mechanism are connected with the power device through an actuating mechanism. The invention is the linear-type bottle cleaning machine with simple and compact structure, small occupying space, wide applying range, low noise, high automation level and working efficiency and good operational quality.

Owner:TRUKING TECH LTD

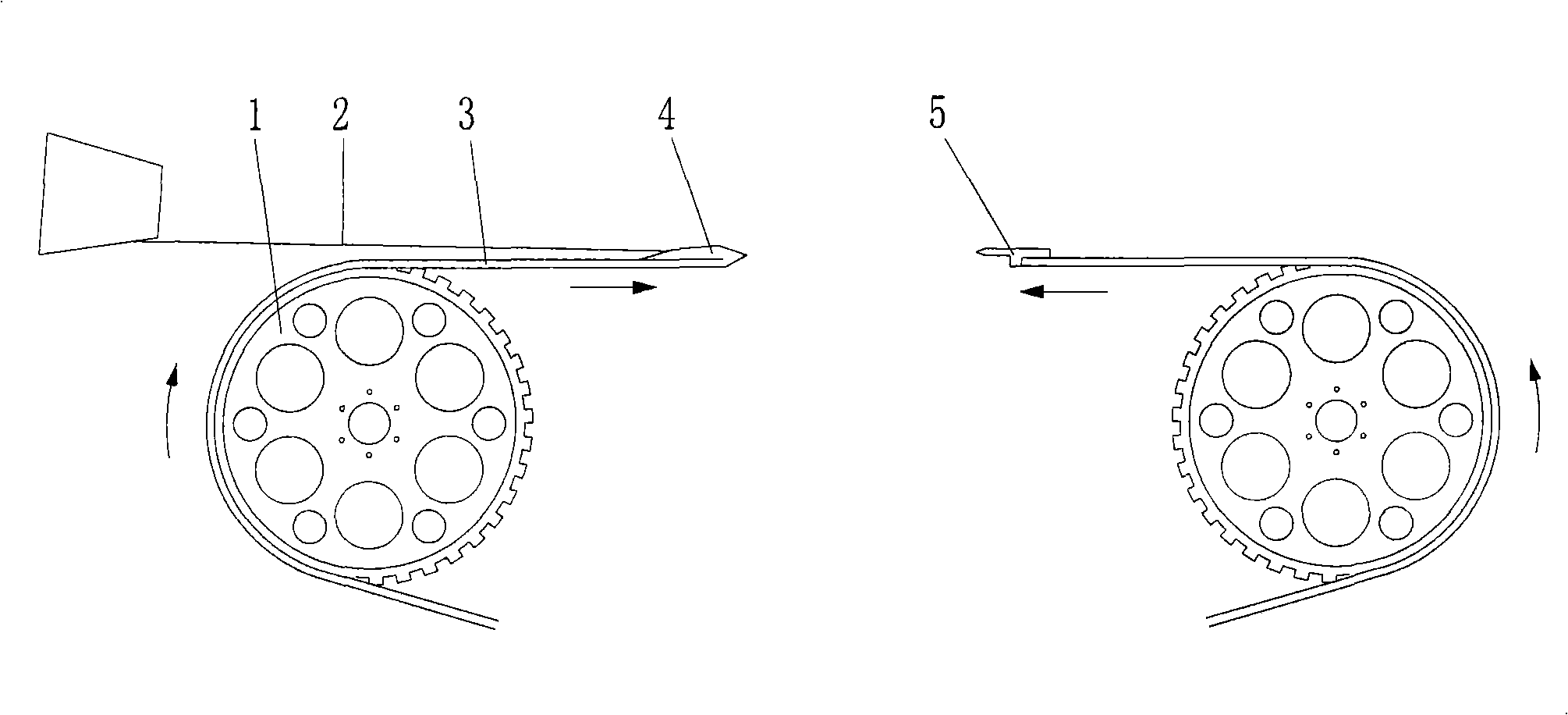

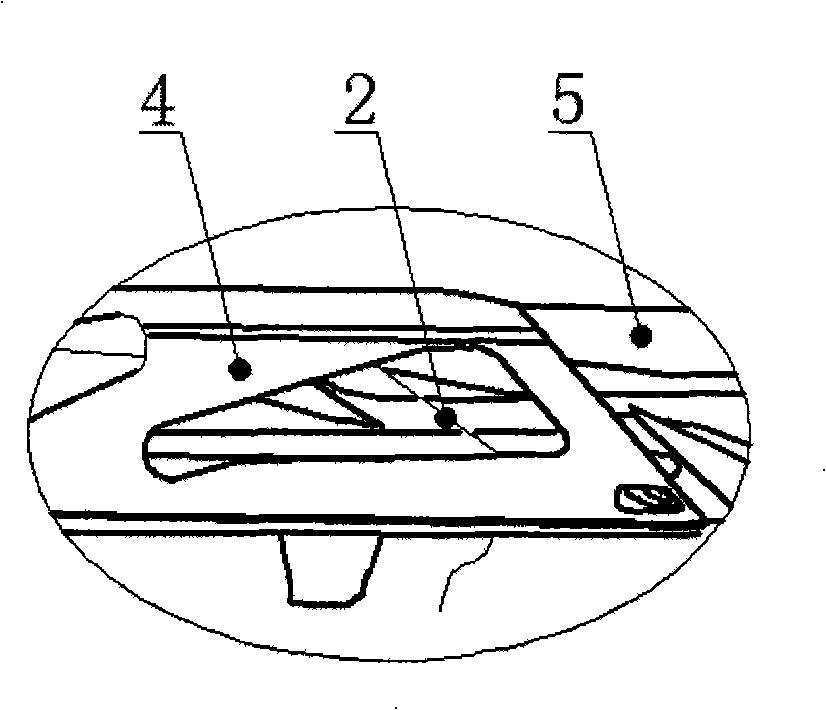

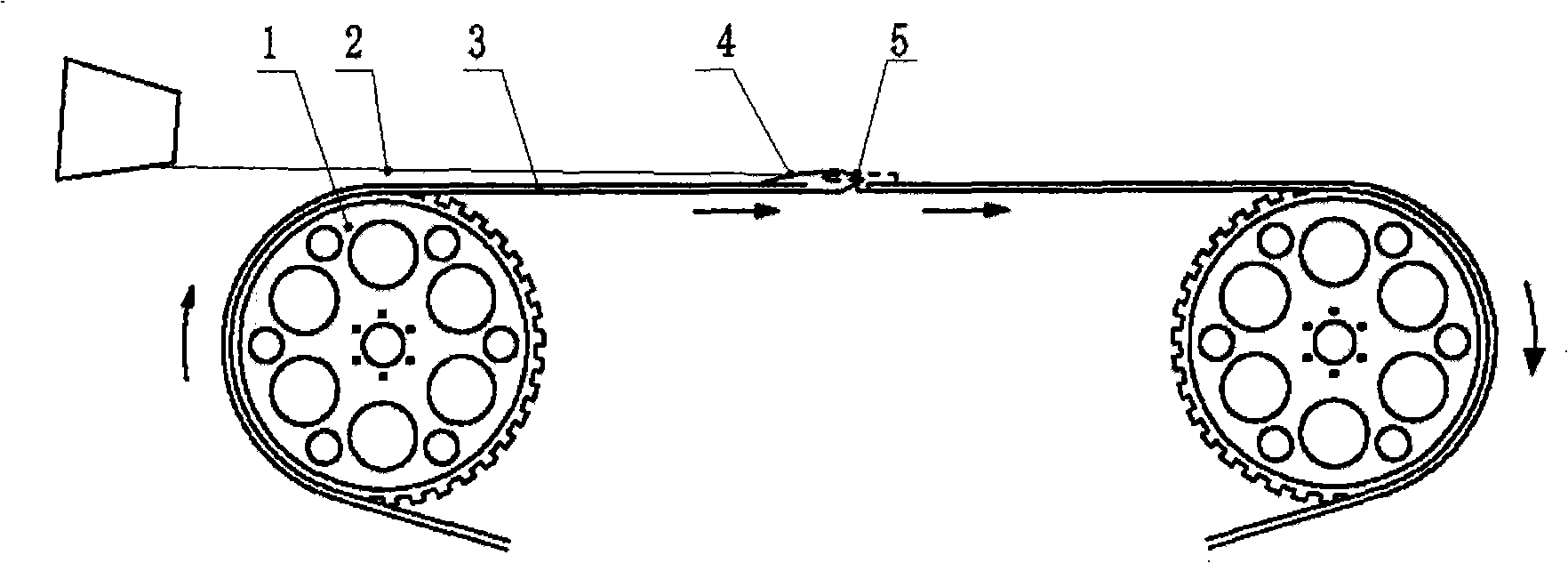

Woof-intersecting method and device thereof for weaving machine

The invention provides a woof-intersecting method and a device thereof for a weaving machine. The method utilizes the motion phase difference between a woof-feeding gripper head and a woof-receiving gripper head, enables the woof-receiving gripper head to move to a limit position in the advance direction and enables yarn brought by the woof-feeding gripper head to get across a yarn-hooking head of the woof-receiving gripper head so that the woof-receiving gripper head starts to retreat, the woof-feeding gripper head still advances to a limit position in the advance direction to finish yarn intersection before the woof-feeding gripper head retreats until the yarn is finished. The device comprises a woof-feeding mechanism and a woof-receiving mechanism which are respectively arranged at both sides of a weaving machine main shaft, and a relative mounting angle between the weaving machine main shaft and a woof-feeding main shaft fixing part at one end of the weaving machine main shaft is larger than a relative mounting angle between the weaving machine main shaft and a woof-receiving main shaft fixing part at the other end of the weaving machine main shaft. The invention enables the tension of the yarn to have little change during the yarn intersection, does not influence the detection of a yarn-stopping device, improves the success rate of the yarn intersection, reduces false yarn stops due to the high-speed motion of the weaving machine and can improve the rotating speed of the weaving machine so as to improve the production efficiency.

Owner:林东

Unloading device for storage and transportation

InactiveCN111620025AReduce volumeEasy to transportConveyorsStorage devicesTransmission beltElectric machinery

The invention discloses an unloading device for storage and transportation, and relates to the technical field of storage and transportation. The unloading device for storage and transportation comprises a support adjustment mechanism, wherein an unloading mechanism is fixed on the support adjustment mechanism, the unloading mechanism comprises a group of support plates and unloading plates, a group of belt rollers are rotationally connected between the two support plates through bearings, and two belt rollers are in transmission fit with conveyor belts. According to the invention, a motor drives a thread screw to rotate, so that the unloading plates and the conveyor belts can be folded together in a screw drive mode, and then the device has smaller volume through the mutual folding of thesupport adjustment mechanism and the unloading mechanism; and the overall length after the unloading plate is combined with the conveyor belt can be adjusted freely in the screw drive mode, the support adjustment mechanism can adjust the inclination of the unloading mechanism, with the mutual cooperation of the support adjustment mechanism and the unloading mechanism, the device can meet the actual unloading demand during storage well.

