Armature opening and closing mechanism for paper transferring mechanism swinging downward

A paper delivery tooth and paper delivery technology, which is applied to printing machines, general parts of printing machinery, printing, etc., can solve the problems affecting the stability of the action and the complex structure of the stop mechanism, and achieve stable and reliable action, simple structure, and reduced vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better understand the technical solution of the present invention, the following will be described in detail through specific embodiments in conjunction with the accompanying drawings:

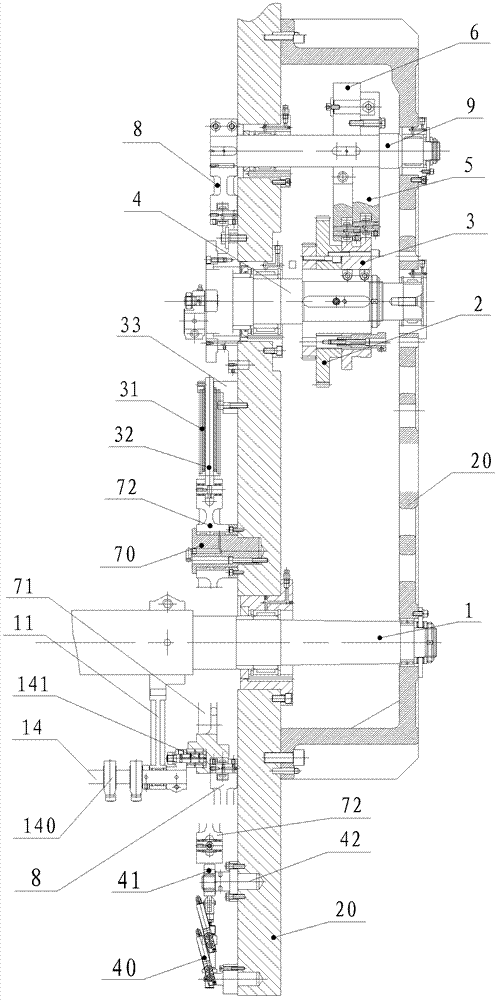

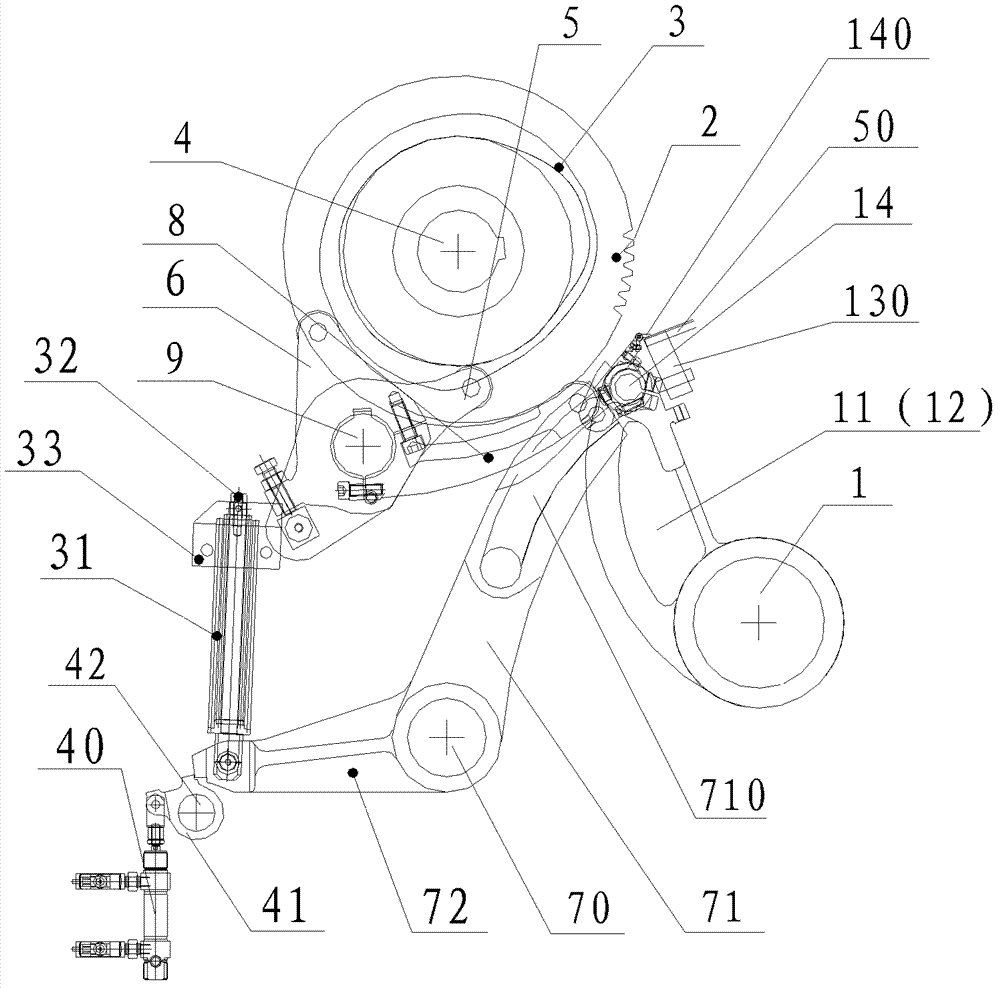

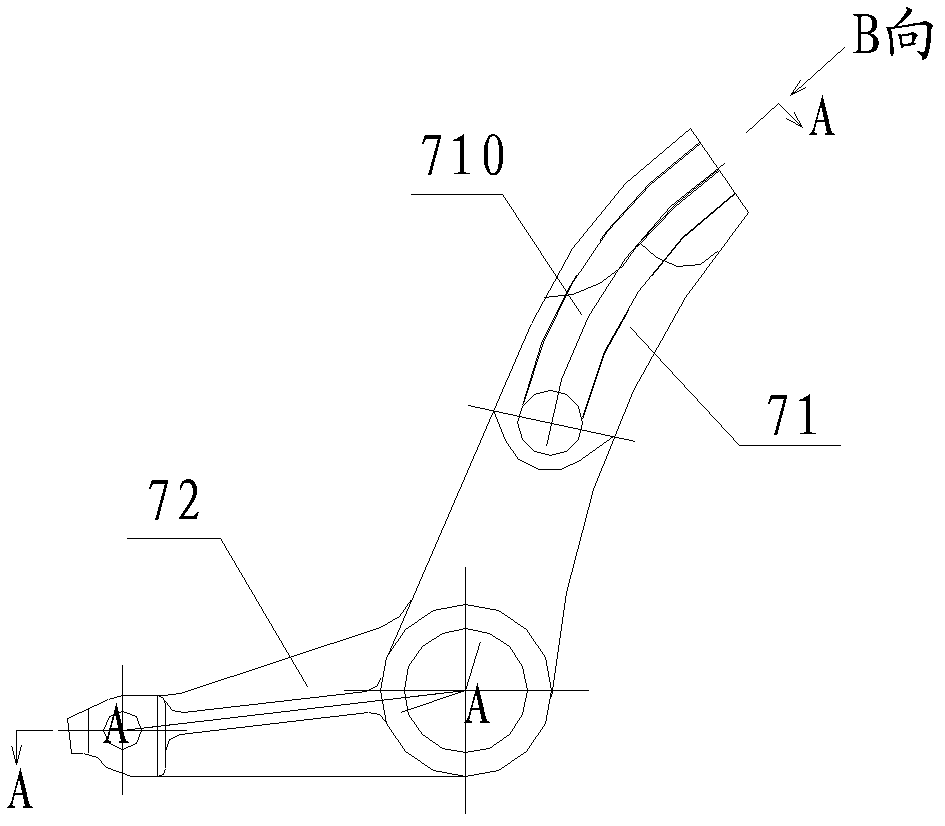

[0014] see figure 1 and figure 2 , a kind of opening and closing teeth mechanism for the bottom swing paper delivery mechanism of the present invention includes a paper delivery hand, a driving mechanism, a driven mechanism, a support frame 30 and a stop mechanism.

[0015] The support frame 30 is connected to the outside of the drive side wall panel 20 of the offset printing machine and has a back brace parallel to the drive side wall panel 20;

[0016] The paper transfer hand includes the paper transfer main shaft 1 spanning between the transmission side wall board 20 and the operation side wall board of the offset printing machine, and the tooth pads connected to the paper transfer main shaft 1 through a pair of paper transfer tooth support arms 11 and 12. Plate 13 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com