Owner:安徽华中机械配套工程有限公司

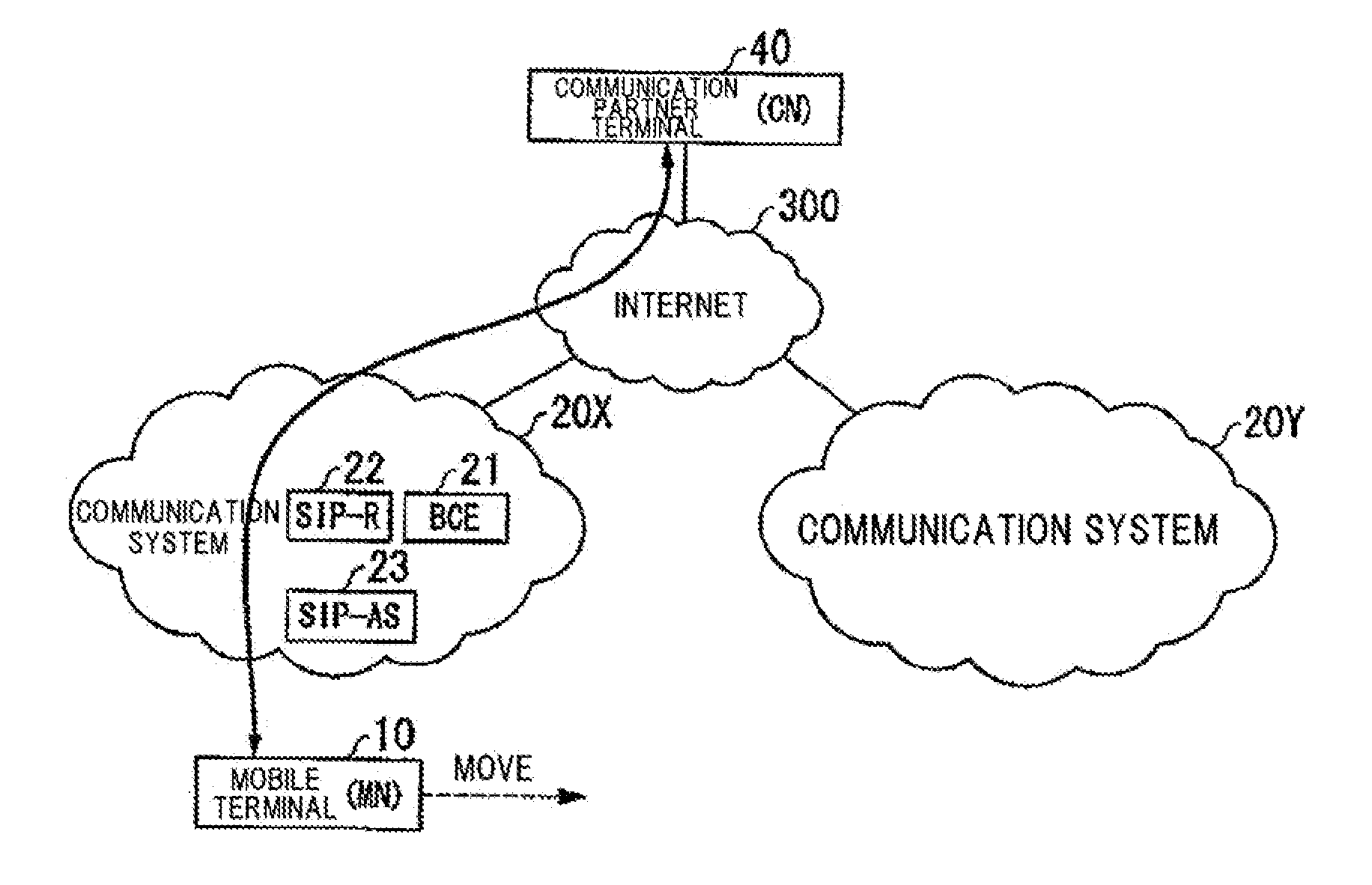

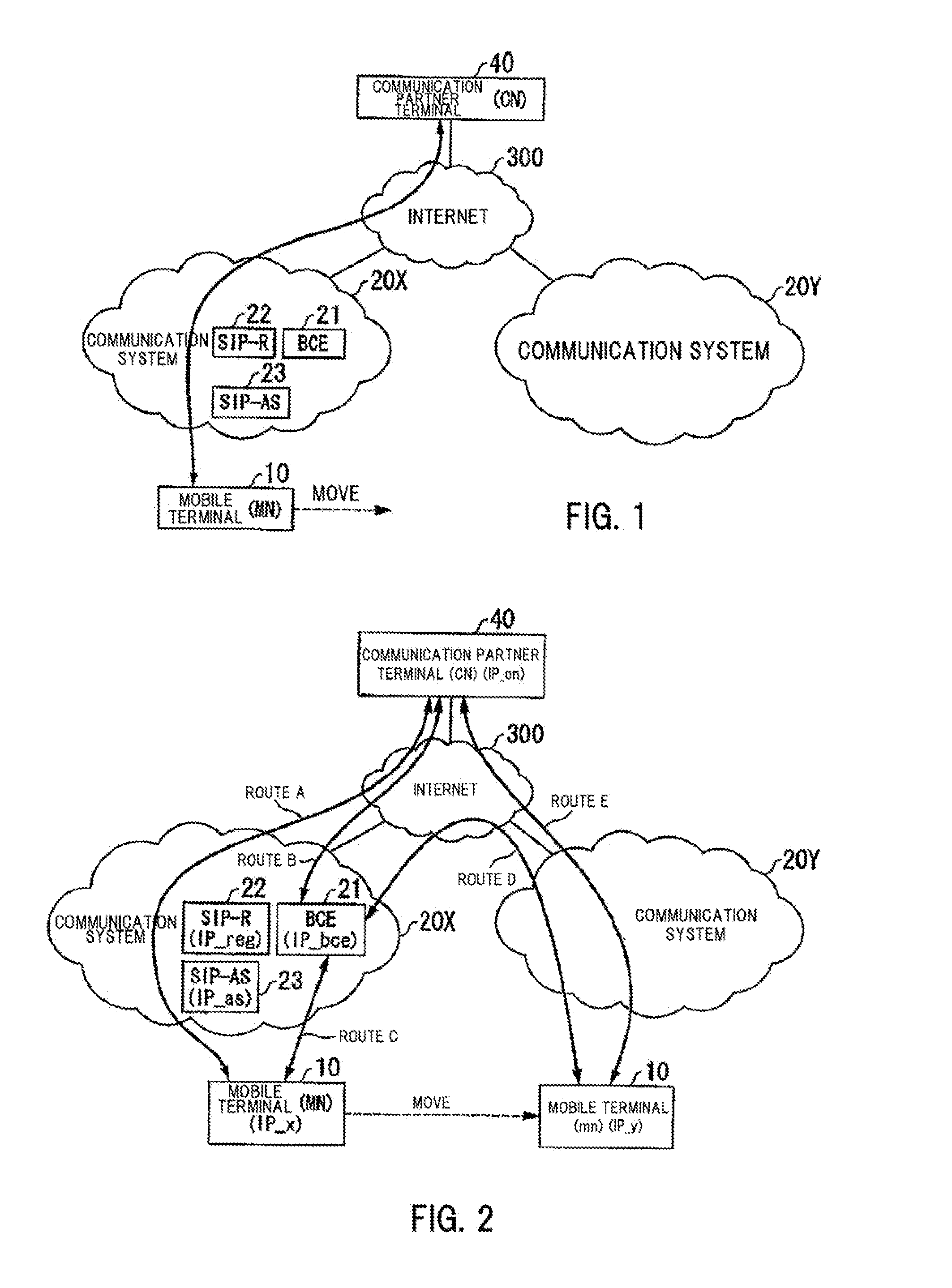

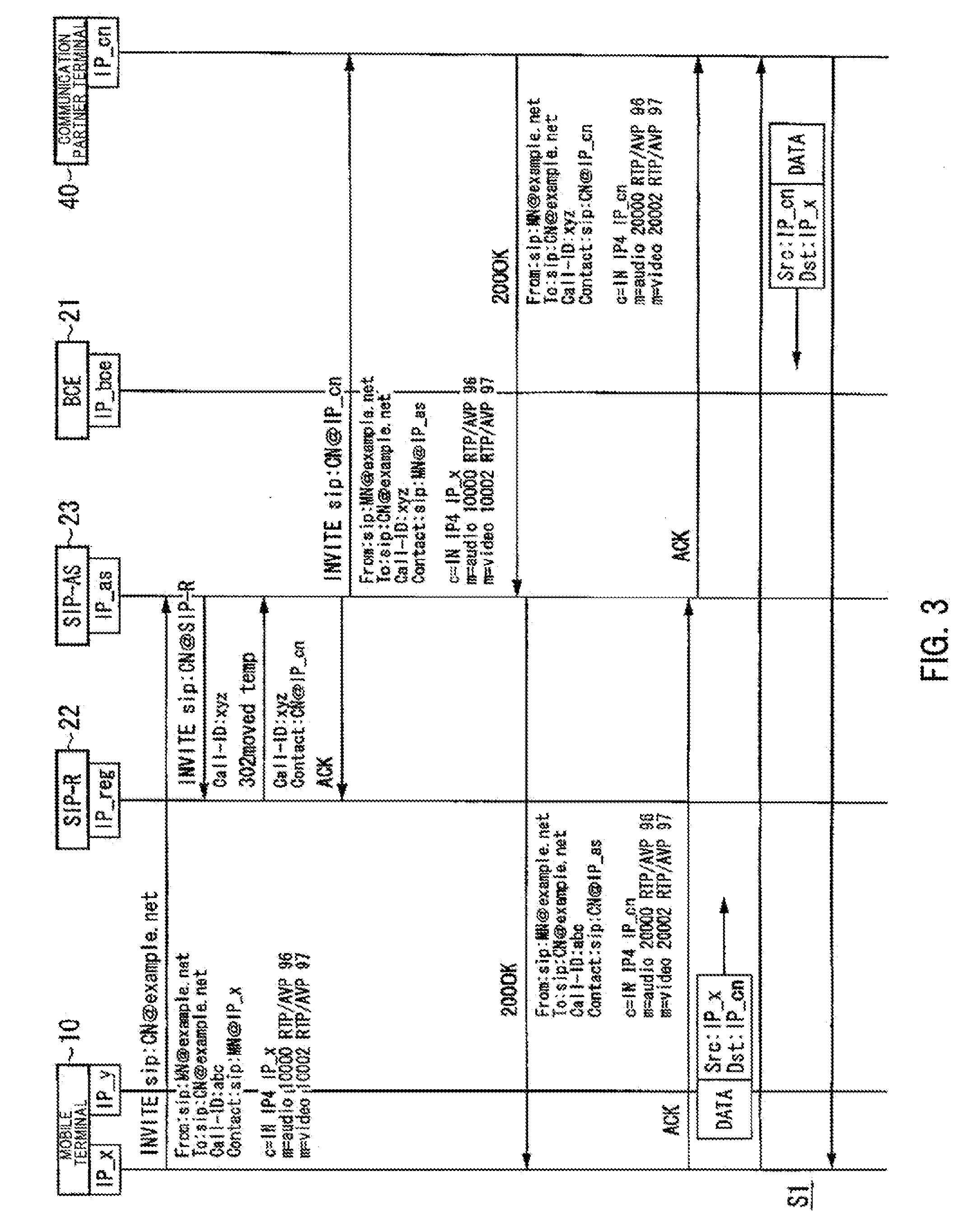

Communication relay apparatus, wireless terminal and computer program

InactiveUS20080039091A1Reduce rapid changePrevent inversionConnection managementWireless network protocolsDelayed timeHandover

In order to continue a communication by performing a handover across or between different communication systems, improvement in redundancy of a communication route and a delay time difference before and after switching the communication system is intended. A bicast entity 21 includes, when a wireless terminal 10 makes a connection and continues a communication across different communication systems 20X and 20Y, bicast means for delivering a packet for each communication route via each of the communication systems 20X and 20Y before and after switching the communication system to which the above described wireless terminal 10 connects, and control means for completing a relay of the packet when the switching of the communication system to which the above described wireless terminal 10 connects is completed.

Owner:MOTOROLA INC +2

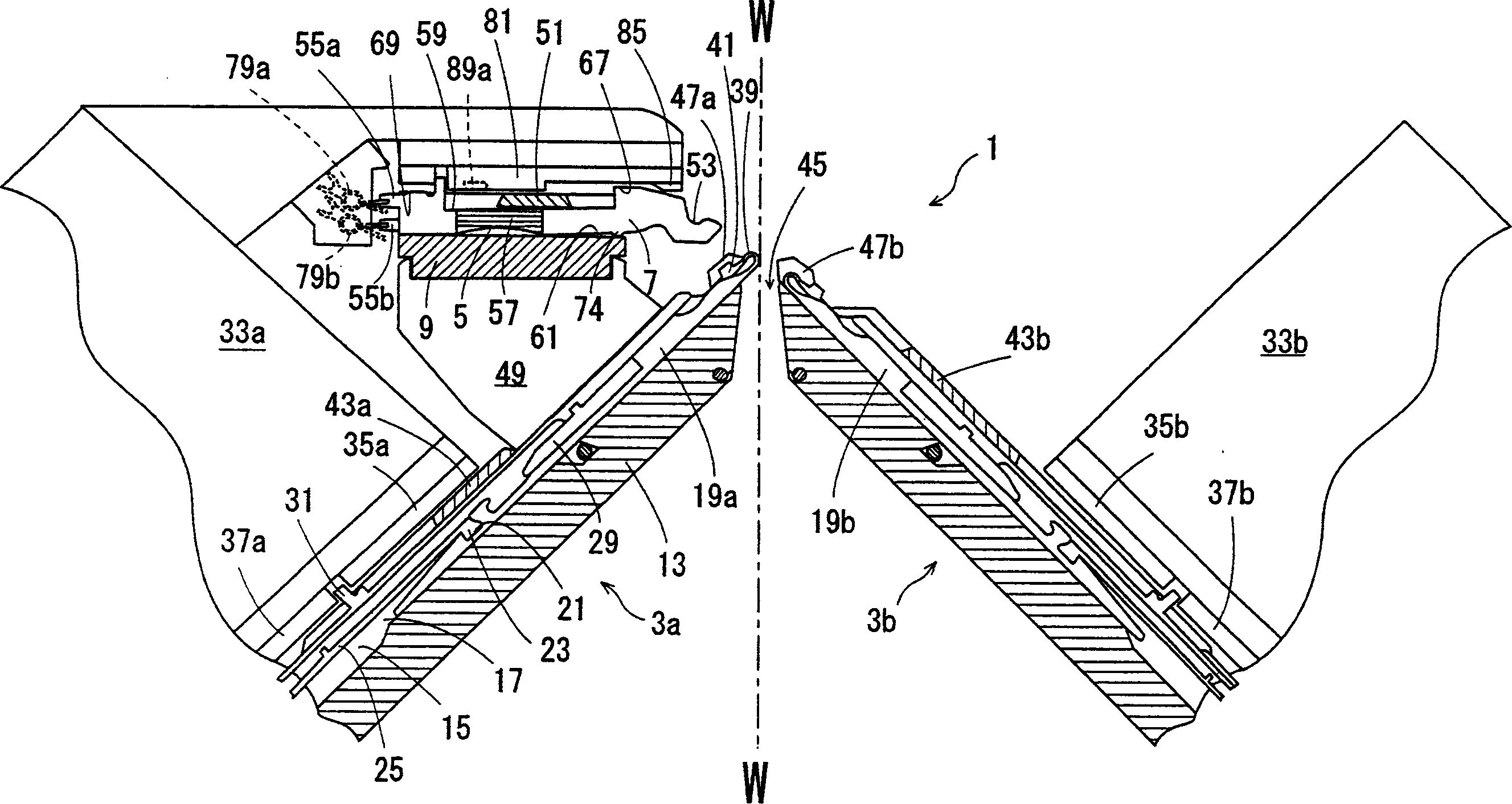

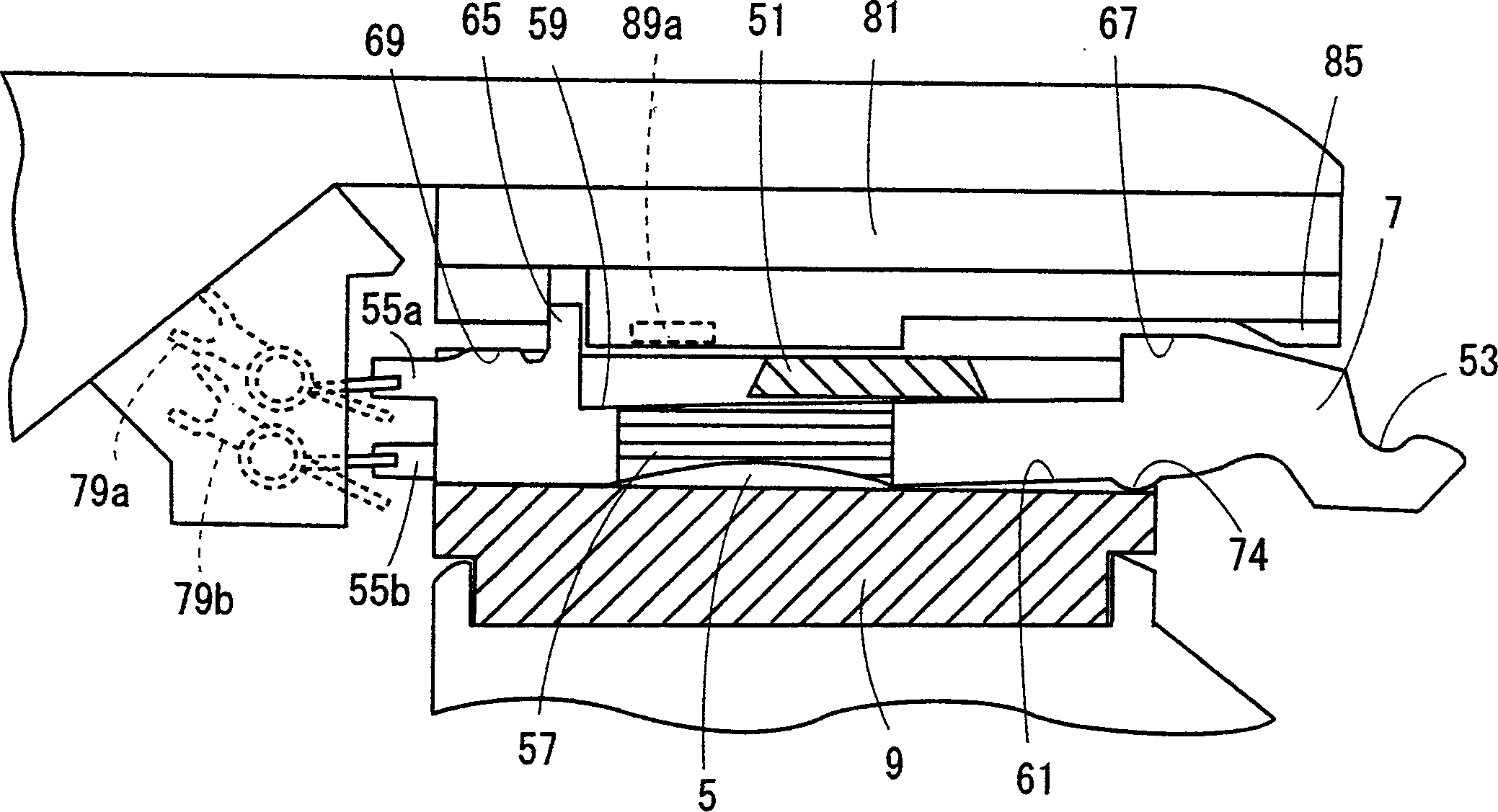

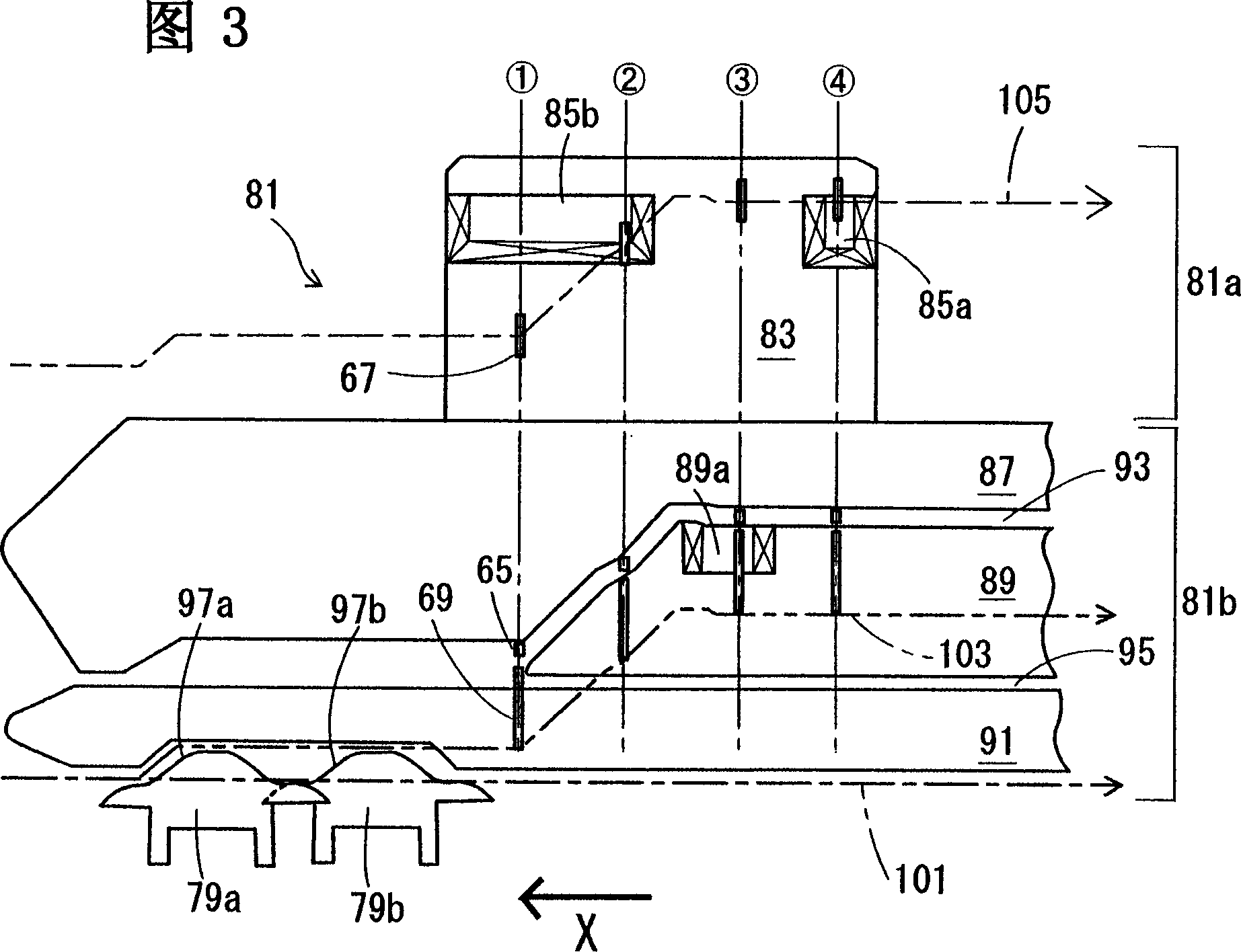

Weft knitting machine with transferring mechanism and transferring method

A weft knitting machine, comprising a transfer jack bed (9) holding a transfer jack (7) so as to be movable forward and backward, wherein, when a transfer is made from the transfer jack (7) to a needle (19), a hook rear surface part (39b) of the needle (19) is advanced into a loop (111) locked to a loop locking part (53) of the transfer jack (7) after the loop locking part (53) of the transfer jack (7) located at an advanced position is lowered to a down position, and a hook front surface part (39a) of the needle is advanced into the loop after the loop locking part (53) is raised to an upper position, whereby the loop can be surely exchanged and the transfer capable of reducing a load on the loop can be made through a common route for the needles of a front bed (13a) and a rear bed (13b).

Owner:SHIMA SEIKI MFG LTD

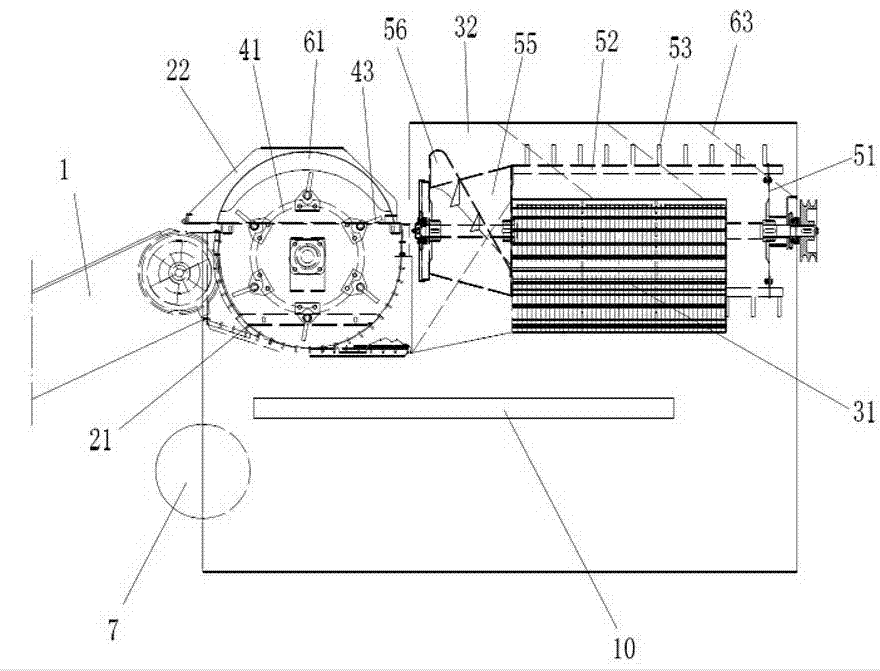

Threshing structure of L-shaped horizontal and longitudinal axial flow full-feeding combine harvester

InactiveCN103609250ALarge amount of feedImprove work efficiencyMowersThreshersTransverse axisEngineering

The invention relates to the technical field of agricultural machinery, in particular to a threshing structure of an L-shaped horizontal and longitudinal axial flow full-feeding combine harvester. The threshing structure comprises a threshing rack, a vibrating screen arranged on the threshing rack, an air blower and a middle conveyor connected on the upper portion of the front end of the threshing rack, a threshing drum communicated with the rear end of the middle conveyor is arranged on the threshing rack and comprises a horizontal axial flow drum and a longitudinal axial flow drum which are in communicated connection and perpendicular to each other to be L-shaped, two ends of the horizontal axial flow drum are connected with the middle conveyor and the longitudinal axial flow drum respectively, and the middle conveyor and the longitudinal axial flow drum are arranged on two sides of the horizontal axial flow drum respectively. The threshing structure is large in feeding quantity and high in operating efficiency during harvesting, connection of a threshing, cleaning and selecting drum and a discharging port of the middle conveyor is smooth and small in loss, crops in the horizontal axial flow drum are good in threshing, cleaning and selecting effect, and a notch board screen is large in separating area.

Owner:曾联

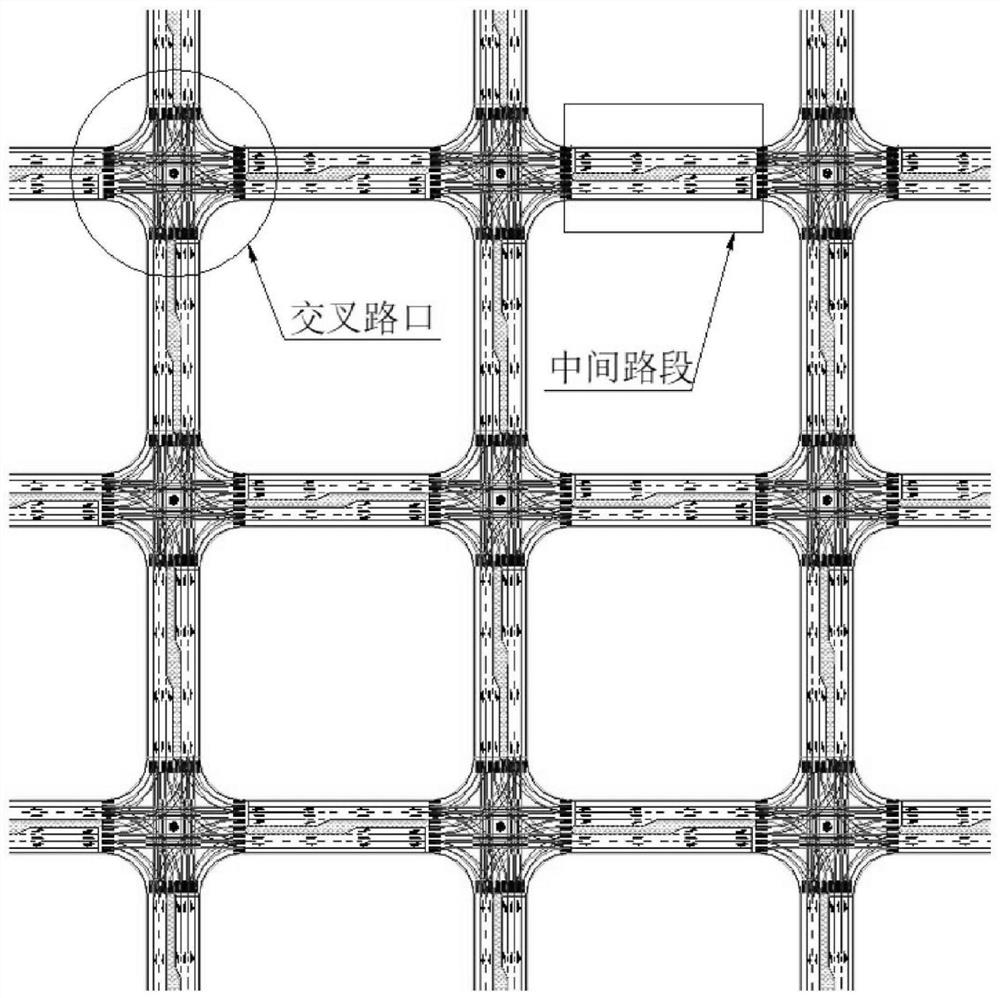

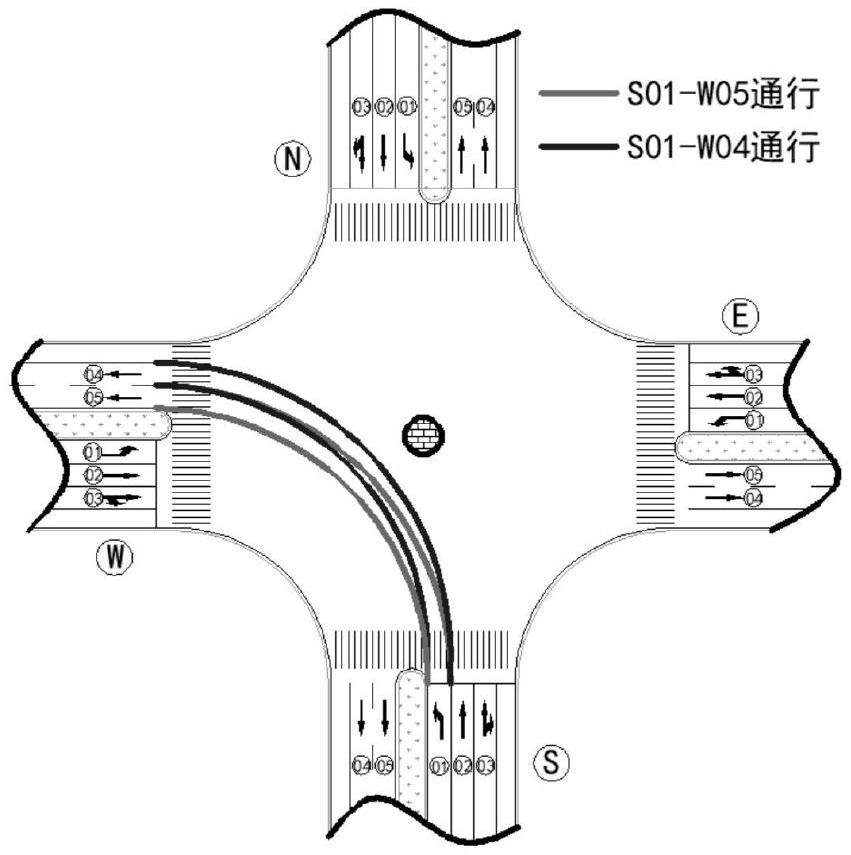

Intelligent traffic system for realizing high-grade automatic driving and efficient transportation

PendingCN112735184AImprove transportation efficiencyAvoid congestionAnti-collision systemsIntelligent transportation system itsTraffic network

The invention discloses an intelligent traffic system for realizing high-grade automatic driving and high-efficiency transportation, which mainly comprises five subsystems: a virtual track subsystem based on a high-precision map, and an intelligent traffic command subsystem which is positioned at an intersection and the like and has other crossed driving working conditions, wherein the intelligent driving vehicle, the motorcade movement and lane changing control subsystem, the road section entrance and exit entry and exit control subsystem and the coordination control subsystem based on the traffic network globally are located in the road section driving working condition. According to the invention, the increasingly mature automatic driving technology at present can be helped to achieve higher-level automatic driving, and by means of the controllability of automatic driving and the macroscopic and microscopic regulation and control of an intelligent traffic network, the transportation efficiency of the traffic network is improved, global control is realized, and congestion is prevented.

Owner:刘元敏 +2

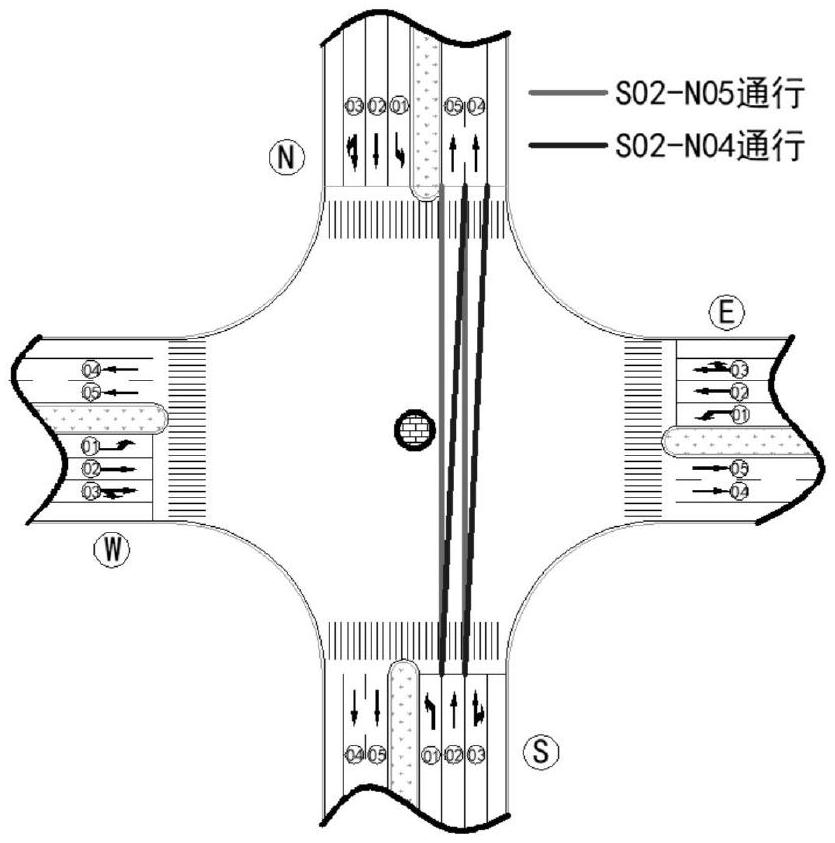

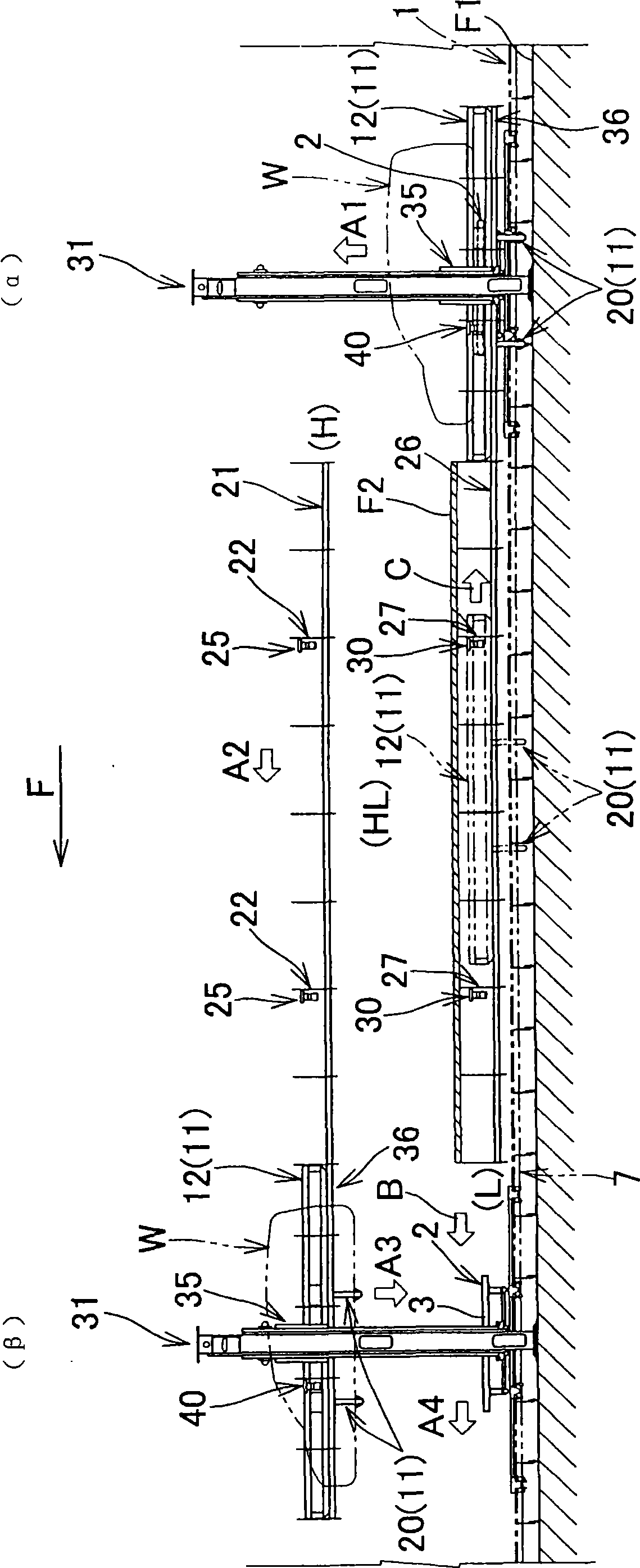

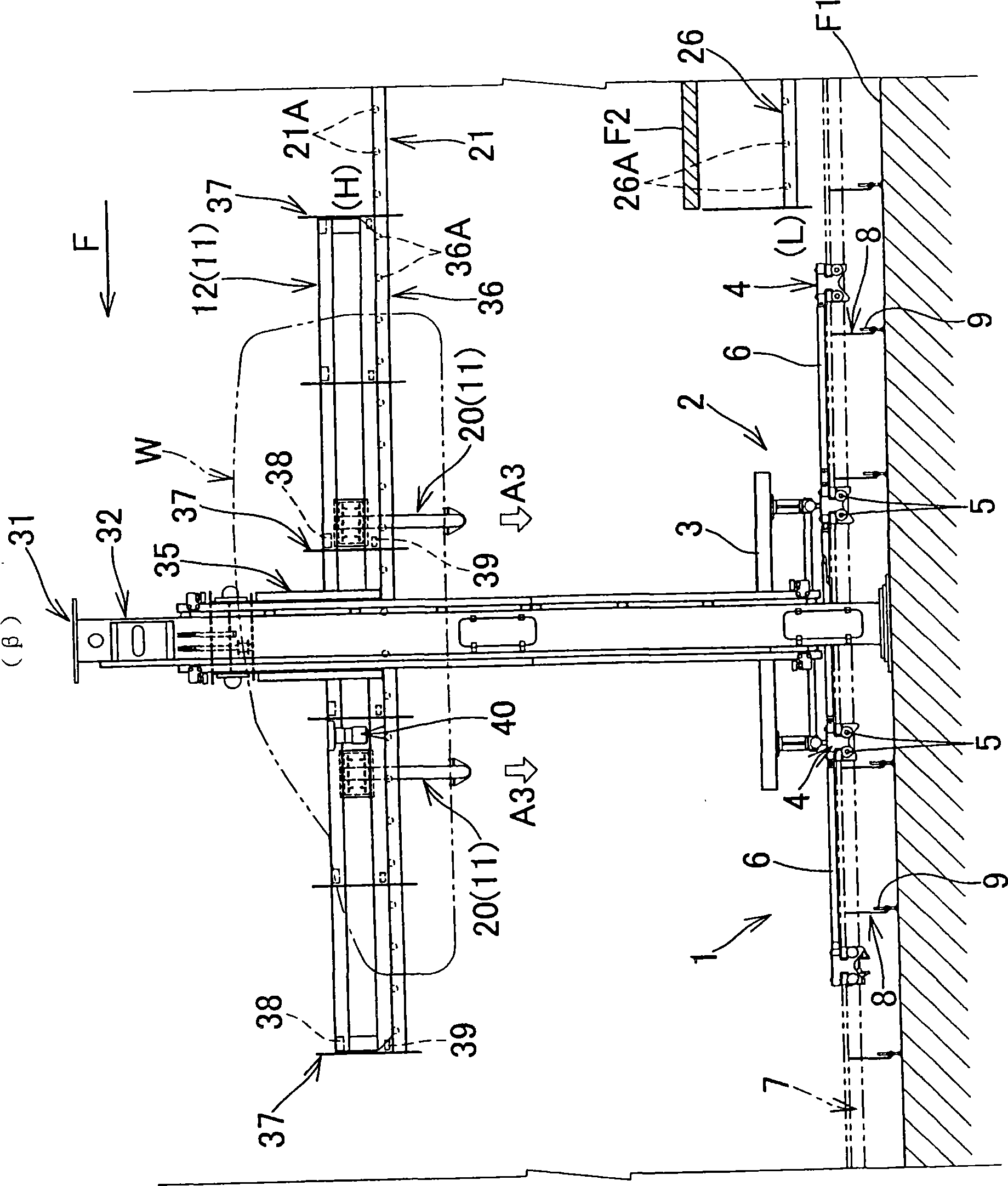

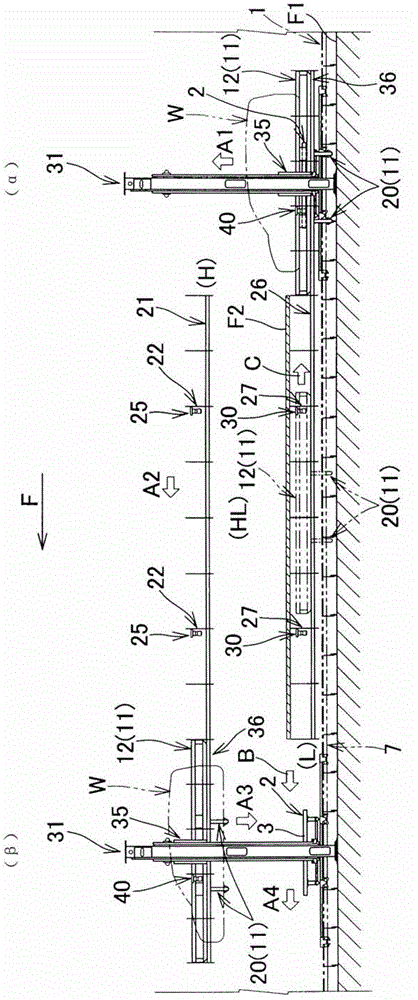

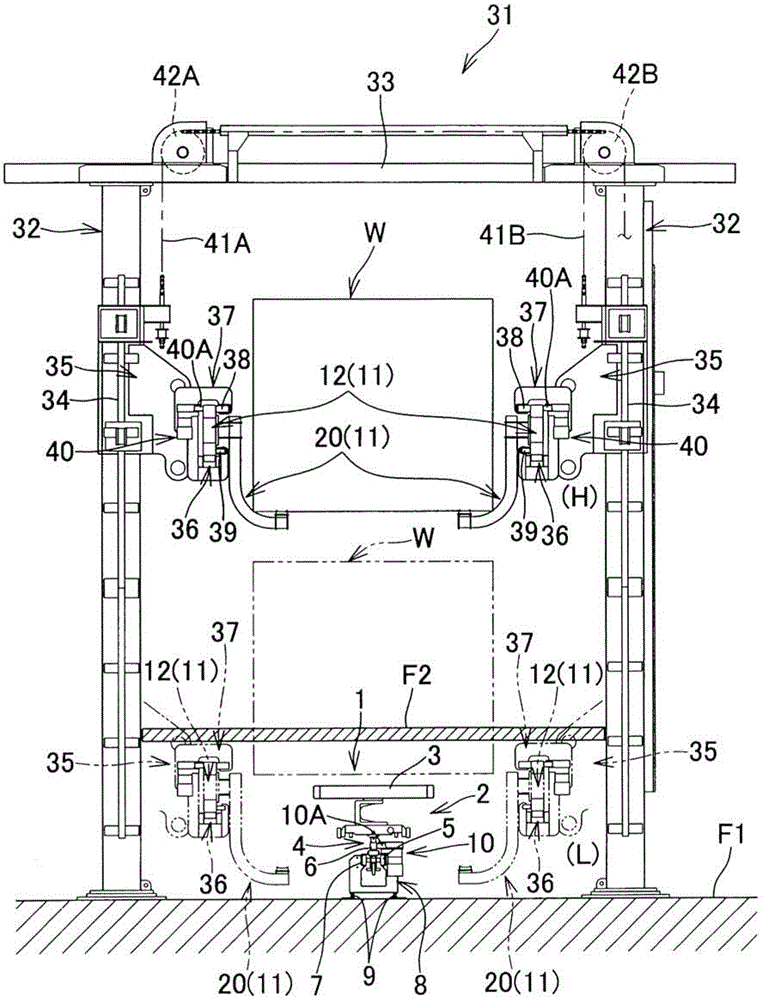

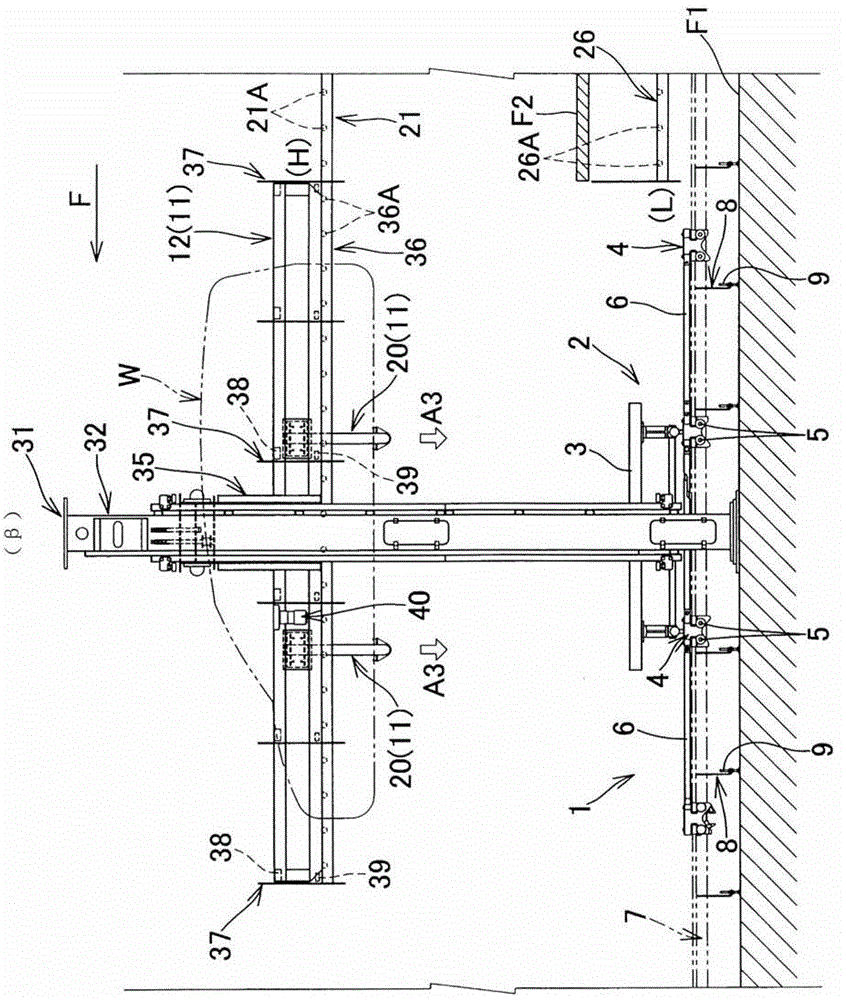

Carrying apparatus

ActiveCN101519165ALow construction costLow costLiquid surface applicatorsConveyorsEngineeringMoving load

The invention provides a carrying apparatus having a lifting operation line HL for moving load to a carrier(11) in the path of carrying a load W on a trolley(2) by a ground carrier(1); the carrier compries a left-and-right pair of rack bodies(12) and a bearing part; a fixed slide rail (21) used for the carrying line and a friction roller type driving device(25) for driving the loaded carrier downstream are arranged in a high position H; a fixed slide rail(26) used for the returning line and a friction roller type driving device(30) for driving the unloaded carrier upstream are arranged in a low position L under the fixed slide rail (21); a lifter(31), equipped with a friction roller type driving device(40) for driving the carrier supported on a lifting slide rail(36) in the fore-and-aft direction, is arranged at the upstream side alpha and the downstream side beta of the lifting operation line HL in a mode where the lifting slide rail is separately conntected with said fixed slide rails.

Owner:NAKANISHI METAL WORKS CO LTD

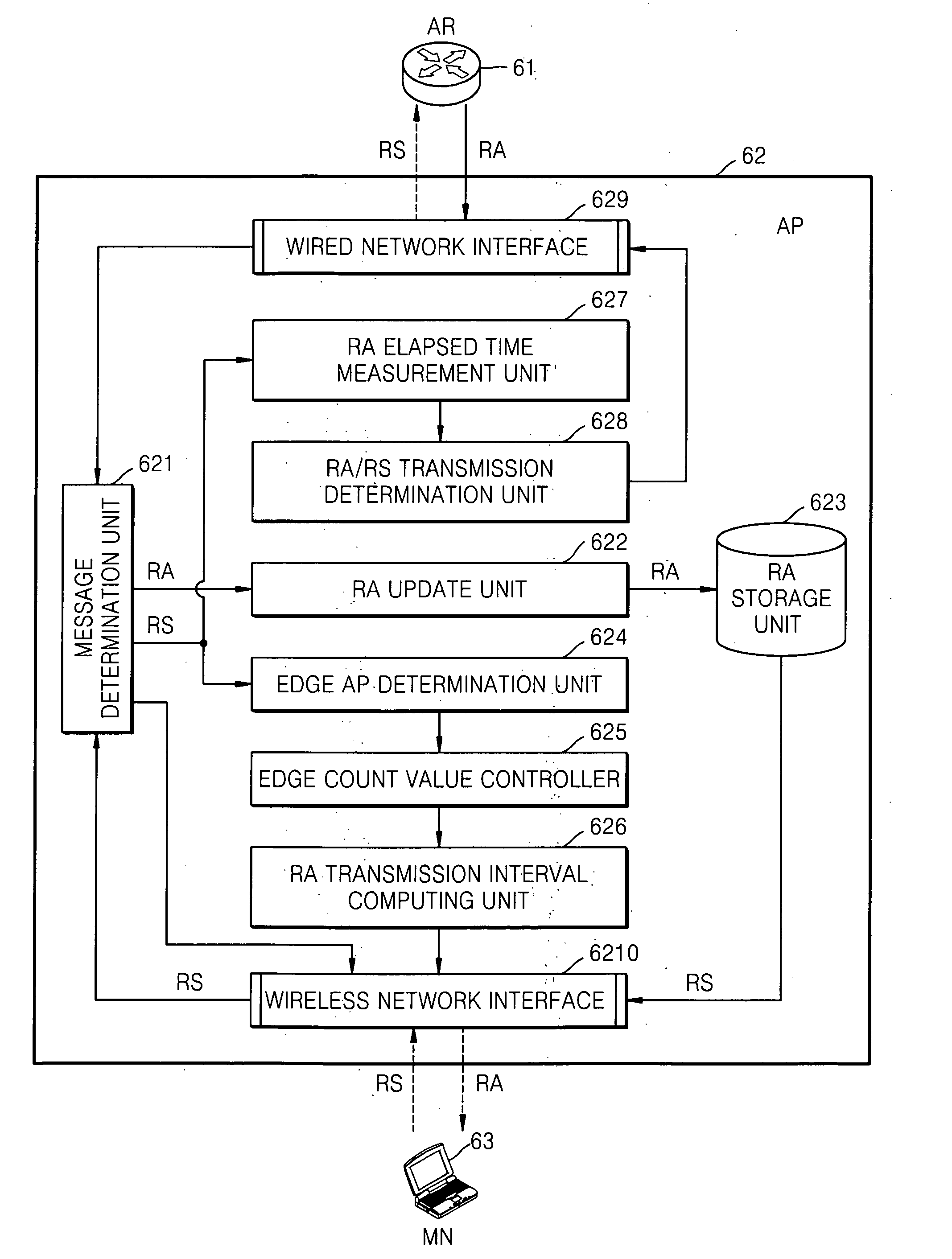

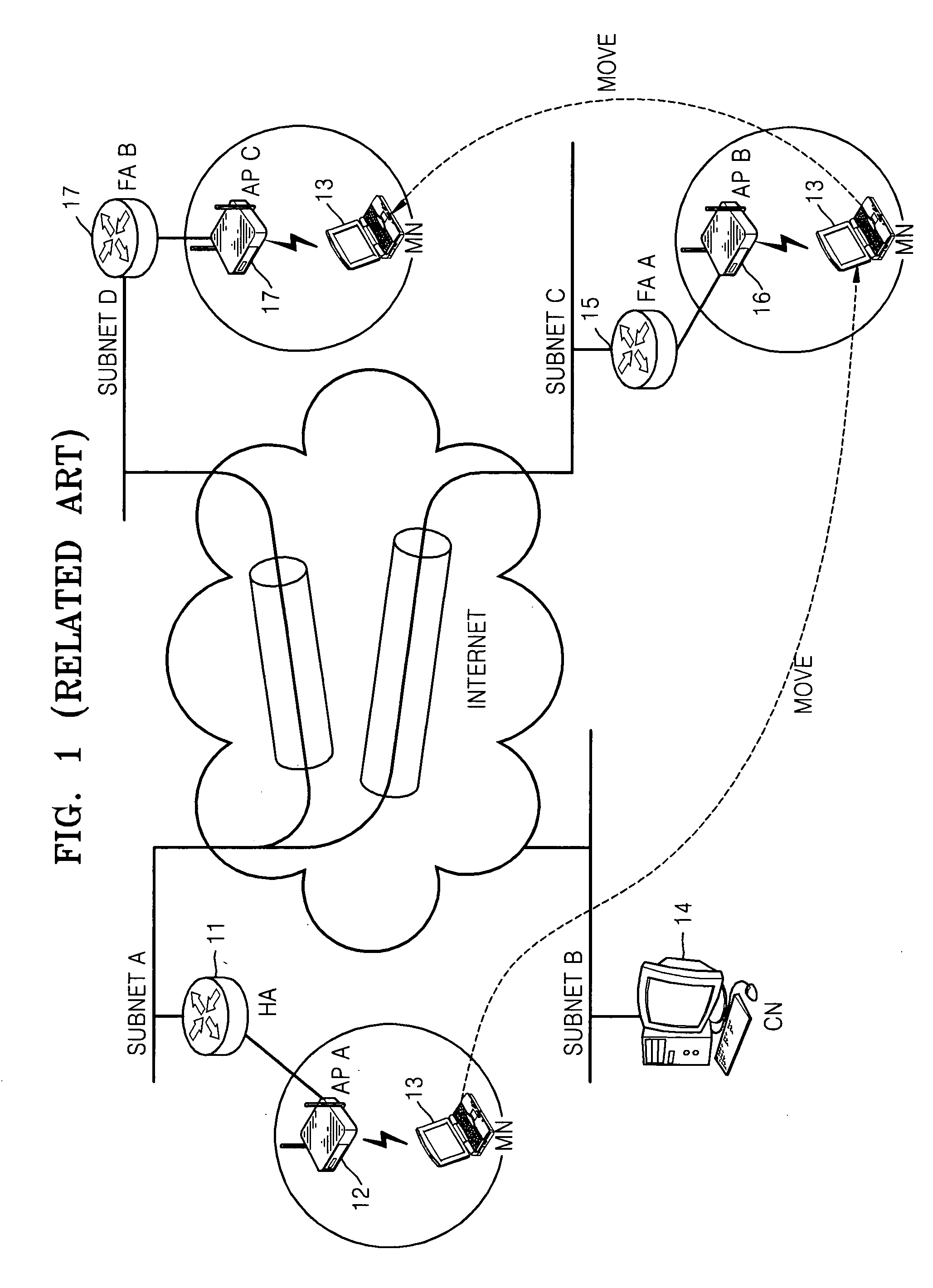

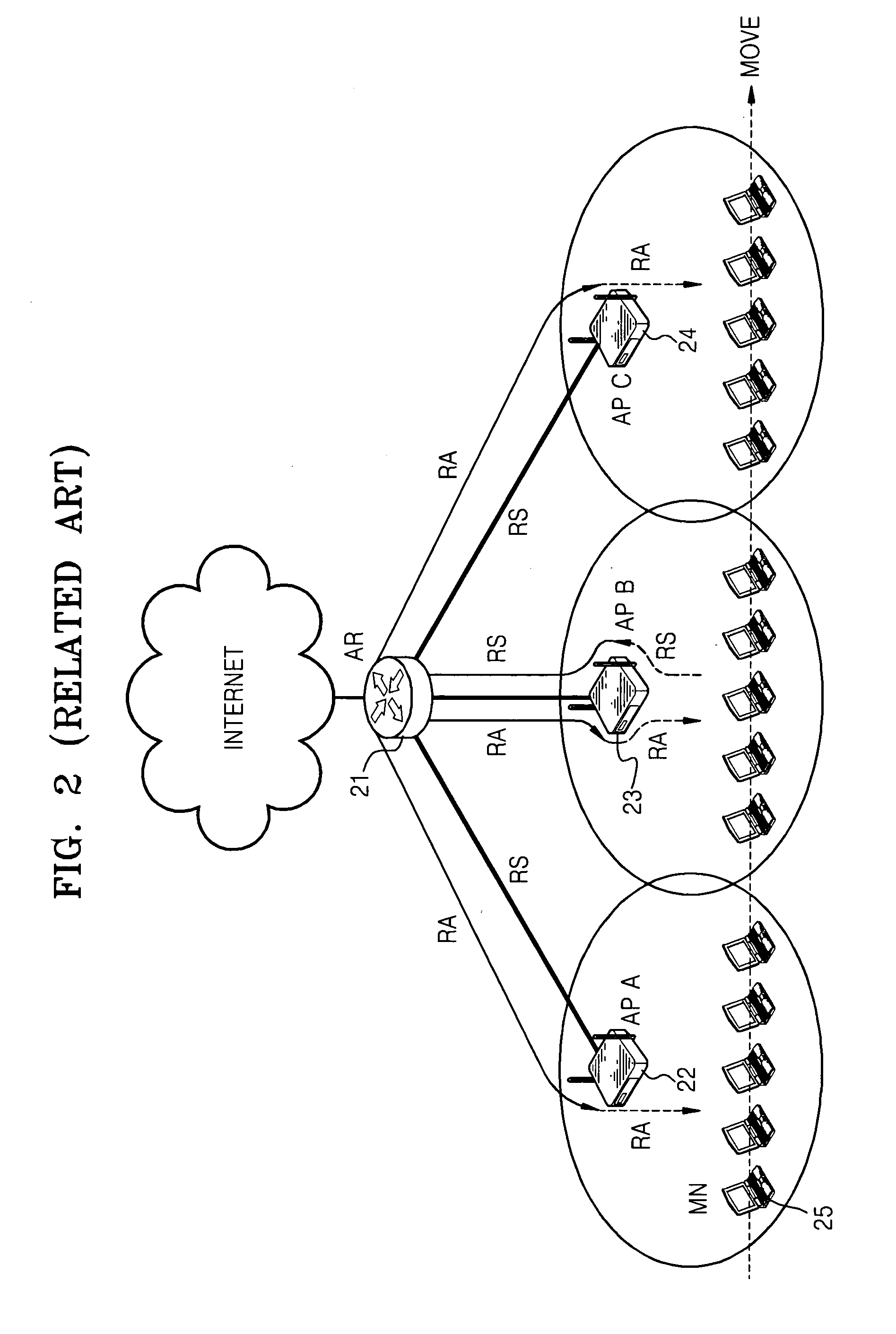

Method and apparatus for transmitting router advertisement and router solicitation messages through access point

ActiveUS20070171873A1Reduce wasteSmooth handoverNetwork traffic/resource managementSpecific water treatment objectivesComputer networkRouter advertisement

A method and apparatus for transmitting a message in a wireless network environment are provided. The method of computing an interval of message transmission in an access point located in a specific subnet, includes determining whether the access point is an edge access point located at a boundary between the specific subnet and a neighboring subnet, and computing an interval of transmission of a router advertisement (RA) message containing information regarding the specific subnet based on the determination result.

Owner:SAMSUNG ELECTRONICS CO LTD

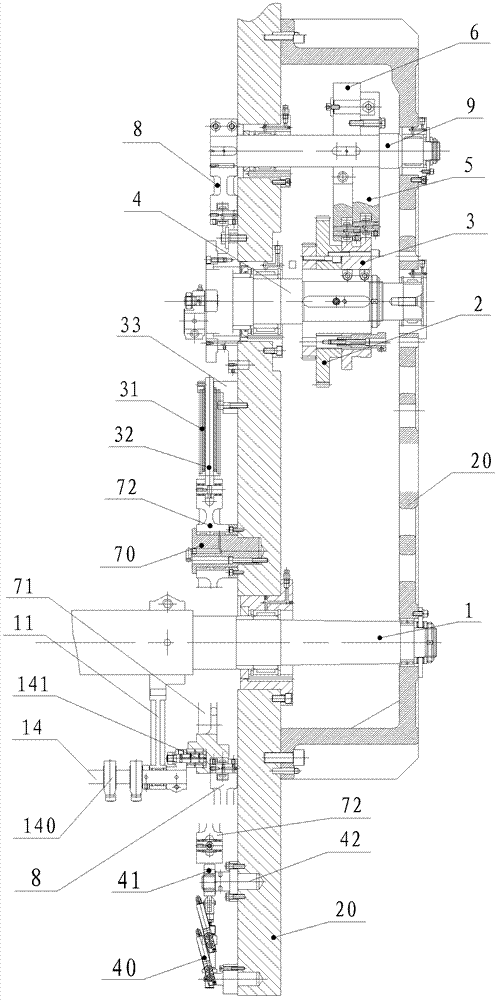

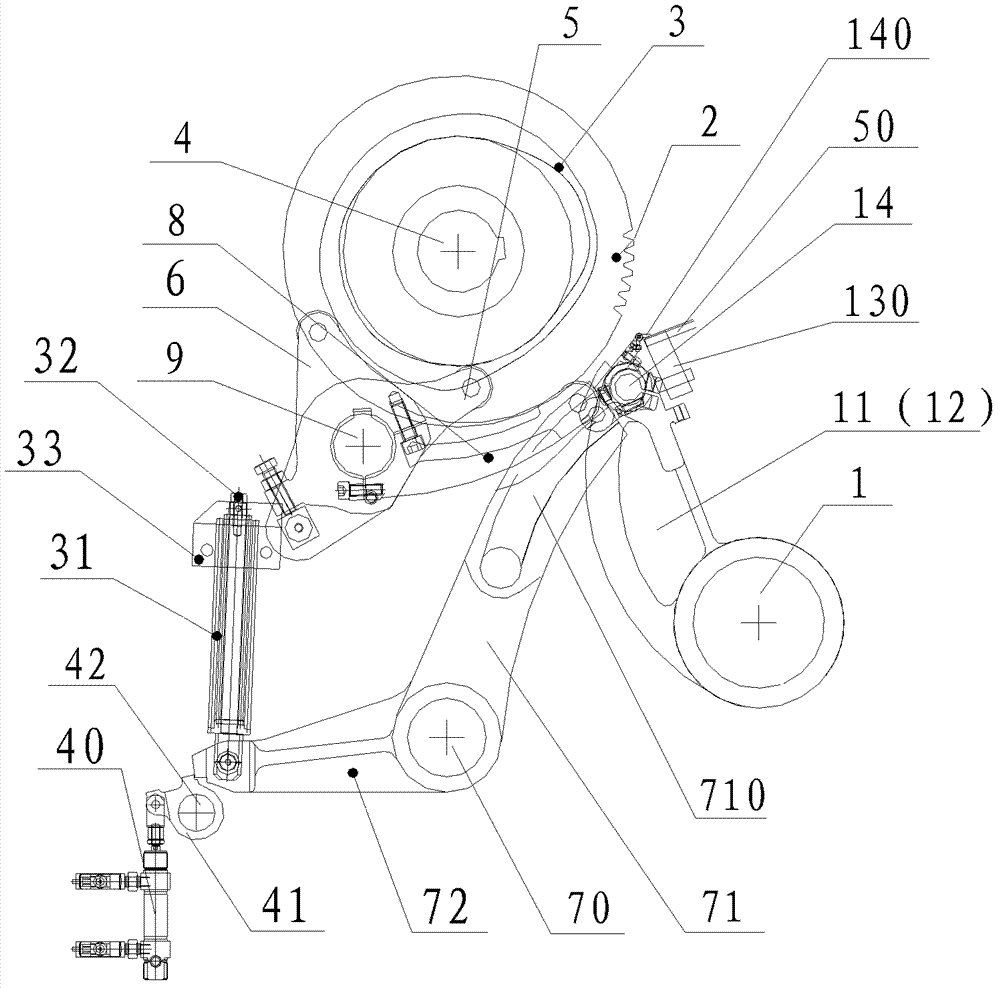

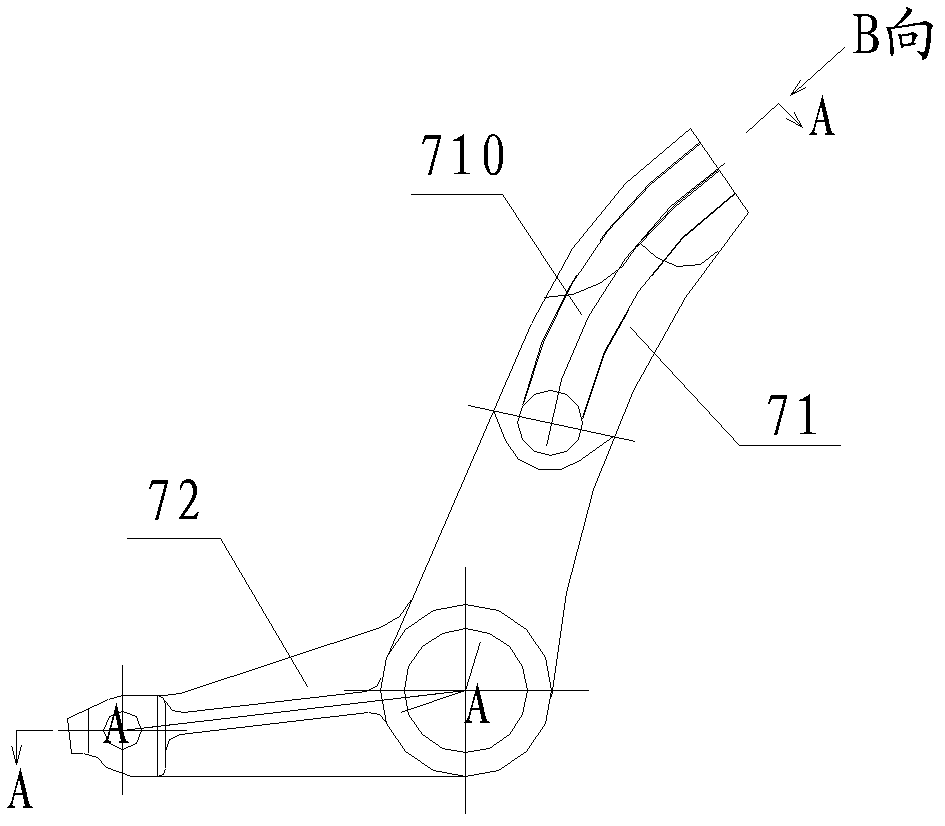

Armature opening and closing mechanism for paper transferring mechanism swinging downward

InactiveCN103085465ASimple structureSmooth and reliable actionPrinting press partsDrive shaftTransfer mechanism

The invention discloses an armature opening and closing mechanism for a paper transferring mechanism swinging downward. The armature opening and closing mechanism for the paper transferring mechanism swinging downward comprises a paper transferring hand, a driving mechanism, a driven mechanism and a stop motion mechanism. The paper transferring hand comprises an engaging shaft and an opening and closing armature ball connected with a driving end of the engaging shaft. A driving gear of the driving mechanism and a paper transferring armature control cam are fixedly installed on a driving shaft. A pair of swing rods of the driven mechanism is fixedly installed on a swing arm shaft, and end heads of the pair of swing rods are respectively arranged on periphery surfaces of the main curve and the conjugate curve of the paper transferring armature control cam in fit mode. A swing rod cam comprises a main body and a tail rod portion, wherein the swing rod cam is fixedly installed on an installing shaft, and a curved groove is arranged on the inner side face of the main body of the swing rod cam, so that the opening and closing armature ball is inserted in the curved groove in scrollable mode. A swing arm is fixedly installed on the swing arm shaft, and the end head of the swing arm is arranged on the periphery surface of the main body of the swing rod cam in fit mode. The stop motion mechanism comprises a protective air cylinder installed on the inner side face of a wallboard on a driving side and a stop block connected onto the end head of a piston rod of the protective air cylinder.

Owner:SHANGHAI GUANGHUA PRINTING MACHINERY +1

Delivery mechanism for radiopharmaceutical drug-drawing conveying device

InactiveCN109674654AEffective isolationReduce exposurePharmaceutical containersMedical packagingEngineeringManipulator

The invention relates to a delivery mechanism for a radiopharmaceutical drug-drawing conveying device. The delivery mechanism is arranged as a chain conveying mechanism; a conveying manipulator used for clamping an injector and moving following a conveying chain is arranged on the conveying chain of the chain conveying mechanism; the conveying manipulator comprises a conveying support plate, conveying clamp pieces, a conveying spring, a needle-taking opening / closing device and a needle-conveying opening / closing piece; the conveying support plate is connected with the conveying chain; two oppositely arranged conveying clamp pieces are hinged on the front end of the conveying support plate; the conveying spring is arranged between the two conveying clamp pieces; an upper part of a push rod of the injector is clamped by the two conveying clamp pieces; the needle-taking opening / closing device is arranged on the outer side of one of the two conveying clamp pieces; the needle-conveying opening / closing piece is arranged on the conveying support plate; the needle-conveying opening / closing piece and the needle-taking opening / closing device are respectively located on the outer side of the conveying clamp pieces. The delivery mechanism for the radiopharmaceutical drug-drawing conveying device is capable of solving the conveying problem of injector, is capable of conveying the injector from a drug-drawing operation platform to an injection platform and requires no manual movement.

Owner:张伟峰

Three-dimensional loom weaving mechanism and using method thereof

InactiveCN105568513BEasy to tightenReduce the number of structuresLoomsOther shedding mechanismInsertion deviceBraid

A three-dimensional loom weaving mechanism comprises a heald lifting opening device, a weft insertion device, a weft sliding device, a weft fixing device and a beating-up device. When the weaving mechanism is used, a warp opening is formed by the heald lifting opening device through vertical staggering of different heald frames, the weft insertion device enables weft moves forward through a weft insertion rod and a weft insertion hook to penetrate through the warp opening, the weft penetrating out of the warp opening is dragged through the weft sliding device and the weft fixing device to facilitate follow-up weaving and beating-up, and the beating-up device conducts beating-up on weft and warp fabric; if a weft anti-carrying device is additionally arranged, weft connection between a vertical pull rod and a fixing rod is facilitated. The design is simple in structure, and high in working efficiency and precise control degree, the warp opening effect is good, the weft anti-carrying function is good, and the environmental protection property is high.

Owner:FOSHAN CIHUI TONGDA SCI & TECH

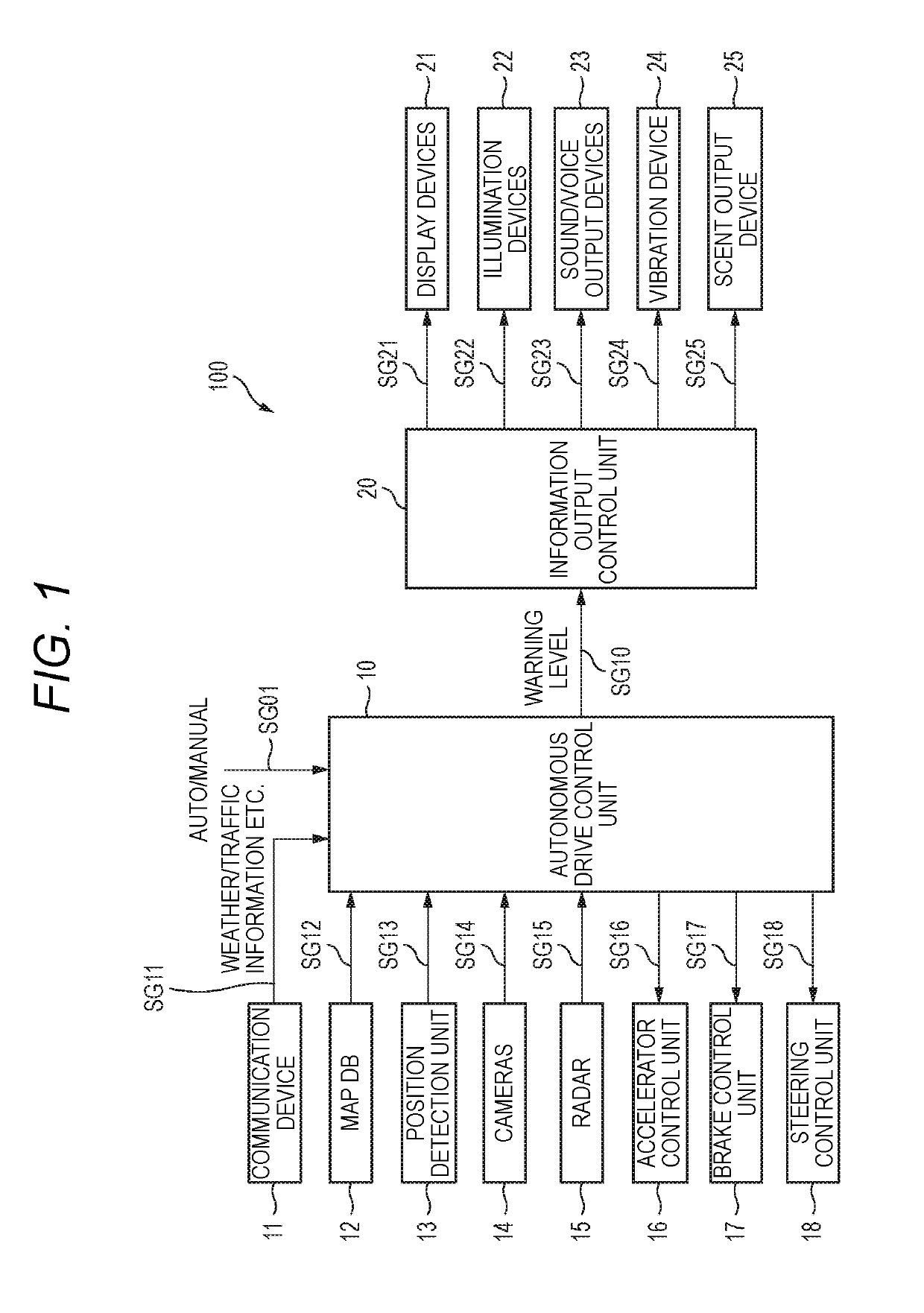

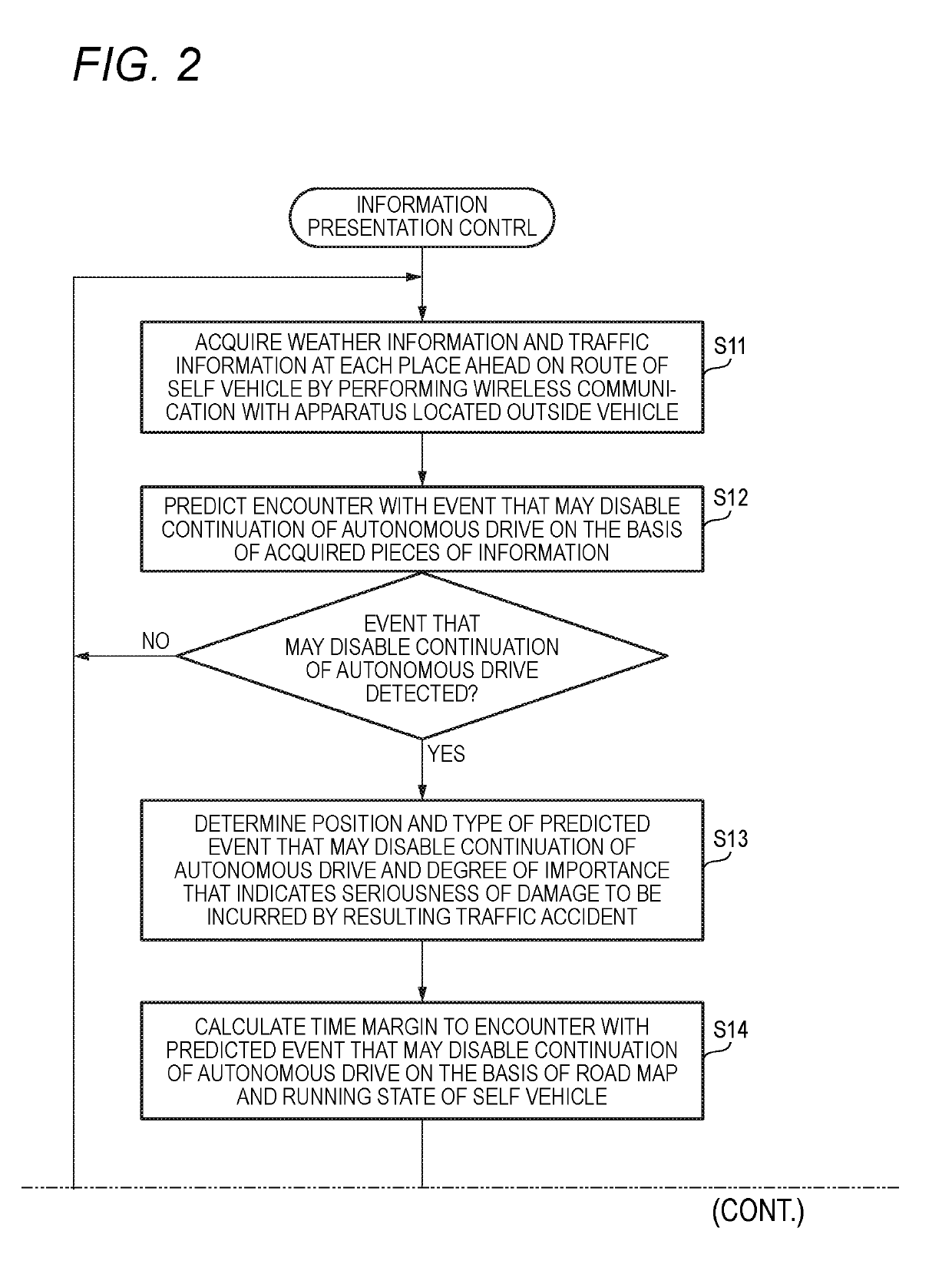

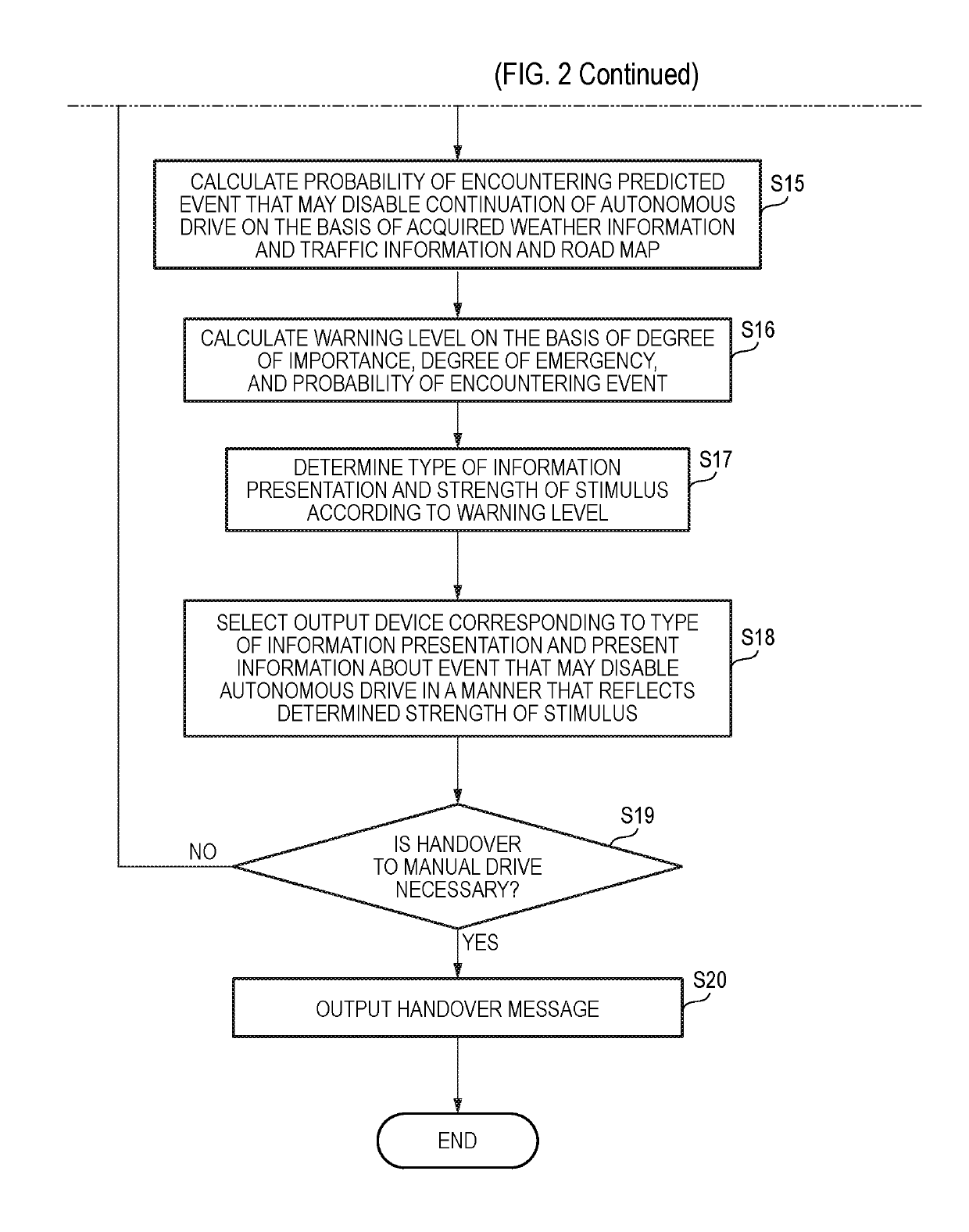

Method for conveying information during an autonomous drive and vehicular information presenting device

InactiveUS20190111942A1Smooth handoverSuppress lowering of comfortabilityControl safety arrangementsAutonomous decision making processContinuationEngineering

If an event that the self vehicle will encounter as it runs along a current course and may disable continuation of an autonomous drive is detected, a warning level is calculated taking into consideration the probability of an encounter, the degree of emergency, the degree of importance, etc. of the event, a form of information presentation and strength of a stimulus are determined automatically according to the warning level, and information is presented with a proper time margin before the vehicle comes close to a position of occurrence of the event. Where the probability of an encounter, the degree of emergency information, and the degree of importance are low, information is presented at a lowest notification level, whereby the comfortability of the autonomous drive can be maintained.

Owner:YAZAKI CORP

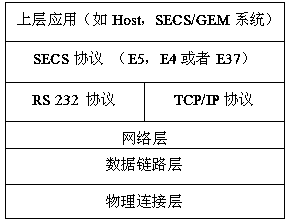

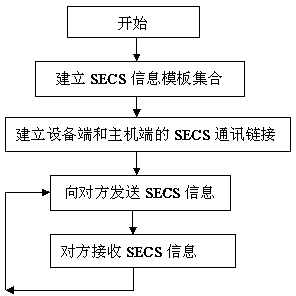

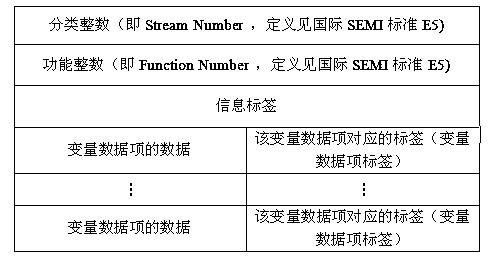

Label-based communication method for semiconductor device in remote control

ActiveCN103513639ARealize localizationIncrease production capacityTransmissionTotal factory controlComputer hardwareDevice material

A label-based communication method for a semiconductor device in remote control comprises the steps of first establishing an SECS information template assembly, establishing SECS connection between the device side and the host side and then performing SECS information transmitting and receiving between the device side and the host side. The SECS information template assembly comprises a device-side SECS information template assembly and a host-side SECS information template assembly, wherein the device-side SECS information template assembly comprises multiple device-side SECS information templates which are respectively configured for each production function, and the host-side SECS information template assembly comprises multiple host-side SECS information templates including SECS information formats corresponding to production functions in international SEMI standard E5 and all of necessary labels. All of necessary labels include one information label and all of necessary variable data item labels, wherein all of necessary variable data item labels are all of variable data item labels owned by the SECS information formats, and one variable data item label is necessarily provided for each variable data item.

Owner:周炳君

Cigarette packet conveying device of cigarette packaging machine

The invention discloses a cigarette packet conveying device of a cigarette packaging machine. The cigarette packet conveying device comprises a conveying belt, a negative pressure conveying guide plate and a negative pressure cavity, wherein negative pressure holes are formed in the negative pressure conveying belt, negative pressure guide holes are formed in the negative pressure conveying guide plate, and the negative pressure cavity is communicated with the negative pressure holes in the negative pressure conveying belt through the negative pressure guide holes in the negative pressure conveying guide plate. Compared with the prior art, the cigarette packet conveying device of the cigarette packaging machine has the advantages that the smooth takeover and transition of a cigarette packet can be realized, the speed and position of the cigarette packet entering a belt with rubber particles can be accurately controlled, and the service life of the negative pressure conveying belt can be greatly prolonged.

Owner:CHINA TOBACCO GUANGDONG IND

Conveying apparatus

The invention provides a conveying apparatus. The conveying apparatus has a hoist work line HL on the way of a path for conveying an object W to be conveyed on a truck with a floor conveyer 1. On the hoist work line HL, the object W to be conveyed on a truck 2 is replaced to a carrier 11 for work. The carrier 11 is provided with a pair of right and left frame bodies 12 and a receiving member. The conveying apparatus is installed with a fixed rail 21 for a conveying line in a high position H and with a friction roller type drive unit 25 for driving an actual carrier 11 to the downstream side. Further, the conveying apparatus is installed with a fixed rail 26 for a return line in a low position L immediately below the fixed rail 21 and with a friction roller type drive unit 30 for driving an empty carrier 11 to the upstream side. In addition, drop lifters 31, each of which is mounted with a friction roller type drive unit 40 for driving a carrier 11 supported by a hoisting and lowering rail 36 in the longitudinal direction, are installed on the upstream side (a) and the downstream side (b) of the hoist work line HL so that the hoisting and lowering rails 36 are connected to the fixed rails, respectively.

Owner:NAKANISHI METAL WORKS CO LTD

Line type supersonic wave bottle cleaning machine with gripping pipe hydrosphere control apparatus

ActiveCN101157086ACompact structureSmall footprintHollow article cleaningCleaning using liquidsSupersonic wavesEngineering

The invention discloses a linear type ultrasonic bottle washing machine having pipe-griping type aqueous vapor controlling devices, and the bottle washing machine comprises a machine frame, an aqueous vapor feeding device, and each component arranged on the machine frame. A water tank of the bottle washing machine is positioned at the lower part of an annular conveying mechanism, an ultrasonic bottle washing device is positioned respectively on the both sides at the bottom part of the annular conveying mechanism, one position of an upper bottle conveying rail of the annular conveying mechanism is connected with a bottle outlet wheel pushing mechanism in a matching way, the other position is connected with a bottle inlet wheel pushing mechanism in a matching way, a tracking flushing mechanism is positioned between the upper bottle conveying rail and a lower bottle conveying rail of the annular conveying mechanism, the aqueous vapor feeding device is mutually connected with the tracking flushing mechanism through a plurality of medium through pipes, the pipe-griping type aqueous vapor controlling devices are arranged on the medium through pipes, the cutting plates of the pipe-griping type aqueous vapor controlling devices are fixed on the machine frame, one end of a controlling unit supporting plate is fixed on the machine frame, a controlling unit is arranged at the other end, the controlling unit is mutually connected with pressing plates, and the pressing plates are positioned over the cutting plates. The invention has the advantages that the structure is simple and compact, the occupied space is small, the application rang is wide, the production efficiency is high, and the working quality is good, etc.

Owner:TRUKING TECH LTD

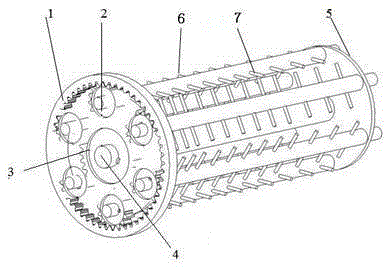

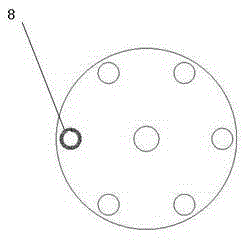

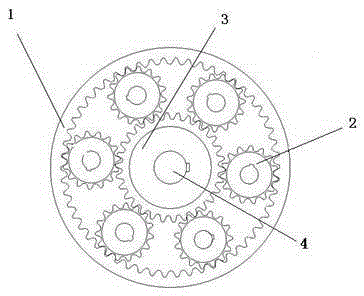

Threshing roller with rotatable toothed bar

The invention relates to a threshing roller with a rotatable toothed bar. The threshing roller comprises an amplification disc and a planetary gear train, wherein the planetary gear train comprises a planetary gear frame, a plurality of planetary gears and a central gearwheel; the inner side of the planetary gear frame is meshed with the planetary gears; each planetary gear is meshed with the central gearwheel; the central gearwheel is in key connection with a main shaft; the other end of the main shaft is in key connection with the amplification disc; each planetary gear is in key connection with a toothed bar shaft; the other end of each toothed bar shaft is fixedly arranged on the amplification disc through a bearing; a plurality of nail teeth are arranged on each toothed bar shaft. The threshing roller has the remarkable characteristics that the crop adaptability is high, blockage can be effectively prevented, the threshing rate of crops is improved, the size of a threshing device can be effectively reduced under the condition of the same feed quantity, and the production cost is reduced.

Owner:JIANGSU UNIV

Film sending and cutting method for plastic film machine

The invention discloses a film sending and cutting method for a plastic film machine. A film sending operation is started, so that a plastic film moves a set distance s so as to flatten out the plastic film, and in the process, a film drawing operation and rotation of a film cutter is not started or paused; the film drawing operation and rotation of the film cutter is started, and the section linear speeds of the film drawing operation and a film sending operation are controlled identical; when the plastic film is operated to the film cutting operation, the section linear speeds of the film drawing operation and the film sending operation are synchronously reduced, so that the film sending operation, the film drawing operation and rotation of the film cutter have the same section linear speed. The film sending and cutting method for the plastic film machine has the advantages of smooth and stable work, high work efficiency and the like.

Owner:TRUKING TECH LTD

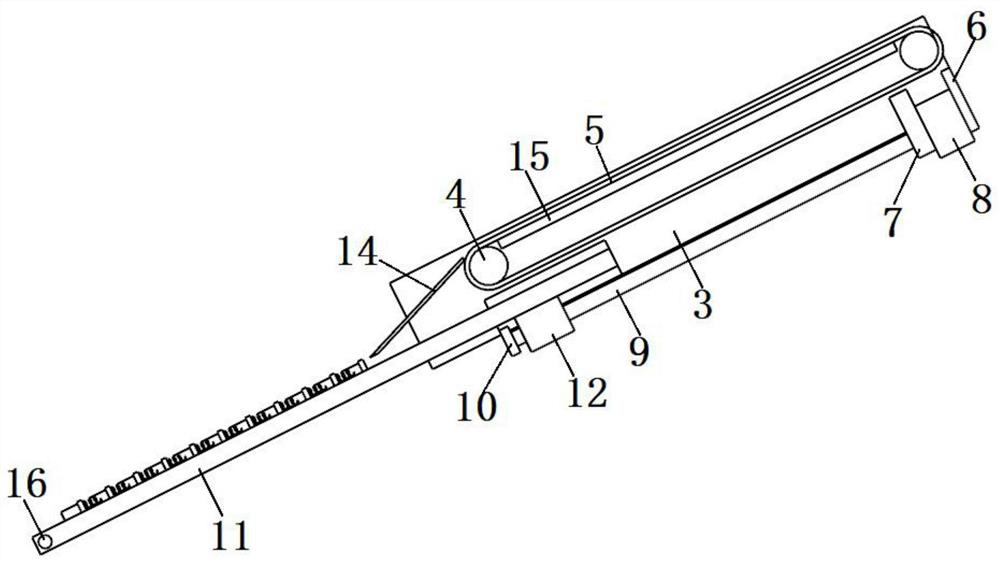

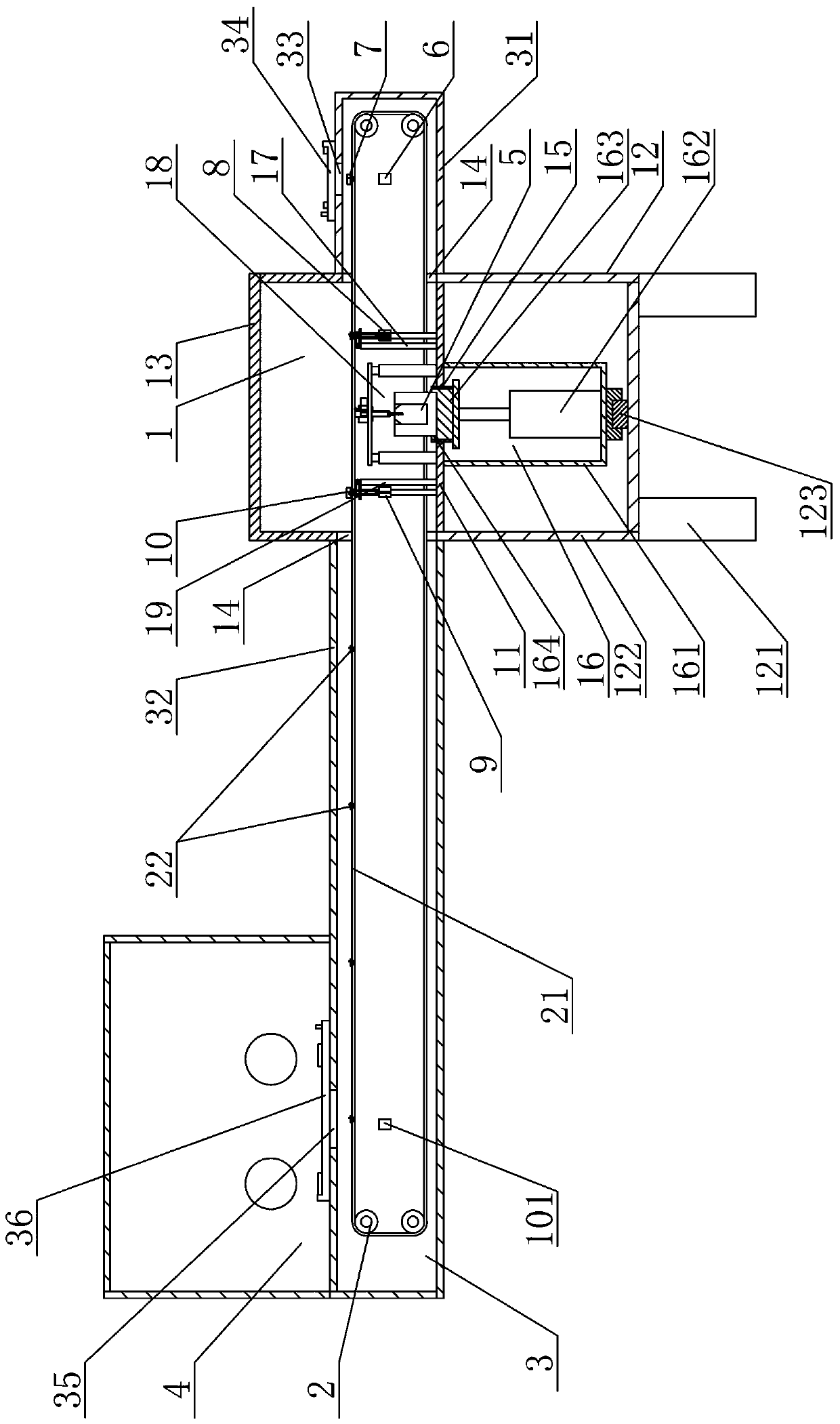

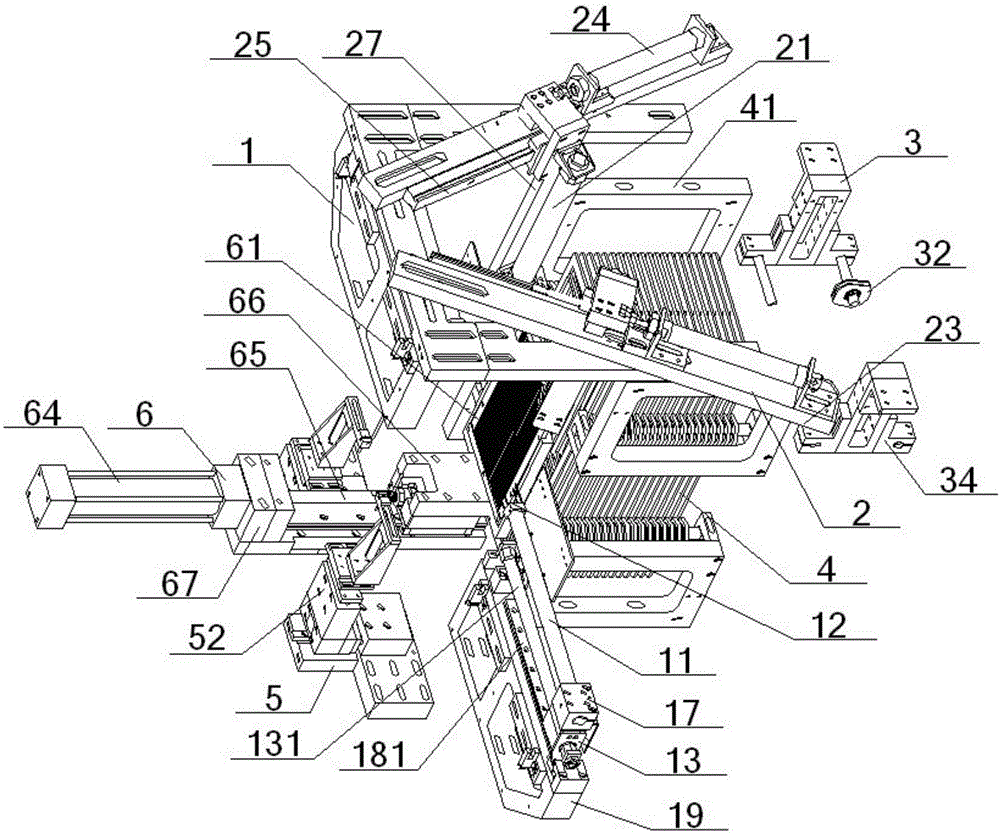

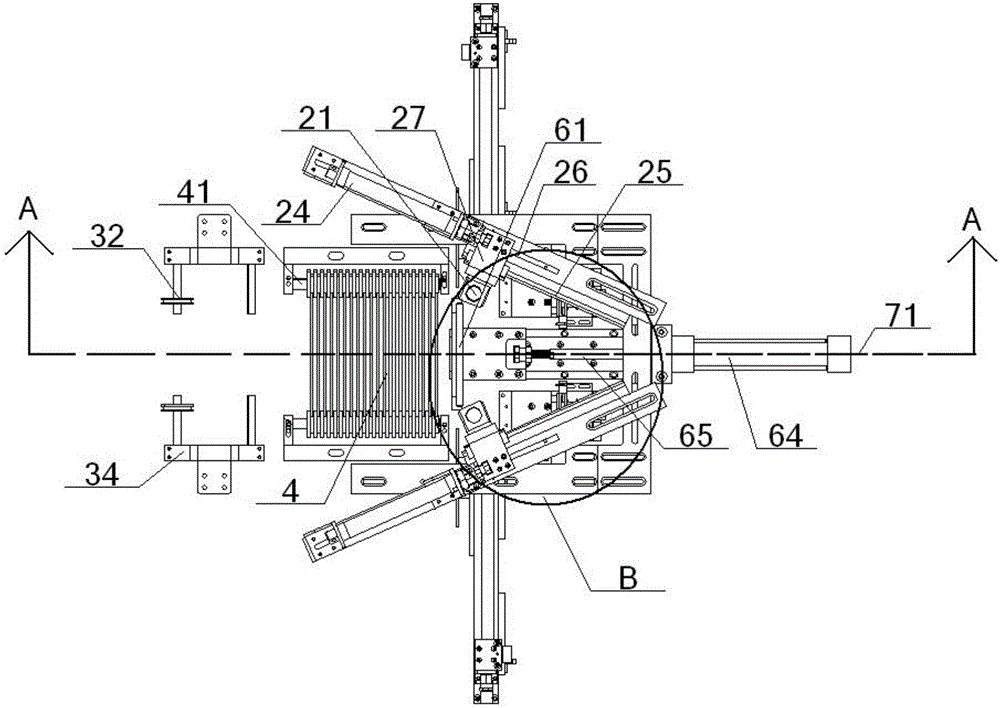

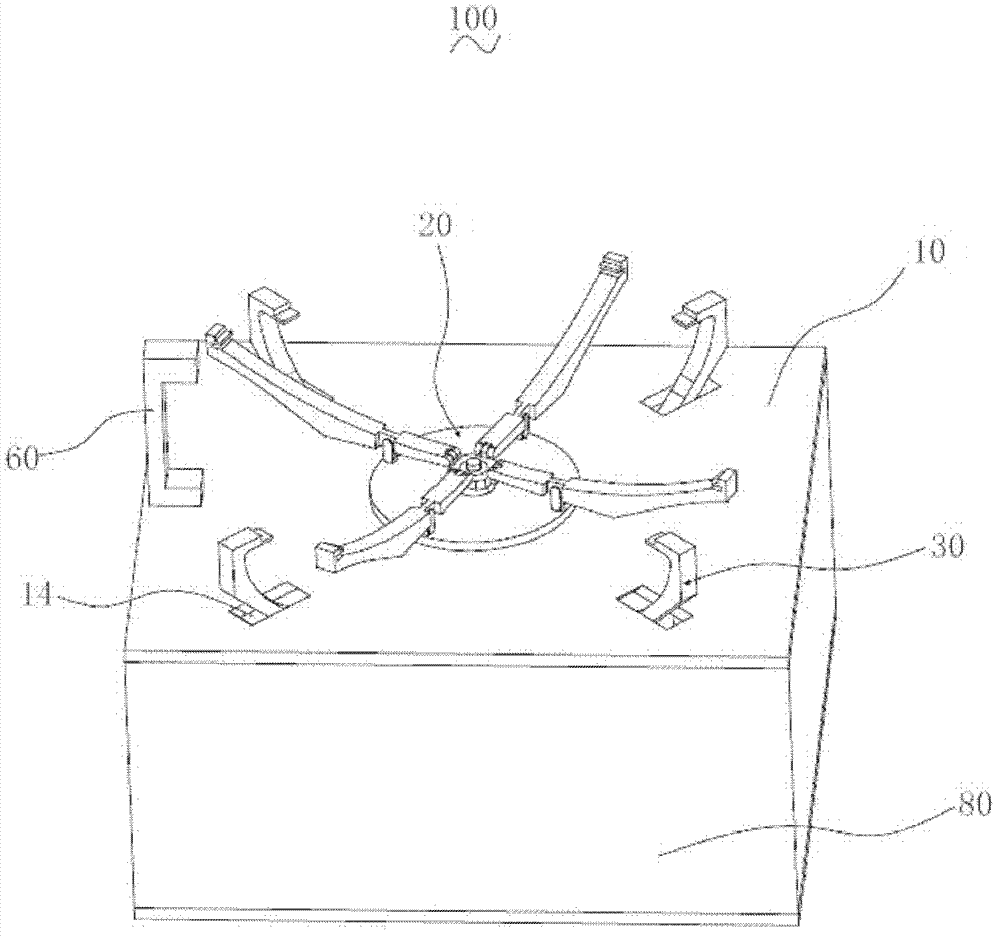

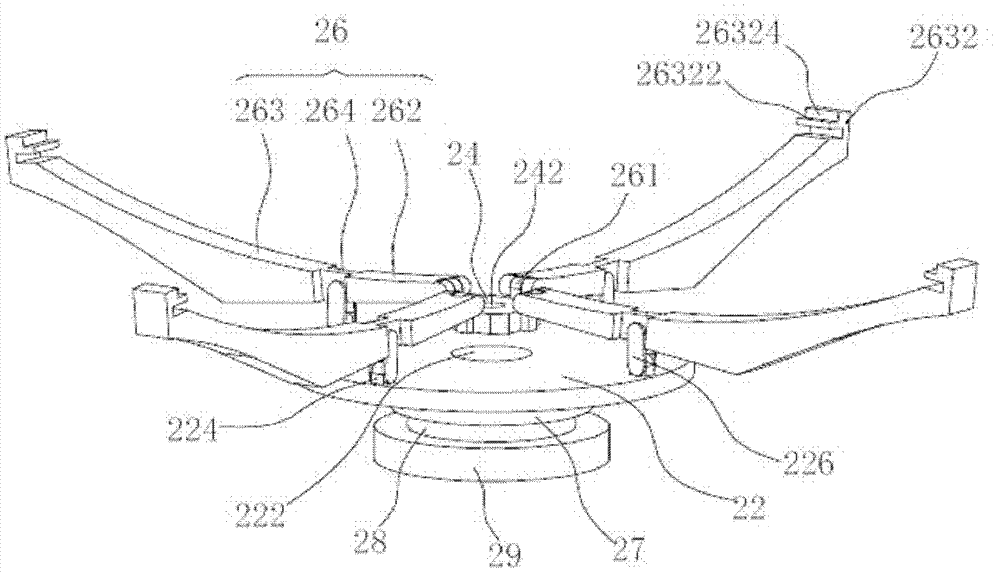

Wafer prealignment device

ActiveCN103199050ARealize handoverSmooth handoverSemiconductor/solid-state device manufacturingArm moving

A wafer prealignment device comprises a base plate, a first support device, a first drive device, a second support device and a second drive device, wherein the first support device is arranged on the base plate, the first drive device is used for driving the first support device to rotate relative to the base plate, part of the second support device is arranged on the lower portion the base plate, and the second drive device is used for driving the second support device to move vertically relative to the base plate. The first support device comprises a plurality of first support arms used for supporting a wafer. The second support device comprises a plurality of second support arms used for supporting the wafer. In the process of prealignment, the handover of the wafer can be achieved through the rotation of the first support device and the vertical movement of the second support device, and the position adjustment of the wafer is achieved in the process of handover. In the process of the rotation of the first support device and the vertical movement of the second support device, the plurality of first support arms or the plurality of second support arms move at the same time, the wafer is enabled to be stressed evenly, the consequence that the wafer cannot be supported can not occur, and wafer stable handover is achieved so as to finish the prealignment. The wafer prealignment device is good in stability and capable of greatly improving the prealignment efficiency.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com